Page 1

HF + 6 m LINEAR AMPLIFIER

ACOM600S

OPERATING MANUAL

Outstanding HF Power Products

Page 2

Table of Contents

1. GENERAL INFORMATION ............................................................................................3

1-1. Inroduction and description..........................................................................................3

1-2. Owner assistance ........................................................................................................3

1-3. Equipment supplied and options..................................................................................3

1-4. Features.......................................................................................................................3

1-5. Safety considerations, explicit denitions ....................................................................4

2. INSTALLATION .............................................................................................................6

2-1. Unpacking and Initial Inspection ..................................................................................6

2-2. Amplier location selection; cooling. ............................................................................6

2-3. Connecting the amplier within the shack ...................................................................7

2-4. Installing options and connecting to external devices

(transceiver, computer etc) ........................................................................................10

3. INITIAL POWER ON AND SETTING INTO OPERATION ...........................................12

3-1. Low-energy (waiting) mode of the power supply .......................................................12

3-2. Front panel - controls and indication...........................................................................13

3-3. Initial turning on – activation of the main power supply .............................................13

3-4. Basic screen ..............................................................................................................14

3-5. Control system – buttons and menus ........................................................................15

3-6. Test transmission .......................................................................................................16

4. OPERATION WITH THE AMPLIFIER ..........................................................................21

4-1. Change of modes RX / TX and Operate / Stand-by; option

AUTO OPERATE .......................................................................................................21

4-2. Band change, standard and expanded frequency coverage .....................................22

4-3. Change of antennas and operation with an external antenna tuner ..........................23

4-4. Cooling and fans operation; modes with increased heat loading ..............................24

4-5. Monitoring the amplier operating regime .................................................................24

4-6. Automatic protection system ......................................................................................24

5. MENUS – USEFUL INSTRUMENTS AND OPTIONS .................................................26

5-1. Menu “Measurements in the amplier” – AMP MEASURE ........................................26

5-2. Menu “Service functions in the amplier” – AMP SERVICE. .....................................27

5-3. Menu “Selection of CAT/AUX interface” – CAT/AUX SETTINGS ..............................28

5-4. Menu “USER PREFERENCES” ................................................................................29

5-5. Reading the FAULTS LOG ........................................................................................31

5-6. Menu “RESTORE DEFAULT SETTINGS” .................................................................32

1

Page 3

6. REMOTE MONITORING AND CONTROL ..................................................................33

6-1. General information ...................................................................................................33

6-2. Commands set...........................................................................................................34

7. MAINTENANCE ...........................................................................................................34

7-1. Periodic maintenance; general checks and cleaning ................................................34

7-2. Replacement of fuses ................................................................................................35

7-3. Simplied schematic diagram; theory of operation ....................................................35

7-4. Using the fault codes (signatures) for diagnostics .....................................................39

7-5. Firmware updates ......................................................................................................39

8. SPECIFICATIONS .......................................................................................................40

8-1. Parameters ................................................................................................................40

8-2. Functions ...................................................................................................................41

8-3. Storage and shipment................................................................................................41

9. DISCLAIMER of LIABILITY ........................................................................................42

2

Page 4

1. GENERAL INFORMATION

1-1. Inroduction and description

This manual describes the installation, operation, and maintenance of the HF+6m solid-state

linear power amplier ACOM 600S.

ACOM 600S is a state-of-the art linear amplier which covers all amateur bands from 1.8

through 54MHz and provides more than 600 W output power (PEP or continuous carrier)

with less than 30W of drive. The working parameters of the amplier are indicated on a multifunctional, high resolution color display. The amplier control is performed with only six buttons

from the front panel, directly by CAT interface from the transceiver or remotely – by RS232

interface.

1-2. Owner assistance

If technical or operating assistance is needed, please contact your local dealer rst. In the

unlikely event you need further information, you may get in touch with ACOM as follows: fax:

+ 359 2 920 96 56, telephone +359 2 920 97 80, e-mail: acom@acom-bg.com, acom@mail.

orbitel.bg or by mail to: blvd. Nikola Mushanov 151, 1330 Soa, Bulgaria. The ACOM Internet

page is: www.acom-bg.com.

1-3. Equipment supplied and options

The amplier is supplied in single box, which includes:

- the amplier ACOM 600S;

- this manual with a CE declaration of compliance;

- four pieces of spare fuses;

Directly from ACOM or from your dealer you can also buy some of the following options:

- CAT interface cables for connecting the supported transceiver models (please specify

the wanted one);

1-4. Features

• 5“ (108x65mm) high resolution color display, 800x480 pixels, and 24-bits colors.

• The nal stage uses eld effect (MOSFET) transistors type MRFE6VP6300H, which,

according to their manufacturer - Freescale Semiconductor - are designed to withstand

high mismatch (SWR) at the output and are intended for operation in aerospace,

industrial, mobile, and radio broadcast applications.

• Compatible with all transceiver models available on the market - does not need any

special signals: „ground on transmit“ (PTT) and 30W of RF drive power is sufcient.

3

Page 5

• Broadband input circuit providing a perfect transceiver load with SWR below 1.2:1

(typically 1.1:1), without retuning throughout the whole frequency range from 1.8 to

54MHz.

• The overall operation of ACOM 600S is extremely simplied: the screen menus are

intuitive and easy to follow and no special skill is required from the operator when

changing frequency bands.

• Possibility of automatic control – when connected to a transceiver with a CAT interface,

the amplier monitors constantly, duly follows the operating frequency, and changes

the bands accordingly.

• Even if not connected with CAT interface, the amplier monitors the frequency of the

input signal through the built-in frequency counter and automatically switches over the

bands.

• Remotely controlled by RS232 interface.

• Takes care of itself during operation due to the continuously working protection circuits

in all modes.

• The operator can monitor digitally more than 10 parameters concerning the working

regime of the amplier.

• Easy maintenance – detailed data (55 parameters) about each of the last 28 hard-fault

protection trips is stored in the amplier’s nonvolatile memory.

• Convenient for expeditions and eld operation: extremely compact and light construction,

extended mains voltage range 93-265VAC and 170-265VAC through changing only

the main fuses - no internal switching), limited inrush current and purely sinusoidal

consumed mains current, automatic Power Factor Correction (PFC) – all signicant

parameters in operation from unstable mains, generators etc. features achieved thanks

to the built-in switching-mode power supply (SMPS).

• Perfect electromagnetic compatibility (EMC) both with the highly sensitive as well as

with the powerful appliances in the radio station (receivers, computers, more ampliers)

exceeding the standard EMC requirements due to the use of PFC and the built-in

additional radio-frequency lters.

1-5. Safety considerations, explicit denitions

The linear amplier ACOM 600S is a device. Class I of protection against electric shock, i.e.

the third grounding lead of its mains cord (colored yellow with two green stripes) and the

grounding stud on the rear panel, marked GND (Fig. 2-1), must be connected to the grounding

system of the shack for safe operation.

The ACOM 600S amplier is designed to meet international safety standards and complies

with CE safety and electromagnetic compatibility requirements, as well as FCC regulations.

This operating manual contains an assortment of precautions, indications for cautions, and

warnings that MUST BE FOLLOWED by the user to ensure safe operation and always maintain

the ACOM 600S amplier in a safe working condition.

4

Page 6

PRECAUTIONS:

The EXPLICIT DEFINITIONS described below apply to this operating manual:

W A R N I N G notes call attention to a procedure which, if not correctly performed,

could result in personal injury, re hazard or electric shock or lightning.

C A U T I O N notes call attention to a procedure which, if not correctly performed,

could result in equipment damage, not only in the ACOM 600S amplier.

N O T E notes call attention to a procedure which, if not correctly performed, could

result in inconvenience.

W A R N I N G HIGH VOLTAGE!

The mains power voltage plus a high DC voltage up

to 500V inside the ACOM 600S amplier are LETHAL!

For your safety, pull the amplier power plug out of the

mains wall outlet and WAIT AT LEAST three minutes

EACH TIME BEFORE you remove the cover of the

amplier.

W A R N I N G HIGH VOLTAGE!

NEVER ALLOW, ESPECIALLY CHILDREN, to push

anything into holes in the case - this will cause

ELECTRIC SHOCk! Never touch an antenna or antenna

isolators during transmission or tuning - this may result

in an electric shock or burn. Never expose the amplier

to rain, snow or any liquids. Avoid placing the amplier

in excessively dusty environments or in direct sunlight.

DO NOT OBSTRUCT COOLING AIR movement areas.

W A R N I N G

Do not undertake your own repairs or changes in

hardware or rmware of your ACOM 600S amplier.

Doing so will endanger your or others‘ health or life or

damage the amplier and the equipment connected to

it. Such repairs or changes are not covered by warranty

and may void the warranty. The manufacturer is not

liable for any such repairs or changes. Any such

repairs or changes are strictly the responsibility of the

person or persons engaging therein.

C A U T I O N

To avoid damage (not covered by the warranty) please read

the INSTALLATION - Section 2 of this operating manual

carefully. If you have any doubts or questions regarding the

installation, operation or safety of the ACOM 600S amplier,

please consult your dealer immediately.

