ACS Motion Control MC4U-19-Piano-enc, MC4U-9-Piano-enc, MC4U-22-Piano-enc, MC4U-11-Piano-enc, MC4U-13-Piano-AX7 Hardware Manual

Page 1

MP4U

Control Module

Hardware Guide

December 2017

Document Revision: 2.50.D

Page 2

MC4UHardwareGuide

MC4U

ReleaseDate: December2017

Copyright

© ACSMotionControlLtd.2017.Allrightsreserved.

Changesareperiodically madetotheinformationinthisdocument.Changesarepublished asreleasenotesandlater

incorporatedintorevisionsof thisdocument.

Nopart of thisdocumentmay bereproducedinanyformwithoutpriorwritten permissionfromACSMotionControl.

Trademarks

ACSMotionControl, SPiiPlus,PEG, MARK, ServoBoost,NetworkBoost and NanoPWMare trademarksof ACS MotionControlLtd.

Windows andVisualBasicare trademarksof MicrosoftCorporation.

EtherCAT is registeredtrademark and patentedtechnology,licensedbyBeckhoff AutomationGmbH,Germany.

Anyother companies and product namesmentioned hereinmaybe thetrademarks of theirrespectiveowners.

Patents

ACS MotionControlLtd.NanoPWMproducts areprotectedunderthefollowingpatents:

IsraelPatent No.235022

US Patent ApplicationNo. 14/532,023

EuropePatentapplication No.15187586.1

JapanPatentApplication No.: 2015-193179

ChinesePatentApplication No.:201510639732.X

Taiwan(R.O.C.)PatentApplication No.104132118

KoreanPatent ApplicationNo.10-2015-0137612

www.acsmotioncontrol.com

support@acsmotioncontrol.com

sales@acsmotioncontrol.com

Notice

Theinformationinthisdocument isdeemedto be correctat thetime ofpublishing.ACSMotionControlreservestherightto

changespecifications withoutnotice.ACSMotionControlis not responsiblefor incidental,consequential,or special damagesof

anykindinconnectionwithusingthisdocument.

Version 2.50.D

2

Page 3

RevisionHistory

Date Revision Description

MC4UHardwareGuide

December

2017

July2017 2.40.D Removed SPiiPlusADKSuitesoftwarediscshipping withMC4U.

November

2016

August

2016

May2016

November

2015

June2015 2.29.01

2.50.D Reformatted

2.30.01.

D

2.30.D

2.29.20.

D

2.29.10.

D

Returned motherboardsectionsnot includedin Version2.30.D

Updated forSPiiPlusADK Suitev2.30.

Updated RelatedDocumentslist.

Addedminimumhardware revisionandSPiiPlusFirmware

versionrequirements.

Updated absoluteencoderbidirectionalschematicdiagram

Updated STOnote

Addednote concerningSTO certification.

Majordocument update:removalof unsupported modules,

informationrevised,documentrestructuredfor usability.

March

2015

2.29 Updated forVersion2.29features.

Version2.50.D

3

Page 4

ConventionsUsedinthisGuide

TextFormats

Format Description

Bold Namesof GUI objects orcommands.

BOLD+UPPERCASE ACSPL+variablesandcommandss

MC4UHardwareGuide

FlaggedText

Monospace + grey

background

Italic Namesof other documents.

Blue Web pages,ande-mailaddresses.

[ ] InGUIsindicatesoptional item(s)

| InGUIsindicateseither/or items

Note -includesadditional information orprogrammingtips.

Caution -describes aconditionthat mayresult indamageto equipment.

Warning -describes acondition thatmayresult inserious bodily injuryor death.

Model -highlightsaspecification, procedure, condition, orstatement that depends

on the product model.

Code example.

Version 2.50.D

Advanced -indicatesatopic for advanced users.

4

Page 5

MC4UHardwareGuide

RelatedDocuments

Documents listed inthe following table provide additionalinformationrelated to this document.

The most updated versionof the documents can be downloaded by authorized users from

www.acsmotioncontrol.com/downloads.

Document Description

Provides communication,configurationand

SPiiPlus Setup Guide

SPiiPlus Utilities User Guide

adjustment procedures for the MC4U Control

Module motion controller.

A guide for usingthe SPiiPlusUser ModeDriver

(UMD) for setting up communicationwith the

SPiiPlusmotion controller.

ACSPL+ Programmer’s Guide

SPiiPlus Command and Variable

Reference Guide

SPiiPlus CLibrary Programmer

Guide

SPiiPlus COMLibrary

Programmer Guide

SPiiPlus .NET Library

Programmer Guide

SPiiPlus MMI Application Studio

User Guide

Guide for usingthe ACSPL+high level

programminglanguage.

Provides complete details ofthe ACSPL+

programminglanguage command andvariable

set for programming SPiiPluscontrollers.

Provides C++andVisual Basic®libraries for host

PCapplications. Thisreference isspecifically

applicable for the MC4UControl Module motion

controller.

Provides COMMethods,Properties, and Events

for Communication with the MC4U Control

Module motion controller.

Provides .NET Methods,Properties,andEvents

for Communication with the MC4U Control

Module motion controller.

A complete guide for using the SPiiPlusMMI

Application Studio and associated monitoring

tools

SPiiPlusNT/DC Motion Controller

Hardware Guide

SPiiPlus PDMnt Product Guide

SPiiPlus SDMnt Product Guide

Version 2.50.D

Provides detailsfor the SPiiPlusNT-LT/HPand

SPiiPlusDC-LT/HPmotion controllers, one of

which isinstalled in the MC4UControl Module.

Technical descriptionof the SPiiPlusPDMnt

Network Interface.

Technical descriptionof the SPiiPlusSDMntStep

Motor DriveModule.

5

Page 6

Document Description

MC4UHardwareGuide

SPiiPlus UDMnt Product Guide

PEGand MARKOperations

Application Notes

Using Absolute Encoderswith

ACS Products AN3.00

HSSIExpansion Modules Guide

SPiiPlus ADK Suite v2.50

Release Notes

Technical descriptionof the SPiiPlusUDMnt

UniversalDrive Module.

Provides detailsonusing the PEG commandsin

SPiiPlussystems.

Addressesthe physicalconnections,

configurationandoperationof absolute

encoderswith ACSMotionControl networking

products.

High-SpeedSynchronousSerialInterface(HSSI)

for expanded I/O, distributed axes, and

nonstandard devices.

Describesnewfeatures andchanges thatwere

introduced sincethe last SPiiPlusNTSuite

version 2.40 release.

