Page 1

AUTOMATIC HF LINEAR AMPLIFIER

ACOM2000A

OPERATING MANUAL

1

Page 2

ACOM Ltd.

Blvd. Nikola Mushanov 151

1330 Soa, Bulgaria

phone: +359 2 920 96 55

fax: +359 2 920 96 56

e-mail: acom@acom-bg.com

acom@mail.orbitel.bg

www.acom-bg.com

2

May 2017

Printed in Bulgaria

Page 3

Table of Contents

1. GENERAL INFORMATION ..................................3

1-1. Introduction and Description.................................3

1-2. Owner Assistance.........................................3

1-3. Equipment Supplied and Options.............................3

1-4. Features ................................................3

1-5. Safety Considerations, Explicit Denitions ......................4

2. INSTALLATION............................................6

2-1. Unpacking and Initial Inspection..............................6

2-2. Line Voltage Selection .....................................6

2-3. Transformer Installation ....................................7

2-4. Connections .............................................8

2-5. Installation of Optional Fan.................................12

3. POWER ON, RCU CONTROLS, INDICATORS AND MENUS .......12

4. AUTO MODE .............................................15

4-1. MAIN MENU............................................15

4-2. AUTO TUNE procedure ...................................19

4-3. Erasing USER segments (return to DEFAULT- tunings) ..........22

5. MANUAL MODES.........................................23

5-1. MANUAL TUNE .........................................23

5-2. MEASURE function ......................................24

5-3. SERVICE procedure......................................26

5-4. CAT SETTINGS .........................................26

5-5. MORE SETTINGS .......................................27

5-6. HELP .................................................29

6. OFF MENU ..............................................29

6-1. CALL SIGN ............................................29

6-2. AUTO ANTENNA CHANGE ................................30

6-3. AUTO OPERATE ........................................30

6-4. SELF ADDRESS ........................................30

3

Page 4

6-5. CLEAR THE USER TUNINGS ..............................30

6-6. CLEAR THE MEMORY ...................................31

7. CAT OPERATION AND CONNECTIONS .......................31

8. MAINTENANCE ..........................................35

8-1. Cleaning ...............................................35

8-2. Backup Battery Replacement ..............................35

8-3. Fuse Replacement ......................................35

8-4. Tube Replacement .......................................36

8-5. The ACOM2000A Simplied Schematic Diagram................36

8-6. Troubleshooting .........................................37

9 SPECIFICATIONS .........................................39

9-1. Parameters.............................................39

9-2. Functions ..............................................40

9-3. Storage and Shipment ....................................41

10. BRIEF MENU GUIDE .....................................42

4

Page 5

1. GENERAL INFORMATION

1-1. Introduction and Description

This manual explains the installation, operation and maintenance of the ACOM2000A automatic

HF linear amplier.

The ACOM2000A is a complete and self-contained linear amplier that covers all amateur bands

from 1.8 through 30MHz, has automatic self-tune capability, and provides up to 1500W output

power with less than 60W exciter drive. The amplier can tolerate loads up to 3:1 VSWR (2:1

on 160 meters) and the process of matching the antenna impedance to the optimum load of the

tubes is automated. It features a Remote Control Unit (RCU), contains nonvolatile memory for

settings on up to ten different antennas per frequency segment, and offers command capability

for use with an external automatic antenna selector and/or automatic antenna tuner. Transmit

/ receive switching is capable of full break-in operation (QSK) via an internal vacuum relay.

All indicators and controls (except the primary mains switch and indicator) are available via the

Remote Control Unit - RCU. All command input to the RCU is menu-driven.

1-2. Owner Assistance

If assistance is needed, you should contact your local dealer. If necessary, your dealer will

contact ACOM for additional guidance. If you still have an issue you need to discuss with one

of ACOM's specialists, the contact information is as follows: fax: + 359 2 920 96 56, e-mail:

acom@acom-bg.com, acom@mail.orbitel.bg or by mail: blvd.”Nikola Mushanov” 151, 1330

Soa, Bulgaria.

1-3. Equipment Supplied and Options

The ACOM 2000A amplier is shipped in two cardboard cartons. One carton contains the power

transformer; the second carton contains the amplier. The remote control unit (RCU) is shipped

inside the amplier in the area where the power transformer will be mounted.

There are several individual purchase options available.

They are:

1) An auxiliary EXTERNAL FAN for continuous modes of operation (rear panel mount)

2) CAT CABLES for connection to the supported transceivers

3) The TECHNICAL SUPPLEMENT to this manual, containing electrical diagrams, technical

details on operation and maintenance, as well as a list of command set and local network rules

for RS232 operation.

The Automatic antenna selector ACOM 2000S and Remote antenna switch ACOM 2000SW

are especially designed to complete your ACOM system.