5

Page 7

2. INSTALLATION

2-1. Unpacking and Initial Inspection

C A U T I O N

Before you start any work on installing the ACOM 600S

amplier, please thoroughly read through this manual. First

carefully inspect the shipped carton and Its contents as

described below for anything missing from the set (S. 1-3) or

mechanical damages. If anything is missing or is obviously

damaged (scratched, bent, smashed or something is

rattling inside or moving freely when turning over, notify

immediately your dealer! The delay may Infringe the

warranty conditions of the carrier.

N O T E

Keep the original packing for possible future transportation.

Take out and inspect carefully the contents of the cardboard carton for possible transportation

damages. On the amplier check the chassis, the front panel, the display and the buttons

below it and on the rear panel – all connectors, the main power switch, the fuses, and the

integrity of the power cable - especially at the area where it comes out from the panel.

Check in the same way the options if such have been ordered.

2-2. Amplier location selection; cooling.

Locate the amplier close to the place where it will be used. You will need an easy access to

the rear panel for connecting cables, and of course, to the buttons and the screen on the front

panel of the amplier.

The ACOM 600S operates with forced air cooling. Locate the amplier so that there are no

objects or devices closer than 10cm (4”). At an ambient temperature of 40ºC (104ºF) the

exhaust air can reach 65ºC (150ºF), this is why if nearby items are sensitive to heating from

outside or use forced air cooling, increase the distances accordingly.

C A U T I O N

Do not leave free papers, cloth or other light materials

around and under the amplier. They may be drawn in by

the cooling air stream and block some ventilation apertures.

Thus the amplier will get easily and frequently overheated

which may age prematurely the materials in its construction

and lead to damages, not covered by the warranty.

6

Page 8

2-3. Connecting the amplier within the shack

W A R N I N G

Before you connect the amplier to external grounding,

you should advise with a licensed electrician and checkup whether such kind of connection is allowed by the

national and local electrical code, safety rules, and

regulations in force. Simultaneous connection to the

earth grounding and bonding may be inadmissible or

may fall under special requirements in some countries!

W A R N I N G

Never use the gas installation tubing as grounding.

This can cause an EXPLOSION!

W A R N I N G

Do not use the steam-heating or water-supply network

tubing as grounding! Thus, you may involuntarily

expose to dangerous voltage not only yourself but also

other people using the same installation.

C A U T I O N

Have in mind that the grounding installation will have to

withstand emergency currents above 15A with minimal

voltage drop on it thus it may be necessary to improve

its conductivity using heavier leads and lower-resistive

grounding path. The grounding lead should be at least

4mm2 (AWG 11 or SWG 13).

For details and recommendation on the grounding and RF counterpoise system concerning

the electromagnetic compatibility see also S. 3-6(g).

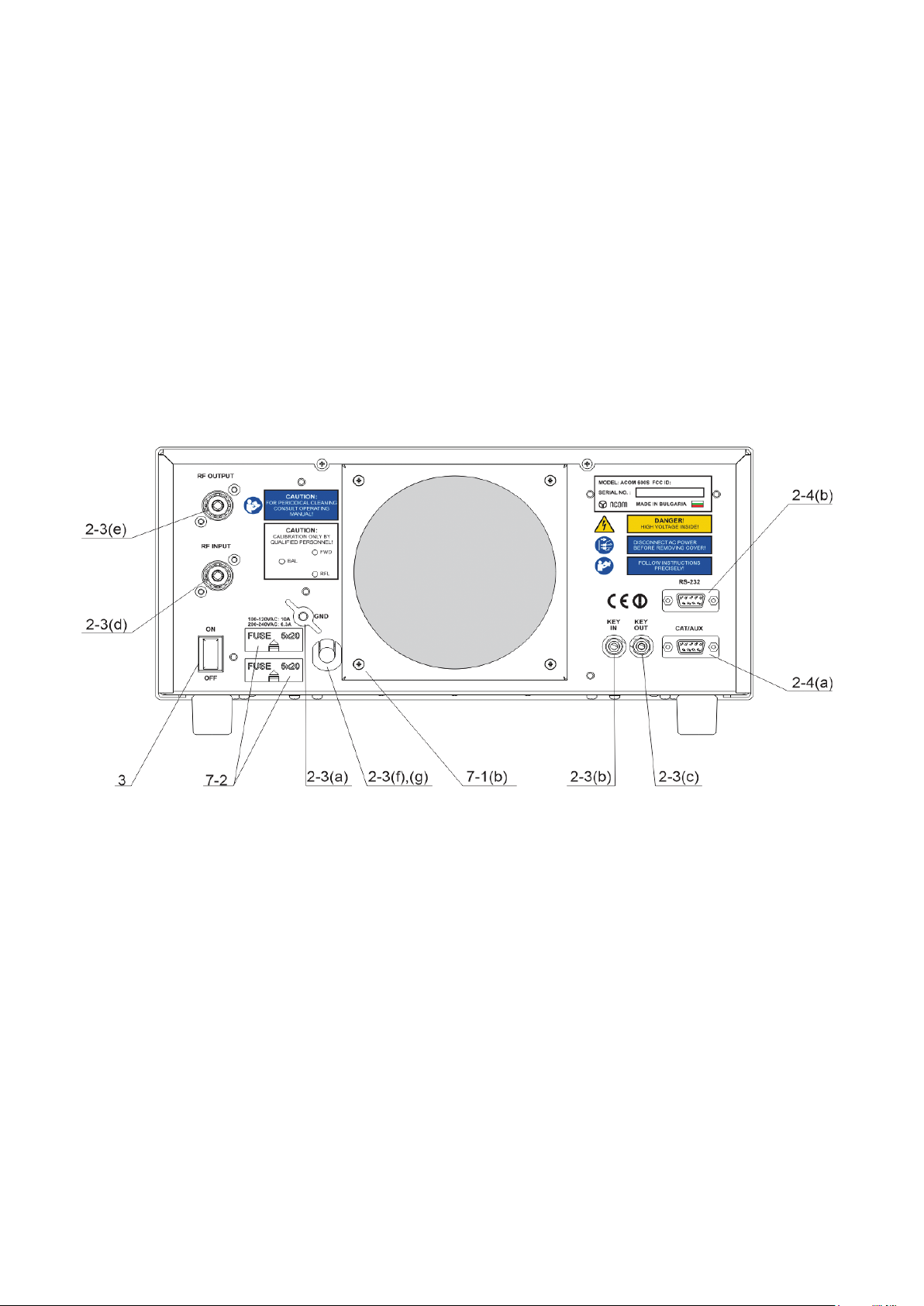

a) GND stud - external grounding connection of the amplier. After having made strictly all

check-ups described above, rst connect the grounding stud of the amplier (located

on the rear panel and marked GND – Fig. 2-1) to the grounding system of the shack.

b) KEY-IN jack - amplier input for receive/transmit control from the transceiver.

The transceiver switches the amplier from receive mode into transmit mode (RX/TX) via

grounding of the KEY-IN input.

Connect a shielded cable from the respective control output of your transceiver, providing

“ground on transmit” (PTT), to the KEY-IN input on the amplier rear panel (RCA PHONO jack

socket – Fig. 2-1). Use a standard “RCA PHONO” jack plug for connection to the amplier.

The manufacturers of transceivers give different names to this output, for example: TX-GND,

SEND, T/R LINE, RELAY, PTT, and others. At some transceivers “ground on transmit” output

should be activated by a software command, a menu or via changing a switch on the rear

panel or inside the transceiver. See instructions in the manual of your transceiver.

7

Page 9

C A U T I O N

Before connecting the KEY-IN input verify the electrical

specications of the transceiver control output (from its

own manual) to make sure of their compatability. The

signal voltage applied by the amplier KEY-IN jack to the

transceiver control output “ground on transmit” does not

exceed +12.6V against ground and its closed-circuit current

is below 6mA. See also S. 8-2(a).

N O T E

Your amplier will not work if the KEY-IN input is not

connected correctly. If you experience any difculty consult

your dealer.

Fig. 2-1 Rear panel connections

c) KEY-OUT jack - transmit-enabling control output from amplier to the transceiver.

The KEY-OUT jack on the rear panel provides an additional control signal from amplier toward

transceiver. It can be used for improving reliability of the receive/transmit (RX/TX) switching.

When the amplier is not powered up, KEY-OUT is connected internally to KEY-IN through the

contacts of a relay inside the amplier, thus always enabling transceiver transmission. Also, in

Stand-by mode KEY OUT unconditionally follows the state of the KEY-IN input. When in Operate

mode however, KEY-OUT follows KEY- IN only when all conditions for safe transmission have

been found OK by the amplier control circuit. At detection of any risk, transmission is quickly

disabled by means of opening the KEY-OUT circuit constrainedly.

8

Page 10

C A U T I O N

KEY-OUT is a low-powered output, this is why make sure

that the signal voltage coming to it from the respective

transceiver connection does not exceed 50VDC (open

circuit) and that its closed-circuit current is below 20mA.

If your transceiver has a suitable input, which disables transmission unless it is grounded

externally, we recommend that you connect it to the KEY-OUT jack of the amplier. Use

shielded cable terminated with а standard “RCA PHONO” jack plug.

