Page 1

Technical Manual

AIR-COOLED

MINI CHILLER

AMAC 20-150 C/CR

A4AC 20-150 C

A4AC 60-150 CR

A5AC 20-55 CR

Page 2

1. NOMENCLATURE .................................................................................................. 1

- PRODUCT LINE UP

2. FEATURES ............................................................................................................. 5

3. APPLICATION INFORMATION............................................................................... 7

- REFRIGERANT CIRCUIT DIAGRAM

- CHILLER PANEL CONTROLLER

- PRECAUTIONS AND INSTALLATION

4. SOUND DATA........................................................................................................57

5. SELECTION PROCESS ........................................................................................64

- WATER PRESSURE DROP VS FLOW RATE

- GLYCOL

6. ENGINEERING AND PHYSICAL DATA ................................................................. 67

- SPECIFICATIONS

TABLE OF CONTENTS

7. PERFORMANCE DATA ....................................................................................... 114

8. OUTLINE AND DIMENSION ............................................................................... 126

9. ELECTRICAL DATA ............................................................................................. 130

10. WIRING DIAGRAMS .........................................................................................138

11. SERVICING AND MAINTENANCE ....................................................................154

12. TROUBLESHOOTING ...................................................................................... 155

13. EXPLODED VIEW AND PART LIST .................................................................. 156

Page 3

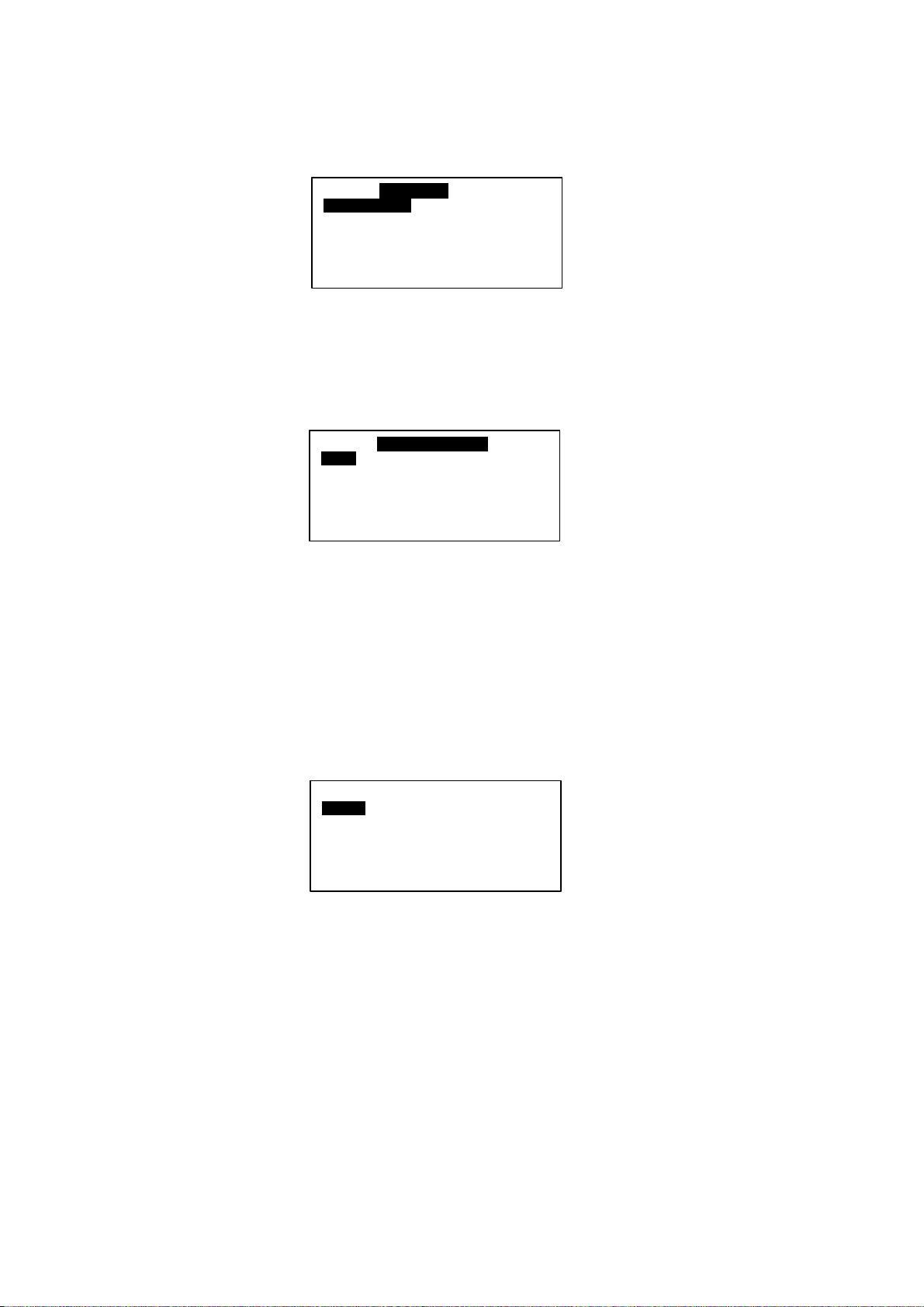

1. NOMENCLATURE

A 4 AC 20 C R

Brand

A :Acson

Refrigerant

“ “ : Omitted if R22

4 : R407C

5 : R410A

Model Name

AC : Air-Cooled Mini Chiller

Capacity Index

020 : 20,000 Btu/h

Chasis

C : C Series

Model Type

“ “ : Omitted if cooling only

R : Heat pump

1

Page 4

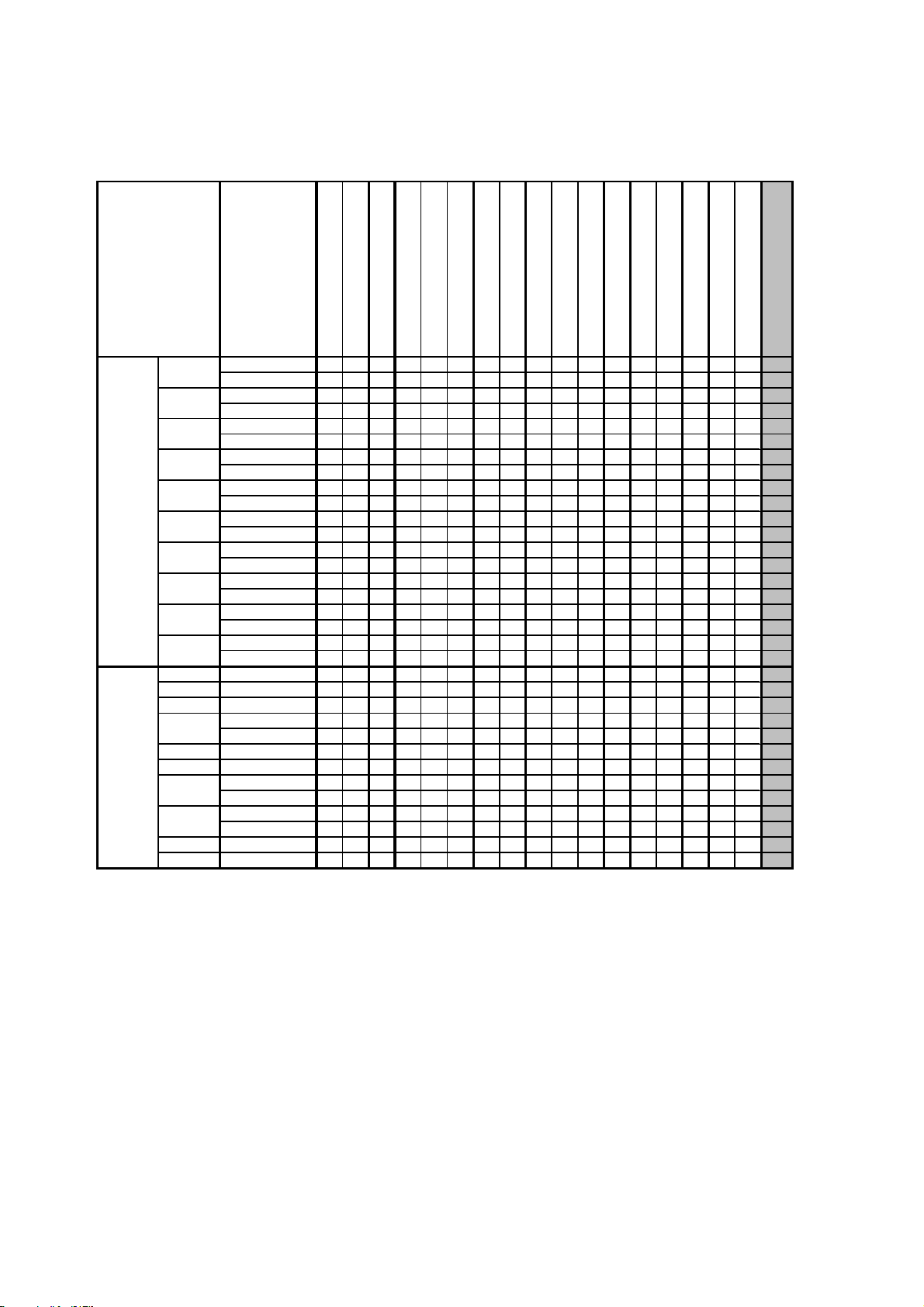

PRODUCT LINE UP

AMAC-C/CR

AMAC

20C

25C

30C

40C

50C

60C

COOLING ONLY

HEATPUMP

80C

100C

120C

150C

20CR AXAB X X

25CR AXAB X X

30CR AXAB X X

40CR

50CR FXAC X X

60CR FXAC X X

80CR

100CR

120CR FXAC X X

150CR FXAC X X

Nomenclature

AXAC

AXAD

AXAC

AXAD

AXAC

AXAD

FXAC

FXAD

FXAC

FXAD

FXAC

FXAD

FXAE

FXAF

FXAE

FXAF

FXAC

FXAD

FXAC

FXAD

FXAC X X

FXAD X X

FXAE X X

FXAF X X

FXAE X X

FXAF X X

PCB-MC01

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Magnetic Contactor

Water Tank + Pump

Without Tank / Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

XXXX

XXXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXX

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XX XXXXXXXX X

XX XXXXXXX X

XXXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXX

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX XXXXXXXX X

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

X

X

X

X

XX

XX X

XX

XX X

XX

XX X

XX X

XXX X

XX X

XXX X

XX X

XXX X

XX X

XX X

XX X

XXX X

XXX X

XXX X

XXX X

Three Phase Fan Motor

Capillary Tube

TXV

2

Page 5

A4AC-C/CR

A4AC

20C

25C

30C

40C

50C

60C

COOLING ONLY

HEATPUMP

80C

100C

120C

150C

20CR

25CR

30CR

40CR

50CR

60CR FXAB X X

80CR

100CR

120CR FXAD X X

150CR FXAD X X

Nomenclature

AXAC

AXAD

AXAC

AXAD

AXAC

AXAD

FXAC

FXAD

FXAC

FXAD

FXAC

FXAD

FXAI

FXAJ

FXAI

FXAJ

FXAG

FXAH

FXAG

FXAH

FXAE X X

FXAF X X

FXAE X X

FXAF X X

PCB-MC01

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

Classification

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Isolator Switch

Magnetic Contactor

Water Tank + Pump

Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

XX

XX

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XXXXXXXXXX X

XXXXXXXXX X

XX X

XX X

XXXXXXXXXX X

XX X

XXXXXXXXXX X

XXXXXXXXXX X

XX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

X

XX

XX

XXXXXX X

XXXXXX X

XXXXXX X

X

X

XX

XX X

XX

XX X

XX

XX X

XX X

XXX X

XX X

XXX X

XX X

XXX X

XXX X

Three Phase Fan Motor

Capillary Tube

TXV

3

Page 6

A5AC-CR

A5AC

20CR AXAA X X

25CR AXAA X X

30CR EXAB X X

40CR EXAC X X

50CR EXAC X X

HEATPUMP

55CR EXAC X X

Classification

Nomenclature

PCB - TC01

PCB - TC1.1r4

LCD Panel - Chiller Panel

CE Mark

Scroll Compressor

Rotary Compressor

CCH (Crank Case Heater)

Terminal Block

Isolator Switch

Magnetic Contactor

Water Tank + Pump

Pump Only

Expansion tank

Gold Fin

Antifreeze & Auto pump on

Phase Protector

Single Phase Fan Motor

Capillary Tube

XX

XX

XX

XX

XX

XX

X

X

X

X

X

X

XX

XX

X

X

X

X

XX X

X

XX X

X

XX XX

X

XX XX

X

XX XX

X

XX XX

X

TXV

4

Page 7

2. FEATURES

REFRIGERANT CIRCUIT

Models AMAC/A4AC80~150C/CR has been designed with two separate refrigerant circuits, i.e. it has two

compressors. By doing so, the unit has part loading capabilities, i.e. 0-50-100% of rated capacity. This will

improve the reliability and energy efficiency of the unit, especially during low loading operations. Each circuit

is factory brazed and evacuated before accurately charged with refrigerant to ensure optimum performance.

Because each circuit is separated, there is no danger of cross-contamination should either one of the

compressor experiences a burnt-up. Each circuit is also equipped with a carefully sized thermostatic expansion

valve (for cooling only units) to give optimum performance characteristic. For the heatpump version, the

expansion process is done with capillary tubes.

