Acorn SV16 User Manual

ACORN ENGINEERING COMPANY

P.O. BOX 3527

CITY OF INDUSTRY, CA 91744

UNITED STATES OF AMERICA

WWW.ACORNENG.COM

Patent Pending

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

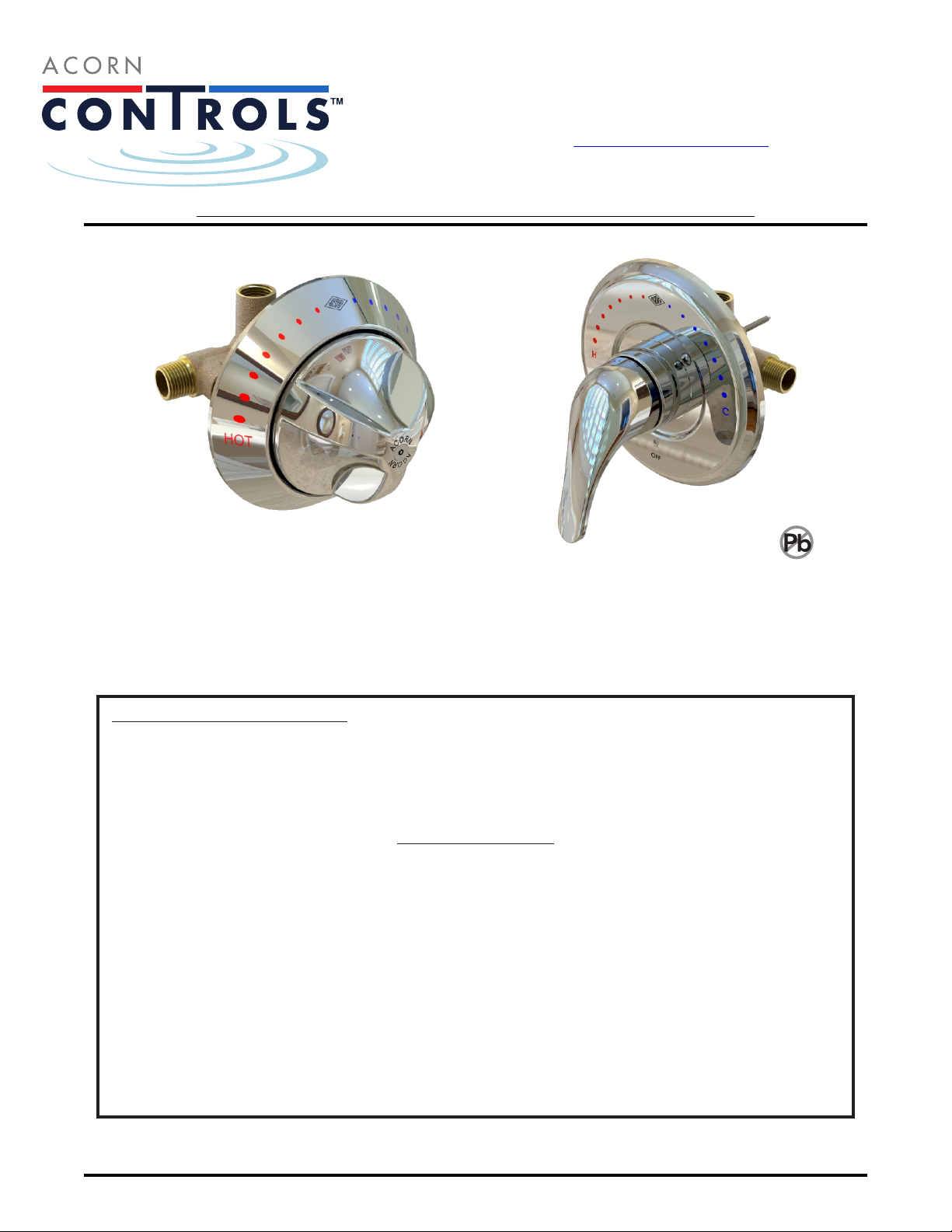

SV16 TEMPERATURE/PRESSURE BALANCING MIXING VALVE

Patented Tri-Lever

Handle

Model SV16

Model SV16-LVR

FOR TECHNICAL ASSISTANCE

1.800.743.8259

fieldservice@acorneng.com

Federal

Public Law

111-380

(No Lead)

NOTES TO THE INSTALLER:

1. Please leave this documentation with the owner of the fixture when finished.

2. Please read this entire booklet before beginning the installation.

3. Check your installation for compliance with plumbing and other applicable codes.

LIMITED WARRANTY

UNITED STATES AND CANADA

Acorn Controls warrants that its products are free from defects in material or workmanship under normal use and

service for a period of one year from date of shipment. Acorn's liability under this warranty shall be discharged solely

by replacement of repair of defective material, provided Acorn is notified in writing within one year from date of

shipment, F.O.B. Industry, California.