The manufacturers of transceivers give different names to this transceiver input, for example:

TX-INHIBIT, MUTE, LINEAR, and others. Check the manual of your transceiver. Approach

your dealer for details. If your transceiver has no such input, do not worry – ACOM 600S will

operate normally without it as well – then KEY-OUT jack can remain not connected.

d) RF INPUT – should be connected to the antenna input/output of the

transceiver.

Connect a 50-Ohm coaxial cable with a connector type PL-259 from the transceiver output

(antenna jack) to the RF INPUT jack on the rear panel of the amplier.

N O T E

When operating with the amplier, do not turn on the

transceiver built-in antenna tuner (if present).

e) RF OUTPUT – should be connected to the antenna, antenna switch or tuner.

Connect a 50-Ohm coaxial cable with a connector type PL-259 from RF OUTPUT on the rear

amplier panel to the antenna switch, tuner or antenna intended for the respective frequency

band.

C A U T I O N

If you use an amplier for the rst time in your shack, pay

serious attention to the size of coaxial cable from your

amplier output to the antenna. The cable must be capable

of handling the increased power safely, particularly on the

10m and 6m bands. This warning refers equally to the

antenna switch, tuner, and the whole antenna system, for

example, for multi-band antennas with resonance circuits

(traps etc).

We recommend that you use coaxial cable sized as a minimum similarly to the following types:

RG8x, RG8MINI, RK50-4-11, RK50-4-13 or better still - RG213 or RK50-7-11. Consult your

local supplier of coaxial cables to make the right choice.

f) Preparation of the mains outlet for the amplier, requirements for the installation

and the mains voltage.

C A U T I O N

Before connecting your amplier to the mains, check-up

with a licensed electrician if it is properly wired and if your

mains is adequate for the current which the amplier can

consume at an emergency (up to10A from 200/240VAC

mains and up to 15A from 100/120VAC mains). Also, make

sure that the grounding lead is connected properly in the

wall mains outlet intended for the amplier. If subsequently

you connect the amplier to a different outlet, make sure

about it as well.

It is preferable for the amplier to use the closest mains outlet. Make sure that the respective

9

Page 11

fuses, the voltage, and the frequency of your power mains match the ACOM 600S amplier

specications (see S. 8-1(g)).

g) Mains cord – installation of mains plug and main fuses suitable for your nominal mains

voltage.

C A U T I O N

If your amplier has only one mounted mains fuse (Fig. 2-1

/ S. 7-2), it is suitable ONLY for power mains networks of

the type 0-220/240VAC, which are standard in the EU.

C A U T I O N

Make sure you check whether the main fuses installed in

your amplier correspond to your mains nominal voltage

and if necessary replace them as described in Section 7-2!

Because of differences among standards in the different countries, the mains plug is supplied

and mounted by your dealer. He connects a standard mains plug for device Class I of protection

against electric shock corresponding to the national and local electrical code, safety rules, and

regulations in force in your country.

C A U T I O N

The lead colored in yellow with two green stripes in the

mains cord is the grounding, while the blue and brown

leads are active. When the amplier is only tted with one

mains fuse, then the fuse is connected in series with the

brown lead, which must be the active.

If you have any doubt if the mains-cord leads are connected correctly in your mains plug,

please consult your dealer immediately. Using a licensed electrician, the user must implement

the checks mentioned above each time the amplier is to be connected to a mains network

outside the country in which it was purchased.

2-4. Installing options and connecting to external devices (transceiver, computer

etc)

a) CAT/AUX interface - connecting and operation with various transceiver models (see

table 2-1 below and the respective menu in S. 5-3 and Fig. 5-3).

Most of the modern transceivers that provide output data of their working frequency by a

serial or parallel port or as an analogue signal (0 to 8V depending on the frequency) can be

connected to the CAT/AUX interface connector of ACOM 600S. This will allow the amplier to

follow the changes of the frequency bands automatically and without any transmission, while

the operator is operating with the transceiver.

For control of the amplier through the CAT/AUX interface you need a special cable between

the transceiver and CAT/AUX connector (type HD-15) on the rear panel of the amplier – Fig.

2-1. Such a cable can be supplied as an option along with the amplier or you can buy it from

your dealer additionally, but you can assemble it yourself as well, using information from table

2-1 and your transceiver’s manual.

Schematics of cables for connecting to many transceiver models are readily available on the

ACOM Internet page (S. 1-2).