Version 2.50.D

6

Page 7

MC4UHardwareGuide

TableofContents

1. Introduction 24

1.1 Document Scope 24

1.2 Product Overview 24

1.2.1 MC4U-9-Piano-enc 24

1.2.2 MC4U-11-Piano-enc 25

1.2.3 MC4U-13-Piano-AX7 26

1.2.4 MC4U-19-Piano-enc 27

1.2.5 MC4U-22-Piano-enc 28

1.3 Software Package 29

2. MC4USpecifications 30

2.1 MC4U PhysicalSpecifications 31

2.1.1 MC4UDimensions 31

2.1.1.1 MC4U-9-Piano-enc Dimensions 31

2.1.1.2 MC4U-11-Piano-encDimensions 32

2.1.1.3 MC4U-13-Piano-AX7 Dimensions 33

2.1.1.4 MC4U-19-Piano-enc Dimensions 34

2.1.1.5 MC4U-22-Piano-enc Dimensions 35

2.1.2 MC4U Weight 36

2.1.3 MC4U PowerDissipation 36

2.1.4 MC4U EnvironmentalParameters 37

2.1.5 MC4U CoolingVents 38

2.2SPiiPlusNT/DC MotionControllers 38

2.2.1 SPiiPlusNT/DC MotionControllersFeatures 40

2.2.2SPiiPlusNT/DC Indicators 46

2.3PSM3UPower Supplies 48

2.3.1 PSM3U Specifications 54

2.3.1.1 PSM3U-48V-XXkW Power Supply 54

2.3.1.2 PSM3U-320V-8kW Power Supply 56

2.4 Motor Drives 64

Version 2.50.D

2.3.1.3 PSM3U-320V-20KWPowerSupply 62

2.4.1 PWM Drives 64

2.4.1.1 DDM3U-X-60V-4A Low-Power Motor Drive 65

2.4.1.1.1 DDM3U-X-60V-4A Specifications 66

7

Page 8

MC4UHardwareGuide

2.4.1.2 DDM3U-1-320V-XX-SRMotor Drive 69

2.4.1.2.1 DDM3U-1-320V-XX-SRSpecifications 70

2.4.1.2.2 DDM3U-1-320V-XX-SRPWMPower Bridge Specification 72

2.4.1.2.3 DDM3U-1-320V-XX-SRDrive Protection Circuits 73

2.4.1.3 DDM3U-2-320V-XA High-PowerMotor Drive 75

2.4.1.3.1 DDM3U-2-320V-XASpecifications 75

2.4.1.3.2 DDM3U-2-320V-XA PWM PowerBridge Specification 81

2.4.1.4 DDM3U-4-320V-XAMotor Drive 86

2.4.1.4.1 DDM3U-4-320V-XA Power SupplyInput Specification 88

2.4.1.4.2 DDM3U-4-320V-XAControl Supply Input Specification 89

2.4.1.4.3 DDM3U-4-320V-XA PWMPowerBridge Specification 90

2.4.1.4.4 DDM3U-4-320V-XADrive Protection Circuits 91

2.4.2 LDM3USingle AxisLinear Drive 92

2.4.2.1 LDM3USpecifications 94

2.5MC4UMotherboards 96

2.5.1 MB4U-ZZW-AX7 96

2.5.1.1 MB4U-ZZW-AX7 Functionality 96

2.5.1.2 J1 -24VLogic & I/OSupply Connector 96

2.5.1.3 J2 -EtherCAT® OUTConnector 97

2.5.1.4 J3 -Ether Cat INConnector 98

2.5.1.5 J4 -Encoder Connector 98

2.5.1.6 J5 -EncoderConnector 102

2.5.1.7 J6 -DriveSupply Connector 105

2.5.1.8 J7-J10 -Motor Connectors 106

2.5.1.9 J11-J14-Motor Connectors 107

2.5.2MB5U-CONT-PS 108

2.5.2.1 MB5U-CONT-PSFunctionality 108

2.5.2.2Encoder andHallConnectors 109

2.5.2.3J7-Squared SIN-COS Connector 111

2.5.2.4J8-Digital and Analog I/OConnector 112

Version 2.50.D

2.5.2.5J9 -Regeneration Connector 114

2.5.2.6J21 -Fast I/O(PEGand Mark) Connector 115

2.5.2.7 J22-Motor LimitsConnector 117

2.5.2.8J4,J5,andJ6-HSSIConnectors 118

2.5.2.9J2andJ3-Ethernet Connectors 119

8

Page 9

MC4UHardwareGuide

2.5.2.10J19 and J20RS-232 CommunicationConnectors 120

2.5.2.11 J14 -Drive Supply Voltage Connector 120

2.5.2.12J1 -24V LogicSupply Connector 121

2.5.2.13MB5U-CONT-PSJumpers 121

2.5.3MB5U-CONT-PS2 124

2.5.3.1 MB5U-CONT-PS2Functionality 124

2.5.3.2J1 -24V Logic Supply Connector 125

2.5.3.3Encoder andHallConnectors 125

2.5.3.4J7 -Squared SIN-COS Connector 127

2.5.3.5J8 -Digital and Analog I/OConnector 128

2.5.3.6J14, J114 -Drive SupplyVoltage Connector 131

2.5.3.7 J21 -Fast I/O(PEGand Mark) Connector 132

2.5.3.8J22-MotorLimitsConnector 134

2.5.3.9J4,J5,andJ6-HSSIConnectors 135

2.5.3.10J2andJ3-Ethernet Connectors 136

2.5.3.11 J19 andJ20RS-232 CommunicationConnectors 137

2.5.3.12J9, J109- Regeneration Connector 137

2.5.3.13J145 -60V Drive SupplyConnector 138

2.5.3.14 MB5U-CONT-PS2Jumpers 138

2.5.4MB5U-Lin 140

2.5.4.1 MB5U-LinMFunctionality 141

2.5.4.2J130(D0)-DriveMotor 141

2.5.4.3MB5U-LinJumpers 142

2.5.5MB5U-LinM 143

2.5.5.1 MB5U-LinMFunctionality 143

2.5.5.2J130(D0) -Drive Motor 143

2.5.5.3MB5U-LinM Jumpers 144

2.5.6MB5U-YYYY 145

2.5.6.1 MB5U-YYYY Functionality 145

2.5.6.2Encoder andHallConnectors 146

Version 2.50.D

2.5.6.3J7 -Squared SIN-COSConnector 148

2.5.6.4 J8 -DigitalandAnalogI/O Connector 149

2.5.6.5J9-Regeneration Connector 151

2.5.6.6J21 -Fast I/O(PEG& Mark)Connector 152

2.5.6.7 J22-Motor LimitsConnector 154

9

Page 10

MC4UHardwareGuide

2.5.6.8J4, J5, andJ6-HSSI Connectors 155

2.5.6.9J2andJ3-Ethernet Connectors 156

2.5.6.10J19 and J20RS-232 CommunicationConnectors 157

2.5.6.11 J14-Drive Supply VoltageConnector 157

2.5.6.12 J1 -24VLogic Supply Connector 158

2.5.6.13 J40-External DriveControl Signals 158

2.5.6.14 J152_$ - Motor DriveOutput Connectors 160

2.5.6.15MB5U-YYYY Jumper Configuration 161

2.5.7 MB5U-Z 164

2.5.7.1 MB5U-Z Functionality 165

2.5.7.2 Encoder and Hall Connectors 166

2.5.7.3 J10 -DigitalandAnalogI/O Connector 167

2.5.7.4 J20-Safety & Fast I/O InputsConnector 170

2.5.7.5J3,J4-Drive Motor Connectors 171

2.5.7.6 J6 and J7 -Ethernet Connectors 172

2.5.7.7 J8 -HSSIConnector 173

2.5.7.8 J19 -RS-232 CommunicationConnector 174

2.5.7.9 J13 -ExternalDrive Control Signals 174

2.5.7.10 J11 -External Regeneration 176

2.5.7.11 J12 -Drive SupplyConnector 176

2.5.7.12 J5 -24V LogicSupply Connector 177

2.5.7.13 MB5U-Z Jumper Configuration 177

2.5.8MB5U-ZV 179

2.5.8.1 MB5U-ZVFunctionality 180

2.5.8.2Encoder andHallConnectors 181

2.5.8.3J10-Digital and Analog I/OConnector 182

2.5.8.4J20-Safety &FastI/OInputs Connector 185

2.5.8.5J1, J3, J21,J22-DriveMotor Connectors 187

2.5.8.6J2andJ4-Drive Motor Connectors 187

2.5.8.7 J8, J9 andJ30-HSSI Connectors 189

Version 2.50.D

2.5.8.8J6andJ7 -Ethernet Connectors 189

2.5.8.9J19 -RS-232CommunicationConnector 190

2.5.8.10J23-Z&CSafety Connector 190

2.5.8.11 J11-External Regeneration 191

2.5.8.12 J12 -DriveSupply Input 191

10

Page 11

MC4UHardwareGuide

2.5.8.13 J5-24VLogicSupply 192

2.5.8.14 MB5U-ZVJumpers 192

2.5.9MB5U-ZZ 195

2.5.9.1 MB5U-ZZFunctionality 196

2.5.9.2Encoder andHallConnectors 196

2.5.9.3J10-Digital and Analog I/OConnector 198

2.5.9.4 J20-Safety &FastI/OInputs Connector 200

2.5.9.5J1, J2, J3,J4-DriveMotor Connectors 202

2.5.9.6J6and J7 -Ethernet Connectors 203

2.5.9.7 J8 and J9-HSSIConnectors 204

2.5.9.8J19 -RS-232CommunicationConnector 204

2.5.9.9J11 -ExternalRegeneration 205

2.5.9.10J12 -DriveSupply Connector 205

2.5.9.11 J5 -24V LogicSupply Connector 206

2.5.9.12 MB5U-ZZJumpers 206

2.5.10MB5U-ZZW 208

2.5.10.1 MB5U-ZZWFunctionality 209

2.5.10.2Encoder andHallConnectors 210

2.5.10.3J7 -Squared SIN-COS Connector 212

2.5.10.4 J8 -DigitalandAnalogI/O Connector 213

2.5.10.5J9-Regeneration Connector 215

2.5.10.6J21 -Fast I/O(PEG& Mark)Connector 216

2.5.10.7 J22 -Motor LimitsConnector 218

2.5.10.8J4, J5, andJ6-HSSIConnectors 219

2.5.10.9J2andJ3-Ethernet Connectors 220

2.5.10.10 J19 andJ20RS-232CommunicationConnectors 221

2.5.10.11 J14-Drive Supply VoltageConnector 221

2.5.10.12 J1 -24VLogic Supply Connector 222

2.5.10.13 J40 -ExternalDriveControl Signals 222

2.5.10.14 J152_$ - Motor DriveOutput 223

Version 2.50.D

2.5.10.15 J125 -ExternalDC Drive Supply Input 225

2.5.10.16 J121 -J124 Low-Power Motor Connectors 226

2.5.10.17 MB5U-ZZW Jumpers 227

2.5.11 MB5U-ZZZ 230

2.5.11.1 MB5U-ZZZFunctionality 230

11

Page 12

MC4UHardwareGuide

2.5.11.2 Encoder and HallConnectors 231

2.5.11.3 J7 -Squared SIN-COS Connector 233

2.5.11.4 J8-Digital and Analog I/OConnector 234

2.5.11.5 J9 -Regeneration Connector 236

2.5.11.6 J21 -FastI/O(PEG& Mark) Connector 237

2.5.11.7 J22-Motor Limits Connector 239

2.5.11.8 J4, J5,andJ6-HSSIConnectors 241

2.5.11.9 J2 andJ3-Ethernet Connectors 241

2.5.11.10 J19andJ20RS-232CommunicationConnectors 242

2.5.11.11 J14 -Drive Supply VoltageConnector 243

2.5.11.12 J1 -24V LogicSupply Connector 243

2.5.11.13 J40-ExternalDrive Control Signals 244

2.5.11.14 J152_$ -Motor DriveOutput 245

2.5.11.15 MB5U-ZZZ Jumpers 246

2.5.12 MB5U-2-45 249

2.5.12.1 J152-0,J152-1-Servo MotorDrive 249

2.5.12.2B5U-2-45Jumpers 250

2.5.13 MB5U-2-20 250

2.5.13.1 J152 -ServoMotor Drive 251

2.5.13.2MB5U-2-20 Jumpers 252

2.5.14 MB5U-4-XX 253

2.5.14.1 MB5U-4-XXFunctionality 254

2.5.14.2 ServoMotor Drive Connectors 254

2.5.14.3 MB5U-4-XXJumpers 256

2.6 MC4U Accessories 256

2.6.1 MC4U-MF-560V MotorFilter 257

2.6.1.1 Motor Filter Operational Specifications 258

2.6.1.2 J1 -Drive Connector 259

2.6.1.3 J2 -Motor Connector 259

2.6.1.4 MotorFilter PhysicalSpecifications 259

3. SafetyandEMCGuidelines 262

3.1 Certification 262

3.2General Safety Guidelines 262

Version 2.50.D

2.6.1.5 Connecting the Motor Filter 261

2.6.2MC4U-REGEN-600 Regeneration Module 261

12

Page 13

MC4UHardwareGuide

3.2.1 MC4U Handling& Maintenance 263

3.2.2Safe Torque Off (STO) 263

