Page 1

Models:

ACK/A5CK 20E/ER

ACK/A5CK 25E/ER

ACK/A5CK 28E/ER

ACK/A5CK 40E/ER

ACK/A5CK 50E/ER

ACK - E - 2009

Ceiling Cassette Split Systems

Page 2

ACK-E-2009 Table of Contents

Table of Contents

Nomenclature......................................................................................................................1

Indoor Unit .....................................................................................................................1

Outdoor Unit ..................................................................................................................2

Product Line-Up .............................................................................................................3

Features.............................................................................................................................10

Application Information ................................................................................................... 11

Operating Range ......................................................................................................... 11

Refrigerant Circuit Diagram .........................................................................................12

Controller ....................................................................................................................17

Installation Guideline ...................................................................................................20

Sound Data ........................................................................................................................33

Sound Pressure Level .................................................................................................33

NC Curve .....................................................................................................................34

Engineering & Physical Data ........................................................................................... 37

General Data ...............................................................................................................37

Component Data .........................................................................................................53

Safety Devices ............................................................................................................69

Performance Data ............................................................................................................. 74

Calculation Steps .........................................................................................................75

Performance Table ......................................................................................................78

Outline and Dimension ..................................................................................................102

Electrical Data ................................................................................................................. 104

Wiring Diagram ............................................................................................................... 112

Service and Maintenance...............................................................................................121

Troubleshooting .............................................................................................................123

Exploded View and Part List .........................................................................................129

“Acson” is a registered trademark of Acson International. All rights reserved.

© 2009 Acson International. All rights reserved throughout the world.

Bulletin illustrations cover the general appearance of Acson International products at the time of publication.

We reserve the right to change design and construction specifi cations at any time without notice.