10

Page 12

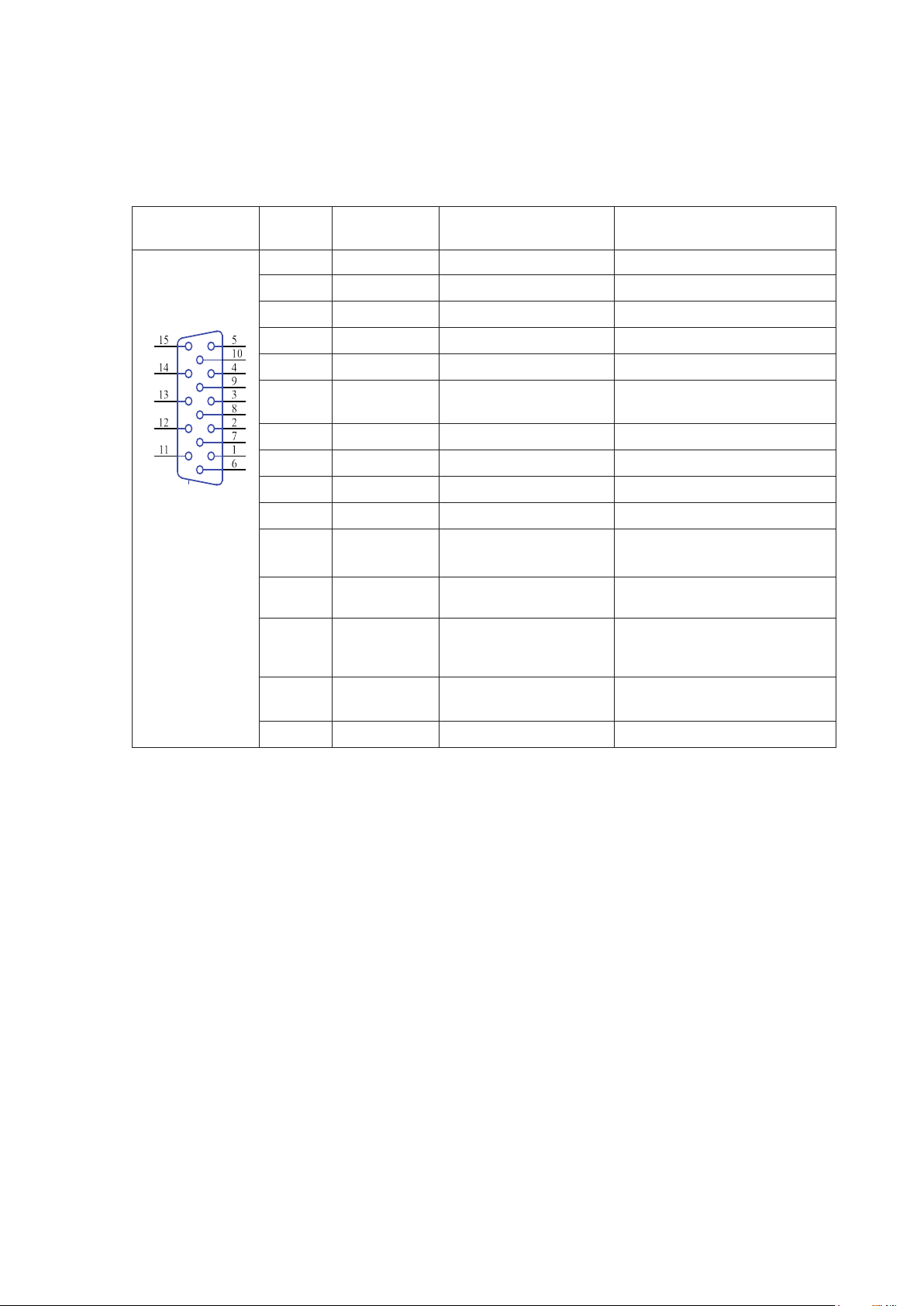

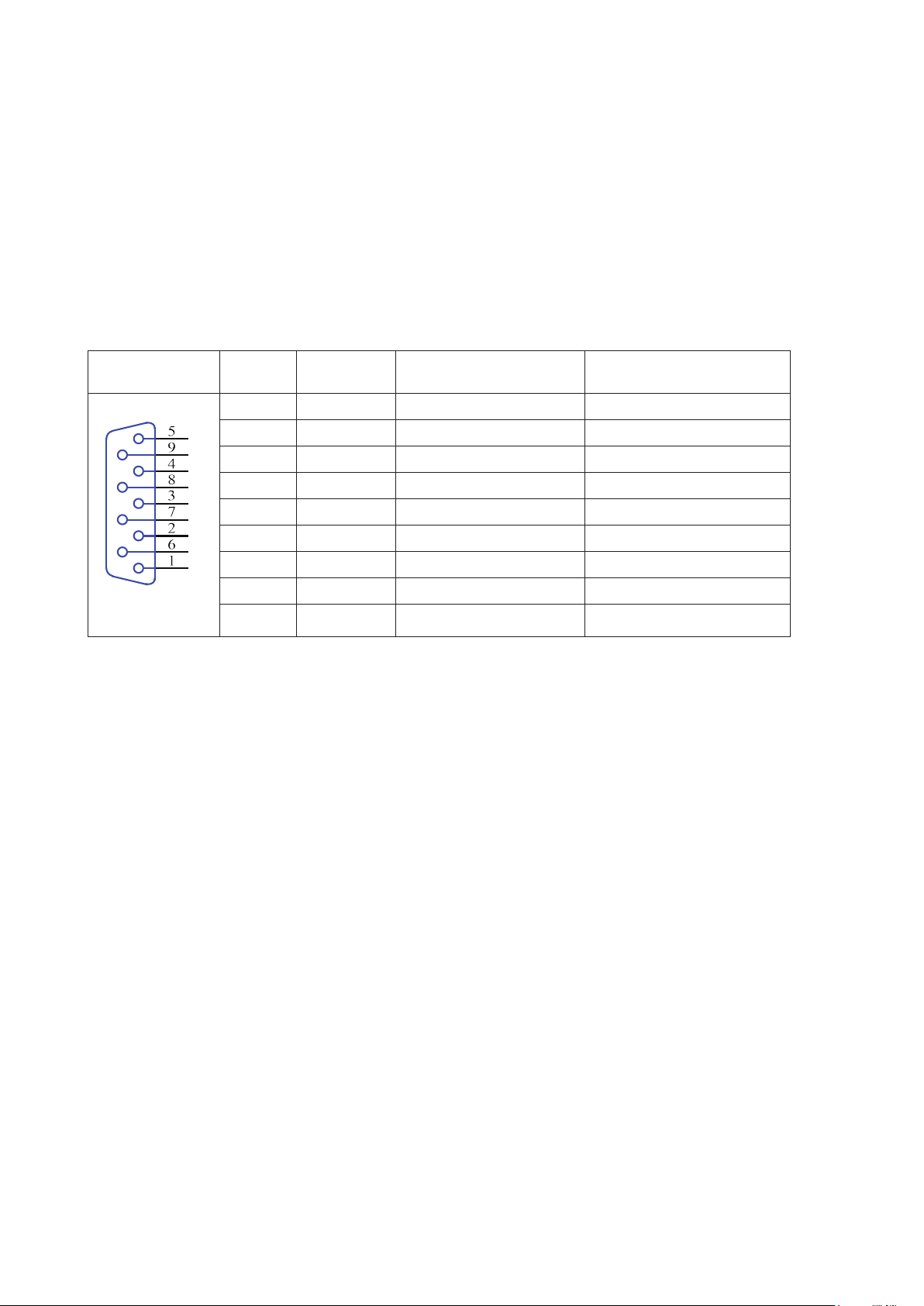

Table 2-1 shows the signals and the pin out of the CAT/AUX connector - rear panel of the

amplier.

Table 2-1

CAT/AUX

interface

PIN

NO.

PIN NAME DESCRIPTION SPECIFICATIONS

1 RxD Received Data TTL input

2 RxD Received Data RS232 input

3 TxD Transmitted Data RS232 output

4 TxD Transmitted Data TTL output

5 GND Ground 0 Volt

6

BAND

voltage

Analogue input 0 to +8V

7 B. data 0 Bit 0 TTL input

8 B. data 1 Bit 1 TTL input

9 B. data 2 Bit 2 TTL input

Rear panel

view

11 ON RMT Remote Pwr On

12

Debug

mode

CPU only Power

Input

+4.5 to +15V / 3mAmax

1 to 2 seconds pulse

+8 to + 15V / 0.4A

Rx/Tx control input

10 B. data 3 Bit 3 TTL input

13 kEY-IN Transmit Request

Less than +12.6V

Less than 6mA

14 kEY-OUT Transmit Enable

O.C. output, 0 to +50V

20mA maximum

15 GND Ground 0 Volt

N O T E

Due to the variety of existing CAT protocols for different

transceivers, the amplier response may be different for

some transceiver models, as described below.

- Some older transceivers employ a rather slow protocol or send frequency data with a

delay of several seconds – then the amplier response will be delayed respectively;

- In some cases, when the transceiver is powered on after the amplier, you may need

to press and hold up for one second the button BAND of the amplier, up or down

(Fig. 3-2), to make the transceiver inform the amplier about its frequency; in other

occasions, the transceiver transmits its frequency only on changes and you may need

to move slightly the main frequency dial knob or change it in another way in order to

announce it to the amplier after an initial power turn on;

- in “split” operation, not all transceivers provide frequency data of VFO A and VFO

B correctly; if your receive and transmit frequencies fall in different frequency bands

(Cross Band Operation) and the amplier unnecessarily switches between them at

11

Page 13

each transition receive/transmit (RX/TX), you may deactivate the amplier’s CAT/AUX

interface control while operating “split” (S. 5-3 and Fig. 5-3).

b) RS232 Interface. Table 2-2 shows signals and pin out of the RS232 connector on the

rear panel of the amplier.

This connector can remain unconnected until you decide to use the amplier with remote

control.

Table 2-2

RS 232

interface

PIN

NO.

PIN

NAME

DESCRIPTION SPECIFICATIONS

1 - Not connected 2 TxD Transmitted Data RS232 level output

3 RxD Received Data RS232 level input

4 - Not connected 5 GND Ground 0 Volt

6 DSR Data Set Ready RS232 level input

7 - Not connected -

Rear panel

view

8 CTS Clear To Send RS232 level input

9 - Not connected -

3. INITIAL POWER ON AND SETTING INTO OPERATION

C A U T I O N

Do not turn on the amplier for at least two hours after it

is unpacked and installed in its operating position. Pay

particular attention whenever the amplier is moved from

a very cold place to a very warm one because unseen

condensation may develop and this could result in damage

to the high voltage circuits of the amplier. Under these

circumstanves, do not turn on the amplier for at least 4

hours. A similar effect could occur following a rapid warming

of the room, such as winter use of a powerful electric heater.

After having mounted and connected the amplier according to the instructions in Section

2 INSTALLATION and have followed all requirements, check whether mains switch on the

rear panel is in turned-off position – in Fig. 2-1 the rocker of the POWER ON switch must

be protruding from the side of the “ON” inscription. Afterwards insert the mains plug of the

amplier into the mains outlet prepared for it. For now the amplier remains turned off.

3-1. Low-energy (waiting) mode of the power supply

Now you can put the mains switch on the rear panel in a turned-on position, pushing its rocker

so that it sinks from the side of the “ON” inscription (Fig. 2-1). This will activate only the lowenergy (waiting) mode of the power supply and will illuminate the red LED above button ON/

OFF on the front panel, while the main power supply is still inactive and the display is dark.

12

Page 14

3-2. Front panel - controls and indication

a) ON/OFF button – serves for manual (local) start up of the power supply from low-energy

(waiting) mode of the power supply (S. 3-1) into working mode, i.e. for activating of the

main power supply and starting operation with the amplier. The same button is used

also for main power supply deactivation – return into the low-energy (waiting) mode of

the power supply at ceasing operation with amplier.

b) LED indicator above the ON/FF button. The red LED indicator glowing above the ON/

OFF button at a dark display shows that mains voltage is fed from the plug, the POWER

ON switch on the rear panel (Fig 2-1) is in a turned-on position, but the power supply

is in its low-energy (waiting) mode (S. 3-1). In this mode activation of the main power

supply is expected to start operation with the amplier.

Fig. 3-1 Front panel

During operation with the amplier the display is illuminated and the red LED above the ON/

OFF button indicates the button location which can be very useful in case of fast switching off

in poor light conditions.

c) Keyboard with 6 buttons for manual (local) control of the amplier. The function of each

button is prompted on the display above it. Depending on the menu displayed, the

buttons may have different functions.

d) The color display shows all the relevant information about the status of the amplier.

3-3. Initial turning on – activation of the main power supply

In order to activate the main power supply at starting amplier operation, press and hold on

the ON/OFF button on the front panel for one or two seconds - аbout three seconds later the

display will ash and show the basic screen showing the amplier status and operation - Fig.

3-2.

13

Page 15

After turning on, the amplier stands in Stand-by or Operate mode – it depends on whether the

AUTO OPERATE option has been activated – see S. 5-4 USER PREFERENCES.

3-4. Basic screen

There are 9 information areas on the basic screen as follows:

a) Information area for the frequency band – the borders of the currently selected BAND

are displayed.

If at start up of the amplier there is no information about the operating frequency (neither

the CAT/AUX nor the RS232 interface is connected), ACOM 600S will switch to the last used

frequency.

Fig. 3-2 Basic screen

b) Information area for measurements or alarm messages.

Any two operator-chosen parameters will be normally displayed in this area on black background

– see the list in S. 5-1 Measurements in the amplier – AMP MEASURE.

The alarm messages (either type WARNING or SOFT FAULT) appear with black font on yellow

background on the area for measurements and are ashing frequently in order to attract the

operator’s attention (Fig. 4-1).

The WARNING type of messages appear only temporarily (for about three seconds), afterwards

the indication of the measurements is restored automatically (S. 4-6(a)).

