Page 1

Commercial Microwave—Technical Information

208/230 VAC, 60 Hz Models

RC17S2 P1333401M RC17SX P1333402M

RC17SDOSI P1333403M RC22S2 P1333404M

DQ22HSI P1333405M MC23MPW2 P1333406M

MC23MPTW2 P1333407M WDYRC22 P1333408M

KFC2W2 P1333409M RC30S2 P1333410M

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual for installation, operating, testing, troubleshooting, and disassembly instruction.

CAUTION

!

All safety information must be followed as provided in Service Manual.

!

WARNING

To avoid the risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

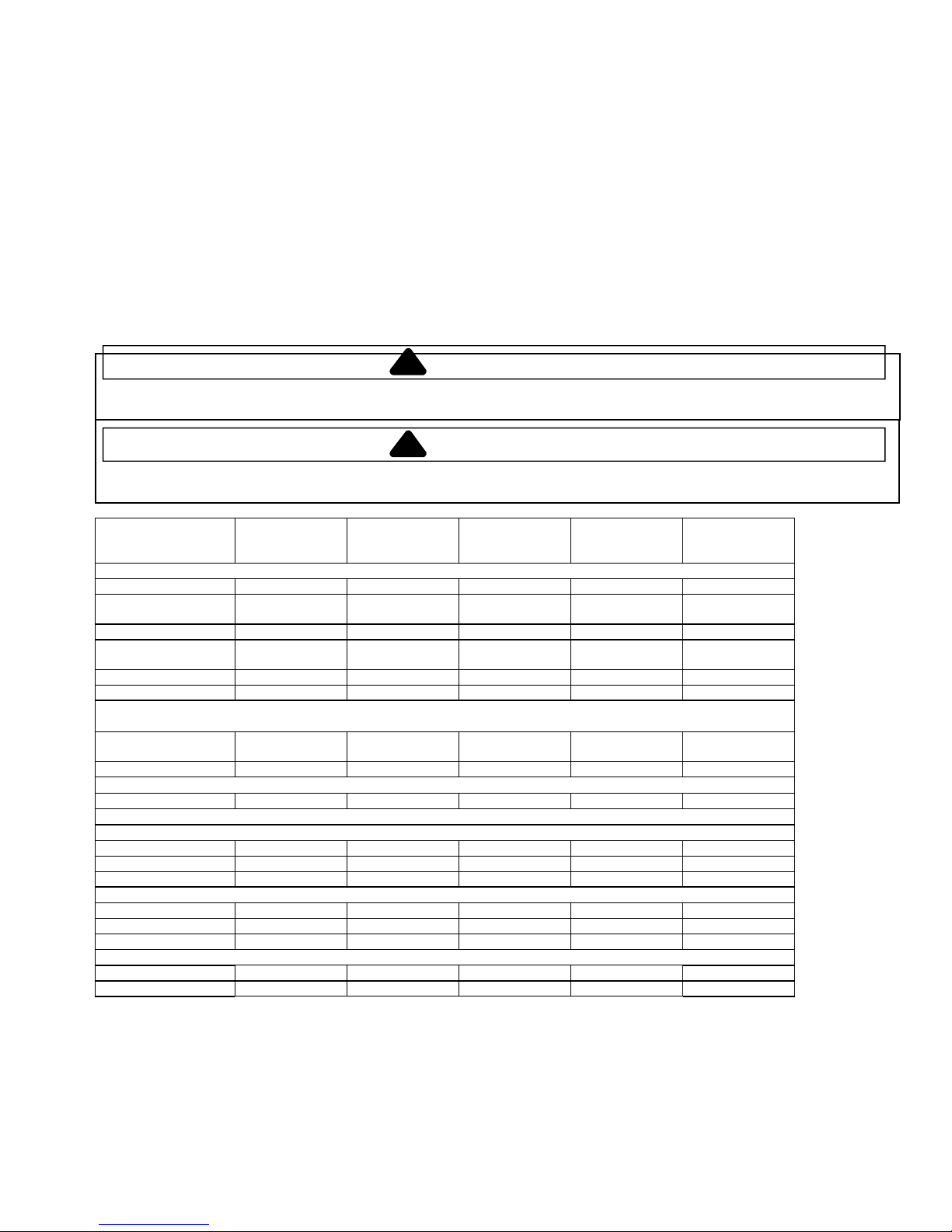

Models RC17S2

Power Source

Voltage AC 208/230 VAC 208/230 VAC 208/230 VAC 208/230 VAC 208/230 VAC

Amperage (Single

Unit)