1-4. Features

• Automated matching of the antenna impedance to the optimum load of the tubes during initial

preparation of user tunings.

• Easy to operate. No operator intervention is required when changing antennas or frequency.

Thus the risk of inadvertent errors, such as incorrect antenna selection or failure to change

band switch, is eliminated.

5

Page 6

• TFT color display. All amplier status indicators and comments are presented on the Remote

Control Unit (RCU) display. The HELP sub-menu gives on-board technical assistance and

troubleshooting suggestions, power-on elapsed time hours etc. Two color strips display peak

forward and reected power. Indicators are provided for OPERATE/STANDBY and for fault

conditions.

• Easy maintenance. Information on the amplier’s internal status is stored in an "INFO BOX"

for the 12 most recent protection faults. This information can be read directly from RCU display

by the operator.

• Less QRM, improved Electro Magnetic Compatibility during tuning. Retuning can be achieved

in three ways: manually via the RCU, by the transceiver’s CAT system, or with a very short

transmission - a single word on SSB or a dot (even at 40 wpm) on the new frequency is enough

to change bands or segments automatically in a second. Also, the initial process of user tuning

settings preparation is done in less than three seconds at a quarter of nominal output power.

• Saves space on the operating table. Since the amplier is controlled by the RCU, the main

unit can be located up to 20 meters (65 feet) from the operating position. The supplied 3 meter

(10 ft) cable may be easily extended to the needed length.

• Operates automatically without special signals from the transceiver - “ground on TX” (PTT)

and 60W RF drive power are sufcient to control and operate the amplier.

• CAT connection to most transceiver models.

• Broadband input matching circuit resulting in very good load to the transceiver over the entire

short wave spectrum.

• Uses two 4CX800A (GU74B / ГУ74Б) Svetlana (Светлана) high performance ceramic-metal

tetrodes with plate dissipation of 800W each (forced air cooling, grid-driven).

• ACOM maintains strict adherence to the tube manufacturer’s specications for cooling and for

the sequence of applying and removing the different tube voltages. Starting lament current is

limited, and there is constant monitoring and protection of all supply voltages and currents. The

Bias Optimizer decreases the heat dissipated from the tubes, and there is automatic protection

against overheating or insufcient air ow.

• A novel and innovative output RF Arc protection is employed. It safeguards the amplier,

antenna, antenna selector and tuner against severe damage in case of possible break down.

• High voltage power supply inrush current protection which eliminates the danger of affecting

sensitive devices, connected to the same mains circuit. The amplier can be congured for 5

nominal line voltages: 100, 120, 200, 220 and 240VAC (50 or 60Hz). Other nominal values

possible on request.

• Continuous measuring and/or monitoring of 20 most important parameters of the amplier,

exciter and antennas via RCU and computer as described in the TECHNICAL SUPPLEMENT.

• All functions are accessible from a computer via RS232 serial port connection. Also, local

networking capability exists for more than one set of amplier / antenna units working in a system.

1-5. Safety Considerations, Explicit Denitions

The ACOM2000A Automatic HF Linear Amplier is a Safety Class I unit, i.e. the third grounding

lead of its mains cord (which is colored yellow with two green stripes) and the ground stud on

the rear panel of the amplier, marked GND, both must be connected to the station's grounding

6

Page 7

system for safe operation. The amplier is designed to meet international safety standards

and complies with CE safety and electromagnetic compatibility requirements, as well as FCC

regulations.

This operating manual contains information, precautions, indications for cautions and warnings

which must be followed by the user to ensure safe operation and to keep the ACOM2000A in

safe operating condition.

PRECAUTIONS:

The EXPLICIT DEFINITIONS described below apply to this operating manual:

W A R N I N G notes call attention to a procedure which, if not correctly performed,

could result in personal injury, re hazard or electric shock.

C A U T I O N notes call attention to a procedure which, if not correctly performed, could

result in equipment damage, not only in the amplier.

N O T E notes call attention to a procedure which, if not correctly performed, could

result in inconvenience.

W A R N I N G HIGH VOLTAGE!

The amplier works with high voltages up to 3000V, which are LETHAL!

Also, for your safety, pull the amplier power plug out of the mains wall

outlet and WAIT AT LEAST 30 minutes EACH TIME BEFORE you remove

the cover of the amplier. Do not touch any part inside while the amplier

is open because some residual voltages may still be present.

W A R N I N G HIGH VOLTAGE!

Never allow anyone, ESPECIALLY CHILDREN, to push anything into

holes in the case - this will cause electric shock. NEVER TOUCH AN

ANTENNA during transmission - this may result in an electric shock or

burn. NEVER EXPOSE the amplier to rain, snow or any liquids. AVOID

placing the amplier in excessively dusty environments or in direct

sunlight. DO NOT OBSTRUCT AIR INTAKE (rear panel) and EXHAUST

(top cover) areas of the amplier. Keep a minimum distance of 10cm (4

inches) to the intake and 50cm (20 inches) to the exhaust.