This warranty does not cover installation or labor charges and does not apply to materials, which have been

damaged by other causes such as mishandling or improper care or abnormal use. The repair or replacement of the

defective materials shall constitute the sole remedy of the Buyer and the sole remedy of Acorn under this warranty.

Acorn shall not be liable under any circumstances for incidental, consequential or direct charges caused by defects in

materials, or any delay in the repair or replacement thereof. This warranty is in lieu of all other warranties expressed

or implied. Product maintenance instructions are issued with each unit and disregard or non-compliance with these

instructions will constitute an abnormal use condition and void the warranty.

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Date: 07/10/14Manual #7802-116-000

SV16 Installation & Operation Manual

WARNING:

!

Thoroughly read all installation instructions and

product safety information before beginning the

installation of this product.

FAILURE TO READ AND FOLLOW PROPER

INSTALLATION AND MAINTENANCE

INSTRUCTIONS MAY RESULT IN PRODUCT

FAILURE WHICH CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY AND/OR

DEATH.

Acorn Controls is not responsible for damages

resulting from improper installation and/or

maintenance. Installation of this valve shall be in

accordance with Uniform Plumbing Code.

TO ENSURE ACCURATE AND RELIABLE

OPERATION OF THIS PRODUCT, IT IS

ESSENTIAL TO:

ŸProperly design the system to minimize

pressure and temperature variations.

ŸImplement an annual maintenance program to

ensure proper operation and temperature

setting of valve(s).

ŸThis valve is factory preset, however it can be

adjusted. It is the responsibility of the installer

and or facility maintenance personal to make

sure valve outlet temperature does not exceed

115°F (46°C) after installation, maintenance or

repair.

SUPPLIES REQUIRED:

(Not provided by Acorn)

1. Wall anchors, screws, nuts and washers as

required.

2. Teflon tape for sealing water connections.

3. Allen wrenches for lever handle and bonnet set

screws.

4. Copper pipe adapters as required.

5. Snap-ring pliers with pins less than 0.03”

!

IMPORTANT

ŸFlush supply lines of all foreign material such

as pipe dope, chips or solder prior to

connecting to mixing valve.

ŸTo ensure proper installation review the

manual thoroughly to verify rough-ins before

beginning any work.

ŸInstallation and field adjustment are the

responsibility of the installer.