Frequency 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

Single Phase, 3 wire

grounded

Receptacle 6-20R 6-20R 6-30R 6-30R **

Plug 6-20P 6-20P 6-30P 6-30P **

Power Output −

Microwave

Nominal microwave

energy (IEC705)

Operating Frequency 2450 MHz 2450 MHz 2450 MHz 2450 MHz 2450 MHz

Power Consumption

Microwave only 2700 Watts 3200 Watts 4400 Watts 4100 Watts 3200 Watts

Dimensions

Cabinet (in cm)

Width 19 1/4" 49 cm 19 1/4" 49 cm 19 1/4" 49 cm 19 1/4" 49 cm 19 1/4" 49 cm

Height 18 1/4" 46 cm 18 1/4" 46 cm 18 1/4" 46 cm 18 1/4" 46 cm 18 1/4" 46 cm

Depth 26 1/4" 67 cm 26 1/4" 67 cm 26 1/4" 67 cm 26 1/4" 67 cm 26 1/4" 67 cm

Oven Interior (in cm)

Width 13" 33 cm 13" 33 cm 13" 33 cm 13" 33 cm 13" 33 cm

Height 8 1/2" 22 cm 8 1/2" 22 cm 8 1/2" 22 cm 8 1/2" 22 cm 8 1/2" 22 cm

Depth 15" 38 cm 15" 38 cm 15" 38 cm 15" 38 cm 15" 38 cm

Weight

Uncrated 94 lbs. 94 lbs. 115 lbs. 115 lbs. 115 lbs.

Crated 101 lbs. 101 lbs. 123 lbs. 123 lbs. 123 lbs.

RC17SX

RC17SD2OSII

20 A 20 A 30 A 30 A 20 A

X X X X X

1700 Watts 2200 Watts 3000 Watts 2700 Watts 2000 Watts

RC22S2

DQ22HSI2

WDYRC22

RC30S2 KFC2W2 MC23MPTW2

MC23MPW2

** MC23MPTW2, MC23MPW2 uses 20A Twist−Loc NEMA L6-20P plug

January 2012 1 16500030

©2012 ACP, Inc.