Page 3

Nomenclature ACK-E-2009

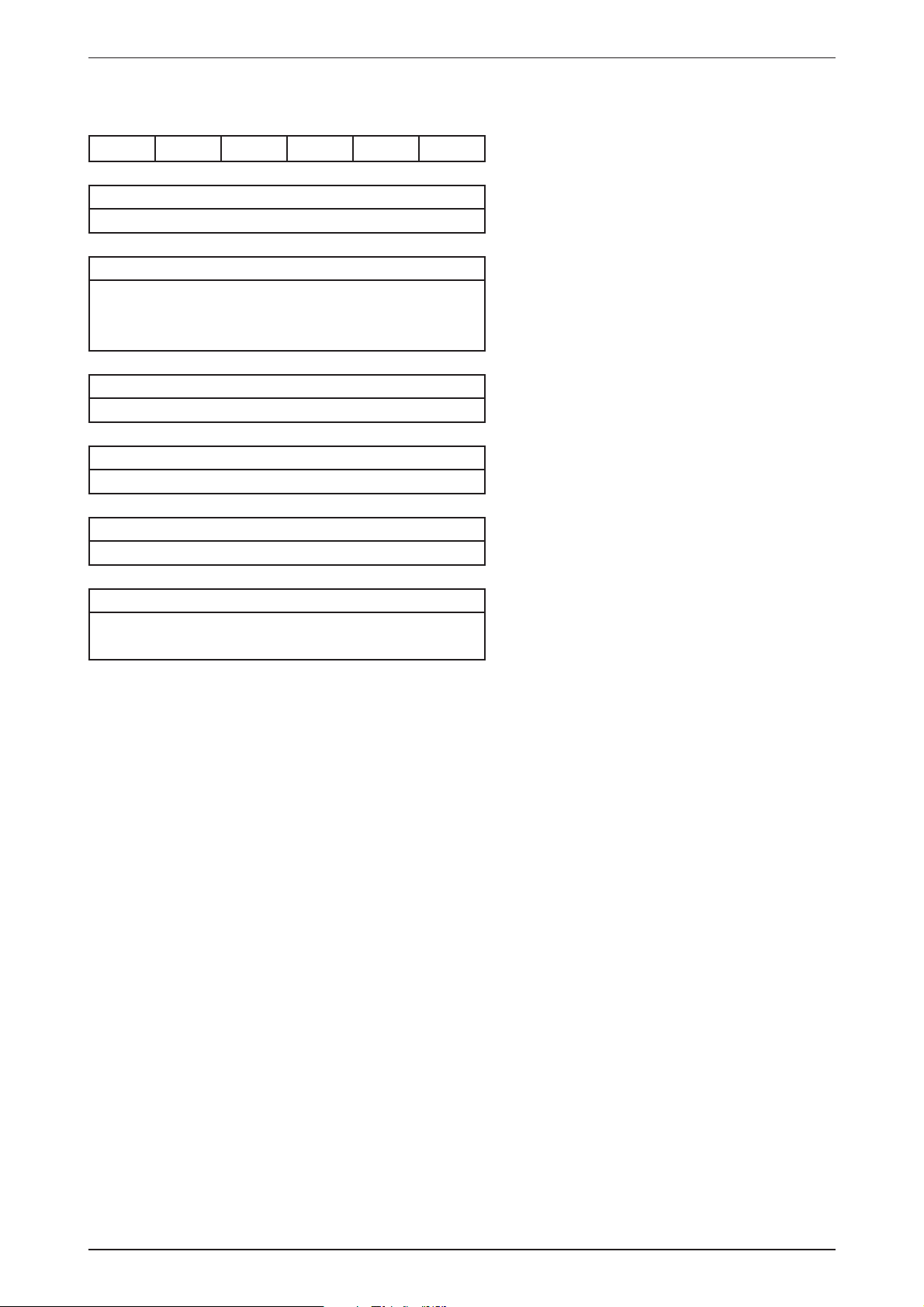

Nomenclature

Indoor

A 5 CK 20 E R

Brand

A : Acson

Refrigerant

“ “

4

5

Model Name

CK : Ceiling Cassette

: Omitted if R22

: R407C

: R410A

Capacity Index

20 : 20,000 Btu/h

Chassis

E : E Series

Model Type

“ “

R

: Omitted if cooling only

: Heatpump

1

Page 4

ACK-E-2009 Nomenclature

Outdoor

A 5 LC 20 C R

Brand

A : Acson

Refrigerant

“ “

4

5

Model Name

LC : Single Split Condensing Unit

Capacity Index

20 : 20,000 Btu/h

: Omitted if R22

: R407C

: R410A

Chassis

E : E Series

Model Type

“ “

R

: Omitted if cooling only

: Heatpump

2

Page 5

Product Line-Up ACK-E-2009

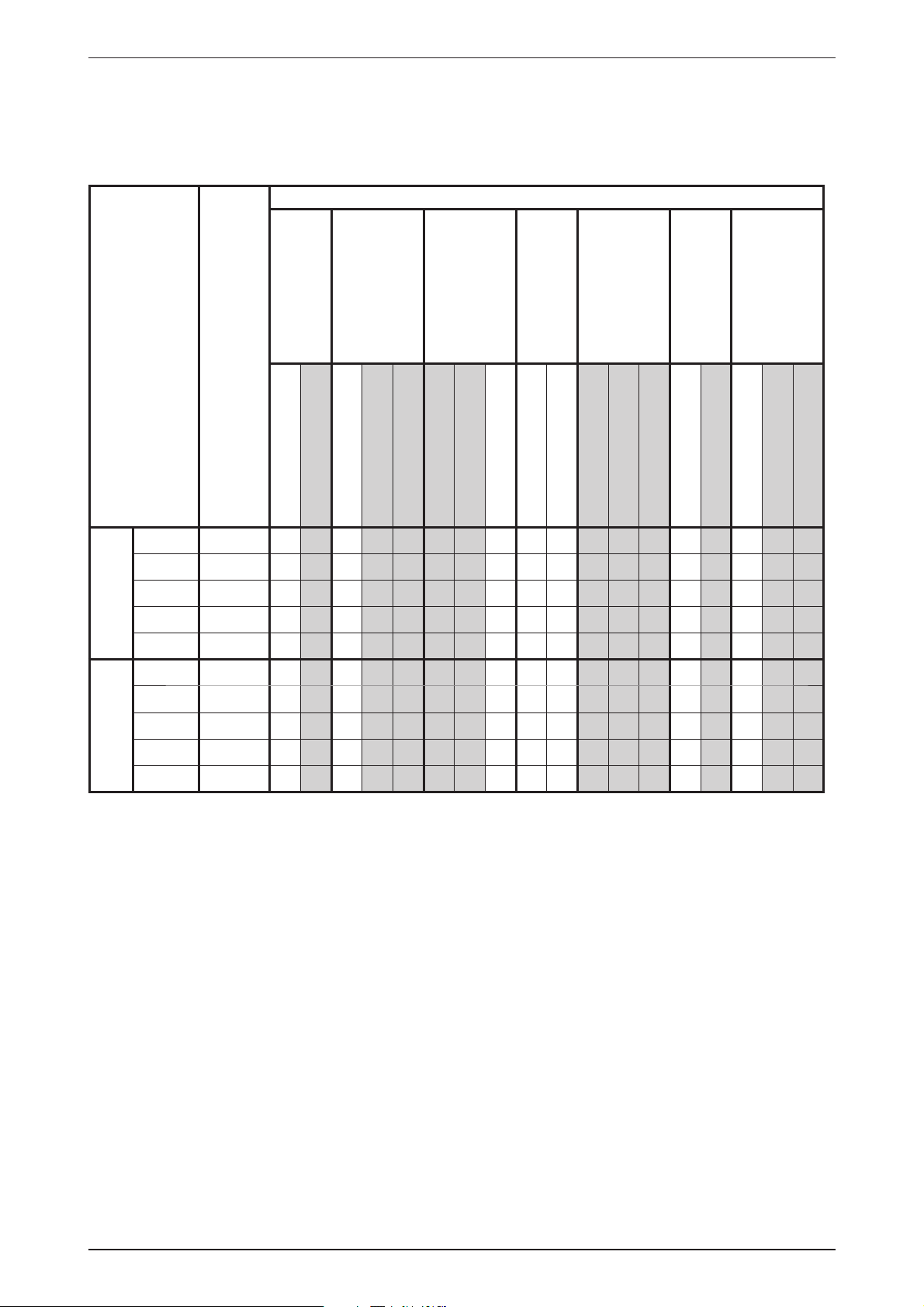

Product Line-Up

Indoor Unit

ACK-E Series

Classifi cation

Model

Nomenclature

20E ACOBA X X X X X X

25E ACOBA X X X X X X

28E ACOBA X X X X X X

40E ACOBA X X X X X X

COOLING ONLY

50E ACOBA X X X X X X

20ER ACOBA X X X X X X

25ER ACOBA X X X X X X

28ER ACOBA X X X X X X

40ER ACOBA X X X X X X

HEATPUMP

50ER ACOBA X X X X X X

PCB

L2 08A

G18

Handset

Fin

Refrigerant Control

Bare

Cap Tube

W/out Cap Tube

Air Purifi cation

Marking

CE

Others

Auto Air Swing

3

Page 6

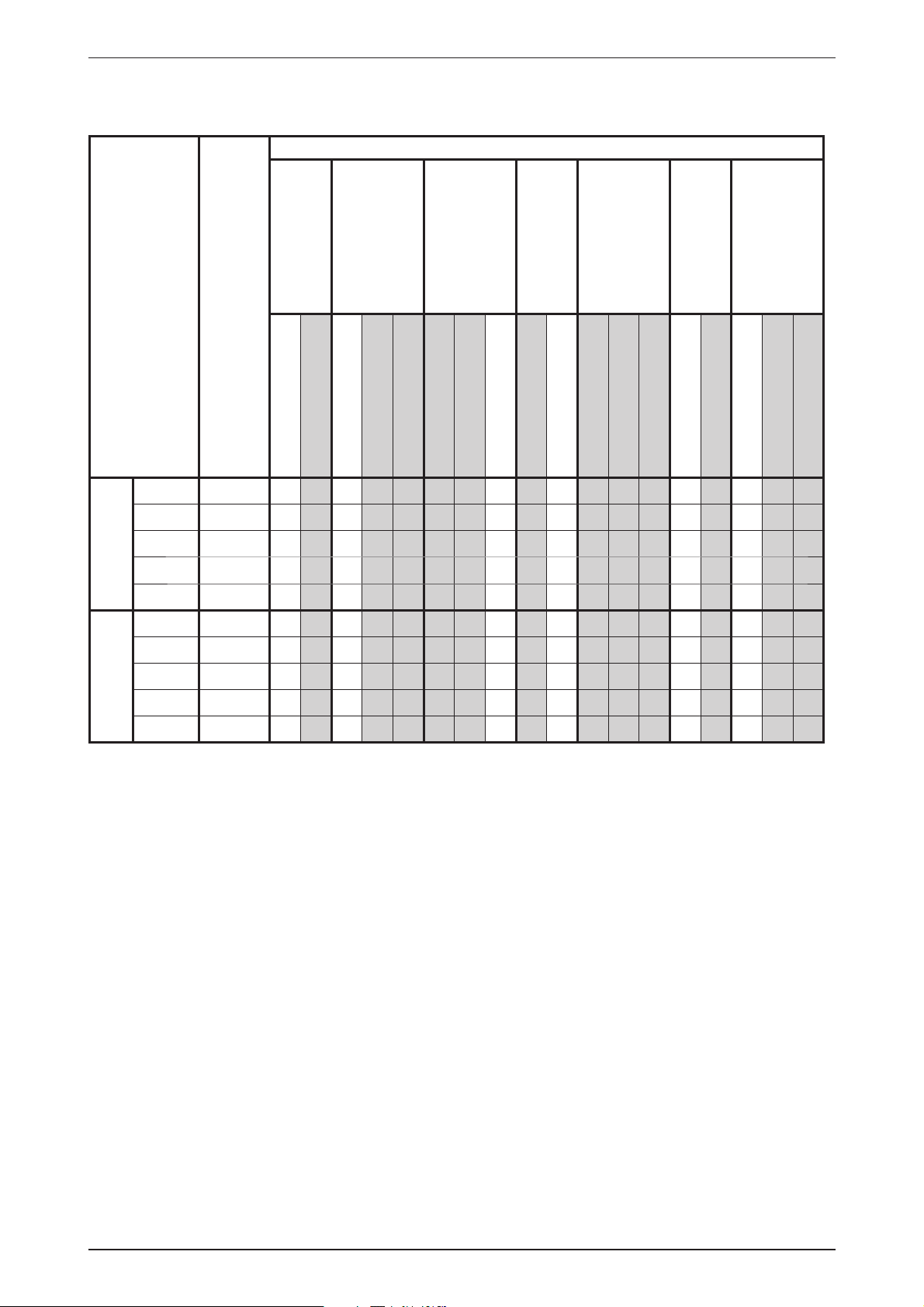

ACK-E-2009 Product Line-Up

Indoor Unit

A5CK-E Series

Classifi cation

Model

Nomenclature

20E ACOBA X X X X X X

25E ACOBA X X X X X X

28E ACOBA X X X X X X

40E ACOBA X X X X X X

COOLING ONLY

50E ACOBA X X X X X X

20ER ACOBA X X X X X X

25ER ACOBA X X X X X X

28ER ACOBA X X X X X X

40ER ACOBA X X X X X X

HEATPUMP

50ER ACOBA X X X X X X

PCB

L2 08A

G18

Handset

Fin

Refrigerant Control

Bare

W/out Cap Tube

Air Purifi cation

Marking

CE

Others

Auto Air Swing

4

Page 7

Product Line-Up ACK-E-2009

Indoor Unit

ACK Panel Product Line Up

Classifi cation

Model

COOLING

Handset

Nomenclature

G18

PLCKE-NG18 X X X

ONLY

PLCKER-NG18 X X X

HEATPUMP

CE

Marking

Others

Auto Air Swing

5

Page 8

ACK-E-2009 Product Line-Up

Outdoor Unit

ALC

Classifi cation

Model

20C

25C

Refrigerant Control

Nomenclature

TXV

Cap Tube

ACPOD X X X X

ACPID X X X X

ACPHB X X X X X

ACPBD X X X X X

ACPOD X X X X

ACPID X X X X

ACPBD X X X X X

ACPHB X X X X X

ACPSD X X X X X

ACHOB X X X

Fin

Gold Coated

Bare

Compressor

Scroll / Digital Scroll

Rotary / Fixed Scroll

Contactor

High Pressure Switch

Safety Devices

Low Pressure Switch

Phase SequencerCEHigh Ambient Kit

Marking

Others

Drain Elbow

28C

35C

COOLING ONLY

40C

50C

ACHIB X X X

ACHBB X X X X

AFGE X X X X X X

AFGG X X X X X X

AFGE X X X X X X

AFGG X X X X X X

FFGE X X X X X X X

FFGF X X X X X X X X

FFGG X X X X X X X

FFGL X X X X X X X

AUCOA X X X X X X

FUDOA X X X X X X

FFGN X X X X X

FFGP X X X X X X X X

FFGQ X X X X X X X

FFGT X X X X X X X X

FUDOA X X X X X X

6

Page 9

Product Line-Up ACK-E-2009

Outdoor Unit

ALC

Classifi cation

Model

20CR

25CR

28CR

35CR

HEATPUMP

Refrigerant Control

Nomenclature

TXV

Cap Tube

ACPOD X X X X

ACPID X X X X

ACPHB X X X X X

ACPOD X X X X

ACPID X X X X

ACPHB X X X X X

ACHOB X X X

ACHIB X X X

AFFB X X X X X X X X

AFFD X X X X X X X X

Fin

Gold Coated

Bare

Compressor

Scroll/ Digital Scroll

Rotary/ Fixed Scroll

Contactor

High Pressure Switch

Safety Devices

Low Pressure Switch

Phase SequencerCEHigh Ambient Kit

Marking

Others

Drain Elbow

AFFB X X X X X X X X

AFFD X X X X X X X X

40CR

FFFB X X X X X X X X X

FFFD X X X X X X X X X

FFFF X X X X X X X X X

50CR

FFFG X X X X X X X X X

7

Page 10

ACK-E-2009 Product Line-Up

Outdoor Unit

A5LC

Classifi cation

Model

20C

25C

28C

Refrigerant Control

Nomenclature

TXV

Cap Tube

ACPIC X X X X

ACPOC X X X X

FCPOC X X X X X X

ACPIC X X X X

ACPOC X X X X

FCPOC X X X X X X

ACPOA X X X X

ACPIA X X X X

FCPOA X X X X X X

ACCOB X X X X X X X

Fin

Gold Coated

Bare

Compressor

Scroll/ Digital Scroll

Rotary/ Fixed Scroll

Contactor

High Pressure Switch

Safety Devices

Low Pressure Switch

Phase Sequencer

Marking

CE

Others

Drain Elbow

ACCGB X X X X X X X

35C

COOLING ONLY

FCCOB X X X X X X X X

FCCGB X X X X X X X X

FCCGB X X X X X X X X

FCCOB X X X X X X X X

40C

ACCOB X X X X X X X

ACCGB X X X X X X X

FCCOB X X X X X X X X

50C

FCCGB X X X X X X X X

8

Page 11

Product Line-Up ACK-E-2009

Outdoor Unit

A5LC

Classifi cation

Model

20CR

25CR

28CR

Refrigerant Control

Nomenclature

TXV

Cap Tube

ACPIC X X X X

ACPOC X X X X

FCPOC X X X X X X

ACPIC X X X X

ACPOC X X X X

FCPOC X X X X X X

ACPOA X X X X

ACPIA X X X X

FCPOA X X X X X X

ACCOB X X X X X X X

Fin

Gold Coated

Bare

Compressor

Scroll / Digital Scroll

Rotary / Fixed Scroll

Contactor

High Pressure Switch

Safety Devices

Low Pressure Switch

Phase Sequencer

Marking

CE

Others

Drain Elbow

HEATPUMP

35CR

40CR

50CR

ACCGB X X X X X X X

FCCOB X X X X X X X X

FCCGB X X X X X X X X

ACCGB X X X X X X X

ACCOB X X X X X X X

FCCOB X X X X X X X X

FCCGB X X X X X X X X

FCCOB X X X X X X X X

FCCGB X X X X X X X X

9

Page 12

ACK-E-2009 Features

Features

Improved Sound Level

The new ACK-E series is equipped with a newly-developed turbo fan, which has improved the sound pressure

level of the unit signifi cantly.