SCROLL COMPRESSOR

Scroll Compressors are used (for model which is available) for the units (AMAC/A4AC20C/CR using rotary

compressor) to give quiet and reliable performance over a wide operating temperature range. However, in

order to protect the compressors from damage, a phase protector (for model which is available) is provided to

prevent the compressors from rotating in the wrong directions.

TANDEM COMPRESSOR

A5AC models are using R410A rotary compressors in tandem configuration. Tandem compressors are highly

efficient and cost saving. It reduces mechanical losses, minimize gas flow losses and turbulence. There are 3

steps capacity loading (0-40-60-100%) for A5AC40/50CR and 2 steps capacity loading (0-50-100%) for A5AC30/

55CR.

CONDENSER FAN MOTOR

Models AMAC/A4AC80~150C/CR is equipped with two high air flow propeller fan blades which are made of

metal. The fans are driven vertically by weather proof motors which are single phase type.

EVAPORATOR

The heat exchanger is made of stainless steel plates closely arranged and brazed together (BPHE) to ensure

high heat exchange efficiency. For models AMAC/A4AC80~150C/CR, the water flow through the BPHE in a

channel on its own, while because of the two compressors, the refrigerant flows through another two separate

channels. The refrigeran t will either be in a counter-flow or parallel-flow with respect to the water, depending

on the mode of operation (cooling or heating).

SAFETY PROCETECTION

The safety protections provided for the mini chiller are:

a) High and low pressure switches

b) Differential water flow switch

c) Compressor, water pump and fan motor overload protectors

d) Anti-freeze protection sensor

During abnormal condition, chiller panel controller will turn off the unit and then display the faults of operation.

WATER TANK AND PIPING CONNECTION

The models A4AC/AMAC80~150C/CR does not come with a water buffer tank. However, the unit does come

with an 8 liters expansion tank. Besides that, an optional 135L hydraulic tank is also available.

The external water piping connection can be made either from the left or right side of the unit. Connection is

done with Ø1-1/4 “ female thread couplings for both supply and return pipes.

Meanwhile, AMAC/A4AC20~60C/CR does come with a 22 L or 40 L (refer to specification) water buffer tank.

5

Page 8

ANTIFREEZE PROTECTION

The chiller unit has several anti-freeze protection features:

1. Brazed plate heat exchanger anti-freeze

The BPHE has a strip heater around it to prevent water freezing inside

2. Auto mode

The chiller controller will force on the unit to the heat mode if the outdoor ambient air temperature

becomes too cold.

MAINTENANCE

In order to facilitate of the controller, a rocker switch is provided to power-off the supply to the PCB. However,

switching off the switch will not disconnect the main incoming power supply to the chiller unit.