Page 2

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

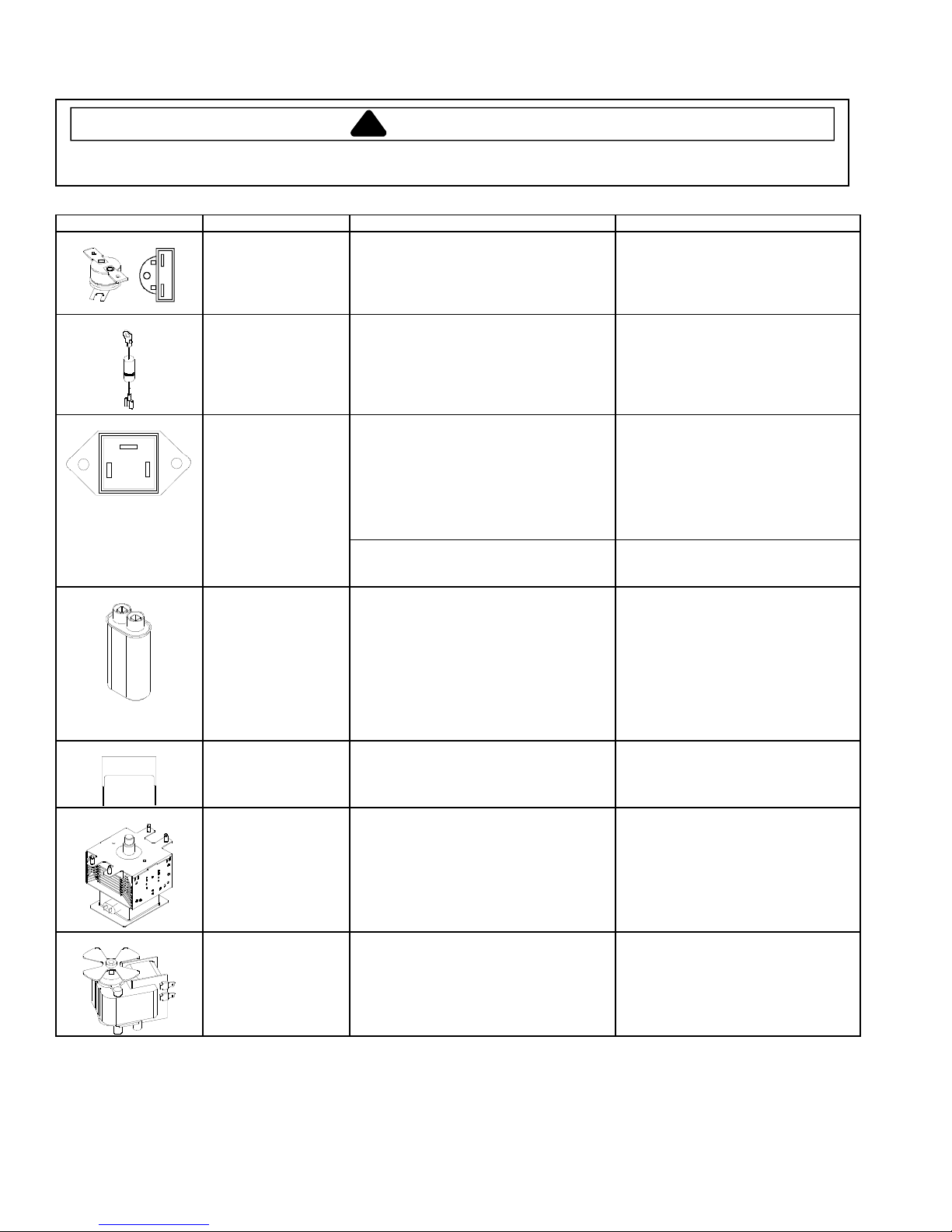

Illustration Component Test Results

MT2

MT1 GATE

Triac 1 (center)

Triac 2 (left)

Triac 3 (right

Thermal cutout Disconnect all wires from TCO.

Diode

Triac

Capacitor

Some units may use

more then one type of

capacitor. Refer to

Parts Manual for

correct capacitor

quantity.

Snubber assembly Disconnect wires to snubber.

Magnetron

Blower motor Remove all wires from motor.

Measure resistance across terminals.

Magnetron TCO ....................................

Cavity TCO ............................................

Discharge Capacitor

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Resistance Check

Disconnect wires to triac.

Measure resistance from:

MT1 to MT2 ...........................................

MT1 to Gate ..........................................

MT2 to Gate ..........................................

All terminals to ground ..........................

Voltage Check

Measure voltage from:

MT1 to Gate

Discharge Capacitor

Remove wires from capacitor terminals

and connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Measure resistance across terminals ........

Discharge Capacitor

Remove wires from magnetron and

connect ohmmeter to terminals. Also

check between each terminal and ground.

Measure resistance across coil .................

Open at 300°F (149°C) and

closed at 257°F (125°C)

Opens at 262°F (128°C)

Infinite resistance should be measured

in one direction and 50KΩ or more in

the opposite direction.

NOTE: Ohmmeter must contain a

battery of 6 volts minimum.

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite

Approximately 60 Ω

Infinite

Infinite

0.8 VAC when energized. If no

voltage, check H.V. board and wiring.

Between Terminals: Meter should

momentarily deflect towards zero then

return to over 5 MΩ. If no deflection

occurs, or if continuous deflection

occurs, replace capacitor.

Terminal to Case: Infinite resistance

Infinite

Between Terminals: Less than 1 Ω

Each terminal to ground measures

Infinite resistance.

Note: This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

Approximately 25 Ω

16500030 January 2012

2

©2012 ACP, Inc.

Page 3

Component Testing Procedures

4

!

