Acson international A5DB125H-FMBNA, A5DB80H-AMBHA, A5DB200H2-FMBNA, A5DB250H2-FMBRA, A5DB150H-FMBNA Technical Manual

...Page 1

Technical Manual

SPLIT SYSTEMS

AIR CONDITIONER

DUCTED BLOWER

H SERIES

A5DB-H series

Cooling only [50Hz]

R410A

TM-5SB-H-AM-A4

Page 2

SPLIT SYSTEMS AIR CONDITIONER

DUCTED BLOWER H SERIES

CONTENTS

1.

NOMENCLATURE

• Indoor

• Outdoor

• Product Line-Up

2. APPLICATION INFORMATION

• Operating Range

• Refrigerant Circuit Diagram

• Installation Guideline

3.

4.

5.

6.

7.

SOUND DATA

• Sound Pressure Level

• Sound Power Level

• NC Curv

SELECTION PROCESS

ENGINEERING & PHYSICAL DATA

PERFORMANCE DATA

• Calculation Steps

• Performance Tables

OUTLINE AND DIMENSION

8. WIRING DIAGRAMS

P.1

P.5

P.15

P.24

P.42

P.46

P.62

P.86

9. SERVICING AND MAINTENANCE

10. TROUBLESHOOTING

* All specifications stated in this technical manual are for Cooling Only unit.

Please contact us for more information about Heat Pump unit.

