Acson international AMAC50C, AMAC30C, AMAC20C, AMAC25C, AMAC60C Technical Manual

...

Technical Manual

AIR-COOLED

MINI CHILLER

AMAC 20-150 C/CR

A4AC 20-150 C

A4AC 60-150 CR

A5AC 20-55 CR

1. NOMENCLATURE .................................................................................................. 1

- PRODUCT LINE UP

2. FEATURES ............................................................................................................. 5

3. APPLICATION INFORMATION............................................................................... 7

- REFRIGERANT CIRCUIT DIAGRAM

- CHILLER PANEL CONTROLLER

- PRECAUTIONS AND INSTALLATION

4. SOUND DATA........................................................................................................57

5. SELECTION PROCESS ........................................................................................64

- WATER PRESSURE DROP VS FLOW RATE

- GLYCOL

6. ENGINEERING AND PHYSICAL DATA ................................................................. 67

- SPECIFICATIONS

TABLE OF CONTENTS

7. PERFORMANCE DATA ....................................................................................... 114

8. OUTLINE AND DIMENSION ............................................................................... 126

9. ELECTRICAL DATA ............................................................................................. 130

10. WIRING DIAGRAMS .........................................................................................138

11. SERVICING AND MAINTENANCE ....................................................................154

12. TROUBLESHOOTING ...................................................................................... 155

13. EXPLODED VIEW AND PART LIST .................................................................. 156

1. NOMENCLATURE

A 4 AC 20 C R

Brand

A :Acson

Refrigerant

“ “ : Omitted if R22

4 : R407C

5 : R410A

Model Name

AC : Air-Cooled Mini Chiller

Capacity Index

020 : 20,000 Btu/h

Chasis

C : C Series

Model Type

“ “ : Omitted if cooling only

R : Heat pump

1

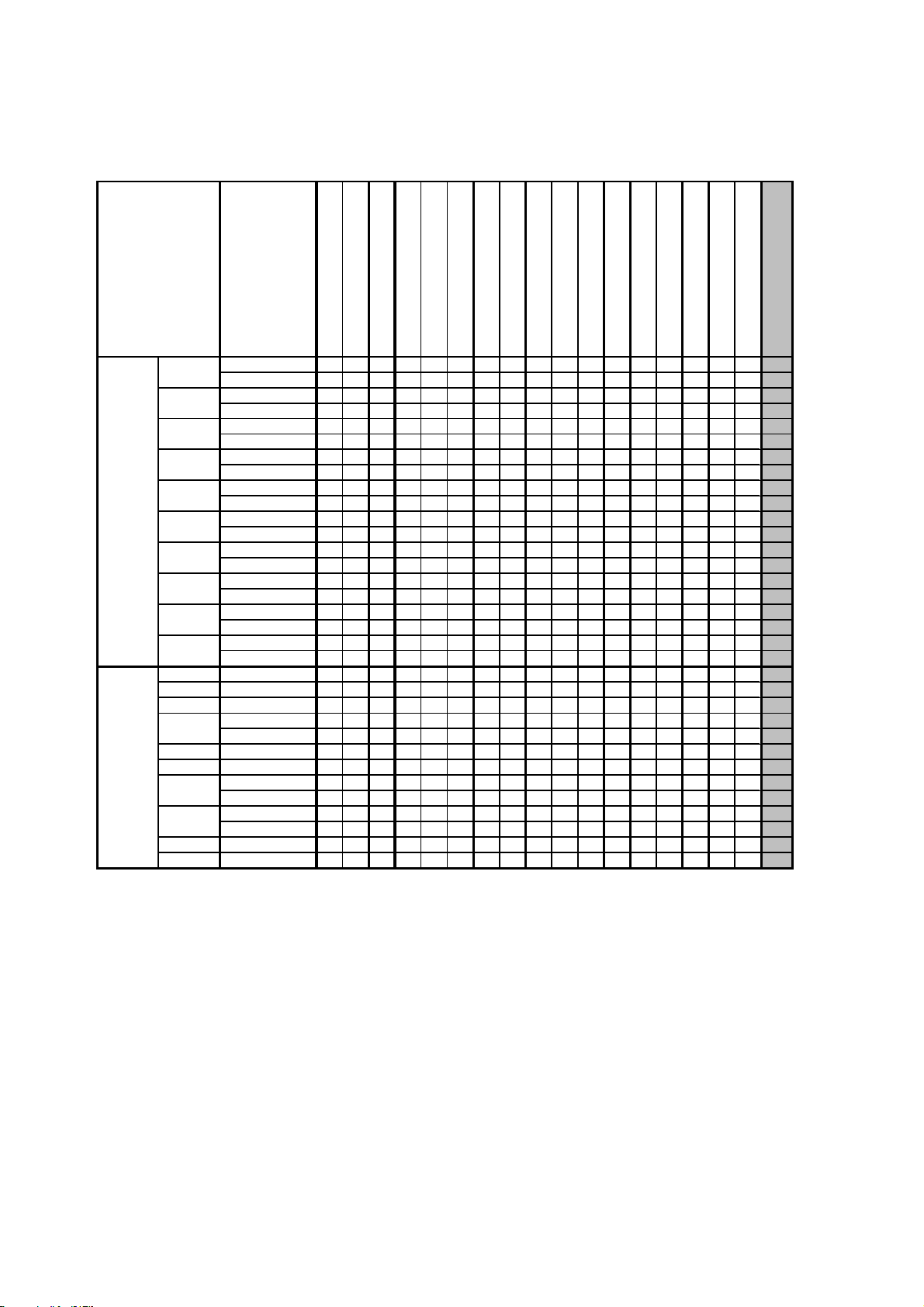

PRODUCT LINE UP

AMAC-C/CR

AMAC

20C

25C

30C

40C

50C

60C

COOLING ONLY

HEATPUMP

80C

100C

120C

150C

20CR AXAB X X

25CR AXAB X X

30CR AXAB X X

40CR

50CR FXAC X X

60CR FXAC X X

80CR

100CR

120CR FXAC X X

150CR FXAC X X

Nomenclature

AXAC

AXAD

AXAC

AXAD

AXAC

AXAD

FXAC

FXAD

FXAC

FXAD

FXAC

FXAD

FXAE

FXAF

FXAE

FXAF

FXAC

FXAD

FXAC

FXAD

FXAC X X

FXAD X X

FXAE X X

FXAF X X

FXAE X X

FXAF X X

PCB-MC01

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Magnetic Contactor

Water Tank + Pump

Without Tank / Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

XXXX

XXXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XXXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