WARN ING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

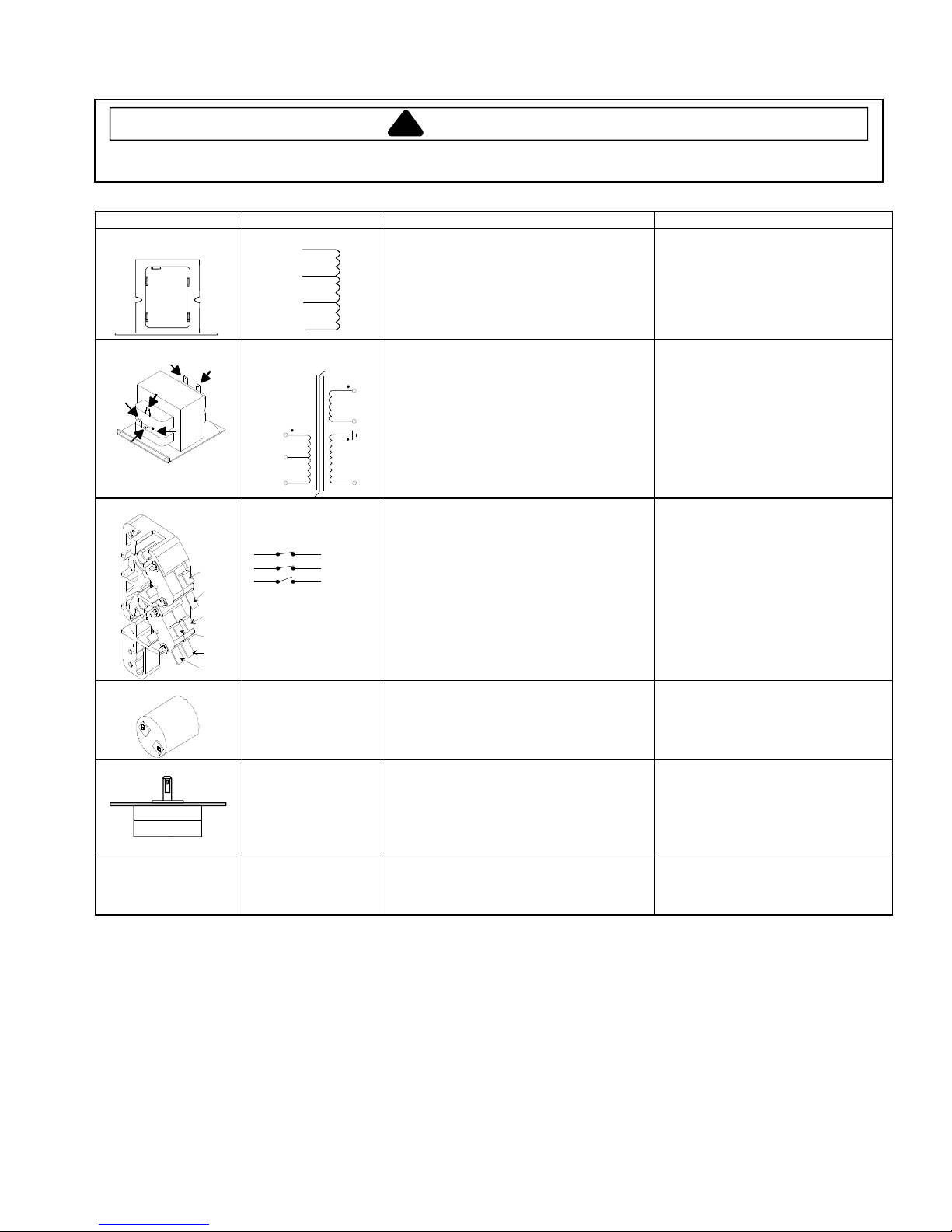

Illustration Component Test Results

COM

0 V

120 V

COM

208

Auto Transformer

230

208 V

230 V

6

4

5

230

7

8

2

3

5

208

120

0

Transformer

COM

208 VAC

230 VAC

Interlock switch

Door Closed

2

4

7

Secondary

3

Primary

5

Monitor

8

Lamp receptacle

Discharge Capacitors

Remove all wires from terminals.

Measure resistance from:

230 V to 0 V ..............................................

208 V to 0 V ..............................................

120 V to 0 V ..............................................

Discharge Capacitor

Remove all wires from terminals.

5

Measure resistance from:

230 to COM ..............................................

6

208 to COM ..............................................

230 to Ground...........................................

208 to Ground...........................................

Terminal 5 to 6 .........................................

4

Terminal 4 to Ground ...............................

Disconnect wires to switch.

With door open measure resistance from:

Terminal 2 to 3 .........................................

Terminal 4 to 5 .........................................

Terminal 7 to 8 .........................................

With door closed measure resistance from:

Terminal 2 to 3 .........................................

Terminal 4 to 5 .........................................

Terminal 7 to 8 .........................................

Test continuity of receptacle terminals. Indicates continuity if bulb is good

(some models)

Approximately 38 Ω

Approximately 37 Ω

Approximately 25 Ω

Less than 1 Ω

Less than 1 Ω

Infinite

Infinite

Less than 1 Ω

Approximately 59 Ω

Infinite

Infinite

Indicates continuity

Indicates continuity

Indicates continuity

Infinite

and screwed in.

Refer to Parts Manual

Antenna motor Remove all wires from terminals.

Power cord Measure resistance of wires. Continuity should be indicated on

for proper power cord

part number.

January 2012 16500030

©2012 ACP, Inc.

Measure resistance from:

Terminal to terminal .....................................

3

Approximately 12K Ω

each wire.

Verify polarity and grounding.

Page 4

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

Illustration Component Test Results

Side touch panel

Top touch panel Removal of touch panel is required to

Continuity is indicated as 100 Ω and

below.

perform test.

Continuity is indicated as 100 Ω and

below.