P.88

P.90

Page 3

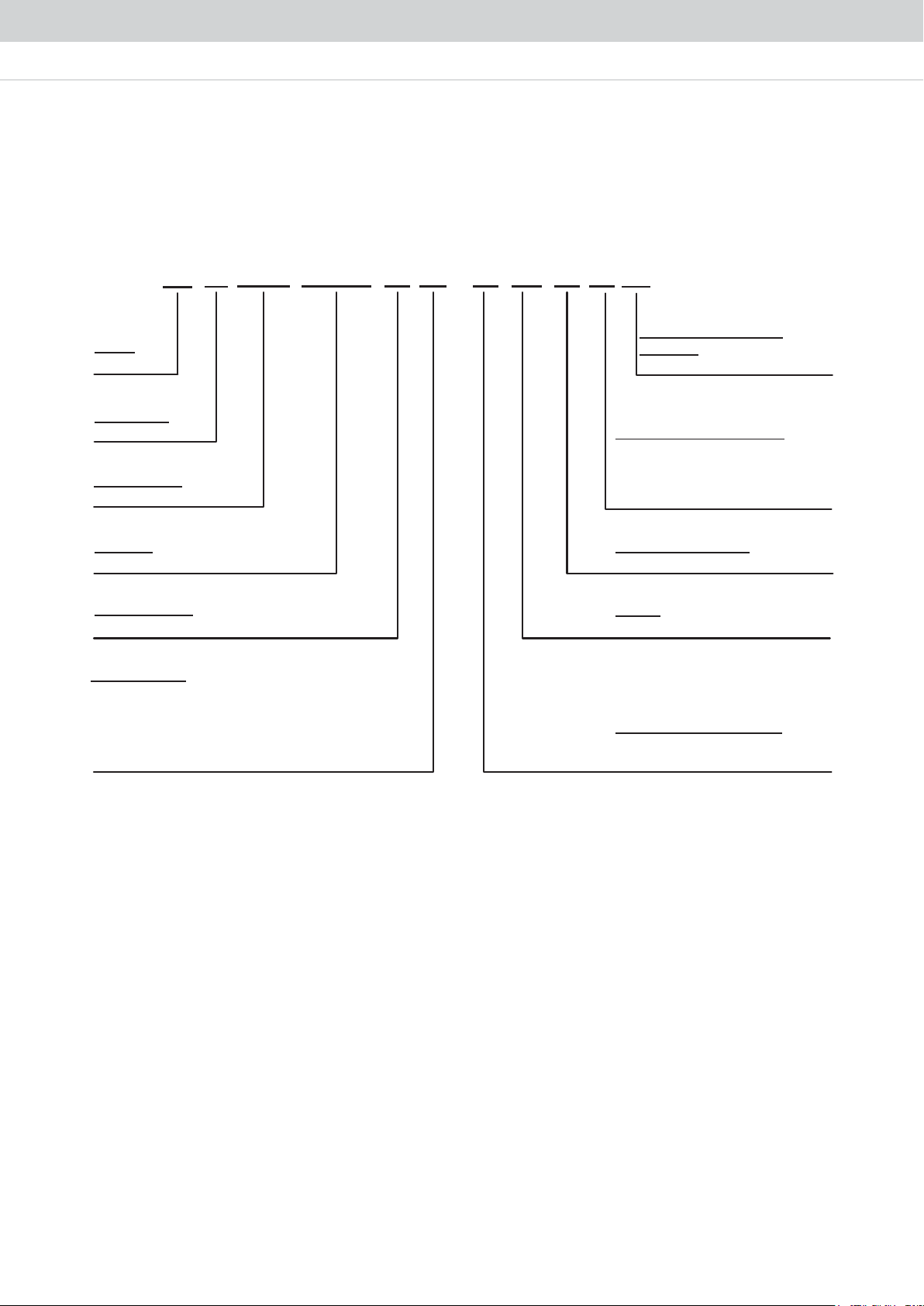

NOMENCLATURE

Indoor

A

Brand

A: Acson

Refrigerant

5: R410A

Product Type

DB: Ducted Blower

Capacity

250: 250,000 Btu/hr

Product Series

H: H series

No. of Circuits

“ ” : 1 Circuit

“2” : 2 Circuits

“3” : 3 Circuits

“4” : 4 Circuits

“5” : 5 Circuits

DB 250 H

5

2

-

F

M

B R

A

Product Specifi cation

Variation

A: Revision

Air Discharge Orientation

H: Horizontal and Not Convertible

N: Horizontal and Convertible

R: Vertical and Convertible

V: Vertical and Not Convertible

Evaporator Fin Type

B: Hydrophilic Blue

Market

M: Malaysia

Electrical Characteristics

A: 1 Phase 50Hz 220-240V

F: 3 Phase 50Hz 380-415V

1

Page 4

Outdoor

A

5

Brand

A: Acson

Refrigerant

5: R410A

Product Type

MC: Modular Condensing Unit

Capacity

125: 125,000 Btu/hr

Product Series

H: H series

MC 125 H

-

F

M

G R

A

Product Specifi cation

Variation

A: Revision

Air Discharge Orientation

H: Horizontal and Not Convertible

R: Vertical and Convertible

Condenser Fin Type

G: Microchannel

F: E-coating Microchannel

Market

M: Malaysia

Power Supply

Y1: 3 Phase 50Hz 380-415V

2

Page 5

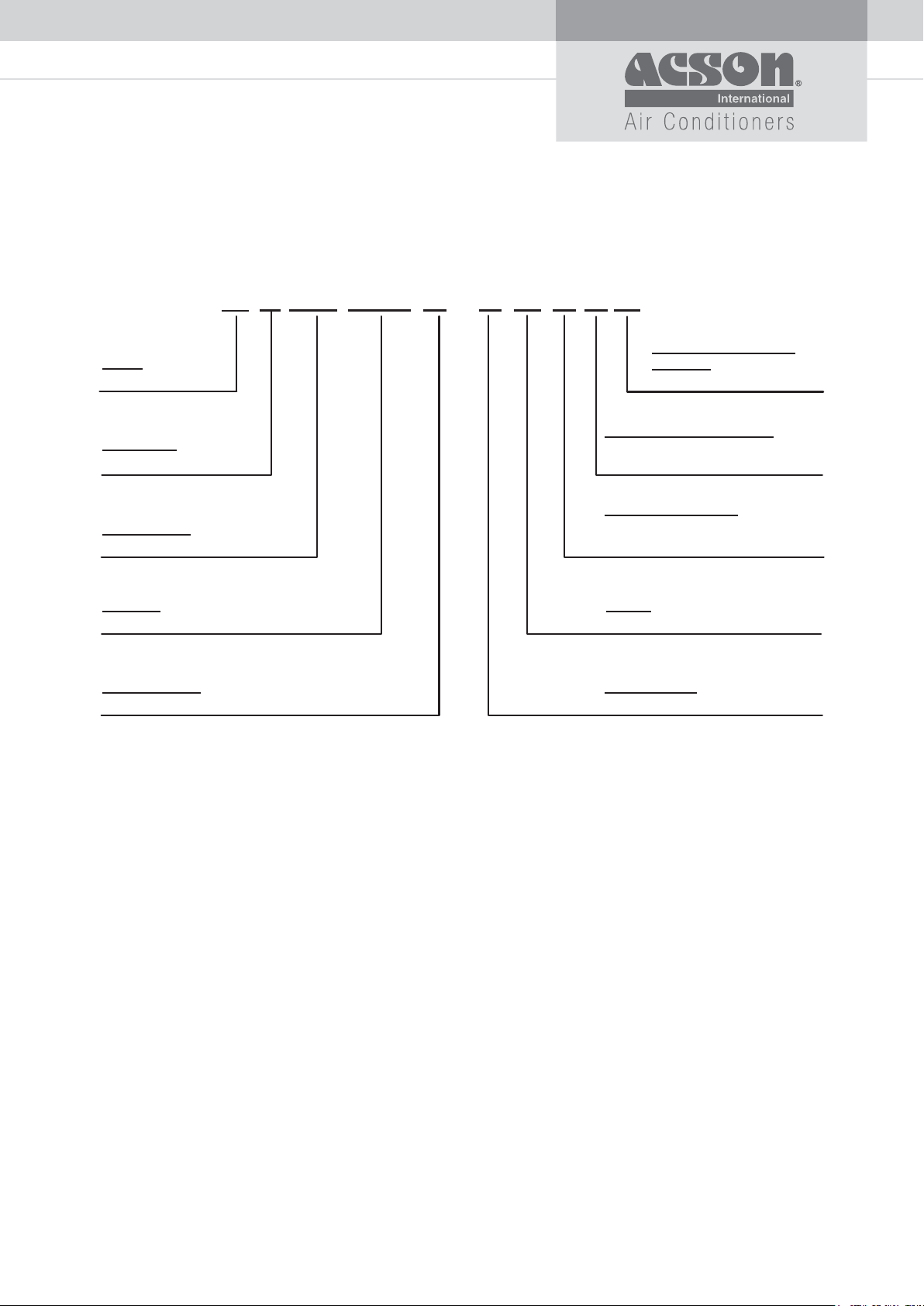

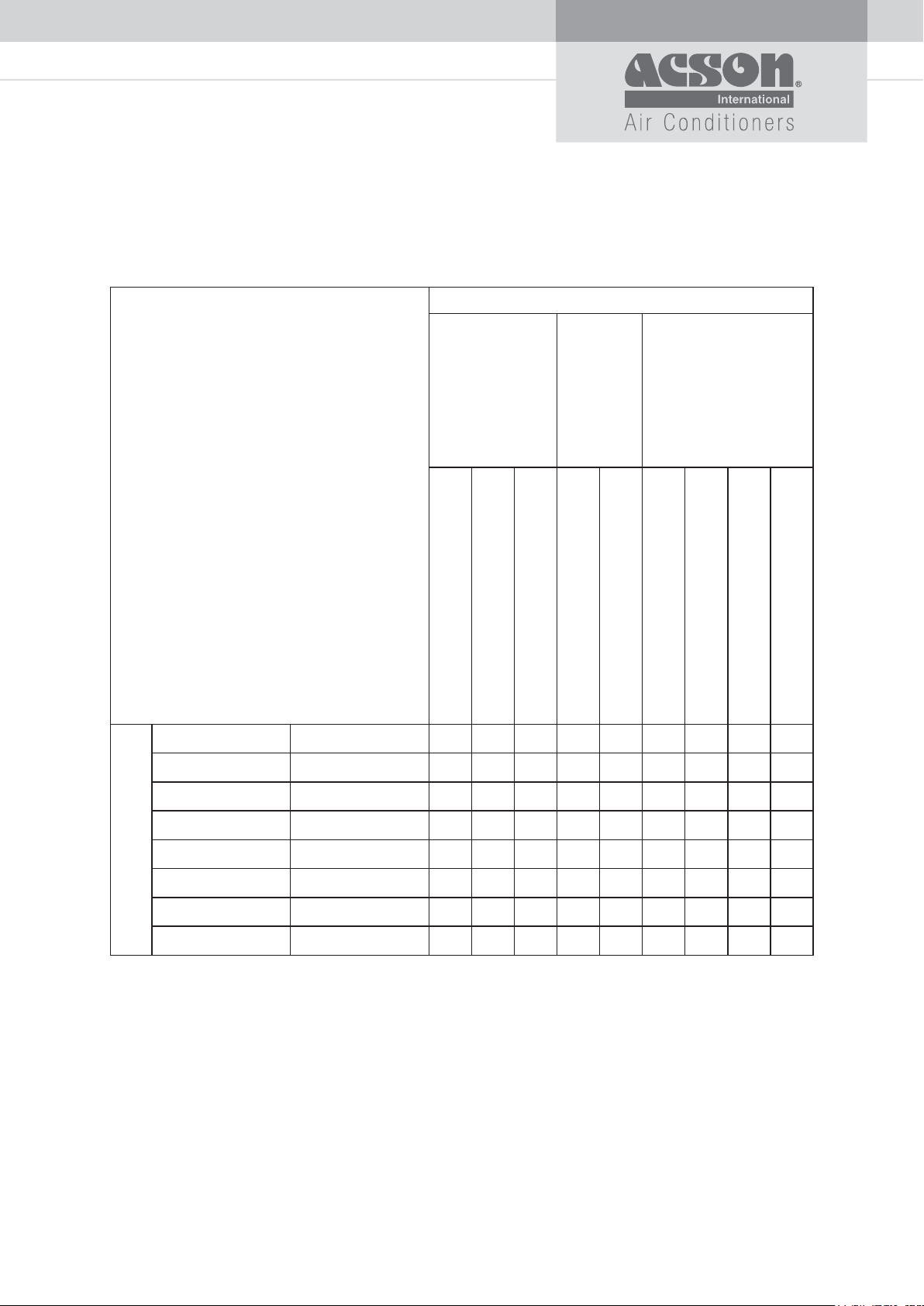

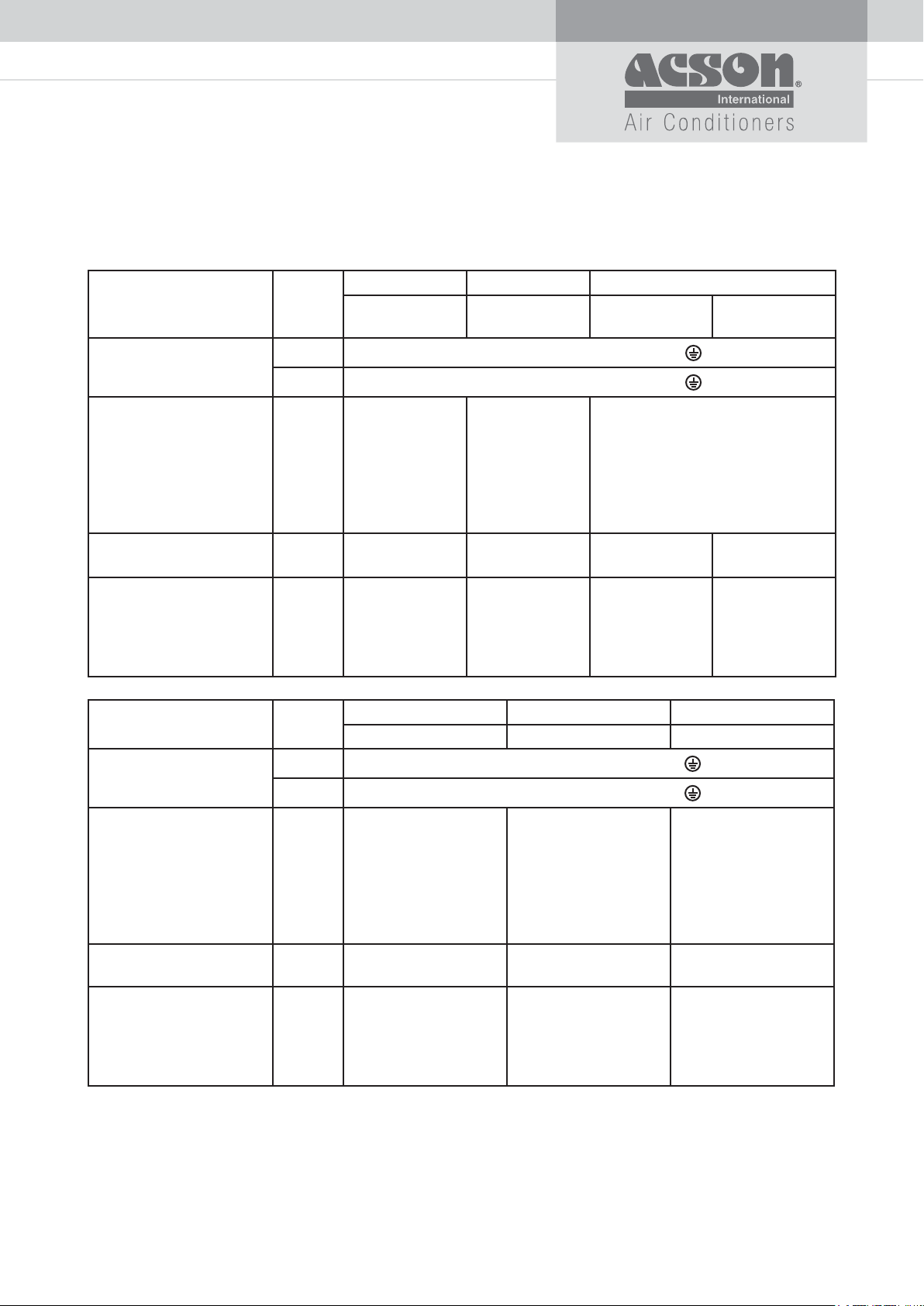

Product Line-Up

Indoor Unit

A5DB-H

Classifi cation

Control

Nomenclature

W/out Control Module

W/out Contactor

A5DB80H AMBHA X X XXX X X

A5DB100H AMBHA X X XXX X X

A5DB125H FMBNA X X XXXX X

A5DB150H FMBNA X X XXXX X

A5DB200H2 FMBNA X X XXXX X

A5DB250H2 FMBRA X X XXX X X

A5DB300H2 FMBRA X X XXX X X

A5DB300H3 FMBRA X X XXX X X

COOLING

A5DB350B3 FMBRA X X XXX X X

Fin

Bare Aluminium

Hydrophilic Coated

Handset

Refrigerant Control

Air Filter

W/out Handset

TXV

W/out Air Filter

Air Discharge

Horizontal & Convertible

Horizontal & Not Convertible

Vertical & Convertible

Vertical & Not Convertible

A5DB400H4 FMBRA X X XXX X X

A5DB450H3 FMBRA X X XXX X X

A5DB500H4 FMBRA X X XXX X X

XXXXXXXAVBMF4H006BD5A

XXXXXXXAVBMF5H057BD5A

3

Page 6

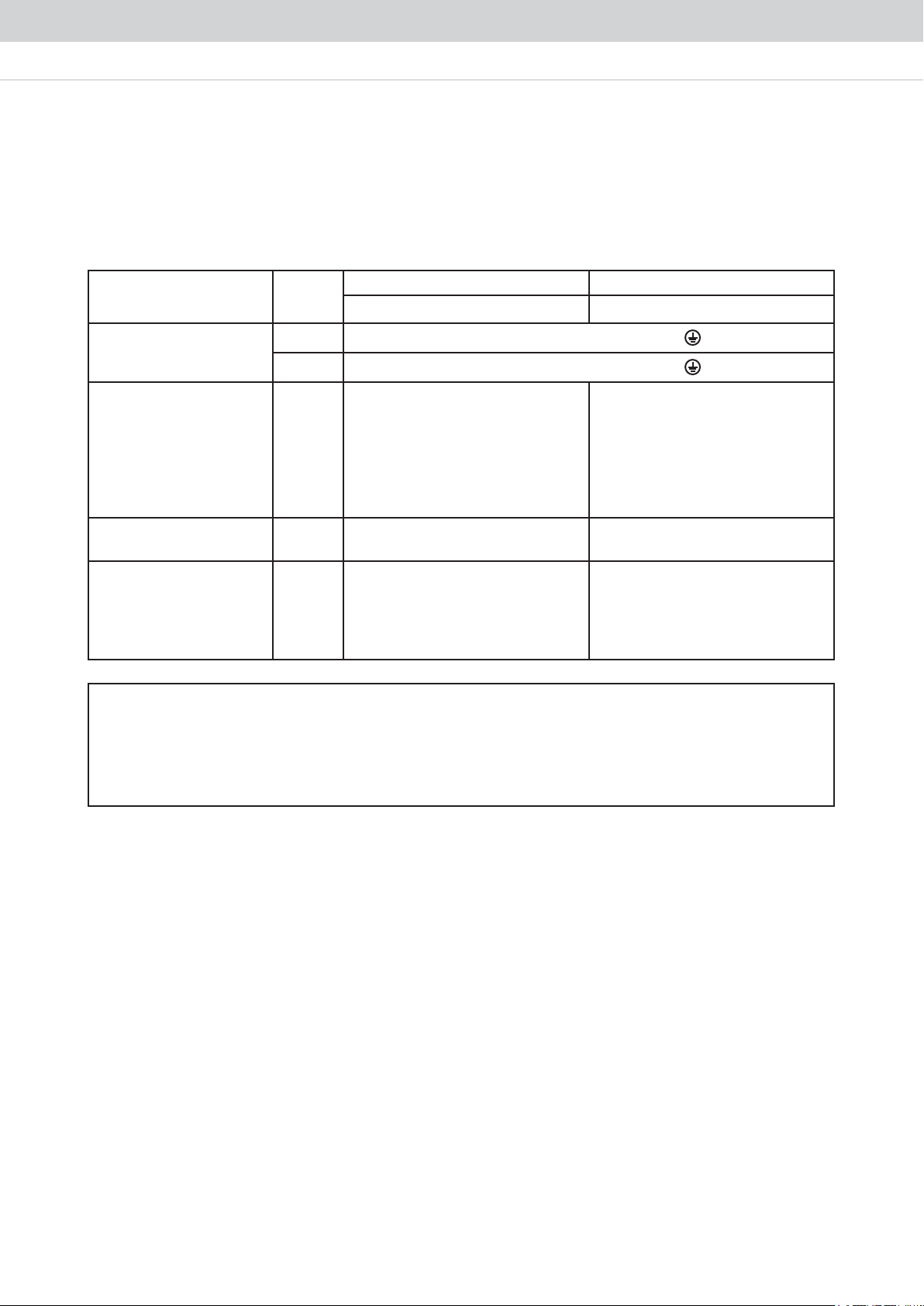

Outdoor Unit

A5MC-H

Classifi cation

Control

Nomenclature

W/out Contactor

With HP/LP Switch/Sensor

With Phase Sequential Protector

A5MC80H FMGHA XXX X X

A5MC80H FMFHA X X X X X

COOLING

A5MC100H FMFRA X X X X X

Fin

Microchannel

E-coating Microchannel

Air Discharge

Horizontal & Convertible

Horizontal & Not Convertible

Vertical & Convertible

Vertical & Not Convertible

XXXXXARGMFH001CM5A

XXXXXARGMFH521CM5A

XXXXXARGMFH051CM5A

A5MC125H FMFRA X X X X X

A5MC150H FMFRA X X X X X

4

Page 7

APPLICATION INFORMATION

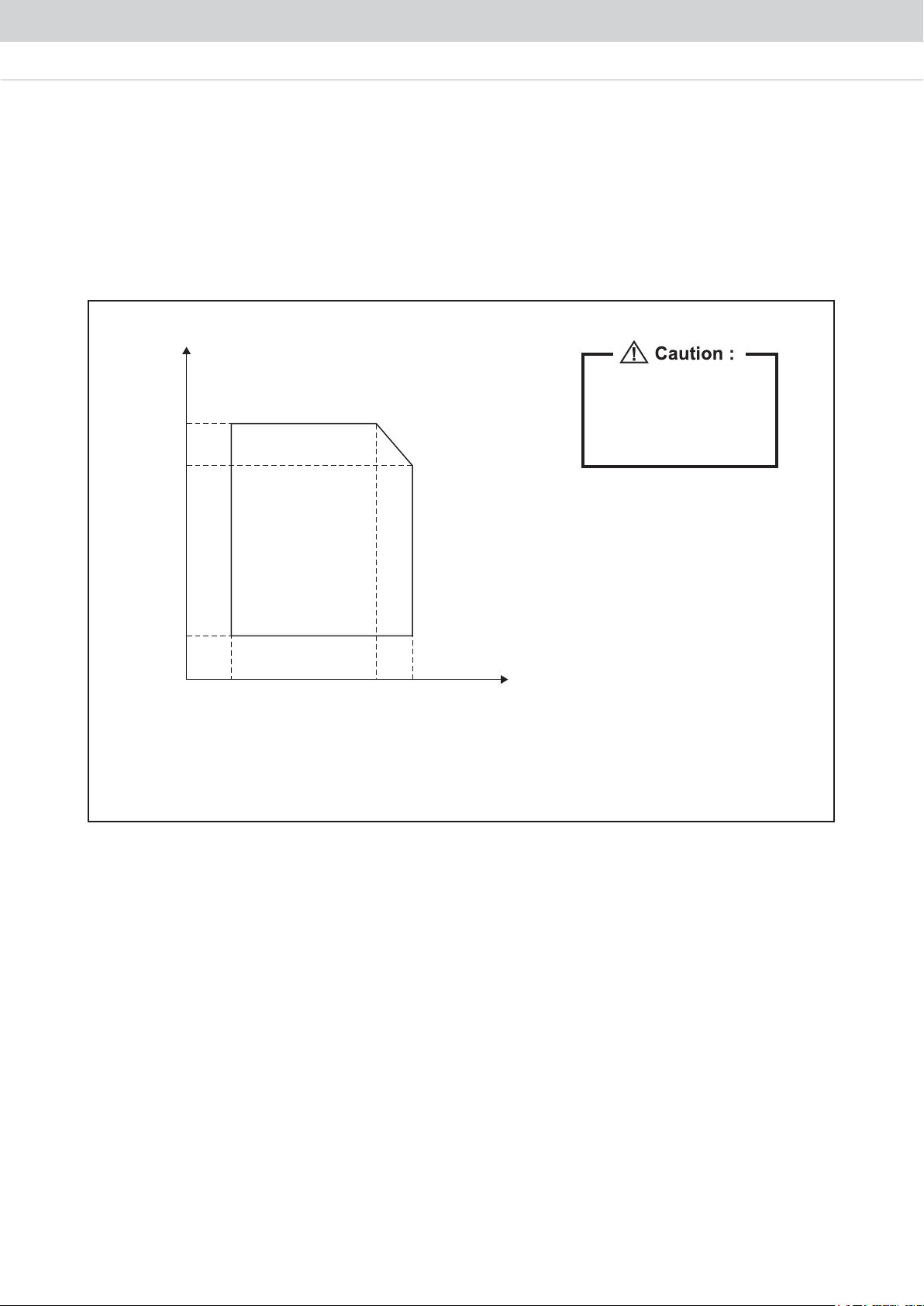

Operating Range

Ensure the operating temperature is in allowance range.

Cooling

Outdoor

DB (°C)

46

43

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

19

Cooling Operation Range

DB: Dry Bulb

WB: Wet Bulb

23 )C°( BW roodnI41

5

Page 8

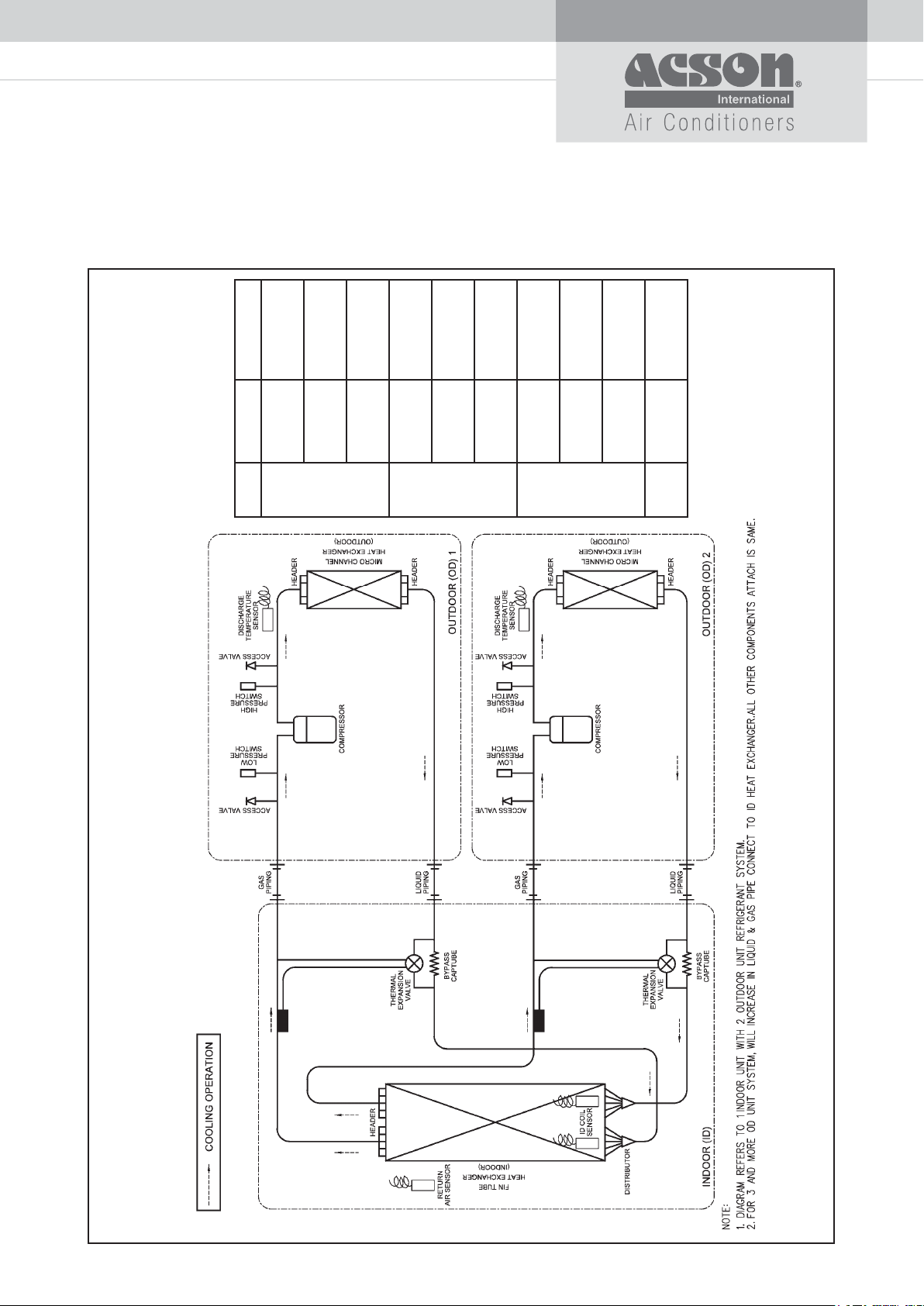

Refrigerant Circuit Diagram

Cooling Only

Outdoor

A5MC100H x 2

Indoor

A5DB200H2

A5MC125H x 2

A5MC150H x 2

A5DB250H2

A5DB300H2

A5MC100H x 3

A5MC100H x 1

A5MC125H x 2

A5DB300H3

A5DB350H3

A5MC150H x 3

A5MC100H x 4

A5DB450H3

A5DB400H4

A5MC125H x 4

A5MC150H x 4

A5DB500H4

A5DB600H4

A5MC150H x 5

A5DB750H5

System

1 IDU

2 ODU

1 IDU

3 ODU

1 IDU

4 ODU

1 IDU

5 ODU

6

Page 9

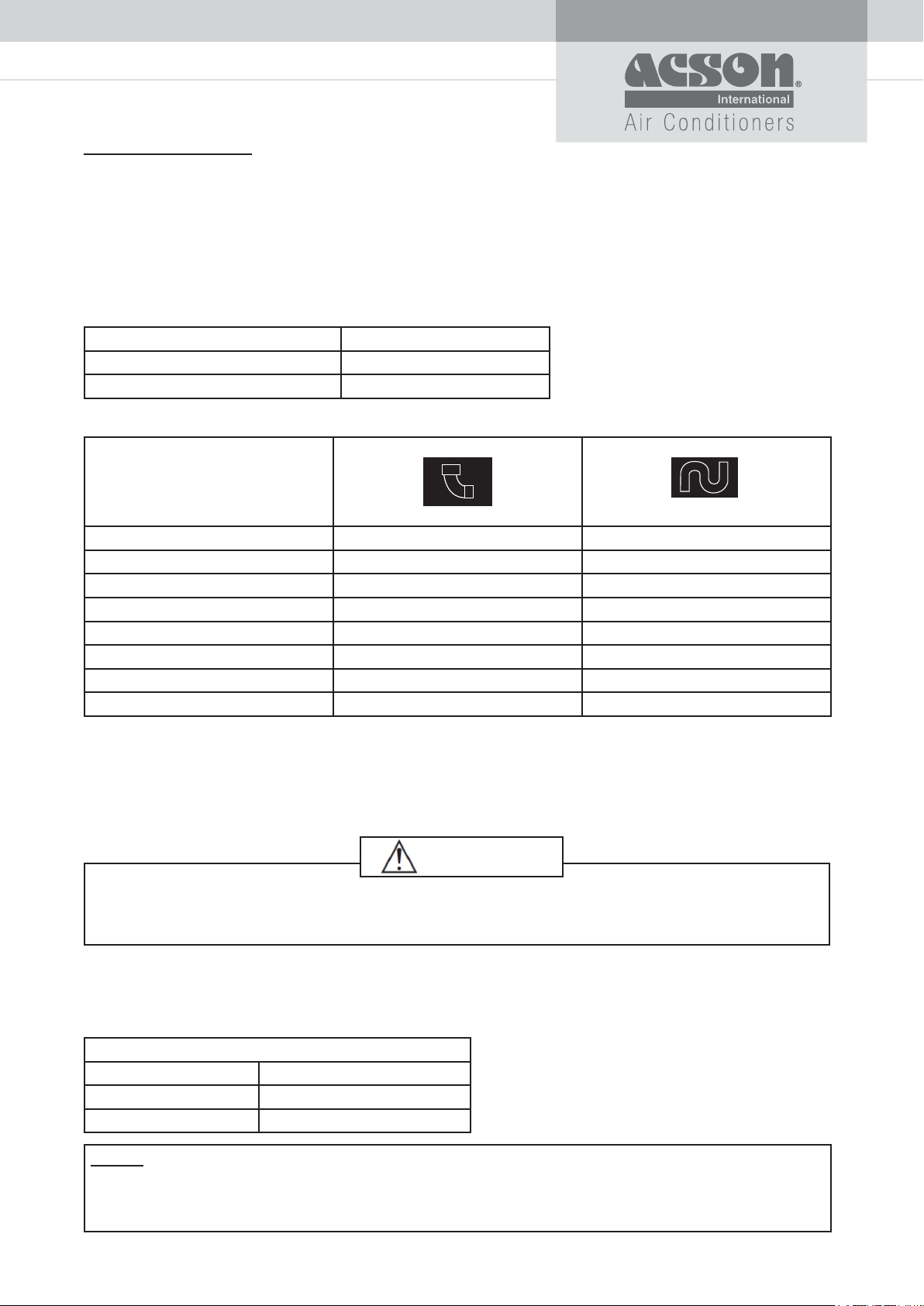

Installation Guideline

INDOOR

PRELIMINARY SITE SURVEY

a) Electrical supply and installation is to conform to local authority’s (e.g. National Electricity Board) codes

and regulations.

b) Voltage supply fluctuation must not exceed +/- 10% of rated voltage. Electricity supply line must be

independent of welding transformers which can cause supply fluctuation.

c) Ensure that the location is convenient for wiring and piping.

MOUNTING

a) For ceiling mounted models, locate a position where piping and ducting work can be kept to a minimum.

Ensure that overhead supports are strong enough to hold the unit’s weight. Position hanger rods and

check for alignment with the unit. Check that hangers are secure and that the base of fan-coil unit is level

in two horizontal directions.

DRAINAGE PIPE SIDE

PIPINGS

Do not use contaminated or damaged copper tubings. If pipings, evaporator or condenser are exposed or

had been opened for 15 seconds or more, vacuum and purge with field supplied refrigerant. Generally, do

not remove plastic/rubber plugs/caps from fittings, tubings and coils until ready to connect suction or liquid

line into fittings.

OPERATIONAL CHECK

After all electrical wiring is completed and the system is charged with refrigerant, make sure unit is operating

properly. Check that:

a) Condenser fans are running, with warm air blowing off the condenser coil.

b) Evaporator blowers are running and discharging cool air.

c) Suction line inside condensing unit feels cool.

d) Liquid line inside condensing unit feels warm.

ELECTRICAL CONNECTION

As wiring regulations differ from country to country, please refer to your LOCAL ELECTRICAL CODES for

eld wiring regulations and ensure that these are complied with. Besides, observe the following general

precautions:

a) Ensure that the rated voltage of the unit corresponds to that of the name plate before commencing wiring

work.

b) Provide a power outlet to be used exclusively for each unit. A power supply disconnect and a circuit

breaker for over-current protection should be provided in the exclusive line.

c) The unit must be GROUNDED to prevent possible hazard due to insulation failure.

d) All wiring must be firmly connected.

e) Electrical wiring must not touch the refrigerant piping, compressor and any moving parts of the fan

motors.