Lower Height Model

To ease installation, the overall height of the ACK-E series has been greatly reduces. (350mm for ACK-E,

290mm for ACK 20-28E/ER, 325mm for ACK 40-50E/ER).

Multi-Comfort – 3 Air Swing Pattern Control

To increase the comfort level of the air conditioned area of ACK-E series, the system had been built in with 3

different type of the air fl ow pattern to suit different requirement.

Built-in High Head Drain Pump

The unit has a built-in high head drain pump (with 700 mm drain head) to provide and ensure smoothness

drainage of condensate water.

Wireless Remote Controller

The compact LCD transmitter is able to operate the air conditioner unit within the distance of 8 meters.

•

Fan speed can be set at high / medium / low / super low or automatic.

•

Sleep mode auto control will gradually increase or decrease the setting temperature to provide a

•

comfortable surrounding for sleeping.

Air fl ow direction can be controlled automatically.

•

Room temperature is controlled by electronic thermostat.

•

The real time timer allows the air conditioner to be switched On and Off automatically based on user

•

settings.

Turbo mode function is available to enables the required set temperature to be achieved in a short time.

•

Personalized Setting allows user to preset and store 2 groups of personal settings (including timer setting)

•

in the handset.

10

Page 13

Application Information ACK-E-2009

Application Information

Operating Range

Ensure the operating temperature is in allowable range.

Cooling only

46

35

19

Outdoor temp. (°CDB)

Standard

point

! Caution :

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

Heat Pump

Outdoor temp. (°CWB)

15

Indoor temp. (°CWB)

Heating

18

6

-9

Standard

15 21

Indoor temp. (°CDB)

Note :

Standard operating range.

point

24

Cooling

46

35

19

Standard

point

Outdoor temp. (°CDB)

37

15

24

Indoor temp. (°CWB)

11

Page 14

ACK-E-2009 Application Information

Refrigerant Circuit Diagram

Model: ACK 20E - ALC 20C A5CK 25E - A5LC 25C

A5CK 20E - A5LC 20C

Model: ACK 25E - ALC 25C

A5CK 28E - A5LC 28C

70034 095231

70034 049972

12

Page 15

Application Information ACK-E-2009

Model: ACK 28E - ALC 28C

Model: ACK 40E - ALC 35/40C

ACK 50E - ALC 50C

70034 049972

13

70034 049181

Page 16

ACK-E-2009 Application Information

Model: A5CK 40E - A5LC 35/40C

A5CK 50E - A5LC 50C

Model: ACK/A5CK 20ER - ALC/A5LC 20CR

A5CK 25ER - A5LC 25CR

70034 097007

70034 095238

14

Page 17

Application Information ACK-E-2009

Model: ACK 28ER - ALC 28CR

Model: ACK/A5CK 28ER - ALC/A5LC 28CR

70034 049972

15

70034 049181

Page 18

ACK-E-2009 Application Information

Model: ACK 30ER - ALC 30CR

ACK 40ER - ALC 35/40CR

ACK 50ER - ALC 50CR

Model: A5CK 40ER - A5LC 35/40CR

A5CK 50ER - A5LC 50CR

70034 095246

08014 085116

16

Page 19

Application Information ACK-E-2009

Controller

G18

1

2

3

4

15

14

13

12

11

10

5

6

7

8

9

Operation Guide

1 Transmission Source

The source where the signal will be transmitted.•

2 Signal Transmission Indication

Blink to confi rm that the last setting has been transmitted

•

to the unit.

3 Temperature Setting

To set the desired room temperature, press the ▲ or ▼

•

button to increase or decrease the set temperature.

The temperature setting range is from 16°C to 30°C

•

(optional setting 20°C to 30°C).

4 Personalize Setting

Press

•

•

•

•

5 Automatic Air Swing (optional)

•

•

6 Silent Function

•

•

•

7 Sleep Mode Setting

•

•

•

and hold for 3s, then will blink. Press again to

cycle between and .

Set the desire setting, then leave the handset for 4s

without pressing any key and it will save the setting into the

programme.

Press once to activate the P1 setting, press again to

cycle between P1 and P2.

Press any key to deactivate the personalize setting.

Press the SWING

button to activate the automatic air

swing function.

To distribute the air to a specifi c direction, press the

SWING button and wait until the louver move to the

desired direction and press the button once again.

Press

for quiet operation.

Fan speed turn to minimum speed.

Press again to deactivate the function.

Press the SLEEP button will activate the sleep mode

function. This function is available under COOL, HEAT and

AUTO mode.

When the unit is operating under cooling mode, the set

temperature is increased by 0.5°C after 30 minutes, 1°C

after an hour, and 2°C after 2 hours.

When the unit is operating under heating mode, the set

temperature is decreased by 1°C after 30 minutes, 2°C

after an hour, and 3°C after 2 hours.

8 Operating Mode

Press the MODE button to select the type of operating

•

mode.

For cooling only unit, the available modes are: COOL (7),

•

DRY (6) and FAN (

).

9 Fan Speed Selection

Press the

•

button continuously will toggle the fan speed

in the following order:

Low B Med B High B Auto

Stop pressing when the desired fan speed appears on the

•

display screen.

10 “ON/OFF” Button

Press one to start the air conditioner unit.

•

Press again to stop the unit.

•

11 Timer Cancel

Press the TIMER CANCEL button to cancel the on timer

•

setting.

12 OFF Timer Setting

Press the OFF TIMER button will activate the off timer

•

function.

Set the desired off time by pressing the OFF TIMER button

•

continuously.

13 ON Timer Setting

Press the ON TIMER button will activate the on timer

•

function.

Set the desired on time by pressing the ON TIMER

•

button continuously. If the timer is set to 7.30am, the air

conditioner will turn on at 7.30am sharp.

14 Turbo Function

Press

•

Fan speed turn to maximum speed.

•

Press again to deactivate the function.

•

for fast cooling.

15 Clock Time Setting

Press

and hold to set the clock time.•

17

Page 20

ACK-E-2009 Application Information

Operating State and Fault Table

Wireless Remote Control

Cooling : LED Indicator Light Display Heatpump : LED Indicator Light Display

POWER TIMER SLEEP

POWER TIMER SLEEP

1 Time

2 Times

3 Times

1 Time

HEAT

POWER

Operation / Faulty Indication

Cool Mode

Time On

Sleep Mode On

Heat Mode

Auto Mode - Cool

Auto Mode - Heat

Compressor Overload

Pump Fault

Gas Leak

Room Sensor Open or Short

TIMER HEAT

2 Times

3 Times

ON

Indoor Coil Sensor Open or Short

Outdoor Coil Sensor Open or Short

ON or OFF Blinking

18

Page 21

Application Information ACK-E-2009

Water Pump

The water pump will on if compressor is on during cooling cycle. The pump will remain on for at least 5 minutes

after the compressor is off.

During mode change from cooling to non-cooling mode, the pump will on for minimum 5 minutes. During

defrost cycle, the pump will on and will on for another 5 minutes once the defrost cycle is terminated.

Water Level Switch

This normally close switch is to detect faults in water pump system. It will confi rm for 30 seconds for switch

open and 60 seconds for switch close.

Once switch is confi rmed open, it will force compressor to cut off. If the switch is closed within 5 minutes, the

compressor is allowed to cut in. If the switch does not close for more than 5 minutes, the system will warn user

regarding the fault, the compressor is not allowed to cut in. If the switch is confi rmed opened twice within 30

minutes, the system assumes there are faults.

Phase Sequencer

The unit with Scroll Compressor can only rotate in one direction. For this reason, a protective device (phase

sequencer) is fi tted to prevent incorrect wiring of the electrical phases. When the three phases are not connected

correctly, the phase sequencer operates, and the unit will not start. This devise is located in the control box of

the outdoor unit.

The following table shows the LED indicator light for phase sequencer under normal operation and fault

conditions.

LED_P

(Red)

Normal Operation On - - -

Reverse Phase Blink Blink Blink Blink

S & T Phase Missing Blink - Blink Blink

T Phase Missing Blink - - Blink

S Phase Missing Blink - Blink -

R Phase Missing - - - -

Overload Blink - - -

Sensor Missing Blink On On On

Notes: 1. “-” means LED off.

2. When R phase missing, no LED or buzzer will indicate the error, but relay 71 (Common) and 81

(NO) will cut off.