Pad

1

2

3

1

4

5

6

7

8

9

0

Start

Stop/Reset

Pad

Time Entry

Power Level

Stage

Program Save

Quantity

Menu

Hidden Pad

Trace

3 & 5

3 & 6

3 & 7

3 & 8

3 & 9

4 & 5

4 & 6

4 & 7

4 & 8

4 & 9

5 & 6

6 & 9

Trace

5 & 7

5 & 8

5 & 9

6 & 7

6 & 8

7 & 9

8 & 9

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

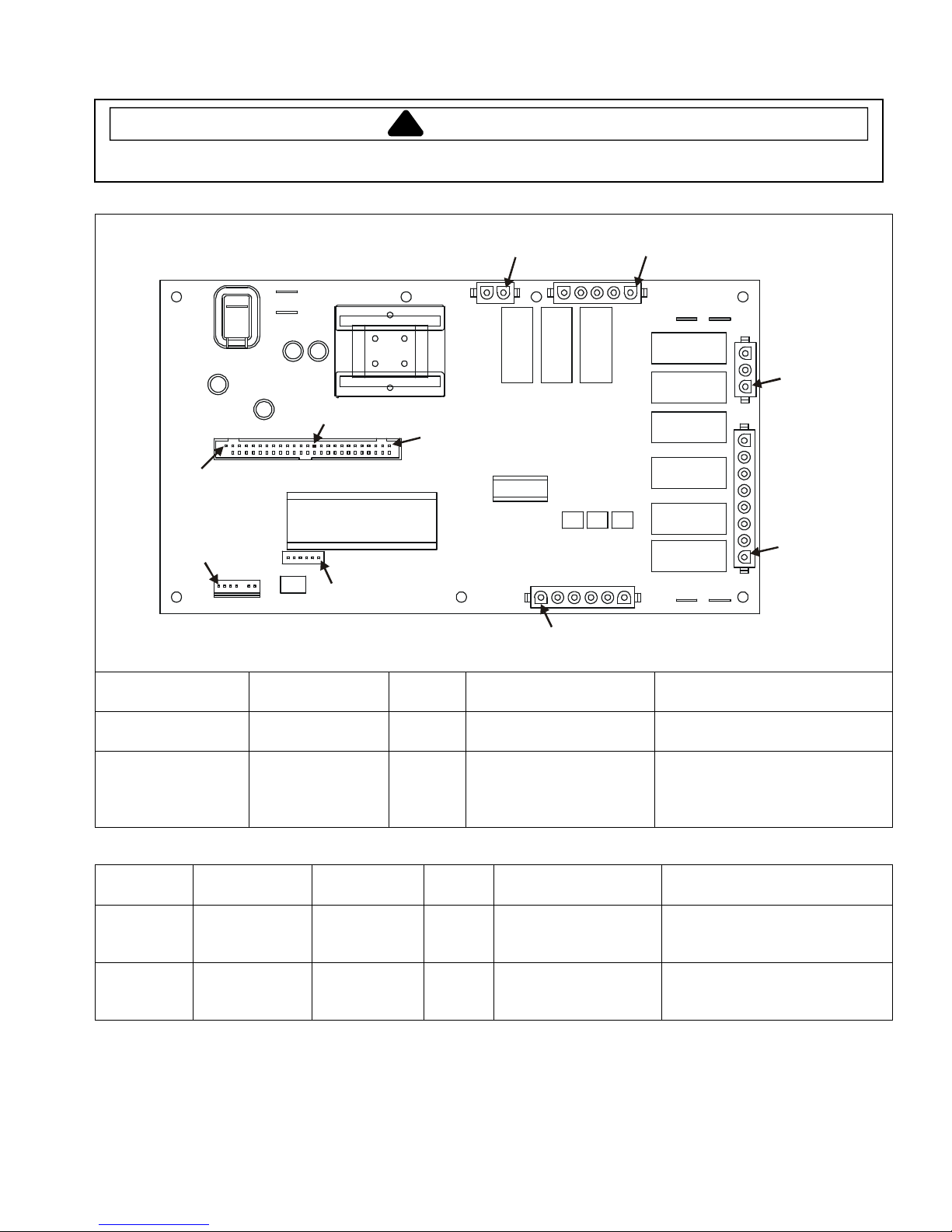

Display board

Pin 1

Side

Touch

Panel

Pin 1

Pin 1

Connector

J5

A B

Test Points

Function Test Set-Up Meter

Setting

Input to Display

Board

At Display

Board

Volts Test points A and B 3.0 VAC

1

Interlock

Connector

J1

J6

Probe Placement Results

H.V. board

Connector

If voltage is present and no display is

indicated, replace display board.

If no voltage is present, check wire

harness connections and H.V. board.

