Acorn SFET User Manual

ACORN ENGINEERING COMPANY

P.O. BOX 3527

CITY OF INDUSTRY, CA 91744

UNITED STATES OF AMERICA

WWW.ACORNENG.COM

SFET EMERGENCY THERMOSTATIC MIXING VALVE SUPPLY FIXTURE

Patent Pending

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Model SFET Series

FOR TECHNICAL ASSISTANCE

1.800.743.8259

fieldservice@acorneng.com

Federal

Public Law

111-380

(No Lead)

NOTES TO THE INSTALLER:

1. Please leave this documentation with the owner of the fixture when finished.

2. Please read this entire booklet before beginning the installation.

3. Check your installation for compliance with plumbing and other applicable codes.

LIMITED WARRANTY

UNITED STATES AND CANADA

Acorn Controls warrants that its products are free from defects in material or workmanship under normal use and

service for a period of one year from date of shipment. Acorn's liability under this warranty shall be discharged solely

by replacement of repair of defective material, provided Acorn is notified in writing within one year from date of

shipment, F.O.B. Industry, California.

This warranty does not cover installation or labor charges and does not apply to materials, which have been

damaged by other causes such as mishandling or improper care or abnormal use. The repair or replacement of the

defective materials shall constitute the sole remedy of the Buyer and the sole remedy of Acorn under this warranty.

Acorn shall not be liable under any circumstances for incidental, consequential or direct charges caused by defects in

materials, or any delay in the repair or replacement thereof. This warranty is in lieu of all other warranties expressed

or implied. Product maintenance instructions are issued with each unit and disregard or non-compliance with these

instructions will constitute an abnormal use condition and void the warranty.

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Date: 04/01/14Manual #7802-119-000

SFET Installation & Operation Manual

WARNING:

!

You are required to thoroughly read all installation

instructions and product safety information before

beginning the installation of this product.

FAILURE TO READ AND FOLLOW PROPER

INSTALLATION AND MAINTENANCE

INSTRUCTIONS MAY RESULT IN PRODUCT

FAILURE WHICH CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY AND/OR DEATH.

Acorn Controls is not responsible for damages

resulting from improper installation and/or

maintenance. Installation of this valve shall be in

accordance with Uniform Plumbing Code.

TO ENSURE ACCURATE AND RELIABLE

OPERATION OF THIS PRODUCT, IT IS ESSENTIAL

TO:

Ÿ Properly design the system to minimize

pressure and temperature variations.

Ÿ Implement an annual maintenance program

to ensure proper operation and temperature

setting of valve(s).

Ÿ This valve is factory preset. However, it can

be adjusted. It is the responsibility of the

installer and/or facility maintenance personnel

to make sure valve outlet temperature does

not exceed 95°F (35°C) after installation,

maintenance or repair.

Ÿ Installer MUST VERIFY operation of the Cold

Water By-Pass after completing installation

and temperature adjustments. Simulate a hot

water supply failure by closing the hot water

supply ball valve or by other means available.

Ÿ In circumstances where chemical reaction is

accelerated by flushing fluid temperature, a

medical advisor should be consulted for the

optimum temperature for each Application.

Ÿ Acorn's optional locking ball valves are the safe

and acceptable method for supply shut-off to this

product, unless installed in a lockable cabinet or

other means to prevent unauthorized supply shut

off. After initial set-up and after each ANSI and

ASSE required testing of this product be CERTAIN

to lock the Acorn or installer supplied ball valve

open. If installing supply shut-off valves by others,

you MUST follow ANSI Z358 and ASSE 1071

requirements that unauthorized supply shut off be

prevented.

Ÿ Verify that no single emergency fixture supplied by

this device has a minimum flow rate less than

1.5 gpm (5.7 lpm).

SUPPLIES REQUIRED:

(Not provided by Acorn)

1. Wall anchors, screws nuts and washers as

required.

2. Lead free solder and flux sealing water

connections.

3. Pipe fitting.

4. Wrench and an allen wrench.

!

IMPORTANT

Flush supply lines of all foreign material such as pipe

Ÿ

dope, chips or solder prior to connecting to mixing

valve.

To ensure proper installation review the manual

Ÿ

thoroughly to verify rough-ins before beginning any

work.

Installation and field adjustment are the responsibility

Ÿ

of the installer.

Maximum water pressure is 125 psi (8.62 bars).

Ÿ

Maximum inlet hot water temperature is 180°F

(82°C). Temperature adjustment range is 60-95°F

(15-35°C). Valve assembly must be drained prior to

being subjected to freezing temperatures. Valve

includes integral check valves.