3.2.2.1 STO Module Connector Type andPinout 265

3.2.3EmergencyStop Device 265

3.2.4 FailSafe LogicRecommendation 265

3.2.5InitialLogicState of Outputs 265

3.2.6Electrical Separation 266

3.2.7 Over-Travel Protection 266

3.2.8ThermalDetection 266

3.2.9Power Supply and Motor Cable Ground 266

3.3General Wiring and EMCGuidelines 266

3.3.1 ExternalACLineFilters 266

3.3.2ACS Motor Filters 267

3.3.3Routing SignalandPowerCables 267

3.3.4 Cable Length 267

3.3.5Grounding 268

3.3.5.1 SafetyGrounding 268

3.3.5.2High Frequency Grounding 268

4. Circuit Protection 269

4.1 InternalIntegratedDrive Protection Circuits 269

4.1.1 Soft Start Circuit 269

4.1.2 MotorRegenerationCircuit 269

4.1.3 PSM3U Low-Power PS 269

4.1.4 PSM3UHigh-PowerPS 270

4.1.5 DDM3U Low-Power Motor Drive 270

4.1.6 DDM3UHigh-Power Motor Drive 271

4.2 Fuses 271

4.2.1 PSM3U Power Supply Fuses 271

4.2.1.1 PSM3ULow-Power AC InputPower Fuses 271

4.3 Fault Handling 273

Version 2.50.D

4.2.1.2 PSM3U Low-Power 24VdcLogicSupply Input Fuses 272

4.2.1.3 PSM3U High-Power ACInputPower Fuses 272

4.2.2 DDM3U Motor DrivesFuses 272

4.2.2.1 DDM3U-X-60V-4A Low-Power Motor DriveFuses 272

4.2.2.2DDM3U-2-320V-YY High-PowerMotor Drive Fuses 272

13

Page 14

MC4UHardwareGuide

5. MC4UConnectivity 276

5.1 MC4U I/ONaming Conventions 276

5.2Incremental Digital Encoder Interface 277

5.3Sin-CosEncoder Input 277

5.4 AbsoluteEncoder Interface 278

5.5I/O Interface 280

5.6HallInterface 281

5.7 Motor Temperature Input 282

5.8EmergencyStop Input 283

5.9MARK1 Registration DigitalInput 283

5.10PEGPulseOutput 284

5.11 JoystickInput Interface 284

6. InstallationandMaintenance 286

6.1 Installing the MC4U 286

6.1.1 Panel-Mountingthe MC4U 286

6.1.2 Rack-Mounting the MC4U-19-Piano-enc andMC4U-22-Piano-enc 287

6.2 Maintenance 288

6.2.1 Replacing MC4UComponents 288

6.2.2Replacing CoolingVents 288

Version 2.50.D

14

Page 15

MC4UHardwareGuide

ListOfFigures

Figure 1-1. MC4U-9-Piano-enc 25

Figure 1-2. MC4U-11-Piano-enc 26

Figure 1-3. MC4U-13-Piano-AX7 27

Figure 1-4. MC4U-19-Piano-enc 28

Figure 1-5. MC4U-22-Piano-enc 29

Figure 2-1. MC4U Components 30

Figure 2-2.MC4U-9-Piano-enc Dimensions 32

Figure 2-3.MC4U-11-Piano-enc Dimensions 33

Figure 2-4.MC4U-13-Piano-AX7 Dimensions 34

Figure 2-5.MC4U-19-Piano-enc Dimensions 35

Figure 2-6.MC4U-22-Piano-encDimensions 36

Figure 2-7. SPiiPlusNT GeneralView 39

Figure 2-8.SPiiPlusNT/DC Indicators(SPiiPlusNTshown) 47

Figure 2-9.DDM3U-4-320V-XAMotor Drive 87

Figure 2-10.LDM3U Single AxisLinearAmplifier 92

Figure 2-11. MB4U-ZZW-AX7 Connectors 96

Figure 2-12. MB5U-CONT-PS Connectors 108

Figure 2-13.MB5U-CONT-PS Jumpers andPinNumbers 122

Figure 2-14. MB5U-CONT-PS2 Connectors 124

Figure 2-15.MB5U-CON-PS2 Motherboard Jumpers andPinNumbers 139

Figure 2-16. MB5U-Lin 141

Figure 2-17. MB5U-LinM 143

Figure 2-18. MB5U-YYYY Connectors 145

Figure 2-19. Source-Type Drive Enable Output (D Axis) 160

Figure 2-20.MB5U-YYYY Motor Drive Connections 161

Figure 2-21. MB5U-YYYY Jumpers 162

Figure 2-22.MB5U-ZConnectors 165

Figure 2-23.MB5U-ZMotor Drive Connections 172

Figure 2-24.Source -Type DriveEnable Output (B Axis) 176

Figure 2-25.MB5U-Z MotherboardJumpers andPinNumbers 178

Figure 2-26.MB5U-ZVConnectors 180

Figure 2-27.MB5U-ZVMotor Drive Connections 188

Figure 2-28.MB5U-ZVJumpers 193

Figure 2-29.MB5U-ZZConnectors 195

Version 2.50.D

15

Page 16

MC4UHardwareGuide

Figure 2-30.MB5U-ZZ Motor DriveConnections 203

Figure 2-31.MB5U-ZZJumpers and PinNumbers 207

Figure 2-32.MB5U-ZZW Connectors 209

Figure 2-33.MB5U-ZZW J152Motor Drive Connections 225

Figure 2-34.MB5U-ZZWJ121-J124Motor DriveConnections 227

Figure 2-35.MB5U-ZZW Motherboard Jumpersand Pin Numbers 228

Figure 2-36.MB5U-ZZZ Connectors 230

Figure 2-37.MB5U-ZZZMotor Drive Connections 246

Figure 2-38.MB5U-ZZZ Jumpers and Pin Numbers 247

Figure 2-39.MB5U-2-45 Connectors 249

Figure 2-40.MB5U-2-20 Connectors 251

Figure 2-41. MB5U-2-20 Motor DriveConnections 252

Figure 2-42.MB5U-4-XXConnectors 254

Figure 2-43.MB5U-4Motor DriveConnections 255

Figure 2-44. MC4U-MF-560V Motor Filter 258

Figure 2-45.Motor Filter ExternalDimensions 260

Figure 2-46.RegenerationModule 261

Figure 3-1. StandardsOrganization Marks 262

Figure 3-2.STO Wiring Scheme 264

Figure 3-3.STO Implementation 264

Figure 3-4.Cable Spacing 267

Figure 3-5.Shielded Cable 267

Figure 3-6.MC4UGrounding Post 268

Figure 5-1. Incremental DigitalEncoder Interface (X-axis) 277

Figure 5-2.Sin-CosEncoder Interface 278

Figure 5-3.Absolute Encoder HiperfaceSchematic Diagram 279

Figure 5-4.Absolute Encoder Schematic Diagram 279

Figure 5-5.Absolute Encoder BidirectionalSchematic Diagram 280

Figure 5-6.I/OInterfaceSchematic Diagram 281

Figure 5-7.HallInterface Schematic Diagram 282

Figure 5-8.Connection to Motor Temperature Input (X-axis) 283

Figure 5-9.Connection for Emergency Stop Input 283

Figure 5-10.Differential Connection for MARK1 Input (X-axis) 284

Figure 5-11. PEGPulse DigitalOutput Connection (X-axis) 284

Figure 5-12.Analog Inputswith 0-10V Configuration 285

Version 2.50.D

16

Page 17

MC4UHardwareGuide

Figure 5-13.A ±5V Differential Joystick through AIN 285

Figure 6-1. MC4U-9-Piano-enc and MC4U-11-Piano-encPanel-Mounting 286

Figure 6-2.MC4U-19-Piano-enc andMC4U-22-Piano-encPanel-Mounting 287

Figure 6-3.MC4U-19-Piano-enc andMC4U-22-Piano-encRackMount 287

Version 2.50.D

17

Page 18

MC4UHardwareGuide

ListofTables

Table 2-1.MC4U-9-Piano-enc Dimensions 31

Table 2-2. MC4U-11-Piano-encDimensions 33

Table 2-3. MC4U-13-Piano-AX7 Dimensions 33

Table 2-4.MC4U-19-Piano-enc Dimensions 34

Table 2-5. MC4U-22-Piano-encDimensions 35

Table 2-6.MC4U Power Dissipation @NominalLoad 37

Table 2-7.MC4UEnvironmental Specification 38

Table 2-8. CTIMEValuesfor MC4UntSPiiPlusNT-LT/HP/LD/NP(Rev. D and later) Controller 41

Table 2-9.SPiiPlusNT/DC-LT/HP/LD AdditionalFeatures 42

Table 2-10.SPiiPlusNT/DCIndicators 47

Table 2-11. PSM3U Power Supplies-General 49

Table 2-12.PSM3U-48V-XXkWLow-Power PSSpecifications 54

Table 2-13.PSM3U-320V-8kWHigh-PowerPS Specifications 57

Table 2-14.Maximum Input Power @Single Phase Input 85 -265Vac 59

Table 2-15.Maximum InputPower @Three PhaseInput 195-265Vac 59

Table 2-16.Maximum Input Current @Single Phase Input 85- 265Vac 60

Table 2-17.Maximum Input Current @ThreePhaseInput 195-265Vac 60

Table 2-18.Output Voltage @SinglePhaseInput 85- 130Vac 60

Table 2-19.Output Voltage @SinglePhaseInput 195-265Vac 60

Table 2-20. Output Voltage @Three PhaseInput 195- 265Vac 61

Table 2-21.Output Power @Single Phase Input 85-130Vac 61

Table 2-22. Output Power @SinglePhaseInput 195-265Vac 61

Table 2-23. Output Power @Three PhaseInput 195-265Vac 61

Table 2-24. PSM3U-320V-10KWPSSpecifications 62

Table 2-25. Maximum Input Power @ Three PhaseInput 195-265Vac 63

Table 2-26. Maximum Input Current @Three Phase Input 195- 265Vac 63

Table 2-27.Output Voltage @Three PhaseInput 195-265Vac 64

Table 2-28. Output Power @Three PhaseInput 195-265Vac 64

Table 2-29. DDM3U-X-60V-4A Power Block Assembly Options 66

Table 2-30. DDM3U-X-60V-4ASpecifications 66

Table 2-31.DDM3U-X-60V-4AMaximum Input Current andInput Power 68

Table 2-32. DDM3U-X-60V-4ATotal Output Current andOutput Power 68

Table 2-33. DDM3U-X-60V-4APower Motor Output Parameters 69

Table 2-34. DDM3U-1-320V-XX-SRSpecifications 70

Version 2.50.D

18

Page 19

MC4UHardwareGuide

Table 2-35. PWMPower Bridge Specifications 72

Table 2-36. DDM3U-2-320V-XA Power Supply Input Specifications 75

Table 2-37.Maximum Input Power[W] @Continuous/PeakCurrent for115Vac+15%, Single

PhaseMainSupply 78

Table 2-38. Maximum Input Power[W] @Continuous/PeakCurrent for 230Vac+15%, Single

PhaseMainSupply 78

Table 2-39. Maximum Input Power [W] @Continuous/Peak Current for 230Vac +15%, Three

PhaseMainSupply 79

Table 2-40. Maximum Input Current (Continuous/Peak) [A] for 115Vac +15%, Single Phase Main

Supply 79

Table 2-41.Maximum Input Current (Continuous/Peak) [A] for 230Vac+15%, Single Phase Main

Supply 80

Table 2-42. Maximum Input Current (Continuous/Peak) [A] for 230Vac+15%, Three PhaseMain

Supply 81

Table 2-43. PWMPowerBridge Specifications 81

Table 2-44.Maximum Phase Output Current (Continuous/Peak) [A] 82

Table 2-45. MinimumOutput Voltage (Phase-to-Phase) [Vrms]@Continuous/Peak Current for

115Vac+15%, Single Phase MainSupply 83

Table 2-46.MinimumOutput Voltage(Phase-to-Phase) [Vrms] @Continuous/PeakCurrent

for 230Vac +15%,Single PhaseMain Supply 83

Table 2-47.MinimumOutput Voltage (Phase-to-Phase) [Vrms]@ Continuous/Peak Current