X

X

X

X

XX

XX X

XX

XX X

XX

XX X

XX X

XXX X

XX X

XXX X

XX X

XXX X

XX X

XX X

XX X

XXX X

XXX X

XXX X

XXX X

Three Phase Fan Motor

Capillary Tube

TXV

2

A4AC-C/CR

A4AC

20C

25C

30C

40C

50C

60C

COOLING ONLY

HEATPUMP

80C

100C

120C

150C

20CR

25CR

30CR

40CR

50CR

60CR FXAB X X

80CR

100CR

120CR FXAD X X

150CR FXAD X X

Nomenclature

AXAC

AXAD

AXAC

AXAD

AXAC

AXAD

FXAC

FXAD

FXAC

FXAD

FXAC

FXAD

FXAI

FXAJ

FXAI

FXAJ

FXAG

FXAH

FXAG

FXAH

FXAE X X

FXAF X X

FXAE X X

FXAF X X

PCB-MC01

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

Classification

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Isolator Switch

Magnetic Contactor

Water Tank + Pump

Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

XX

XX

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XX X

XX X

XXXXXXXXXX X

XX X

XXXXXXXXXX X

XXXXXXXXXX X

XX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

XX

XXXXXX X

XXXXXX X

XXXXXX X

X

X

XX

XX X

XX

XX X

XX

XX X

XX X

XXX X

XX X

XXX X

XX X

XXX X

XXX X

Three Phase Fan Motor

Capillary Tube

TXV

3

A5AC-CR

A5AC

20CR AXAA X X

25CR AXAA X X

30CR EXAB X X

40CR EXAC X X

50CR EXAC X X

HEATPUMP

55CR EXAC X X

Classification

Nomenclature

PCB - TC01

PCB - TC1.1r4

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Isolator Switch

Magnetic Contactor

Water Tank + Pump

Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

Single Phase Fan Motor

Capillary Tube

XX

XX

XX

XX

XX

XX

X

X

X

X

X

X

XX

XX

X

X

X

X

XX X

X

XX X

X

XX XX

X

XX XX

X

XX XX

X

XX XX

X

TXV

4

2. FEATURES

REFRIGERANT CIRCUIT

Models AMAC/A4AC80~150C/CR has been designed with two separate refrigerant circuits, i.e. it has two

compressors. By doing so, the unit has part loading capabilities, i.e. 0-50-100% of rated capacity. This will

improve the reliability and energy efficiency of the unit, especially during low loading operations. Each circuit

is factory brazed and evacuated before accurately charged with refrigerant to ensure optimum performance.

Because each circuit is separated, there is no danger of cross-contamination should either one of the

compressor experiences a burnt-up. Each circuit is also equipped with a carefully sized thermostatic expansion

valve (for cooling only units) to give optimum performance characteristic. For the heatpump version, the

expansion process is done with capillary tubes.

SCROLL COMPRESSOR

Scroll Compressors are used (for model which is available) for the units (AMAC/A4AC20C/CR using rotary

compressor) to give quiet and reliable performance over a wide operating temperature range. However, in

order to protect the compressors from damage, a phase protector (for model which is available) is provided to

prevent the compressors from rotating in the wrong directions.

TANDEM COMPRESSOR

A5AC models are using R410A rotary compressors in tandem configuration. Tandem compressors are highly

efficient and cost saving. It reduces mechanical losses, minimize gas flow losses and turbulence. There are 3

steps capacity loading (0-40-60-100%) for A5AC40/50CR and 2 steps capacity loading (0-50-100%) for A5AC30/

55CR.

CONDENSER FAN MOTOR

Models AMAC/A4AC80~150C/CR is equipped with two high air flow propeller fan blades which are made of

metal. The fans are driven vertically by weather proof motors which are single phase type.

EVAPORATOR

The heat exchanger is made of stainless steel plates closely arranged and brazed together (BPHE) to ensure

high heat exchange efficiency. For models AMAC/A4AC80~150C/CR, the water flow through the BPHE in a

channel on its own, while because of the two compressors, the refrigerant flows through another two separate

channels. The refrigeran t will either be in a counter-flow or parallel-flow with respect to the water, depending

on the mode of operation (cooling or heating).

SAFETY PROCETECTION

The safety protections provided for the mini chiller are:

a) High and low pressure switches

b) Differential water flow switch

c) Compressor, water pump and fan motor overload protectors

d) Anti-freeze protection sensor

During abnormal condition, chiller panel controller will turn off the unit and then display the faults of operation.

WATER TANK AND PIPING CONNECTION

The models A4AC/AMAC80~150C/CR does not come with a water buffer tank. However, the unit does come

with an 8 liters expansion tank. Besides that, an optional 135L hydraulic tank is also available.

The external water piping connection can be made either from the left or right side of the unit. Connection is

done with Ø1-1/4 “ female thread couplings for both supply and return pipes.

Meanwhile, AMAC/A4AC20~60C/CR does come with a 22 L or 40 L (refer to specification) water buffer tank.

5

ANTIFREEZE PROTECTION

The chiller unit has several anti-freeze protection features:

1. Brazed plate heat exchanger anti-freeze

The BPHE has a strip heater around it to prevent water freezing inside

2. Auto mode

The chiller controller will force on the unit to the heat mode if the outdoor ambient air temperature

becomes too cold.

MAINTENANCE

In order to facilitate of the controller, a rocker switch is provided to power-off the supply to the PCB. However,

switching off the switch will not disconnect the main incoming power supply to the chiller unit.