3. The unit will check the discharge sensor availability only during power up.

4. All errors can only recover through manually reset.

LED_R

(Yellow)

LED_S

(Yellow)

LED_T

(Yellow)

19

Page 22

ACK-E-2009 Application Information

Installation Guideline

Caution

Sharp edges and coil surfaces are potential injury hazard. Avoid from contact with them.•

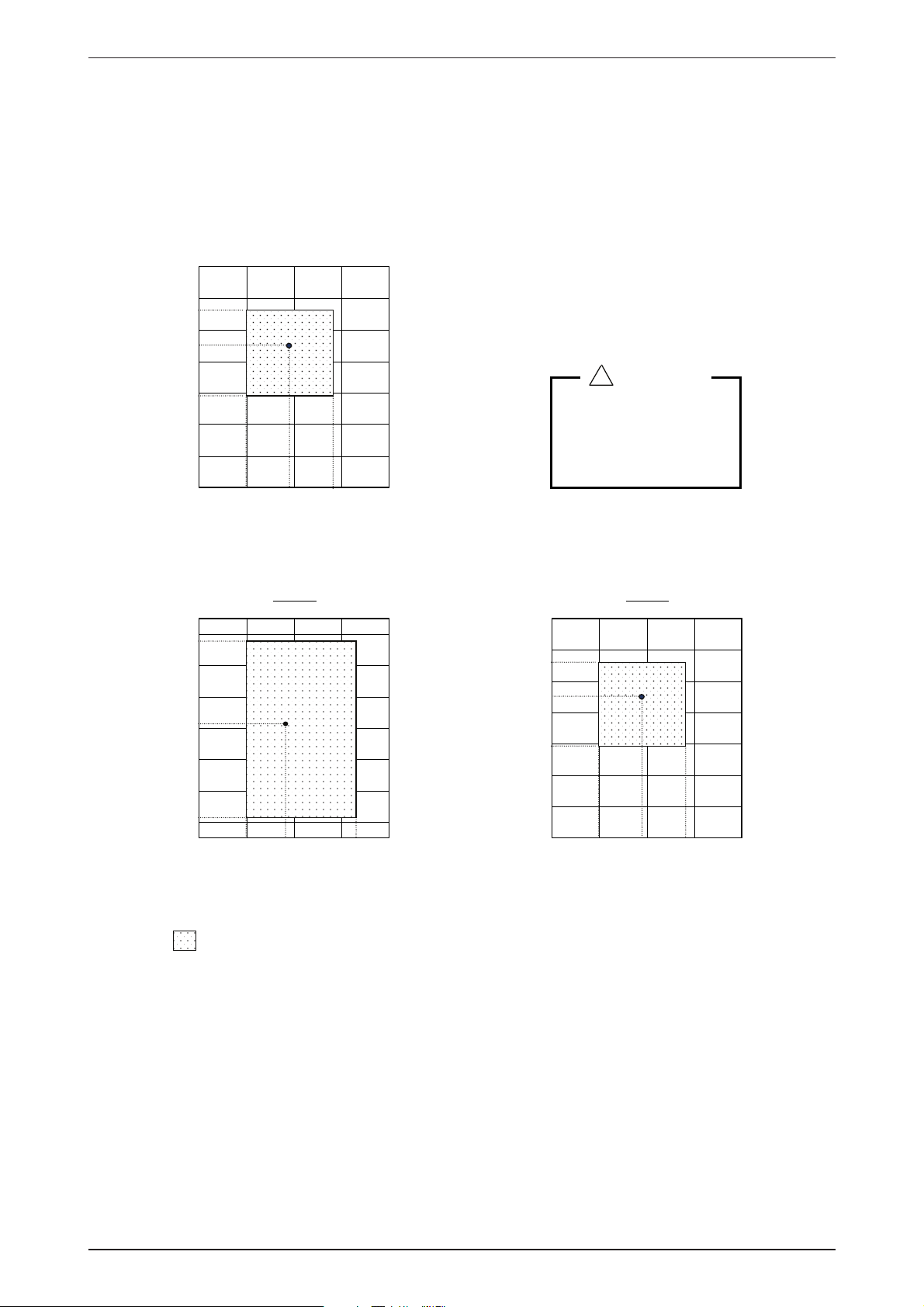

(1) Installation Of Indoor Unit

Preliminary Site Survey

Electrical supply and installation is to confi rm to local authority’s (e.g. National Electrical Board) codes and

•

regulations.

Voltage supply fl uctuation must not exceed ± 10% of rated voltage. Electricity supply lines must be

•

independent of welding transformers which can cause high supply fl uctuation.

Ensure that the location is convenient for wiring, piping and drainage.

•

The indoor unit must be installed in such that free from any obstacles in path of cool air discharge and

•

warm air return, and must allow spreading or air throughout the room (near the centre of the room).

Clearance must be provided for the indoor unit from the wall and obstacles as shown in the fi gure.

•

maeB

m0.1.niM

m0.3.xaM

Obstacle

Floor

The installation place must be strong enough to support a load of 4 times the indoor unit weight to avoid

•

m5.0.niMm5.0.niMm5.0.niM

m3.0.xaM

amplifying noise and vibration.

The installation place (handling ceiling surface) must be level and the height in the ceiling is 350mm or

•

more.

Unit Installation

770.0 mm (Hanging rod)

)dorgnignaH(mm0.226

Piping Direction

The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

•

Measure and mark the position for the hanging rod. Drill the hole for the angle nut on the ceiling and fi x

•

the hanging rod.

The installation template is extended according to temperature and humidity. Check on dimensions in

•

using.

The dimensions of the installation template are same as those of the ceiling opening dimensions.

•

Before ceiling laminating work is completed, be sure to fi t the installation template to the indoor unit.

•

Note: Be sure to discuss the ceiling drilling work with the installers concerned.

20

Page 23

Application Information ACK-E-2009

Unit Hanging

Ceiling

Board

35.0mm

ACK-E

Confi rm the pitch of the hanging rod is 770mm x 622mm sharp.

•

Hold the unit and hand it on the hanging rod with the nut and washer.

•

Adjust the unit height to 35.0mm between the indoor unit bottom surface and the ceiling surface.

•

Confi rm with a level gauge that the unit is installed horizontally and tighten the nut and bol to prevent unit

•

falling and vibration.

Open the ceiling board along the outer edge of the paper installation template.

•

Drain Piping Work

Drain Test

Drain pipe must be downward gradient for smooth drainage.

•

Avoid the drain pipe from up and down slope to prevent

•

reversal fl ow.

During the drain piping connection, be careful not to exert extra

•

force on the drain connector at indoor unit.

The outside diameter of the drain connection at the fl exible

•

drain hose is 20mm.

Be sure to provide heat insulation (polyethylene foam with

•

thickness more than 8.0mm) on the drain piping to avoid the

condensed water dripping inside the room.

Connect the main drain pipe to the fl exible drain hose.

•

Feed water from fl exible drain hose and check the piping for

•

leakage.

When the test is completed, connect the fl exible drain hose to

•

the drain connector on the indoor unit.

Note: This indoor unit use drain pump for condensed water drainage. Install the unit horizontally to

prevent water leakage or condensation around the air outlet.

21

Page 24

ACK-E-2009 Application Information

Panel Installation

The front panel can only be fi tted in one direction, follow the piping direction. (Follow piping arrow sticker

•

on the front panel).

Be sure to remove the installation template before installing the front panel.

•

Open the air intake grille by pulling back the catchers and remove it together with fi lter from panel.

•

Install the front frame panel onto the indoor unit by using 4 screws and tighten it completely to prevent cool

•

air leakage.

Connect the LED wire and air swing wire to the indoor unit (Optional).

•

Note: Install the front frame panel fi rmly to prevent cool air leakage which will cause condensation

and water dripping.

22

Page 25

Application Information ACK-E-2009

Short Duct Specifi cation

The indoor unit is provided with air discharge and air intake “knock-out” hole for duct connection. However

•

the connection of the short duct for air discharge is possible on only one side.

The use of short duct for air discharge will improve air fl ow distribution if there is an obstruction (such as

•

alighting fi xture) or in a long, narrow room or an L-shaped room. It is also used for air-conditioning of two

rooms simultaneously.

Possible Direction For Air Discharge and Air Intake

Air DischargeAir Discharge

Air Intake

egrahcsiDriAegrahcsiDriA

Possible Opening Dimension for Duct Connection

Note: 1. Avoid to use the short duct on which the air discharge grille can be completely closed, to

prevent evaporator freezing.

2. In order to prevent condensation forming, be sure that there is suffi cient thermal insulation

and no leakage of cool air when installing the short duct.

3. Keep the introduction of fresh air intake within 20% of total air fl ow. Also provide a chamber

and use a booster fan.

23

Page 26

ACK-E-2009 Application Information

(2) Installation Of Outdoor Unit

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to achieve

maximum cooling capacity, the location selected for outdoor unit should fulfi ll the following requirements:

Install the condensing (outdoor) unit in a way such that hot air distributed by the outdoor condensing unit

•

cannot be drawn in again (as in the case of short circuit of hot discharge air). Allow suffi cient space for

maintenance around the unit.

Ensure that there is no obstruction of air fl ow into or out of the unit. Remove obstacles which block air

•

intake or discharge.

The location must be well ventilated, so that the unit can draw in and distribute plenty of air thus lowering

•

the condensing temperature.

A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

•

A place protected from direct sunlight. Otherwise use an awning for protection, if necessary.

•

The location must not be susceptible to dust or oil mist.