for 230Vac +15%,Three Phase MainSupply 84

Table 2-48.Maximum Output Power[W] @Continuous/PeakCurrent for115Vac+15%, Single

PhaseMainSupply 84

Table 2-49.Maximum Output Power[W] @Continuous/PeakCurrent for230Vac +15%,Single

PhaseMainSupply 85

Table 2-50. Maximum Output Power[W] @Continuous/PeakCurrent for230Vac +15%,Three

PhaseMainSupply 86

Table 2-51.DDM3U-4-320V-XAPowerSupply Input Specifications 88

Table 2-52. DDM3U-4-320V-XAControl Supply InputSpecifications 89

Table 2-53. 24VLogic Supply Connector Pinout 97

Table 2-54. EtherCAT OutConnector Pinout 97

Table 2-55. EtherCAT In Pinout 98

Table 2-56. J4-Encoder Pinout 99

Table 2-57. J5-Encoder Pinout 102

Table 2-58. J6-DriveSupply Pinout 106

Table 2-59. J7-J10-DriveSupply Pinout 107

Table 2-60. J11-J14 -DriveSupply Pinout 107

Table 2-61.Encoder/Hall Pinout 109

Version 2.50.D

19

Page 20

MC4UHardwareGuide

Table 2-62. J7 -Squared Sin-Cos Pinout 111

Table 2-63. J8-Digital and Analog I/OPinout 112

Table 2-64.J9-Regeneration Pinout 115

Table 2-65. J21-PEGand MarkFastI/O Pinout 115

Table 2-66. J2andJ3-Ethernet Pinout 119

Table 2-67.J19andJ20-RS-232Communication Pinout 120

Table 2-68. J14 -DriveSupply Voltage Pinout 121

Table 2-69. J1 -24V LogicSupply Pinout 121

Table 2-70.I/OJumpers 122

Table 2-71.Encoder Supply 123

Table 2-72.Default Jumper Settings 123

Table 2-73.I2C Address 123

Table 2-74.GeneralPurpose AnalogInput Jumpers 123

Table 2-75.J1 -24VLogicSupply Pinout 125

Table 2-76.Encoder/Hall Pinout 126

Table 2-77.J7 -Squared Sin-CosPinout 127

Table 2-78.J8-DigitalandAnalog I/OPinout 129

Table 2-79.J14, J114 -DriveSupply VoltagePinout 131

Table 2-80. J21-PEGand MarkFastI/O Pinout 132

Table 2-81.J22-Motor Limits Pinout 134

Table 2-82. J4,J5,andJ6-HSSIPinout 135

Table 2-83. J2andJ3-Ethernet Pinout 136

Table 2-84. J19 and J20-RS-232 CommunicationPinout 137

Table 2-85. J9,J109-Regeneration Pinout 137

Table 2-86. J145 -60VDrive Supply Pinout 138

Table 2-87.I/O Jumpers 139

Table 2-88. Encoder Supply 140

Table 2-89. I2CAddress 140

Table 2-90. GeneralPurpose AnalogInput Jumpers 140

Table 2-91.J130(D0)- Drive Motor Pinout 141

Table 2-92. MB5U-Lin Jumper Settings 142

Table 2-93. J130(D0)-DriveMotor Pinout 143

Table 2-94.MB5U-LinM Jumper Settings 144

Table 2-95. Encoder/Hall Pinout 146

Table 2-96. J7 -Squared Sin-Cos Pinout 148

Version 2.50.D

20

Page 21

MC4UHardwareGuide

Table 2-97.J8-DigitalandAnalog I/OPinout 149

Table 2-98. J9-Regeneration Pinout 152

Table 2-99. J21 -Fast I/OPinout 152

Table 2-100. J2andJ3-Ethernet Pinout 156

Table 2-101.J19 and J20- RS-232 CommunicationPinout 157

Table 2-102. J14 -DriveSupply Voltage Pinout 158

Table 2-103. J1 -24V LogicSupply Pinout 158

Table 2-104.J40- ExternalDrive Control SignalsPinout 159

Table 2-105. J152_$ -MotorDrive Output Pinout 161

Table 2-106.MB5U-YYYY Jumper Settings 162

Table 2-107.I/OJumper Setup 163

Table 2-108.Encoder Supply 164

Table 2-109.Default Jumper Settings 164

Table 2-110.Encoder/Hall Connector Pinout 166

Table 2-111. J10-DigitalandAnalog I/OPinout 168

Table 2-112.J20-Safety and FastI/O Pinout 170

Table 2-113.J3andJ4-Drive Motor Pinout 171

Table 2-114. J6 andJ7 -Ethernet Pinout 173

Table 2-115.J8-HSSIPinout 173

Table 2-116.J19 -RS-232CommunicationPinout 174

Table 2-117. J13-ExternalDrive Control Signals Pinout 175

Table 2-118.J11 -ExternalRegenerationPinout 176

Table 2-119. J12-DriveSupply Pinout 176

Table 2-120. J5-24VLogic Supply Pinout 177

Table 2-121.I/O Jumpers 178

Table 2-122.Encoder Supply 179

Table 2-123.Default Jumper Settings 179

Table 2-124.Encoder/Hall Pinout 181

Table 2-125. J10-Digital and Analog I/OPinout 183

Table 2-126.J20- Safety andFast I/O InputsPinout 186

Table 2-127.J1, J3, J21andJ22- Drive Motor Pinout 187

Table 2-128.J2and J4-Drive Motor Pinout 188

Table 2-129.J8,J9and J30-HSSIPinout 189

Table 2-130. J6andJ7 -Ethernet Pinout 189

Table 2-131.J19 -RS-232CommunicationPinout 190

Version 2.50.D

21

Page 22

MC4UHardwareGuide

Table 2-132.J23 Pinout 191

Table 2-133.J11 Pinout 191

Table 2-134.J12Pinout 192

Table 2-135. J5Pinout 192

Table 2-136.Safety andI/OSupply Configuration 193

Table 2-137.I/O Jumpers 194

Table 2-138.Encoder Supply 195

Table 2-139.Default Jumper Settings 195

Table 2-140.Encoder/Hall Connector Pinout 197

Table 2-141. J10-DigitalandAnalog I/OPinout 198

Table 2-142.J20- Safety andFast I/O Pinout 201

Table 2-143.J1,J2,J3andJ4-Drive MotorPinout 202

Table 2-144.J6andJ7 -Ethernet Pinout 203

Table 2-145.J8and J9 -HSSI Pinout 204

Table 2-146.J19 -RS-232CommunicationPinout 205

Table 2-147. J11 -ExternalRegeneration Pinout 205

Table 2-148.J12-Drive Supply Pinout 206

Table 2-149.J5-24V LogicSupply Pinout 206

Table 2-150. I/O Jumpers 207

Table 2-151.Encoder Supply 208

Table 2-152. Default Jumper Settings 208

Table 2-153. Encoder/HallPinout 210

Table 2-154.J7-Squared Sin-CosPinout 212

Table 2-155. J8-Digital and Analog I/OPinout 213

Table 2-156.J9 -Regeneration Pinout 216

Table 2-157.J21-Fast I/O Pinout 216

Table 2-158.J4, J5,andJ6-HSSIPinout 220

Table 2-159.J2and J3-Ethernet Pinout 220

Table 2-160.J19andJ20- RS-232 CommunicationPinout 221

Table 2-161.J14 -DriveSupply Voltage Pinout 222

Table 2-162.J1-24VLogicSupply Pinout 222

Table 2-163.J40- ExternalDrive Control SignalsPinout 223

Table 2-164.J152_$ -Motor Drive Pinout 224

Table 2-165.J125- ExternalDC DriveSupport Pinout 226

Table 2-166.J121-J124-Low-Power Motor Pinout 226

Version 2.50.D

22

Page 23

MC4UHardwareGuide

Table 2-167.MB5U-ZZWJumpers 228

Table 2-168.Default Jumper Settings 229

Table 2-169.Encoder/Hall Pinout 231

Table 2-170.J7-Squared Sin-CosPinout 233

Table 2-171. J8- Digital and Analog I/OPinout 234

Table 2-172.J9-Regeneration Pinout 237

Table 2-173.J21-FastI/OPinout 237

Table 2-174. J22 -MotorLimitsPinout 239

Table 2-175.J4,J5,andJ6-HSSI Pinout 241

Table 2-176.J2andJ3-Ethernet Pinout 241

Table 2-177. J19andJ20- RS-232 CommunicationPinout 242

Table 2-178.J14 -DriveSupply Voltage Pinout 243

Table 2-179.J1 -24V LogicSupply Pinout 243

Table 2-180.J40 -ExternalDrive Control Signals Pinout 244

Table 2-181.J152_$ -Motor DrivePinout 245

Table 2-182.MB5U-ZZZ Jumpers 247

Table 2-183.Default Jumper Settings 248

Table 2-184.J152-0, J152-1Servo MotorDrive Pinout 249

Table 2-185.MB5U-2-45A Jumper Settings 250

Table 2-186.J152-ServoMotor DrivePinout 251

Table 2-187.MB5U-2-20 Jumper Settings 253

Table 2-188.J121-J124-Low-Power Motor Pinout 255

Table 2-189.MB5U-4-XX Jumper Settings 256

Table 2-190.MC4U Optional Accessories 256

Table 2-191. MotorFilter OperationalSpecifications 258

Table 2-192.J1-Drive Connector Pinout 259

Table 2-193.J2- Motor Connector Pinout 259

Table 3-1.International Standards& Certificates Applicable to MC4U 262

Table 3-2. STO Connector Type 265

Table 3-3. STO Pinout 265

Table 3-4.Line Filtersfor Single Phase AC Input 266

Table 3-5. LineFilters for ThreePhaseAC Input 266

Table 4-1.Fault Handling 273

Table 5-1.Absolute Encoder Reference 278

Version 2.50.D

23

Page 24

MC4UHardwareGuide

1. Introduction

1. Introduction

1.1 DocumentScope

The guide covers all versionsof the MC4U Control Module, andprovides detailed hardware

information.For eachversion thisguide includes the following information:

> Detailed mechanicalandelectricaldescriptionsof the components making up the MC4U

Control Module

> Installationinstructions

For asetup procedure of the MC4U Control Module,refer tothe SPiiPlus Setup Guide. It includes:

> Howto establishcommunication

> Howto configure the drive, motor, feedbackfor anaxis

> Howto adjust(tune) the parameters of an axis

The remaining tasksinvolved in operating the MC4Uare described in the SPiiPlus Programmer’s

Guide, including:

> Howto program motion

> Howto program I/Oevents

> Additionalproduct features

1.2 Product Overview

The MC4UControl Module isa multi-axis machineand motioncontrol module. The MC4Ucontainsa

motion controller,power supply, and motor drives allintegrated in asingle unit. All components are

housed in“upright piano”enclosure that can be either panel- orrack-mounted.

The specific components,controller,drives, and power supplies can be tailored to the needs ofthe

application, thusoptimizing the performance-to-cost ratio.

The MC4Ufamily includesthe following models:

> MC4U-9-Piano-enc

> MC4U-11-Piano-enc

> MC4U-13-Piano-AX7

> MC4U-19-Piano-enc

> MC4U-22-Piano-enc

1.2.1 MC4U-9-Piano-enc

MC4U-9-Piano-enc candirectly control two axes and containsthe following plug-in components:

> A SPiiPlusNT/DCcontroller

> A power supply

> One high-power dualaxisDDM3U-2-320V-YY motor drive

> A specific motherboard thataccommodatesthe plug-in components and external

interfaceconnectors

Version 2.50.D

24

Page 25

The unit canonly be panel-mounted.

1.2.2 MC4U-11-Piano-enc

MC4UHardwareGuide

1. Introduction

Figure 1-1. MC4U-9-Piano-enc

MC4U-11-Piano-enccandirectly control up tofour axesandcontainsthe following:

> A SPiiPluscontroller

> A power supply

> Two high-power dualaxis DDM3U-2-320V-YY motor drives

> A specific motherboard thataccommodatesthe plug-in components and external

interfaceconnectors

The unit canonly be panel-mounted.

Version 2.50.D

25

Page 26

MC4UHardwareGuide

1. Introduction

Figure 1-2. MC4U-11-Piano-enc

1.2.3 MC4U-13-Piano-AX7

MC4U-13-Piano-AX7 cancontrol 4or 8axes,dependingon the SPiiPlusMotion Controllerthat is

installed. Itcancontain:

> A SPiiPlusNT/DCmotion controller

> A PSM3U-320V-4kW(inthe 4 axes version)or aPSM3U-320V-8kW (inthe 8axesversion)

power supply

> Two multi-axis motor drives

> MB4U-ASMB motherboard

The unit caneither rack-or panel-mounted.

Version 2.50.D

26

Page 27

Figure 1-3. MC4U-13-Piano-AX7

MC4UHardwareGuide

1. Introduction

1.2.4 MC4U-19-Piano-enc

MC4U-19-Piano-enc cancontrol up to8axes.Itprovides the mostflexibilitywith regards totype of

drives (PWM, linear), matching powersupplies andaccessories.It can containthe following:

> A SPiiPlusNT/DCmotion controller

> A power supply withone or two motor voltages

> Up to four multi-axis motor drives

> One ormore motherboards thataccommodate the plug-incomponents andthe external

interfaceconnectors.

The unit caneither rack-or panel-mounted.