6

3. APPLICATION INFORMATION

REFRIGERANT CIRCUIT DIAGRAM

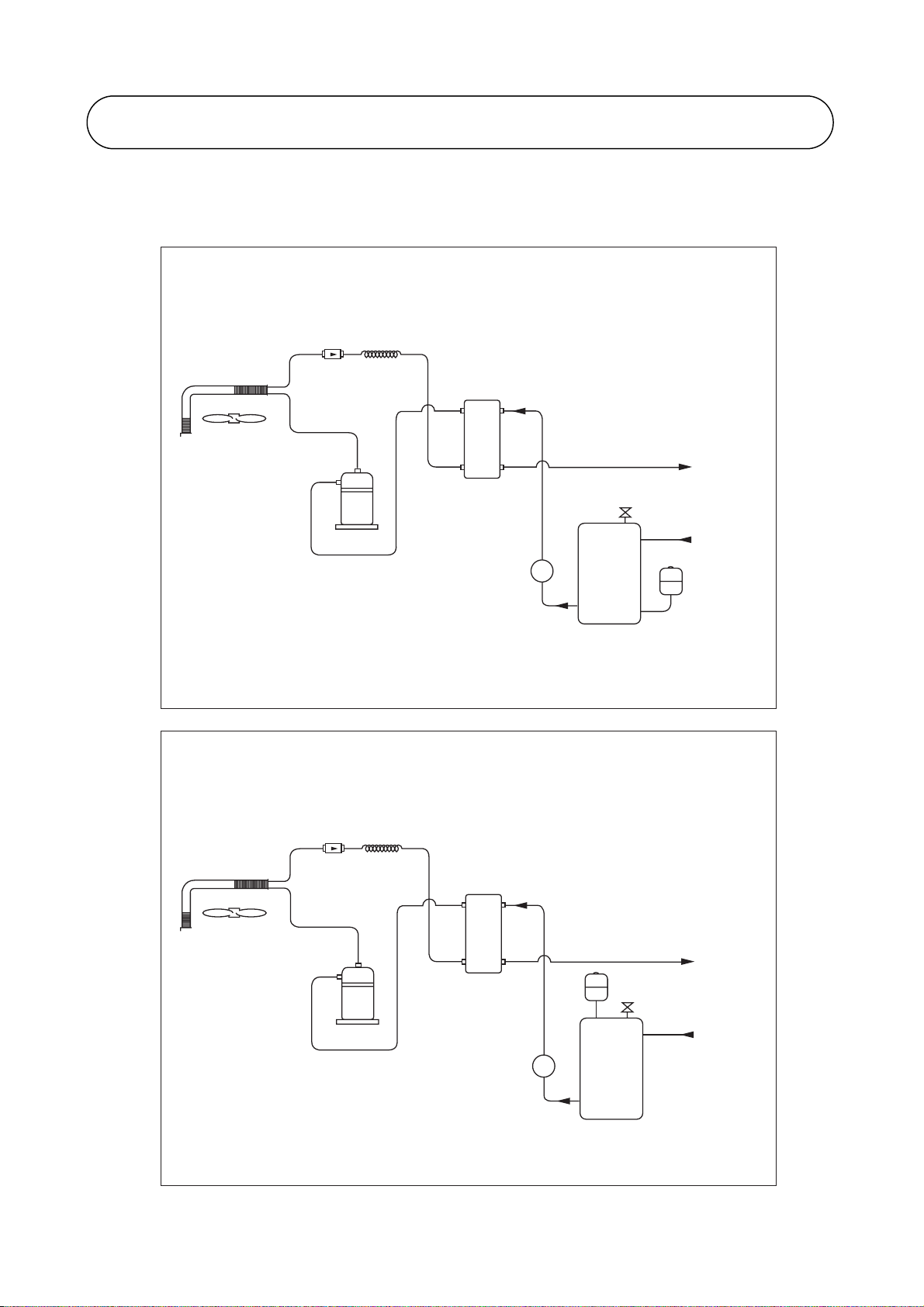

A4AC / AMAC 20C / 25C / 30C

Water / Refrigerant Circuit Diagram

FIL TER

DRIER

CAP TUBE

BPHE

AUT O PRESS RELIEF V ALVE

WATER

OUT

COMPRESSOR

WATER PUMP

P

WATER ST ORAGE

TANK

A4AC / AMAC 40C / 50C / 60C

Water / Refrigerant Circuit Diagram

FIL TER

DRIER

CAP TUBE

BPHE

EXP ANSION

COMPRESSOR

WATER

IN

EXP ANSION

TANK

PART NO : 70-03-4-067460

WATER

OUT

TANK

AUT O PRESS RELIEF V ALVE

WATER

IN

WATER PUMP

7

P

WATER ST ORAGE

TANK

PART NO : 70-03-4-087461

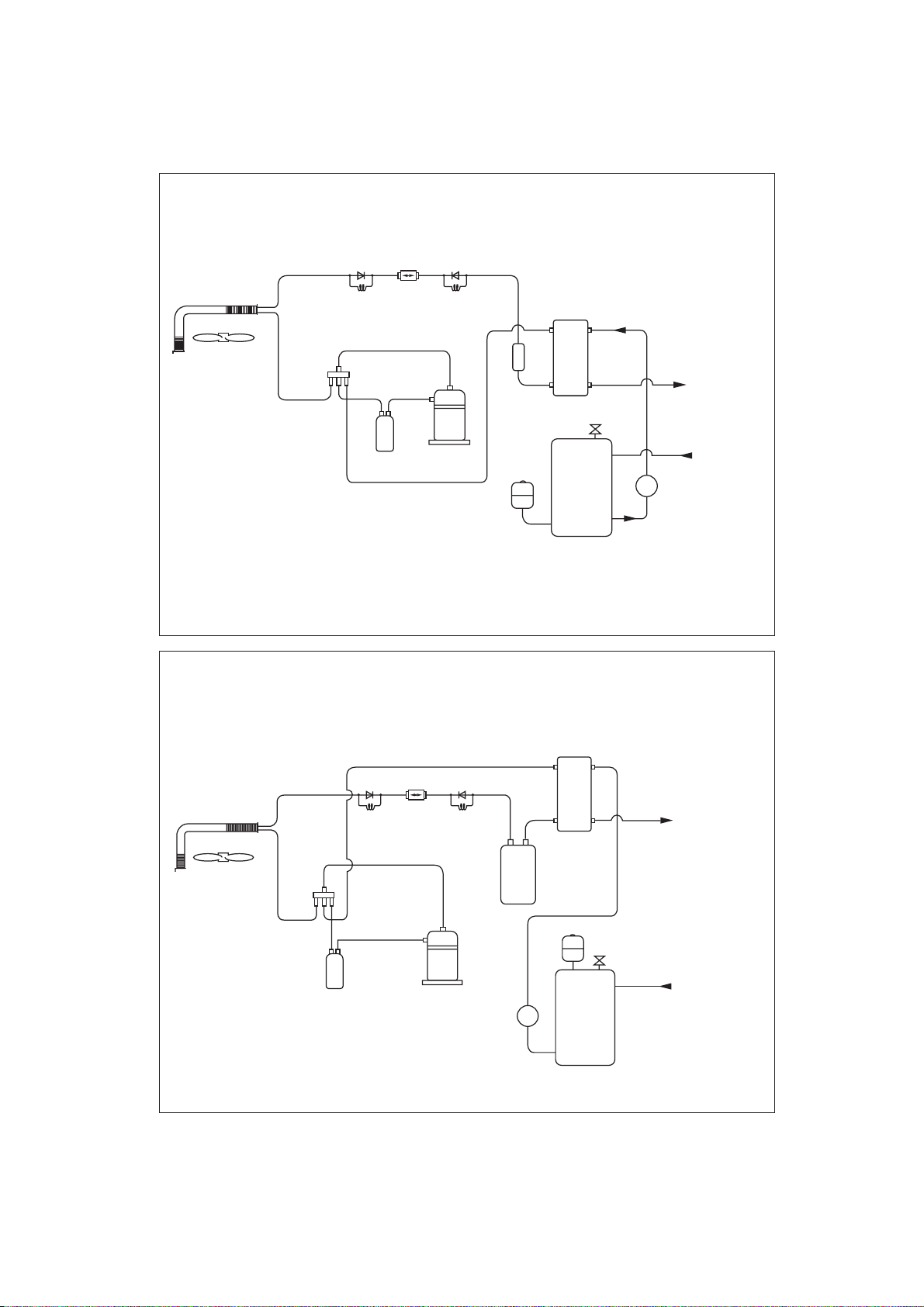

A4AC / AMAC 20CR / 25CR / 30CR

Water / Refrigerant Circuit Diagram

CHECK

VALV E

HEATING

CAP

TUBE

SUCTION

ACCUMULATOR

FILTER

DRIER

CHECK

VALV E

COOLING

CAP

TUBE

COMPRESSOR

EXPANSION

TANK

BPHE

CHARGE

COMPENSATOR

AUTO PRESS RELIEF VALVE

WATER STORAGE

TANK

PART NO : 70-03-4-067458

AMAC 40CR / 50CR, A4AC/ AMAC 60CR

Water / Refrigerant Circuit Diagram

WATER

OUT

WATER

IN

P

HEATING

SUCTION

ACCUMULATOR

CHECK

VALV E

CAP

TUBE

FILTER

DRIER

COOLING

COMPRESSOR

CHECK

VALV E

CAP

TUBE

WATER PUMP

LIQUID

RECEIVER

P

WATER STORAGE

BPHE

TANK

EXPANSION

TANK

AUTO PRESS RELIEF VALVE

PART NO : 70-03-4-067459

WATER

OUT

WATER

IN

8

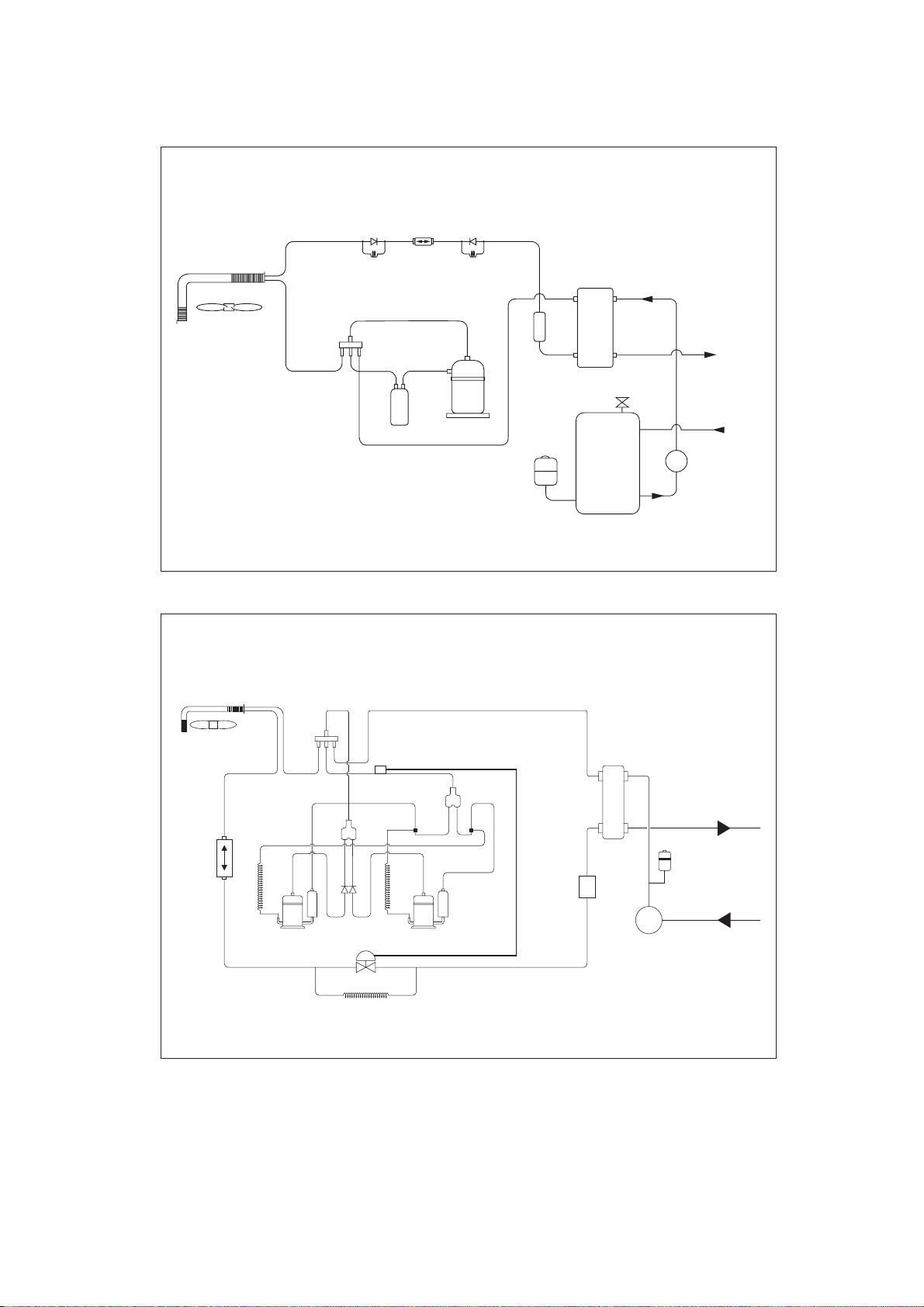

A4AC / AMAC 80C / 100C / 120C / 150C

Water / Refrigerant Circuit Diagram

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

FIL TER DRIER FIL TER DRIER

COMPRESSOR COMPRESSOR

A4AC / AMAC 80CR / 100CR / 120CR / 150CR

THERMOST ATIC

EXP ANSION

VA L V E

BRAZED PLA TE

HEA T EXCHANGER

WATER

OUTLET

WATER

INLET

THERMOST ATIC

EXP ANSION

VA L V E

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

Water / Refrigerant Circuit Diagram

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

HEA TING

FIL TER

DRIER

COOLING

WATER

OUT

CAP

TUBE

CAP

TUBE

HEA TING

TUBE

COOLING

TUBE

