Page 1

INSTALLATION MANUAL

Model: IM-5ACV210CR-0706-ACSON

MINI CHILLER

AIR COOLED CHILLER

(R410A INVERTER MODEL)

Page 2

Page 3

5ACV 210CR

OUTLINE AND DIMENSIONS

DETAIL A

WATER OUTLET

50.0

1998.4

2092.5

1992.5

30.0

50.0

128.0

256.0

1683.3

1786.3

SEE DETAIL A

100.0

38.0

70.0

624.5

504.5

174.0

WATER INLET

1199.2

98.7

1192.2

! Caution

injury hazards. Avoid from being in contact with these places.

! Avertissement

Sharp edges and coil surfaces are potential locations which may cause

! Vorsicht

! Cautela

! Cuidado

!

Scharfe Kanten und WŠrmetauscherflŠchen stellen eine Gefahrenquelle dar.

Jeglicher Kontakt mit diesen Stellen ist zu vermeiden.

Per preservarsi da eventuali ferite, evitare di toccare gli spigoli affilali e la

superficie della serpentina.

Los Bordes afilados y la superficie del serpent’n pueden producir lesiones.

Evite tocarlos.

Les bords coupants et les surfaces du refroidisseur tuulaire prŽsentent

un risque de blessure. Mieux vaut Žviter le contact avec ces endroits.

.

.

i

Page 4

5ACV 210CR

UNIT INSTALLATION

700.0

500.0 500.0

700.0

ii

Page 5

E

P

s

la r

ééé

é

t

ййкйй

é

V

euillez

é

tre ces centres. Ceci

p

é

.

G

ten (WEEE

tes

ü

ö

r

ü

ö

r

n

W

ndiges

A

r

Hinweis gilt nur f

nder der Europ

.

.

ritirato da un centro incaricato del ritiro e smaltimento. Per conoscere il

n

t

locali. Questa disposizione

è

i

dell

U.E.

é

ó

n

e

fico

i

ó

i

ó

n

.

!!

! CAUTION

!!

• Improper handling of unit during installation could result in leaks, electrical shock or unit malfunction.

• Contact your dealer for reinstallation or dismantling of unit.

• Do not introduce foreign objects such as fingers, sticks etc. into the air inlet and air outlet.

• Do not climb or place objects on top of mini chiller.

!!

! AVERTISSEMENT

!!

• De mauvaises manoeuvres lors de l’installation peuvent entraîner des fuites, des chocs électriques ou des disfonctionnements

de l’appareil.

• Contacter le distributeur pour la réinstallation ou le démontage de l’appareil.

• Ne pas introduire d’objets étrangers comme les doigts, des petits bâtons, etc., dans l’ouverture d’entrée et de sortie d’air.

• Ne pas grimper ou déposer des objets sur le dessus du mini-refroidisseur.

!!

! VORSICHT

!!

• Unsachgemäße Handhabung des Geräts bei der Installation kann zu Lecks, Stromschlägen und Fehlfunktionen beim

Gerät führen.

• Wenden Sie sich für die Wiederinstallation oder fürs Abmontieren des Geräts an Ihren Händler.

• Führen Sie keine Fremdkörper wie Finger, Stäbe etc. in die Lufteintritts- bzw. Luftaustrittsöffnung ein.

• Steigen Sie nicht auf das Mini-Kühlgerät und stellen Sie keinerlei Objekte auf das Gerät.

!!

! ATTENZIONE

!!

• Una movimentazione impropria dell’unità durante l’installazione può provocare perdite, elettroshock o un

malfunzionamento dell’apparecchio.

• Contattare il proprio fornitore per una reinstallazione o smontaggio dell’apparecchio.

• Non introdurre oggetti estranei, come dita, bastoncini, ecc., nell’entrata e nello scarico dell’aria.

• Non salire e non porre oggetti nella parte superiore dell’unità.

!!

! CUIDADO

!!

• El manejo incorrecto de la unidad podría tener como resultado escapes, un funcionamiento defectuoso o descargas eléctricas.

• Solicite a su distribuidor la instalación, reinstalación o desmontaje de la unidad.

• No introduzca objetos extraños tales como los dedos, palos, etc. en las tomas y salidas de aire.

• No coloque objetos sobre la unidad ni se suba a ella.