Version 2.50.D

27

Page 28

MC4UHardwareGuide

1. Introduction

Figure 1-4. MC4U-19-Piano-enc

1.2.5 MC4U-22-Piano-enc

MC4U-22-Piano-enc can control up to8axes.Itisdesigned to support PWMdriveswith matching

power supplies and accessories. It cancontainthe following:

> A SPiiPlusNT/DCmotion controller

> One PSM3U-320V-10KW320V, 20kW power supply

> Up to four DDM3U-1-320V-XX-SR single-axis digital PWM motor drives320V, 30/45A

> Motherboard:

- MB5U-CON-PS2 -Motherboard for SPiiPlusNT/DC controller andtwo PSM3U-320V-

10KW powersupplies

- MB5U-2-90A -Motherboardfor DDM3U-1-XXX-XX drivers

The unit caneither rack orpanel-mounted.

Version 2.50.D

28

Page 29

MC4UHardwareGuide

1. Introduction

Figure 1-5. MC4U-22-Piano-enc

1.3 SoftwarePackage

The MC4Uissupported bythe SPiiPlusADK (AdvancedDevelopment Kit) which isintended for

aiding programmers indeveloping ACSPL+ basedapplications and host basedprograms.

The latest versionsof all software are downloadable (for registered customers)from

https://www.acsmotioncontrol.com/downloads.

The kit contains:

> SPiiPlusMMIApplication Studio -a fullyintegrated GUI providing allthe toolsneeded for

programmingandmonitoring motion

> SPiiPlusCLibrary -for hostprogramminginC/C++

> SPiiPlusCOMLibrary -for hostprogramminginC#, C++, Visual Basic™, VBScript,LabView

andother programming languagesthat support the use ofCOMcomponents

> SPiiPlusUtilities -containing the SPiiPlus User Mode Driver (UMD) for establishing the

communication between the host computer andthe MC4U

> SPiiPlusSimulator -controller simulator for fast application development

> ACSPL+and C/C++ training filesandprogrammingexamples.

Version 2.50.D

29

Page 30

MC4UHardwareGuide

2.MC4U Specifications

2. MC4USpecifications

This sectionprovidesdetailed specifications of the MC4U family and its components. The

componentsconsist of:

> SPiiPlusMotion Controller

> PSM3UPowerSupply

> Motor Drive(up to amaximumof 3units)

> MC4UInterface(Motherboard) Connectors

The functionalityof anyspecific MC4UControl Moduleisdetermined by the motherboard thatis

installed. See MC4U Motherboardsfor detailsof thevariousmotherboardsincorporated inthe

MC4UControl Module models.

Version 2.50.D

Figure 2-1. MC4U Components

30

Page 31

MC4UHardwareGuide

2.MC4U Specifications

2.1 MC4UPhysicalSpecifications

2.1.1 MC4U Dimensions

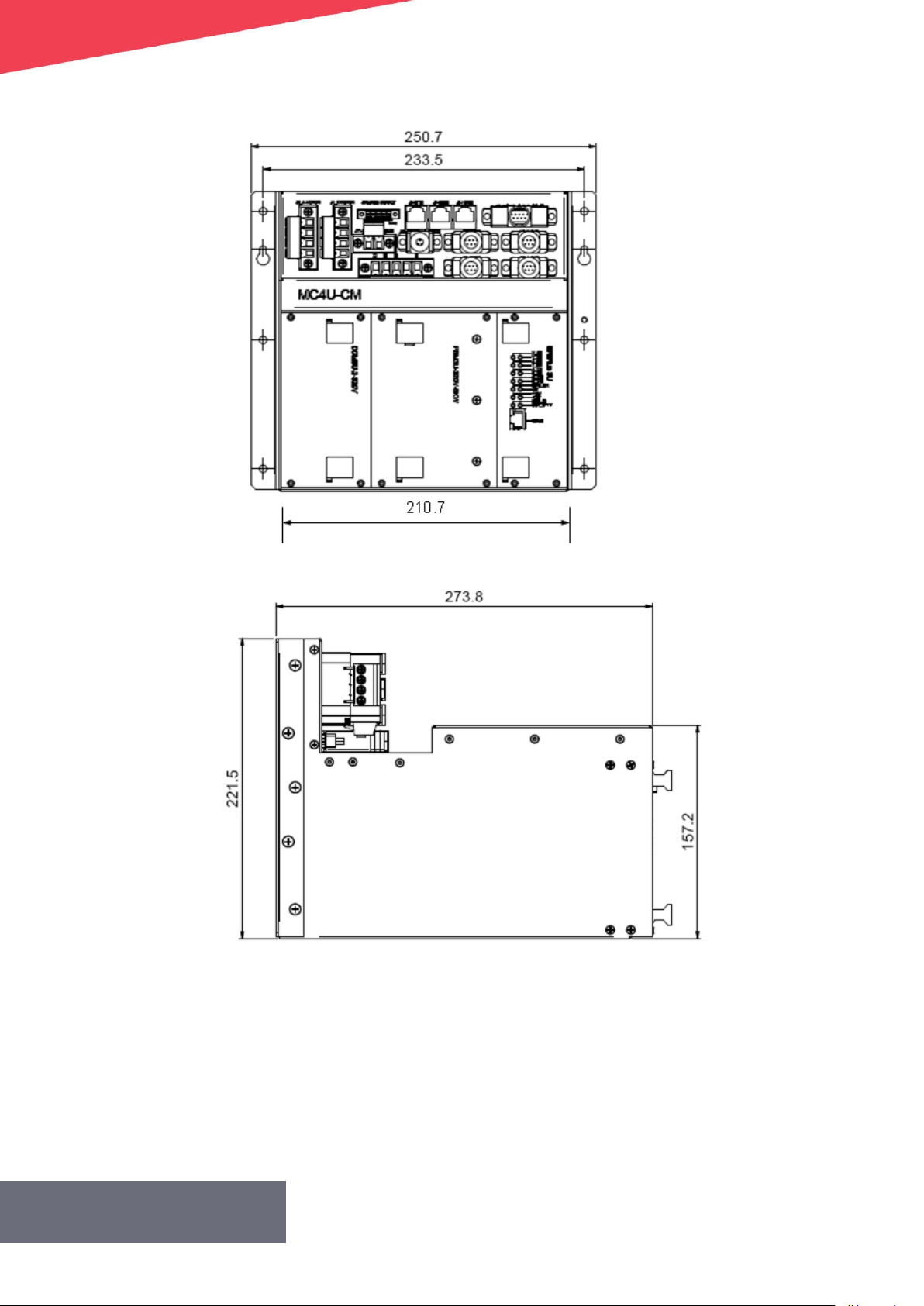

2.1.1.1 MC4U-9-Piano-enc Dimensions

The following table provides the mechanical dimensions ofthe MC4U-9-Piano-enc.

Table 2-1.MC4U-9-Piano-enc Dimensions

Height 221.5 ±1mm

Width 273.8 ±1mm(with extractors 287.3mm)

Length

The following figuredisplaysthe overalldimensions of the MC4U-9-Piano-encunit.

211 ±1mm (withmounting-bracket

250.7±1mm)

Version 2.50.D

31

Page 32

MC4UHardwareGuide

2.MC4U Specifications

Figure 2-2.MC4U-9-Piano-enc Dimensions

2.1.1.2 MC4U-11-Piano-enc Dimensions

The following table provides the mechanical dimensions ofthe MC4U-11-Piano-enc.

Version 2.50.D

32

Page 33

MC4UHardwareGuide

2.MC4U Specifications

Table 2-2. MC4U-11-Piano-encDimensions

Height 221.5±1mm

Width 273.8±1mm (withextractors287.3mm)

Length 276.7±1mm(with mounting-bracket 316.7±1mm)

The following figuredisplaysthe overalldimensions of the MC4U-11-Piano-enc unit.

Figure 2-3.MC4U-11-Piano-enc Dimensions

2.1.1.3 MC4U-13-Piano-AX7Dimensions

The following table provides the mechanical dimensions ofthe MC4U-13-Piano-AX7.

Table 2-3. MC4U-13-Piano-AX7 Dimensions

Height 185 ±0.2mm

Width

Version 2.50.D

> 340±0.2mm(without mounting

33

Page 34

MC4UHardwareGuide

2.MC4U Specifications

brackets)

> 383±0.2mm(withmounting

brackets)

Length 292±1mm

The following figuredisplaysthe overalldimensions of the MC4U-13-Piano-AX7unit.

Figure 2-4.MC4U-13-Piano-AX7 Dimensions

2.1.1.4 MC4U-19-Piano-enc Dimensions

Table 2-4.MC4U-19-Piano-enc Dimensions

The following table provides the mechanical dimensions ofthe MC4U-19-Piano-enc.

Height 221.5±1mm

> 483±1mm (withfront

bracket)

Width

Length 292±1mm

The following figuredisplaysthe overalldimensions of the MC4U-19-Piano-encunit.

Version 2.50.D

> 476 ±1mm(with rear

bracket)

> 436±1mm (withno

bracket)

34

Page 35

MC4UHardwareGuide

2.MC4U Specifications

Figure 2-5.MC4U-19-Piano-enc Dimensions

2.1.1.5 MC4U-22-Piano-enc Dimensions

The following tableprovides the mechanical dimensions ofthe MC4U-22-Piano-enc.

Table 2-5. MC4U-22-Piano-encDimensions

Height 221.5±1mm

> 542±1mm (with rear

Width

Length 292±1mm

The following figuredisplaysthe overalldimensions of the MC4U-22-Piano-encunit.

bracket)

> 502±1mm(with no

bracket)

Version 2.50.D

35

Page 36

MC4UHardwareGuide

2.MC4U Specifications

Figure 2-6.MC4U-22-Piano-encDimensions

2.1.2 MC4U Weight

The MC4U-9-Piano-enc hasa maximum weight of 5.2kg.

The MC4U-11-Piano-enchasa maximum weight of 6.5kg.

The MC4U-13-Piano-AX7 hasamaximum weight of 9.1kg.

The MC4U-19-Piano-enc hasamaximum weight of 11.5 kg.

The MC4U-22-Piano-enc has amaximum weight of 17kg.

2.1.3 MC4U Power Dissipation

The following table provides the power dissipationof the modules for both the lowand high-

power versionsof the MC4U.

Version 2.50.D

36

Page 37

Table 2-6.MC4U Power Dissipation @NominalLoad

Component HeatDissipation

SPiiPlusNT-LT Motion Controller 14W

SPiiPlusNT-HP Motion Controller 18W

SPiiPlusDC-LT Motion Controller 9W

SPiiPlusDC-HPMotion Controller 13W

PSM3U-48V-0.7kW PowerSupply 85W

PSM3U-100V-3KwPowerSupply 100W

PSM3U-320V-4kWPower Supply 70W

PSM3U-320V-8kWPower Supply 135W

MC4UHardwareGuide

2.MC4U Specifications

PSM3U-320V-10kWPower Supply 235W

PSM3U-320V-11kW PowerSupply 186W

PSM3U-320V-20kWPowerSupply 470W

DDM3U-4-06-02Motor Drive 25W

DDM3U-2-320V-5A Motor Drive 87W (for 2axes)

DDM3U-2-320V-10AMotor Drive 138W (for 2axes)

DDM3U-2-320V-15AMotor Drive 226W (for 2axes)

DDM3U-2-30-20Motor Drive 212W(for axis1-nominalload,andaxis2 -halfload)

DDM3U-4-320V-1A Motor Drive 25W

DDM3U-4-320V-2AMotor Drive 45W

DDM3U-4-320V-3AMotor Drive 62W

DDM3U-1-320V-30A-SRMotor Drive 235W

DDM3U-1-320V-45A-SRMotorDrive 346W

2.1.4 MC4UEnvironmental Parameters

The following table provides the environmentalparametersfor MC4Uoperation.