Pin 1

J4

Top

Touch

Panel

Connector

16500030 January 2012

4

©2012 ACP, Inc.

Page 5

Component Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

H.V. board

E2

E1

E3

WARN ING

Pin 1

J1

Pin 1

J2

E4 E5

Pin 1

J5

Pin 28

Pin 50

J3

Pin 1

Pin 1

J6

Pin 1

J8

Pin 1

J7

Pin 1

Function Test Set-Up Meter

Setting

Input to H.V. board At H.V. board Volts J1 pin 1 (Brown wire)

Output to display

board

NOTE: For the following test, place oven in Service Test Mode (see page 11).

Relay Function Test Set-Up Meter

K1 at

230 VAC

line voltage

K2 at

208 VAC

line voltage

Blower motor

Antenna motor

Cavity light

Blower motor

Antenna motor

Cavity light

Disconnect

J5 connector,

blower runs

continuously

Disconnect

J2 connector

Disconnect

J2 connector

Volts J5 pin 28 &

Setting

Ohms J1 pin 1 (Brown wire)

Ohms J1 pin 1 (Brown wire)

Probe Placement Results

& J1 pin 2 (White wire)

J5 pin 50

Probe Placement Results

& J2 pin 4

& J2 pin 3

E7 E6

Line voltage

- 24 VDC

Test mode 5 off − no continuity

Test mode 5 on − < 1 Ω

Test mode 5 off − no continuity

Test mode 5 on − < 1 Ω

J4

January 2012 16500030

©2012 ACP, Inc.

5

Page 6

Component Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

H.V. Board − Relay Test

Three Magnetron Models − KFC2W2, MC23MPTW2, MC23MPW2,and RC30S2

Relay Function Test Set-Up Meter

Setting

K8

K9 Magnetron 1

K4

K5 Magnetron 2

K6

K7 Magnetron 3

Magnetron 1

(Top rear) at

230 VAC

(Top rear) at

208 VAC

Magnetron 2

(Top front) at

230 VAC

(Top front) at

208 VAC

Magnetron 3

(Bottom) at

230 VAC

(Bottom) at

208 VAC

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

VAC E2 (Black wire)

VAC E2 (Black wire)

VAC E5 (Red wire)

VAC E5 (Red wire)

VAC J4 pin 4 (Black wire)

VAC J4 pin 4 (Black wire)

Probe Placement Results

Test mode 1 off − line voltage

& J4 pin 2 (Red wire)

& J4 pin 1 (White wire)

& J3 pin 1 (Gray wire)

& J3 pin 3 (Orange wire)

& J4 pin 6 (Black wire)

& J4 pin 5 (Brown wire)

Test mode 1 on − 0 volts

Test mode 1 off − line voltage

Test mode 1 on − 0 volts

Test mode 2 off − line voltage

Test mode 2 on − 0 volts

Test mode 2 off − line voltage

Test mode 2 on − 0 volts

Test mode 3 off − line voltage

Test mode 3 on − 0 volts

Test mode 3 off − line voltage

Test mode 3 on − 0 volts

Two Magnetron Models − DQ22HSI2, RC17S2, RC17SX, and RC22S2

Relay Function Test Set-Up Meter

K8

K9 Magnetron 1

K6

K7 Magnetron 3

16500030 January 2012

Magnetron 1

(Top rear) at

230 VAC

(Top rear) at

208 VAC

Magnetron 3

(Bottom) at

230 VAC

(Bottom) at

208 VAC

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

All wires

connected to

H.V. board

Probe Placement Results

Setting

VAC E5 (Red wire)

& J4 pin 2 (Red wire)

VAC E5 (Red wire)

& J4 pin 1 (White wire)

VAC J4 pin 4 (Black wire)

& J4 pin 6 (Black wire)

VAC J4 pin 4 (Black wire)

& J4 pin 5 (Brown wire)

6

Test mode 1 off − line voltage

Test mode 1 on − 0 volts

Test mode 1 off − line voltage

Test mode 1 on − 0 volts

Test mode 3 off − line voltage

Test mode 3 on − 0 volts

Test mode 3 off − line voltage

Test mode 3 on − 0 volts

©2012 ACP, Inc.

Page 7

Component Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARN ING

Three Magnetron Models

# 3

# 1

# 2

# 2

# 1

# 2

# 1

# 3

# 2

H.V. System # 1 H.V. System # 2 H.V. System # 3

Top Rear Magnetron

Center Transformer

Bottom Center Capacitor

Diode

Center Triac

Top Front Magnetron

Left Transformer

Top Left Capacitor

Diode

Left Triac

# 3

# 3

# 1

Bottom Magnetron

Right Transformer

Right Capacitor

Diode

Right Triac

January 2012 16500030

©2012 ACP, Inc.