!!

! ОСТОРОЖНО

!!

• Неправильное обращение с аппаратом во время установки может стать причиной протеканий,

поражения электрическим током или неправильной работы аппарата.

• Если необходимо переустановить или демонтировать аппарат, обращайтесь к своему дилеру.

• Не вставляйте в воздухозаборные и воздуховыпускные отверстия посторонних предметов, таких как

пальцы, палки и т.п.

• Не взбирайтесь на аппарат и не ставьте на него никаких предметов.

NOTICE

This product is subjected toWste of Electrical and Electronic Equipment Regulations (WEE

Regulations). The waste

lease refer to local authority for these centres.This is only applicable to European Union countrie

Ce produit est soumis

cifique.

est uniquement applicable aux pays de l'Union Euro

enne

lectriques e

er

ll bei Ihrer

Questo prodottoè soggetto alle disposizioni RAEE (Rifiuti di apparecchiature elettriche ed elettroniche)

Il prodotto da

ome del centro pertinente, contattarele autori

de colecc

solamente aplicable a los pases de la Un

tlichen

ischen Union

Europea

Ihrem

ctrico y Electr

iii

tliche

bfall-Amt. Diese

valida solamente i paes

ico en materia d

Page 6

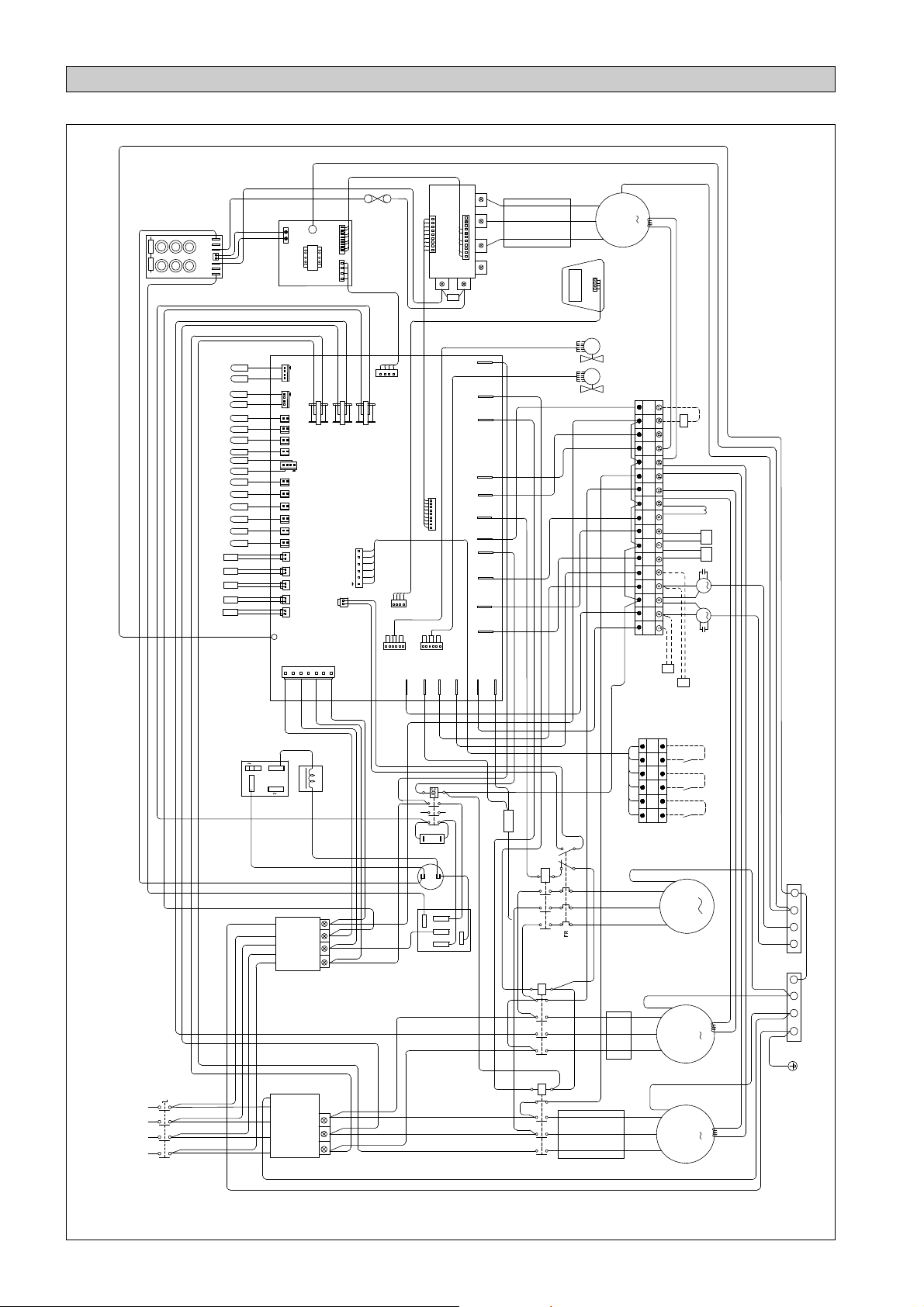

MODEL : 5ACV 210CR

ELECTRICAL WIRING DIAGRAM

W

FUSE

DC_OUT

JP_POWER

L1 FL2 FL1

IC090102

MAIN BOARD

JP14

ON/OFF

ALARM

CH

JK8

PWM1

JP_POWER1

JP1

BL

BL

RD BL BROR

JP232

EV1EV2

FAN-2-2

R_PHASE

U V

POWER1

IPM BOARD

N

P

0.47uF

C

R_PHASE

CP2

CP1

CC_H1

BOILER