14

Page 16

The SOFT FAULT type of messages appear in the same eld (on the area for measurements)

however they remain and persist on the screen until the AUTO OPERATE time is elapsed (S.41(c)) or until the operator presses any button, then the measurements indication is restored,

too.

c) Indicator for the working mode - OPR, STB or AUTO OPER (S. 4-1).

d) Indicator RX/TX reects the state of the request for transmit (KEY-IN input). The RX

indication is green and the TX is red. When a request is present but it could not be

performed for any reason, the respective indicator RX or TX is ashing frequently.

e) Bar-graph and digital indicator for forward power at the output. Reads the power fed

from the amplier to the antenna.

f) Bar-graph and digital indicator for output reected power. Entering the red zone is

inadmissible.

g) Bar-graph and digital indicator for temperature of the nal stage. Entering the red area

is inadmissible.

h) Information label for activated CAT/AUX interface. When CAT/AUX is deactivated, this

label is shaded.

i) Information label for activated REMOTE CONTROL – ashes after feeding one or

more commands by the RS232 interface. Dies out (remains shaded) after feeding one

or more manual (local) commands from the buttons or by the CAT/AUX interface from

the transceiver.

3-5. Control system – buttons and menus

a) The OPR/STB and the BAND (up and down) buttons are used for manual (local)

control of the amplier in the basic screen (Fig. 3-2):

- the left-most button – OPR/STB is for alternative switching of the amplier mode

between Operate and Stand-by;

- the next two buttons – BAND up and down arrows – serve for manual change of the

frequency bands in ascending or descending order; pressing and holding on either up

or down arrow for one second will refresh the information about the operating frequency

on the CAT/AUX INTERFACE;

b) The right-most button – MENU (Fig. 3-2) – serves for access to the list of menus.

All necessary instruments, as well as the control and service options of the amplier are

structured in six menus. Each of them has only one hierarchical level (menu depth) – Section

5 and Fig. 5. This simplied structure gives the operator maximum clarity and possibility of

easy navigation. More handiness is provided by the uniform approach to the different menus:

- in each screen (the menu list and all tools in them) the left-most button is always HELP

and the right-most – always EXIT;

- the HELP button can be used at any time for obtaining of auxiliary information concerning

15

Page 17

the currently activated screen (context sensitive help);

- the currently chosen menu title (for example AMP MEASURE) is always present at the

top of the menu;

- the EXIT button can be used at any time to leave the currently used menu or the menu

list for possibly easiest and fastest “return” to the basic screen (Fig. 3-2).

For more details on the control system and use of the menus see Section 5. MENUS – USEFUL

INSTRUMENTS AND OPTIONS.

3-6. Test transmission

To make sure that you have installed the amplier correctly, before you put it in operation,

make a test transmission as described below. Repeat these tests for each new band and

antenna, as well as after installing a new or repaired antenna, antenna switch, tuner, and / or

connecting cables.

a) Check of RF by-pass path at non-driven amplier.

For this check the amplier must be completely installed and connected withing the shack

according to Section 2, but not powered by the mains, i.e. the mains power plug must be pulled

out from the mains outlet or the POWER ON switch on the rear panel must be in turned off

position. In any case the LED above ON/OFF button must be dark for this test.

First, check if the transceiver reception is normal. If you observe a signicant worsening of

reception, search for the problem rst in the coaxial connections to the amplier (S. 2-3(d),(e)).

If reception is normal, prepare the transceiver as follows:

- select a continuous carrier mode (CW, RTTY, FM);

- switch the microphone off (decrease the mic gain), ban the FSK respectively;

- reduce the output power control to a minimum;

- select a suitable indication so that you can watch the RF power and SWR at the

transceiver output;

- if the transceiver has an incorporated antenna tuner – switch it off.

Now in receive mode select a frequency which is not occupied at the moment and press shortly

the transmit actuator (the PTT or the TX key) while observing the output power and the SWR

indicators. If the power or the SWR at the transceiver output are too high (over 5W or SWR

over 2:1) immediately release the actuator and search for the reason as follows:

- check again whether the output control is set at minimum;

- check whether the frequency on which you are transmitting is within the operating

range of the selected antenna;

- check the good working order of the connecting coaxial cables, connectors, and feed

16

Page 18

lines from the transceiver antenna jack through the amplier, the antenna switch or

external tuner (if there is one) to the BALUN transformer, and the antenna itself (S.

2-3(e)).

In case of difculty use antenna measurement instruments or contact your dealer.

If the power and SWR are as expected, then go transmitting again and while watching the power

and the SWR indicators, increase transceiver power gradually from minimum to maximum (but

not more than 200W, in order not to overload the RF by-pass circuit of the amplier).

If SWR remains below 2:1 (preferably below 1.5:1) at the last test, decrease the power from

the transceiver to minimum again and continue with the next check. Otherwise you will have to

make corrections on the antenna and / or feed-line matching or use an external tuner for this

antenna. The tuner should handle the maximum output power of the amplier (S. 8-1(b)) at the

respective antenna SWR.

b) Check in Stand-by mode.

After a successful check-up with non-powered amplier, item (a), turn it on and run it to the

basic screen, as described in Sections 3-1 to 3-4 (Fig. 3-2).

For this check it is necessary that the amplier is in the Stand-by mode. If the AUTO OPER

option has been activated at any previous switching on of the amplier, it will automatically start

in the AUTO OPER mode (Fig. 3-2 and S. 5-4) immediately after turning power on. In such a

case, press once the OPR/STB button to return the amplier manually to the Stand-by mode.

In this state repeat the receive and transmit tests with the transceiver through the amplier

RF by-pass path, as it was described in the preceding item (a). During these tests note also

whether the bar-graphs and digital indicators for forward and reected power in the basic

screen (S. 3.4(e),(f)) show respective RF power presence. If the reected power exceeds the

forward power, verify that you have not interchanged involuntarily the input and output coaxial

cables to the amplier (S. 2-3(d),(e)).

N O T E

The power indication is optimized around the 600W level and

normally it is unreliable below 50W.

c) Entering Operate mode.

After a successful check in Stand-by mode, item (b), while you are in the basic screen, press

the MENU button. From the list select menu AMP MEASURE (Fig. 5-1). In the left-side of the

screen select PA DC VOLTAGE and in the right-side – PA DC CURRENT (use the ITEM1 or

ITEM2 buttons to scroll the list if needed). Press twice the rightmost EXIT button to return to

the basic screen. The two selected parameters – PA DC VOLTAGE and PA DC CURRENT -

will be indicated in the basic screen as well – S. 3-4(b). In Stand-by mode they must be zero.

Now press the OPR/STB button to put manually the amplier in Operate mode (S. 3-2 and Fig.

3-2). The OPER or the AUTO OPER indicator must ash and the indicator RX/TX must remain

in condition RX. Besides this, PA DC VOLTAGE must become 48-52V while PA DC CURRENT

must remain zero.

At entering the Operate mode the receiving of the transceiver should not suffer. If it worsens

17

Page 19

and together with this the indicator RX changes into TX and any current appears on the drain

(PA DC CURRENT) although the transceiver is in the receive mode, check if they normalize at

return to the Stand-by mode.

If the problem occurs only at transition into the Operate mode and disappears at return to

Stand-by, check the control cable connected to the KEY-IN input – S. 2-3(b) – it is possible that

the conductor is shorted to the shield (ground) or the connection to the transceiver is wrong,

thus wrongly requesting transmit mode toward the amplier during transceiver reception.

d) Check of the RX/TX switching and the amplier idling current without RF power.

Put the transceiver in such a mode that at pressed PTT or TX button a transmit request is

applied to the amplier but with no RF power on the transceiver output. For example, select

SSB mode with microphone gain control reduced to zero or CW mode with Morse key up to

avoid any RF power while requesting transmit mode to the amplier by pressing the PTT or the

TX button (do not use automatic CW keyer or VOX).

At pressing the PTT or the TX button without RF drive at the amplier input, the green label

“RX” on the basic screen must become red “TX”. Note that the indicator reects the TX request

and not its performance. Neither forward, nor reected power must appear at the output.

If at pressing the PTT or the TX button and without RF drive at the amplier input any indication

of RF power at the output still appears, it might be due to self-oscillation or it may be externally

induced by co-sited powerful transmitters. If you suspect self oscillation, check-up the coaxial

cables to the input and output of the amplier, in particular the contact of their shields to the

coaxial connectors (S. 2-3(d),(e)). To check for externally induced RF power (especially if the

reected power is higher than the forward power) connect the antenna to a dummy load via an

external RF wattmeter - it should read zero RF power.

e) Test transmission.

In the basic screen (Fig. 3-2) check whether the currently selected frequency band of the

amplier and the transceiver frequency match the antenna band. If needed (when the CAT/

AUX interface between the amplier and the transceiver is not connected), use BAND buttons

(up and down) of the amplier to switch to the desired frequency band manually.