7

Page 8

Component Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

Two Magnetron Models

# 1

# 1

# 1

# 3

# 3

# 1

H.V. System # 1 H.V. System # 3

Top Rear Magnetron

Left Transformer

Top Capacitor

Diode

Left Triac

# 3

Bottom Magnetron

Right Transformer

Bottom Capacitor

Diode

Right Triac

# 3

16500030 January 2012

8

©2012 ACP, Inc.

Page 9

Power Testing Procedure

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

All Amana and Menumaster microwave oven power outputs are rated using the IEC705 standards. Using the

IEC705 test method requires precision measurements and equipment that is not practical to be performed in the

field. Using the test shown below will indicate if the oven performance is satisfactory.

WARN ING

Test equipment required:

• 1000 ml test container and thermometer (ACP power test bowl part # 12018801).

• Digital watch / watch with a second hand for use on ovens with electromechanical timers.

Important Notes:

• Low line voltage will cause low temperature rise / power output.

• Ovens must be on a dedicated circuit, properly grounded, and polarized. Other equipment on the same

circuit may cause a low temperature rise / power output.

• This test and results are not a true IEC705 test procedure and are only intended to provide servicers with an

easy means of determining if the microwave oven cooking output is correct.

Procedure

1. Fill the test container to the 1000 ml line with cool tap water.

NOTE: Water temperature should be approximately 60°F / 16°C

2. Using the thermometer, stir water for five to ten seconds; measure, and record the temperature (T1).

3. Place test container of water in the center of oven cavity and close door.

4. Heat the water for a 33-second full power cycle.

NOTE: Use a digital watch or a watch with a second hand for ovens with electromechanical timers.

5. At end of the cycle, remove test container. Using the thermometer, stir water for five to ten seconds and record

temperature (T2).

6. Subtract the starting water temperature (T1), from the ending water temperature (T2) to obtain the temperature

rise (∆T).

7. If the temperature rise (∆T) meets or exceeds the minimum, the test is complete. If the temperature rise (∆T)

fails to meet the minimum temperature rise, test the line voltage to verify it is correct. Then repeat steps 1 - 6

making sure to change the water. If the temperature rise (∆T) fails to meet the minimum temperature rise again

the oven will require service.

Minimum Temperature Rise at Thirty -Three (33) Seconds Run Time

∆T Cooking ∆T Cooking ∆T Cooking ∆T Cooking

(°F) Power Output (°F) Power Output (°C) Power Output (°C) Power Output

10.................. 1000 20 ................. 2000 5 ............... 1000 11 ............ 2000

11.................. 1100 21 ................. 2100 5.5 ............. 1100 11.5 ......... 2100

12.................. 1200 22 ................. 2200 6.5 ............. 1200 12 ............ 2200

14.................. 1400 24 ................. 2400 7.5 ............. 1400 13 ............ 2400

17.................. 1700 25 ................. 2500 9.5 ............. 1700 13.5 ......... 2500

18.................. 1800 27 ................. 2700 10 .............. 1800 15 ............ 2700

19.................. 1900 30 ................. 3000 10.5 ........... 1900 16.5 ......... 3000

January 2012 16500030

©2012 ACP, Inc.

9

Page 10

Display Diagnostics

•

•

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

CAUTION

!

All repairs as described in this troubleshooting section are to be performed only after the caution procedures one through eight

listed below have been followed.

1. Check grounding before checking for possible causes.

2. Be careful of the high voltage circuit.

3. Discharge high voltage capacitor.

4. When checking the continuity of the switches or the high voltage transformer, disconnect one lead wire from these parts and

then check continuity with the AC plug removed. To do otherwise may result in a false reading or damage to your meter.

5. Do not touch any parts of the circuitry on the P.C. Board circuit since static electric discharge may damage this control

panel. Always touch yourself to ground while working on this panel to discharge any static charge in your body.

6. 208/230 VAC is present in the high voltage circuit board, power relay and primary circuit of low voltage transformer.

7. When troubleshooting, be cautious of possible electrical hazard.

Error Codes

During operation, the display may show the following service codes:

NOTE: Before scheduling service for any error codes, instruct customer to unplug oven for 1 minute,

reconnect power, and retest. If unit operates properly, no service call is required.

Display Description Corrective Action

Err1 Failed H.V. Board Replace H.V. board.

Err2 Shorted Touch Panel

Failed H.V. Board

Shorted Display Board

Shorted Cable HV to Display Board

Err3 Failed H.V. Board Replace H.V. board.