PUMP

AU_H

JDC

BP_H

4WV2

4WV1

FAN-2-1

FAN-1-2

FAN-1-1

PHASE

BOARD

PE

TSR

PE

DC_IN

JP3

JK2 JK1 JK4 JK3 JK7 JP8 JP2 JP4 JP5 JP7 JP6 JP17 JP18 JP19 JP20 JP11 JP9

J-RST

N

DC+

DC1 +

DC2 +

JP_DC

DC DC1 DC2 -

CAPACITOR BOARD

TOR /

/

LP2 HP1 FLW HP2 LP1

POWER

TBPE-2

TBPL-2

TWE

TWL

TCS2

TCD2

TCS1

TOA

TBPL-1

TBPE-1

TOC2

TCD3

TCD1

TOC3

TOC4

TOC1

OR AISLANTE

BLACK

W

V

WHITE

COMP

U

RED

LCD

DISPLAY

PANEL

EV1EV2

GREEN/YELLOW

PART NO : 50 13 4 085020

AU_H

BP_H

4WV24WV1

CF1

18uF

FM1FM2

FAN-2-1 FAN-2-2 N FAN-1-2 FAN-1-1 4WV1 N 4WV2 BP_H N CC_H3 CC_H2 N CC_H1 BOIL N AU_H

TB3

CF2

18uF

FSC2

FSC1

AVEC INTERRUPTEUR ISOLANT / MIT SCHWINGUNGSISOLA

TOR SWITCH /

WITH ISOLA

OTERMICO / CON INTERRUPT

TORE MAGNET

CON SEZIONA

-

+

N

N

L2 L3

S T

L1

R

380~415V / 3PH / 50Hz

SWITCH

ISOLATOR

L

BR-1P

LA LB

G

N'

N

C'

C

(25A)

FTR2

B'

B

A

A'

G

N

C

C'

(50A)

FTR1

B

B'

A

A'

A2

A1

T3

T2

L1 L2 L3

T1

1

2

EST

1 2

PFC

R

-

S

T

+

BR-3P

97

98

A1

A2

96

95

PUMP

L1 L2 L3

T1 T2 T3

A1

A2

CP2

21

22

L1 L2 L3

T1 T2 T3

A1

A2

CP1

21

22

L1 L2 L3

T1 T2 T3

OR BL

BL

ON/OFF ON/OFFALARM ALARM

H/C H/C

RD BL BR

TB2

BLACK

V

WHITE

RED

BLACK

V

WHITE

RED

BLACK

V

WHITE

RED

HEAT/COOL ON/OFF ALARM

GREEN/YELLOW

W

PUMP

U

GREEN/YELLOW

W

U

GREEN/YELLOW

W

COMP 1 COMP 2

U

GROUND PLATE

TB4 TB5

iv

Page 7

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the

chiller.