CHECK

4-WAY VAL VE

COMPRESSOR COMPRESSOR

SUCTION

ACCUMULA TOR

VA L V E

CHECK

VA L V E

LIQUID

RECEIVER

CAP

CAP

WATER

FIL TER

DRIER

IN

LIQUID

RECEIVER

CHECK

VA L V E

CHECK

VA L V E

HEA T EXCHANGER

SUCTION

ACCUMULA TO R

FIN TUBE

(SYSTEM 2)

4-WAY VA LVE

PAR T NO : 70-03-4-056764

9

A5AC 20CR / 25CR

Water / Refrigerant Circuit Diagram

CHECK

VALV E

FILTER

DRIER

CHECK

VALV E

WATER / REFRIGERANT

HEATING

CAP

TUBE

SUCTION

ACCUMULATOR

COOLING

CAP

TUBE

COMPRESSOR

EXPANSION

CHARGE

COMPENSATOR

TANK

BPHE

AUTO AIR VENT

WATER STORAGE

TANK

A5AC 30CR

Water / Refrigerant Circuit Diagram

WATER

OUT

WATER

IN

WATER PUMP

P

PART NO : 70-03-4-080547

FILTER

DRIER

OIL

RETURN

TUBE

4WV

COMPRESSOR 1

CHECK

VALV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

TWIN TUBE

JOINT

CHARGE

COMPENSATOR

BPHE

WATER OUT

EXPANSION TANK

WATER IN

PUMP

10

W

A5AC 40 / 50CR

Water / Refrigerant Circuit Diagram

4WV

SUB ACCUMULATOR

TWIN TUBE

JOINT

BPHE

WATER

OUT

FILTER

DRIER

RETURN

TUBE

WATER / REFRI

OIL

COMPRESSOR 1

4WV

CHECK

VALV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

A5AC 55CR

LIQUID RECEIVER

Water / Refrigerant Circuit Diagram

BPHE

SUB ACCUMULA TO R

TWIN TUBE

JOINT

PUMP

EXPANSION

TTANK

WATER

WATER

OUT

IN

FIL TER

DRIER

OIL

RETURN

TUBE

COMPRESSOR 1

CHECK

VA LV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

11

LIQUID RECEIVER

PUMP

EXP ANSION

TANK

WATER

IN

CHILLER PANEL CONTROLLER

1. SAFETY CONSIDERATION

Only specially trained and technicians and installers are authorized to install and service this

equipment..

1.1 General Installation Recommendations

• Only supply DC voltage (9-17V, typically 12V, maximum current 200mA) as a power source

to the device.

• Input contact voltage supply should limit to 12VDC or 24VAC.

• Isolated all the low voltage wiring (communication bus, etc) from high voltage power supply

wiring.