Err4 Failed H.V. Board Replace H.V. board.

Err5 Shorted Touch Panel

Err6 Failed H.V. Board Replace H.V. board.

HOT

Door Door Interlock Primary Switch

Replace Touch Panel.

Replace H.V. board.

Replace Display Board.

Replace Cable.

NOTE: If Touch Panel is pressed for more than 30 seconds, this error code

will appear.

1. Disconnect oven from power supply.

2. Disconnect side touch panel connector from display board (J5).

3. Reconnect oven to power supply.

4. If “Err5” reappears after 30 seconds, replace top touch panel.

5. If “Err5” does not reappear after 30 seconds, replace side touch panel.

• Open TCO (magnetron).

• Blower motor inoperative.

• Restricted air filter.

• High ambient temperature.

• Oven operated empty or with light loads.

• Broken or loose wire.

H.V. board inoperative.

• Verify latch mechanism moves freely on door.

• Verify J1 connector on display board is properly seated.

• Test interlock switch assembly and perform door adjustment if necessary.

Replace interlock switch assembly.

16500030 January 2012

10

©2012 ACP, Inc.

Page 11

Service Test

NOTE: Unit must be in OFF condition

or

INITIAL power up mode.

To Enter Service Test Mode, oven door must be closed.

NOTE: Pads will not beep when accessing Service Test Mode.

To EXIT Service Test Mode press STOP/RESET pad.

REG MENU

MISC

MC units

DQ22HSI and KFC2

RC units

Pad 1

Pad 2

Mode Name

Entry

Functional

Description

Display

S e r v i

6 0 H Z 2 0 8 V

Mode Name

Entry

Functional

Description

Display

M a g n e t r

0 0 : 4 5 A m p s : 1 2

Mode Name

Entry

Functional

Description

Display

Service Mode

Pressing Hidden Pad, 1, 3, 5, 7, 9 while in the ready mode:

Main Service Mode Menu

c e M o d e

Service Pad 1

Pressing Pad 1 while in Service Mode

Magnetron #1 shall be toggled. When on, it shall run for 62 seconds.

Service Pad 2

Pressing Pad 2 while in Service Mode

Magnetron #2 shall be toggled. When on, it shall run for 62 seconds.

o n # 1 : O N

M a g n e t r

0 0 : 4 5 A m p s : 1 2

Note: Not applicable on two magnetron models:

Pad 3

January 2012 16500030

©2012 ACP, Inc.

Mode Name

Entry

Functional

Description

Display

M a g n e t r

0 0 : 4 5 A m p s : 1 2

o n # 2: O N

Service Pad 3

Pressing Pad 3 while in Service Mode

Magnetron #3 shall be toggled. When on, it shall run for 62 seconds.

o n # 3: O N

11

Page 12

Service Test

Pad 5

Pad 7

Mode Name

Entry

Functional

Description

Display

A u x . O

Mode Name

Entry

Functional

Description

Display

M a g n e t r

0 0 1 7 4 3

Service Pad 5

Pressing Pad 5 while in Service Mode

Auxiliary Output shall be toggled.

u t p u t : O N

Service Pad 7

Pressing Pad 7 while in Service Mode

Displays Tube Hours stored in EEPROM

o n H o u r S

Pad 8

Pad 9

Mode Name

Entry

Functional

Description

Display

D o o r

0 0 2 4 5 3 8 0

Mode Name

Entry

Functional

Description

Display

P r e s s S

C l e a r s e r v . i n f o

Service Pad 8

Pressing Pad 8 while in Service Mode

Displays Door Cycles stored in EEPROM. Will always be a multiple of

ten.

C y c l e s

Service Pad 9

Pressing Pad 9 while in Service Mode

Prompts user to clear service information.

T A R T t o

16500030 January 2012

12

©2012 ACP, Inc.

Page 13

Service Test

DQ22HSI2 RC17S2 RC17SX RC22S2

January 2012 16500030

©2012 ACP, Inc.

12719301

13

Page 14

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

DQ22HSI2 RC17S2 RC17SX RC22S2

16500030 January 2012

12719301

DANGER

!

HIGH VOLTAGE

14

©2012 ACP, Inc.

Page 15

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

KFC2W2 MC23MPW2 MC23MPTW2 RC30S2

January 2012 16500030

©2012 ACP, Inc.

12719101

15

Page 16

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

WARNING

KFC2W2 MC23MPW2 MC23MPTW2 RC30S2

16500030 January 2012

12719101

DANGER

!

HIGH VOLTAGE

16

©2012 ACP, Inc.

Loading...

Loading...