Special adjustments may be necessary to suit local requirements.

Before using the chiller, please read this instruction manual carefully and keep it for future reference.

AIR COOLED INVERTER CHILLER

MODEL

HEAT PUMP

English

R410A

5ACV210CR / A5ACV210CR

!!

! WARNING

!!

Installation and maintenance should be performed by qualified persons who are familiar with local code and

regulation, and experienced with this type of appliance.

Part No.: A08019028696

IM 5ACV210CR-0706 (0)-Acson

Page 8

INDEX

- Outline And Dimensions page i

- Unit Installation page ii

- Electrical Wiring Diagram page iv

- Transportation page 1

- Installation Location page 1

- Physical Data page 2

- Water Piping and Fitting page 2

- Electrical And Wiring page 3

- Electrical Data page 3

!!

! CAUTION

!!

- Recommended Fuse And Calbe Sizes page 3

- Refrigerant Circuit page 4

- Special Precautions When Dealing With R410A Unit

- Refrigerant Circuit Diagrams page 5

- Control Operation Guide page 6

- LCD Panel Installation page 6

- Maintenance page 7

- Troubleshooting page 7

Please take note of the following important points when installing.

Do not install the unit where leakage of flammable gas may occur.

If gas leaks and accumulates around the unit, it may cause fire ignition.

Do not over charge the unit.

This unit is factory pre-charged. Overcharge will cause over-current or damage to the compressor.

page 4

Sharp edges and aluminium fin coil surface are potential location which may cause injury hazards

Avoid from being in contact with these locations.

TRANSPORTATION

The unit should be lifted using a crane. Ensure that the hanger belts are not touching

panel and the coil, top front panel (use protective panel) as shown in Figure 1.

The bolt of the base and channel support can be removed after putting the unit on the

fixed location.

Protective Panel

Figure 1

Hanging Belt

Hanger

08 02 4 087984

INSTALLATION LOCATION

Installation work should be done by the authorized dealer or qualified contractor.

Make sure there is sufficient airflow around the unit.

Vibration isolator should be provided to prevent vibration and noise from the unit.

There should be sufficient space allocated fro servicing and maintenance.

1-1

Page 9

PHYSICAL DATA

Table A-1 : R410A - Heat Pump

Model 5ACV210CR

Nominal cooling capacity kW 58.56

Nominal heating capacity kW 61.49

Operating Weight kg 682.0

Refrigerant charge R410A kg 9.5 / 8.5

Compressor 2 Scroll + 1 Inverter Compressor

Control system LCD Electronic Control

Refrigerant - water heat exchanger Brazed Plate Heat Exchanger

Water connections (BSP) inches 1 1/2

Maximum water pressure kPa 1000

Hydr onic circuit

Pump Horizontal Multistage End-Suction

Available pressure (Cooling/Heating) kPa 258.5 / 244.0

Water inlet connection (BSPT) inches 1 1/2

Water outlet connection (BSPT) inches 1 1/2

Drain tap coupling (BSPT) inches 1/2

Closed expansion tank water volume litre 8

Refrigerant - air heat exchanger

Tube diameter mm 9.52

No. of rows 2

Tubes/row 62

Fin spacing mm

Fan

Diameter/Number of O/D fan mm 32 x 2

No. of blades 6

Air flow (high speed) m

Fan speed (high speed) r/min 550

3

/hr 11890

0.6299

English

Note: For cooling nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature, 35°C air ambient

temperature.

Note: For heating nominal values are based on 40°C / 45°C entering / leaving evaporator water temperature, 7°C DB / 6°C

WB air ambient temperature.

WATER PIPING AND FITTING

All water pipe must be insulated to prevent capacity losses and condensation.

Install a 40-60 mesh strainer to ensure water quality is good.

Water pipe recommended are black steel pipe and copper pipe.

During installation, the piping of the unit should be clamp before rotating the installation pipe to reduce the moment induce

on the unit piping.

Users are recommended to install the pipe and accessories as shown in Figure 2.

An air vent must be installed at the highest position, while a drainage plug at the lowest position of the water circuit. Open

the air vent to release any air trap in the water circuit.

Run the clean water through the water inlet and operate the pump to drain out the dirty water. Clean the strainer after

running the pump for 30 minutes.