W A R N I N G

Do not undertake on your own repairs or changes in hardware or software

of the amplier in order not to endanger your or other’s health and life

and not to damage the amplier and the equipment connected with it,

not covered by warranty. The manufacturer is not liable for another’s

actions and responsibility shall be assumed by the doer.

C A U T I O N

To avoid damage (not covered under warranty) read the Installation - Section 2

of this operating manual carefully. If you have any doubts about the installation,

operation or safety of the amplier, please consult your dealer.

7

Page 8

2. INSTALLATION

2-1. Unpacking and Initial Inspection

N O T E

Before you start any action on installing the amplier, thoroughly read through

this manual. First, carefully inspect both cardboard cartons and their contents

for physical damage. If damage is apparent, notify your dealer immediately.

Delay may infringe carrier's warranty conditions. Keep all packing for possible

future transportation!

In order to take the RCU out of the amplier, remove the cover by removing all screws except

the eight located in the tube exhaust areas. Remove the plastic tubes holders but keep them

for possible future transportation. Do not remove the silicone rubber chimneys!

W A R N I N G HIGH VOLTAGE!

Check the HV Crowbar (Fig. 2-1) - it must reliably short the HV lead to

the chassis when the cover is removed.

Take the RCU out and free the compartment for installing the transformer. Carefully inspect the

RCU and the amplier main components for any possible shipping damage.

Check carefully the serial numbers of amplier and tubes with the Table of

Individual Data (Table 2-1). If you nd any discrepancies, notify your dealer

immediately to have your warranty information corrected.

Voltage Selector Position

Optional Fan Output Voltage

Table 2-1. ACOM2000A Individual Data

2-2. Line Voltage Selection

To avoid damage (not covered under warranty), verify that the voltage for

which the amplier is set corresponds to your mains nominal voltage. Most

120V and especially 100V domestic mains installations may not withstand the

current consumption and you will have to reduce the output power to about

1000W PEP. In USA, 240V is strongly recommended.

N O T E

AMP s/n

Front tube s/n

Rear tube s/n

C A U T I O N

8

Page 9

Normally the amplier is supplied with Voltage Selector set for a nominal mains voltage of

240V. There might be exceptions in cases of special delivery and then the voltage set is noted

in the Table of Individual Data (Table 2-1). If your mains has a different nominal voltage, it will

be necessary for you to contact your dealer or see the TECHNICAL SUPPLEMENT for details.

2-3. Transformer Installation

C A U T I O N

After installing the transformer, the weight of the unit is about 35kg (78 lbs),

which should preferably be handled by two persons. An assistant may be

needed to hold the amplier steady during transformer installation.

Position the amplier, with the transformer not yet installed, at on a table near the place where

it will be used. During the process described below, when the amplier cover is removed, take

care not to torque or twist the chassis nor let the amplier stand on edge. Do not lift the unit by

only one corner.

Orient the amplier on the table so that the transformer compartment is in front of you (Fig.2-1)

HV PCB

HV Crowbar

AC Power

Console

Mains Connector

HV Connector

Motor Voltage Connector

SG Voltage Connector

Fig.2-1 Transformer Installation

Take the transformer out of the carton and remove the shipping board but do not discard the

shipping board or the bolts. For transformer mounting, four shorter bolts (M8x16mm) are

provided in a polyethylene envelope inside the same carton. Use the polyethylene envelope to

store the longer shipping bolts. Keep the board together with the four long bolts and all packing

for possible future transportation of the transformer.

9

Page 10

Move the transformer, using its rope sling handle, into the compartment. Take care not to

damage the wiring or components and position the transformer so that the captive nuts are

aligned with the corresponding chassis holes. Make sure that the transformer is centered. The

transformer bolts must be installed NOW for safe operation.

Holding its two sides (front and back) simultaneously, pull the amplier towards you just far

enough that the two outside transformer captive nuts appear off the table edge. Support the

amplier until your assistant loosely screws in the two outside transformer-mounting bolts. Pull

the amplier a further 12-13cm (about 5 inches) until the other two captive nuts appear off

the table edge. Keep supporting the amplier until your assistant loosely screws them in. After

checking that the transformer is centered, tighten all 4 bolts. Now move the amplier back over

the table.

The transformer's Mains Connector plugs into the AC power console (Fig.2-1). The other three

connectors (HV, Motors Voltage & Screen Grid Voltage) plug into the HIGH VOLTAGE PCB,

clearly seen on top.

Replace the cover and carefully reinstall all screws.

2-4. Connections

The amplier is now ready to be connected to your station. Connection must be accomplished

in the order described below, before you apply mains voltage to the amplier.