2. GENERAL DESCRIPTION

2.1 General

The chiller panel controller is designed to control the chiller operation. This device allows the

user to have customized control for each connected unit.

2.2 Features

The requirements of user friendly and easy to use have been taken into account in designing

this chiller panel controller. It can do the task as follow:

• Whole system configuration

• Unique parameter settings

• Operation status display

• Tracing fault record (easy in hardware troubleshooting)

The display is shown in an 8-lines graphical LCD display. There are 8 dedicated keys available

in the panel,

• Menu selection

• Navigation on the screen

• Modification of the selected value

During first start-up, the panel will have a default configuration (timer schedule, set point,

miscellaneous settings, etc) User can do the changes on that particular configuration later.

2.3 Panel Position

The chiller panel controller can be installed anywhere, as long as it is easy to accessed by

authorized personnel.

The requirements of installation are:

• Avoid exposure to shocks

• Avoid any source of electromagnetic pollution

• Avoid installation on uneven vertical surface

2.4 Operation Environmental Condition

• Temperature:

-10°C to 65°C operating temperature

-20°C to 85°C storage temperature

• Relative Humidity:

0 to 95% non-condensing

12

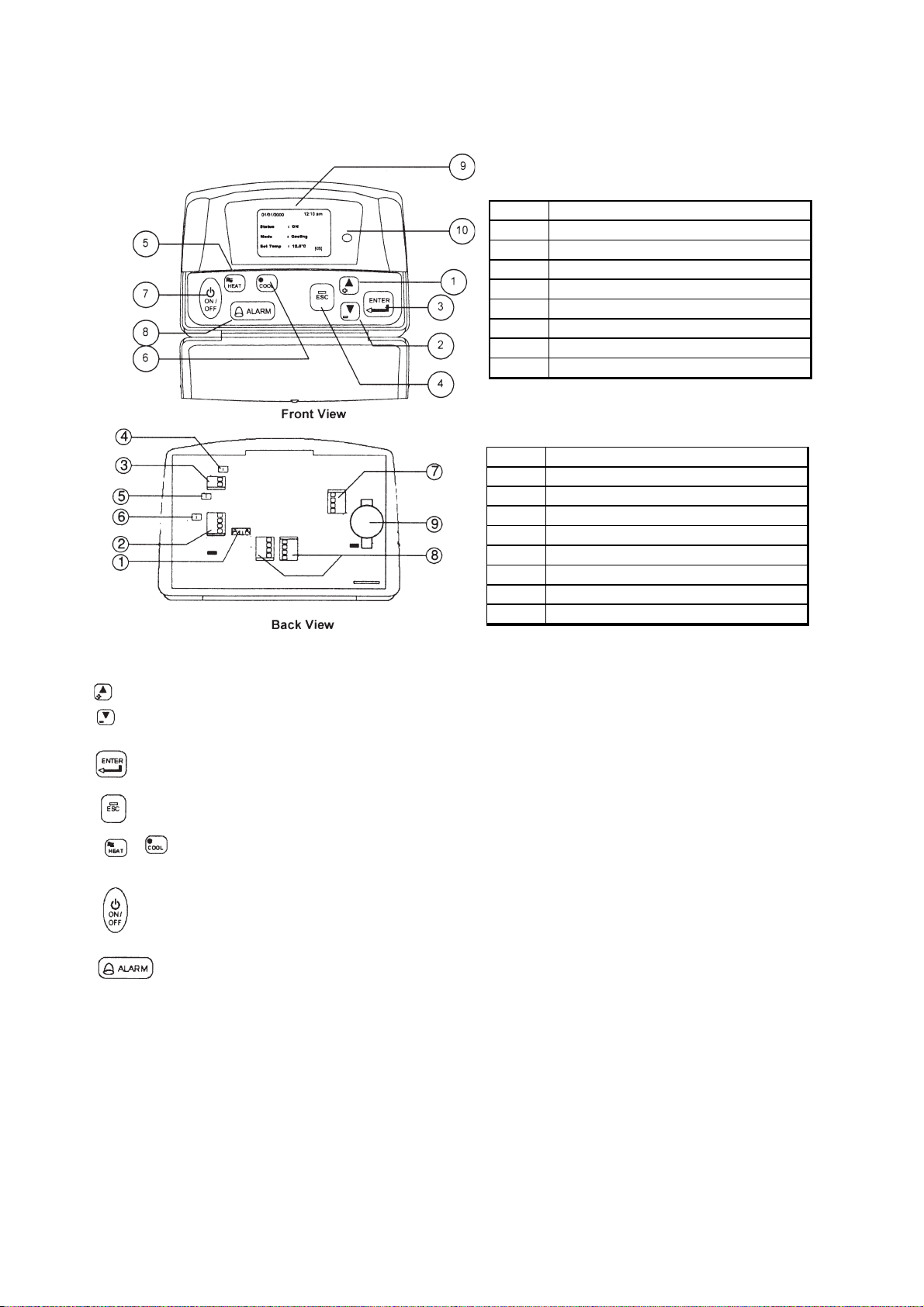

3. HARDWARE DESCRIPTION

Legend

3.1 Key Explanation

1 & 2

Navigation key

3 Execute instruction key

4 Cancel instruction key

5 Switching to heat mode shortcut key

6 Switching to cool mode shortcut key

7 Toggle ON/OFF shortcut key

8 Show alarm k ey

9 Graphical LCD display

10 ON/OFF indicator

Legend

1 & 2

Chiller terminal unit connection

3 Not avai lab le

4 CMOS rset jumper (JH2)

5 Chiller bus resist or configuration (JH3)

6 Not avai lab le

7 Not avai lab le

8 Not avai lab le

9 Not avai lab le

10 Bac kup battery

The 2 navigation keys permit item selection and modifying the selected value.