In order to continue with the test transmission, prepare the transceiver mode in the same way

as it was done in item (a) above: with continuous carrier mode and minimum power. Now in the

Operate / RX mode choose a frequency which is presently not occupied and press the actuator

for transmit (PTT) briey, while watching the following indicators of the amplier:

- RX mode must be changed to TX;

- the reected power must be below 20W;

- the forward power must be between 20 and 150W with minimum drive power from the

transceiver (between 1 and 5W expected with the power control set at minimum);

- PA DC VOLTAGE must be within 48-52V;

- PA DC CURRENT must be between 1 and 8A (depending on the transceiver power

with its power control set at minimum).

If the above test goes normally, push briey the transmit actuator (PTT) once again, this time

18

Page 20

watching the transceiver SWR indicator (i.e. the input SWR of the amplier) – it must be below

1.2:1.

f) Setting of drive level and typical operation.

After the successful passing of tests (a) to (e), in the same mode with continuous carrier and

minimum power, press the transmit actuator (PTT) for several seconds, observing the forward

and reected power at the output, as well as the direct current drawn by the nal stage – PA

DC CURRENT. Increase the drive power gradually – from minimum until the forward power at

the amplier output reaches 600W. Observe at the same time that none of the indicators of the

amplier or the transceiver enters the colored alarm areas.

Reaching 600W forward power, check-up the following parameters (continuous carrier

operation):

- the reected power must not exceed 70W (for SWR 2:1) or better still to be below 25W

(for SWR 1.5:1);

- PA DC CURRENT must be between 20 and 26A; it is normal that the current varies

within these limits at changing of the operating frequency and the antenna impedance;

- PA DC VOLTAGE must be within 48 – 52V;

- the SWR indication of the transceiver must be below 1.2:1.

Enter menu MEASURE and check-up additionally:

- the drive power from the transceiver must be between 20 and 30W;

- PA BIAS must be between 2.5 and 2.9V (typically 2.8V);

- PA TEMPERATURE must be between the ambient and 80ºC (176ºF) depending on the

power level and the duration of transmission.

When possible, listen to the quality of the amplied signal using a monitoring receiver or ask

some regular correspondents for signal evaluation and comparison with and without amplier.

g) Elimination of electromagnetic compatibility (EMC) problems.

If you use an amplier for the rst time in your shack, you may need to make some improvements

in the set-up. It is possible you might nd tingling from metallic objects due to the stronger

radiated RF eld. It could affect the operation of your station or systems outside it, if the

latter are too sensitive – typical examples are the microphone, the Morse keyer, the computer

keyboard / mouse, as well as domestic radio / TV receivers, Hi-Fi, intercom or telephone

setups and others.

For instance, induction of RF currents into the microphone, Morse keyer or computer keyboard,

may lead to rough distortions in the peaks or self-oscillation in SSB mode, “sticking” or breaking

off the dots or dashes from the Morse keyer, or garbles on the computer screen, coming from

the keyboard or mouse. For the elimination of similar problems we recommend that you take

the following general measures:

19

Page 21

- minimize the radiation from the feed lines by reducing the common mode currents in

them; improve the balance of the antennas themselves and how they are fed;

- in case you use asymmetric antennas (GP and similar) install as many radials as

practical (a more developed counterpoise system);

- ground the coaxial cable shield additionally on at least one spot between the antenna

and the shack or if it is possible run the greater part of the feed line under ground;

- add current BALUN transformers in the coaxial feeders at the antenna itself, as well as

at the feeder entering the building (although this may seem unnecessary at GP);

- take away as far as possible (also by height) the radiating elements of the antennas

from the premises where the affected apparatus is located; in this sense, asymmetrical

antennas without a feeder (type Long Wire, simple Windom, and other similar) may

cause more interference because their radiating element begins immediately from the

shack (it is the feeder itself);

- if the use of asymmetrical directly fed “wire” antennas is inevitable, use mainly half

wave or half wave multiple – they have a high input impedance, operate respectively

with a small current in the feed point, and in the grounding of the shack; thus you can

reduce the strength of the disturbing RF elds in the whole more than 10 times (at the

same radiated power) compared to the case with quarter-wave and multiple to quarterwave antennas of this class – you should avoid them because they have a low input

impedance and operate with a large RF current in the grounding system and in the

power supply network respectively, i.e. they create stronger disturbances (RFI);

- improve the RF grounding system: use the shortest and widest possible metal strips for

the connections to ground and between the different gear in the shack; connect one or

more counterpoises (sized for the problematic band) to the feeder shield at the point,

where it enters the building, and the same point - with the possibly shortest and widest

connections - to the grounding system: this is a very efcient measure, in particular if

the shack is located on a high oor above ground;

- to reduce the RF impedance of the grounding connections sheet metal strips instead

of exible braids are preferred;

- thread ferrite beads with medium permeability (800-4000) over the power cord,

the feeder and the signal cables leading to the affected devices (TV etc); there are

suitable “split” ferrites on the market for this purpose with different sizes, shapes and

parameters, inserted in locking plastic shells, which do not need to be threaded through

the connectors on the cable ends and are simply put and locked over it; besides the

size, consider the frequency range in which the offered ferrites are effective – normally

they are optimized for suppression of interferences on HF (with larger permeability),

with medium permeability for HF-VHF or with low permeability - only the VHF range.

The latter are ineffective for HF;

- whenever possible use shielded cables and ground their shields at both ends;

- screen (at least partly) the disturbed apparatus, for example, put under the keyboard,

the mouse, the desk microphone or the Morse keyer a large metal sheet, connected to

the grounding system of the shack;

20

Page 22

- the addition of even quite simple low pass L/C or R/C lters directly to the disturbed

inputs or outputs of the apparatus is very effective, provided it is practically applicable.

Last but not least, have in mind that the benet of the above measures is two-fold. Firstly - they

reduce the interferences from your transmissions to the ambient environment and secondly

- they reduce the background noise oor for your reception. Practically, with no great efforts,

implementing the above measures, you can reduce the background noise oor with one or

more S-units across the different bands. This will allow you not to miss weaker stations, which

will hear you because of your increased transmission power.

4. OPERATION WITH THE AMPLIFIER

4-1. Change of modes RX / TX and Operate / Stand-by; option AUTO

OPERATE

a) In Stand-by mode, as well as with un-powered amplier, receiving and transmitting

with the transceiver is implemented via RF by-pass between RF INPUT and RF

OUTPUT of the amplier. At transmission in Stand-by, RF power of the transceiver

is not amplied by the amplier, the control KEY-IN input does not inuence over

its operation, and the KEY-OUT output (S. 2-3(c)) follows the state of the KEY-IN

input unconditionally.

b) In Operate mode the nal stage of the amplier is powered and it is fully functioning;

the receive-transmit (RX / TX) direction is controlled by the KEY-IN input:

- at open KEY-IN (Operate/RX mode), the transceiver receives the signals from the

antenna through the same RF by-pass path between RF INPUT and RF OUTPUT

through which receiving is done with amplier turned off or in Stand-by mode;

- at grounded KEY-IN (Operate/TX mode) the amplier input relay connects the RF

INPUT connector (drive from the transceiver) toward the nal stage input and the output

relay feeds the amplied signal from the nal stage output to the antenna through the

RF OUTPUT connector.

C A U T I O N

In order to provide time for the relays and the nal stage

in the amplier to switch safely from receive to transmit,

the transceiver should provide a dead time i.e. must “notify”

the amplier in due time grounding its control KEY-IN input

not later than 10ms before feeding drive power toward

the amplier RF input. Otherwise, the “HOT SWITCHING

ATTEMPT” protection will trip.

In Operate mode the KEY-OUT output (S. 2-3(c)) follows the state of the KEY-IN input only

after all conditions for safe transmission have been satised and found OK by the amplier

control unit. The KEY-OUT output duly disables transmission, if this is inadmissible or there is

a potential risk for the amplier or the transceiver.

The two modes - Operate and Stand-by - may alternatively be changed in three different,

21

Page 23

independent ways as described below:

- manually (locally) – by successive pressing the OPR/STB button – Fig. 3-2;

- remote control – through the respective command “OPR” or “STB”, received through

the serial RS232 Interface;

- automatic control – if the AUTO OPERATE option is activated – see next item and S.

5-4(b).

N O T E

Access to the Operate mode can be banned in the menu

AMP SERVICE, the OPERATE ACCESS option (S. 5-2 and

Fig. 5-2). The ban is universal.

c) AUTO OPERATE option - can be activated or deactivated by the operator in the

USER PREFERENCES menu – S. 5-4 and Fig. 5-4 - or through remote commands

by the RS232 interface.

When the AUTO OPERATE option is deactivated, the two modes Operate and Stand-by can be

changed alternatively via the OPR/STB button or by commands OPR and STB by the RS232

interface. Besides this, at a protection trip of the type SOFT FAULT, the amplier returns to and

remains in Stand-by mode, waiting for external intervention. For restoring of the operation, the

operator must press the OPR/STB button manually or to feed remote command OPR by the

RS232 interface.

When AUTO OPERATE is active (S. 5-4), the amplier goes automatically to Operate mode

immediately after power on without waiting for an OPR command by the interface or pressing

the STB/OPR button by the operator. At a protection trip of the type SOFT FAULT, the amplier

will rst go to Stand-by mode (same as at the deactivated option), but afterwards it will return

automatically to Operate mode after about 4 seconds without need of the operator to press

any button. Thus, the amplier will automatically seek to “support” Operate mode always when

this is admissible.