Version 2.50.D

37

Page 38

MC4UHardwareGuide

2.MC4U Specifications

Table 2-7.MC4UEnvironmental Specification

Parameter Value

Ambient Temperature Rated range of operation from 0to +40°C

Environmental conditions:Storage IEC 60721-3-1(class 1K3 and 1M3)

Environmental conditions:Transportation IEC60721-3-2(class2K4and 2M3)

Environmental conditions:Operating IEC60721-3-3 (class 3K3and 3M4)

2.1.5 MC4U Cooling Vents

The number of MC4Ucoolingv ventsdependsonthe MC4Umodel asfollows:

> MC4U-9-Piano-enc -onecooling vent

> MC4U-11-Piano-enc-twocooling vents

> MC4U-13-Piano-AX7 -twocooling vents

> MC4U-19-Piano-enc -threecooling vents

> MC4U-22-Piano-enc -four coolingvents

Eachvent providesamaximum of 120CFMairflow for the internalcooling of the circuit boards

within the mechanicalhousing. The coolingventsoperate off the24Vlogic supply. The cooling

ventscurrent consumption is1Aor less(dependingon the number of vents).

For information regarding cooling vent periodical maintenance, see Replacing Cooling Vents.

2.2SPiiPlusNT/DC MotionControllers

This sectionprovidestechnical detailsof the SPiiPlusNT/DCmotion controllers.For

completedetails, refer tothe SPiiPlusNT/DC Motion Controller Hardware Guide.

The minimum SPiiPlusNT/DC-LT/HP/LDhardware revisionisD and SPiiPlusNT-SC FW

v2.29.04.00.

The MC4Uisavailable inthe following configurations:

Version 2.50.D

38

Page 39

MC4UHardwareGuide

2.MC4U Specifications

Figure 2-7. SPiiPlusNT GeneralView

The SPiiPlusNTandSPiiPlusDCcontrollersdiffer bytheir networking capabilities:

> The SPiiPlusNTservesasa network master:in addition toits regular control ofthe MC4U

axes,itsupportsanEtherCAT port and the control softwarerequired to expandthe

network. Network expansionisprovided by the addition of network elements suchas

otherMC4Us(which containa SPiiPlusDCcontroller), UDMnt, PDMnt,SDMnt and others.

> The SPiiPlusDCservesasa slave controller in aEtherCAT network, serving the local MC4U

axes.Inthisslave role, the MC4Uisanetwork element, being part of larger network

wherebyamaster MC4U (containing aSPiiPlusNT controller) oranNTMcontrolsthe overall

network. The SPiiPlusDChasanincomingport fromaprevious network element from

which itreceives the profilesandcommandsintended for its axes,and outgoing portto

connect the next network element (if exists)andmaintainthe communicationnetwork.

The SPiiPlusDCisphysicallysimilarto the SPiiPlusNT, except that it doesnot have anMPU

board anddoes notinclude EtherCATconnector J3.

A network mustcontainone master and canhave any number ofslaves.

Both motion controller versionshave the following features:

> Controller -the servocontrol algorithm executes atanuncompromising rate of20kHzfor

each axis regardless ofthe number of axes,providing verylarge bandwidth, exceptional

dynamic tracking, fast settling,andexcellent smoothness at low velocities.

The controller ismanufactured under ISO9001 certified quality management system, meeting

stringentsafety andEMCstandardsandisCEmarked.

> Communication Channels-communicationwith the controller through all channelscanbe

done simultaneously:

Version 2.50.D

39

Page 40

MC4UHardwareGuide

2.MC4U Specifications

- The controller communicateswith acomputer hostviaan RS-232 serialchannelor

Ethernet 10/100BaseT channel.

- Inaddition it can communicate withother computers via asecond RS-232 serial

channel (115,200baud)or Ethernet 10/100BaseTchannel.

- The SPiiPlusNTandSPiiPlusDChave 1/2EtherCAT channels, operating at100Mbs.The

EtherCAT connectors are located on the controllers front panel.

> Discrete InterfaceSignals-the controllerscome with digitalandanalog I/Os used for

generalpurpose andfor functional anddedicated purposes.These signalsare accessible

to the user from the MC4U’sconnector panel only.Inaddition, digital inputscanbe used

for hardware-based position registration andoutputs canbe usedto trigger position-

based eventswith sub-µSecdelay accuracy.

Configurationof the digital I/Osare byjumpers onthe SPiiPlusNT/DC controller. See the

appropriate SPiiPlusNT/DCMotionController Hardware Guide for detailed information.

> ACSPL+-complex applicationsareeasyto develop withACSPL+,apowerful,true

multitasking, high-level languagethat isoptimized for motion control applications. Ten

programscan run simultaneously,enabling multiple interacting andsynchronized

processes.ACSPL+enablesimplementationof highly complex motion-time-event

sequences with accurate positioning and timing. The program can run directly on the

controller orcanbe implemented in ahostPCapplication using librariesprovided for C,

C++, COM,and .NET.

> Suite of Tools-powerfulsoftware toolsare provided for setup, tuning, and programming.

Application development isparticularlyeasywith the integrated four-channelsoft scope

andmulti-axismotion simulator.

The SPiiPlusNT/DC controllers are availablein the followingmodels:

> High PerformanceControllers:

- SPiiPlusNT/DC-HP-a high performancedrive controller with 16-bit A2Dfor motor

currentand analog SIN-COS encoder measurements.

- SPiiPlusNT/DC-LD-a high performancedrive controller based onthe SPiiPlusNT/DC-HP

with an additional module for 16-bit analog commandstolinear drives.

> Light Controllers

- SPiiPlusNT/DC-LT-aneconomicaldrive controller that uses12-bit A2Dfor motor

currentand analog SIN-COS encoder measurements.

2.2.1 SPiiPlusNT/DC Motion ControllersFeatures

The SPiiPlusNT/DC features aredescribed inthe following tables:

The CTIMEvalues inare for aSPiiPlusNT systemwith additionalslave drives, including MC4U slave

drives with SPiiPlusDC controllers.

Version 2.50.D

40

Page 41

SPiiPlusADK Suite 2.50 Hardware Guide

2.MC4U Specifications

Table 2-8. CTIMEValuesfor MC4UNT SPiiPlusNT-LT/HP/LD/NP (Rev. D and later) Controller

Maximum

Number of

Controller

(tobe insertedinto MC4UNT)

SPiiPlus NT-LT-4 4 4 10 4 10 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-4 4 8 10 8 10 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-4 4 16 16 16 16 √⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-4 4 32 32 32 32 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-4 4 64 64 64 64 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-8 8 8 10 8 10 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-8 8 16 16 16 16 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-8 8 32 32 32 32 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-LT-8 8 64 64 64 64 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 -

SPiiPlus NT-HP-4 /NT-LD-4 /NT-NP-2 4 4 10 4 10 √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ 0.5 √

SPiiPlus NT-HP-4 /NT-LD-4 /NT-NP-2 4 8 10 8 10 √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾⁾ √ ⁽³⁾ ⁽⁵⁾ 0.5 √

SPiiPlus NT-HP-4 /NT-LD-4 /NT-NP-2 4 16 16 16 16 √⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽³⁾ ⁽⁵⁾ - 0.5 √

SPiiPlus NT-HP-4 /NT-LD-4 /NT-NP-2 4 32 32 32 32 √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ - - 0.5 √

SPiiPlus NT-HP-4 /NT-LD-4 /NT-NP-2 4 64 64 64 64 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 √

SPiiPlus NT-HP-8/ NT-LD-8/ NT-NP-4 8 8 10 8 10 √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽³⁾ ⁽⁵⁾ 0.5 √

SPiiPlus NT-HP-8/ NT-LD-8/ NT-NP-4 8 16 16 16 16 √⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽³⁾ ⁽⁵⁾ - 0.5 √

SPiiPlus NT-HP-8/ NT-LD-8/ NT-NP-4 8 32 32 32 32 √ ⁽⁴⁾ ⁽⁵⁾ √ ⁽⁴⁾ ⁽⁵⁾ - - 0.5 √

SPiiPlus NT-HP-8/ NT-LD-8/ NT-NP-4 8 64 64 64 64 √ ⁽⁴⁾ ⁽⁵⁾ - - - 1 √

⁽¹⁾Ifthe MPU processing power is not sufficient,thenuse the MC4Udc version with an externalSPiiPlusNTM-yy-xx-xx-xx-xxx-H-xor SPiiPlusEC-yy-xx-xx-xx-xxx-x-xtypecontroller.

⁽²⁾Ifthe MPU processing power is not sufficient,thenuse the UDMpm /UDMba /UDMhp / UDMhv versionwith anexternal SPiiPlusNTM-yy-xx-xx-xx-xxx-H-xor SPiiPlusEC-yy-xx-xx-xx-xxx-x-xtype

controller.

⁽³⁾2-axes Extended Segmented Motion(XSEG) with limitations: a.Segment length> 5ms,b. IMM VEL =… command shouldn't be used

⁽⁴⁾6-axes Extended Segmented Motion(XSEG) with limitation: Segment length >1ms. Theuser's responsibilityis to ensure that theUSAGEdoesn't exceed 80%.

⁽⁵⁾NetworkBoost (RingTopology) with limitations: a.CTIME=1 msec -up to64 axes b.CTIME=0.50msec -up to 24axes c.CTIME=0.25msec - upto 8axes d. CTIME =0.20 msec -up to 4axes

*Supported orderingoption.

**Upto64 buffers supported with ordering option.

Number

ofBuilt-

inDrives

Maximum

Number

ofAxes

DefaultNumberof

AvailableACSPL+

Buffers**

Simultaneously

Running

Motors

ACSPL+

Buffers

1(msec)

2(msec)

Controller CycleTime

0.50

(msec)

0.25

(msec)*

0.20

(msec)*

Default

Value

(msec)

ServoBoost

Supported

Version 2.50.D

41

Page 42

Table 2-9.SPiiPlusNT/DC-LT/HP/LD AdditionalFeatures

HWFeature SPiiPlusNT/DC-LT/HP/LD Remarks

ProfileGeneration

Motion Profile

generation

rate

Feedback

Incremental

Digital Encoder

1, 2,4or 5kHz

One per axis: A&B,I;UP/DN,I;

CLK/DIR,I.

Type:RS-422

Max. rate: 40millionencoder

counts/sec.

MC4UHardwareGuide

2.MC4U Specifications

Sin-Cos

Encoder

(optional)

One per axis

SPiiPlusNT/DC-HP/LD:

Multiplication factor: Fromx4to

x65,536.

Rate:HPversion:Up to500*10³ sine

periods/sec;

LDversion:4*10⁶sine periods/sec.

Sin-Cosoffset,gain,phase

compensation: programmable with

automatic calibration.Offset is

hardware compensated, +/-50%of

signalrange.

Maximum acceleration: 4x10⁸sine

periods/sec².

SPiiPlusNT/DC-LT:

Multiplication factor: Fromx4to

x4,096Sin-Cosoffset gain,phase

compensation: programmable with

automatic calibration.Rate:250*10³

sine periods/sec.