7

Page 10

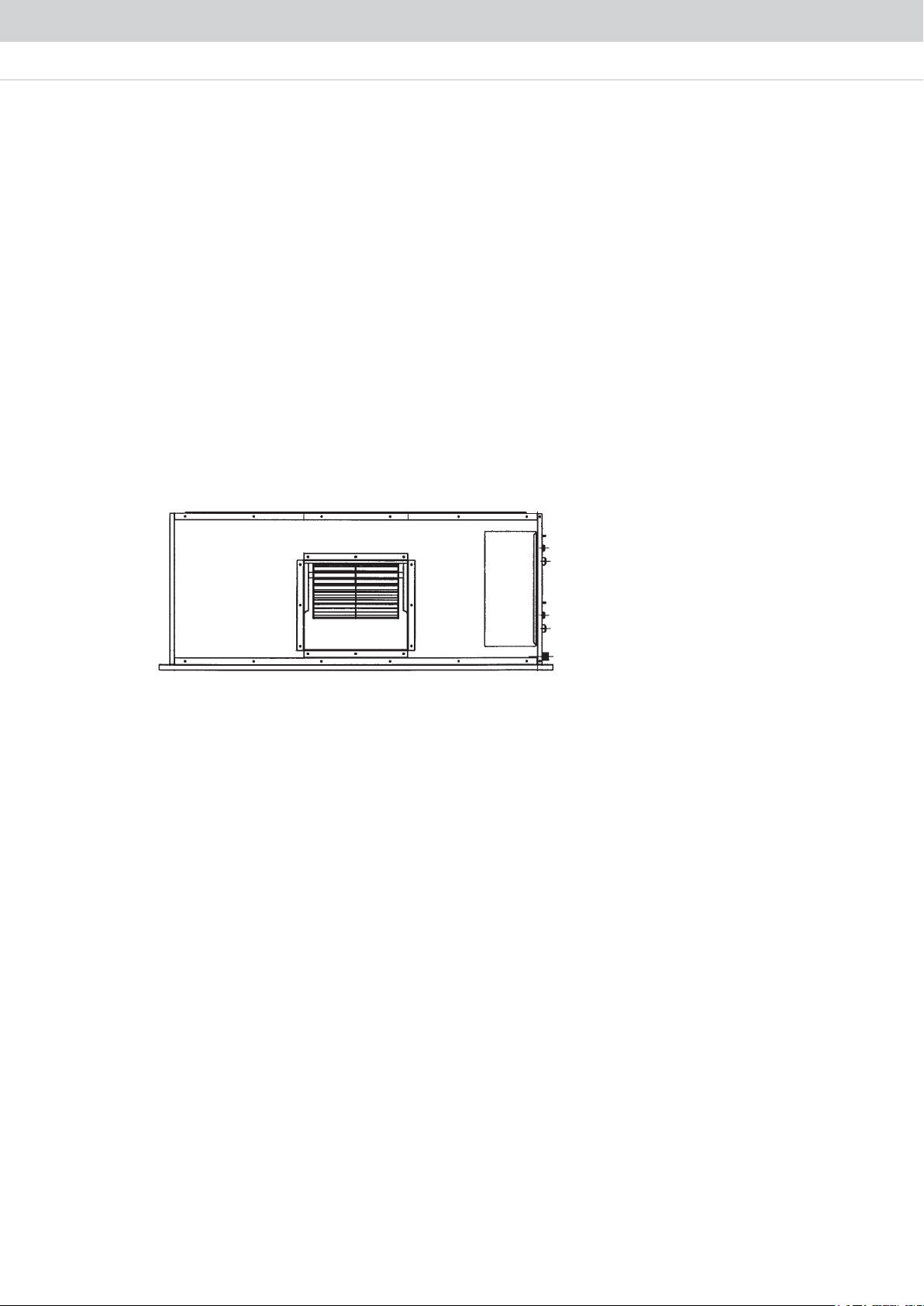

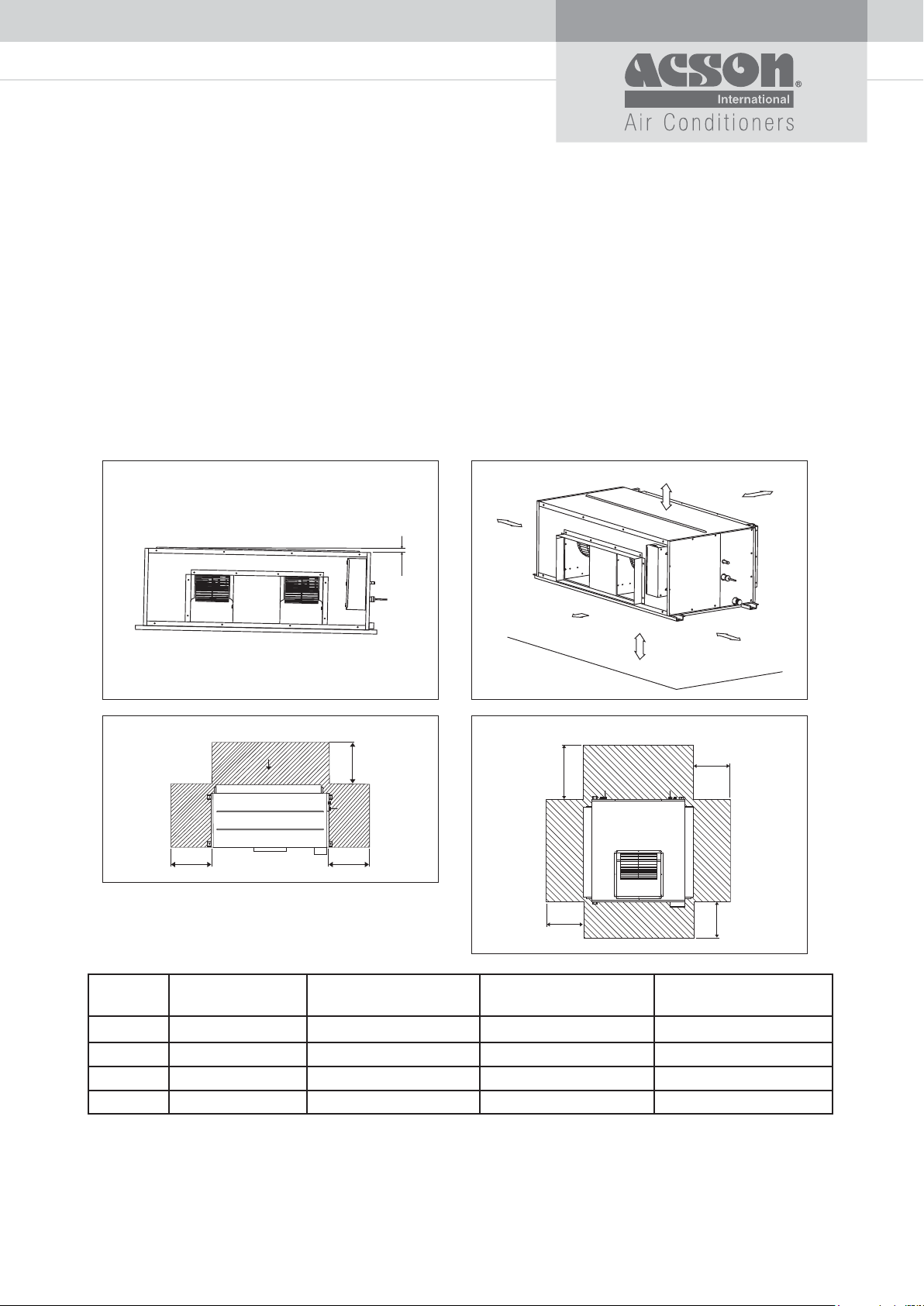

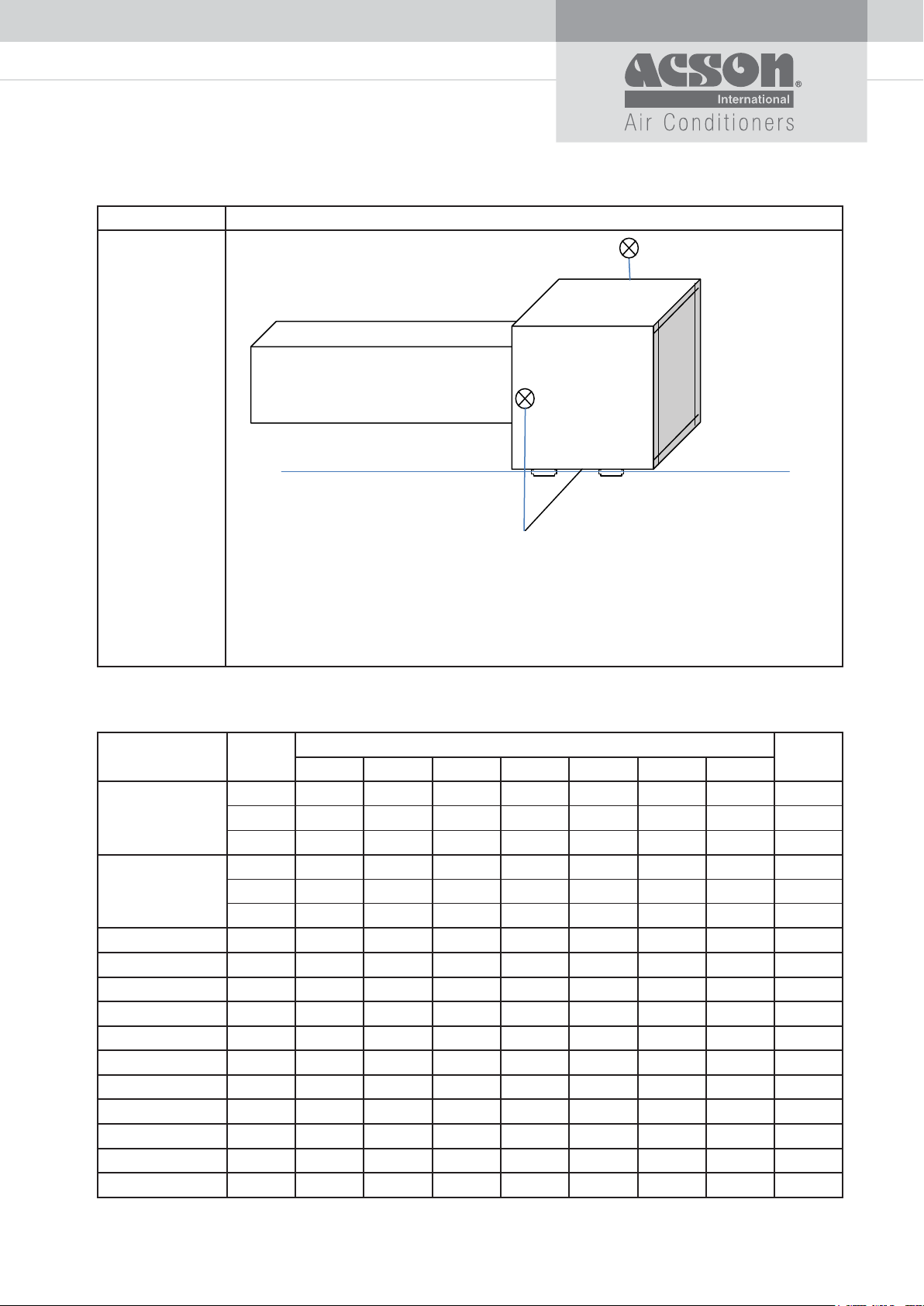

INDOOR CLEARANCE

Mounting

Ensure that the overhead supports are strong enough to hold the unit’s weight. Position hanger rods and

check for alignment with the unit. Check that hangers are secure and that the base of fan-coil unit is level in

the two horizontal directions, taking into account the gradient recommended for drainage flow as shown.

Check the gradient recommended for drainage flow as follow.

Provide clearance for servicing and optimal air flow as shown in the diagram.

The indoor unit must be installed such that there is no short circuit of cool discharge with air discharge.

Respect the installation clearance.

Do not put the indoor unit where there is direct sunlight on unit. The location is suitable for piping and

drainage and it must be have a large distance between a door and unit.

50mm

300mm

10.0

300mm

300mm*

500mm

* for free return of air

Horizontal air discharge

A

All dimensions in mm

B

A

Vertical air discharge

B

A

D

C

Model A5DB80/100H A5DB125/150/200H A5DB250/300/350H A5DB400/450/500H

A5DB600/750H

A (mm) 800 800 800 800

B (mm) 800 800 800 800

008008--)mm( C

D (mm) - - 1000 1500

8

Page 11

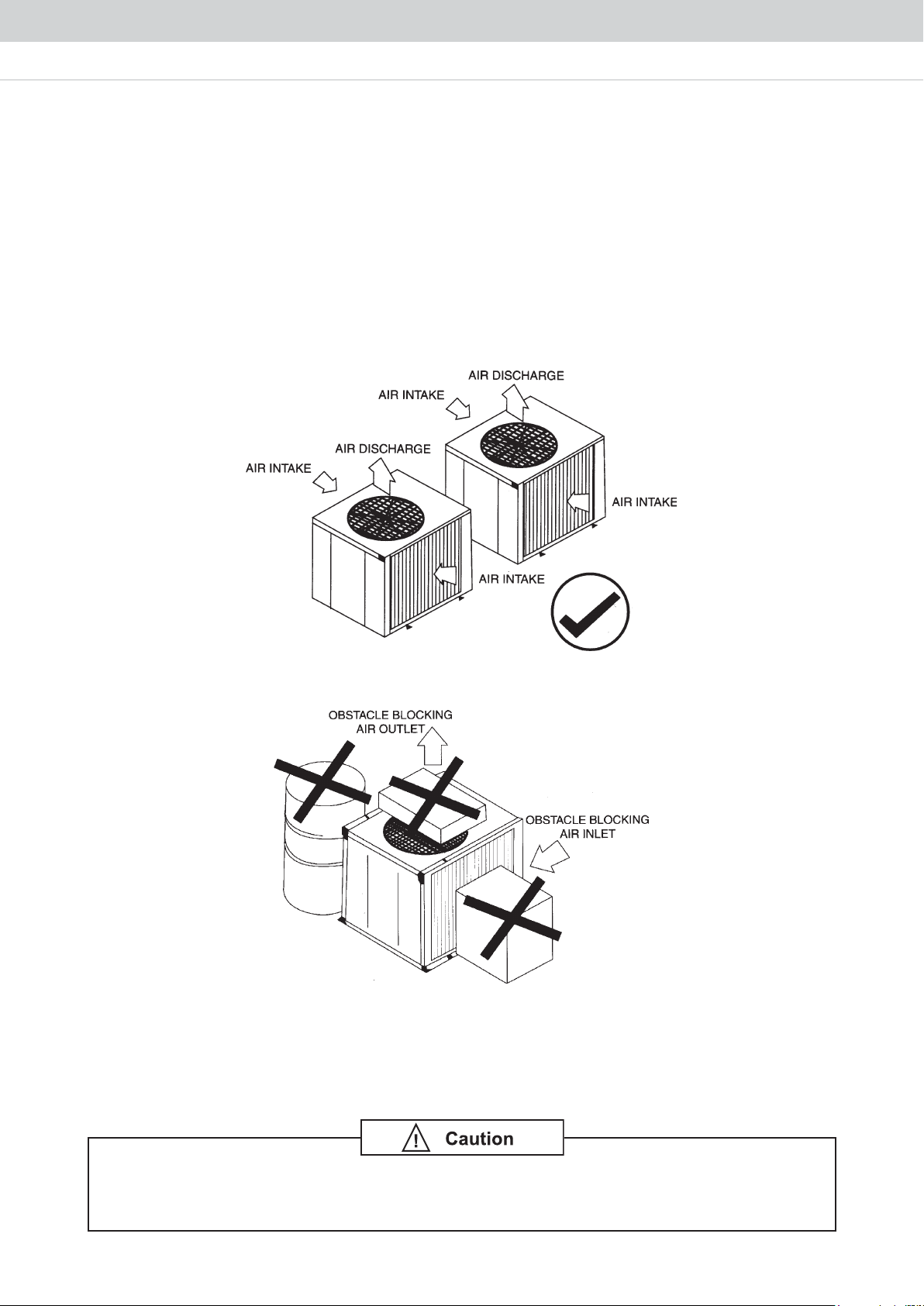

OUTDOOR

LOCATION FOR INSTALLATION OF THE CONDENSING UNITS

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to

achieve maximum cooling capacity, the location selected should ful fill the following requirements:-

a) Install the condensing (outdoor) unit in a way such that hot air distributed by the outdoor condensing unit

cannot be drawn in again (as in the case of short circuit of hot discharge air). Allow sufficient space for

maintenance around the unit.

b) Ensure that there is no obstruction of air

intake or discharge.

c) The location must be well ventilated, so that the unit can draw and distribute plenty of air thus lowering

the condensing temperature.

d) A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

e) A place protected from direct sunlight. Otherwise use an awning for protection, if necessary.

f) A place where the hot air discharge and operating sound level will not annoy the neighbours.

g) The location must not be susceptible to dust or oil mist.

flow into or out of the unit. Remove obstacle which block air

If the condensing unit is operated in an atmosphere containing oils (including machine

oils), salt (coastal area), sulphide gas (near hot spring, oil refinery plant), such as

substances may lead to failure of the unit.

9

Page 12

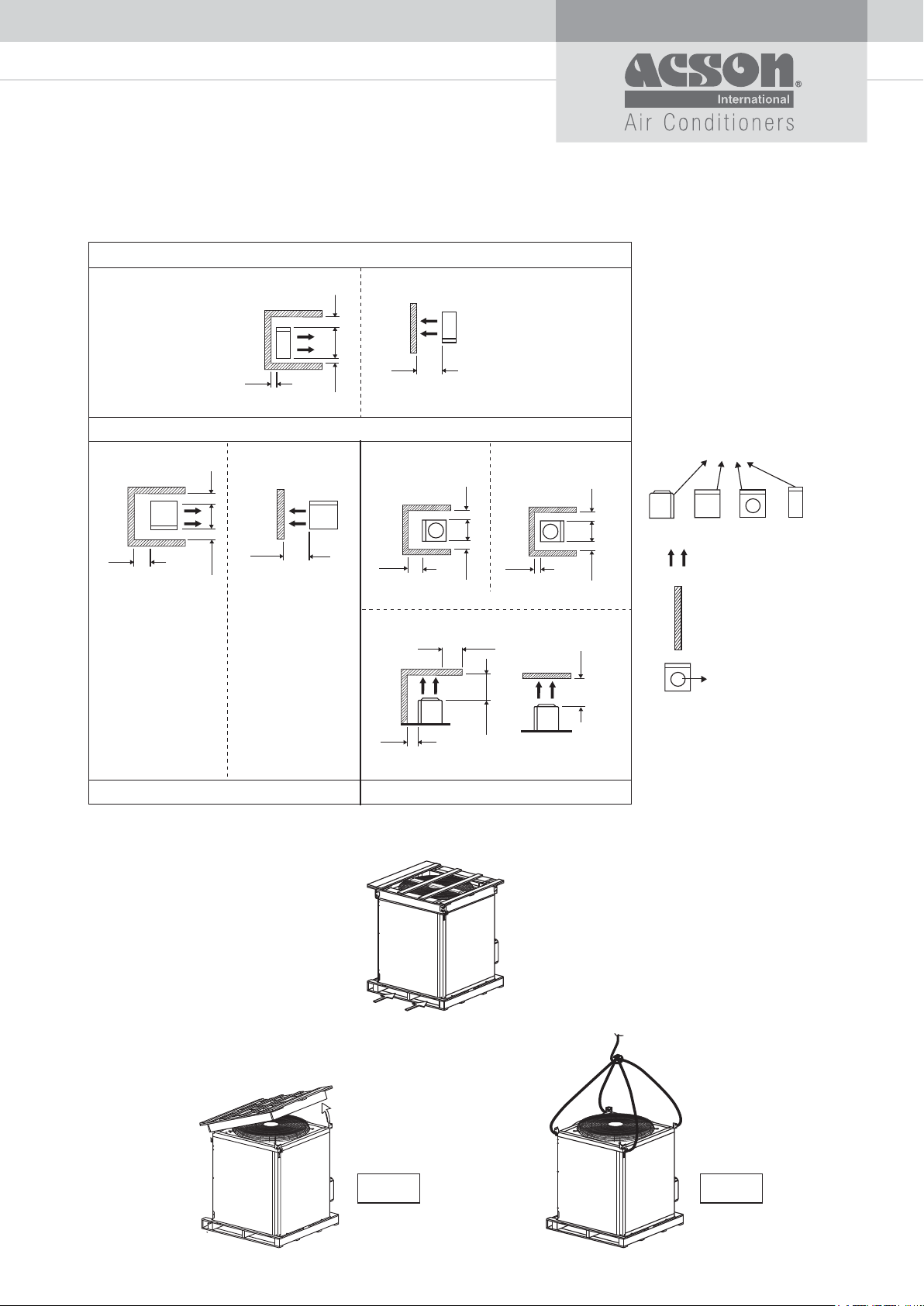

OUTDOOR CLEARANCE

SINGLE UNIT

300

PATTERN 1

300

600

300

1500

PATTERN 1

TOP VIEW

PATTERN 2

TOP VIEWTOP VIEW

300 600

A5MC80H

PATTERN 2

1200

TOP VIEW

PATTERN 1

300100

600

TOP VIEW TOP VIEW

600

SIDE VIEW

300

PATTERN 3

<1500

1500

PATTERN 2

FRONT VIEW

A5MC100/125/150H VERTICAL A5MC100/125/150H HORIZONTAL

1500

100

300

SERVICE PANEL

AIR DISCHARGE

DIRECTION

WALL / CEILING

AIR DISCHARGE GRILL

NOTE :

1) ALL DIMENSION ARE IN MM.

2) ALL DIMENSION MENTIONED ARE

MINIMUM DISTANCE REQUIRED.

UNLESS OTHERWISE SPECIFIED.