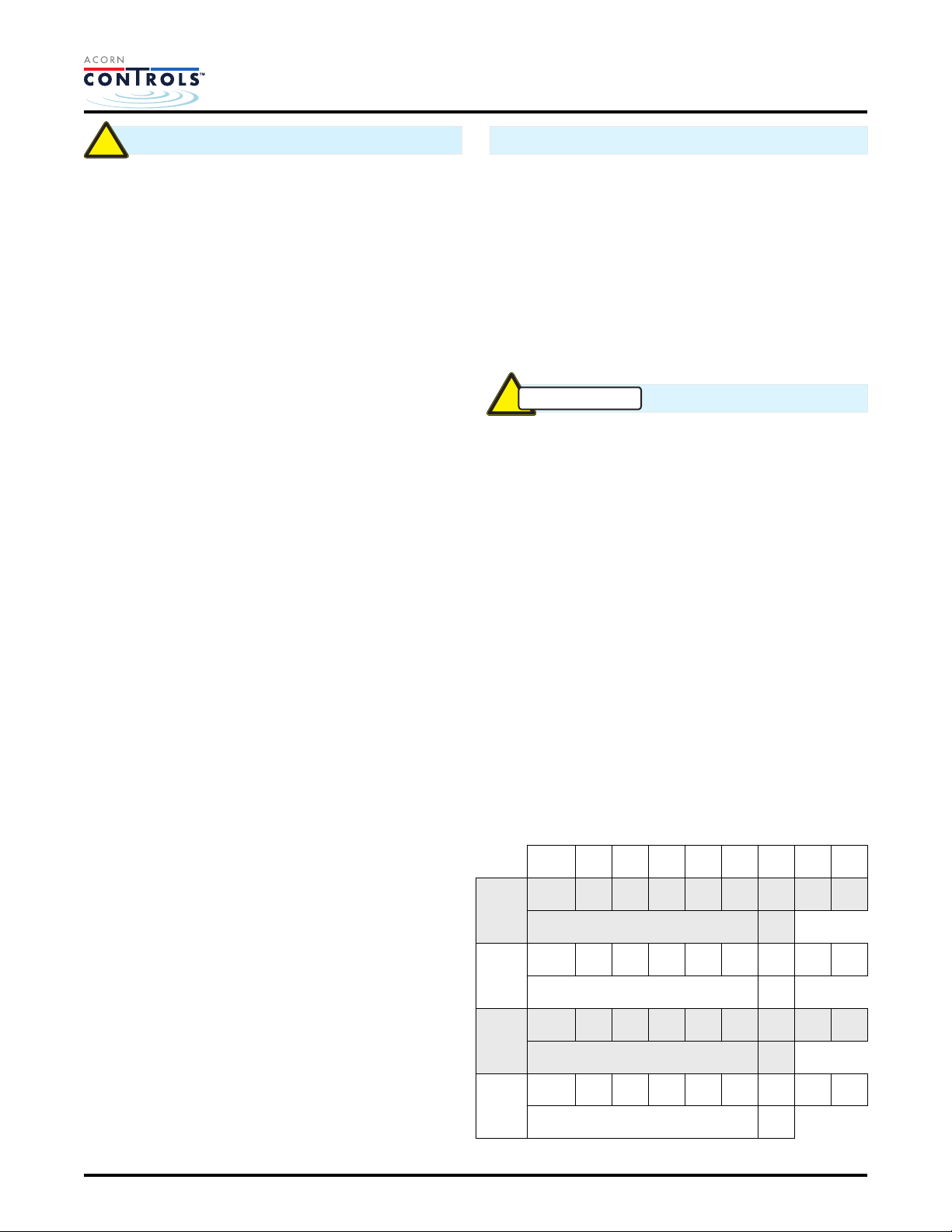

ET71-1

12 GPM

(45 LPM)

ET71-2

43 GPM

(163 LPM)

ET71-3

86 GPM

(325.5 LPM)

ET71-4

150 GPM

(568 LPM)

PRESSURE

DROP

PSID (KPA)

FLOW RATE

GPM (LPM)

COLD WATER BYPASS ONLY

FLOW RATE

GPM (LPM)

COLD WATER BYPASS ONLY

FLOW RATE

GPM (LPM)

COLD WATER BYPASS ONLY

FLOW RATE

GPM (LPM)

COLD WATER BYPASS ONLY

CV

1.8

6.4

12.8

22.4

5

(34)

4

(15.1)

14.3

(54.1)

28.7

(108.6)

50

(189.2)

10

(69)

5.66

(21.4)

20.3

(76.8)

40.5

(153.3)

70.7

(267.6)

15

(103)

6.9

(26.1)

24.8

(93.9)

49.7

(188.1)

86.6

(327.8)

20

(138)

8

(30.2)

28.7

(108.6)

57.3

(217)

100

(378.5)

30

45

(207)

(310)

9.8

12

(37.1)

(45.4)

6.5

(24.5)

35.1

(132.9)43(162.8)

25

(94.6)

70.2

(265.7)86(325.5)

60

(227)

122

150

(461.8)

(567.8)

80

(302.8)

60

(414)

13.9

(52.6)

49.7

(188)

99.3

(375.9)

173

(654.8)