Fill up the water circuit after connecting all the pipes and equipment. Check water leakages at all connections and joints.

Do not start the unit when the system is leaking. To optimize the capacity of the system. ensure that the system is free of air

bubbles. The air trapped in the system would make the system unbalanced.

1-2

Page 10

AIRVENT (INSTALL

HIGHEST POSITION)

PRESSURE GAUGE

GATE

VALVE

THERMOMETER

FLEXIBLE

THERMOMETER

FLEXIBLE

GATE

VALVE

GATE

BALANCING

VALVE

VALVE

GATE

VALVE

!!

! CAUTION

!!

BALANCING

VALVE

STRAINER

CHECK

VALVE

GATE

VALVE

PRESSURE

DIFFERENTIAL

VALVE

(LOWER POSITION

FOR DRAINAGE)

MAKE UP

VALVE

FAN COIL UNIT/AIR HANDLING UNIT

GATE VALVE

Do not allow water remain in the water pipes if the unit is not operating for a long period.

Water must be drained out if the unit is not running during winter. failing to do so would cause the pipe to crack.

Do not drink the chilled water in the unit.

ELECTRICAL AND WIRING

Refer to the wiring diagram provided on the unit when making electrical wiring.

Do not ground any electrical equipment to the water piping.

Figure 2

ELECTRICAL DATA

Table B-1 : R410A - Heat Pump

Model 5ACV210CR

Power supply V-ph-Hz 400 / 3 / 50

Voltage range V 380-415

Nominal Power Input (Cooling/Heating) kW 23.2 / 22.9

Nominal Current Input (Cooling/Heating) A 38.5 / 38.1

System 1(inv)* System 1 System 2

Compressor Maximum Continuous Current A 21.0 17.0 29.0

Compressor Full Load Current (FLA) A 16.4 10.7 22.2

Compressor Locked Rotor Current (LRA) A - 90 118

Pump Power Input (Cooling/Heating) W 1175 / 1294

* Readings taken at rated compressor frequency. The Power Input and Current differ depending on the combination of

outdoor temperature and entering water temperature. For further details, please refer to Technical Manual.

RECOMMENDED FUSE AND CALBE SIZES

Heat Pump

Model 5ACV 210 CR

Voltage Range ** 380 - 415V /3Ph /50Hz + N +

Recommended Fuse * A 100

Power Supply Cable Size * mm

Number of Conductor 5

Interconnection Cable Size mm

2

2

10

1.5

IMPORTANT : * The figures shown in the table are for information purpose only. They should be checked and selected to

comply with the local/national codes of regulations. This is also subject to the type of installation and

conductors used.

** The appropriate voltage range should be checked with label data on the unit.

1-3

Page 11

!!

! CAUTION

!!

• All field wiring must be installed in accordance with the national wiring regulation.

• All the terminals and connections must be tightened. Improper connection and fastenings could cause electric shock,

short circuit and fire.

• Ensure that the rated voltage of the unit corresponds to that of the name plate before commencing wiring work

according to the wiring diagram.

• The unit must be GROUNDED to prevent possible hazards due to insulation failure.

• All electrical wiring must not touch the refrigerant piping, compressor, pump, fan motor or any moving parts of

the fan motors.

• Do not operate the chiller with wet hands. It would result in electric shock.

• Do not use fuse of different amperage than stated. Using wire etc. to replace a fuse could cause equipment damage

or fire.

Electrical Wiring Diagram (please refer to Appendix 3).

REFRIGERANT CIRCUIT

• All mini chillers units are pre-charged with R410A refrigerant.

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

• R410A is a near azeotrope refrigerant blend of hydro fluorocarbon (HFC) which is environmental friendly. It has Zero

Ozone Depletion Potential (ODP=0) and this conforms to Montreal Protocol regulations. It has no flame propagation and

a low toxic refrigerant (rated as A1 by ARI). R410A is a mixture of R32 (50%) and R125 (50%).

• POE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22 compressor.

During installation or servicing, extra precaution must be taken not to expose the R410A system too long to moist air.

Residual POE oil in the piping and components can absorb moisture from the air.

• Refrigerant R410A is more easily affected by dust of moisture compared with R22, make sure to temporarily cover the

ends of the tubing prior to installation.

• No additional charge of compressor oil only is permitted.