ENTER key is used to execute the navigation instruction

ESC key is used to cancel the navigation instruction

Shortcut key to switch the operation mode in the summary pages

Shortcut key to trigger ON/OFF in the summary pages

Shortcut key to show fault / alarm in the summary pages

13

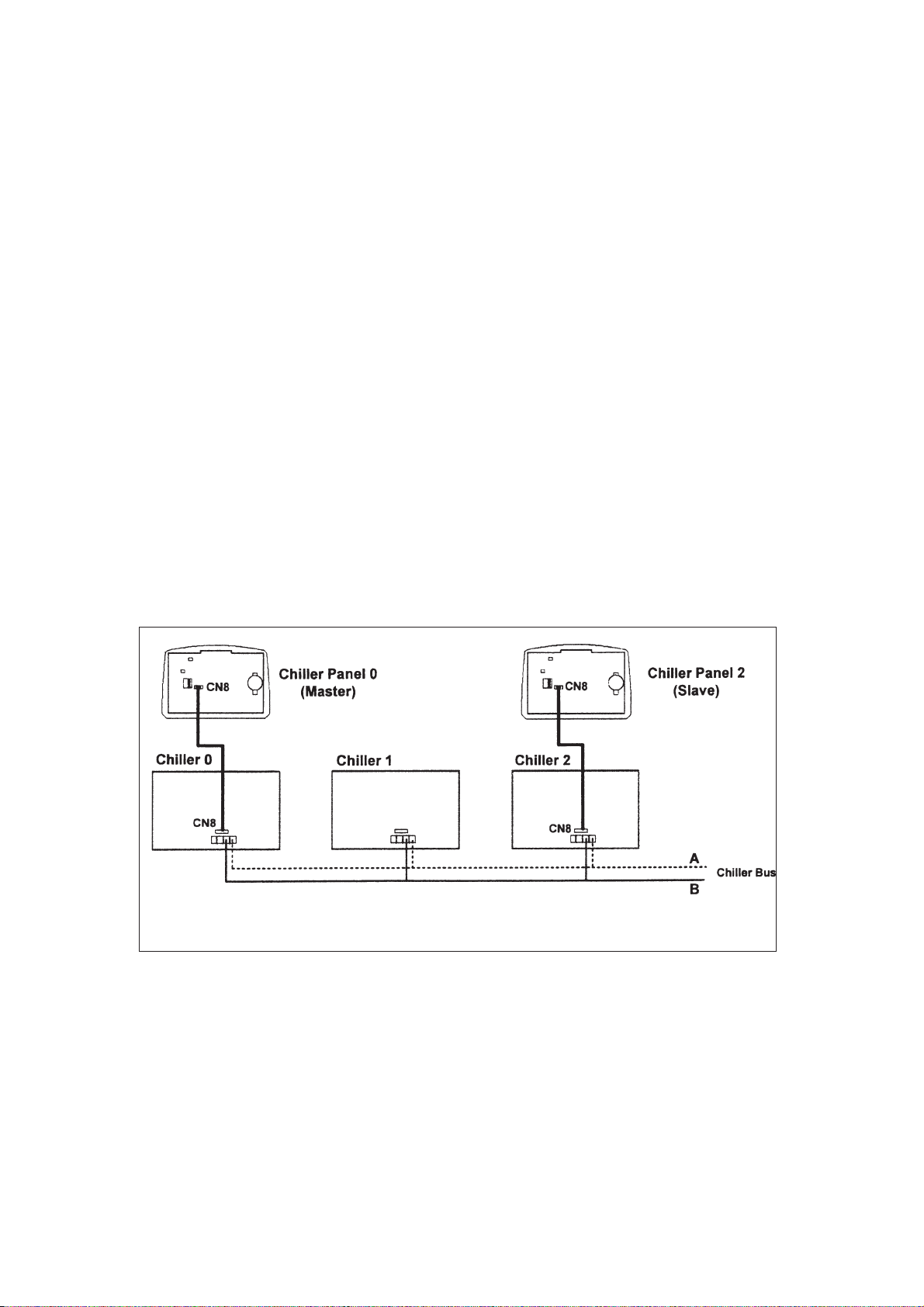

4. INSTALLATION

4.1 Chiller Bus

Supported up to 50 units of Chiller

Chiller 0 Chiller 1 Chiller 2

5 way wire (CM8)

Chiller

Communication bus

Chiller Panel 0 Chiller Panel 1

(Master) (Slave)

Chiller Network

Chiller panel needs to be energized with +12Vdc. The 5 way wires that provided is once on the easiest

solution to establish a communication between the panel and chiller main board (CN8-CN8). If the 5-way

wires socket has been occupied in main board, just using 2 insulation wired are needed to establish a

communication between panel and chiller main board.

Chiller panel can support maximum up to 50 units of chiller. In the chiller network, duplication of main board

unit address is not allowed. Each chiller main board should have their unique unit address (0-50).

For first time running, user need to assign a unique unit address to each main board in the chiller network.

User should follow the procedure below:

• Only power ON one main board at once time. Make sure not others main boards are energize.

• By using the panel connected to the main board.

<ENT ER> <ENT ER>

Summary Pages Main Menu Setting Menu

<ENTER>

G7 Unit No 1. General Set Paraameter

<ENT ER> <ENT ER>

key in "0001" as p assw ord

• Key in unique unit address and press ENTER to execute.

• De-energized the main board and repeat the procedures again all the main boards have been

assigned a unique unit address.

IMPORTANT : Do not assign a same unit address to more than one chiller main board.

RECOMMENDATION : Please select a coherant model (G1 Model) to all the chiller main boards in

the same network.

14

4.2 Others Configuration

• JH2 in chiller panel should let it open (put the jumper header on one pin only) all the time

unless user need to do CMOS reset to that particular panel.

• JH3 should let it open (put the jumper header on one pin only) all the time as well.

• Remember to put in the coin cell battery on the panel. Without the backup battery, the panel will

always reset the time to 12:00am, 1st Jan 2000.

4.3 Installation of the Chiller Panel Controller

• Disconnect the unit and ensure no others unit energy source that supplies the panel.

• Open the rear panel of the Chiller Panel (insert a ‘flat-head’ screwdriver in the top joint of main

casing with rear panel to open the real panel).

• Pass the necessary wires of the panel across the large opening in the rear panel. Place the rear

panel flat support against the wall and make marks on the wall through the four installation holes

(inner and outer).

• Drill four appropriate holes in the marked places.

• Attach the rear panel to the wall and put on the screws on it. Ensure that all cables are passed

through the hole of the rear panel.

• Connect the wires to the corresponding terminal according to the wiring bus network. The

power supply and communication wires must be correctly connected to ensure that the

panel works.

• Close the chiller panel (ensure the bottom joint is aligned for the casing, then complete others joint

part. Ensure that the contacts at the back of the panel are aligned with each others).

Bus Wiring Diagram

15

5. SOFTWARE DESCRIPTION

5.1 Introduction

The Chiller Panel Controller can be used to control / display the status of Chiller.

Status viewing:

• ON/OFF status

• Mode (Cooling / Heating/ Boiling)

• Mode set temperature

• Compressor status (ON/OFF/ DEFROST)

• Water in, Water Out, Outdoor air and Panel temperature

• Chiller model (Chiller, Heat Pump, Chiller/ Boiler, Chiller+Boiler, Heat Pump/Boiler, Heat Pump+

Boiler

• Advance parameter settings

• Defrost sensor temperatures

• Compressor discharge sensor temperatures

• Compressor run times

• Incoming alarm/ fault/ error

Status settings:

• ON/OFF switching

• Mode setting (Cooling / Heating/ Boiling)

• Mode set temperature

• Manual entering defrost

• Advance parameter settings

• Password changing

• Panel option setting (Backlight, Alarm Buzzer, Screen saver, Contrast, Brightness, temperature

unit)