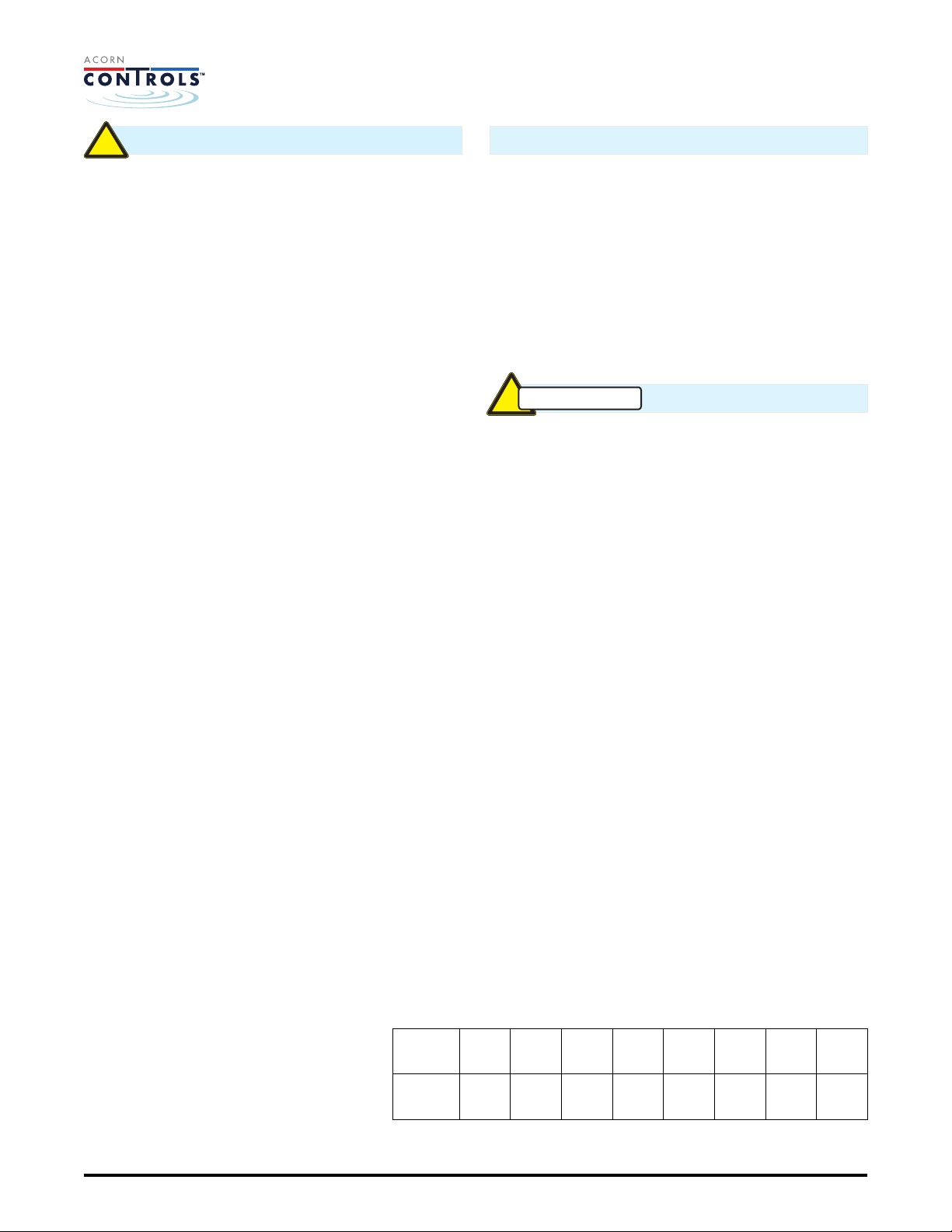

ŸMaximum water pressure is 125 psi (8.62

bars). Maximum inlet hot water temperature is

180°F (82°C). Temperature adjustment range

is 85-115°F (29-46°C). Valve assembly must

be drained prior to being subjected to freezing

temperatures. Valve includes integral checks

stops.

PRESSURE

DROP

PSID (KPA)

FLOW RATE

GPM (LPM)

CV

0.6

5

(34)

1.3

(5)

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Manual #7802-116-000 Date: 07/10/14

10

(69)

1.9

(7.1)

15

(103)

2.3

(8.7)

20

(138)

2.7

(10)

30

(207)

3.3

(12.4)

45

(310)

4

(15.1)

60

(414)

4.6

(17.5)