• No refrigerant other than R410A is permitted.

• Tools designed specifically for R410A only.

i) Manifold gauge and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adaptor

v) Flare tools

vi) Refrigerant recovery machine

English

!!

! CAUTION

!!

• R410A must be charged as liquid. Usually R410A cylinder is equipped with a dip-pipe for liquid withdrawal.

If there is no dip-pipe, the cylinder should be inverted so as to withdraw liquid R410A from the valve.

• Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit thoroughly and then

charge the unit with fresh R410A according to the amount recommended in the specification.

• Do not touch the compressor or refrigerant piping when the chiller is running. If necessary wear protective gloves.

1-4

Page 12

5ACV 210CR

Refrigerant Circuit Diagram

TWIN

TUBE JOINT

OIL

SEPARATOR

VARIABLE SPEED

COMPRESSOR

OIL

RETURN

TUBE

TWIN

TUBE JOINT

FIN TUBE

HEAT EXCHANGER

(SYSTEM 1)

4-WAY VALVE

OIL

SEPARATOR

COMPRESSOR

SUCTION

ACCUMULATOR

EXV

LIQUID

RECEIVER

WATER

FILTER

DRIER

CHECK

VALVE

OUT

EXV

LIQUID

RECEIVER

WATER

IN

FILTER

DRIER

CHECK

VALVE

HEAT EXCHANGER

4-WAY VALVE

SUCTION

ACCUMULATOR

FIN TUBE

(SYSTEM 2)

COMPRESSOR

1-5

Page 13

CONTROL OPERATION GUIDE

The unit is equipped with a microprocessor controller board. The microprocessor controller is provided to give temperature

control for the system by accurately measuring and controlling the water entering and water leaving temperature. The temperature setting in the unit is preset in the factory. It is not recommended to change the setting unless necessary. A wired

controller handset is connected to the microprocessor board. Every parameter setting and reading can be observed from the

LCD of the handset.

JP14

JP7

JP10

JP6

JP5 JP4 JP3

SW1

JP-Y

JDC

CC-H1

BOILER

4WV1

SW2

4WV2

BP-H

AU-H

JK3 JK7

MAIN BOARD

PUMP

JK4

JK1 JK2

FAN2

FAN1

JP9

JP8 JP2

JP11

JP13

R-PHASE

1. Handset location

The handset is located on a metal bracket behind the right door panel.

2. LED Display (microprocessor board)

The keypad LED will light up when the unit is powered up.

The LCD will light up when the unit is turned on.

3. LCD display (controller handset)

During normal operations, the LCD can display the entering water temperature, the leaving water temperature, the entering water setpoint temperature, compressor on or off status and outdoor air temperature. When malfunctioning occurred,

the LCD would blink. The display would show the faulty parameter and the date and time of the occurrence.

4. Controller functioning specification

There is a 3 minute delay for the compressor and fan motor to restart (default setting).

During defrosting, fan motor is not running.

English

!!

! CAUTION

!!

• Use the controller handset to switch on / off the unit. Do not plug off the main power supply directly, it would cause

the unit to breakdown. In case of emergency switch off the isolator switch located on the front panel of the unit.

• Do not change the settings of the safety devices.

LCD PANEL INSTALLATION

• The unit comes with a LCD panel installed. To change the position or re-install the LCD panel, follow the installation

guide below.

When fastening the LCD panel to the bracket,

Step 1 Step 2

When removing the LCD panel from the bracket,

Step 1 Step 2

Hook the LCD panel

from the top first

Push to fasten the LCD

panel to the bracket

Remove the

LCD panel

Remove the LCD panel

from the bottom part first

with help of a screw driver

1-6

Page 14

1. A 3V DC battery is supplied with the LCD. It is used to ensure that the LCD displays real time once the timer is set.

2. The LCD is wired to the main board via CN8 connection. (This is factory installed)

If the wiring between the LCD and PCB must be longer, an alternative is used. Use a 4-core wire of the desired length and

connect this wire between the terminal block CN2 on the LCD to the terminal block CN5 on the PCB. Ensure that the

correct wire terminals are connected.