6

Page 9

3. APPLICATION INFORMATION

REFRIGERANT CIRCUIT DIAGRAM

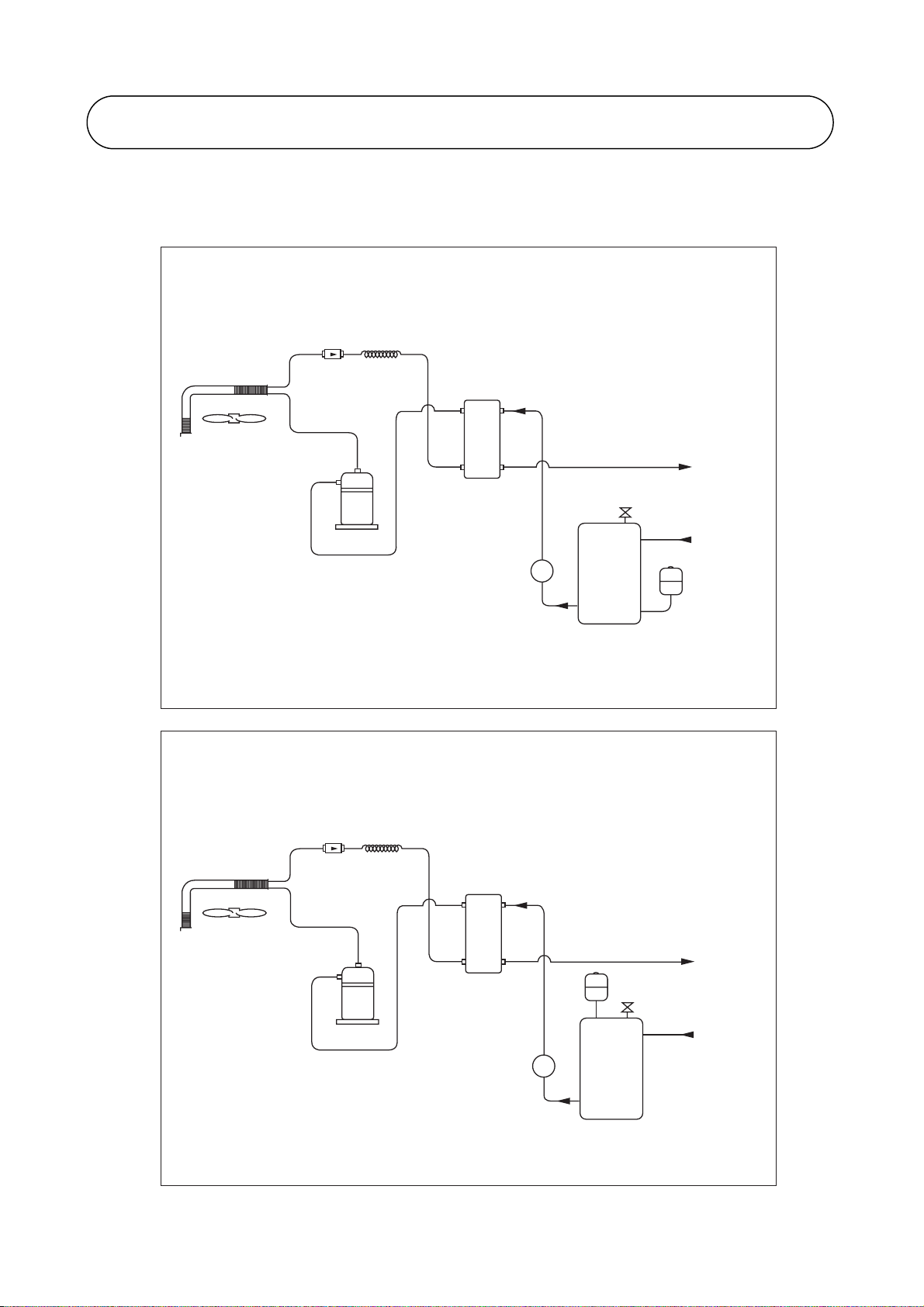

A4AC / AMAC 20C / 25C / 30C

Water / Refrigerant Circuit Diagram

FIL TER

DRIER

CAP TUBE

BPHE

AUT O PRESS RELIEF V ALVE

WATER

OUT

COMPRESSOR

WATER PUMP

P

WATER ST ORAGE

TANK

A4AC / AMAC 40C / 50C / 60C

Water / Refrigerant Circuit Diagram

FIL TER

DRIER

CAP TUBE

BPHE

EXP ANSION

COMPRESSOR

WATER

IN

EXP ANSION

TANK

PART NO : 70-03-4-067460

WATER

OUT

TANK

AUT O PRESS RELIEF V ALVE

WATER

IN

WATER PUMP

7

P

WATER ST ORAGE

TANK

PART NO : 70-03-4-087461

Page 10

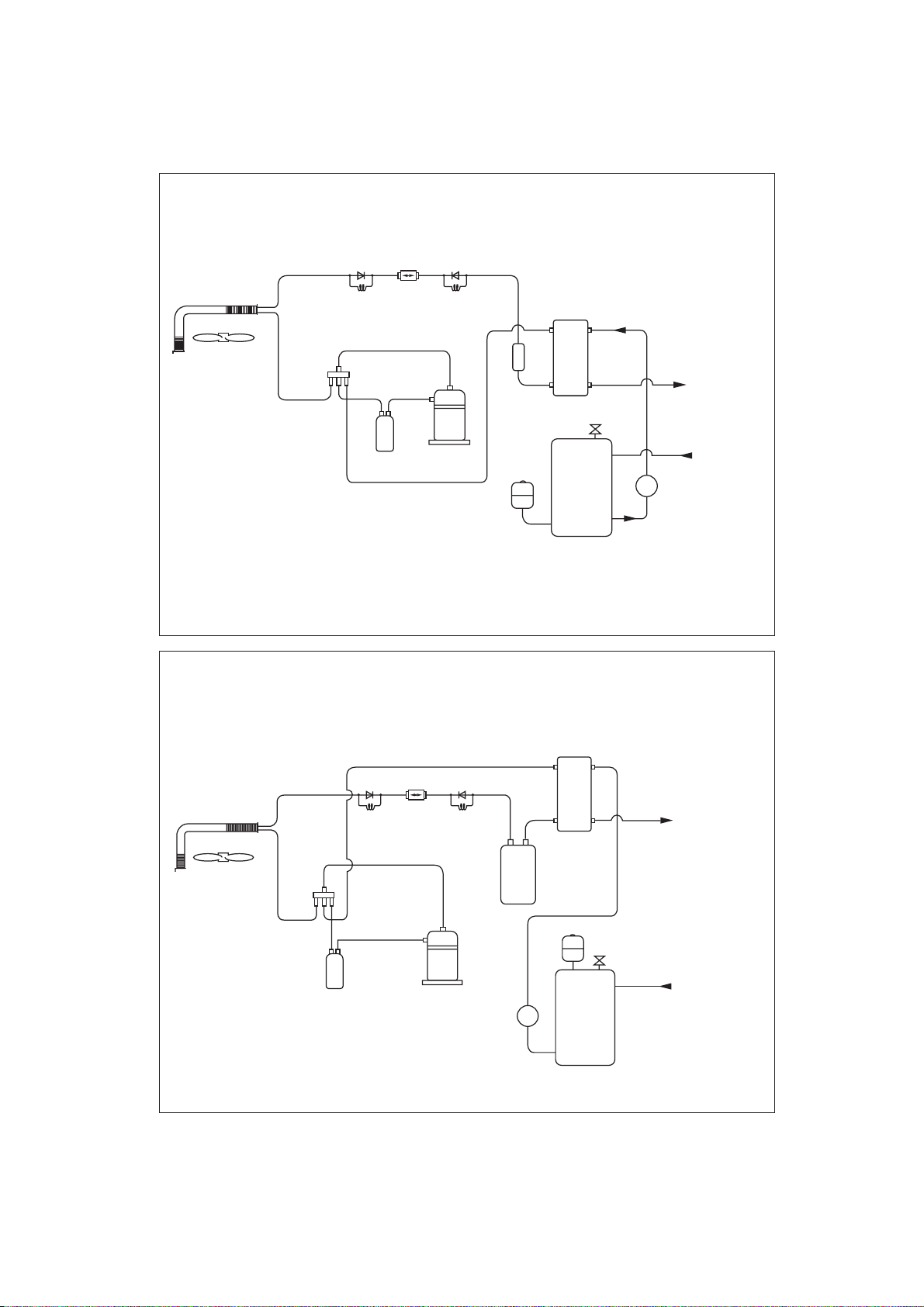

A4AC / AMAC 20CR / 25CR / 30CR

Water / Refrigerant Circuit Diagram

CHECK

VALV E

HEATING

CAP

TUBE

SUCTION

ACCUMULATOR

FILTER

DRIER

CHECK

VALV E

COOLING

CAP

TUBE

COMPRESSOR

EXPANSION

TANK

BPHE

CHARGE

COMPENSATOR

AUTO PRESS RELIEF VALVE

WATER STORAGE

TANK

PART NO : 70-03-4-067458

AMAC 40CR / 50CR, A4AC/ AMAC 60CR

Water / Refrigerant Circuit Diagram

WATER

OUT

WATER

IN

P

HEATING

SUCTION

ACCUMULATOR

CHECK

VALV E

CAP

TUBE

FILTER

DRIER

COOLING

COMPRESSOR

CHECK

VALV E

CAP

TUBE

WATER PUMP

LIQUID

RECEIVER

P

WATER STORAGE

BPHE

TANK

EXPANSION

TANK

AUTO PRESS RELIEF VALVE

PART NO : 70-03-4-067459

WATER

OUT

WATER

IN

8

Page 11

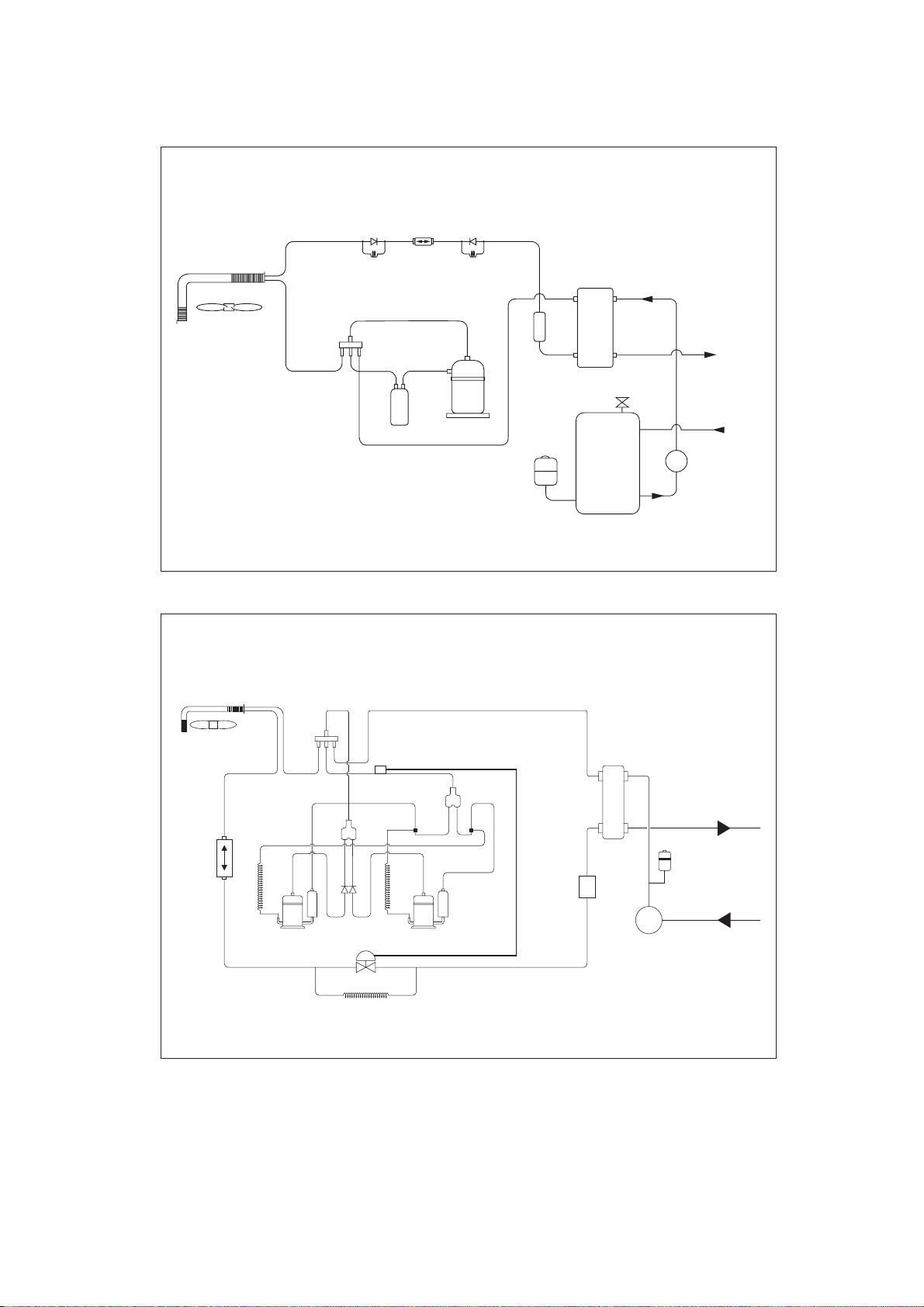

A4AC / AMAC 80C / 100C / 120C / 150C

Water / Refrigerant Circuit Diagram

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

FIL TER DRIER FIL TER DRIER

COMPRESSOR COMPRESSOR

A4AC / AMAC 80CR / 100CR / 120CR / 150CR

THERMOST ATIC

EXP ANSION

VA L V E

BRAZED PLA TE

HEA T EXCHANGER

WATER

OUTLET

WATER

INLET

THERMOST ATIC

EXP ANSION

VA L V E

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

Water / Refrigerant Circuit Diagram

FIN TUBE

HEA T EXCHANGER

(SYSTEM 1)

HEA TING

FIL TER

DRIER

COOLING

WATER

OUT

CAP

TUBE

CAP

TUBE

HEA TING

TUBE

COOLING

TUBE

CHECK

4-WAY VAL VE

COMPRESSOR COMPRESSOR

SUCTION

ACCUMULA TOR

VA L V E

CHECK

VA L V E

LIQUID

RECEIVER

CAP

CAP

WATER

FIL TER

DRIER

IN

LIQUID

RECEIVER

CHECK

VA L V E

CHECK

VA L V E

HEA T EXCHANGER

SUCTION

ACCUMULA TO R

FIN TUBE

(SYSTEM 2)

4-WAY VA LVE

PAR T NO : 70-03-4-056764

9

Page 12

A5AC 20CR / 25CR

Water / Refrigerant Circuit Diagram

CHECK

VALV E

FILTER

DRIER

CHECK

VALV E

WATER / REFRIGERANT

HEATING

CAP

TUBE

SUCTION

ACCUMULATOR

COOLING

CAP

TUBE

COMPRESSOR

EXPANSION

CHARGE

COMPENSATOR

TANK

BPHE

AUTO AIR VENT

WATER STORAGE

TANK

A5AC 30CR

Water / Refrigerant Circuit Diagram

WATER

OUT

WATER

IN

WATER PUMP

P

PART NO : 70-03-4-080547

FILTER

DRIER

OIL

RETURN

TUBE

4WV

COMPRESSOR 1

CHECK

VALV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

TWIN TUBE

JOINT

CHARGE

COMPENSATOR

BPHE

WATER OUT

EXPANSION TANK

WATER IN

PUMP

10

Page 13

W

A5AC 40 / 50CR

Water / Refrigerant Circuit Diagram

4WV

SUB ACCUMULATOR

TWIN TUBE

JOINT

BPHE

WATER

OUT

FILTER

DRIER

RETURN

TUBE

WATER / REFRI

OIL

COMPRESSOR 1

4WV

CHECK

VALV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

A5AC 55CR

LIQUID RECEIVER

Water / Refrigerant Circuit Diagram

BPHE

SUB ACCUMULA TO R

TWIN TUBE

JOINT

PUMP

EXPANSION

TTANK

WATER

WATER

OUT

IN

FIL TER

DRIER

OIL

RETURN

TUBE

COMPRESSOR 1

CHECK

VA LV E

TXV

OIL

RETURN

TUBE

COMPRESSOR 2

11

LIQUID RECEIVER

PUMP

EXP ANSION

TANK

WATER

IN

Page 14

CHILLER PANEL CONTROLLER

1. SAFETY CONSIDERATION

Only specially trained and technicians and installers are authorized to install and service this

equipment..

1.1 General Installation Recommendations

• Only supply DC voltage (9-17V, typically 12V, maximum current 200mA) as a power source

to the device.

• Input contact voltage supply should limit to 12VDC or 24VAC.

• Isolated all the low voltage wiring (communication bus, etc) from high voltage power supply

wiring.

2. GENERAL DESCRIPTION

2.1 General

The chiller panel controller is designed to control the chiller operation. This device allows the

user to have customized control for each connected unit.

2.2 Features

The requirements of user friendly and easy to use have been taken into account in designing

this chiller panel controller. It can do the task as follow:

• Whole system configuration

• Unique parameter settings

• Operation status display

• Tracing fault record (easy in hardware troubleshooting)

The display is shown in an 8-lines graphical LCD display. There are 8 dedicated keys available

in the panel,

• Menu selection

• Navigation on the screen

• Modification of the selected value

During first start-up, the panel will have a default configuration (timer schedule, set point,

miscellaneous settings, etc) User can do the changes on that particular configuration later.

2.3 Panel Position

The chiller panel controller can be installed anywhere, as long as it is easy to accessed by

authorized personnel.

The requirements of installation are:

• Avoid exposure to shocks

• Avoid any source of electromagnetic pollution

• Avoid installation on uneven vertical surface

2.4 Operation Environmental Condition

• Temperature:

-10°C to 65°C operating temperature

-20°C to 85°C storage temperature

• Relative Humidity:

0 to 95% non-condensing

12

Page 15

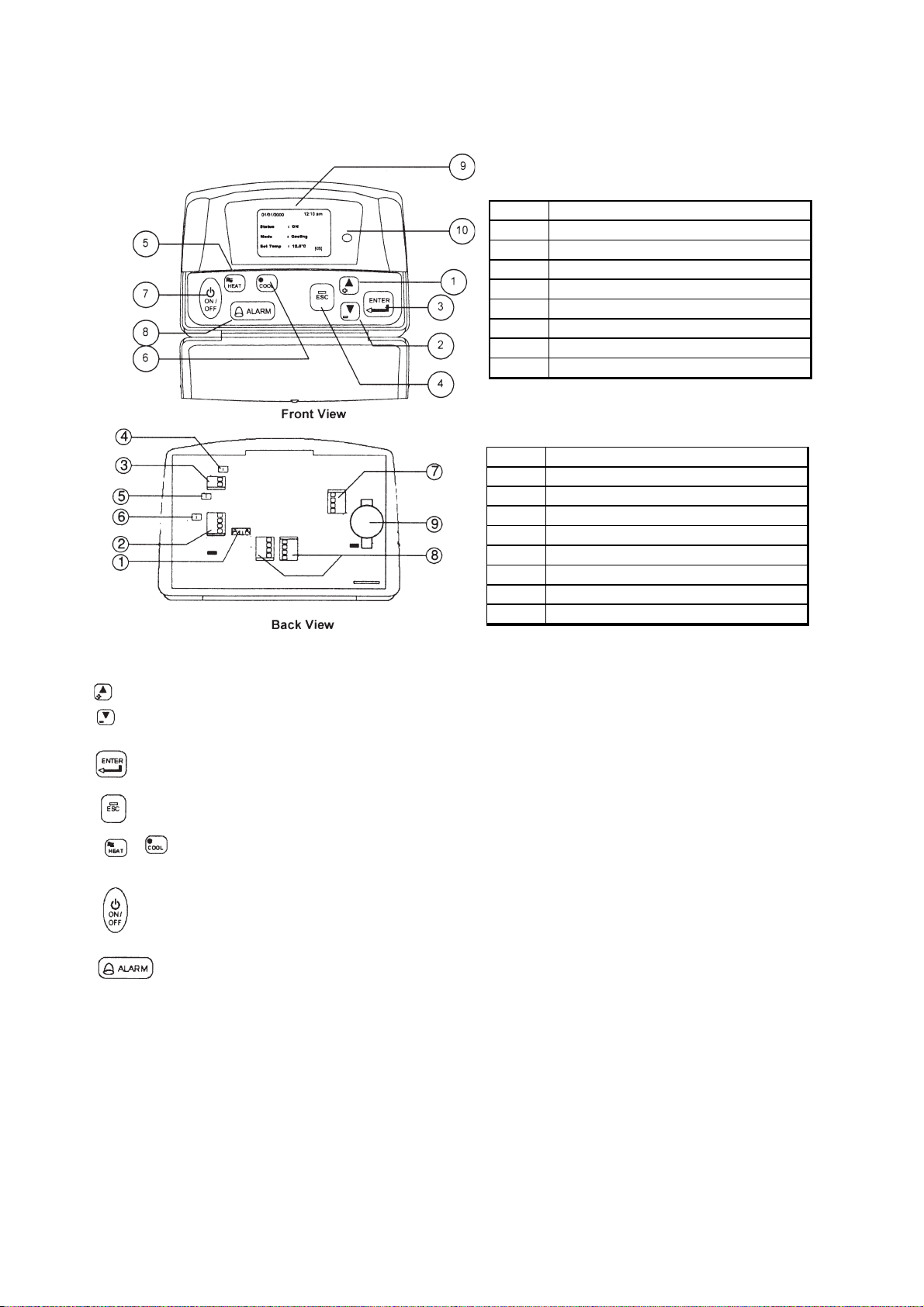

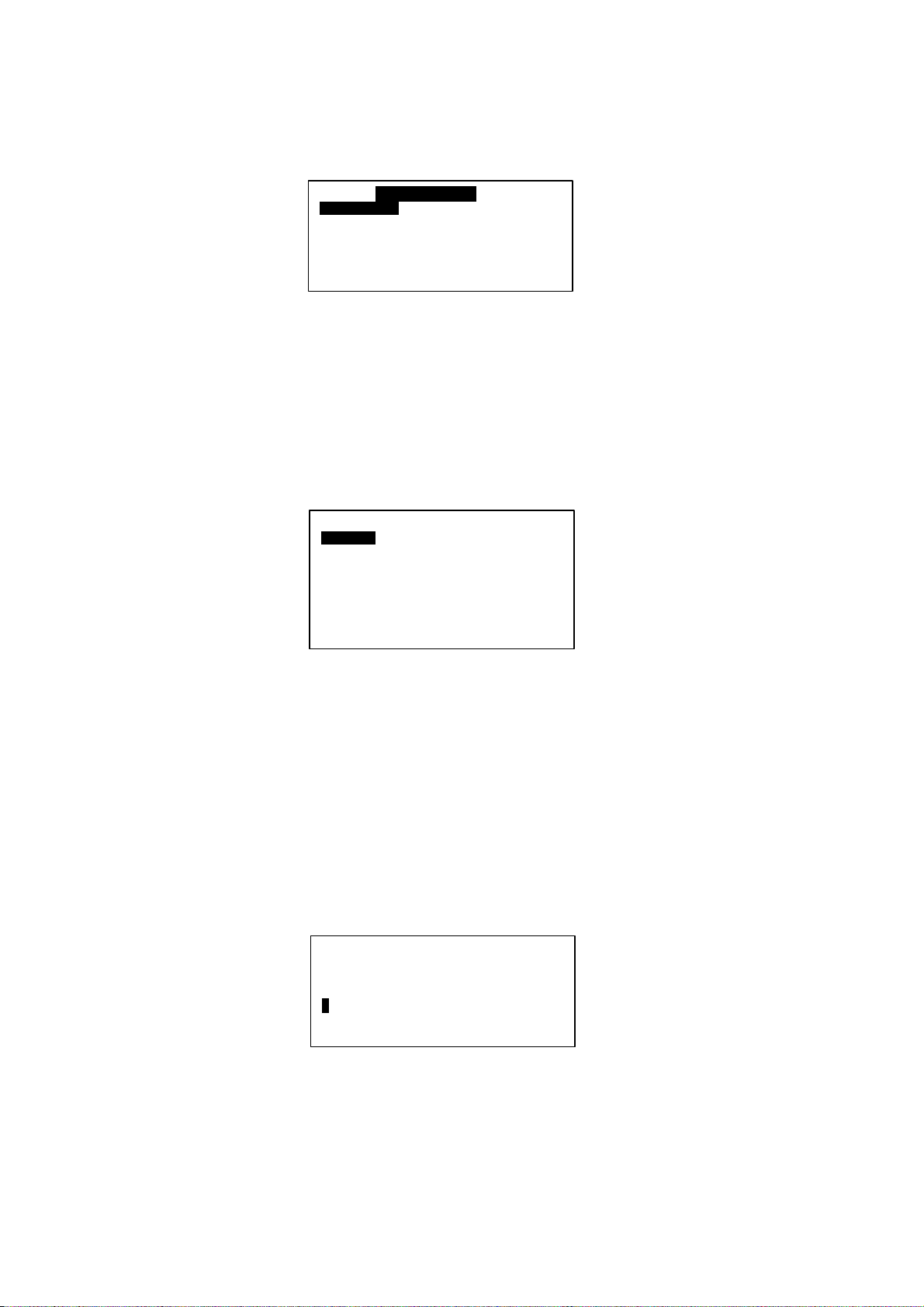

3. HARDWARE DESCRIPTION

Legend

3.1 Key Explanation

1 & 2

Navigation key

3 Execute instruction key

4 Cancel instruction key

5 Switching to heat mode shortcut key

6 Switching to cool mode shortcut key

7 Toggle ON/OFF shortcut key

8 Show alarm k ey

9 Graphical LCD display

10 ON/OFF indicator

Legend

1 & 2

Chiller terminal unit connection

3 Not avai lab le

4 CMOS rset jumper (JH2)

5 Chiller bus resist or configuration (JH3)

6 Not avai lab le

7 Not avai lab le

8 Not avai lab le

9 Not avai lab le

10 Bac kup battery

The 2 navigation keys permit item selection and modifying the selected value.

ENTER key is used to execute the navigation instruction

ESC key is used to cancel the navigation instruction

Shortcut key to switch the operation mode in the summary pages

Shortcut key to trigger ON/OFF in the summary pages

Shortcut key to show fault / alarm in the summary pages

13

Page 16

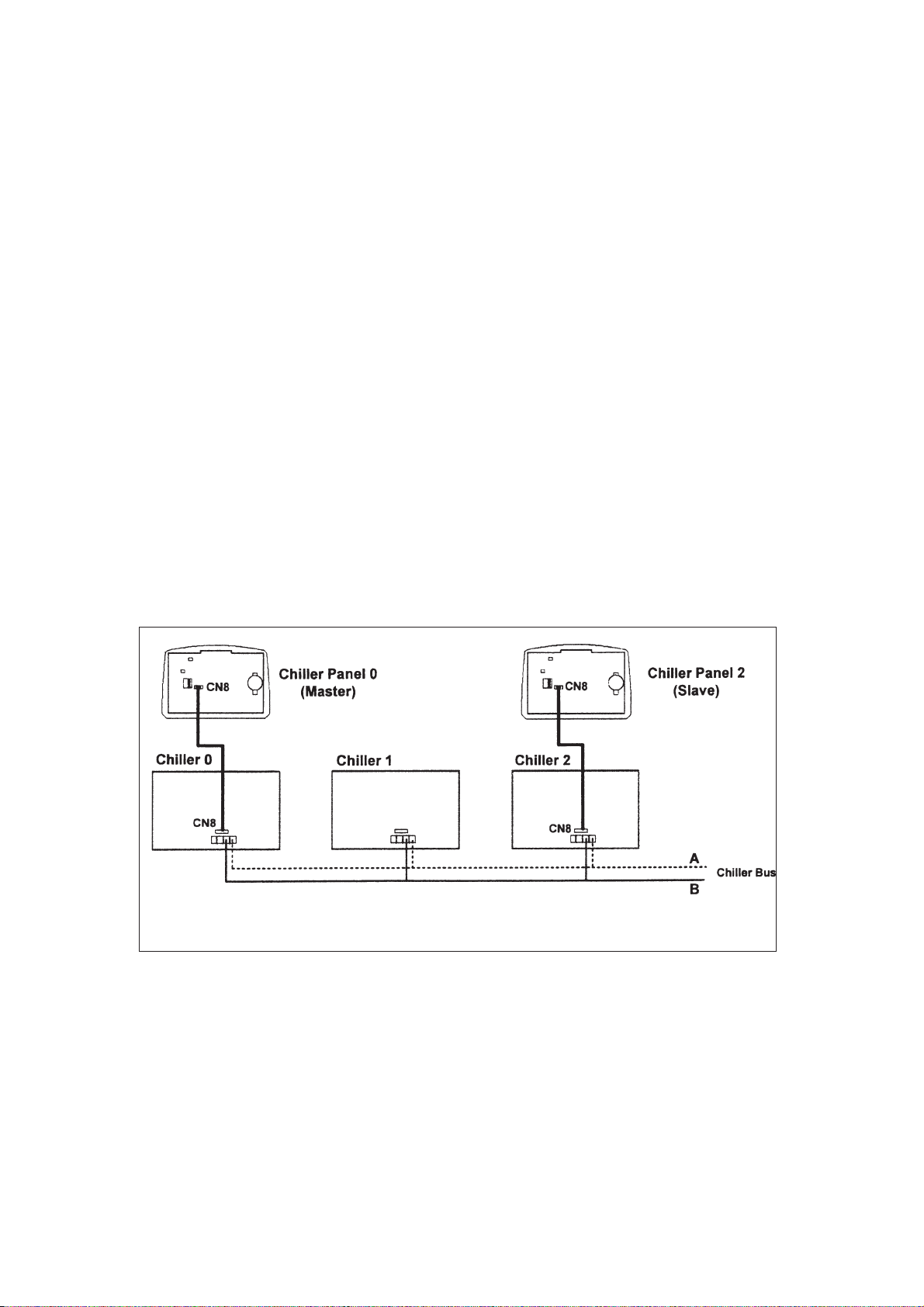

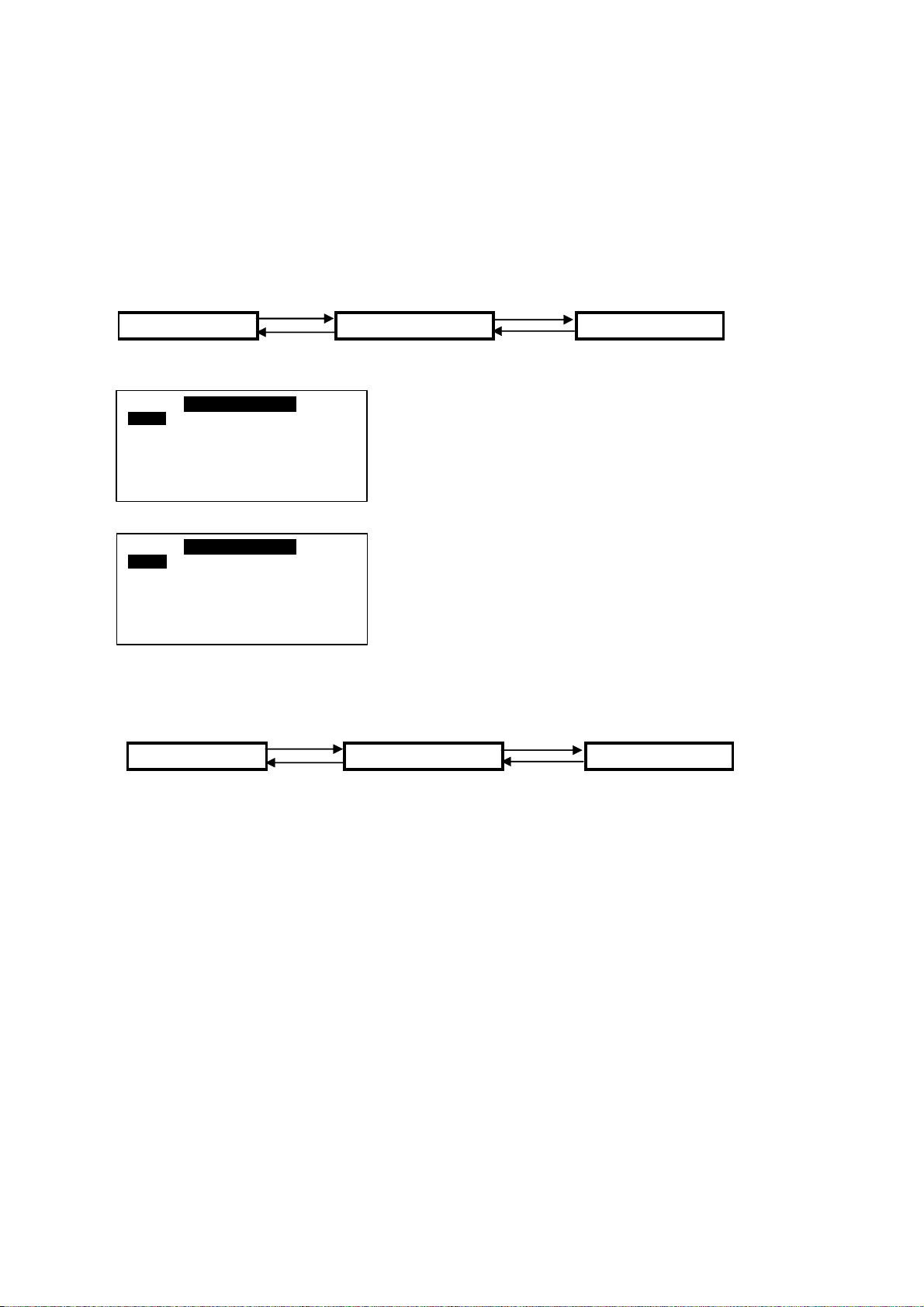

4. INSTALLATION

4.1 Chiller Bus

Supported up to 50 units of Chiller

Chiller 0 Chiller 1 Chiller 2

5 way wire (CM8)

Chiller

Communication bus

Chiller Panel 0 Chiller Panel 1

(Master) (Slave)

Chiller Network

Chiller panel needs to be energized with +12Vdc. The 5 way wires that provided is once on the easiest

solution to establish a communication between the panel and chiller main board (CN8-CN8). If the 5-way

wires socket has been occupied in main board, just using 2 insulation wired are needed to establish a

communication between panel and chiller main board.

Chiller panel can support maximum up to 50 units of chiller. In the chiller network, duplication of main board

unit address is not allowed. Each chiller main board should have their unique unit address (0-50).

For first time running, user need to assign a unique unit address to each main board in the chiller network.

User should follow the procedure below:

• Only power ON one main board at once time. Make sure not others main boards are energize.

• By using the panel connected to the main board.

<ENT ER> <ENT ER>

Summary Pages Main Menu Setting Menu

<ENTER>

G7 Unit No 1. General Set Paraameter

<ENT ER> <ENT ER>

key in "0001" as p assw ord

• Key in unique unit address and press ENTER to execute.

• De-energized the main board and repeat the procedures again all the main boards have been

assigned a unique unit address.

IMPORTANT : Do not assign a same unit address to more than one chiller main board.

RECOMMENDATION : Please select a coherant model (G1 Model) to all the chiller main boards in

the same network.

14

Page 17

4.2 Others Configuration

• JH2 in chiller panel should let it open (put the jumper header on one pin only) all the time

unless user need to do CMOS reset to that particular panel.

• JH3 should let it open (put the jumper header on one pin only) all the time as well.

• Remember to put in the coin cell battery on the panel. Without the backup battery, the panel will

always reset the time to 12:00am, 1st Jan 2000.

4.3 Installation of the Chiller Panel Controller

• Disconnect the unit and ensure no others unit energy source that supplies the panel.

• Open the rear panel of the Chiller Panel (insert a ‘flat-head’ screwdriver in the top joint of main

casing with rear panel to open the real panel).

• Pass the necessary wires of the panel across the large opening in the rear panel. Place the rear

panel flat support against the wall and make marks on the wall through the four installation holes

(inner and outer).

• Drill four appropriate holes in the marked places.

• Attach the rear panel to the wall and put on the screws on it. Ensure that all cables are passed

through the hole of the rear panel.

• Connect the wires to the corresponding terminal according to the wiring bus network. The

power supply and communication wires must be correctly connected to ensure that the

panel works.

• Close the chiller panel (ensure the bottom joint is aligned for the casing, then complete others joint

part. Ensure that the contacts at the back of the panel are aligned with each others).

Bus Wiring Diagram

15

Page 18

5. SOFTWARE DESCRIPTION

5.1 Introduction

The Chiller Panel Controller can be used to control / display the status of Chiller.