Unit Lifting

a) By pallet truck / fork lift

b) By crane

LEFT BY PALLET TRUCK/FOKLIFT

LEFT BY CRANE USING BELT

CONNECT TO 4 CORNER HOIST BRACKET

REMOVE THE TOP CRATE

Step 1 Step 2

10

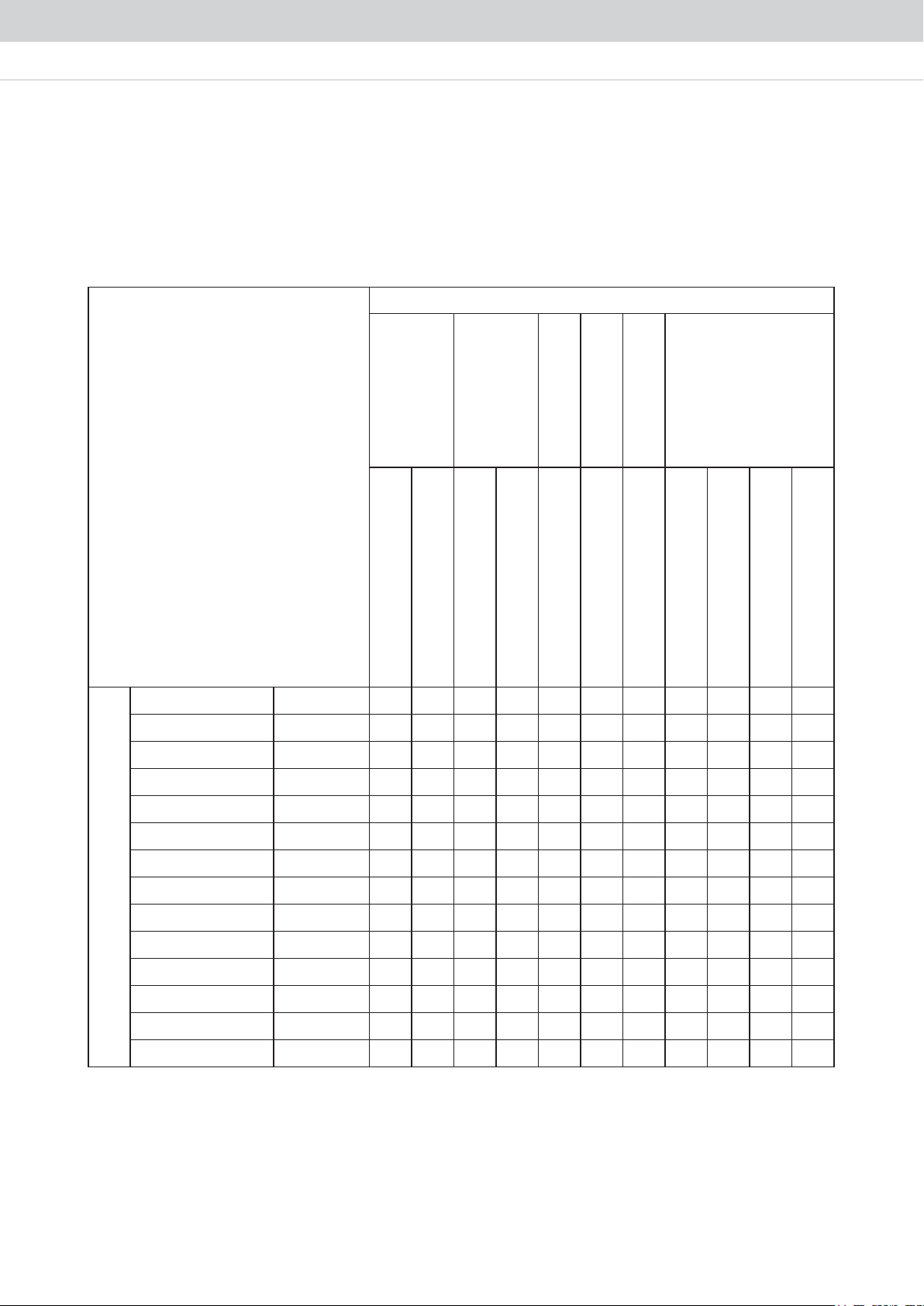

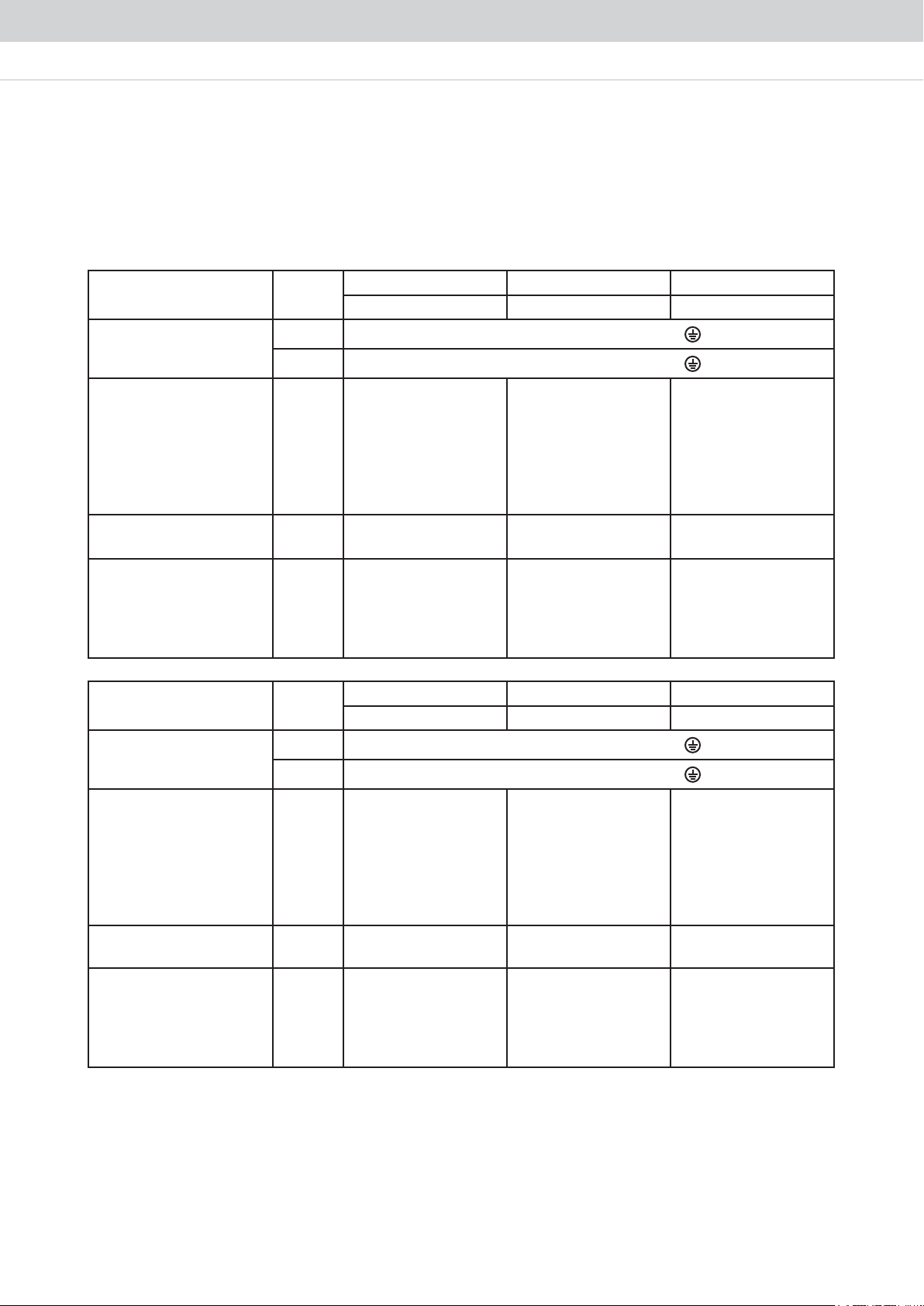

Page 13

CABLE SIZE

Cooling only

Model Unit

Voltage range**

Power supply cable size*

a) Indoor Unit

b) Outdoor Unit

c) Total

Number of conductors

a) Indoor Unit

b) Outdoor Unit

Interconnection cable size*

Number of conductors

Recommended fuse/

circuit breaker rating*

a) Indoor Unit

b) Outdoor Unit

c) Total

Model Unit

Voltage range**

Power supply cable size*

a) Indoor Unit

b) Outdoor Unit

c) Total

Number of conductors

a) Indoor Unit

b) Outdoor Unit

Interconnection cable size*

Number of conductors

Recommended fuse/

circuit breaker rating*

a) Indoor Unit

b) Outdoor Unit

c) Total

Indoor

Outdoor

2

mm

2

mm

2

mm

2

mm

A

A

A

Indoor

Outdoor

2

mm

2

mm

2

mm

2

mm

A

A

A

A5DB80H A5DB100H A5DB125H

A5MC80H A5MC100H A5MC125H

380 - 415V / 3Ph /50Hz + N +

380 - 415V / 3Ph /50Hz + N +

1.0

2.5

2.5

-

5

1

4

6

32

32

1.0

2.5

2.5

-

5

1

4

16

32

40

1.0

2.5

2.5

5

5

-

-

4

40

40

A5DB150H A5DB200H2 A5DB250H2

A5MC150H

A5MC100H x 2 A5MC125H x 2

380 - 415V / 3Ph /50Hz + N +

380 - 415V / 3Ph /50Hz + N +

1.0

4.0

4.0

5

5

-

-

6

50

50

1.0

2.5

6.0

5

5

-

-

10

32

50

1.0

2.5

10.0

5

5

-

-

16

40

63

11

Page 14

Model Unit

Voltage range**

Power supply cable size*

a) Indoor Unit

b) Outdoor Unit

c) Total

Number of conductors

a) Indoor Unit

b) Outdoor Unit

Interconnection cable size*

Number of conductors

Recommended fuse/

circuit breaker rating*

a) Indoor Unit

b) Outdoor Unit

c) Total

Indoor

Outdoor

2

mm

2

mm

2

mm

2

mm

A

A

A

A5DB300H2 A5DB300H3 A5DB350H3

A5MC150H

x 2

A5MC100H

x 3

A5MC100H

380 - 415V / 3Ph /50Hz + N +

A5MC125H

380 - 415V / 3Ph /50Hz + N +

1.0

4.0

16.0

5

5

-

-

16

50

80

1.0

2.5

16.0

5

5

-

-

16

40

63

1.0

2.5

16.0

5

5

-

-

16

32

80

x 2

-

-

16

40

80

Model Unit

Voltage range**

Power supply cable size*

a) Indoor Unit

b) Outdoor Unit

c) Total

Number of conductors

a) Indoor Unit

b) Outdoor Unit

Interconnection cable size*

Number of conductors

Recommended fuse/

circuit breaker rating*

a) Indoor Unit

b) Outdoor Unit

c) Total

Indoor

Outdoor

2

mm

2

mm

2

mm

2

mm

A

A

A

A5DB400H4 A5DB450H3 A5DB500H4

A5MC100H x 4

380 - 415V / 3Ph /50Hz + N +

A5MC150H x 3 A5MC125H x 4

380 - 415V / 3Ph /50Hz + N +

1.0

2.5

25.0

5

5

-

-

20

32

80

1.0

4.0

25.0

5

5

-

-

20

50

100

2.5

2.5

25.0

5

5

-

-

32

40

100

12

Page 15

Model Unit

Voltage range**

Indoor

Outdoor

A5MC150H x 4 A5MC150H x 5

380 - 415V / 3Ph /50Hz + N +

380 - 415V / 3Ph /50Hz + N +

Power supply cable size*

a) Indoor Unit

b) Outdoor Unit

c) Total

mm

mm

mm

2

2

2

2.5

4.0

35.0

2.5

4.0

50.0

Number of conductors

a) Indoor Unit

b) Outdoor Unit

Interconnection cable size*

Number of conductors

mm

5

5

2

-

-

5

5

-

-

Recommended fuse/

circuit breaker rating*

a) Indoor Unit

b) Outdoor Unit

c) Total

A

A

A

32

50

125

50

50

175

IMPORTANT:

* These values are for information only. They should be checked and selected to

comply with local and/or national codes and regulations.

They are also subject to the type of installation and size of conductors.

** The appropriate voltage range should be checked with label data on the unit.

5H057BD5A4H006BD5A

13

Page 16

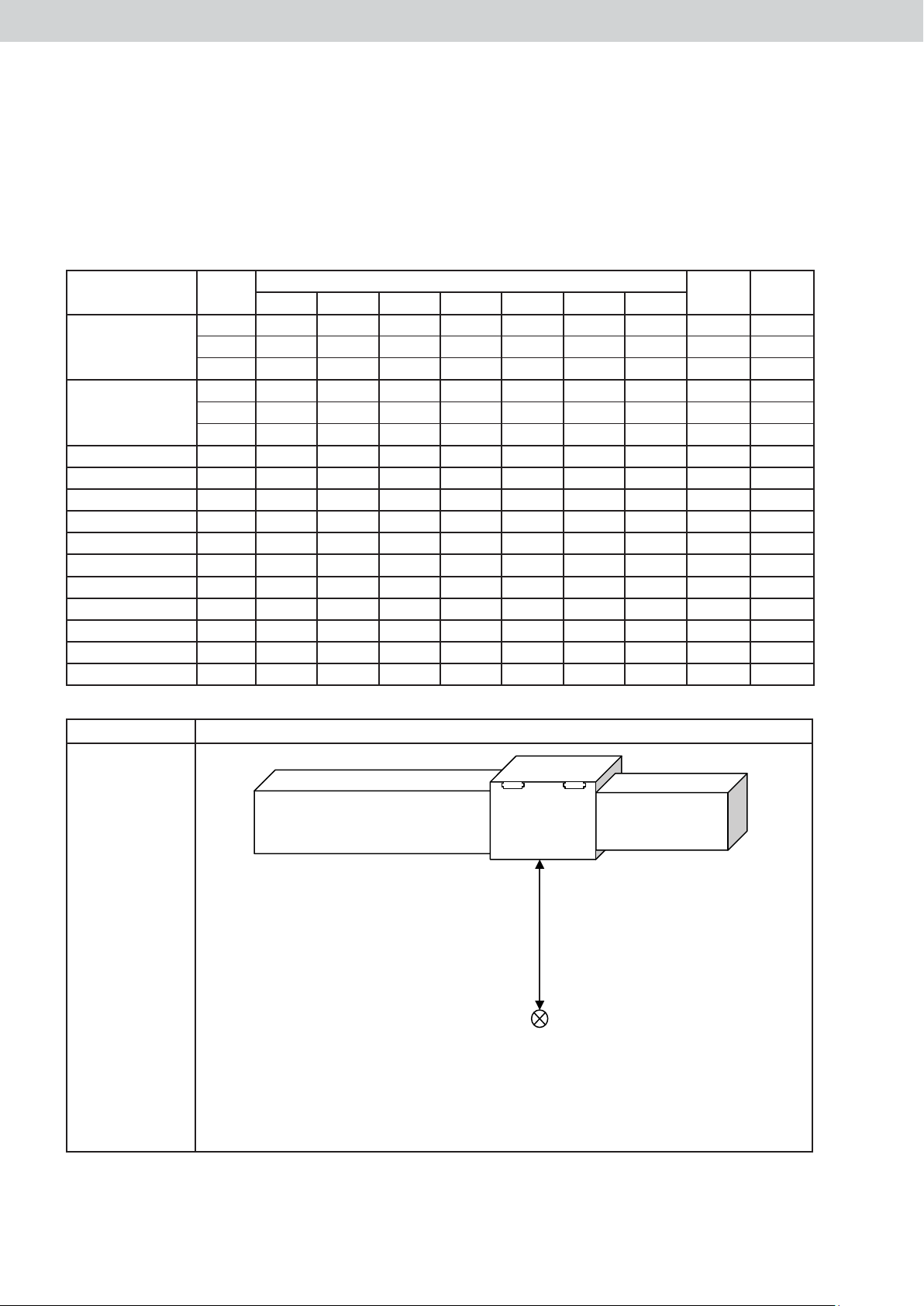

REFRIGERANT PIPING

Maximum Piping Length and Maximum Number of Bends

When the pipe length becomes too long, both the capacity and reliability will drop and as the number of

bends increases, system piping resistance to the refrigerant flow increases, thus lowering the cooling

capacity. As a result the compressor may become defective. Always choose the shortest path and follow the

recommendation as tabulated below:

Cooling Only Model

Outdoor A5MC80/100/125/150H

Maximum Allowable Length, m 75

Maximum Allowable Elevation, m 30

Equivalent length for various fitting (meter)

tnioj LeziS epiP Trap bend

03.181.0)mm25.9 DO( ”8/3

05.102.0 )mm07.21 DO( ”2/1

00.252.0)mm88.51 DO( ”8/5

01.253.0 )mm50.91 DO( ”4/3

00.304.0 )mm32.22 DO( ”8/7

04.354.0 )mm04.52 DO( ”1

07.305.0 )mm85.82 DO( ”8/1 1

04.406.0 )mm29.43 DO( ”8/3 1

Notes:

1. Equivalent piping length is obtained with actual length of gas piping.

2. 90° bend of piping is equivalent to L joint.

Bending must be carefully made so as not to crush the pipe.

Use a pipe bender to bend a pipe where possible.

CAUTION

Our guarantee on the performance of our air-conditioners is strictly revoked if the height

and/or length of the refrigerant piping system installed is beyond the limit above.

Additional Charge

For Brazed type, if the piping is less than 7.5m, follow the charge level on serial number sticker. When the

piping is more than 7.5m, use the table below.

R410A

Liquid Pipe OD (in) Additional Charge (kg/m)

80.0’’2/1

41.0’’8/5

NOTE:

The additional refrigerant charge amount recommended is a guideline for long piping

application. The actual charge required may be different from the guideline due to different

application and variation in site condition.

14

Page 17

SOUND DATA

SOUND PRESSURE LEVEL

Indoor

Model Speed

High 57 48 50 45 46 40 29 52 47

A5DB80H

A5DB100H

A5DB125H High 53 52 53 46 43 39 28 53 49

A5DB150H High 54 54 56 48 45 41 32 56 53

A5DB200H2 High 58 60 60 55 54 48 42 61 57

A5DB250H2 High 62 57 59 59 57 52 43 63 58

A5DB300H2/H3 High 66 60 62 61 59 54 44 66 60

A5DB350H3 High 67 60 62 62 59 54 44 66 61

A5DB400H4 High 67 64 63 63 59 54 45 66 62

A5DB450H3 High 68 64 65 63 60 55 46 68 62

A5DB500H4 High 69 66 66 64 61 56 47 68 63

A5DB600H4 High 70 68 68 66 62 57 48 70 65

A5DB750H5 High 71 69 69 67 63 57 48 71 66

Med 55 48 51 45 46 39 28 52 47

Low 60 47 50 44 45 38 27 52 46

High 64 54 52 48 48 42 34 55 50

Med 64 53 51 47 48 42 33 54 50

Low 64 52 50 45 48 41 32 54 50

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz

1/1 Octave Sound Pressure (dB, ref 20μPa)

Overall

(dBA)

Criteria

Noise

A5DB80H

A5DB100H

A5DB125H

A5DB150H

A5DB200H2

noitacoL gnirusaeM ledoM roodnI

2m discharge duct length

UNIT

1.5m

1m return duct length

Microphone position:

1.5m below centre of the unit.

(Tested with 2m length duct at the air discharge outlet and 1m length air return inlet)

Standard: JIS B 8615

15

Page 18

A5DB250H2

A5DB300H2/H3

A5DB350H3

A5DB400H4

A5DB450H3

A5DB500H4

A5DB600H4

A5DB750H5

noitacoL gnirusaeM ledoM roodnI

UNIT

2m discharge duct length

1m

1m

Microphone position:

1m away from every side panel of the unit and 1m above the fl oor level.

(Tested with 2m length duct at the air discharge outlet only)

Standard: JIS B 8615

Free return duct

Sound Power Level

Model Speed

*A5DB80H

*A5DB100H

High

Med

Low

High

Med

Low

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz

68 67 70 69 64 62 54 73

69 64 68 68 61 59 60 70

66 62 66 63 58 56 46 67

74 72 74 73 66 65 59 77

73 70 73 71 64 62 55 75

70 68 71 68 60 59 49 72

1/1 Octave Sound Power Level (dB) ref 1pW

*A5DB125H High 75 76 78 70 69 62 58 78

*A5DB150H High 74 77 78 75 72 69 63 80

*A5DB200H2 High 83 84 83 81 77 73 68 85

A5DB250H2 High 85 86 85 83 79 75 70 87

A5DB300H2/H3 High 87 88 87 85 81 77 72 89

A5DB350H3 High 90 91 90 87 84 80 75 92

A5DB400H4 High 88 89 88 86 82 78 73 90

A5DB450H3 High 91 92 91 89 85 81 76 93

A5DB500H4 High 94 95 94 92 88 84 79 96

A5DB600H4 High 87 88 87 85 81 77 72 89

A5DB750H5 High 91 92 91 89 85 81 76 93

Overall

(dBA)

*Remarks: Test with 5ft length discharge duct, terminated flush with the internal wall of reverberation room.