3. Networking between chillers can be carried out. Connect the wire as shown

JP13

Factory installed

LCD Panel

CN8

CN2

GND

12V

B

A

Alternative wiring between LCD panel and PCB

For networking only

Main Board unit 00

CN5

A

B

A

B

12V

GND

GND

12V

PCB unit 01

MAINTENANCE

• Maintenance service of the mini chiller must be carried out by qualified persons.

• The unit is easily accessible for servicing and maintenance by accessing the front panel of the unit (for electrical compo-

nents) and the panel door (for refrigerant and water circuit).

• For consistent performance it is recommended that a routine maintenance of cleaning the coil surfaces to conducted

because of dusty surroundings.

• It is also recommended that regular checks on the water strainer to be conducted. Change the water strainer if it is dirty or

choked.

!!

! CAUTION

!!

• Do not attempt to do any service or maintenance when the unit is operating.

• Do not spray any chemical agents or flammable agents to the unit. It could cause fire or explosion.

TROUBLESHOOTING

When any malfunction is occurred, immediately switch off the power supply to the unit, and contact the local dealer, if

necessary. Some simple troubleshooting tips are given below :

SYMPTOMS POSSIBLE CAUSES REMEDIAL ACTION

1. Compressor does

not start.

2. Fan does not work.

3. Unit does work,

but insufficient

cooling.

4. Flow Switch Error

• No power supply.

• Fuses blown or automatic circuit breakdown open.

• Defective contactor or coil.

• Unit is stopped because safety device has

tripped.

• Loose wires.

• Compressor faulty.

• No power supply.

• Fan motor faulty.

• Thermostat setting too high.

• Condenser coil dirty.

• Obstacle blocking air inlet or outlet of the

unit.

• Insufficient refrigerant in the system.

• Improper water flow rate.

• Water in the system is contaminated.

• No water in the system.

• Low water level in the system.

• Check power supply.

• Look for short circuit or grounded wires in

motor windings. Replace fuses and reset

circuit breakers when the fault has been

corrected. Check tightness and soundness of

all electrical connections.

• Repair or replace.

• Determine the type of safety shut down and

correct the default before the unit is restarted.

• Check wire connections and tighten terminal

screws.

• Contact local dealer.

• Check power supply.

• Contact local dealer.

• Reset thermostat.

• Contact local dealer.

• Remove the obstacle.

• Contact local dealer.

• Contact local dealer.

• Contact local dealer.

• Check water supply.

• Check water supply.

!!

! CAUTION

!!

• Troubleshooting must be performed by qualified personnel.

1-7

Page 15

Page 16

• In the event that there is any conflict in the interpretation of this manual and any translation of the same in any language,

the English version of this manual shall prevail.

• The manufacturer reserves the right to revise any of the specification and design contain herein at any time without prior

notification.

• En cas de désaccord sur l’interprétation de ce manuel ou une de ses traductions, la version anglaise fera autorité.

• Le fabriquant se réserve le droit de modifier à tout moment et sans préavis la conception et les caractéristiques techniques

des appareils présentés dans ce manuel.

• Im Falle einer widersprüchlichen Auslegung der vorliegenden Anleitung bzw. einer ihrer Übersetzungen gilt die Ausführung

in Englisch.

• Änderungen von Design und technischen Merkmalen der in dieser Anleitung beschriebenen Geräte bleiben dem Hersteller

jederzeit vorbehalten.

• Nel caso ci fossero conflitti nell’interpretazione di questo manuale o delle sue stesse traduzioni in altre lingue, la versione

in lingua inglese prevale.

• Il fabbricante mantiene il diritto di cambiare qualsiasi specificazione e disegno contenuti qui senza precedente notifica.

• En caso de conflicto en la interpretación de este manual, y en su traducción a cualquier idioma, prevalecerá la versión

inglesa.

• El fabricante se reserva el derecho a modificar cualquiera de las especificaciones y diseños contenidos en el presente

manual en cualquier momento y sin notificación previa.

• В случае противоречия перевода данного руководства с другими переводами одного и того же текста,

английский вариант рассматривается как приоритетный.

• Завод-изготовитель оставляет за собой право изменять характеристики и конструкцию в любое время

без предварительного уведомления.

OYL MANUFACTURING COMPANY SDN. BHD.

JALAN PENGAPIT 15/19, P.O. BOX 7072, 40702 SHAH ALAM, SELANGOR DARUL EHSAN, MALAYSIA.

Loading...

Loading...