Status viewing:

• ON/OFF status

• Mode (Cooling / Heating/ Boiling)

• Mode set temperature

• Compressor status (ON/OFF/ DEFROST)

• Water in, Water Out, Outdoor air and Panel temperature

• Chiller model (Chiller, Heat Pump, Chiller/ Boiler, Chiller+Boiler, Heat Pump/Boiler, Heat Pump+

Boiler

• Advance parameter settings

• Defrost sensor temperatures

• Compressor discharge sensor temperatures

• Compressor run times

• Incoming alarm/ fault/ error

Status settings:

• ON/OFF switching

• Mode setting (Cooling / Heating/ Boiling)

• Mode set temperature

• Manual entering defrost

• Advance parameter settings

• Password changing

• Panel option setting (Backlight, Alarm Buzzer, Screen saver, Contrast, Brightness, temperature

unit)

• Time and date settings

• Clearing compressor run time

16

Page 19

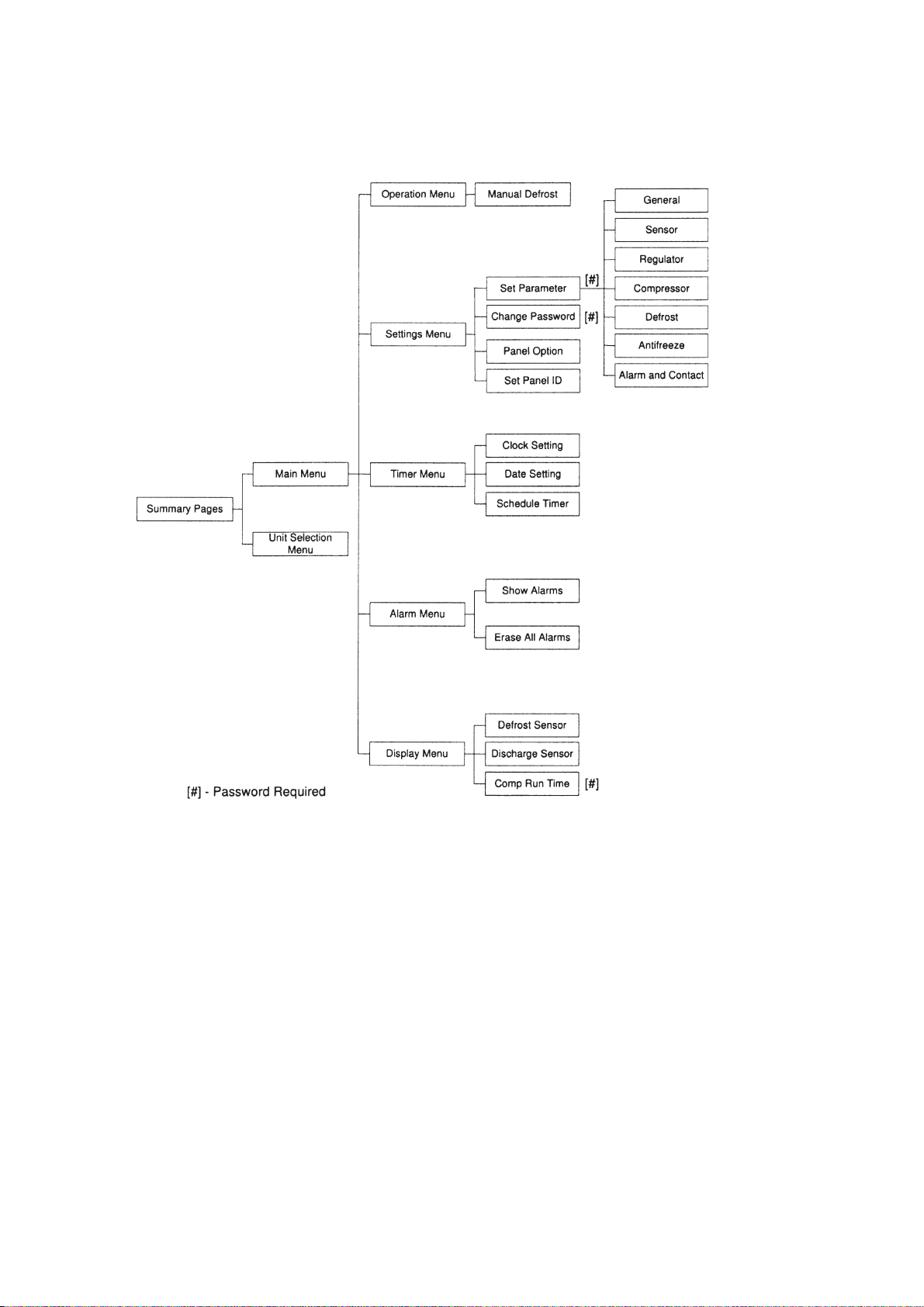

5.2 Menu Structures

Menu Structure Diagram for Chiller

17

Page 20

5.3 Chiller Menu Structure

5.31 Summary Pages

There are 4 pages in [Summary Pages]. Press UP or DOWN for page scrolling. Press ENTER to go to

[Main Menu]. Time and date are shown on top of each page. Beside that, the bottom of each page shows

current control unit of the Chiller.

For example: [00] - Chiller Panel controls Chiller ID 0 currently

[03] - Chiller Panel controls Chiller ID 3 currently

[All] - Chiller Panel controls all Chiller currently

1st page: Display ON/OFF status, Mode settings and Temperature settings.

01/01/2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12.0°C

[00]

2nd page: Display Compressor status.

01/01/2000 12:00am

Compressor : ON

[00]

3rd page: Display Water In, Water Out, Outdoor air and Panel temperature

01/01/2000 12:00am

Water In :19.8°C

Water Out : 25.6°C

Outdoor Air : 32.2°C

Panel : 20.5°C

[00]

4th page: DisplayChiller model, Compressor No. and Chiller ID.

01/01/2000 12:00am

Model : Chiller

No. Comp : 1 Comp

Unit No : 0

18

Page 21

5.3.2 Main Menu

Press ENTER in [Summary Pages] to go into this menu

MA I N MENU

Operating Menu

Setting Menu

Ti me r Me nu

A larm Men u

Dis play Menu

There are 5 sub menus in [Main Menu]. Press UP or DOWN to select sub menus, ENTER to enter into

the sub menu or press ESC to exit to [Summary Pages]

5.3.2.1 Operation Menu

Select [Operation Menu] in [Main Menu] and press ENTER to go into this menu.

OPERAT ION MENU

Status : ON

Mode : Cooling

Cool Te mperature : 12.0° C

Heat Te mperature : 40.0° C

Some normal settings can be found here. Press UP or DOWN to select each settings, ENTER to start the

setting or press ESC here to exit to [Main Menu]

Settings : -ON/OFF unit

- Mode changing (Cooling/ Heating/ Boiling)

- Cooling temperature setting

- Manual Defrost Selection

5.3.2.1.1 Manual Defrost

Select [Manual Defrost] in [Operation Menu] and press ENTER to go into this menu.

This menu lets user select one compressor to enter into defrost cycle manually, as long as the

environment fulfill the defrost requirement.

Def r ost Compres s or

Co mp 1

19

Page 22

5.3.2.2 Settings Menu

Select [Settings Menu] in [Main Menu] and press ENTER to go into this menu.

SETTINGS MENU

Set Parameter

Change Passw ord

Panel Option

Set Panel ID

Some advance settings can be found here. Press UP or DOWN to select settings, ENTER to start the

setting or press ESC here to exit to [Main Menu].

Settings - Set Parameter

- Password Changing

- Panel Option

- Set Panel ID

5.3.2.2.1 Set Parameter

Select [Set Parameter] in [Settings Menu] and press ENTER to go into this menu.

1.General

2. Sensor

3. Regulator

4. Compressor

5. Def rost

6. Antif reeze

7. Alarm and Contact

There are 7 groups of advance parameters for user to set in this menu, Press UP or DOWN to

select the group, ENTER to go into the group or ESC to exit to [Setting Menu].

Settings:- General

- Sensor

- Regulator

- Compressor

- Defrost

- Antifreeze

- Alarm and Contact

5.3.2.2.2 Password Changing

Select [Password Changing] in [Setting Menu] and Press ENTER to go into this menu.

Please enter the

Old password ………..

0

- - - -

User can change the old password in this menu.

Press ESC to exit to [Settings Menu].

20

Page 23

5.3.2.2.3 Panel Option

Select [Panel Option] in [Setting Menu] and Press ENTER to go into this menu.

Back light :

Buzzer : On

Scree n Saver : Disable

Timeout : 5m

Contrast : 50%

Br ig ht ness : Me dium

Temp Unit : ° C

: Nor m a l

User can do some miscellaneous for the panel. These settings would not affect whole system performance.

Settings - Toggle Backlight

- Alarm Buzzer

- Enable / Disable Screen Saver

- Screen Saver timeout

- Contrast display

- Backlight brightness

- Temperature unit

Press ESC to exit to [Settings Menu]

5.3.2.2.4 Set Panel ID

Select [Set Panel ID] in [Settings Menu] and press ENTER to go into this menu.

Ple ase enter the

Panel ID……

=> Unit 0

User can assign the ID no, to the panel.

Example: If ID no. 0 has been assigned, the panel acts like Master Panel Unit. It can choose to control

each Chiller in the network.

If other ID no. (1-50) has been assigned, the panel acts like Slave Panel Unit. It is dedicated to

one particular Chiller. It can only control the Chiller with same ID in the network.

Press [ESC] to exit to [Settings Menu]

21

Page 24

5.3.2.3 Time Menu

Select [Time Menu] in [Main Menu] and press ENTER to go into this menu.

Cl o ck Se tting :

Dat e Setting

Time Schedule

Timer : Dis able

TIMER MENU

All the timer/ schedule settings are included in this menu. Press UP or DOWN to select each settings.

ENTER to start the setting or press ESC here to exit to [Main Menu].

Settings: - Set Clock

- Set Date

- Set Schedule ( 7 days Programmable Timer)

- Enable/ Disable Timer Schedule

5.3.2.3.1 Set Clock

Select [Clock Setting] in [Timer Menu] and press ENTER to go into this menu.

Se t Time :

hh: mm

00: 00

User can set the time in this menu. The time setting is in 24-hour format.

Pres [ESC] to exit to [Timer Menu].

22

Page 25

5.3.2.3.2 Set Date

Select [Date Setting] in [Timer Menu] and press ENTER to go into this menu.

Set Time :

yyyy hh mm

2000 /01 / 01

User can set the date in this menu. The date is set according to sequence below:

(year) / (month) / (day)

Press [ESC] to exit to [Timer Menu].

5.3.2.3.3 Set Schedule

Select [Schedule Timer] in [Timer Menu] and press ENTER to go into this menu.

Timer 1 Timer2

Sun 0800 1600 _ _ _ _ _ _ _ _

Mon 0800 1600 _ _ _ _ _ _ _ _

Tue 0800 1600 _ _ _ _ _ _ _ _

Wed 0800 1600 _ _ _ _ _ _ _ _

ON OFF ON OFF

This is the 7 days programmable timer schedule menu. There are 2 ON/OFF events in one day. User can

choose to set each day of week (Sunday - Saturday) ON/OFF timer. Before this schedule carry their

effect to the Chiller, user need to set the [Timer] in [Timer Menu] to enable.

Press [ESC] to exit to [Timer Menu].

5.3.2.4 Alarm Menu

Select [Alarm Menu] in [Main Menu] and press ENTER to go into this menu.

ALARAM MENU

Show Alarms

Erase All Alarm

This place keeps records for all previous occurred fault/ alarms. User can view the alarm history and

clear

that record (alarm history) as well. The panel can keep up to 20 fault/ alarm records.

Press ESC to exit to [Main Menu]

23

Page 26

5.3.2.4.1 Show Alarms

Select [Show Alarms] in [Alarm Menu] and press ENTER to go into this menu.

[Ch 0]

Alarm 1

Comp 1 over load

01/ 01/ 00 12:00am

User can view all the fault/ alarm records in this menu.

The record shows - Alarm type

- Alarm occurred date

- Alarm occurred time

- Alarm occurred unit (Chiller ID)

Beside that, user can erase the alarm record in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.4.2 Erase All Alarms

Select [Erase All Alarms] in [Alarm Menu] and press ENTER to go into this menu.

Are you sure ?

Press Enter to er ase,

or ESC to exit.

User can rase all the alarm / fault records at once in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.5 Dispaly Menu

Select [Display Menu] in [Main Menu] and press ENTER to go into this menu.

DISPL AY M ENU

De fr ost Se nsor

Dis char ge Sens or

Comp Run Time

This menu display Defrost Sensor temperature, Compressor Discharge sensor temperature and

Compressor Run Time. Beside that, user can clear each Compressor Run Time for Chiller.

Press [ESC] to exit to [Main Menu]

24

Page 27

5.3.2.5.1 Defrost Sensor

Select [Defrost Sensor] in [Display Menu] and press ENTER to go into this menu.

De fr os t Se nsor

Comp 1 : 12.8° C

User can view the defrost sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu]

5.3.2.5.2 Discharge Sensor

Select [Discharge Sensor] in [Display Menu] and press ENTER to go into this menu.

Dis ch arges Sens or

Comp 1 : 36.5° C

User can view the discharge sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu].

5.3.2.5.3 Comp Run Time

Select [Comp Run Time] in [Display Menu] and press ENTER to go into this menu.

Comp Run Time

Comp 1 : 13579h

User can view the compressor run time for each compressor in the Chiller. Beside that, user can

clear each compressor run time in this menu. User needs to key in the correct password before

clearing the compressor run time.

Press [ESC] to exit to [Display Menu].

25

Page 28

6. OPERATION USER MANUAL

6.1 Starting

Chiller panel can be set as Master or Slave panel unit. When the Panel ID is set to ‘0’, it acts like a Master

panel, whereas it is Slave panel if Panel ID is set to others number (1-50).

Chiller panel can control the Chiller if both ID no. (Panel ID and Chiller ID) are same.