•

Installation Clearance

Outdoor units must be installed such that there is no short circuit of the hot discharge air or obstruction to

•

smooth air fl ow. Select the coolest possible place where intake air should not be hotter than the outside

temperature (max. 45˚C).

ALL MODELS A B C D

Minimum Distance 300 mm 1000 mm 300 mm 500 mm

CAUTION : If the condensing unit is operated in an atmosphere containing oils (including machine oils), salt (coastal area),

sulphide gas (near hot spring, oil refi nery plant), such substances may lead to failure of the unit.

24

Page 27

Application Information ACK-E-2009

(3) Refrigerant Piping

Maximum Piping Length and Maximum Number of Bends

When the pipe length becomes too long, both the capacity and reliability drop. As the number of bends

increases, system piping resistance to the refrigerant fl ow increases, thus lowering the cooling capacity,

and as the result the compressor may become defective. Always choose the shortest path and follow the

recommendation as tabulated below:

Model

Maximum Length, m 15 15 15 45 45

Maximum Elevation, m 8 8 8 25 25

Maximum No. of Bends 10 10 10 10 10

Indoor 20E/ER 25E/ER 28E/ER 40E/ER 50E/ER

Outdoor 20C/CR 25C/CR 28C/CR 35/40C/CR 50C/CR

Piping Sizes (Flare Connection Type)

Piping sizes are as follows:

R22

Model ALC 20C/CR ALC 25C/CR

Liquid (mm/in) 6.35 / 1/4 9.52 / 3/8

Suction (mm/in) 15.88 / 5/8 15.88 / 5/8

Model ALC 28C/CR ALC 35/ 40C/CR ALC 50C/CR

Liquid (mm/in) 9.52 / 3/8 9.52 / 3/8 9.52 / 3/8

Suction (mm/in) 15.88 / 5/8 19.05 / 3/4 19.05 / 3/4

R410A

Model A5LC 20C/CR A5LC 25C/CR

Liquid (mm/in) 6.35 / 1/4 6.35 / 1/4

Suction (mm/in) 12.70 / 1/2 15.88 / 5/8

Model A5LC 28C/CR A5LC 35C/CR A5LC 40C/CR A5LC 50C/CR

Liquid (mm/in) 9.52 / 3/8 9.52 / 3/8 9.52 / 3/8 9.52 / 3/8

Suction (mm/in) 15.88 / 5/8 15.88 / 5/8 15.88 / 5/8 15.88 / 5/8

25

Page 28

ACK-E-2009 Application Information

Piping Connection To The Units

Align the centre of the piping and tighten the fl are nut suffi ciently with fi ngers.

•

Finally tighten the fl are nut with torque wrench unit the wrench clicks.

•

When tightening the fl are nut with torque wrench, ensure the direction for tightening follows the arrow on

•

the wrench.

(4) Wiring

Electrical Connections

Wiring regulations on wire diameters differ from country to country. Please refer to your LOCAL ELECTRICAL

CODES for fi eld wiring rules. Be sure that installation is complied with such rules and regulations

.

General Precautions

Ensure that the rated voltage of the unit corresponds to the nameplate before carrying out proper wiring

•

according to the wiring diagram.

Provide a power outlet to be used exclusively for each unit. A power supply disconnects and a circuit

•

breaker for over current protection should be provided in the exclusive line.

All wiring must be GROUNDED to prevent possible hazards due to insulation failures.

•

All wiring must be fi rmly connected.

•

All wiring must not come in contact with the hot refrigerant piping, compressor or any moving parts of fan

•

motors.

Do not use joined and twisted wires for incoming power supply

•

26

Page 29

Application Information ACK-E-2009

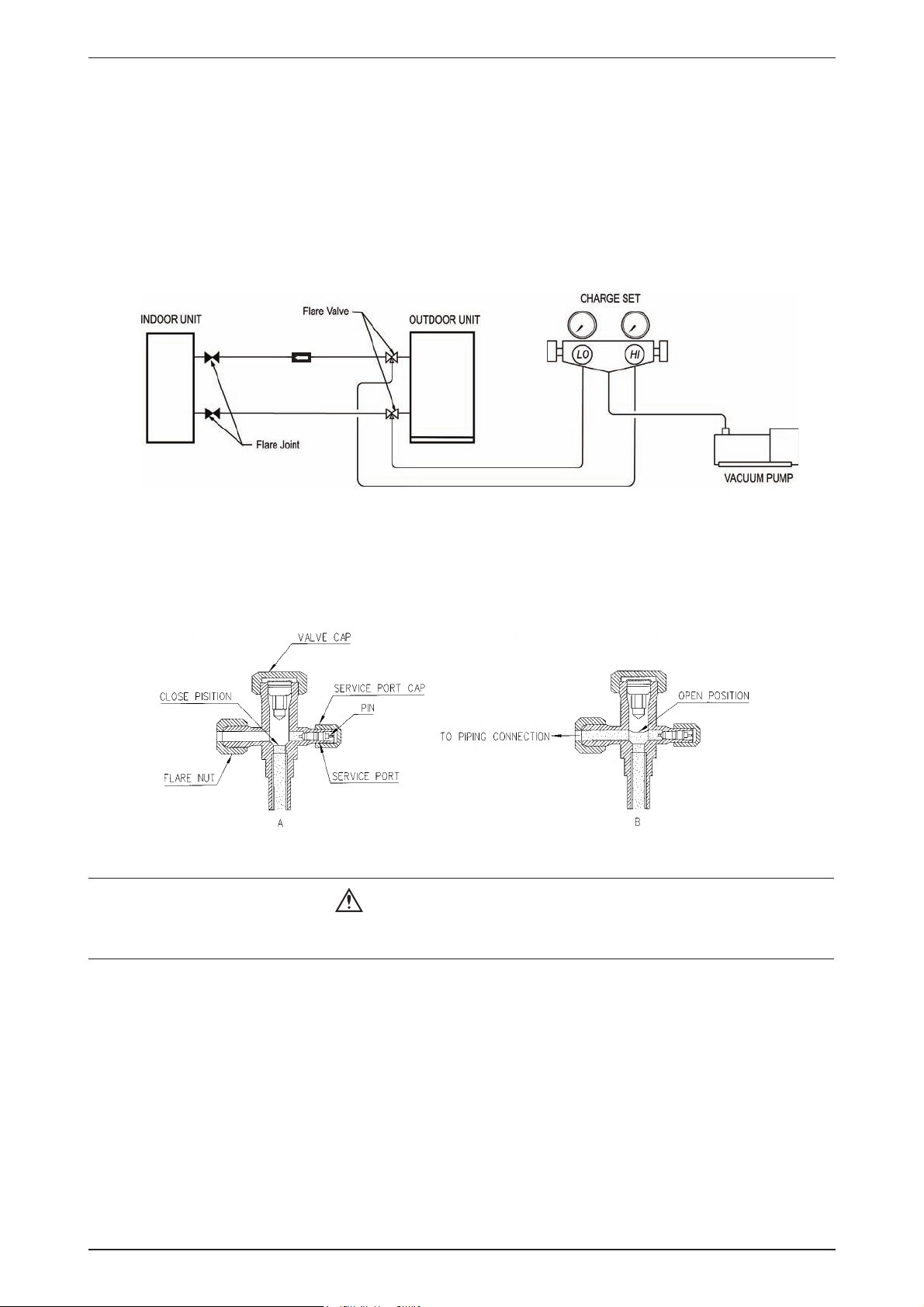

(5) Vacuuming and Charging

The pre-charged outdoor unit does not need any vacuuming or charging. However once it is connected, the

connecting pipe line and the indoor unit need to be vacuumed before releasing the R22/R407C/R410A from

the outdoor unit.

1. Open the service port core cap.

2. Connect pressure gauge to the service port.

3. Connect the line to vacuum pump. Open the charging manifold valve and turn the pump on. Vacuum to -0.1

MPa (-760mmHg) or lower. (Evacuation time varies by the pump but averagely in 1 hour).

Filter Dryer

(Mclecular-Sieve Type

Note : R407C- Fix filter dryer

R22 - Nil

R410A - Nil

4. After evacuation, unscrew the spindle (diagram B) for the gas to run to indoor unit.

Caution For R407C / R410A

Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit thoroughly

•

and then charge the unit with fresh R407C according to the amount recommended in the specifi cation.

27

Page 30

ACK-E-2009 Application Information

(6) Additional Charge

The refrigerant charge has already charged into the outdoor unit. For the piping length of 7.6m, additional

•

refrigerant charge after vacuuming is not necessary.

When the piping length is more than 7.6m, please use the table below (unit in gram).

•

R22

Model 10m 12m 15m 25m 35m 45m

20C/CR 38 / 53 70 / 96 118 / 162 - - -

25C/CR 94 / 53 172 / 98 289 / 164 - - -

28C/CR 94 / 133 172 / 244 291 / 411 - - -

30C/CR 133 / 133 244 / 243 410 / 409 964 / 961 1518 / 1514 2072 / 2067

35C/CR 130 / 136 238 / 248 400 / 418 940 / 983 1481 / 1547 2021 / 2112

40C/CR 134 / 136 245 / 248 412 / 418 968 / 983 1525 / 1547 2081 / 2112

50C/CR 130 / 134 238 / 245 400 / 412 942 / 968 1483 / 1525 2024 / 2081

R410A

Model 10m 15m 20m 25m 35m 45m

20C/CR 24 / 40 44 / 73 74 / 123 - - -

25C/CR 24 / 23 45 / 43 75 / 72 - - -

28C/CR 58 / 91 106 / 167 178 / 281 - - -

35C/CR 65 / 98 118 / 180 199 / 303 469 / 712 738 / 1122 1007 / 1531

40C/CR 61 / 97 112 / 178 189 / 299 445 / 703 700 / 1107 956 / 1511

50C/CR 50 / 87 92 / 159 155 / 267 363 / 628 572 / 989 781 / 1350

28

Page 31

Application Information ACK-E-2009

The additional refrigerant charge amount recommended is a guideline for longer piping application. The

actual charge required may be different from the guideline due to different application and variation in site

conditions.