Anyway, even at activated AUTO OPERATE option, the operator can return to and remain in

the Stand-by mode also manually – through the OPR/STB button or by STB command by the

serial RS232 interface. This will suppress temporarily the AUTO OPERATE function and the

amplier will go to and remain in the Stand-by mode. The next pressing of the OPR/STB button

or sending OPR command by the interface will turn the amplier in the Operate mode and will

restore the normal operation of the AUTO OPERATE option (provided this had been active

before the command).

4-2. Band change, standard and expanded frequency coverage

When the amplier is connected to a transceiver with the CAT/AUX interface or to a computer

with the RS232 interface, the change of the frequency bands (i.e. change of the amplier output

lters) occurs automatically, following the operating frequency changes from the transceiver or

from the computer.

22

Page 24

N O T E

In the Stand-by mode the change of bands through the

CAT/AUX interface is deactivated temporarily; It is restored

at returning to the Operate mode.

The RS232 band change commands operate continuously. If the amplier gets a band change

command during transmission, the transmission is blocked temporarily while the command is

being performed; the amplier operation is restored after the change of the low-pass lters for

the new band.

When the amplier is not connected to any interface, the band changes can be accomplished

manually or again automatically – through the built-in frequency counter in the amplier.

Manual changes of the frequency bands can be done from the basic screen (Fig. 3-2) by the

BAND buttons – up and down. They can be done also in the Stand-by mode as well in the

Operate mode, but only at RX mode.

Automatic change of a frequency band via the built-in frequency counter of the amplier or

with CAT/AUX is performed only in the Operate mode. In the Stand-by mode the frequency

changes are continuously followed (with the frequency counter – only during transceiver

transmissions) but are not performed physically by the low-pass lters. The latest frequency

change is performed at entering the Operate mode.

When you rely on an automatic change with the built-in frequency counter, you have to make

a one quite short “preliminary” transmission (100ms is enough - a CW dit, or s sound on

SSB) and leave a pause (also short) before the main transmission. During this pause the

amplier will change the band according to the new frequency without RF power, after which

the operator can continue his operation as usual.

If the new frequency is within the range admissible for the amplier but outside the currently

selected band, the amplier control unit temporarily blocks transmission while the change of

the harmonics lter for the respective new band lasts, after which the transmission continues

on the new frequency as usual.

If the new frequency is out of the range admissible for the amplier (S. 8-1(a)), the transmission

request is denied and the following fault message appears on the screen:

“FREQUENCY OUT OF RANGE”

The standard frequency bands within which all amplier parameters are guaranteed are listed

in S. 8-1(a)). Extension or changes of the bands could be negotiated with the manufacturer.

4-3. Change of antennas and operation with an external antenna tuner

At a band change or moving frequency from one to the other end of the band it may be

necessary that you change the antenna and eventually retune the antenna tuner (unless your

antenna is a multibander and / or is broadband enough).

At antenna SWR over 1.5:1, it is preferable that you use an external tuner. Usually the

procedure for retuning the tuner requires a continuous carrier signal and small power. In such

a case, go to the STBY mode of the amplier and feed the power necessary for tuning from the

23

Page 25

transceiver only. After you have retuned the antenna tuner on the new operating frequency or

with the new antenna, return to the Operate mode and adjust again the drive power according

to the operating mode used – S. 3-6(f)).

4-4. Cooling and fans operation; modes with increased heat loading

During operation in modes with increased heat loading (continuous carrier, RTTY, SSTV,

some digital modes, and others), the amplier itself will monitor its temperature, automatically

increasing or decreasing fans speed depending on the loading and ambient conditions

(temperature, humidity, atmospheric pressure etc.).

4-5. Monitoring the amplier operating regime

Because of the availability of a continuously operating protection system in the amplier (S. 4-6),

the operator is not required to monitor its regime regularly. However, whenever he wishes, he

can digitally measure the 11 most important parameters connected with the amplier operating

regime. Besides this, the operator can select two of them arbitrarily for indication also in the

basic screen (Fig. 3-2, S. 5-1).

4-6. Automatic protection system

The control unit (S. 7-3(b)) keeps track with most amplier analogue and logic signals in all

modes. Monitored are, for example, the control signal receive/transmit, the output relay contact

status and switching times, the RF drive frequency and drive power (the input power), the DC

current and the DC voltage on the drains of the nal transistors, the bias voltage of their

gates and the temperature of their heat sink, the temperature of the main components in the

power supply unit, the forward and reected power at the RF output, and others. Besides this,

monitored and assessed are some derivative parameters, such as the power gain, the SWR,

the heat power dissipated by the nal transistors dynamically etc.

If anything abnormal has been found out in an arbitrary moment, the amplier will assess the

risk of the situation and can use three levels of protection according to the problem nature and

seriousness, as described in items (a) to (c) below. Every event is accompanied by a warning

text on the screen (Fig. 4-1), which is blinking to attract the operator’s attention. Besides this,

a sound signal is produced, whose volume, can be reduced by the operator if he so wishes –

menu “USER PREFERENCES” – Fig. 5-4.

24

Fig. 4-1 – Appearance of an alarm message

Page 26

a) The rst protection level is the WARNING type. Only a warning message appears

on the screen accompanied by a sound signal, but without any physical reaction

from the amplier – Fig. 4-1. This occurs when some of the values monitored by the

control unit approach too close the threshold of tripping the respective protection.

The transmission is not interrupted, but a message appears – for example “Drive

Power too High”, “Drain Current too High”, or another.

You can continue to transmit in these conditions, but you also have to take some measures,

for example, to reduce a little the drive power from the transceiver, because the respective

protection trip will be too close. The warnings for the rst level remain on the screen for at least

three seconds so that they can be read through and they disappear by themselves after the

reason has dropped off.

b) The second protection level is the SOFT FAULT type – it trips at crossing the

threshold of some protection, as long as it had not been fatal (then the third level

trips – see item (c) below).

At the second level (SOFT FAULT) the amplier itself does not turn off fully but only returns into

Stand-by mode for four seconds or permanently - depending on whether the “AUTO OPERATE”

option had been activated. Return into Stand-by mode is accompanied with the respective

message on the screen, for example “Excessive Reected Power”, “Excessive Drain Current”,

and others, as well as with a sound signal (unless its volume had not been decreased to zero

– S. 5-4).

Unlike those for a WARNING, the SOFT FAULT messages remain on the screen and persist

until the operator presses any button (including the two unused in the basic screen) - thus it

is understood that he has read the message - or until the AUTO-OPERATE function returns

automatically the OPERATE mode if the option is active – S. 5-4.

SOFT FAULTs presume performing fast and simple correcting actions by the operator, such as,

for example, reducing the drive power, improving of load SWR through retuning of the antenna

tuner, selection of another antenna, another frequency etc.

c) The third and most serious protection level is the HARD FAULT type, which turns

off the amplier automatically to avoid possible further damages.

At tripping the third level of protection, the amplier turns off its main power supply automatically,

stores all data about the fault in its nonvolatile memory, the front panel screen blanks and a

specic sound signal is emitted (namely a series of Morse letters F, which continues until the

control unit still has residual energy).

If it is not obvious due to what reason the protection has tripped, you can try to turn on the

amplier again. If the amplier allows turning on after the fault, the display will be lit but instead

of the basic screen, a fault message will appear with information about the reason for the latest

automatic turning off (for example, overheating of the power supply unit or of the nal stage

and others).

After pressing any button, the fault message will disappear; the display will show the basic

screen – Fig. 3-2, and if there are no current problems (for example, the overheated unit has

already cooled down), the amplier operation will restore. If any problem is being found out

again, a new message will appear on the screen, or the protection will trip again immediately,

after the attempt.

If the problem persists, refer to your dealer – S. 1-2.

25

Page 27

At each “HARD FAULT” turning off in the nonvolatile memory of the amplier is stored data

concerning its control and values, the problem occurrence time, and others. Your dealer or his

service may ask you to read through this data (by RS232 interface or from the amplier screen)

and store it in a computer le – see menu FAULTS LOG, Sections 5-5 and 7-4.

5. MENUS – USEFUL INSTRUMENTS AND OPTIONS

From the basic screen (Fig. 3-2), pressing of the same-name MENU button (the rightmost),

the list with the six menus appears (Fig. 5). Each of them can be selected by means of buttons

ITEM (up and down) and SELECT. Each menu contains one group of topically related “items” –

these are some useful instruments and options for control and operation of the amplier – Fig.

5-1 to FIg. 5-6.

Fig. 5 - MENU SELECTION

The items in each menu are selected and controlled by the same six buttons as in the menu,

but on the display above them appear inscriptions for their new functions. Through activation

and deactivation of the options in the menu, the operator can adapt the amplier to the set up

and the specics of his shack, in order to maximize its potential.

Service operations can be performed in the AMP MEASURE and the AMP SERVICE menus:

measurements, functional and parametric tests, as well as reading the faults log from the

nonvolatile memory (if such have been registered during operation) etc.