For example: Panel ID 1 can only control Chiller ID 1

Master Panel can choose to control each Chiller or control all Chiller at once in the network.

For example : Panel ID 0 (master) can control Chiller ID 0 / ID 1/ ID 32 .... or all Chillers at once.

Panel ID can be set in Set Panel ID in Settings Menu.

Ple ase enter the

Panel ID ……

=> Unit 0

26

Page 29

6.2 Chiller Operation Control

[00]

[00]

[00]

6.2.1 Starting

During power on for the Chiller Panel, it needs to take several times to collect information from the Chiller.

At this time, all the status will show “--”. Please ensure the particular Chiller exists in the network. When

the process is completed, user can start to control the Chiller using the panel.

01/ 01/ 2000 12:00am

Status : --

Mode : --

Cool Temp : --

01/ 01/ 2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12° C

In gathering information process Gathering information completed

6.2.2 Changing Display Unit

Chiller Panel (Master) can choose to choose to control / display each Chiller status. This can be done in

[Summary Pages] only.

01/ 01/ 2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12° C

Unit Selection :

Select All

Select One : 0

In [Summary Pages], press and hold ENTER buttom

(1 second) to go into [Unit Selection] menu.

Select “Select All” and press ENTER if user want to

control all Chilelr in the network, or select “Select One”

to control a particular Chiller. Press ESC to exit to

[Summary Pages].

Unit Selection :

Select All

Select One : 0

Select a Chiller ID via UP or DOWN and press ENTER

to confirm or ESC to cancel.

27

Page 30

6.2.3 Switching ON/OFF

There are several ways to switch ON/OFF for the Chiller.

i) [Summary Pages]

Press and hold ON/OFF button (hold 1 second). Please note that the ON/OFF button will only function

in

[Summary Pages].

ii) [Operation Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Operation Menu

<ESC> <ESC>

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

In [Operation Menu], select “Status” and press

ENTER.

Toggle ON/OFF via UP or DOWN button, and then

press ENTER to confirm the change or ESC to cancel.

iii) [Timer Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Timer Menu

<ESC> <ESC>

7 days programmable time can turn chiller ON/OFF. User can set the schedule in this

[Timer Menu]. Please refer 6.2.11 (page 27) for schedule settings.

28

Page 31

6.2.4 Switching Mode

There are several ways to switch the mode for the Chiller. Please take note that some mode cannot be set

due to current Chiller model settings.

Mode

Chiller Model

Chiller √ ×× √ - Allow to set

Heat Pump √√× × - Not Allow to set

Chiller / Boiler √ × √ Auto - Turn ON automatically

Heat Pump /Boiler √√√

Chiller + Boiler √ ×Auto

Heat Pump + Boiler √√Auto

Cooling Heating Boiling

i) [Summary Pages]

Cooling - Press and hold COOL button.

Heating - Press and hold HEAT button (if it allows to set).

Boiling - Press and hold HEAT button again (if it allows to set).

ii) [Operation Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Operation Menu

<ESC> <ESC>

OPERATION MENU

Status : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

In [Operation Menu], select “Mode” and press

ENTER to start setting or ESC to exit to [Main

Menu]

Toggle ON/OFF via UP or DOWN button, and then

press ENTER to confirm the change or ESC to

cancel.

29

Page 32

6.2.5 Changing Mode Set Temperature

There are 2 ways to change the mode set temperature for the Chiller.

i) [Operation Menu]

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temperature : 12.0°C

Heat Temperature : 40.0°C

In [Operation Menu], select “Cool Temp” / “Heat

Temp”and press ENTER start setting or ESC to exit

to [Main Menu].

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temperature : 12.0°C

Heat Temperature : 40.0°C

Change value via UP or DOWN button, and then

press

ENTER to confirm the change or ESC to cancel.

ii) [Set Parameter]

<ENTER> <ENTER>

Summary Pages Main Menu Settings Menu

<ESC> <ESC>

<ENTER> <ESC>

Key in Password

Set Parameter

1. General

2. Sensor

3. Regulator

4. Compressor

5. Defrost

6. Antifreeze

7. Alarm and Contact

R1 Cool SP : 12.0° C

R2 Cool Diff : 3.0° C

R3 Heat SP : 40.0° C

R4 Heat Diff : 3.0° C

R5 Min Cool SP : -20° C

R6 Max Cool SP : 40° C

R7 Min Heat SP : -20° C

In [Set Parameter], select “Regulator” and press

ENTER. Press ESC tp exit to [Main Menu].

Select “R3”/ “R5” and press ENTER to start setting or ESC to exit to [Set Parameter] menu.

R1 Cool SP : 12.0° C

R2 Cool Diff : 3.0° C

R3 Heat SP : 40.0° C

R4 Heat Diff : 3.0° C

R5 Min Cool SP : -20° C

R6 Max Cool SP : 40° C

R7 Min Heat SP : -20° C

Change value via UP or DOWN button. The

boarderline is limited by R5&R6 (cool),

R7&R8(heat).

Press ENTER to confirm or ESC to cancel.

30

Page 33

6.2.6 Manual Defrost

User can choose which compressor will go into manual defrost cycle by using the Chiller Panel, as long

as the condition is fulfilled with defrost condition. This can be done in [Operation Menu].

<ENTER> <ENTER>

Summary Pages Main Menu Operation Menu

<ESC> <ESC>

Please take note that “Manual Defrost” option will only available in HEATING mode. It will disappear in

COOLING/ BOILING mode.

OPERATION M ENU

Stat us : O N

Mode : Cooling

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

OPERATION MENU

Status : O N

Mode : He at in g

Coo l Tem per ature : 12.0° C

Heat Temperature : 40.0° C

“Manual Defrost” disappear when Chiller not in HEATING mode

OPERATION M ENU

Status : O N

Mode : He ating

Cool Temperature : 12.0° C

Heat Temperature : 40.0° C

Manual Defrost

Defrost Compressor

Comp 1

In [Operation Menu], select [Manual Defrost], press

ENTER to go into it, or ESC to exit to [Main Menu].

Select which compressor to go into defrost cycle via

UP or DOWN button. Press ENTER to confirm or ESC

to exit to [Operation Menu].

31

Page 34

6.2.7 Advance Parameter Settings

The Chiller Panel provide user a lot of advance parameter settings for the Chiller. The parameters are

divided into 7 groups. There all are stored in [Set Parameter] menu and it is password-procteted layer

in the panel.

* CAUTION : INPROPER SETTINGS WILL CAUSE PERMANENT DAMAGE TO THE CHILLER !!!

<ENTER> <ENTER>

Summary Pages Main Menu Settings Menu

<ESC> <ESC>

<ENTER> <ESC>

Key in Password

Set Parameter

7 groups of Advance Parameter:

1) General

G1 Model : Chiller

G2 No. Comp : 1 Comp

G3 On/Off in : Disable

G4 Col/ Heat In : Disable

G5 Ext Alarm in : Disable

G6 Water Sys : Isolated

G7 Unit No : 0

2) Sensor

S1 Water Enter : 0.0° C

S2 Water Leave : 0.0° C

S3 Air Sensor : 0.0° C

S4 Defrost 1 : 0.0° C

S5 Defrost 2 : 0.0° C

S6 Defrost 3 : 0.0° C

S7 Defrost 4 : 0.0° C

3) Regulator

R1 Cool SP : 12.0° C

R2 Cool Diff : 3.0° C

R3 Heat SP : 40.0° C

R4 Heat Diff : 3.0° C

R5 Mix Cool SP : -20° C

R6 Max Cool SP : 40° C

R7 Min Heat SP : -20° C

S8 Cp Dish 1 : 0.0° C

S9 Cp Dish 2 : 0.0° C

S10 Cp Dish 3 : 0.0° C

S11 Cp Dish 4 : 0.0° C

R8 Max Heat SP : 90° C

R9 Ax Heat SP : 5.0° C

R10 Ax Heat Diff : 2.0° C

R11 Au Bo SP : 5.0° C

R12 Au Bo Diff : 2.0° C

R13 Au Bo Start : 30m

32

Page 35

4) Compressor

A

C1 Min Run : 12s

C2 Min Stop : 240s

C3 2On Interval : 360s

C4 2Cp ON Dly : 15s

C5 P-Cp ON Dly : 60s

C6 Cp-P OFF Dly : 60s

C7 Cp Cut Off : 120° C

5) Condenser Defrost

D1 Start Temp : -3° C

D2 End Temp : 14° C

D3 Max Dura : 10m

D4 Interval : 45m

D5 Dly Bfr Def : 0s

D6 Dly Aft Def : 0s

6) Cool Mode Antifreeze

1 Heater SP : 5° C

A2 Heater Diff : 2.0° C

A3 Sensor : Leave

A4 Alarm SP : 3° C

A5 Alarm Diff : 2.0° C

7) Alarm and Contact

P1 FS Confirm : 5s

P2 FS Delay : 180s

P3 LP Delay : 30s

P4 CO Reset : Manual

P5 HP Rest : Auto

P6 LP Reset : Auto

P7 FO Reset : Manual

P8 RO Reset : Manual

P9 FS Reset : Manual

P10 Aux Reset : Manual

P11 A/F Reset : Manual

P12 CO Contact : Normal

P13 HP Contact : Normal

P14 LP Contact : Normal

Please refer to 8. APPENDIX for detail desciption.

P15 FO Contact : Normal

P16 PO Contact : Normal

P17 FS Contact : Normal

P18 EA Contact : Normal

P19 DE Contact : Normal

33

Page 36

6.2.8 Changing Password

For security purpose, some places in the panel are password-proctected. User can change the password

at anytime.

<ENTER> <ENTER>

Summary Pages Main Menu Settings Menu

<ESC> <ESC>

<ENTER> <ESC>

Change Password

Please enter the

Old password -----------

0

----

Password accepted . . .

Access granted !

User needs to enter the old password in order to change

the password.

Change the 1st digit value via UP or DOWN. Press

ENTER to start enter 2nd digit and the rest, or ESC to

exit at anytime.

If password correct, this message will be

shown and proceed to new password

settings.

Please enter the

New password -----------

0

----

Password error . . .

Access denied !

If password not correct, this message will be

shown and exit to [settings Menu]

Same as previous, UP DOWN to change value, ENTER

to go to next digit, ESC to exit.

User is not allowed to set the password to 0000.

New password

Has been set …….

If new password is accepted, this message

will be shown and then exit to [Settings Menu].

New password

‘0 0 0 0’

Is not accepted ………

If new password is ‘0000’, this message

will be shown and then exit to [Settings Menu].

The password remains as previous.

34

Page 37

6.2.9 Clock Setting

User can set the clock for the panel.

<ENTER> <ENTER>

Summary Pages Main Menu Timer Menu

<ESC> <ESC>

<ENTER> <ESC>

Se t Time :

hh mm

00 : 00

UP or DOWN to change ‘hour’. ENTER to set ‘minute’

or ESC to exit to [Timer Menu].

UP or DOWN to change ‘minute’. ENTER to confirm

or ESC to set ‘hour’again.

6.4.10 Date Setting

User can set the date for the panel.

<ENTER> <ENTER>

Summary Pages Main Menu Timer Menu

<ESC> <ESC>

<ENTER> <ESC>

Set Time

Se t Time :

yyyy hh mm

2000 /01 / 01

Set Time

UP or DOWN to change ‘year’. ENTER to set ‘month’ or

ESC to exit to [Timer Menu].

UP or DOWN to change ‘month’. ENTER to set ‘day’ or

ESC to set ‘year’ again.

UP or DOWN to change ‘day’. ENTER to confirm or

ESC to set ‘month’ again.

35

Page 38

6.2.11 7 days Programmable Setting

_ _ _ _

_ _ _ _

The are 2 ON/OFF events in one day for the schedule. This schedule is applicable to all the chillers in

the network.

Timer 1 Timer 2

ON OFF ON OFF

Sun 0800 1600 _ _ _ _ _ _ _ _

Mon 0800 1600 _ _ _ _ _ _ _ _

Tue 0800 1600 _ _ _ _ _ _ _ _

Wed 0800 1600

_ _ _ _

UP or DOWN select day of week, ENTER

to select event or ESC to exit to [Timer Menu].

Timer 1 Timer 2

ON OFF ON OFF

Sun 0800 1600 _ _ _ _ _ _ _ _

Mon 0800 1600 _ _ _ _ _ _ _ _

Tue 0800 1600 _ _ _ _ _ _ _ _

Wed 0800 1600

_ _ _ _

UP or DOWN select event. ENTER to start

setting or ESC to back to select day of week.

Event setting is same like time setting. User can

disable the event by set it to ‘- - - -’

Before the schedule will carry the effect, user need to set ENABLE for “TIMER” in [Timer Menu].

TIMER MENU

Set Time

Set Date

Set Schedule

Timer : Disable

Select “Timer” and press ENTER to start the

settings. UP or DOWN to toggle Enable/ Disable,

ENTER to confirm or ESC to cancel.

36

Page 39

6.2.12 Viewing Alarm / Erase Alarm Record

Whenever a new fault/ alarm is occurred, there will be a message pop up to show the fault/ alarm.

Backlight will blinking with beeping sound (if “Alarm Buzzer” is set ON). If the fault/ alarm has not been

dissolved from the Chiller, a sign [A] will be shown in the [Summary Pages].(from pop up menu)

automatically if the fault/ alarms have been dissolved.