16

Page 19

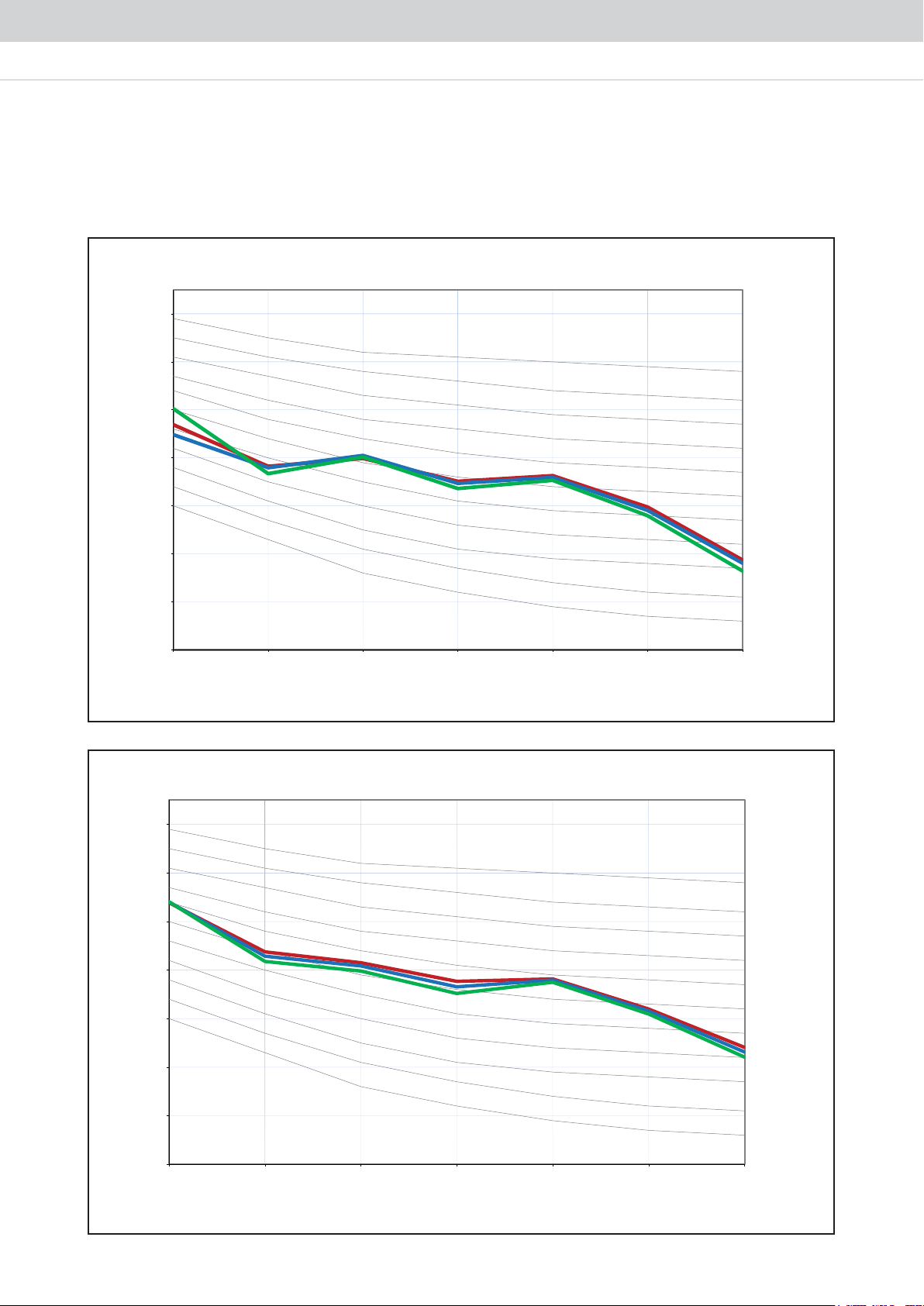

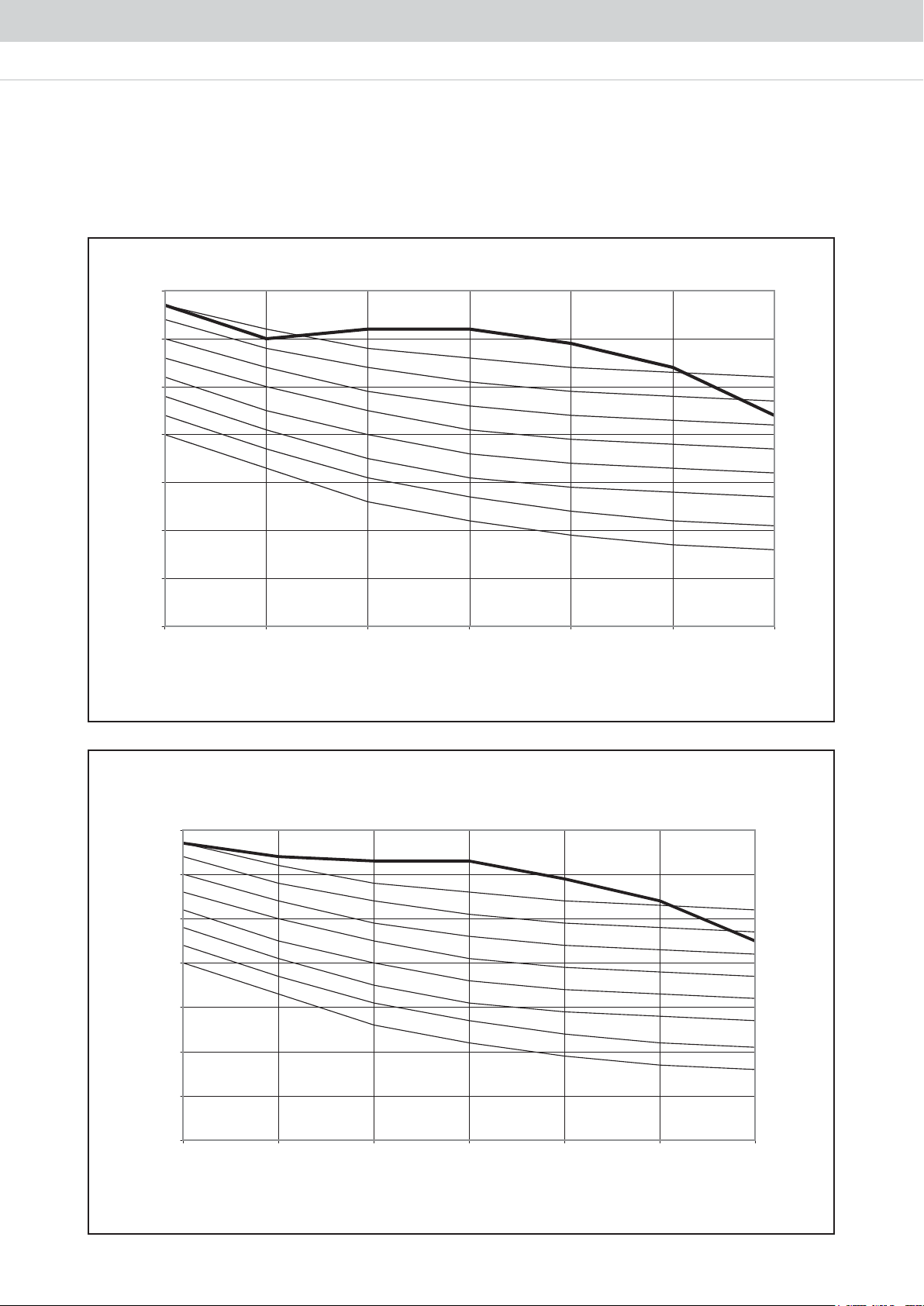

NC Curve

80

A5DB80H

70

Pa)

μ

60

H

M

L

50

40

30

Sound pressure level (dB, ref 20

20

10

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

0008000400020001005052521

Octave-band frequency (Hz)

A5DB100H

17

Sound pressure level (dB, ref 20μPa)

80

70

60

NC70

NC65

NC60

50

40

H

M

L

NC55

NC50

NC45

NC40

30

NC35

NC30

20

NC25

NC20

10

0008000400020001005052521

Octave-band frequency (Hz)

Page 20

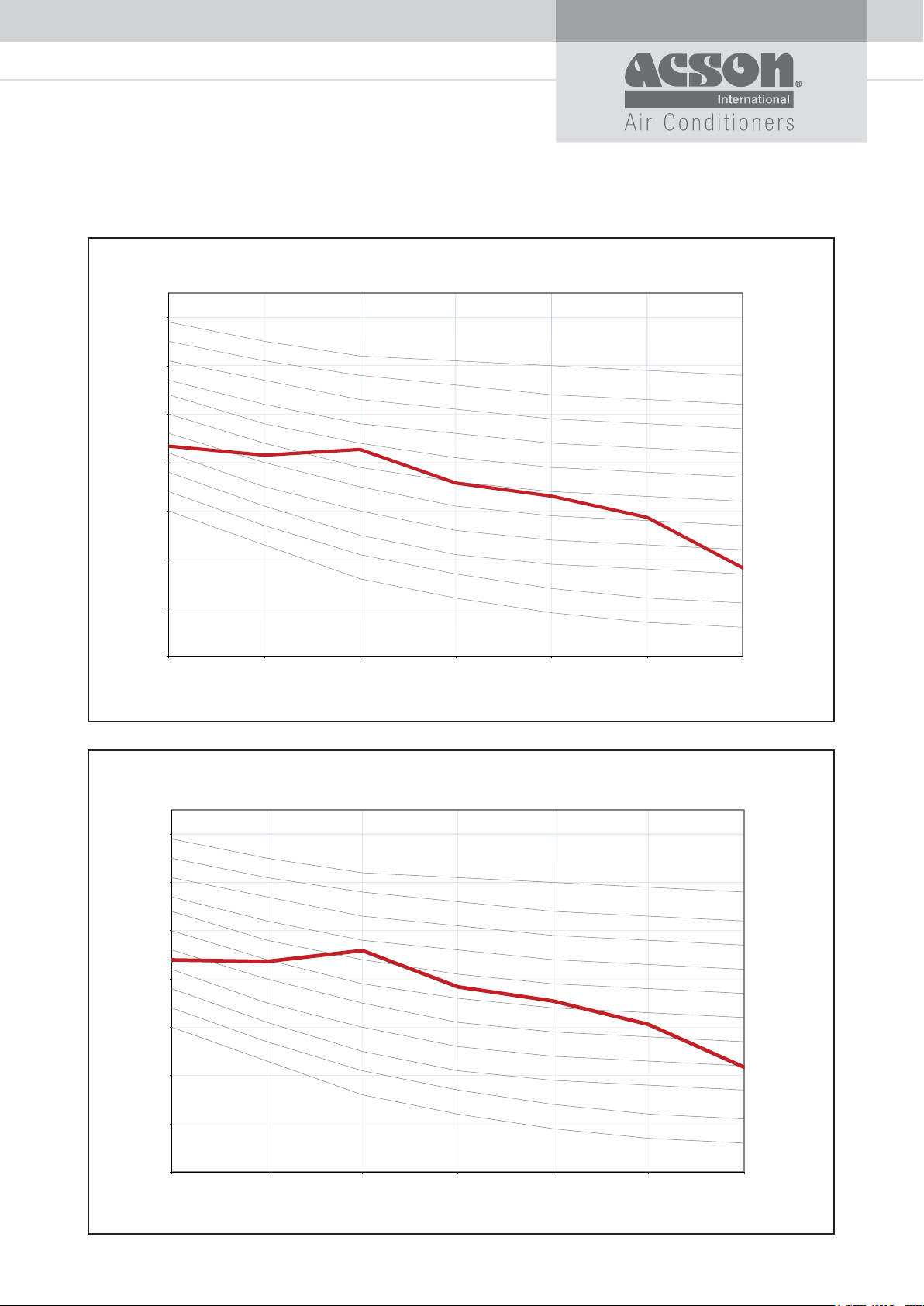

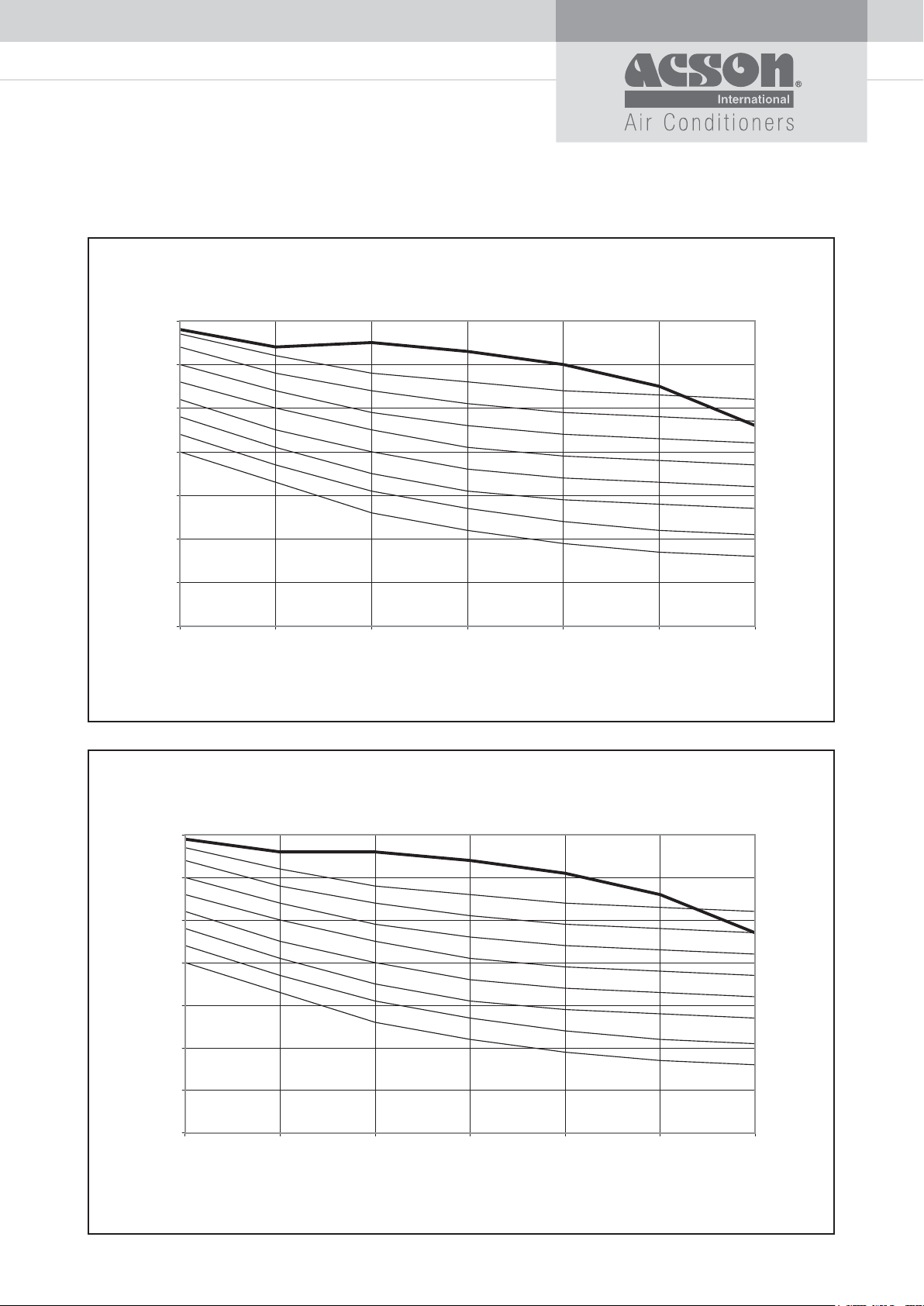

A5DB125H

80

Sound pressure level (dB, ref 20μPa)

70

60

NC70

NC65

NC60

50

40

H

NC55

NC50

NC45

NC40

30

NC35

NC30

20

NC25

NC20

10

0008000400020001005052521

Octave-band frequency (Hz)

A5DB150H

80

70

μPa)

60

50

40

30

Sound pressure level (dB, ref 20

20

10

H

Octave-band frequency (Hz)

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

0008000400020001005052521

18

Page 21

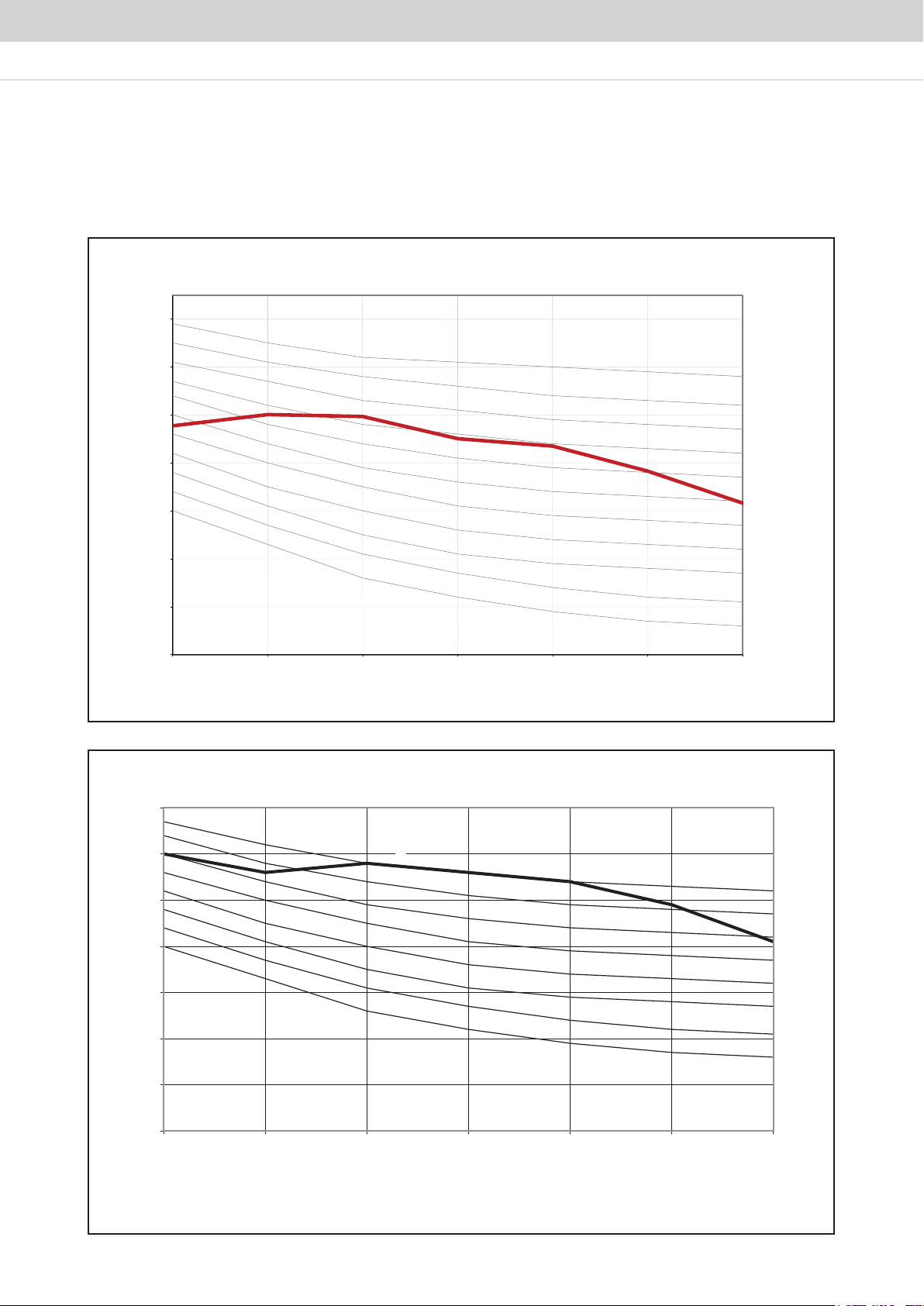

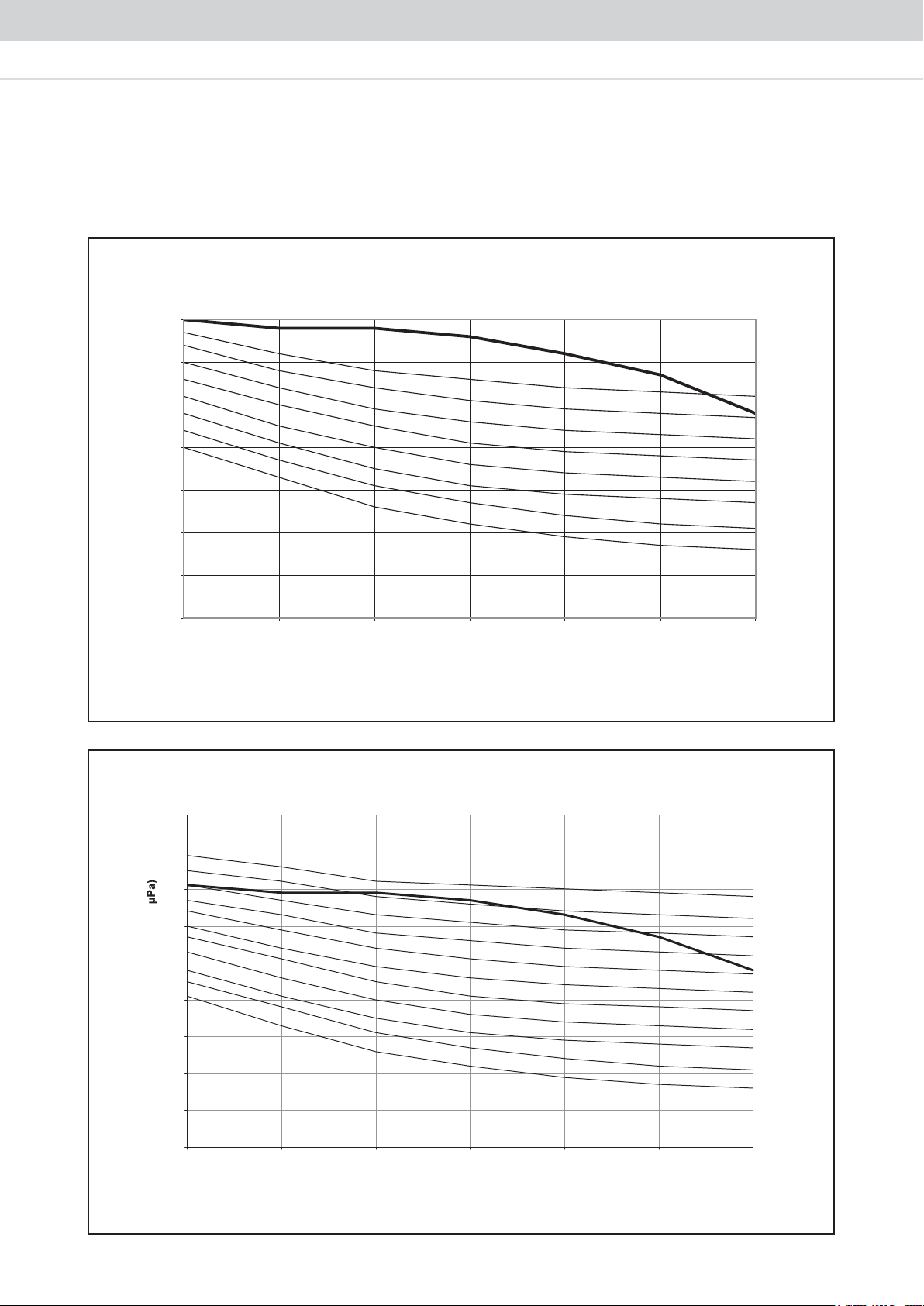

A5DB200H2

80

Sound pressure level (dB, ref 20μPa)

70

70

60

H

50

40

30

20

10

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

0008000400020001005052521

Octave-band frequency (Hz)

A5DB250H2

19

60

H

NC-55

50

NC-50

NC-45

40

NC-40

NC-35

30

NC-30

NC-25

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

NC-20

Octave-band frequency (Hz)