5-1. Menu “Measurements in the amplier” – AMP MEASURE

The menu AMP MEASURE (Fig. 5-1) is accessible from the MENU SELECTION screen (Fig. 5)

in all modes. It is possible to measure digitally 11 parameters in it, characterizing the amplier

operator.

26

Page 28

Fig. 5-1 Menu “Measurements in the amplier” – AMP MEASURE

Two identical lists appear on the left and the right halves of the screen, each one having the 11

parameters, whose values are refreshed continuously.

An arbitrary parameter can be selected in each screen half. Using buttons ITEM1 and ITEM2

(up and down) select the desired item (parameter) – it will be marked with color. Upon reaching

either the top or bottom edge of any half-screen, further movement in the same direction will

cause the screen to scroll up or down, respectively, so you can reach all the items in the list.

The two marked parameters will be indicated continuously in the digital measurements area on

the basic screen (S. 3-2(b), Fig. 3-2) - after leaving this menu (EXIT button).

5-2. Menu “Service functions in the amplier” – AMP SERVICE.

The amplier service menu (Fig. 5-2) is accessible from the MENU SELECTION screen (Fig.

5) only during reception (RX mode).

C A U T I O N

The AMP SERVICE menu is used for check and adjustment

of the zero-signal (idling) drain current of the nal transistors

and for tests of some functions and circuits in the amplier

during repair. We recommend thеsе procedures are carried

out only by a trained service technician!

With the ITEM buttons (up and down) the necessary service function is selected – it is colored.

With the SELECT buttons (left or right) the selected function or test item is turned ON or OFF.

The inactive functions are grey and the active - red. At leaving a function, its parameters are

turned off and deactivated automatically. Pressing the EXIT button all service functions (except

for the OPERATE ACCESS) are turned off (deactivated), menu AMP SERVICE is abandoned,

27

Page 29

and the MENU SELECTION screen comes back (Fig. 5). At another pressing of the EXIT

button, the basic screen returns (Fig. 3-2).

Fig. 5.2 Menu “Service functions in the amplier” – AMP SERVICE

Blocking access to the Operate mode can be controlled using the OPERATE ACCESS option.

When the amplier is locked (LOCK is selected), it remains in the Stand-by mode and cannot

be turned to Operate mode by random actions unless unlocked by the selection of UNLOCK

before that. Passwords are not used - only simple protection is envisaged against possible

child actions, or involuntary switching to Operate mode. While locked, an attempt for entering

Operate mode will trigger a reminder:

“OPERATE MODE IS LOCKED”

The status of the OPERATE ACCESS option can be changed manually as well as with remote

commands by the RS232 interface.

5-3. Menu “Selection of CAT/AUX interface” – CAT/AUX SETTINGS

The type and parameters of the CAT/AUX interface for your transceiver are assigned here. If

your transceiver has no CAT interface control, nor parallel or analogue voltage output (BCD /

VOLTAGE BAND DATA), you should select [OFF] at the uppermost row which will disable the

amplier CAT/AUX interface.

The manual selection of CAT/AUX interface (CAT/AUX SETTINGS) is accessible only during

reception – Fig. 5 and 5-3. After entering the menu, with the ITEM buttons (up and down) the

operator can mark the group of parameters which he will set (top to bottom, as listed on the

screen). The selected group is marked with color. Afterwards with the SELECT buttons (left or

right) the desired parameter is set – it is enclosed within square brackets.

First choose the type of interface: Serial (RS232 or TTL levels), Parallel (BCD band data) or

VOLTAGE (analogue band data).

28

Page 30

Choosing a serial interface requires additional settings according to the transceiver model.

The different transceiver brands and models have a great variety of controls and settings of

their CAT/AUX interfaces. For maximum exibility and clarity, they are divided into several

groups - 1 to 5. In order to select the command set and protocol parameters (BAUD RATE,

BYTE SPACING, and POLLING TIME) suitable for your transceiver, see the attached to this

manual list of brands and models.

If your transceiver is not presented in the published list, it could still be connected with CAT/

AUX to the ACOM 600S if its commands set and protocol are compatible with those proposed

in the CAT/AUX SETTINGS menu. If needed, consult your dealer.

Fig. 5-3 Menu “Selection of CAT/AUX interface” – CAT/AUX SETTINGS

At leaving the menu (by pressing the EXIT button), the parameters enclosed currently within

square brackets remain selected (become effective).

5-4. Menu “USER PREFERENCES”

Here the operator can adjust some secondary (minor) functions of the amplier according to

his personal preferences.

29

Page 31

Fig. 5-4 – Menu USER PREFERENCES

In order to select the user preference which has to be changed, rst with the ITEM buttons

(up and down) position the large colored window. Afterwards with the SELECT buttons (left or

right) position the marker onto the desired value – Fig. 5-4.

a) AUTOMATIC MENU EXIT.

To activate or deactivate the option, rst select menu USER PREFERENCES (S. 5-4 and Fig.

5-4) and position the large colored window upon the AUTOMATIC MENU EXIT option with the

ITEM buttons (up and down). Select ON or OFF with the SELECT buttons (left or right). Finally,

exit the menu with the EXIT button – this will activate the currently selected state ON or OFF.

When the option is activated (ON), the amplier exits the currently selected menu if no button

has been pressed for more than 5 minutes.

If the option is deactivated (OFF), the amplier remains in the currently selected menu until

operator’s intervention.

b) Activation and deactivation of option AUTO OPERATE.

The AUTO OPERATE option can be activated manually, as well as by remote commands on

the RS232 interface.

To control it manually, rst select the USER PREFERENCES menu (S. 5-4 and Fig. 5-4) and

in it – the AUTO OPERATE option by means of the ITEM buttons (up and down).

The option is activated or deactivated by selecting ON or OFF through the SELECT buttons

(left or right). Finally, exit the menu by pressing the EXIT button – the currently selected value

will be accepted.

30

Page 32

For the role and functioning of the AUTO OPERATE option see Sections 3-3, 4-1(c), and

4-6(b).

c) CALL SIGN edit.

To compose an arbitrary text (for instance the operator’s call sign), after the row CALL SIGN is

selected with the ITEM button, the small pointer must be set with the SELECT button (right) on

the position you wish to be edited. Afterwards, again with the ITEM button, the symbol for this

position is changed – they appear one after another in the order of the ASCII code. Then with

SELECT (right) the next symbol for editing is selected etc. Finally, again with SELECT (left)

the small pointer returns backwards until it comes out of the cells for editing and only then with

ITEM can be selected another row (user preference). When the EXIT button is pressed the

edited values are memorized. The call sign entered will appear only in the amplier Fault Log

and will not be displayed at the start up.

The other preference items need no explanation.

5-5. Reading the FAULTS LOG

When selected from the menus list (Fig. 5), the FAULTS LOG function provides a possibility to

read and/or download the information from the nonvolatile memory of the amplier, registered

at the last 28 automatic protection trips of the type “serious failure” (HARD FAULT - S. 4-6(c)).

The information can be read or pictures can be taken from the amplier display, or more

comfortably – it can be downloaded and archived in a plain-text format le through the RS232

interface and a computer using a standard terminal emulating program (TTY). The RS232

protocol is: 9600, 8 N 1 (9600bit/s, 8 information bits, no parity check, 1 stop bit).

An example view of the screen is shown in Fig. 5-5.

In the le title individual information about the amplier and the options is given: model, user

call sign, serial number, revisions of the hardware, the rmware, and the boot loader, number

of worked hours, availability and model of an automatic antenna tuner and/or antenna selector.

Further on, for each of the stored faults hexadecimally coded information is given about the

values of the 55 monitored parameters, concerning the regime and the state of the amplier,

including: the number of worked hours, the operating frequency, the parameter which has

caused the protection trip, the regime in which the amplier has been in, as well as the values

of all analogous and logic inputs and outputs of the control unit at the time of the event.

31

Page 33

Fig. 5-5 Function FAULTS LOG

Pressing the button FILE, the data can be downloaded in a plain text format through the built-in

RS232 interface - see S. 7-4 for details.

5-6. Menu “RESTORE DEFAULT SETTINGS”

The factory default settings for the user preferences and some other data can be reset here.

While selecting the menu (Fig. 5-6) the bottom part of the screen is empty (no warning). The

colored window is moved with the ITEM buttons (up or down) to select the position for which

you want to restore the default settings.

All proposed actions initially are set on “NO” for all positions and nothing happens at reconrming “NO” (i.e. pressing the ACTION - right arrow button). At pressing EXIT this menu

is left without changing anything and the control goes back to the MENU SELECTION screen

(Fig. 5).

At rst pressing of the ACTION - left button, “YES” for the selected row is proposed and at the

bottom of the display a warning text appears about the action that would be implemented after

conrming it. At this stage, the operator still has the opportunity to quit the execution of the

prepared action - he can press either the ACTION - right (NO) or the EXIT button.

The time for conrmation of the prepared action (by selecting “YES”) is limited to 60 seconds

in this state regardless of the current status of the AUTOMATIC MENU EXIT option (S.

5-4(a)). If nothing is pressed within 60 seconds, “ NO “ (ACTION - right) is automatically

selected.

32

Page 34

In order to conrm the selected action the operator must press the ACTION - left (YES) button

once more. After its implementation the control returns to the MENU SELECTION screen - Fig.