While the fault/ alarms have not been dissolved (sign [A]), user can check that fault/ alarm by to into

[Alarm Menu]. If all the fault/ alarm have been dissolved, user can view the fault/alarm historty records

in [Alarm Menu] as well. Screen saver will be deactivated while all the alarms have not been dissolved.

If panel ID is set 0 (Master panel), it can receive and view all the fault / alarms from all chillers in the

network.

[Ch 0]

New Alarm 1

Comp 1 over load

12:00am 01/ 01/ 2000

[Ch 0] show alarm occurred unit.

Press any button to stop backlight blinking and beeping.

Press ESC again to exit to normal page.

[Ch 0]

New A l arm 1

Comp 1 overload

01 / 01/ 00 12:00am

Er a s e Al ar m ?

Please Enter to Er ase,

Or ESC to e xit

Press UP or DOWN to scroll the record.

Press ENTER if user want to erase the reocrd, or ESC

to exit to [Alarm Menu].

Press ENTER to erase the alarm, or ESC to cancel.

User can erase all the fault/ alarm record at once time through [Erase All Alarm] in [Alarm Menu].

37

Page 40

6.2.13 Viewing Defrost Sensor Temperature

The Chiller Panel displays defrost sensor temperature for each compressor in [Defrost Sensor]

in [Display Menu].

De fr ost Senso r

Comp 1 : 12.8° C

Press ESC to exit to [Display Menu]

6.2.14 Viewing Compressor Discharge Temperature

The Chiller Panel displays compressor discharge temperature for each compressor in [Discharge Sensor]

in [Display Menu].

Discharge Sensor

Comp 1 : 36.5° C

Press ESC to exit to [Display Menu]

38

Page 41

6.2.15 Viewing/ Clear Compressor Run Time

User can view/ clear the compressor run time for the Chiller in [Comp Run Time] in [Display Menu].

Comp Run Time

Comp 1 : 13579h

Clear Run Time ?

Press Enter to Clear

Or ESC to exit.

Press UP or DOWN to select teh compressor. ENTER

to start clear the run time, or ESC to exit to [Display

Menu].

Press ENTER and key in the password to confirm or

ESC to cancel

6.2.16 Miscellaneous Settings

User can do some miscellaneous settings to the panel.

Backlight : Normal :

Buzzer : On

Screen Saver : Disable

Timeout : 5m

Contrast : 50%

Brightness : Medium

Temp Unit : ° C

Press UP or DOWN to select the item. ENTER to set,

or ESC to exit to [Settings Menu].

Press UP or DOWN to toggle the value. ENTER to confirm,

or ESC to cancel.

39

Page 42

Parameter Value Description

Backlight

Normal Turn ON backlight for 30s via key press

Always Always ON backlight

Buzzer

*Screen Saver

ON Enable beeping sound when fault/ alarm occurred

OFF Disable beeping sound when fault/ alarm occurred

Enable Show screen saver when timeout

Disable No screen save

*Timeout 1-30m Timeout for showing screen saver

Contrast 0-100% Adjust the contrast setting for the LCD panel

Brightness

Tem p Unit

OFF No backlight

Low, Medium, High Adjust the backlight intensity

°C Display temperature in degree Celsius

°F Display temperature in degree Fahrenheit

* This product must be branded. Screen saver will be deactivated for brand less panel

6.3 CMOS Reset

• CMOS reset allows user to reset some settings to default value such as:

Password -> 0001

Backlight -> Normal

Buzzer -> ON

Screen Saver -> Disable

Timeout -> 5m

Contrast -> 50%

Brightness -> Medium

Temp Unit -> C

• Procedures

1. Power OFF the panel

2. Close the jumper JH2 with the provided jumper header

3. Power ON the panel and the LCD panel should display as follow:

CM OS is re setting ……… …

4. Remove the jumper header (put the jumper header on 1 pin only), power OFF and then

power ON the panel.

CMOS reset complete d !

Ple ase remove JUM PER

and res tart the panel

40

Page 43

0

7. PROBLEM AND TROUBLESHOOTING

Symptom s Poss ible Caus e Troubles hooting

1 Panel gets hot - Wiring fault in 12VDC s upply - Change a new panel m odule and turn ON the unit again

abnormally after the verification

2 The LCD no display - Wiring fault in 12VDC supply - Correct the wiring problem

(blank screen) - No power supply - Check the wiring and supply 12VDC to panel

- Voltage supply too low - Check the power source

- Module defective - Change a new panel module

3 - -' for all status -Panel cannot/ not yet - Ensure the selected unit exits in the network

(quite a long time) received the information - Ensure the wiring is correct

from chiller or FCU completely - Ensure the wiring is not defective

-Ensure the wiring has been isolated from high power cable

- That particular unit addres s - Select a coherent unit address on the panel (refer to

is not recognized by the panel 6.2.2)

- Module defective - Change a new module

4 ON/ OFF, COOL or - Software limitation - Ensure it is pressed (hold 1s) in [Summary Pages]

HEAT button not not in other menu.

function - Module defective - Change a new module

5 Cannot switch to - Software limitation - Ensure this mode is available in current "Model" of

HEATING mode Chiller, please refer to 6.2.4

6 Cannot switch to - Software limitation - Ensure this mode is available in current "Model" of

BOILING mode Chiller, please refer to 6.2.4

7 No "Manual Defrost" - Software limitation - Ensure current running mode is HEATING

item

8 Cannot step ins ide - Software limitation. Panel has - Refer to symptoms 3

[Set Parameter] not received all the information

from chille r completely

9 7 Days Programmable - Software limitation. User Control of Chiller:

Timer not function did not activate the schedule - Ensure the "Timer" in [Timer Menu] is set ENABLE

Control of Chiller:

- Ensure the 'Timer" in [Operation Menu] is set ENABLE

10 No beeping sound - Software lim itation. User - Ensure "Buzzer" in [Panel Option] is set ON

when new alarm did not set ON to the alarm

occurred buzzer

11 No screen s aver after - Software limitation. User did - Ens ure "Screen Saver" in [Panel Option] I set ENABLE

timeout not set ENABLE to the screen

s ave r

12 Time always reset to - No backup battery - Replace coin cell battery

12:00am, 1st Jan 200

13 Panel stop operation. - Uns table power s upply - Power off the panel. Take out the backup battery as well.

Whole operation - Energy of the backup battery is Replace with a new 3V coil cell battery if necessary. Put

freezing (hang) low back the backup battery into the panel and power on again

- Energy of the backup battery is

low

41

Page 44

8. APPENDIX

G1

G2

G3

G4

G5

G6

G7 Unit number F Flag 0 0 50 1

Gene ral Type Unit Def ault Min M ax Reso lution

Model F Flag 4 0 2 1

0=Chiller (Chille r+Boiler)

1=He at pump,

2=Chiller / Boiler ,

3=He at pu mp / Boiler, 4=Chiller +Boile r

5=He at pump+Boiller

Number of compressor F Flag 1 1 4 1

1=1 compressor,

2=2 compressor,

3=3 compressor,

4=4 compressor

On/Off input F Flag 0 (dis able) 0 1 1

0=disable, 1=enable

Coo/ Heat input F Flag 0 (dis able) 0 1 1

0=disable, 1=enable

External alarm input F Flag 0 (disable) 0 1 1

0=disable, 1=enable

Water sys tem for chille r ne twork F Flag 0 (dis able) 0 1 1

0=independent, 1=modular

S1 Enter ing w ater sens or calibr ation U °C (F) 0 (0) -12 (21.6) - 12 (21.6) 0.1

S2 Le avin g w ate r s en sor calibr ation U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S3 Air se ns or calibration U °C (F) 0 (0) -12 (21.6) - 12 (21.6) 0.1

S4 De frost(condenser) sensor 1 calibr ation U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S5 De frost(condenser) sensor 2 calibr ation U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S6 De frost(condenser) sensor 3 calibr ation U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S7 De frost(condenser) sensor 4 calibr ation U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S8 Compressor discharge sensor 1 calibration U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S9 Compressor discharge sensor 2 calibration U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S10 Com pressor discharge sensor 3 calibration U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

S11 Com pressor discharge sensor 4 calibration U °C (F) 0 (0) -12 (21.6) -12 (21.6) 0.1

R1 Cooling se t-point D °C (F) 12 (53.6) R5 R6 0.1

R2 Cooling differ ent ial U °C (F) 1.5* (2.7) 0.4 (0.7) 10 (18) 0.1

R3 Heating se t-point D °C (F) 40 (104) R7 R8 0.1

R4 Heating d iffe re ntial U °C (F) 1.5* ( 2.7) 0.4 (0.7) 10 (18) 0.1

R5 Minimum Cooling s et-point U °C (F) 7 (44.6) -20 (-4) R6 1

R6 Maxim um Co oling s et-point U °C (F) 20 (68) R5 40 (104) 1

R7 Minimu m He ating set- point U °C (F) 30 (68) -20 (-4) R8 1

R8 Maxim um Heat ing s et -point U °C (F) 50 ( 122) R7 90 (194) 1

R9 Auxiliary h eater se t-p oint(thre shold below U °C (F) 5 (9) 0 (0) 40 (72) 0.1

R10 Auxiliar y he ater dif fere ntial U °C (F) 2 (3.6) 0.4 (0.7) 10 (18) 0.1

R11 Auto boiler se t-point(threshold below U °C (F) 5 (9) 0 (0) 40 (72) 0.1

R12 Aut o boile r d iffe re ntial U °C (F) 2 (3.6) 0.4 (0.7) 10 (18) 0.1

R13 Auto boiler start tim e thre shold U min 30 0 199 1

C1 Compressor minimum run time U sec 120 0 1990 10

C2 Compressor minimum stop time U sec 180 0 1990 10

C3 Tim e in terval be tw een tw o star ts U sec 450 0 1990 10

C4 Start delay betw een tw o compressors U sec 15 0 199 1

C5 Pump on ? compressor on delay U sec 180 0 1990 10

C6 Com p off ? pum p off delay U se c 60 0 199 10

C7 Discharge cu t-off-s e t-po int U °C (F) 120(248) 0 (32) 150 (302) 1

SENSOR Type Unit Default Min Max Resolution

REGULATOR Type Unit Default Min Max Resolution

below heating set-point)

He ating set-point)

COMPRESSOR Type Unit Def ault Max M in Res olution

D1 Star t defros t temperature U °C (F) 0 (32) -20 (-4) D2 1

D2 En d de fro st temp er atur e U °C (F) 14 (57) D1 40 (104) 1

D3 Maxim um duration of def ros t cycle U m in 10 1 40 1

D4 Defrost inte rval time U min 45 0 199 1

D5 Delay be for e defr osting U se c 0 0 1990 10

D6 Delay afte r defrostin g U se c 120 0 1990 10

CONDENSSOR Type Unit Def ault Max M in Res olution

42

Page 45

A1 Antifreeze heater set-point °C (F) 5 (41) -40 (-40) 40 (104) 1

V

V

V

V

V

A2 Antifreeze heater differential °C (F) 2 (3.6) 0.4 (0.7) 10 (18) 0.1

A3 Antifreeze sens or select Flag 0 0 1 1

A4 Antifreeze alarm set-point °C (F) 3 (37) -40 (-40) 40(104) 1

A5 Antifreeze alarm differential °C (F) 2 (3.6) 0.4 (0.7) 10 (18) 0.1

COOL MODE ANTIFREEZ E Unit Default Min Max Resolution

0=Leaving water, 1=Entering water (leaving)

P1 Flow switch confirmation time sec 5 0 199 1

P2 Flow switch alarm delay at pump start sec 120 0 199 1

P3 Low pressure alarm delay at compressor start up sec 30 0 199 1

P4 Comp overload alarm reset type Flag 0 0 1 1

P5 High pressure alarm reset type Flag 1 0 1 1

P6 Low pressure alarm reset Flag 1 0 1 1

P7 Fan overload alarm reset type Flag 1 0 1 1

P8 Pump overload alarm reset type Flag 0 0 1 1

P9 Flow switch alarm reset type Flag 0 0 1 1

P10 Auxiliary alarm reset type Flag 1 0 1 1

P11 Antifreeze alarm reset type Flag 0 0 1 1

P12 Comp overload contact type Flag 0 0 1 1

P13 High pressure contact type Flag 0 0 1 1

P14 Low pressure contact type Flag 0 0 1 1

P15 Fan overload contact type Flag 0 0 1 1

P16 Pump overload contact type Flag 0 0 1 1

P17 Flow switch contact type Flag 0 0 1 1

P18 External alarm contact type Flag 0 0 1 1

P19 Defrost end contact type Flag 0 0 1 1

1 Compressor frequency Hz Auto 0 120 1

2 EXV Opening Flag Auto 0 480 1

3 Compressor manual setting

4 EXV Manual setting

5 Defrost Mode

ALARM AND CONTACT Unit Default Min Max Resolution

0=Manual reset, 1=Auto reset (manual)

0=Manual reset, 1=Auto reset (auto)

0=Manual reset, 1=Auto reset (auto)

0=Manual reset, 1=Auto reset (auto)

0=Manual reset, 1=Auto reset (manual)

0=Manual reset, 1=Auto reset (manual)

0=Manual reset, 1=Auto reset (auto)

0=Manual reset, 1=Auto reset (manual)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

0=Normally close(NC) 1=Normally open(NO) (NC)

INVERTER Unit Default Min Max Resolution

0= disable 1= enable

0=disable 1= enable

0= disable 1= enable

Flag 0(disable)

Flag 0(disable) 0 1 1

011

1Flag 0(disable) 0 1

43

Page 46

PRECAUTIONS AND INSTALLATION

SPECIAL PRECAUTIONS WHEN DEALING WITH REFRIGERANT R407C UNIT

1) WHAT IS NEW REFRIGERANT R407C?