W A R N I N G

Have in mind that the grounding system may have to withstand currents

over 20A with insignicant voltage drop on it. Therefore it may be

necessary to improve it considerably (to become lower-resistive, i.e.

with heavier leads and lower-resistive ground path). The grounding leads

should be at least 8mm2 (AWG 8 or SWG 10).

10

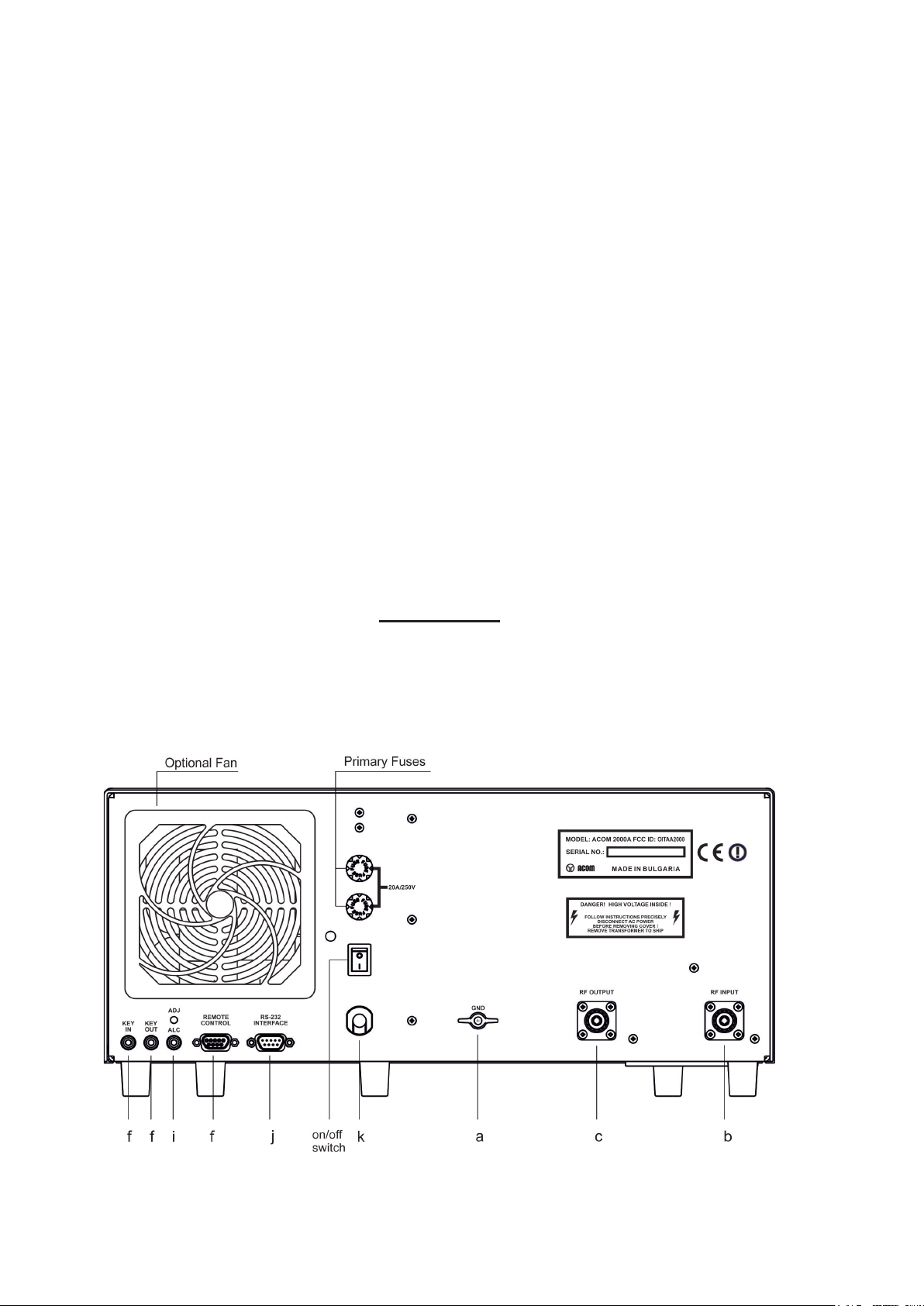

Fig. 2-2 Amplier Main Unit Connections

Page 11

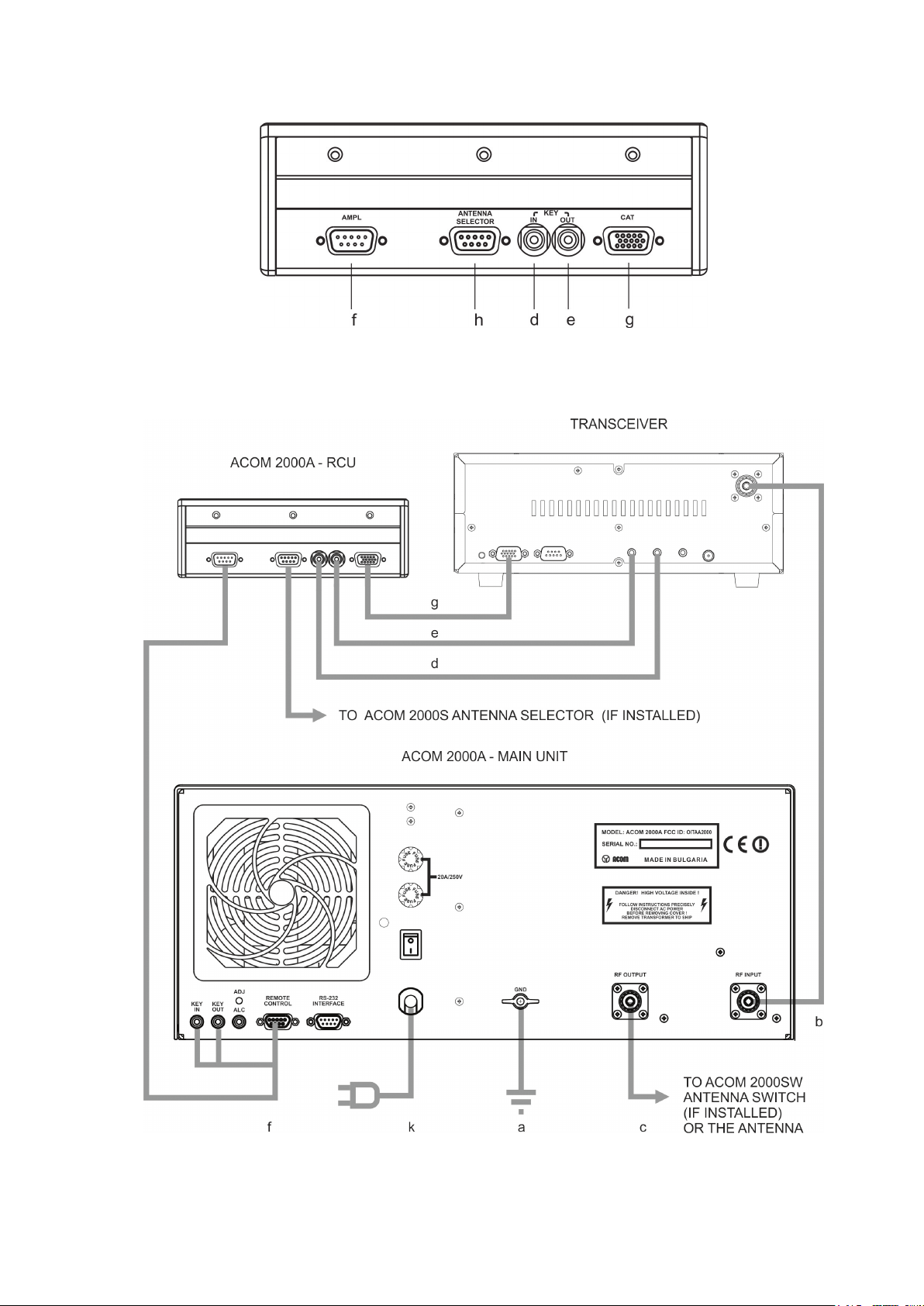

Fig.2-3 Amplier Remote Control Unit Connections

Fig.2-4 Main Unit, RCU, Antenna Selector, and Transceiver connections

11

Page 12

a) Connect the ground stud of the amplier Main Unit (on the rear panel, marked GND) to

the station's grounding system (Fig.2-2, Fig.2-3 & Fig 2-4).

b) Connect a coaxial cable with a PL-259 plug from the transceiver output to the amplier

rear panel RF INPUT socket.

C A U T I O N

If this is the rst time you will use a high power amplier in your station, pay

attention to the coaxial cable type from the amplier’s output. It must handle

the increased power safely - particularly on the higher frequency bands. We

recommend you use RG213 or better coaxial cable. Similar good quality coaxial

cable should be used throughout your antenna system. Check the power

capability of the antenna selector, the tuner and the antenna itself (especially

multiband trap antennas).

C A U T I O N

Do not use your transceiver’s internal tuner with the 2000A –this can damage

the input of the 2000A

c) Connect a coaxial cable from the amplier output (on the rear panel, marked RF OUTPUT)

with a PL-259 plug to the antenna selector or tuner or to the antenna for the respective band

N O T E

Your amplier will not work if KEY-IN is not connected properly.

Transceiver producers give different names to this output and they are for instance TX-GND,

SEND, T/R-LINE, etc. Some transceivers require that “ground on transmit” is implemented via

a software command, or by changing the setting of a switch on the rear panel, or interior of the

transceiver. Check your transceiver’s manual.

d) Run a cable terminated in a RCA phono plug from the transceiver socket providing “ground

on transmit” to the RCU rear panel KEY-IN socket.