Page 22

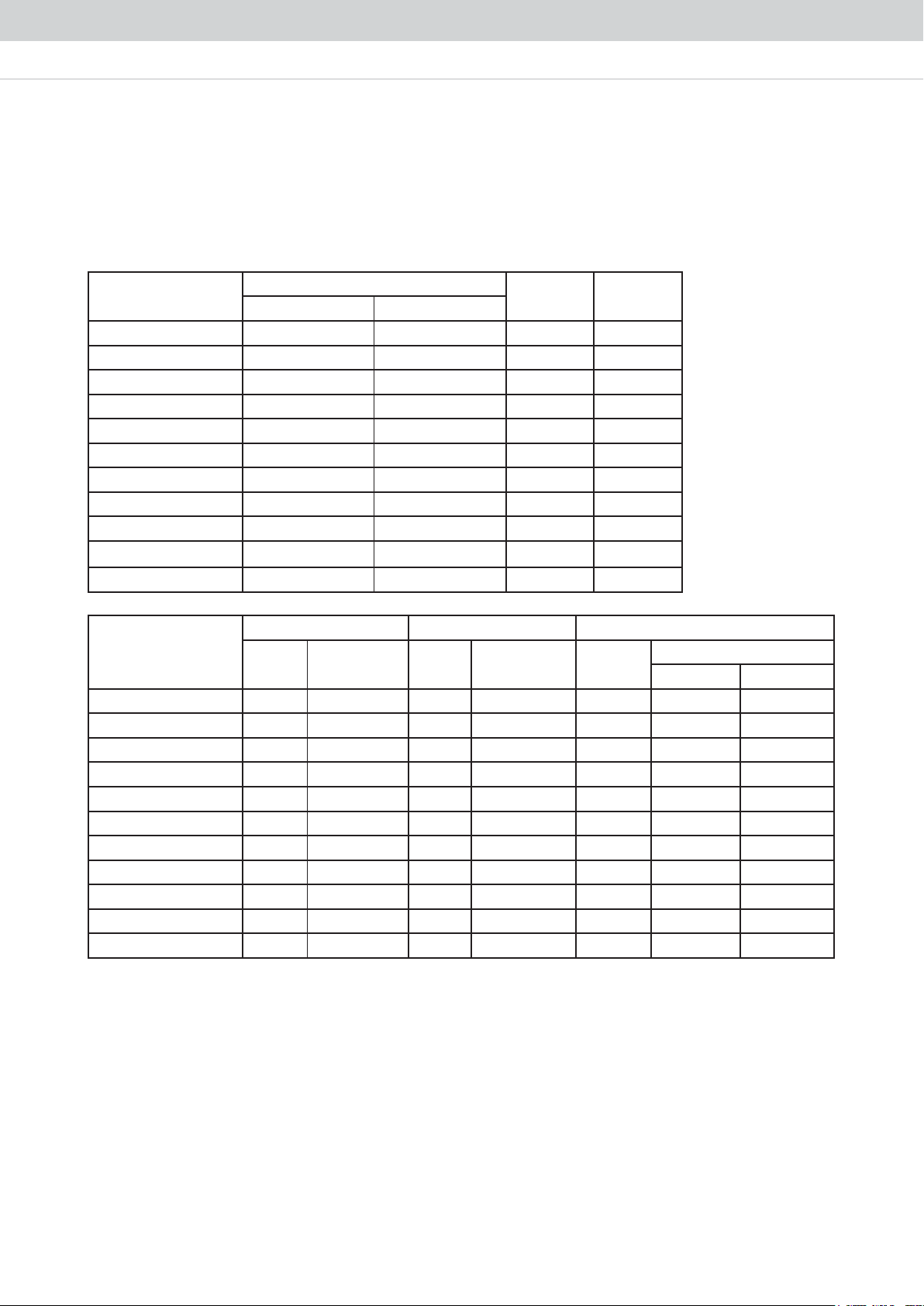

A5DB300H2

70

60

NC-55

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

Octave-band frequency (Hz)

H

A5DB300H3

70

60

50

40

30

20

10

Sound pressure level (dB, ref 20μPa)

0

125 250 500 1000 2000 4000 8000

H

NC-45

NC-35

Octave-band frequency (Hz)

NC-55

NC-50

NC-40

NC-30

NC-25

NC-20

20

Page 23

A5DB350H3

70

H

60

NC-55

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

21

A5DB400H4

70

H

60

NC-55

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

Page 24

A5DB450H3

70

H

60

NC-55

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

A5DB500H4

70

60

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

H

Octave-band frequency (Hz)

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

22

Page 25

A5DB600H4

70

H

60

NC-55

50

40

30

20

Sound pressure level (dB, ref 20μPa)

10

0

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

A5DB750H5

90

80

70

60

50

40

30

20

Sound Pressure Level (dB, ref 20

10

0

125 250 500 1000 2000 4000 8000

H

NC-50

Octave-band Freque ncy (Hz)

NC-70

NC-65

NC-60

NC-55

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

23

Page 26

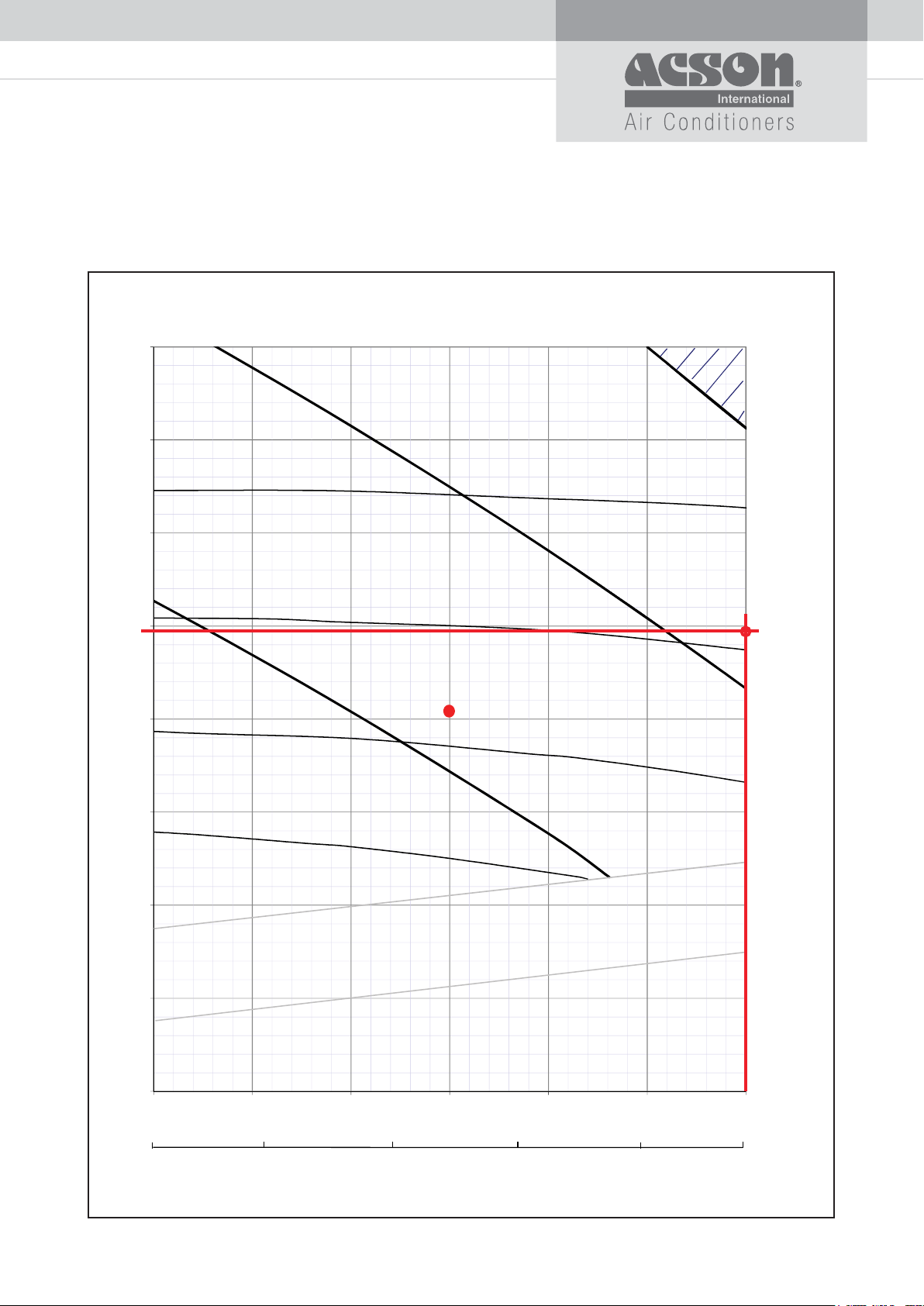

SELECTION PROCESS

Fan Performance Chart

Example 1 :

The following are the design requirements for A5DB250H2 unit:

Model: A5DB250H2

Supply Air Quantity = 9000 CFM

External Static Pressure = 350 Pa

Step 1: From the fan curve (at 9000 CFM),

Standard operating system;

Total Static Pressure = 410 Pa

Internal Static Pressure, ISP = 110 Pa

External Static Pressure, ESP = 300 Pa

External Static Pressure of 300 Pa did not fulfil the design requirements.

Step 2: Therefore at 9000 CFM and 350 Pa external static pressure,

Total Static Pressure = ISP + ESP Pa

= 140 + 350 Pa

= 490 Pa

Step 3: From the fan curve, the design requirement calls for RPM about 810, whereas the unit can only deliver

RPM about 715 under the same CFM. Therefore, it is necessary to RPM about 810 under the same CFM.

Therefore, it is necessary to resize the pulley sizes.

From the table:

Motor pulley = 90 mm

Blower pulley = 200 mm

Motor RPM = 1440

In order to obtain 810 RPM, we recalculate the new blower pulley as:

(while maintaining the motor pulley)

)018/0441( x 09 = bD

mm 0.061 =

The nearest pulley size will be a diameter of 160mm

Recheck, with Db = 160mm

Blower pulley = 1440 x (90/160)

= 810

We thus need to change the blower pulley from 200mm to 160mm in order to obtain the higher operating

static pressure.

Step 4: When the pulley is changed, the V-belt length must be rechecked. We have for horizontal air throw

con guration:

V-belt length, L = 2C + 1.57 (Db + Dm) + (Db - Dm)2 / 4C

99.1 + )09 + 061( 75.1 + )516 x 2( =

mm94.4261 =

We thus can use a belt with a length of 1637mm

where, C = distance between the centres of the two pulleys

Db = diameter of blower pulley

Dm = diameter of motor pulley

Step 5: From the fan curve, we can also notice that the motor power input has increased, which is now higher than

the standard 4.0 kW. At the new operating point, the power is approximately 4.2 kW.

Thus, the existing motor is not sufficient to drive the blower with the smaller 180mm pulley.

Summary:

i) Fan motor kW = 5.5 kW

ii) Blower pulley diameter = 160 mm

iii) V-belt size = 1637 mm

24

Page 27

The following table summarizes the pulley data, motor size used for the A5DB-H series, as manufactured:

Model

A5DB125H 265 240 1.5 1500

A5DB150H 265 260 1.5 1500

A5DB200H2 360 325 3.0 1420

A5DB250H2 620 615 4.0 1440

A5DB300H2/H3 635 610 4.0 1440

A5DB350H3 870 850 5.5 1440

A5DB400H4 805 750 5.5 1440

A5DB450H3 795 745 7.5 1440

A5DB500H4 770 725 11.0 1460

A5DB600H4 515 335 11.0 1460

A5DB750H5 510 330 15.0 1460

Model

A5DB125H SPZ 85 / 1210 SPZ 180 / 1610 SPZ 900 1060

A5DB150H SPZ 71 / 1108 SPZ 140 / 1610 SPZ 800 962

A5DB200H2 SPZ 75 / 1210 SPZ 2 140 / 1610 SPZ 1010 1060

A5DB250H2 SPZ 2 90 / 1610 SPZ 2 180 / 2012 SPZ 1700 1700

A5DB300H2/H3 SPZ 2 95 / 1610 SPZ 2 180 / 2012 SPZ 1650 1700

A5DB350H3 SPZ 2 85 / 1610 SPZ 2 150 / 2012 SPZ 2060 2120

A5DB400H4 SPA 2 100 / 1610 SPA 2 250 / 2517 SPA 2060 2160

A5DB450H3 SPA 2 112 / 1610 SPA 2 250 / 2517 SPA 2060 2160

A5DB500H4 SPA 3 125 / 2012 SPA 3 250 / 2517 SPA 2032 2132

A5DB600H4 SPA 3 125 / 2012 SPA 3 400 / 3020 SPA 1532 1850

A5DB750H5 SPA 3 132 / 2012 SPA 3 400 / 3020 SPA 1500 1850

Pulley Centre Distance, C

Horizontal (mm) Vertical (mm)

Motor Pulley, Dm Blower Pulley, Db V-Belt

Type

Diameter

(mm)

Type

Motor

(kW)

Diameter

(mm)

Motor

Type

RPM

Length (mm)

Horizontal Vertical

25

Page 28

Example 1:

A5DB250H2 Blower Curve

800

700

4.0 kW

5.5 kW

RPM

900

600

Selected

500

490

3.0 kW

Point

800

Standard

Point

400

700

Total Static Pressure (Pa)

300

200

100

0

6000 6500 7000 7500 8000 8500 9000

2830

3100

3300

3700

600

Internal Static

Pressure with

filter

Internal Static

Pressure w/o

filter

4100

Air Flow

9000

4250

CFM

L/s

26

Page 29

FAN PERFORMANCE CURVE

760

900

1320

1040

1180

SUPER HIGH

140

LOW

120

100

A5DB80H (with filter)

MEDIUM

SUPER HIGH

HIGH

27

80

External Static Pressure (Pa)

60

40

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800

470

620

CFM

L/s

Air Flow

Page 30

160

A5DB80H (without filter)

140

120

LOW

MEDIUM

HIGH

SUPER

HIGH

External Static Pressure (Pa)

100

80

1320

CFM

L/s

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800

470

620

760

900

1040

1180

Air Flow

28

Page 31

160

140

120

A5DB100H (with filter)

LOW

MEDIUM

HIGH

100

External Static Pressure (Pa)

80

60

1700

CFM

L/s

2000 2200 2400 2600 2800 3000 3200 3400 3600

950

1080

1210

1320

1450

1570

Air Flow

29

Page 32

200

A5DB100H (without filter)

180

160

140

120

LOW

MEDIUM

HIGH

100

External Static Pressure (Pa)

80

60

40

2000 2200 2400 2600 2800 3000 3200 3400 3600

950

1080

1210

1320

1450

1570

1700

CFM

L/s

Air Flow

30

Page 33

500

450

400

350

300

A5DB125H

1.5 kW

RPM

RPM

RPM

RPM

250

200

Total Static Pressure (Pa)

150

500

100

50

0

2950 3150 3350 3550 3750 3950 4150 4350 4550

1390

1580

Internal Static

Pressure with

filter

Internal Static

Pressure w/o

filter

1770

1960

2150

700

600

CFM

L/S

31

Air Flow

Page 34

500

80

1.5 kW

A5DB150H

RPM

RPM

RPM

RPM

Total Static Pressure (Pa)

450

400

350

300

250

200

900

1.1kW

700

150

100

50

0

3600 3800 4000 4200 4400 4600 4800 5000 5200 5400

1700

1910

2120

600

Internal Static

Pressure with

filter

Internal Static

Pressure w/o

filter

2340

Air Flow

2550

CFM

L/S

32

Page 35

A5DB200H2

600

550

500

450

400

350

300

250

3.0 kW

Standard

Point

1000

900

RPM

RPM

RPM

RPM

33

Total Static Pressure (Pa)

200

150

600

100

50

0

4800 5000 5200 5400 5600 5800 6000 6200 6400 6600 6800 7000 7200

2260

2550

2830

700

Internal Static

Pressure with

Internal Static

Pressure w/o

3110

Air Flow

3400

800

CFM

L/S

Page 36

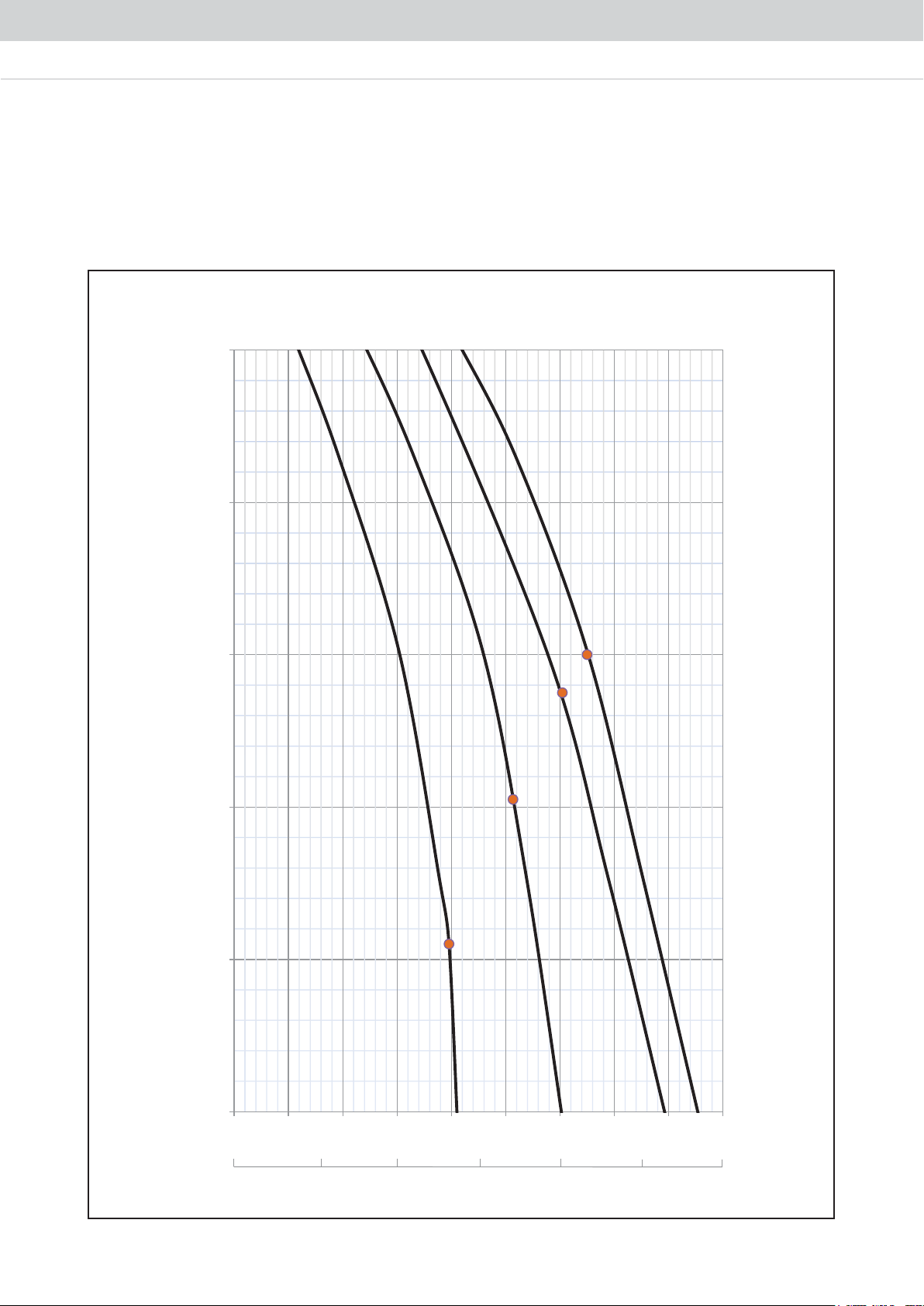

A5DB250H2

800

700

4.0 kW

5.5 kW

RPM

900

600

500

3.0 kW

800

Standard

Point

400

700

Total Static Pressure (Pa)

300

200

100

0

6000 6500 7000 7500 8000 8500 9000

2830

3100

3300

3700

600

Internal Static

Pressure with

filter

Internal Static

Pressure w/o

filter

4100

Air Flow

4250

CFM

L/s

34

Page 37

A5DB300H2/H3

800

700

600

500

400

4.0 kW

3.0 kW

5.5 kW

RPM

900

800

Standard

Point

Total Static Pressure (Pa)

300

Internal Static

Pressure with

Internal Static

Pressure w/o

4700

4100

600

4400

200

100

0

7500 8000 8500 9000 9500 10000 10500

3540

3800

Air Flow

4960

700

CFM

L/s

35

Page 38

A5DB350H3

800

700

600

500

400

5.5 kW

4.0 kW

7.5 kW

Standard

Point

RPM

900

800

Total Static Pressure (Pa)

300

700

200

100

0

9000 9500 10000 10500 11000 11500 12000

4250

4500

4800

5100

Internal Static

Pressure with

filter

Internal Static

Pressure w/o

filter

5400

Air Flow

CFM

5660 L/s

36

Page 39

800

700

600

500

400

5.5 kW

A5DB400H4

7.5 kW

RPM

800

700

4.0 kW

Standard

Point

600

Total Static Pressure (Pa)