R407C is a zeotropic refrigerant mixture which has Zero Ozone Depletion Potential (ODP = 0) and thus

conformed to the Montreal Protocol regulation. It requires Polyol-ester oil (POE) oil for its compressor’s

lubricant. Its refrigerant capacity and performance are about the same as the refrigerant R22.

2) COMPONENTS

Mixture weight compositionR32(23%), R125(25%), R134a(52%)

3) CHARACTERISTIC

• R407C liquid and vapor components have different compositions when the fluid evaporates or condenses.

Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant mixture left in the

system will change and subsequently affect the system performance. DO NOT add new refrigerant to

leaked system. It is recommended that the system should be evacuated thoroughly before recharging

with R407C.

• When refrigerant R407C is used, the composition will differ depending on whether it is in gaseous or

liquid phase. Hence when charging R407C, ensure that only liquid is being withdrawn from the cylinder

or can. This is to make certain that only original composition of R407C is being charged into the system.

• POE oil is used as lubricant for R407C compressor, which is different from the mineral oil used for R22

compressor. Extra precaution must be taken not to expose the R407C system too long to moist air.

4) CHECK LIST BEFORE INSTALLATION/SERVICING

• Tubing

Refrigerant R407C is more easily affected by dust of moisture compared with R22, make sure to temporarily

cover the ends of the tubing prior to installation

• Compressor oil

No additional charge of compressor oil is permitted.

• Refrigerant

No other refrigerant other that R407C

• Tools

Tools specifically for R407C only (must not be used for R22 or other refrigerant)

i) Manifold gauge and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

5) HANDLING AND INSTALLATION GUIDELINES

Like R22 system, the handling and installation of R407C system are closely similar. All precautionary measures;

such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and thorough leak

check and vacuuming are equally important requirements. However, due to zeotropic nature of R407C and its

hydroscopic POE oil, additional precautions must be taken to ensure optimum and trouble free system operation.

a) Filter dryer must be installed along the liquid line for all R407C air conditioners. This is to minimise the

contamination of moisture and dirt in the refrigerant system. Filter dryer must be of molecular sieve type.

For a heat pump system, install a two--way flow filter dryer along the liquid line.

b) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

44

Page 47

c) Ensure that the compressor is not expose to open air for more than the recommended time specified by

its manufacturer (typically less than 10 minutes). Removed the seal plugs only when the compressor is

about to be brazed.

d) The system should be thoroughly vacuumed to 1.0 Pa ( 700mmHg) or lower. This vacuuming level is

more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

e) When charging R407C, ensure that only liquid is being withdrawn from the cylinder or can. This is to

ensure that only the original composition of R407C is being delivered into the system. The liquid

composition can be different from the vapor composition.

R32 / R125 / R134

23% / 25% / 52%

33% / 33% / 34%

Composition of R407C in vapour phase

is different from liquid phase.

f) Normally, the R407C cylinder or can is being equipped with a dip pipe for liquid withdrawal. However, if

the dip pipe is not available, invert the cylinder or can so as to withdraw liquid from the valve at the

bottom.

Dip-pipe Invert cylinder

without dip-pipe

Liquid

withdrawal

g) When servicing leak, the top up method, commonly practiced for R22 system, is not recommended for

R407C system. Unlike R22 where the refrigerant is of a single component, the composition of R407C,

which made up of three different components, may have changed during the leak. Consequently, a top

up may not ensure that the R407C in the system is of original composition. This composition shift may

adversely affect the system performance. It is recommended that the system should be evacuated

thoroughly before recharging with R407C.

45

Page 48

SPECIAL PRECAUTIONS WHEN DEALING WITH REFRIGERANT R410A UNIT

1) WHAT IS NEW REFRIGERANT R410A?

R410A is a new HFC refrigerant which does not damage the ozone layer. The working pressure of this new

refrigerant is 1.6 times higher than conventional refrigerant (R22), thus proper installation / servicing is

essential.

2) COMPONENTS

Mixture of composition by weight : R32(50%) and R125(50%)

3) CHARACTERISTIC

• R410A liquid and vapor components have different compositions when the fluid evaporates or

condenses. Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant

mixture left in the system will change and subsequently affect the system performance. DO NOT

add new refrigerant to leaked system. It is recommended that the system be

evacuated thoroughly before recharging with R410A.

• When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or

liquid phase.

Hence when charging R410A, ensure that only liquid is being withdrawn from the cylinder or can. This is

to make certain that only original composition of R410A is being charged into the system.

• POE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22

compressor.

Extra precaution must be taken to avoid exposing the R410A system to moist air.

4) CHECK LIST BEFORE INSTALLATION / SERVICING

• Tubing

Refrigerant R410A is more easily affected by dust or moisture compared with R22, make sure to

temporarily cover the ends of the tubing prior to installation

• Compressor oil

No additional charge of compressor oil is permitted.

• Refrigerant

No other refrigerant other that R410A

• Tools (size of service port is different from R22 system)

Tools specifically for R410A only (must not be used for R22 or other refrigerant)

i) Gauge manifold and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

5) HANDLING AND INSTALLATION GUIDELINES

Like R22 systems, the handling and installation of R410A system are closely similar. All precautionary

measures; such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and

thorough leak check and vacuuming are equally important requirements. However, due to its hydroscopic

POE oil, additional precautions must be taken to ensure optimum and trouble-free system operation.

a) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

b) Ensure that the compressor is not expose to open air for more than the recommended time specified by

its manufacturer (typically less than 10 minutes). Removed the seal-plugs only when the compressor is

about to be brazed.

c) The system should be thoroughly vacuumed to 1.0 Pa ( 700mmHg) or lower. This vacuuming level is

more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

46

Page 49

d) When charging R410A, ensure that only liquid is being withdrawn from the cylinder or can. This is to

ensure that only the original composition of R410A is being delivered into the system. The liquid

composition can be different from the vapor composition.

Dip-pipe Invert cylinder

without dip-pipe

Liquid

withdrawal

e) Normally, the R410A cylinder or can is being equipped with a dip-pipe for liquid withdrawal. However, if

the dip-pipe is not available, invert the cylinder or can so as to withdraw liquid from the valve at the

bottom.

47

Page 50

INSTALLATIONS

AMAC 20/ 25/ 30 C/CR, A4AC 20/25/30 C, A5AC 20 / 25 / 30CR

AMAC 40/ 50/60 C/CR, A4AC 40/50 C, A4AC 60 C/CR, A5AC 40 / 50 / 55 CR

48

Page 51

A4AC/ AMAC 80/ 100/ 120/ 150 C/CR

500

O

A

A

N

500

AMAC 20 / 25 / 30 / 40 / 50 / 60 C/CR, A4AC 20 / 25 / 30 / 40 / 50 C, A4AC60 C/CR,

A5AC 20 / 25 / 30 / 40 / 50 / 55CR

500 500

W

IR FL

1

IR FLOW

IR FLOW

I

500

For single unit installation

49

Page 52

0

O

O

O

A

A

A

A

MIN

0

AMAC 20 / 25 / 30 / 40 / 50 / 60 C/CR, A4AC 20 / 25 / 30 C, A4AC 60 C/CR,

A5AC 20 / 25 / 30 / 40 / 50 / 55 CR

500

W

IR FL

1000

50

W

IR FL

For multiple unit installation (mm)

1000 500

W

IR FL

IR FLOW

IR FLOW

IR FLOW

IR FLOW

50

50 50

For floor installation (mm)

SAFETY PRECAUTIONS

Before installing the air conditioner unit, please read the following safety precautions carefully

Warning

!

• Installation and maintenance should be performed by qualified persons who are familiar

with local code and regulation, and experienced with this type of appliance.

• All field wiring must be installed in accordance with the national wiring regulation.

• Ensure that the rated voltage of the unit corresponds to that of the name plate before

commencing wiring work according to the wiring diagram.

• The unit must be GROUNDED to prevent possible hazards due to installation failure.

• All electrical wiring must not touch the refrigerant piping, compressor or any moving

parts of the fan motors.

• Confirm that the unit has been switched OFF before installing or servicing the unit.

• Do not touch the compressor or refrigerant piping without wearing gloves.

IMPORTANT

DO NOT INSTALL OR USE THE AIR CONDITIONER UNIT IN A LAUNDRY ROOM

50

Page 53

Caution

!

Please take note of the following important points when installing.

• Do not install the unit where leakage of flammable gas may occur.

If gas leaks and accumulates around the unit, it may cause fire ignition.

• Ensure that the drainage piping is connected properly.

If the drainage piping is not connected properly, it may cause water leakage which will dampen the

furniture.

!

• Do not overcharge the unit.

This unit is factory pre-charged. Overcharge will cause over-current or damage to the compressor.

• Ensure that the units panel is closed after service or installation.

Unsecured panels will cause unit to operate noisily.

!

INSTALLATION LOCATION

• Installation work should be done by the authorized dealer or qualified contractor. Never install the unit

yourself.

• Make sure there is sufficient airflow around the unit.

• Vibration isolator should be provided to reduce the vibration and noise of the unit.

• There should be sufficient space allocated for servicing and maintenance when installing the unit.

TRANSPORTATION

• The unit should be lifted using a crane. Ensure that the hanger belts

are not touching the coil, top panel and front panel (use protective panel)

as shown in Figure 1.

• The bolt of the base and channel support can be removed after

putting the unit on the fixed location. Figure 1

WATER PIPING AND FITTING

• All water pipe must be insulated to prevent capacity losses and condensation.

• Install a 40-60 mesh strainer to ensure water quality is good.

• Water pipe recommended are black steel pipe and copper pipe.

• During installation, the piping of the unit should be clamp before rotating the installation pipe to reduce the

moment induce on the unit piping.

• Users are recommended to install the pipe and accessories as shown in Figure 2 & 3.

• An air vent must be installed at the highest position, while a drainage plug at the lowest position of

the water circuit. Open the air vent to release any air trap in the water circuit.

• Run the clean water through the water inlet and operate the pump to drain out the dirty water. Clean

the strainer after running the pump for 30 minutes.

• Fill up the water circuit after connecting the pipes and equipment. Check water leakage at all

connections and joints. Do not start the unit when the system is leaking.

• To optimize the capacity of the system, ensure that the system is free of air bubbles. The air trapped

in the system would make the system unbalanced.

51

Page 54

PRESSU

UGE

GA

GA

G

R

GA

VE (LOWER

)

AIR

VENT (INST

ALL

)

L

UNIT/AIR HANDLING UNIT

GA

R

GA

GA

S

R

CHEC

M

P

(DIFFER ENT

PRESSU

UGE

GA

GA

H

R

VE (LOWER

(INST

)

AN COIL

UNIT/AIR HANDLING UNIT

GA

R

S

R

M

UP

(DIFFER ENT

)

AMAC 20 / 25 / 30 C/CR, A4AC 20 / 25 / 30 C, A5AC 20 / 25 / 30 CR

HIGHEST POSITION

RE GA

HERMOMETE

HERMOMETE

BALANCIN

TRAINE

AN COI

K

POSITION FOR DRAINAGE

AKE U

AMAC 40 / 50 / 60 C/CR, A4AC 40 / 50 C, A4AC 60 CR, A5AC 40 / 50 / 55 CR

RE GA

ERMOMETE

HERMOMETE

TRAINE

HIGHEST POSITION

TYPE

AKE

Figure 2

A4AC / AMAC 80 / 100 / 120 / 150 C/CR

AIRVENT (INSTALL

HIGHEST POSITION)

PRESSURE GAUGE

FLEXIBLE

FLEXIBLE

!

GATE

VALVE

THERMOMETER

THERMOMETER

GATE

VALV E

GATE

BALANCING

VALVE

VALVE

GATE

VALV E

CAUTION

BALANCING

VALVE

STRAINER

CHECK

VALVE

GATE

VALV E

PRESSURE

DIFFERENTIAL

VALV E

MAKE UP

VALVE

GATE VALVE

(LOWER POSITION

FOR DRAINAGE)

FAN COIL UNIT/AIR HANDLING UNIT

Figure 3

• Do not allow water to remain in the water pipes if the unit is not operating for a long period.

Water must be drained out if the unit is not running during winter. Failing to do so would cause the pipe

to crack.

• Do not drink the chilled water in the unit.

52

Page 55

ELECTRICAL AND WIRING

Remove this

e

g

n

sp

r

W

sp

(

F

O

O

3

3

O

O

OUT_F

O

1

CAP

ACIT

O

z

3

3

z

e

g

d

olle

8

n

r

3

1

2

m

z

d

ese

es

n

• Refer to the wiring diagram provided on the unit when making electrical wiring.

• Install an isolator (optional) to prevent electrical shock.

• Do not ground any electrical equipment to the water piping.

• Operation of the mini chiller without any fan speed controller (Field supply) is limited to an ambient

temperature of 20C. With the fan speed controller (Field supply), the unit is able to operate down

to -5C.

All mini chillers will have a 1/4” access valve provided for along the liquid

line of the refrigerant circuit.This valve is for direct pressure connection

to the fan speed controller. To install the fan speed controller, screw in

the female adaptor to the 1/4” access valve. Use a pair of spanners to

tighten properly(max. torque 15Nm). See Fig. 8. Ensure there is no leakage at

the joint. Wire the fan speed controller to the terminal blocks.