Maximum acceleration: 4x10⁸sine

periods/sec².

Hallinputs

Absolute

encoder

Version 2.50.D

Set of three per axis.

Single-ended, 5V, source, opto-

isolated.

Input circuit current: <7mA.

SupportsEnDat2.1/2.2 (Digital

only), Smart-ABS, Panasonic, Biss-C,

SSI,Hiperface,SanyoDanki.

42

Page 43

HWFeature SPiiPlusNT/DC-LT/HP/LD Remarks

Indices:X(0),Y(1), (Z(4) and T(5).

DriveInterface

MC4UHardwareGuide

2.MC4U Specifications

Analog

commands

(SPiiPlusNT/DC-

LDonly):

PWMdrive

commands

Drive Current

Feedback

External drives

Two phasesper axis.

Type:±10V,differential, 16bit

resolution.

Offsetcompensation:

programmable, 0.3mV resolution.

Three phasesper axis.

Control algorithm: digital PIfilters

with field oriented control and

spacevector modulation.

PWMfrequency:40kHz onthe

motor.

Two phasesper axis.

Current loop sampling rate:20kHz.

Current feedback resolution:

SPiiPlusNT/DC-HP/LD:16bit.

SPiiPlusNT/DC-LT:12bit.

SPiiPlusNT/DC-LD:twophasesper

axis

Drive command analogoutputs

are supported onlyby the

SPiiPlusNT/DC-LDproduct.

Supported only byfollowing

motherboards:

> MB5U-Z

> MB5U-YYYY

DigitalI/O

SafetyInputs:

Emergency

stop input

Left andright

limit inputs

DigitalInputs:

> MB5U-ZZZ

> MB5U-ZZW

One per controller.

Type:two-terminal,sink orsource,

opto-isolated.

One pairper axis.

Type:single-ended, sink (default)

or source, configurable by jumper,

opto-isolated.

Supply: 5Vor 24V.

Input current: <15mA.

Version 2.50.D

43

Page 44

HWFeature SPiiPlusNT/DC-LT/HP/LD Remarks

Eight.

MC4UHardwareGuide

2.MC4U Specifications

General

Purpose Inputs

MARK(position

capture) inputs

DigitalOutputs

General

purpose

outputs

Type:single-ended, 5Vor24V,sink

(default)or source,opto-isolated.

Input current: <15mA.

Up to four.

Type:RS-422.

Propagation delay:<0.1 μsec.

Eight.

Type:single-ended, 5Vor24V,sink

(default)or source,opto-isolated.

Output current:100mA per output.

One per axis.

Four additionalMARKinputs

(MARK2),single-ended and opto-

isolated, are availablethrough

generalpurpose digital inputs

IN4,IN5, IN6 andIN7

Refer to PEGand MARK

Operations Application Notesfor

detailed information.

Dependsoncontroller

configuration.

Dualusage,canbe usedas

MechanicalBrake.

Mechanical

Brake Outputs:

General purpose digital outputs can be configured asMechanicalBrake Outputs.

Dynamicbrake signalisavailable onlyfor internal MC4Udrivers and isnot accessibleasan

externalsignal.

PEGpulse

outputs:

PEGstate

outputs

Type:single-ended, 5V,source

only, opto-isolated

Output current:7mA per output.

Six.

Type:RS-422.

Propagation delay:<0.1μsec.

PEGpulsewidth: 25nsec to 1.7msec.

PEGposition accuracy: ±1count at

speeds up to18x10⁶ counts/sec.

Up to six.

Type:RS-422.

Propagation delay:<0.1μsec.

Default configurationisdynamic

brake.

Refer to PEGand MARK

Operations Application Notesfor

detailed information.

Refer to PEGand MARK

Operations Application Notesfor

detailed information.

Version 2.50.D

44

Page 45

HWFeature SPiiPlusNT/DC-LT/HP/LD Remarks

Up to three.

HSSIExpansion

Channels

AnalogI/O

Analog Inputs

General

Purpose Inputs

Eachchannel provides64 inputbits

and64 output bits per channel,

sampled and updatedevery

50μsec.Type: RS-422.

Up to 16.

Type:1Vptp, differential.

Resolution and SNR:

SPiiPlusNT-HP/LD:16bit, SNR>72db.

SPiiPlusNT-LT: 12bit, SNR>52db.

SPiiPlusNT-HP/LD:

Four dedicated generalpurpose

inputs.

Type:±10V,differential.

Resolution: 16bits.

SPiiPlusNT-LT:

Up to four (whenaxesnumber 3

and/ or 7Sin-Cosencoders arenot

used.

Type:±10V,differential.

Resolution: 12bits.

Unused Sin-Cosencoder inputs

canbe usedasgeneral purpose

analoginputs.

MC4UHardwareGuide

2.MC4U Specifications

General

Purpose

Outputs

CommunicationChannels

Serial

Ethernet

EtherCAT

2,4.

Type:±10V,PWM filtered.

Resolution: 10bit.

SPiiPlusNTonly:

Two.

RS-232.

Up to 115,200bps

SPiiPlusNTonly:

One.

TCP/IP, 10/100Mbits/sec.

SPiiPlusNT:Oneor twomaster

ports.

SPiiPlusDC:Oneinput, one output.

SPiiPlusNTonly:Simultaneous

communication through all

channelsisfully supported.

Modbus protocol asmaster or

slave issupported via all

channels

SPiiPlusNTonly:Optional

network failure detection and

recovery with ring topology.

Version 2.50.D

45

Page 46

HWFeature SPiiPlusNT/DC-LT/HP/LD Remarks

MPU(SPiiPlusNTonly)

Processor Intel® Atom™ N26001.6 GHz

MC4UHardwareGuide

2.MC4U Specifications

Memory

Powerup Time

Environment& Standards

Operating

Temperature

Storage

Temperature

Humidity 90%RH,non-condensing

Standards

RAM:1GB

FlashNVmemory:1GB

25-100sec. according to system

andnetwork configuration

0˚Cto 55˚C

40˚Cto 70˚C

CE(EMC),ULcertified and RoHS

compliant

2.2.2 SPiiPlusNT/DC Indicators

The indicators arelocated onthe front panel of the module and indicate the statusof the power

supplies andaxesas showninthe example giveninFigure 2-8

Version 2.50.D

46

Page 47

MC4UHardwareGuide

2.MC4U Specifications

Figure 2-8.SPiiPlusNT/DC Indicators(SPiiPlusNTshown)

The indicators aredetailed in Table2-10.

Table 2-10.SPiiPlusNT/DCIndicators

Label Description Remarks

EtherCAT status

IN

OUT

Axis#

(Axis)

MPU_

ON

Two yellowLEDs:

> On:Linkconnected 100MHzspeed

> Blink: transmitter isactive

> Off:not connected

AxisStatus

Four -onefor each axis

Bicolor (Green/Red)LEDs:

> Green On:axis enabled

> Red On:axis failed

> Off:axis disabled

MPUStatus

Bicolor (Green/Red)LED

> Red LED

Version 2.50.D

47

Page 48

Label Description Remarks

- On:Communication fault

> Green LED

- On:Control Unit functioning

properly

- Blink: Processor and

communicationsfunctioning

properly

- Off:Noconnection with MPU

-5VStatus

MC4UHardwareGuide

2.MC4U Specifications

-5V

+12V

-12V

IO_PWR

SFTY_

PWR

Green LED

> On:-5Vavailable

> Off:No-5V

+12V Status

Green LED

> On:+12V available

> Off:No+12V

-12VStatus

Green LED

> On:-12Vavailable

> Off:No-12V

I/O Power Status

Green LED

> On:voltage isavailable

> Off:Novoltage

Safety Power Status

Green LED

> On:voltage isavailable

> Off:Novoltage

Two LEDs:Green andYellow

Green LED

J3

> On:Linkpresent

> Blink: Linkactive

Yellow LED

> ON:communicationat100MHz

SPiiPlusNT-LT/HP/LDRevD and

later only.

2.3PSM3UPower Supplies

There are sixtypesof PSM3U power supplies. These powersupplies mustbe matched tothe

motherboard installedin the MC4U Control Module (seeTable 2-11). Allpower suppliesneed two

Version 2.50.D

48

Page 49

input voltage supplies:

> 24Vdc inputsupply for internal logiccircuit

> AC drivesupply for motor operation

The 24Vdc inputpower supply should notbe connected to aDC distribution network;

anexternal AC/DC supply witha24Vdc,5Aoutput must be used.

Whenever anyMC4Umaintenance has to beperformed and aPSM3U-48V-xx power

supply isinstalled,after disconnectingthe unit from external power, awaiting period

of 30minutes mustbe observed inorderto allowcomplete voltagedischarge before

disassembling any of the MC4Ucomponents. Otherwise damage couldoccur to the

unit.

Table 2-11. PSM3U Power Supplies-General

Nominal

Input

Power

Supply

Number

ofInput

Phases

Voltage

Range

[Vrms]

-15%

+10%

MaxCont.

InputCurrent

PerPhase

[Arms]

MaxCont.

InputPower

[W]

MC4UHardwareGuide

2.MC4U Specifications

Applicable

Motherboard

PSM3U-

48V-

0.5kW

PSM3U-

48V-

0.7kW

PSM3U-

48V-

1.4KW

100-

240

1

1

1

phase

to

neutral

100-

240

phase

to

neutral

100-

240

phase

to

neutral

3.2 600

3.1 900

6.2 1800

MB5U-CONT-

PSMB5U-

YYYYMB5U-

ZZZMB5U-

ZVMB5U-ZZ

MB5U-CONT-

PSMB5U-

YYYYMB5U-

ZZZMB5U-

ZVMB5U-ZZ

MB5U-CONT-

PSMB5U-

ZZWMB5U-

ZVMB5U-ZZ

Version 2.50.D

49

Page 50

Power

Supply

Number

ofInput

Phases

Nominal

Input

Voltage

Range

[Vrms]

-15%

+10%

MaxCont.

InputCurrent

PerPhase

[Arms]

MaxCont.

InputPower

[W]

MC4UHardwareGuide

2.MC4U Specifications

Applicable

Motherboard

PSM3U-

48V-4KW

PSM3U-

320V-

8kW

100-

240

1

3

1

3

phase

to

neutral

100-

240

phase

to

phase

100-

240

phase

to

neutral

100-

240

phase

to

phase

13 3000

11 4200

25.8with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

24 with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

25.8with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

24 with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

6200with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

5760with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

10730with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

9977 with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

MB5U-CONT-

PS

MB5U-CONT-

PS2

MB5U-Z

MB5U-ZV

MB5U-ZZ

MB5U-YYYY

MB5U-ZZZ

MB5U-ZZW

MB5U-CONT-

PS

MB5U-CONT-

PS2

MB5U-Z

MB5U-ZV

MB5U-ZZ

MB5U-YYYY

MB5U-ZZZ

MB5U-ZZW

Version 2.50.D

50

Page 51

Power

Supply

Number

ofInput

Phases

Nominal

Input

Voltage

Range

[Vrms]

-15%

+10%

MaxCont.

InputCurrent

PerPhase

[Arms]

MaxCont.