300

200

500

Internal Static

Pressure with

100

0

4720

5200

5700

6200

filter

Internal Static

Pressure w/o

filter

6610

0004100031000210001100001

CFM

L/s

Air Flow

37

Page 40

A5DB450H3

M

800

700

7.5 kW

11.0 kW

RPM

800

kW

5.5

600

500

Standard

Point

700

400

Total Static Pressure (Pa)

600

300

200

100

0

10500 11500 12500 13500 14500 15500 16500

4960

58805350

500

Internal Static

Pressure with

Internal Static

Pressure w/o

6360 6840 7310

7800

CF

L/s

38

Page 41

A5DB500H4

800

700

600

500

400

7.5 kW

5.5 kW

Standard

Point

11.0 kW

RPM

800

700

39

Total Static Pressure (Pa)

300

200

100

0

12500 13500 14500 15500 16500 17500

5900

6500

600

Internal Static

Pressure with

Internal Static

Pressure w/o

7080

7670

Air Flow

8260

CFM

L/s

Page 42

A5DB600H4

1000

900

800

700

600

500

400

Total Static Pressure (Pa)

11.0 kW

7.5 kW

5.5 kW

RPM

600

500

Standard

Point

400

300

200

100

0

15000 16000 17000 18000 19000 20000 21000

7070

7500

8000

Internal Static

Pressure with

Internal Static

Pressure w/o

8500

9000

9500

9910

CFM

L/s

40

Page 43

A5DB750H5

Total Static Pressure (Pa)

1000

900

800

700

600

500

400

11 kW

15 kW

Standard

Point

RPM

600

500

41

300

200

Internal Static

Pressure with

100

Internal Static

Pressure w/o

0

18000 19000 20000 21000 22000 23000 24000 25000 26000 27000

8500

9000

9500

10500

400

11000

000210051100001

12500

Air Flow

12700

CFM

L/s

Page 44

ENGINEERING & PHYSICAL DATA

Engineering Data – R410A COOLING MODEL

MODEL

NOMINAL COOLING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 7,100 10,000 11,350 14,800

REFRIGERANT CONTROL (EXPANSION DEVICE) TXV

REFRIGERANT TYPE R410A

CONTROL

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa 05107 / 58 / 00108 / 59 / 001

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 553 X 1402 X 605 553 X 1402 X 605 776 X 1540 X 850 776 X 1540 X 850

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 700 X 1522 X 880 700 X 1522 X 880 920 X 1783 X 1184 920 X 1783 X 1184

FAN

FAN MOTOR

INDOOR UNIT

COIL

AIR QUALITY FILTER

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 929 X 1235 X 496 1067 X 880 X 880 1067 X 980 X 980 1166 X 980 X 980

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1085 X 1385 X 684 1231 X 1030 X 1058 1231 X 1130 X 1158 1321 X 1130 X 1158

PIPE

CONNECTION

FAN

FAN MOTOR

OUTDOOR UNIT

COMPRESSOR

COIL

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

AIR DISCHARGE DUCTED

OPERATION WIRED HANDSET

THGIEW TINU 9514838

TYPE CENTRIFUGAL

DRIVE TLEBTCERID

TYPE INDUCTION

INDEX OF PROTECTION (IP) 55PI02PI

INSULATION GRADE CLASS F

RATED INPUT POWER W 620 1350 1060 1420

RATED RUNNING CURRENT A 2.79 5.76 2.46 2.90

POLES 4446

TUBE

FIN

SIZE

TYPE PROPELLER

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 790 750 820 1650

RATED RUNNING CURREN

POLES 6666

TYPE SCROLL

OIL TYPE POE

RATED INPUT POWER W 5690 7900 9470 11730

RATED RUNNING CURRENT A 10.40 14.10 16.00 22.80

LOCKED ROTOR AMP. A 101 139 144 174

TUBE MATERIAL ALUMINIUM

FIN

HIGH CFM 2300 3000 3750 4500

MEDIUM CFM 2200 2800 N/A N/A

LOW CFM 2000 2500 N/A N/A

MATERIAL INNER GROOVE

MATERIAL ALUMINIUM

ROW 333

FIN PER INCH 18

TYPE R15

LENGTH X WIDTH X

THICKNESS

TYPE BRAZED

LIQUID mm / in. 12.70 / ½ 12.70 / ½ 12.70 / ½ 15.88 / ⅝

GAS mm / in. 22.23 / ⅞ 25.40 / 1 28.58 / 1⅛ 34.92 / 1 ⅜

T A 3.44 3.28 3.59 2.97

MATERIAL ALUMINIUM

ROW 1111

FIN PER INCH 12121232

Btu/h 80,000 100,000 125,000 150,000

W 23,400 29,300 36,600 44,000

A)GNILOOC( TNERRUC GNINNUR LANIMON 12.5 17.1 19.7 28.7

W/WREE 3.30 2.93 3.23 2.97

gkEGRAHC TNAREGIRFER 2.50 3.40 4.80 5.20

zH/hP/VECRUOS REWOP Indoor: 220-240 / 1 / 50, Outdoor: 380-415 / 3 / 50

ABd)L/M/H( LEVEL ERUSSERP DNUOS 653545 / 45 / 5525 / 25 / 25

gk

mmEZIS NIARD ETASNEDNOC 34

WTUPTUO ROTOM 375 x 2 360 X 2 1500 1500

mmRETEMAID 7

2

mAERA ECAF

mm 64 X 586 X 73664 X 816 X 734

cpYTITNAUQ 22

RUOLOCGNISAC IVORY WHITE

MFCWOLF RIA 4400 6400 6900 10400

ABdLEVEL ERUSSERP DNUOS 07565696

gkTHGIEW TINU 111 135 157 177

WTUPTUO ROTOM 580 580 680 1500

3

1774 2513 3253 3253

mcTNUOMA LIO

2

mAERA ECAF

RUOLOCGNISAC IVORY WHITE

GNITAEHGNILOOC

0.50 0.60 0.94 0.94

0.98 1.41 1.61 1.76

H051BD5AH521BD5AH001BD5AH08BD5ATINU ROODNI

H051CM5AH521CM5AH001CM5AH08CM5ATINU ROODTUO

42

Page 45

Engineering Data – R410A COOLING MODEL

MODEL

NOMINAL COOLING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 19,700 23,880 30,520 29,710

REFRIGERANT CONTROL (EXPANSION DEVICE) TXV

REFRIGERANT TYPE R410A

CONTROL

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 885 X 1794 X 850 1231 X 1766 X 1069 1231 X 1766 X 1069 1231 X 1766 X 1069

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1154 X 2052 X 1188 1506 X 2034 X 1412 1506 X 2034 X 1412 1506 X 2034 X 1412

FAN

FAN MOTOR

INDOOR UNIT

COIL

AIR QUALITY FILTER

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 1067 X 880 X 880 1067 X 980 X 980 1166 X 980 X 980 1067 X 880 X 880

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1231 X 1030 X 1058 1231 X 1130 X 1158 1321 X 1130X 1158 1231 X 1030 X 1058

PIPE

CONNECTION

FAN

FAN MOTOR

OUTDOOR UNIT

COMPRESSOR

COIL

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

AIR DISCHARGE DUCTED

OPERATION WIRED HANDSET

S NIARD ETASNEDNOC 34

TYPE CENTRIFUGAL

DRIVE BELT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 2400 3300 3760 3760

RATED RUNNING CURRENT A 4.73 6.10 7.10 7.10

POLES 4444

MATERIAL INNER GROOVE

TUBE

MATERIAL ALUMINIUM

FIN

ROW 3333

FIN PER INCH 18

TYPE R15

LENGTH X WIDTH X

THICKNESS

TYPE BRAZED

SIZE

TYPE PROPELLER

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 750 820 1650 750

RATED RUNNING CURRENT A 3.28 3.59 2.97 3.28

POLES 6666

TYPE SCROLL

OIL TYPE POE

RATED INPUT POWER W 7900 9470 11730 7900

RATED RUNNING CURRENT A 14.10 16.00 22.80 14.10

LOCKED ROTOR AMP. A 139 144 174 139

TUBE MATERIAL ALUMINIUM

FIN

LIQUID mm / in. 12.70 / ½ 12.70 / ½ 15.88 / ⅝ 12.70 / ½

GAS mm / in. 25.40 / 1 28.58 / 1⅛ 34.92 / 1 ⅜ 25.40 / 1

MATERIAL ALUMINIUM

ROW 1121

FIN PER INCH 12121212

Btu/h 200,000 250,000 300,000 300,000

W 58,600 73,200 88,000 88,000

A)GNILOOC( TNERRUC GNINNUR LANIMON 35.1 40.6 58.7 52.6

W/WREE 2.97 3.07 2.88 2.96

gkEGRAHC TNAREGIRFER 3.60 x 2 4.00 x 2 4.70 x 2 3.20 x 3

zH/hP/VECRUOS REWOP 380-415 / 3 / 50

MFCWOLF RIA 6000 7500 9000 9000

aP ERUSSERP CITATS LANRETXE 200 200 200 200

ABdLEVEL ERUSSERP DNUOS 66663616

gkTHGIEW TINU 196 323 337 337

mmEZI

WTUPTUO ROTOM 3000 4000 4000 4000

mmRETEMAID 7

2

mAERA ECAF

mm 543 X 738 X 46 534 X 529 X 46 534 X 529 X 46 534 X 529 X 46

cpYTITNAUQ 6663

RUOLOCGNISAC IVORY WHITE

MFCWOLF RIA 6400 6900 10400 6400

ABdLEVEL ERUSSERP DNUOS 56075656

gkTHGIEW TINU 135 157 177 135

WTUPTUO ROTOM 580 680 1500 580

3

2513 3253 3253 2513

mcTNUOMA LIO

2

mAERA ECAF

RUOLOCGNISAC IVORY WHITE

GNITAEHGNILOOC

1.32 1.52 1.69 1.69

1.41 2.26 1.76 1.41

3H003BD5A2H003BD5A2H052BD5A2H002BD5ATINU ROODNI

3 x H001CM5A2 x H051CM5A2 x H521CM5A2 x H001CM5ATINU ROODTUO

43

Page 46

Engineering Data – R410A COOLING MODEL

MODEL

NOMINAL COOLING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 039,54033,93055,43

REFRIGERANT CONTROL (EXPANSION DEVICE) TXV

REFRIGERANT TYPE R410A

CONTROL

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 1486 X 2022 X 1069 1486 X 2174 X 1336

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1766 X 2279 X 1412 1766 X 2431 X 1684 1766 X 2431 X 1684

FAN

FAN MOTOR

INDOOR UNIT

COIL

AIR QUALITY FILTER

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 1067 X 880 X 880 1067 X 980 X 980 1067 X 880 X 880 1166 X 980 X 980

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1231 X 1030 X 1058 1231 X 1130 X 1158 1231 X 1030 X 1058 1321 X 1130 X 1158

PIPE

CONNECTION

FAN

FAN MOTOR

OUTDOOR UNIT

COMPRESSOR

COIL

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

AIR DISCHARGE DUCTED

OPERATION WIRED HANDSET

TYPE CENTRIFUGAL

DRIVE BELT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 097503740235

RATED RUNNING CURRENT A 00.2105.908.01

POLES 444

MATERIAL INNER GROOVE

TUBE

MATERIAL ALUMINIUM

FIN

ROW 333

FIN PER INCH 18

TYPE R15

LENGTH X WIDTH X

THICKNESS

TYPE BRAZED

SIZE

TYPE PROPELLER

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 750 820 750 1650

RATED RUNNING CURRENT A 3.28 3.59 3.28 2.97

POLES 6666

TYPE SCROLL

OIL TYPE POE

RATED INPUT POWER W 7900 9470 7900 11730

RATED RUNNING CURRENT A 14.10 16.00 14.10 22.80

LOCKED ROTOR AMP. A 139 144 139 174

TUBE MATERIAL ALUMINIUM

FIN

LIQUID mm / in. 12.70 / ½ 12.70 / ½ 12.70 / ½ 15.88 / ⅝

GAS mm / in. 25.40 / 1 28.58 / 1⅛ 25.40 / 1 34.92 / 1 ⅜

MATERIAL ALUMINIUM

ROW 1111

FIN PER INCH 12121212

Btu/h 000,054000,004000,053

W 009,131002,711005,201

A)GNILOOC( TNERRUC GNINNUR LANIMON 3.982.074.06

W/WREE 78.289.279.2

gkEGRAHC TNAREGIRFER 3.10 4.70 x 2 3.40 x 4 4.60 x 3

zH/hP/VECRUOS REWOP 380-415 / 3 / 50

MFCWOLF RIA 005310002100501

aPERUSSERP CITATS LANRETXE 052052002

ABdLEVEL ERUSSERP DNUOS 866666

gkTHGIEW TINU 335884134

mmEZIS NIARD ETASNEDNOC 34

WTUPTUO ROTOM 005700550055

mmRETEMAID 7

2

mAERA ECAF

mm 64 X 756 X 07664 X 756 X 916

cpYTITNAUQ 66

RUOLOCGNISAC IVORY WHITE

MFCWOLF RIA 6400 6900 6400 10400

ABdLEVEL ERUSSERP DNUOS 07565656

gkTHGIEW TINU 135 157 135 177

WTUPTUO ROTOM 580 680 580 1500

3

2513 3253 2513 3253

mcTNUOMA LIO

2

mAERA ECAF

RUOLOCGNISAC IVORY WHITE

GNITAEHGNILOOC

1.41 1.61 1.41 1.76

1486 X 2174 X 1336

3H054BD5A4H004BD5A3H053BD5ATINU ROODNI

3 x H051CM5A4 x H001CM5A2 x H521CM5AH001CM5ATINU ROODTUO

64.224.253.2

44

Page 47

Engineering Data – R410A COOLING MODEL

MODEL

NOMINAL COOLING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 046,87026,16099,94

REFRIGERANT CONTROL (EXPANSION DEVICE) TXV

REFRIGERANT TYPE R410A

CONTROL

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 1486 X 2174 X 1336 1918 X 2174 X 1775 2197 X 2174 X 1775

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1766 X 2431 X 1684 2122 X 2399 X 2005 2401 X 2399 X 2005

FAN

FAN MOTOR

INDOOR UNIT

COIL

AIR QUALITY FILTER

UNIT DIMENSION HEIGHT X WIDTH X DEPTH mm 1067 X 980 X 980 1166 X 980 X 980 1166 X 980 X 980

PACKING DIMENSION HEIGHT X WIDTH X DEPTH mm 1231 X 1130 X 1158 1321 X 1130 X 1158 1321 X 1130 X 1158

PIPE

CONNECTION

FAN

FAN MOTOR

OUTDOOR UNIT

COMPRESSOR

COIL

ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 (NON-DUCTED UNIT) OR ISO 13253 (DUCTED UNIT).

INDOOR: 27°C DB/ 19°C WB INDOOR: 20°C DB

OUTDOOR: 35°C DB/ 24°C WB OUTDOOR: 7°C DB/ 6°C WB

AIR DISCHARGE DUCTED

OPERATION WIRED HANDSET

TYPE CENTRIFUGAL

DRIVE BELT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 0471100180388

RATED RUNNING CURRENT A 02.3208.5108.61

POLES 444

MATERIAL INNER GROOVE

TUBE

MATERIAL ALUMINIUM

FIN

ROW 334

FIN PER INCH 18

TYPE R15

LENGTH X WIDTH X

THICKNESS

TYPE BRAZED

SIZE

TYPE PROPELLER

DRIVE DIRECT

TYPE INDUCTION

INDEX OF PROTECTION (IP) IP55

INSULATION GRADE CLASS F

RATED INPUT POWER W 05610561028

RATED RUNNING CURRENT A 79.279.295.3

POLES 666

TYPE SCROLL

OIL TYPE POE

RATED INPUT POWER W 03711037110749

RATED RUNNING CURRENT A 08.2208.2200.61

LOCKED ROTOR AMP. A 471471441

TUBE MATERIAL ALUMINIUM

FIN

LIQUID mm / in. / 88.51½ / 07.21 ⅝ 15.88 / ⅝

GAS mm / in. 28.58 / 1⅛ 34.92 / 1 ⅜

MATERIAL ALUMINIUM

ROW 111

FIN PER INCH 121212

Btu/h 000,057000,006000,005

W 009,912058,571005,641

A)GNILOOC( TNERRUC GNINNUR LANIMON 1.2519.8116.58

W/WREE 08.258.239.2

gkEGRAHC TNAREGIRFER 5 x 05.44 x 07.44 x 05.4

zH/hP/VECRUOS REWOP 380-415 / 3 / 50

MFCWOLF RIA 005220008100051

aP ERUSSERP CITATS LANRETXE 053003052

ABdLEVEL ERUSSERP DNUOS 1707

gkTHGIEW TINU 649998085

mmEZIS NIARD ETASNEDNOC 34

WTUPTUO ROTOM 000510001100011

mmRETEMAID 7

2

mAERA ECAF

mm 670 X 657 X 46 670 X 577 X 46 670 X 670 X 46

cpYTITNAUQ 996

RUOLOCGNISAC IVORY WHITE

MFCWOLF RIA 00401004010096

ABdLEVEL ERUSSERP DNUOS 070756

gkTHGIEW TINU 771771751

WTUPTUO ROTOM 00510051086

3

352335233523

mcTNUOMA LIO

2

mAERA ECAF

RUOLOCGNISAC IVORY WHITE

GNITAEHGNILOOC

86

34.92 / 1 ⅜

5H057BD5A4H006BD5A4H005BD5ATINU ROODNI

5 x H051CM5A4 x H051CM5A4 x H521CM5ATINU ROODTUO

20.482.336.2

67.167.116.1

45

Page 48

PERFORMANCE DATA

Calculation Steps

Interpolation method can be used to get the total

cooling capacity, TC and sensible cooling capacity,

SC and power input, PI at those temperatures which

are not stated out in the table. Extrapolation method

is not allowed to be used.

Example:

Model: A5DB100H – A5MC100H

Indoor Condition: 25°C DB, 17°C WB

Outdoor Condition: 37°C DB

Fan Speed: High (3000 CFM)

1st Step

Interpolation of Indoor WB

Find TC, SC & PI

(a) Indoor: 25°C DB, 16°C WB

Outdoor: 35°C DB

(b) Indoor: 25°C DB, 19°C WB

Outdoor: 35°C DB

(c) Indoor: 25°C DB, 16°C WB

Outdoor: 40°C DB

(d) Indoor: 25°C DB, 19°C WB

Outdoor: 40°C DB

2nd Step

Interpolation of Indoor DB

Find TC, SC & PI

(a) Indoor: 25°C DB, 17°C WB

Outdoor: 35°C DB

(b) Indoor: 25°C DB, 17°C WB

Outdoor: 40°C DB

Solution:

Based on the Performance Table,

1. Refer to the Indoor DB column,

- 25°C is located between 24°C & 27°C

for 16°C WB.

- 25°C is located between 24°C & 27°C

for 19°C WB.

- Thus, Interpolation needs to be applied.

2. Refer to the Indoor WB column,

- 17°C is located between 16°C & 19°C

for 25°C DB.

- Thus, Interpolation needs to be applied.

3. Refer to the Outdoor DB column,

- 37°C is located between 35°C & 40°C.

- Thus, Interpolation needs to be applied.

3rd Step

Interpolation of Outdoor DB

Find TC, SC & PI

(a) Indoor: 25°C DB, 17°C WB

Outdoor: 37°C DB

Details of Calculation:

1st Step:

To obtain the TC, SC & PI for

(a) Indoor Condition: 25°C DB, 16°C WB

Outdoor Condition: 35°C DB

Outdoor temperature

EWB EDB

24 26.67 23.01 9.83

16

25

27 27.44 26.09 9.88

TC SC PI

35°C

x

y

1

1

By Interpolation Method

25°C – 24°C

27°C – 24°C 27.44kW – 26.67kW

= 26.93kW

x

1

=

x1 – 26.67kW

Similarly,

y

= 24.04kW

1

= 9.85kW

z

1

z

1

46

Page 49

(b) Indoor Condition: 25°C DB, 16°C WB

Outdoor Condition: 35°C DB

Outdoor temperature

EWB EDB

35°C

By Interpolation Method

25°C – 24°C

27°C – 24°C 29.30kW – 29.18kW

x

= 29.22kW

2

=

x2 – 29.18kW

TC SC PI

Similarly,

y

= 19.11kW

2

= 9.99kW

z

2

19

24 29.18 18.11 9.99

25

x

y

2

2

z

2

27 29.30 21.10 10.00

st

Repeat the same process for (c) & (d) in 1

Step

(c) x3 = 24.78kW; y3 = 22.37kW; z3 = 10.68kW (d) x4 = 26.82kW; y4 = 17.83kW;

= 10.84kW

z

4

nd

2

Step:

To obtain the TC, SC & PI for

(a) Indoor Condition: 25°C DB, 17°C WB

Outdoor Condition: 35°C DB

Outdoor temperature

EWB EDB

35°C

TC SC PI

16

17

25

26.93 24.04 9.85

x

y

5

5

z

5

19 29.22 19.11 9.99

Repeat the same process for (b) in 2nd Step

(c) x6 = 24.46kW; y6 = 20.86kW; z6 = 10.73kW

rd

Step:

3

To obtain the TC, SC & PI for

(a) Indoor Condition: 25°C DB, 17°C WB

Outdoor Condition: 37°C DB

By Interpolation Method

17°C – 16°C

19°C – 16°C 29.22kW – 26.93kW

x

= 27.69kW

5

=

x5 – 26.93kW

Similarly,

y

= 22.40kW

5

= 9.90kW

z

5

Outdoor temperature

EWB EDB

35°C 37°C 40°C

TC SC PI TC SC PI TC SC PI

25 17 27.69 22.40 9.90 xyz 24.46 20.86 10.73

By Interpolation Method

37°C – 35°C

40°C – 35°C 24.46kW – 27.69kW

=

x – 27.69kW

Similarly,

y = 21.78kW

z = 10.23kW

x = 226.40kW

47

Page 50

Performance Tables

R410A Cooling Only

Model: A5DB80H – A5MC80H

Cooling Mode

AFR

EWB EDB

(CFM)

21°C

24°C

16°C

27°C

30°C

24°C

27°C

19°C

2000

2200

2300

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are gross capacities which do not include a deduction for indoor fan motor heat.