N O T E

If there is a CAT connection between your amplier and your transceiver, which

carries also the KEY-IN signal, you don’t need a separate KEY-IN cable. Not

all transceivers however have this capability. Please see section 7 for more

details.

e) The KEY-OUT socket on the RCU rear panel provides an extra control signal from the amplier

to the transceiver. It could be used to improve the transmit/receive switching.

If your transceiver has a suitable input that disables transmission, we recommend that you

connect it with a cable terminated in a Phono connector to the KEY-OUT socket of the RCU.

Transceiver producers give different names to this input and they are for instance TX-INHIBIT,

MUTE, LINEAR, etc. Check your transceiver’s manual. Consult your dealer or see the

TECHNICAL SUPPLEMENT for details.

If your transceiver has not such an input don’t worry - the amplier will function normally as well

and then the KEY-OUT may remain unused.

12

Page 13

N O T E

If there is a CAT connection between your amplier and your transceiver,

which carries also the KEY-OUT signal, you don’t need a separate KEY-OUT

cable. Please see section 7.

f) Connect the supplied DB9 / DB9+2RCA control cable between the RCU connector marked

AMPL and the amplier REMOTE CONTROL connector. Plug in the two Phono connectors

marked KEY-IN and KEY-OUT to the respective amplier sockets. Screw in the knurled screws

g) To control the amplier via CAT you will need a special cable from the transceiver to the High

Density HD-15 connector on the RCU rear panel, marked CAT. The HD-15 pinout and cable

diagrams for various transceivers are shown in section 7. The cable can be supplied as an

option with the amplier or purchased separately or you can assemble your own. Check with

your dealer for cable options for your transceiver.

h) Automatic antenna selector ACOM 2000S can be connected to the respective connector on

the RCU rear panel.

i) The ALC output of the amplier normally remains unused. In case of need of ALC for your

transceiver, which we do not recommend, you may contact your dealer or see the TECHNICAL

SUPPLEMENT.

j) The connector on the amplier rear panel, marked RS232 INTERFACE, remains unused

until you decide to use the amplier with a computer or in a local network as described in the

TECHNICAL SUPPLEMENT.

C A U T I O N

Do not connect to the connector, marked RS-232 a "standard" cable because

this may result in damage in both - amplier or connected equipment. In order

to use the RS-232 interface, a special cable must be prepared. Contact your

dealer or see TECHNICAL SUPPLEMENT for details.

k) Mains plug and fuses.

W A R N I N G

If your amplier is only tted with one mains fuse, it is suitable for

0-220/240 VAC electricity supplies ONLY (these supplies are standard in

the European Community). Your dealer will check that your amplier is

correctly fused before it is shipped to you. Customers should check with

a qualied electrician if the amplier is to be used outside the country

in which it was purchased.

Due to the different standards in different countries, the mains plug is supplied and mounted by

the dealer. He connects to the mains cord end a standard mains plug which meets the Safety

Class I units standard in your country. The ground lead of the amplier's mains cord is colored

yellow with two green stripes and the blue and brown leads are active. When the amplier is to

be used with only one mains fuse, it is connected in series with the brown lead which must be

the active. If you have any doubts about the correct way of connecting the wires, consult your

dealer. All ampliers sold in the USA will have two fused leads.

l) Preparation of wall outlet for the amplier.

13

Page 14

W A R N I N G

Before connecting the amplier to your mains supply, be sure that the

supply is correctly wired, and is adequate for the current drawn by the

amplier. Make certain that the grounding lead is connected properly in

the wall outlet for the amplier.

It is preferable that you use the wall outlet closest to the source. The installation leads should

be at least 2.5mm2 (AWG 12 or SWG 15). Check if the respective fuses can handle current up

to 20A, as well as if the voltage corresponds to the voltage for which the amplier is set (S.2-2).

If you connect the amplier to a different mains outlet, be sure that you check it, too.

Make sure the main Power Switch on the front panel is in OFF position (so that the red strip on

the switch is hidden) and insert amplier's mains plug into the wall outlet prepared for it. The

amplier remains switched off.

2-5. Installation of Optional Fan

This fan is not necessary in SSB and CW modes, nor in continuous carrier modes (RTTY, SSTV

etc.) with carrier down times of maximum 15 minutes and a subsequent pause of 3 minutes. For

higher duties the fan is recommended. The auxiliary fan (119x119mm) is supplied as an option

with a set of 8 screws, nuts and washers. It may be mounted by the manufacturer or dealer

on request (Fig. 2-2). Contact your dealer or see the TECHNICAL SUPPLEMENT for details.