Diagram shows typical charging method:

(Mclecular-Sieve Type)

Note : R407C - Fix filter dryer

R22 - Nil

R410A - Nil

Caution For R407C / R410A

Avoid prolong exposure of an opened compressor, or the internal part of refrigerant piping to moist air.

•

The POE oil in the compressor and piping can absorb moisture from air.

29

Page 32

ACK-E-2009 Application Information

Special Precautions When Dealing With Refrigerant R410A Unit

(1) What is New Refrigerant R410A?

R410A is a new HFC refrigerant which does not damage the ozone layer. The working pressure of this

new refrigerant is 1.6 times higher than conventional refrigerant (R22), thus proper installation / servicing

is essential.

(2) Components

Mixture weight composition R32(50%) and R125(50%)

(3) Characteristic

R410A liquid and vapor components have different compositions when the fl uid evaporates or

•

condenses. Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant

mixture left in the system will change and subsequently affect the system performance. DO NOT add

new refrigerant to leaked system. It is recommended that the system should be evacuated thoroughly

before recharging with R410A.

When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or

•

liquid phase. Hence when charging R410A, ensure that only liquid is being withdrawn from the cylinder

or can. This is to make certain that only original composition of R410A is being charged into the system.

POE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22

•

compressor. Extra precaution must be taken not to expose the R410A system too long to moist air.

(4) Check List Before Installation / Servicing

Tubing

•

Refrigerant R410A is more easily affected by dust of moisture compared with R22, make sure to

temporarily cover the ends of the tubing prior to installation.

Compressor oil

•

No additional charge of compressor oil is permitted.

Refrigerant

•

No other refrigerant other that R410A

Tools (size of service port is different from R22 system)

•

Tools specifi cally for R410A only (must not be used for R22 or other refrigerant)

i) Gauge manifold and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

(5) Handling and Installation Guidelines

Like R22 system, the handling and installation of R410A system are closely similar. All precautionary

measures; such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and

thorough leak check and vacuuming are equally important requirements. However, due to its hydroscopic

POE oil, additional precautions must be taken to ensure optimum and trouble free system operation.

(a) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system to

moist air. Residual POE oil in the piping and components can absorb moisture from the air.

(b) Ensure that the compressor is not exposed to open air for more than the recommended time specifi ed

by its manufacturer (typically less than 10 minutes). Removed the seal plugs only when the compressor

is about to be brazed.

(c) The system should be thoroughly vacuumed to 1.0 Pa (700mmHg) or lower. This vacuuming level is

more stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

30

Page 33

Application Information ACK-E-2009

(d) When charging R410A, ensure that only liquid is being withdrawn from the cylinder or can. This is

to ensure that only the original composition of R410A is being delivered into the system. The liquid

composition can be different from the vapor composition.

Invert cylinder

Dip-pipe

without dip-pipe

Liquid

withdrawal

(e) Normally, the R410A cylinder or can is being equipped with a dip pipe for liquid withdrawal. However,

if the dip pipe is not available, invert the cylinder or can so as to withdraw liquid from the valve at the

bottom.

31

Page 34

ACK-E-2009 Application Information

(7) Overall Checking

Ensure the following, in particular:

•

1. The unit is mounted solidly and rigid in position.

2. Piping and connections are leak proof after charging.

3. Proper wiring has been done.

Drainage check – pour some water into drain pan.

•

Test run

•

1. Conduct a test run after water drainage test and gas leakage test.

2. Watch out for the following:

(a) Is the electric plug fi rmly inserted into the socket?

(b) Is there any abnormal sound from the unit?

(c) Is there any abnormal vibration with regard to the unit itself or piping?

(d) Is there smooth drainage of water?

Check that:

•

1. Outdoor fan is running, with warm air blowing off the outdoor unit (cooling cycle).

2. Indoor blower is running and discharge cool air (cooling cycle).

3. Suction (low side) pressure is as per recommendations.

4. The remote controller has incorporated a 3 minutes delay in the circuit. Thus, it requires about 3 minutes

before the outdoor unit can start up.

(8) Standard Operating Condition

Cooling Only Unit

Temperature

Minimum Indoor Temperature 19.4 / 66.9 13.9 / 57.0

Maximum Indoor Temperature 26.7 / 80.1 19.4 / 66.9

Minimum Outdoor Temperature 19.4 / 66.9 13.9 / 57.0

Maximum Outdoor Temperature 46 / 114.8 24 / 75.2

Heat Pump Unit

Temperature

Minimum Indoor Temperature 10 / 50 -

Maximum Indoor Temperature 26.7 / 80.1 -

Minimum Outdoor Temperature -8 / 17.6 -9 / 15.8

Maximum Outdoor Temperature 24 / 75.2 18/ 64.4

Ts : Dry Bulb Temperature Th : Wet Bulb Temperature

Ts °C / °F Th °C / °F

Ts °C / °F Th °C / °F

32

Page 35

Sound Data ACK-E-2009

Sound Data

ACK-E/ER

Model

ACK 20E/ER

ACK 25E/ER

ACK 28E/ER

ACK 40E/ER

ACK 50E/ER

Speed

1/1 Octave A-Weighted Sound Pressure (dBA), ref 20μPa

125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Overall

A (dBA)

Noise

Criteria

High 37 38 35 26 17 8 6 34 30

Medium 34 34 33 21 11 5 6 31 28

Low 32 30 30 17 8 4 5 28 24

Super Low 32 28 29 16 7 4 5 27 23

High 39 40 37 29 22 13 6 37 32

Medium 37 38 35 26 18 9 5 34 30

Low 35 35 32 22 13 6 5 31 26

Super Low 34 34 31 20 10 5 6 30 25

High 45 43 42 35 29 22 11 41 37

Medium 40 41 39 30 24 15 7 38 34

Low 38 38 35 26 19 9 5 35 30

Super Low 35 35 33 23 14 5 4 32 28

High 48 45 44 38 30 28 15 44 39

Medium 49 42 41 34 25 21 8 41 36

Low 48 39 38 31 21 13 6 38 33

Super Low 45 35 36 26 15 5 5 35 31

High 50 48 46 42 33 32 20 47 41

Medium 52 45 43 38 29 27 13 44 38

Low 53 43 42 37 27 24 10 43 37

Super Low 51 41 39 32 23 16 6 39 34

Model Measuring location

ACK/A5CK 20E/ER

ACK/A5CK 25E/ER

ACK/A5CK 28E/ER

ACK/A5CK 40E/ER

ACK/A5CK 50E/ER

1.4m

Microphone

Standard : JIS C 9612

1.5m

Microphone

Standard : JIS B 8615

33

Page 36

ACK-E-2009 Sound Data

ACK 20E/ER NC Curve

80

70

60

50

40

Sound pressure level (dB, ref 20μPa)

30

Super High Fan

High Fan

20

Medium Fan

Low Fan

10

63 125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

ACK 25E/ER NC Curve

80

70

60

50

40

30

Sound pressure level (dB, ref 20μPa)

20

10

63 125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

Super High Fan

High Fan

Medium Fan

Low Fan

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

34

Page 37

Sound Data ACK-E-2009

ACK 28E/ER NC Curve

80

70

60

50

40

Super High Fan

30

Sound pressure level (dB, ref 20μPa)

High Fan

Medium Fan

20

Low Fan

10

63 125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

ACK 40E/ER NC Curve

80

70

60

50

40

30

Sound pressure level (dB, ref 20μPa)

20

10

63 125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

Super High Fan

High Fan

Medium Fan

Low Fan

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

35

Page 38

ACK-E-2009 Sound Data

ACK 50E/ER NC Curve

80

70

60

50

40

Super High Fan

Sound pressure level (dB, ref 20μPa)

30

High Fan

Medium Fan

20

10

63 125 250 500 1000 2000 4000 8000

Low Fan

Octave-band frequency (Hz)

NC70

NC65

NC60

NC55

NC50

NC45

NC40

NC35

NC30

NC25

NC20

36

Page 39

Engineering & Physical Data ACK-E-2009

Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 1960 2540

NOMINAL RUNNING CURRENT A 8.8 11.5

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.91 2.89

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa / in.wg. 00

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 31 / 28 37 / 34 / 31

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT (UNIT + PANEL) kg/lb 29+6 / 63.9+13.2 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE

AIR FLOW l/s / CFM 614 / 1300 755 / 1600

SOUND PRESSURE LEVEL dBA 51 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130 62 / 137

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1 / 2.20 1.25 / 2.76

OPERATION WIRELESS OR WIRED MICRO-

HIGH l/s / CFM 280 / 600 320 / 680

MEDIUM l/s / CFM 250 / 530 280 / 600

LOW l/s / CFM 200 / 430 250 / 530

INDOOR UNIT ACK 20E ACK 25E

OUTDOOR UNIT ALC 20C ALC 25C

Btu/h 19500 25000

W 5715 7327

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) /10.43 (13.39) 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33) 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

mm/in 19.1 / 0.75 19.1 / 0.75

HEIGHT mm/in 654 / 25.7 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 9.5 / 3/8

GAS mm/in 15.9 / 5/8 15.9 / 5/8

mm/in 710 / 28.0 810 / 31.9

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.4m BELOW FASCIA.