2.

shows nominal capacities.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

22°C

16°C

19°C

22°C

16°C

19°C

22°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

21°C

24°C

27°C

30°C

24°C

27°C

30°C

33°C

27°C

30°C

33°C

36°C

19°C 25°C 30°C 35°C 40°C 46°C

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

22.07 14.37

22.10 17.21

22.27 19.51

22.96 22.96

24.35 13.42

24.36 15.35

24.40 18.94

24.69 24.69

26.78 13.13

26.79 16.01

26.81 18.69

26.89 21.20

22.96 14.98

23.03 18.19

23.31 20.65

24.28 24.28

25.29 14.17

25.34 16.32

25.46 20.14

25.88 25.88

27.79 13.88

27.83 17.03

27.88 19.95

28.05 22.56

23.81 15.63

23.93 18.99

24.32 21.76

25.53 25.53

26.20 14.99

26.28 17.34

26.50 21.34

27.07 27.07

28.75 14.66

28.81 18.08

28.91 21.19

29.17 23.92

5.40

5.40

5.40

5.43

5.48

5.48

5.48

5.50

5.58

5.58

5.58

5.59

5.44

5.45

5.46

5.50

5.53

5.53

5.54

5.56

5.63

5.64

5.64

5.65

5.49

5.49

5.51

5.56

5.58

5.58

5.59

5.62

5.68

5.69

5.69

5.70

21.29 14.00

21.32 16.82

21.53 19.07

22.30 22.30

23.49 13.08

23.50 15.01

23.56 18.54

23.88 23.88

25.86 12.82

25.87 15.66

25.88 18.34

26.01 20.77

22.13 14.60

22.20 17.76

22.52 20.17

23.57 23.57

24.39 13.82

24.43 15.96

24.57 19.70

25.10 25.10

26.81 13.55

26.84 16.68

26.91 19.57

27.14 22.13

22.93 15.23

23.06 18.54

23.52 21.20

24.79 24.79

25.25 14.62

25.34 16.95

25.56 20.88

26.28 26.28

27.73 14.34

27.79 17.74

27.91 20.82

28.26 23.49

5.84

5.84

5.85

5.88

5.93

5.93

5.94

5.95

6.05

6.05

6.05

6.05

5.89

5.89

5.91

5.95

5.99

5.99

6.00

6.02

6.10

6.11

6.11

6.12

5.93

5.94

5.96

6.02

6.04

6.04

6.06

6.09

6.16

6.16

6.17

6.19

Outdoor temperature

20.50 13.62

20.53 16.42

20.78 18.62

21.63 21.63

22.63 12.73

22.64 14.66

22.72 18.13

23.11 23.11

24.91 12.49

24.92 15.31

24.94 17.97

25.10 20.34

21.29 14.21

21.37 17.33

21.75 19.65

22.86 22.86

23.48 13.46

23.52 15.60

23.69 19.26

24.29 24.29

25.82 13.21

25.84 16.30

25.92 19.17

26.19 21.67

22.05 14.83

22.19 18.09

22.73 20.61

24.02 24.02

24.29 14.25

24.38 16.55

24.64 20.40

25.47 25.47

26.69 13.98

26.74 17.35

26.89 20.38

27.28 22.97

6.32

6.32

6.33

6.38

6.43

6.43

6.43

6.45

6.55

6.55

6.56

6.57

6.38

6.38

6.40

6.46

6.49

6.49

6.50

6.53

6.62

6.62

6.62

6.64

6.43

6.44

6.46

6.53

6.54

6.55

6.56

6.61

6.67

6.68

6.69

6.71

19.68 13.23

19.71 16.02

19.99 18.14

20.93 20.93

21.73 12.37

21.75 14.31

21.86 17.69

22.32 22.32

23.94 12.15

23.95 14.94

23.96 17.60

24.19 19.89

20.42 13.81

20.51 16.90

20.96 19.07

22.11 22.11

22.53 13.09

22.58 15.23

22.79 18.79

23.49 23.49

24.79 12.85

24.82 15.92

24.90 18.76

25.24 21.16

21.14 14.42

21.30 17.61

21.91 19.97

23.23 23.23

23.31 13.86

23.40 16.15

23.70 19.89

24.63 24.63

25.61 13.62

25.67 16.96

25.83 19.93

26.30 22.40

6.85

6.85

6.87

6.92

6.97

6.97

6.98

7.01

7.11

7.11

7.11

7.12

6.91

6.92

6.94

7.01

7.03

7.04

7.05

7.09

7.17

7.18

7.18

7.20

6.97

6.98

7.01

7.09

7.09

7.10

7.12

7.18

7.23

7.24

7.25

7.28

18.07 12.31

18.10 14.96

18.45 16.88

19.40 19.40

19.97 11.52

19.99 13.38

20.13 16.55

20.65 20.65

22.01 11.32

22.02 13.99

22.05 16.52

22.31 18.65

18.74 12.86

18.84 15.77

19.36 17.71

20.49 20.49

20.69 12.20

20.74 14.24

20.98 17.57

21.76 21.76

22.78 11.99

22.81 14.91

22.91 17.60

23.29 19.81

19.39 13.43

19.56 16.44

20.25 18.50

21.51 21.51

21.39 12.92

21.49 15.10

21.82 18.58

22.82 22.82

23.53 12.71

23.58 15.88

23.76 18.68

24.30 20.90

7.43

7.44

7.46

7.52

7.56

7.57

7.57

7.61

7.71

7.71

7.71

7.73

7.50

7.50

7.54

7.62

7.63

7.63

7.65

7.71

7.78

7.78

7.79

7.82

7.56

7.57

7.61

7.70

7.69

7.70

7.72

7.80

7.85

7.85

7.87

7.90

16.68 11.58

16.75 14.11

17.17 15.86

18.15 18.15

18.47 10.85

18.49 12.68

18.67 15.66

19.31 19.31

20.38 10.67

20.39 13.27

20.44 15.70

20.74 17.69

17.29 12.10

17.41 14.88

18.03 16.57

19.15 19.15

19.12 11.50

19.18 13.48

19.47 16.60

20.34 20.34

21.07 11.31

21.10 14.15

21.23 16.71

21.71 18.68

17.87 12.64

18.07 15.50

18.87 17.27

20.09 20.09

19.75 12.19

19.86 14.29

20.26 17.51

21.34 21.34

21.74 12.00

21.81 15.05

22.01 17.73

22.67 19.67

8.20

8.20

8.23

8.31

8.34

8.34

8.35

8.40

8.50

8.50

8.50

8.52

8.26

8.27

8.32

8.41

8.41

8.41

8.43

8.51

8.57

8.57

8.59

8.63

8.33

8.34

8.40

8.50

8.47

8.48

8.51

8.61

8.64

8.65

8.66

8.72

48

Page 51

Model: A5DB100H – A5MC100H

Cooling Mode

AFR

EWB EDB

(CFM)

21°C

24°C

16°C

27°C

30°C

24°C

2500

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

21°C

24°C

16°C

27°C

30°C

24°C

2800

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

21°C

24°C

16°C

27°C

30°C

24°C

3000

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are gross capacities which do not include a deduction for indoor fan motor heat.

shows nominal capacities.

2.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

19°C 25°C 30°C 35°C 40°C 46°C

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

27.63 18.77

27.67 22.48

27.89 25.49

28.75 28.75

30.48 17.53

30.50 20.05

30.55 24.75

30.91 30.91

33.53 17.16

33.54 20.91

33.56 24.42

33.67 27.69

28.75 19.57

28.83 23.76

29.18 26.98

30.40 30.40

31.67 18.52

31.73 21.33

31.88 26.31

32.41 32.41

34.80 18.13

34.84 22.25

34.90 26.07

35.12 29.47

29.81 20.42

29.97 24.81

30.45 28.44

31.97 31.97

32.81 19.59

32.91 22.66

33.18 27.89

33.90 33.90

36.00 19.16

36.08 23.62

36.20 27.68

36.52 31.26

7.60

7.60

7.61

7.65

7.72

7.72

7.72

7.74

7.86

7.86

7.86

7.87

7.67

7.67

7.69

7.74

7.79

7.79

7.80

7.83

7.94

7.94

7.94

7.95

7.73

7.74

7.76

7.83

7.86

7.86

7.88

7.91

8.01

8.01

8.02

8.03

26.66 18.28

26.69 21.97

26.96 24.91

27.92 27.92

29.41 17.08

29.43 19.60

29.49 24.22

29.90 29.90

32.37 16.74

32.38 20.46

32.40 23.95

32.56 27.13

27.71 19.07

27.80 23.20

28.20 26.36

29.52 29.52

30.54 18.05

30.59 20.86

30.77 25.74

31.42 31.42

33.57 17.70

33.61 21.79

33.69 25.57

33.98 28.91

28.72 19.90

28.87 24.23

29.45 27.70

31.04 31.04

31.62 19.10

31.72 22.14

32.00 27.28

32.90 32.90

34.72 18.74

34.79 23.18

34.95 27.20

35.38 30.69

8.22

8.22

8.23

8.28

8.36

8.36

8.36

8.38

8.51

8.51

8.52

8.53

8.29

8.30

8.32

8.39

8.43

8.44

8.45

8.48

8.60

8.60

8.60

8.62

8.36

8.37

8.40

8.48

8.50

8.51

8.53

8.58

8.67

8.68

8.69

8.71

Outdoor temperature

25.66 17.79

25.70 21.46

26.01 24.32

27.07 27.07

28.33 16.63

28.35 19.15

28.45 23.68

28.93 28.93

31.19 16.32

31.20 20.00

31.22 23.48

31.43 26.57

26.66 18.56

26.76 22.65

27.23 25.68

28.62 28.62

29.40 17.58

29.45 20.38

29.67 25.17

30.42 30.42

32.32 17.26

32.36 21.30

32.45 25.05

32.80 28.31

27.61 19.38

27.79 23.63

28.46 26.93

30.08 30.08

30.42 18.61

30.53 21.63

30.86 26.66

31.89 31.89

33.42 18.27

33.48 22.67

33.66 26.63

34.16 30.02

8.90

8.90

8.92

8.98

9.05

9.06

9.06

9.09

9.23

9.23

9.23

9.25

8.98

8.99

9.01

9.09

9.14

9.14

9.16

9.20

9.32

9.32

9.33

9.35

9.05

9.06

9.10

9.20

9.21

9.22

9.24

9.31

9.40

9.40

9.42

9.45

24.63 17.28

24.67 20.92

25.03 23.70

26.20 26.20

27.21 16.16

27.23 18.69

27.37 23.11

27.95 27.95

29.97 15.87

29.98 19.52

30.00 22.99

30.28 25.98

25.57 18.04

25.68 22.08

26.25 24.91

27.69 27.69

28.21 17.10

28.27 19.90

28.53 24.55

29.41 29.41

31.04 16.79

31.08 20.80

31.18 24.52

31.60 27.65

26.47 18.84

26.67 23.01

27.44 26.09

29.09 29.09

29.18 18.11

29.30 21.10

29.67 25.99

30.84 30.84

32.07 17.79

32.14 22.16

32.34 26.04

32.93 29.27

9.65

9.65

9.68

9.75

9.82

9.82

9.83

9.87

10.01

10.01

10.01

10.03

9.73

9.74

9.78

9.87

9.91

9.91

9.93

9.99

10.10

10.11

10.12

10.15

9.81

9.83

9.88

9.99

9.99

10.00

10.02

10.11

10.19

10.20

10.21

10.25

22.62 16.08

22.67 19.54

23.10 22.06

24.29 24.29

25.01 15.05

25.03 17.48

25.20 21.61

25.86 25.86

27.56 14.79

27.57 18.27

27.61 21.58

27.93 24.36

23.46 16.80

23.59 20.60

24.23 23.14

25.65 25.65

25.91 15.93

25.97 18.61

26.27 22.95

27.24 27.24

28.52 15.66

28.56 19.48

28.68 23.00

29.16 25.88

24.28 17.54

24.49 21.47

25.35 24.17

26.94 26.94

26.78 16.88

26.90 19.73

27.32 24.27

28.57 28.57

29.46 16.60

29.53 20.75

29.75 24.41

30.42 27.30

10.47

10.47

10.50

10.59

10.65

10.65

10.67

10.72

10.86

10.86

10.87

10.89

10.56

10.57

10.62

10.73

10.75

10.75

10.78

10.86

10.96

10.96

10.98

11.01

10.64

10.66

10.72

10.85

10.83

10.85

10.88

10.98

11.05

11.06

11.08

11.13

20.88 15.13

20.97 18.44

21.49 20.71

22.72 22.72

23.12 14.17

23.15 16.56

23.38 20.45

24.17 24.17

25.51 13.94

25.52 17.33

25.59 20.50

25.97 23.11

21.64 15.81

21.80 19.44

22.58 21.65

23.98 23.98

23.94 15.02

24.01 17.62

24.37 21.69

25.47 25.47

26.38 14.78

26.42 18.49

26.58 21.83

27.19 24.41

22.38 16.51

22.63 20.25

23.63 22.57

25.16 25.16

24.73 15.92

24.86 18.67

25.36 22.88

26.72 26.72

27.23 15.68

27.31 19.67

27.56 23.16

28.38 25.70

11.54

11.55

11.59

11.70

11.74

11.74

11.76

11.84

11.96

11.97

11.97

12.01

11.64

11.65

11.72

11.84

11.84

11.85

11.88

11.98

12.07

12.08

12.09

12.15

11.73

11.75

11.84

11.98

11.93

11.95

11.99

12.12

12.17

12.18

12.20

12.28

49

Page 52

Model: A5DB125H – A5MC125H

Cooling Mode

AFR

EWB EDB

(CFM)

21°C

24°C

16°C

27°C

30°C

24°C

3375

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

21°C

24°C

16°C

27°C

30°C

24°C

3750

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

21°C

24°C

16°C

27°C

30°C

24°C

4125

30°C

27°C

19°C

33°C

27°C

30°C

22°C

33°C

36°C

Remark:

AFR: Air flow rate (CFM)

EWB: Entering Wet Bulb Temp. (°C)

EDB: Entering Dry Bulb Temp. (°C)

TC: Total Cooling Capacity (kW)

SC: Sensible Cooling Capacity (kW)

PI: Power Input (kW)

Notes:

1. Ratings shown are gross capacities which do not include a deduction for indoor fan motor heat.

shows nominal capacities.

2.

3. Direct interpolation is permissible. Do not extrapolate.

4. Unit is able to operate at ambient from 19°C to 46°C DB without pressure trip.

19°C 25°C 30°C 35°C 40°C 46°C

TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI TC SC PI

36.17 25.85

36.31 30.79

36.44 35.44

37.89 37.89

39.74 24.42

39.84 28.53

39.99 34.82

40.23 40.23

43.60 22.94

43.66 28.36

43.78 33.05

43.91 37.63

36.93 26.89

37.12 32.06

37.38 37.16

39.32 39.32

40.55 25.38

40.70 29.71

40.89 36.44

41.53 41.53

44.44 23.83

44.55 29.60

44.72 34.61

44.87 39.57

37.58 27.62

37.83 32.92

38.35 38.37

40.58 40.58

41.22 26.56

41.43 31.10

41.65 38.32

42.87 42.87

45.15 24.93

45.30 31.00

45.51 36.41

45.74 41.70

8.90

8.91

8.92

9.01

9.13

9.13

9.14

9.16

9.38

9.38

9.39

9.40

8.95

8.96

8.98

9.10

9.18

9.19

9.20

9.24

9.43

9.44

9.45

9.46

8.99

9.01

9.04

9.18

9.22

9.24

9.25

9.33

9.48

9.49

9.50

9.52

35.02 25.28

35.16 30.15

35.33 34.78

36.93 36.93

38.50 23.89

38.60 27.95

38.73 34.18

39.08 39.08

42.22 22.44

42.29 27.80

42.41 32.46

42.54 37.04

35.75 26.32

35.94 31.40

36.27 36.37

38.31 38.31

39.26 24.85

39.42 29.12

39.58 35.80

40.46 40.46

43.02 23.32

43.13 29.01

43.30 34.01

43.45 38.96

36.35 26.98

36.60 32.26

37.29 37.74

39.51 39.51

39.89 26.02

40.11 30.48

40.29 37.65

41.76 41.76

43.68 24.42

43.84 30.39

44.04 35.79

44.37 40.93

9.52

9.53

9.54

9.64

9.75

9.76

9.77

9.79

10.01

10.02

10.02

10.03

9.56

9.58

9.60

9.74

9.80

9.81

9.83

9.89

10.07

10.08

10.09

10.10

9.61

9.62

9.67

9.82

9.85

9.86

9.88

9.98

10.11

10.13

10.14

10.16

Outdoor temperature

33.80 24.68

33.95 29.47

34.14 34.07

35.90 35.90

37.18 23.33

37.28 27.33

37.40 33.52

37.94 37.94

40.79 21.92

40.86 27.21

40.98 31.84

41.09 36.41

34.47 25.69

34.68 30.71

35.14 35.42

37.22 37.22

37.89 24.28

38.05 28.48

38.20 35.12

39.34 39.34

41.53 22.80

41.65 28.39

41.81 33.38

41.98 38.27

35.05 26.30

35.29 31.56

36.19 37.00

38.37 38.37

38.48 25.44

38.69 29.82

38.91 36.94

40.59 40.59

42.15 23.88

42.32 29.76

42.51 35.14

42.97 40.02

10.23

10.24

10.25

10.38

10.47

10.48

10.49

10.53

10.74

10.75

10.76

10.77

10.27

10.29

10.32

10.47

10.52

10.53

10.55

10.63

10.80

10.81

10.82

10.83

10.32

10.33

10.40

10.56

10.57

10.58

10.60

10.73

10.84

10.86

10.87

10.91

32.50 24.04

32.65 28.76

32.93 33.19

34.81 34.81

35.78 22.73

35.89 26.68

35.99 32.82

36.80 36.80

39.28 21.37

39.35 26.58

39.47 31.20

39.59 35.77

33.12 24.99

33.33 29.98

34.00 34.32

36.06 36.06

36.43 23.68

36.60 27.82

36.76 34.42

38.15 38.15

39.96 22.25

40.08 27.75

40.24 32.72

40.53 37.46

33.68 25.58

33.91 30.82

35.01 36.16

37.16 37.16

36.98 24.82

37.20 29.14

37.45 36.15

39.35 39.35

40.55 23.34

40.72 29.09

40.90 34.47

41.58 38.98

11.03

11.05

11.07

11.21

11.28

11.29

11.31

11.37

11.56

11.57

11.58

11.59

11.08

11.10

11.15

11.31

11.34

11.35

11.36

11.47

11.62

11.63

11.65

11.67

11.12

11.14

11.23

11.40

11.38

11.40

11.42

11.57

11.67

11.68

11.70

11.76

29.24 21.94

29.40 26.32

29.81 30.22

31.62 31.62

32.23 20.78

32.34 24.43

32.45 30.18

33.46 33.46

35.42 19.55

35.50 24.37

35.61 28.70

35.75 32.95

29.81 22.79

29.99 27.45

30.84 31.28

32.74 32.74

32.80 21.67

32.97 25.49

33.14 31.64

34.68 34.68

36.03 20.38

36.15 25.45

36.29 30.12

36.74 34.62

30.29 23.32

30.49 28.23

31.74 32.87

33.72 33.72

33.30 22.68

33.49 26.72

33.84 33.05

35.75 35.75

36.54 21.41

36.70 26.70

36.86 31.74

37.80 35.84

11.94

11.95

11.99

12.14

12.20

12.21

12.22

12.31

12.48

12.49

12.50

12.52

11.99

12.00

12.08

12.24

12.25

12.26

12.28

12.42

12.54

12.55

12.57

12.61