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Manual #7802-119-000

Page 2 of 7

Date: 04/01/14

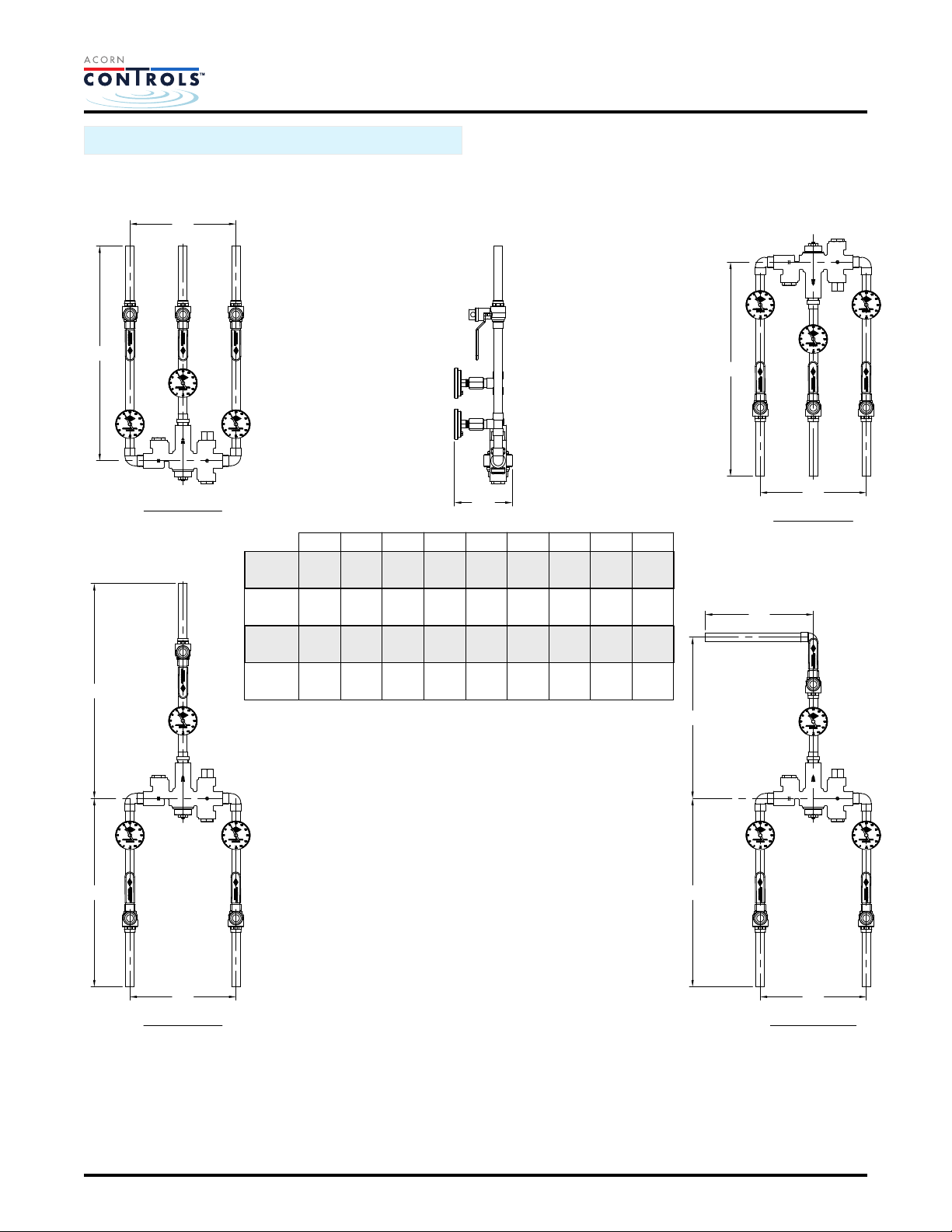

ROUGH-IN DIMENSIONS:

"A"

"B"

SFET Installation & Operation Manual

"B"

"D"

"C"

SFET-T-T-ITG

SFET-1

SFET-2

SFET-3

SFET-4

INLET "A" "B" "C" "D"OUTLET

1/2"

1/2"

NCT NCT

3/4" 1"

NCT NCT

1" 1-1/4"

NCT NCT

1-1/4" 1-1/2"

NCT NCT

7-3/4"

(197)

10-3/4"

(273)

16-3/4"

(425)

17-1/4"

(438)

15"

(381)

18-5/8"

(473)

23"

(584)

23"

(584)

"G"

13"

(330)

15-5/8"

(397)

17-1/2"

(446)

17-7/8"

(454)

12-7/8"

(327)

17-1/8"

(435)

19-7/8"

(505)

23-1/8"

(587)

"E" "F"

10-5/8"

(270)

15-3/4"

(400)

18-3/4"

(476)

22-1/4"

(565)

7-7/8"

4-1/4"

(200)

(108)

9-5/8"

4-7/8"

(244)

(124)

12-5/8"

(321)6"(152)

13"

6-1/4"

(330)

(159)

"A"

SFET-B-B-ITG

"G"

"F"

"E"

"C"

"A"

NOTE;

ALL DIMENSIONS ARE IN INCHES (MM).

Acorn Controls Division of Acorn Engineering Company®, A member of Morris Group International™

Manual #7802-119-000

"A"

SFET-B-SL-ITGSFET-B-T-ITG

Page 3 of 7

Date: 04/01/14

Loading...

Loading...