37

Page 40

ACK-E-2009 Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER

NOMINAL RUNNING CURRENT A 12.3

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50

EER W/W 2.91

REFRIGERANT TYPE R22

REFRIGERANT CONTROL (EXPANSION DEVICE) INDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 410 / 860

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa / in.wg. 0

SOUND PRESSURE LEVEL (H/M/L) dBA 41 / 38 / 35

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT (UNIT + PANEL) kg/lb 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 741 / 1570

SOUND PRESSURE LEVEL dBA 54

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 68 / 150

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.20 / 4.85

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 340 / 725

LOW l/s / CFM 290 / 620

INDOOR UNIT ACK 28E

OUTDOOR UNIT ALC 28C

Btu/h 27000

W 7913

W 2720

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 756 / 29.8

WIDTH mm/in 855 / 33.7

DEPTH mm/in 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0

DEPTH mm/in 415 / 16.3

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 15.9 / 5/8

mm/in 810 / 31.9

38

Page 41

Engineering & Physical Data ACK-E-2009

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY - 1Ø <3Ø>

NOMINAL TOTAL INPUT POWER - 1Ø <3Ø>

NOMINAL RUNNING CURRENT - 1Ø <3Ø> A 14.4 16.7 <5.8>

POWER SOURCE - 1Ø <3Ø>

EER - 1Ø <3Ø> W/W 3.41 3.31 / <3.59>

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) INDOOR CAP. TUBE INDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 490 / 1030 490 / 1030

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa / in.wg. 00

SOUND PRESSURE LEVEL (H/M/L) dBA 44 / 41 / 38 44 / 41 / 38

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT (UNIT + PANEL) kg/lb 42+6 / 92.6+13.2 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75 19.1 / 0.75

AIR FLOW l/s / CFM 1605 / 3400 1605 / 3400

SOUND PRESSURE LEVEL dBA 58 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 95 / 209 100 / 221

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.7 / 5.95 2.95 / 6.50

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 410 / 860 410 / 860

LOW l/s / CFM 350 / 740 350 / 740

INDOOR UNIT ACK 40E ACK 40E

OUTDOOR UNIT ALC 35C ALC 40C

Btu/h 35000 39000 <40000>

W 10258 11430 <11723>

W 3010 3450 <3260>

V/Ph/Hz 220 - 240 / 1 / 50

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 300 (375) / 11.81 (14.76) 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3) 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.5 850 / 33.5

WIDTH mm/in 1030 / 40.6 1030 / 40.6

DEPTH mm/in 400 / 15.8 400 / 15.8

HEIGHT

WIDTH mm/in 1200 / 47.2 1200 / 47.2

DEPTH mm/in 560 / 22.1 560 / 22.1

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8 9.5 / 3/8

GAS mm/in 19.1 / 3/4 19.1 / 3/4

mm/in 1000 / 39.4 1000 / 39.4

220 - 240 / 1 / 50

<380 - 415 / 3 / 50>

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

39

Page 42

ACK-E-2009 Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER

NOMINAL RUNNING CURRENT A 7.9

POWER SOURCE V/Ph/Hz 380 - 415 / 3 / 50

EER W/W 3.03

REFRIGERANT TYPE R22

REFRIGERANT CONTROL (EXPANSION DEVICE) INDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 570 / 1200

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa / in.wg. 0

SOUND PRESSURE LEVEL (H/M/L) dBA 47 / 44 / 43

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT (UNIT + PANEL) kg/lb 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 1605 / 3400

SOUND PRESSURE LEVEL dBA 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 105 / 232

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.55 / 5.62

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 490 / 1030

LOW l/s / CFM 440 / 930

INDOOR UNIT ACK 50E

OUTDOOR UNIT ALC 50C

Btu/h 47500

W 13921

W 4600

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.5

WIDTH mm/in 1030 / 40.6

DEPTH mm/in 400 / 15.8

HEIGHT

WIDTH mm/in 1200 / 47.2

DEPTH mm/in 560 / 22.1

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 19.1 / 3/4

mm/in 1000 / 39.4

40

Page 43

Engineering & Physical Data ACK-E-2009

General Data - Heat Pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 1960 2540

NOMINAL TOTAL INPUT POWER (HEATING) W 1690 2310

NOMINAL RUNNING CURRENT (COOLING) A 8.8 11.5

NOMINAL RUNNING CURRENT (HEATING) A 7.6 10.4

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.91 2.89

COP W/W 3.38 3.17

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 280 / 600 320 / 680

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) mmAq 00

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 31 / 28 37 / 34 / 31

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT kg/lb 29+6 / 63.9+13.2 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75 19.1 / 0.75

AIR FLOW l/s / CFM 614 / 1300 755 / 1600

SOUND PRESSURE LEVEL dBA 51 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130 62 / 137

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.8 / 3.97 1.88 / 4.14

MEDIUM l/s / CFM 250 / 530 280 / 600

LOW l/s / CFM 200 / 430 250 / 530

INDOOR UNIT ACK 20ER ACK 25ER

OUTDOOR UNIT ALC 20CR ALC 25CR

Btu/h 19500 25000

W 5715 7327

Btu/h 19500 25000

W 5715 7327

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) /10.43 (13.39) 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33) 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 654 / 25.7 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 9.5 / 3/8

GAS mm/in 15.9 / 5/8 15.9 / 5/8

mm/in 710 / 28.0 810 / 31.9

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.4m BELOW FASCIA.

41

Page 44

ACK-E-2009 Engineering & Physical Data

General Data - Heat Pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 2720

NOMINAL TOTAL INPUT POWER (HEATING) W 2350

NOMINAL RUNNING CURRENT (COOLING) A 12.3

NOMINAL RUNNING CURRENT (HEATING) A 10.9

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50

EER W/W 2.91

COP W/W 3.50

REFRIGERANT TYPE R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 410 / 860

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) mmAq 0

SOUND PRESSURE LEVEL (H/M/L) dBA 41 / 38 / 35

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT kg/lb 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 741 / 1570

SOUND PRESSURE LEVEL dBA 54

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 68 / 150

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.85 / 4.08

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 340 / 725

LOW l/s / CFM 290 / 620

INDOOR UNIT ACK 28ER

OUTDOOR UNIT ALC 28CR

Btu/h 27000

W 7913

Btu/h 28000

W 8206

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 756 / 29.8

WIDTH mm/in 855 / 33.7

DEPTH mm/in 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0

DEPTH mm/in 415 / 16.3

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 15.9 / 5/8

mm/in 810 / 31.9

42

Page 45

Engineering & Physical Data ACK-E-2009

General Data - Heat Pump (R22)

MODEL

NOMINAL COOLING CAPACITY - 1Ø <3Ø>

NOMINAL HEATING CAPACITY - 1Ø <3Ø>

NOMINAL TOTAL INPUT POWER (COOLING) - 1Ø <3Ø> W 3010 3450 / <3260>

NOMINAL TOTAL INPUT POWER (HEATING) - 1Ø <3Ø> W 2750 3250 / <3200>

NOMINAL RUNNING CURRENT (COOLING) - 1Ø <3Ø> A 14.4 16.7 / <5.8>

NOMINAL RUNNING CURRENT (HEATING) - 1Ø <3Ø> A 13.4 15.9 / <6.0>

POWER SOURCE - 1Ø <3Ø>

EER - 1Ø / <3Ø> W/W 3.41 3.31 / <3.59>

COP - 1Ø / <3Ø> W/W 3.73 3.70 / <3.84>

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE + TXV OUTDOOR CAP. TUBE + TXV

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 490 / 1030 490 / 1030

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) mmAq 00

SOUND PRESSURE LEVEL (H/M/L) dBA 44 / 41 / 38 44 / 41 / 38

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT kg/lb 42+6 / 92.6+13.2 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75 19.1 / 0.75

AIR FLOW l/s / CFM 1605 / 3400 1605 / 3400

SOUND PRESSURE LEVEL dBA 58 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 95 / 209 100 / 221

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.7 / 5.95 2.95 / 6.50

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 410 / 860 410 / 860

LOW l/s / CFM 350 / 740 350 / 740

INDOOR UNIT ACK 40ER ACK 40ER

OUTDOOR UNIT ALC 35CR ALC 40CR

Btu/h 35000 39000 / <40000>

W 10258 11430 / <11723>

Btu/h 35000 41000 / <42000>

W 10258 12010 / <12309>

V/Ph/Hz

HEIGHT mm/in 300 (375) / 11.81 (14.76) 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3) 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.5 850 / 33.5

WIDTH mm/in 1030 / 40.6 1030 / 40.6

DEPTH mm/in 400 / 15.8 400 / 15.8

HEIGHT

WIDTH mm/in 1200 / 47.2 1200 / 47.2

DEPTH mm/in 560 / 22.1 560 / 22.1

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8 9.5 / 3/8

GAS mm/in 19.1 / 3/4 19.1 / 3/4

mm/in 1000 / 39.4 1000 / 39.4

220 - 240 / 1 / 50

<380 - 415 / 3 / 50>

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

220 - 240 / 1 / 50

<380 - 415 / 3 / 50>

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

43

Page 46

ACK-E-2009 Engineering & Physical Data

General Data - Heat Pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 4600

NOMINAL TOTAL INPUT POWER (HEATING) W 4070

NOMINAL RUNNING CURRENT (COOLING) A 7.9

NOMINAL RUNNING CURRENT (HEATING) A 7.1

POWER SOURCE V/Ph/Hz 380 - 415 / 3 / 50

EER W/W 3.03

COP W/W 3.46

REFRIGERANT TYPE R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE + TXV

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 570 / 1200

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) mmAq 0

SOUND PRESSURE LEVEL (H/M/L) dBA 47 / 44 / 43

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

UNIT WEIGHT kg/lb 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 1605 / 3400

SOUND PRESSURE LEVEL dBA 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 105 / 232

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.9 / 6.39

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 490 / 1030

LOW l/s / CFM 440 / 930

INDOOR UNIT ACK 50ER

OUTDOOR UNIT ALC 50CR

Btu/h 47500

W 13921

Btu/h 48000

W 14068

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.5

WIDTH mm/in 1030 / 40.6

DEPTH mm/in 400 / 15.8

HEIGHT

WIDTH mm/in 1200 / 47.2

DEPTH mm/in 560 / 22.1

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 19.1 / 3/4

mm/in 1000 / 39.4

44

Page 47

Engineering & Physical Data ACK-E-2009

General Data - Cooling Only (R410A)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 1740 1940

NOMINAL RUNNING CURRENT W 7.7 8.7

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.08 3.36

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 280 / 600 320 / 680

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa (in.wg.) 00

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 31 / 28 37 / 34 / 31

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

WEIGHT (UNIT + PANEL) kg/lb 29+6 / 63.9+13.2 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 3/4 19.1 / 3/4

AIR FLOW l/s / CFM 614 / 1300 755 / 1600

SOUND PRESSURE LEVEL dBA 52 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130 62 / 137

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.75 / 3.86 1.85 / 4.08

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.4m BELOW FASCIA.