3. POWER ON, RCU CONTROLS, INDICATORS AND MENUS

C A U T I O N

Before you turn the amplier on, at least 2 hours should have expired since

it was brought in and unpacked in the room where it will be used. Pay

particular attention when you move it from a very cold into a very warm place

- condensation is likely and this could result in damage to the high voltage

circuits. In such a case, wait at least 4 hours. A similar effect can occur after

a rapid warming of the operating room (for instance after switching on a

powerful heater).

C A U T I O N

To avoid damage (not covered under warranty) carefully check that the voltage

for which the amplier is set corresponds to your mains nominal voltage (see

S.2-2 and table 2-1).

After following all instructions in S.2, you can turn ON the Main power switch on the rear

panel (Fig. 2-2). The front-panel red indicator must light and a picture will appear on the RCU

(Fig.3-1):

12

Page 15

Fig.3-1 Remote Control Unit (RCU)

N O T E

The owner's call sign will be only displayed after it has been programmed into

the RCU. See Section 6-1 for details on programming your callsign.

In this condition, only the RCU is operational, while the amplifier itself is still fully off.

Nevertheless, you have access to the HELP feature (at the left bottom corner, see S5.6) and

you can switch antennas if the ACOM2000S automatic antenna selector and the ACOM2000SW

remote antenna switch are installed. The assigned number and name of the currently used

antenna is shown at the right bottom corner of the display, just above the antenna-change key.

Except for the main power switch on the front panel, the amplier is controlled via the RCU

(see Fig 3-1).The amplier is toggled ON or OFF by pressing the red ON/OFF button. There

are two more “xed function” buttons located at the left bottom – the OPR button which is used

to toggle between OPERATE and STANDBY (STB) modes, and the SET/EXIT button - to enter

and exit the menus.

The six buttons immediately below the bottom of the display are “soft keys” and their function

can vary depending on what the context is at the time. As you explore the various functions of

the amplier, the functions of these buttons are explained in detail.

The control of the amplier is structured in two menus - OFF and MAIN, each having several

sub-menus (g.3-2):

13

Page 16

Fig.3-2 Menu Structure (see also S.10)

N O T E

We recommend that before powering up the amplier for the rst time, you

familiarize yourself with the functions of the RCU in the OFF menu. The

available controls and indications seen on the RCU are similar in both the

OFF and MAIN menus.

You can proceed in one of two directions:

a) you can enter the OFF menu (see below) or:

b) you can turn on the amplier and begin the warm-up sequence. After 2.5 minutes you will

enter the MAIN menu (see S.4-1) and may start operating the amplier.

The OFF-menu (see also section 6) can be reached by pressing the SET/EXIT button:

14

Page 17

Fig.3-3 RCU display - OFF MENU

By means of the UP and DOWN keys you can select one of the listed items. Then with the left

and right arrow buttons you choose the desired value or move the colored frame on it.

The call sign character positions are selected by left and right arrow buttons. The character

in a selected position is changed by means of the UP and DOWN keys. Push the left button

repeatedly to return to the items list.

To exit the OFF menu, press the SET/EXIT button again.

The purpose and use of the OFF menu settings are described in detail in Section 6, after the

description of the basic functions and use of the amplier.

4. AUTO MODE

Operation of the 2000A amplier is simplied a great deal due to the high degree of automation.

You can start operation immediately after it is installed. However, to make full use of its

possibilities and to fully congure the amplier we recommend that you thoroughly read the

following information.

4-1. MAIN MENU

a) TURNING ON

In order to turn on the amplier, while the rear panel Switch (Fig. 2-2) is on, press the red button

on the RCU and hold it on for about one second and you will hear "TEST" being sent in CW.

After successfully passing the INITIAL SELFTEST, the following display appears:

15

Page 18

Fig.4-1 RCU display during warmup

A 2.5 minutes tube warm-up period follows during which heater and bias voltages are applied.

During warm-up the amplier remains in STB, so you can operate with the transceiver only.

You can also change the antennas manually or read the HELP texts during the warm-up period.

N O T E

When you intend to have a brief pause in operating (e.g. less than 30 minutes),

it is better to leave the amplier in STB mode instead of turning it off. Tube life

may be shortened by repeatedly turning on and off the tube heater supply. If

you are concerned about this, discuss it with your dealer.

N O T E

However, if you unintentionally power-off the amplier, it is best to switch it

on again immediately. When the pause is short (up to one minute) and the

cathodes are still warm, the warm-up period is shortened signicantly, which

reduces the waiting time and prolongs the tube's expected life.

b) MAIN MENU

After the indicated warming up period expires, all voltages are automatically applied to the tubes

in the correct sequence. At the same time the stepper motors conduct a self-test and nally

tune the plate circuit to the frequency segment on which the amplier was last used. You hear

"R" being sent in CW and the MAIN MENU appears on the TFT display (see gure 4-2 below)

16

Page 19

:

Fig.4-2 RCU display - MAIN MENU

The RCU display provides information about the current operational condition of the amplier. You

can see three bar graphs: Forward Power, Reected Power (RFL) and Exhaust Air Temperature.