• Time and date settings

• Clearing compressor run time

16

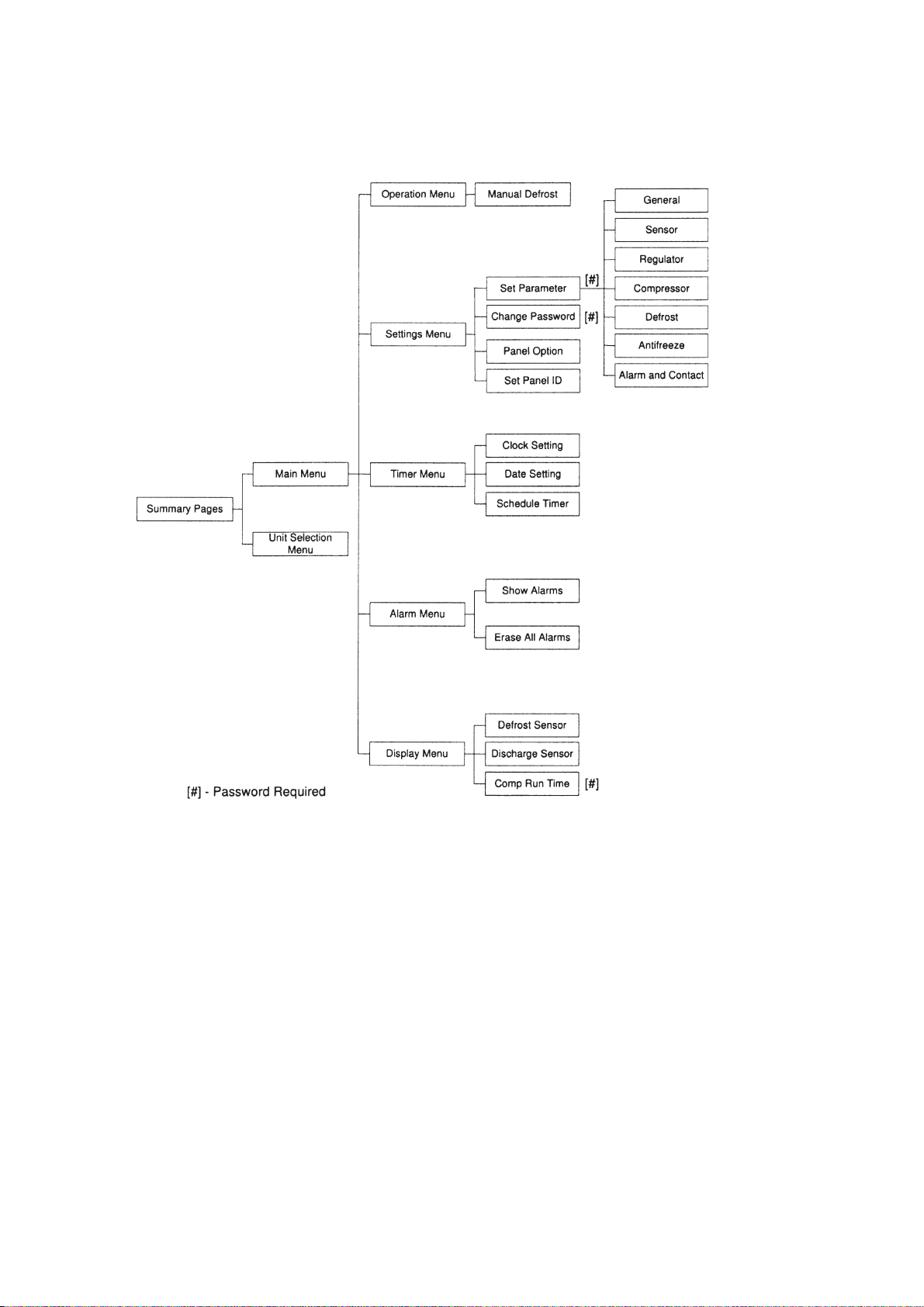

5.2 Menu Structures

Menu Structure Diagram for Chiller

17

5.3 Chiller Menu Structure

5.31 Summary Pages

There are 4 pages in [Summary Pages]. Press UP or DOWN for page scrolling. Press ENTER to go to

[Main Menu]. Time and date are shown on top of each page. Beside that, the bottom of each page shows

current control unit of the Chiller.

For example: [00] - Chiller Panel controls Chiller ID 0 currently

[03] - Chiller Panel controls Chiller ID 3 currently

[All] - Chiller Panel controls all Chiller currently

1st page: Display ON/OFF status, Mode settings and Temperature settings.

01/01/2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12.0°C

[00]

2nd page: Display Compressor status.

01/01/2000 12:00am

Compressor : ON

[00]

3rd page: Display Water In, Water Out, Outdoor air and Panel temperature

01/01/2000 12:00am

Water In :19.8°C

Water Out : 25.6°C

Outdoor Air : 32.2°C

Panel : 20.5°C

[00]

4th page: DisplayChiller model, Compressor No. and Chiller ID.

01/01/2000 12:00am

Model : Chiller

No. Comp : 1 Comp

Unit No : 0

18

5.3.2 Main Menu

Press ENTER in [Summary Pages] to go into this menu

MA I N MENU

Operating Menu

Setting Menu

Ti me r Me nu

A larm Men u

Dis play Menu

There are 5 sub menus in [Main Menu]. Press UP or DOWN to select sub menus, ENTER to enter into

the sub menu or press ESC to exit to [Summary Pages]

5.3.2.1 Operation Menu

Select [Operation Menu] in [Main Menu] and press ENTER to go into this menu.

OPERAT ION MENU

Status : ON

Mode : Cooling

Cool Te mperature : 12.0° C

Heat Te mperature : 40.0° C

Some normal settings can be found here. Press UP or DOWN to select each settings, ENTER to start the

setting or press ESC here to exit to [Main Menu]

Settings : -ON/OFF unit

- Mode changing (Cooling/ Heating/ Boiling)

- Cooling temperature setting

- Manual Defrost Selection

5.3.2.1.1 Manual Defrost

Select [Manual Defrost] in [Operation Menu] and press ENTER to go into this menu.

This menu lets user select one compressor to enter into defrost cycle manually, as long as the

environment fulfill the defrost requirement.

Def r ost Compres s or

Co mp 1

19

5.3.2.2 Settings Menu

Select [Settings Menu] in [Main Menu] and press ENTER to go into this menu.

SETTINGS MENU

Set Parameter

Change Passw ord

Panel Option

Set Panel ID

Some advance settings can be found here. Press UP or DOWN to select settings, ENTER to start the

setting or press ESC here to exit to [Main Menu].

Settings - Set Parameter

- Password Changing

- Panel Option

- Set Panel ID

5.3.2.2.1 Set Parameter

Select [Set Parameter] in [Settings Menu] and press ENTER to go into this menu.

1.General

2. Sensor

3. Regulator

4. Compressor

5. Def rost

6. Antif reeze

7. Alarm and Contact

There are 7 groups of advance parameters for user to set in this menu, Press UP or DOWN to

select the group, ENTER to go into the group or ESC to exit to [Setting Menu].

Settings:- General

- Sensor

- Regulator

- Compressor

- Defrost

- Antifreeze

- Alarm and Contact

5.3.2.2.2 Password Changing

Select [Password Changing] in [Setting Menu] and Press ENTER to go into this menu.

Please enter the

Old password ………..

0

- - - -

User can change the old password in this menu.

Press ESC to exit to [Settings Menu].

20

5.3.2.2.3 Panel Option

Select [Panel Option] in [Setting Menu] and Press ENTER to go into this menu.

Back light :

Buzzer : On

Scree n Saver : Disable

Timeout : 5m

Contrast : 50%

Br ig ht ness : Me dium

Temp Unit : ° C

: Nor m a l

User can do some miscellaneous for the panel. These settings would not affect whole system performance.

Settings - Toggle Backlight

- Alarm Buzzer

- Enable / Disable Screen Saver

- Screen Saver timeout

- Contrast display

- Backlight brightness

- Temperature unit

Press ESC to exit to [Settings Menu]

5.3.2.2.4 Set Panel ID

Select [Set Panel ID] in [Settings Menu] and press ENTER to go into this menu.