MEDIUM l/s / CFM 250 / 530 280 / 600

LOW l/s / CFM 200 / 430 250 / 530

INDOOR UNIT A5CK 20E A5CK 25E

OUTDOOR UNIT A5LC 20C A5LC 25C

Btu/h 18300 22200

W 5363 6506

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) / 10.43 (13.39) 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820(990) / 32.3 (38.98) 820(990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33) 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 654 / 25.7 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 6.4 / 1/4 6.4 / 1/4

GAS mm/in 12.7 / 1/2 15.9 / 5/8

mm/in 710 / 28.0 810 / 31.9

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

45

Page 48

ACK-E-2009 Engineering & Physical Data

General Data - Cooling Only (R410A)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 2790

NOMINAL RUNNING CURRENT A 13.1

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50

EER W/W 2.84

REFRIGERANT TYPE R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 410 / 860

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa (in.wg.) 0

SOUND PRESSURE LEVEL (H/M/L) dBA 41 / 38 / 35

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

WEIGHT (UNIT + PANEL) kg/lb 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 684 / 1450

SOUND PRESSURE LEVEL dBA 54

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 68 / 150

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.125 / 4.68

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL SPECIFICATIONS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 340 / 725

LOW l/s / CFM 290 / 620

INDOOR UNIT A5CK 28E

OUTDOOR UNIT A5LC 28C

Btu/h 27000

W 7913

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 756 / 29.8

WIDTH mm/in 855 / 33.7

DEPTH mm/in 328 / 12.9

HEIGHT

WIDTH mm/in 990 / 39.0

DEPTH mm/in 415 / 16.3

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 15.9 / 5/8

mm/in 810 / 31.9

46

Page 49

Engineering & Physical Data ACK-E-2009

General Data - Cooling Only (R410A)

MODEL

NOMINAL COOLING CAPACITY - 1Ø / <3Ø>

NOMINAL TOTAL INPUT POWER (COOLING) - 1Ø / <3Ø> W 2820 / <2770> 3920 / <3840>

NOMINAL RUNNING CURRENT - 1Ø / <3Ø> A 13.6 / <5.2> 17.8 / <6.9>

POWER SOURCE - 1Ø <3Ø>

EER - 1Ø / <3Ø> W/W 3.03 / <3.28> 2.92 / <2.98>

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 490 / 1030 490 / 1030

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa (in.wg.) 00

SOUND PRESSURE LEVEL (H/M/L) dBA 44 / 41 / 38 44 / 41 / 38

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

WEIGHT (UNIT + PANEL) kg/lb 42+6 / 92.6+13.2 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75 19.1 / 0.75

AIR FLOW l/s / CFM 1605 / 3400 1605 / 3400

SOUND PRESSURE LEVEL dBA 58 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 95 / 209 100 / 221

PIPE CONNECTION

REFRIGERANT CHARGE - 1Ø / <3Ø> kg/lb 2.175 / 4.80 / <2.15 / 4.74> 2.45 / 5.40 / <2.425 / 5.35>

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL SPECIFICATIONS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 410 / 860 410 / 860

LOW l/s / CFM 350 / 740 350 / 740

INDOOR UNIT A5CK 40E A5CK 40E

OUTDOOR UNIT A5LC 35C A5LC 40C

Btu/h 29200 / <31000> 39000 / <39000>

W 8558 / <9086> 11430 / <11430>

V/Ph/Hz

HEIGHT mm/in 300 (375) / 11.81 (14.76) 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3) 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6) 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.5 850 / 33.5

WIDTH mm/in 1030 / 40.6 1030 / 40.6

DEPTH mm/in 400 / 15.8 400 / 15.8

HEIGHT

WIDTH mm/in 1200 / 47.2 1200 / 47.2

DEPTH mm/in 560 / 22.1 560 / 22.1

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8 9.5 / 3/8

GAS mm/in 15.8 / 5/8 15.9 / 5/8

mm/in 1000 / 39.4 1000 / 39.4

220 - 240 / 1 / 50 /

<380 - 415 / 3 / 50>

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

220 - 240 / 1 / 50 /

<380 - 415 / 3 / 50>

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

47

Page 50

ACK-E-2009 Engineering & Physical Data

General Data - Cooling Only (R410A)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 4390

NOMINAL RUNNING CURRENT A 7.6

POWER SOURCE V/Ph/Hz 380 - 415 / 3 / 50

EER W/W 2.87

REFRIGERANT TYPE R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 570 / 1200

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa (in.wg.) 0

SOUND PRESSURE LEVEL (H/M/L) dBA 47 / 44 / 43

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

WEIGHT (UNIT + PANEL) kg/lb 42+6 / 92.6+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 0.75

AIR FLOW l/s / CFM 2171 / 4600

SOUND PRESSURE LEVEL dBA 68

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 105 / 231.5

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 2.3 / 5.07

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL SPECIFICATIONS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.5m BELOW FASCIA.

MEDIUM l/s / CFM 490 / 1030

LOW l/s / CFM 440 / 930

INDOOR UNIT A5CK 50E

OUTDOOR UNIT A5LC 50C

Btu/h 43000

W 12603

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 300 (375) / 11.81 (14.76)

WIDTH mm/in 820 (990) / 32.3 (38.98)

DEPTH mm/in 820(990) / 32.3 (38.98)

HEIGHT mm/in 335 (110) / 13.19 (4.3)

WIDTH mm/in 916 (1030) / 36.1 (40.6)

DEPTH mm/in 916 (1030) / 36.1 (40.6)

HEIGHT mm/in 850 / 33.46

WIDTH mm/in 1030 / 40.55

DEPTH mm/in 400 / 15.75

HEIGHT

WIDTH mm/in 1200 / 47.24

DEPTH mm/in 560 / 22.05

TYPE FLARE VALVE

SIZE

LIQUID mm/in 9.5 / 3/8

GAS mm/in 15.9 / 5/8

mm/in 1000 / 39.37

48

Page 51

Engineering & Physical Data ACK-E-2009

General Data - Heat Pump (R410A)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 1740 1940

NOMINAL TOTAL INPUT POWER (HEATING) W 1490 1760

NOMINAL RUNNING CURRENT (COOLING) A 7.7 8.7

NOMINAL RUNNING CURRENT (HEATING) A 6.6 7.9

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.08 3.36

COP W/W 3.48 3.41

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

AIR DISCHARGE

CONTROL

OPERATION

HIGH l/s / CFM 280 / 600 320 / 680

AIR FLOW

EXTERNAL STATIC PRESSURE (H/M/L) Pa (in.wg.) 00

SOUND PRESSURE LEVEL (H/M/L) dBA 34 / 31 / 28 37 / 34 / 31

UNIT DIMENSION

INDOOR UNIT

( ) - WITH PANEL

PACKING DIMENSION

( ) - PANEL

WEIGHT (UNIT + PANEL) kg/lb 29+6 / 63.9+13.2 29+6 / 63.9+13.2

CONDENSATE DRAIN SIZE mm/in 19.1 / 3/4 19.1 / 3/4

AIR FLOW l/s / CFM 614 / 1300 755 / 1600

SOUND PRESSURE LEVEL dBA 52 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130 62 / 137

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.75 / 3.86 1.85 / 4.08

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1.4m BELOW FASCIA.

MEDIUM l/s / CFM 250 / 530 280 / 600

LOW l/s / CFM 200 / 430 250 / 530

INDOOR UNIT A5CK 20ER A5CK 25ER

OUTDOOR UNIT A5LC 20CR A5LC 25CR

Btu/h 18300 22200

W 5363 6506

Btu/h 17700 20500

W 5188 6008

4 WAY AUTOMATIC LOUVER

(UP & DOWN)

WIRELESS OR WIRED MICRO-

COMPUTER REMOTE CONTROL

HEIGHT mm/in 265 (340) / 10.43 (13.39) 265 (340) / 10.43 (13.39)

WIDTH mm/in 820 (990) / 32.3 (38.98) 820 (990) / 32.3 (38.98)

DEPTH mm/in 820(990) / 32.3 (38.98) 820(990) / 32.3 (38.98)

HEIGHT mm/in 300 (110) / 11.8 (4.33) 300 (110) / 11.8 (4.33)