InputPower

[W]

MC4UHardwareGuide

2.MC4U Specifications

Applicable

Motherboard

PSM3U-

320V-

10kW

32with

MB5U-CONT-

PS2,MB5U-ZZ,

100-

240

1

3

phase

to

neutral

100-

240

phase

to

phase

MB5U-ZV,

MB5U-Z

24 with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

32with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

24 with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

7680with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

5760with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

13300with

MB5U-CONT-

PS2,MB5U-ZZ,

MB5U-ZV,

MB5U-Z

9980with

MB5U-CONT-

PS, MB5U-

YYYY, MB5U-

ZZZ,MB5U-

ZZW

MB5U-CONT-

PS

MB5U-CONT-

PS2

MB5U-Z

MB5U-ZV

MB5U-ZZ

MB5U-YYYY

MB5U-ZZZ

MB5U-ZZW

PSM3U-

320V-

11kW

Version 2.50.D

100-

240

1

3

phase

to

neutral

100-

240

phase

to

phase

30(24

depending on

motherboard

setup)

30(24

depending on

motherboard

setup)

51

6900(5500

depending on

motherboard

setup)

MB5U-CONT-

PSMB5U-Z

12000(9600

depending on

motherboard

setup)

Page 52

Power

Supply

Number

ofInput

Phases

Nominal

Input

Voltage

Range

[Vrms]

-15%

+10%

MaxCont.

InputCurrent

PerPhase

[Arms]

MaxCont.

InputPower

[W]

MC4UHardwareGuide

2.MC4U Specifications

Applicable

Motherboard

PSM3U-

320/48V-

8/0.7kW

PSM3U-

320V-

20kW

100-

240

1

3

1

3

phase

to

neutral

100-

240

phase

to

phase

100-

240

phase

to

neutral

100-

240

phase

to

phase

28.5(24with

the applicable

motherboard)

24.4 (24with

the applicable

motherboard)

54 10600

76 30000

6700(5500

with the

applicable

motherboard)

9400(9200

with the

applicable

motherboard)

MB5U-CONT-

PSMB5U-

ZZWMB4U-

ZZW-AX7

The following isabrief description ofeach power supply:

> PSM3U-48V-0.7kW

The PSM3U-48V-0.7kW isalow-power, regulated powersupply andsupplies:

- One 51VdcnominalBUS voltage,up to700W(motor supply), providing power for

motor drivers suchasDDM3U-4 drive and the like. (If 700Wis not enough power, use

the PSM3U-48V-1.4kWpower supply.)

- All voltagesfor the SpiiPlusMotion Controller.

The PSM3U-48V-0.7kW issupplied from:

- Single AC externalpower supply within the voltage fluctuation range:85-265Vac

- 24Vdc±10% for logicsupply

> PSM3U-320V-8kW

The PSM3U-320V-8kWisahigh-power, non-regulated power supply andsupplies:

Version 2.50.D

52

Page 53

MC4UHardwareGuide

2.MC4U Specifications

- VACinx1.4 nominalBUS voltage,up to8.3kW (motor supply), providing power for the

motor drivers suchasDDM3U-2 and the like.(If 8.3kWisnot enough power,use the

PSM3U-320V-11kW power supply.)

- All voltagesfor SpiiPlusMotion Controller.

The PSM3U-320V-8kWissupplied from:

- Single or three-phase AC external powersupply within the voltagefluctuation range

85-265Vac

- 24Vdc ±10%for logic supply

> PSM3U-48V-1.4kW

The PSM3U-48V-1.4kWisalow-powerregulated powersupply, withdual DCbusvoltageoutputs

(up to 1.4kW), and supplies:

- Two 51VdcnominalBUS voltageoutputs,upto 700W(motor supply), for each output

for the motor driverssuch asDDM3U-4 or the like.

- All voltagesfor the SpiiPlusMotion Controller.

The PSM3U-48V-1.4kWissupplied from:

- Single AC externalpower supply within the voltage fluctuation range85-265Vac

- 24Vdc ±10%for logic supply

> PSM3U-320V-11kW

The PSM3U-320V-11kW isahigh-power, non-regulated power supply, withdualDC busvoltage

outputs(up to11 kW)andsupplies:

- Two outputs, VACin x1.4 nominalBUS voltageup to8.3kW for each outputand upto

12kW for both outputs simultaneously,for the motor drivers suchasDDM3U-2 orthe

like.

- All voltagesfor SpiiPlusMotion Controller.

The PSM3U-320V-11kW issupplied from:

- Single or three-phase AC external powersupply within the voltagefluctuation range

85-265Vac

- 24Vdc ±10%for logic supply

> PSM3U-320/48V-0.7/8kW

The PSM3U-320/48V-0.7/8kW isrequired ifDDM3U-2and DDM3U-4motor drivers are

installed together inthe 19” MC4U.

The PSM3U-320/48V-0.7/8kW isadualoutput, mixed voltagespower supply, high (upto 8kW)and

low-power (upto 0.7 kW) andsupplies:

- VACinx1.4 nominalBUS voltage,up to8 kW(motor supply), for the DDM3U-2 orthe

- 320VdcnominalBUS voltage,up to 8kW(motor supply), for the DDM3U-2

- 48Vdc nominal BUS voltage, upto 700W (motor supply), for the DDM3U-4 drive or the

- All voltagesfor SpiiPlusMotion Controller

Version 2.50.D

like

like

53

Page 54

MC4UHardwareGuide

2.MC4U Specifications

The PSM3U-320/48V-0.7/8kW issupplied from:

- Single or three-phase AC external powersupply within the voltagefluctuation range

85-265Vac.

- 24Vdc ±10%for logic supply.

When usingboth lowandhigh-power suppliesinthe same unit, the lowvoltageis

connectedto J30(V2) onthe motherboard, and the high voltage isconnected to J29

(V1) onthe motherboard.

> PSM3U-320V-20kW

The PSM3U-320V-20kWisanunregulated power supply (it isa combinationof twoPSM3U-320V-

10KW powersupplies). This supply isused to generate the two separateDC BUSvoltages(motor

supply) for the motor drivers (PWMor linear).

The PSM3U-320V-20kWissupplied from aone-or three-phase AC external power supply withinthe

voltage rangeof 100-230Vacnominaland generatestwoseparate DCBUS output voltagesof

140Vdc to320Vdc nominal.

2.3.1 PSM3U Specifications

2.3.1.1 PSM3U-48V-XXkWPowerSupply

The following table liststhe PSM3U-48V-XXkWspecifications.

Table 2-12.PSM3U-48V-XXkWLow-Power PSSpecifications

Parameter Description Remarks

AC Input voltage (drivesupply):

> Fluctuation Range:single phase 85-

265Vac

Input frequency:

> Nominalfrequency:50Hz

Power Input

> Minimumfrequency: 47Hz

> Maximum frequency: 63Hz

Inrush current: 50A peak

Maximum input current:

> 10.67A @85Vac (for 700W unit)

> 21.3A @85Vac(for 1400Wunit)

Efficiency:81%

Power

Output

Version 2.50.D

Maximum output current:

For 700Wunit:

> 14A (continuous and peak) @

Vin=265Vac

> 10A continuous14A peak @

Vin=85Vac

54

Page 55

MC4UHardwareGuide

2.MC4U Specifications

Parameter Description Remarks

Output voltage:

> Nominalvoltage:51Vdc

> Minimumvoltage:45Vdc

> Maximum voltage:57Vdc

Output power:

> Maximum output power: 700W

(continuous and peak) for 700Wunit

@Vin=265Vac and500W continuous

@Vin=85Vac

The Logic Supply isused to generate all

necessary lowvoltages for the SPiiPlus

Motion Controller.

The Logic Supply ispowered from an

Logic Supply

external24Vdc control supply, andhasthe

following characteristics:

> Input voltage:

- Nominalvoltage:24Vdc

- Minimumvoltage:

21.6Vdc

- Maximum voltage:

26.4Vdc

> Input power: 55W, max.

> Input current: 2.9A, max., @21.6V

control supply input voltage

> Supply inrush current

- Maximum inrush

currentvalueisless

than 4Armsmeasured

within first 400ms after

logic supply input

voltage isapplied.

- After the first 400ms,

the inrush current value

continuously decreases

anddropsbelow2.9A

within 1sec.

> Supply input voltage ripple:

- Maximum input voltage

rippleamplitude: 5V

peak-to-peak at100Hz

frequency

- Inanycondition: the

input voltage level

including the voltage

rippleamplitude must

Version 2.50.D

55

Page 56

MC4UHardwareGuide

2.MC4U Specifications

Parameter Description Remarks

not be lower than21.6V

andnot greater than

26.4V

I2C Circuit

±12Vsupply

for third

party drive

(DC/DC unit)

Power

Supply Fault

output

signal

See I2CCircuit.

The PSM3U-48V-0.7kW PowerSupply

provides the option for supportingadditional

±12Vfor third party drives.

This signal goes to“0” logiclevel and remains

in thislevelif one ofthe power supply

protection circuits isactivated.

2.3.1.2 PSM3U-320V-8kW Power Supply

The following table liststhe PSM3U-320V-8kWspecifications.

For overvoltage fault

recovery,the AC input

must beremoved and

reapplied.

Version 2.50.D

56

Page 57

MC4UHardwareGuide

2.MC4U Specifications

Table 2-13.PSM3U-320V-8kWHigh-PowerPS Specifications

Parameter Description Remarks

Input voltagefluctuation range:

> Single phase 85-265Vac input

(phase-to-neutral)

> Three phase 85-265Vac input

(phase-to-phase)

Input frequency:

> Nominalfrequency:50Hz

> Minimumfrequency: 47Hz

Power Input

> Maximum frequency: 63Hz

Inrush current:

> Maximum inrush current valueis

3.75Arms measured for the first

20msafter power supply input

voltage isapplied.

> After the first 20ms, the inrush

currentvaluecontinuously

decreasesanddrops below

1.3Armswithin 5sec.

Efficiency:

The maximuminput

currentfor the AC

input (drive supply)

must notbe more

than 30A due to the

AC input in

connector J14 of the

MC4UInterface(see

J14 -DriveSupply

Voltage Connector)

> 68% -for 85 -265Vac single phase

supply

> 68% -for 195- 265Vac three

phase supply

Input Power:see Table 2-14 andTable 2-15.

Input Current: see Table 2-16 andTable 2-

17.

Parameter Description Remarks

Maximum output current:

> 16A continuous, 32A peak for 85-

130Vac single phaseinput supply

> 15.5A continuous,31A peakfor

Power Output

195 -265Vacsinglephase input

supply

> 23Acontinuous, 62Apeak for 195

-265Vac three phase input

supply

Version 2.50.D

57

Page 58

MC4UHardwareGuide

2.MC4U Specifications

Parameter Description Remarks

Output Voltage: see Table2-18,Table 2-19

andTable 2-20.

Output Power: see Table2-21,Table 2-22,

andTable 2-23.

The Logic Supply isused to generate all

necessary lowvoltages for the SPiiPlus

Motion Controller.

The Logic Supply ispowered from an

external24Vdc control supply, andhas

the following characteristics:

> Input voltage:

- Nominalvoltage:24Vdc

- Minimumvoltage:21.6Vdc

- Maximum voltage:26.4Vdc

> Input power: 55W, max.

> Input current: 2.9A, max., @21.6V

control supply input voltage

> Supply inrush current

- Maximum inrush current

Logic Supply

> Supply input voltage ripple:

valueislessthan4Arms

measured within first 400ms

after logic supply input

voltage isapplied.

- After the first 400ms, the

inrush current value

continuously decreases and

dropsbelow2.9A within

1sec.

- Maximum input voltage

rippleamplitude: 5Vpeak-to-