Ple ase enter the

Panel ID……

=> Unit 0

User can assign the ID no, to the panel.

Example: If ID no. 0 has been assigned, the panel acts like Master Panel Unit. It can choose to control

each Chiller in the network.

If other ID no. (1-50) has been assigned, the panel acts like Slave Panel Unit. It is dedicated to

one particular Chiller. It can only control the Chiller with same ID in the network.

Press [ESC] to exit to [Settings Menu]

21

5.3.2.3 Time Menu

Select [Time Menu] in [Main Menu] and press ENTER to go into this menu.

Cl o ck Se tting :

Dat e Setting

Time Schedule

Timer : Dis able

TIMER MENU

All the timer/ schedule settings are included in this menu. Press UP or DOWN to select each settings.

ENTER to start the setting or press ESC here to exit to [Main Menu].

Settings: - Set Clock

- Set Date

- Set Schedule ( 7 days Programmable Timer)

- Enable/ Disable Timer Schedule

5.3.2.3.1 Set Clock

Select [Clock Setting] in [Timer Menu] and press ENTER to go into this menu.

Se t Time :

hh: mm

00: 00

User can set the time in this menu. The time setting is in 24-hour format.

Pres [ESC] to exit to [Timer Menu].

22

5.3.2.3.2 Set Date

Select [Date Setting] in [Timer Menu] and press ENTER to go into this menu.

Set Time :

yyyy hh mm

2000 /01 / 01

User can set the date in this menu. The date is set according to sequence below:

(year) / (month) / (day)

Press [ESC] to exit to [Timer Menu].

5.3.2.3.3 Set Schedule

Select [Schedule Timer] in [Timer Menu] and press ENTER to go into this menu.

Timer 1 Timer2

Sun 0800 1600 _ _ _ _ _ _ _ _

Mon 0800 1600 _ _ _ _ _ _ _ _

Tue 0800 1600 _ _ _ _ _ _ _ _

Wed 0800 1600 _ _ _ _ _ _ _ _

ON OFF ON OFF

This is the 7 days programmable timer schedule menu. There are 2 ON/OFF events in one day. User can

choose to set each day of week (Sunday - Saturday) ON/OFF timer. Before this schedule carry their

effect to the Chiller, user need to set the [Timer] in [Timer Menu] to enable.

Press [ESC] to exit to [Timer Menu].

5.3.2.4 Alarm Menu

Select [Alarm Menu] in [Main Menu] and press ENTER to go into this menu.

ALARAM MENU

Show Alarms

Erase All Alarm

This place keeps records for all previous occurred fault/ alarms. User can view the alarm history and

clear

that record (alarm history) as well. The panel can keep up to 20 fault/ alarm records.

Press ESC to exit to [Main Menu]

23

5.3.2.4.1 Show Alarms

Select [Show Alarms] in [Alarm Menu] and press ENTER to go into this menu.

[Ch 0]

Alarm 1

Comp 1 over load

01/ 01/ 00 12:00am

User can view all the fault/ alarm records in this menu.

The record shows - Alarm type

- Alarm occurred date

- Alarm occurred time

- Alarm occurred unit (Chiller ID)

Beside that, user can erase the alarm record in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.4.2 Erase All Alarms

Select [Erase All Alarms] in [Alarm Menu] and press ENTER to go into this menu.

Are you sure ?

Press Enter to er ase,

or ESC to exit.

User can rase all the alarm / fault records at once in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.5 Dispaly Menu

Select [Display Menu] in [Main Menu] and press ENTER to go into this menu.

DISPL AY M ENU

De fr ost Se nsor

Dis char ge Sens or

Comp Run Time

This menu display Defrost Sensor temperature, Compressor Discharge sensor temperature and

Compressor Run Time. Beside that, user can clear each Compressor Run Time for Chiller.

Press [ESC] to exit to [Main Menu]

24

5.3.2.5.1 Defrost Sensor

Select [Defrost Sensor] in [Display Menu] and press ENTER to go into this menu.

De fr os t Se nsor

Comp 1 : 12.8° C

User can view the defrost sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu]

5.3.2.5.2 Discharge Sensor

Select [Discharge Sensor] in [Display Menu] and press ENTER to go into this menu.

Dis ch arges Sens or

Comp 1 : 36.5° C

User can view the discharge sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu].

5.3.2.5.3 Comp Run Time

Select [Comp Run Time] in [Display Menu] and press ENTER to go into this menu.

Comp Run Time

Comp 1 : 13579h

User can view the compressor run time for each compressor in the Chiller. Beside that, user can

clear each compressor run time in this menu. User needs to key in the correct password before

clearing the compressor run time.

Press [ESC] to exit to [Display Menu].

25

6. OPERATION USER MANUAL

6.1 Starting

Chiller panel can be set as Master or Slave panel unit. When the Panel ID is set to ‘0’, it acts like a Master

panel, whereas it is Slave panel if Panel ID is set to others number (1-50).

Chiller panel can control the Chiller if both ID no. (Panel ID and Chiller ID) are same.

For example: Panel ID 1 can only control Chiller ID 1

Master Panel can choose to control each Chiller or control all Chiller at once in the network.

For example : Panel ID 0 (master) can control Chiller ID 0 / ID 1/ ID 32 .... or all Chillers at once.

Panel ID can be set in Set Panel ID in Settings Menu.

Ple ase enter the

Panel ID ……

=> Unit 0

26

6.2 Chiller Operation Control

[00]

[00]

[00]

6.2.1 Starting

During power on for the Chiller Panel, it needs to take several times to collect information from the Chiller.

At this time, all the status will show “--”. Please ensure the particular Chiller exists in the network. When

the process is completed, user can start to control the Chiller using the panel.

01/ 01/ 2000 12:00am

Status : --

Mode : --

Cool Temp : --

01/ 01/ 2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12° C

In gathering information process Gathering information completed

6.2.2 Changing Display Unit

Chiller Panel (Master) can choose to choose to control / display each Chiller status. This can be done in

[Summary Pages] only.

01/ 01/ 2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12° C

Unit Selection :

Select All

Select One : 0

In [Summary Pages], press and hold ENTER buttom

(1 second) to go into [Unit Selection] menu.

Select “Select All” and press ENTER if user want to

control all Chilelr in the network, or select “Select One”

to control a particular Chiller. Press ESC to exit to

[Summary Pages].

Unit Selection :

Select All

Select One : 0

Select a Chiller ID via UP or DOWN and press ENTER

to confirm or ESC to cancel.

27

6.2.3 Switching ON/OFF

There are several ways to switch ON/OFF for the Chiller.

i) [Summary Pages]

Press and hold ON/OFF button (hold 1 second). Please note that the ON/OFF button will only function

in

[Summary Pages].

ii) [Operation Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Operation Menu

<ESC> <ESC>

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

In [Operation Menu], select “Status” and press

ENTER.

Toggle ON/OFF via UP or DOWN button, and then

press ENTER to confirm the change or ESC to cancel.

iii) [Timer Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Timer Menu

<ESC> <ESC>

7 days programmable time can turn chiller ON/OFF. User can set the schedule in this

[Timer Menu]. Please refer 6.2.11 (page 27) for schedule settings.

28

Loading...

Loading...