Page 2 of 8

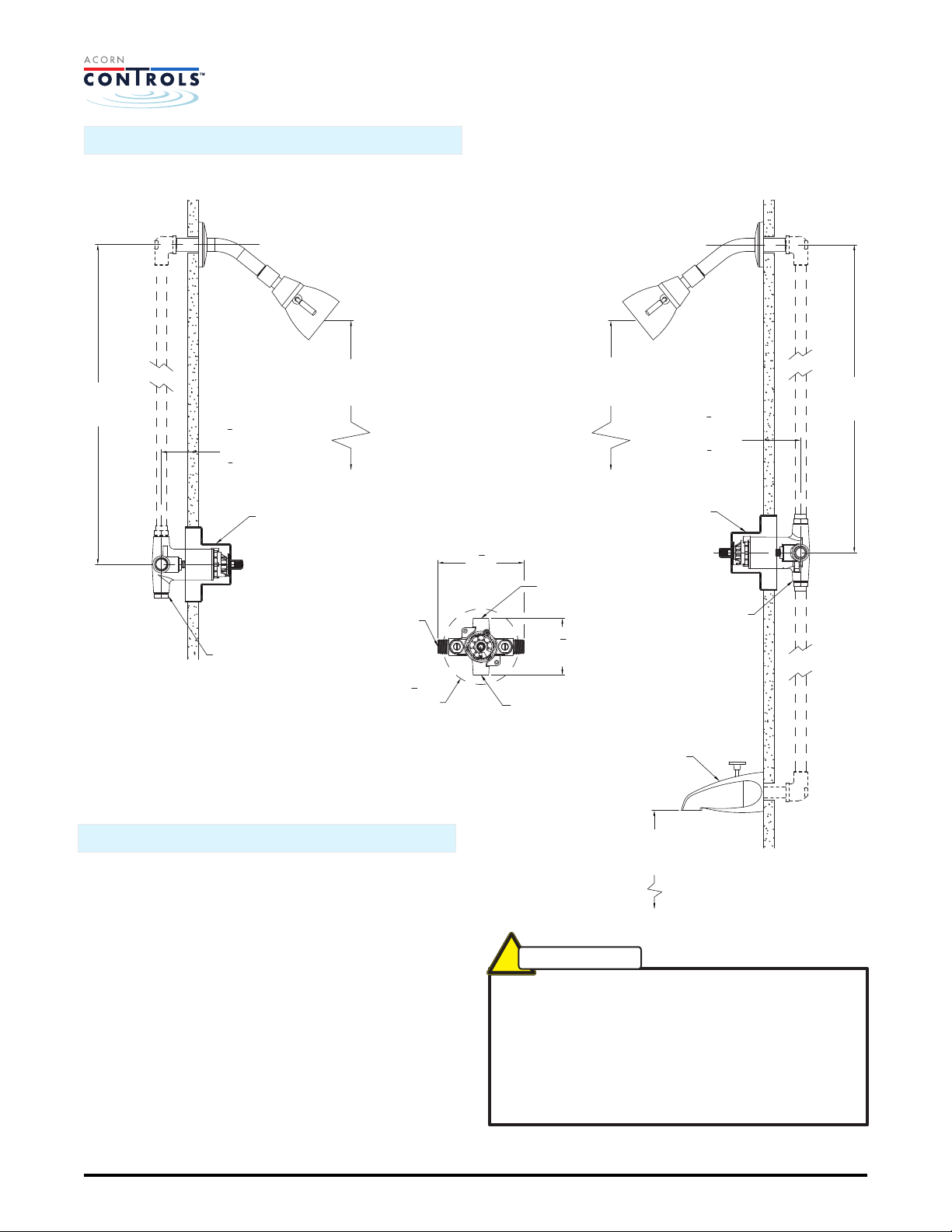

ROUGH-IN DIMENSIONS:

SV16 Installation & Operation Manual

72"

(1829)

A.F.F.

3

1

" (44)

4

MIN.

1

2

" (64)

2

MAX.

ROUGH-IN

GUIDE

1/2" NPT

3

"

8

TUB SPOUT

CONNECTION

OPTIONAL

24"

(610)

REF.

FIGURE 1

3

1

" (44)

4

MIN.

1

2

" (64)

2

MAX.

ROUGH-IN

GUIDE

1/2" NPT PLUG

72"

(1829)

A.F.F.

COMBINATION

1/2" NPT AND

1/2" SWEAT

CONNECTIONS

Ø4

(114)

ROUGH-IN

1

5

"

8

(130)

1

"

2

1/2" NPT

FEMALE

CONNECTION

3

(86)

1/2" NPT

FEMALE

CONNECTION

Patent Pending

SPECIFICATIONS:

Connections: ................... Combination 1/2" NPT and

20"

(508)

A.F.F.

1/2” sweat Inlet-Connections

Riser Connection: ...................................... 1/2" NPT

FIGURE 2

Flow Rate: ........... 4 gpm (15 lpm) @ 45 psi (310 kpa)

Differential

Hot Water Supply Temp.: ........ 110°-180°F (43°-82°C)

Cold Water Supply Temp.: ......... 35°-80°F (1.7°-27°C)

Approach Temperature*: .......................

10°F (5.5°C)

Maximum Operating Pressure: .......... 125psi (862kpa)

Temperature Ranges*: .................

Minimum Flow: ............................................

85°-115°F (29-46°C)

1.25 gpm (4.7 lpm)

*Please refer to ASSE 1016-2011 for other test condition

which may or may not equal installed conditions.

NOTE;

ALL DIMENSIONS ARE IN INCHES (MM).

!

IMPORTANT

Excessive overheating of valve during soldering

may damage the cartridge and checkstops. Do

not heat valve any higher than needed to flow

solder. If a higher temperature method is being

used all internal components must be

removed. See figures 8 for cartridge removal

and 10 for temperature limit setting.

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Manual #7802-116-000

24"

(610)

REF.

Page 3 of 8

Date: 07/10/14

Loading...

Loading...