Unless transmitting, only the last one is active, indicating the Exhaust Air temperature in degrees

C.

The whole HF spectrum is divided into 250 segments. Segment width increases with frequency

from 25kHz on 160m to 300kHz on 10m. You can use up to ten different antennas and tunings

per segment. This may be useful with narrow-bandwidth antennas.

The frequency segment on which the amplier is tuned (in MHz) is indicated on the left-hand

side on the display. (28.300 to 28.600 in Figure 4-2 above).

Below the frequency segment, the number of the antenna in use is displayed along with its

name, and how the antenna was selected – manual or auto.

If the CAT connection to the transceiver is turned on, the transceiver type is shown at the left

side under the antenna eld.

At the bottom left it is shown the tune type for the current frequency segment and antenna (in

Figure 4-2, DEFAULT is shown indicating as factory programmed). The amplier may also be

user-tuned by means of the AUTO TUNE procedure as explained in Section 4-2.

Next to the tune type there is an indication for operate (OPR) or Standby (STB) mode.

At the bottom right there are three indicators available which warn you with yellow light when

the heater voltage, the plate current, or the drive RF power are approaching their limits.

c) ON AIR

If the VSWR of the antenna is acceptable (below 1.5:1) or you have fresh USER TUNINGS readily

prepared (see S.4-2), you may start operating the amplier immediately after pressing the OPR

(Operate) button. The label STB on the display changes to OPR and you may transmit. The

bar graph on the upper line indicates the power fed into the antenna (forward power) and the

smaller bar graph below - the power reected from the antenna (RFL). The difference between

17

Page 20

the two is the real output power delivered from the amplier. The red TX sign illuminates (See

g 4-3) whenever KEY-IN input is keyed, i.e. the transceiver goes into transmit mode.

If the CAT connection is active and the amplier is in OPERATE mode, it will continuously track

the transceiver frequency and will automatically tune up when entering a new segment.

If there is no active CAT connection to the transceiver, and you start transmitting on a frequency

different from the indicated segment (and the amplier is in OPERATE mode), it automatically

senses your operating frequency, selects the corresponding segment, and tunes up on it. This

retuning takes less than one second and you are immediately ready to operate on the new

band. Example:

Fig. 4-3 RCU display Main Menu during transmission

In the example, a signal frequency between 3650 and 3700kHz was applied and antenna No

3 (named DIPOLE) was last used there with tuning done by the user.

N O T E

If in the OFF-menu (see S.6-2) AUTO ANTENNA CHANGE is set to OFF, then

the antenna number would not change.

A new frequency segment can be selected in three ways:

- as mentioned above, by the CAT system;

- by the internal frequency counter, after a short duration transmission from the transceiver

(with the amplier in OPR mode) - a single word in SSB or a dot in CW (even at 40 wpm) would

be enough;

- manually, in the MAIN-menu by selecting the desired segment by means of the BAND

SEGMENT up and down buttons.

- You can select the automatic segment change mode by means of the CAT (FREQ) leftmost

button.

d) A new antenna can be selected while in the MAIN-menu by the means of the ANTENNA up

18

Page 21

or down buttons . If you don’t have the Automatic antenna selector ACOM 2000S (and ACOM

2000SW remote antenna switch) installed, pushing these buttons would change only the settings

stored in the amplier memory for each antenna.

e) TURNING OFF

In order to turn the amplier off, press the red ON/OFF button on the RCU. If you are not going

to use the amplier for a long time (more than 30 minutes), it is best to turn off the amplier

using the rear panel switch (Fig. 2-2) as well.

4-2. AUTO TUNE procedure

a) Let us examine the difference between the two types: DEFAULT- and USER- tunings.

DEFAULT tuning settings are permanently available in your amplier memory. They are normally

used when the load VSWR at the input end of the feed line is very low.

Real loads often have VSWR greater than 1.5:1, which usually requires the use of an outboard

antenna tuner. Your amplier will perform adequately with up to a VSWR 3:1, or up to 2:1 on

160m if you prepare USER tunings. This is a fully automatic procedure of matching the real

load impedance to the optimum tubes load. Note: This is NOT equivalent to using an external

antenna tuner and does not change the SWR your transceiver will “see” when the amplier is

in STB mode.

User tuning settings are memorized and stored in a nonvolatile memory. They will be retrieved

automatically each time you change the operating frequency or antenna number as described

in the previous section. This may enable you to use the amplier without an outboard antenna

tuner over a wider frequency range and to change frequencies and antennas faster than would

otherwise be possible with other ampliers.

The amplier is capable of memorizing up to 10 different antenna tunings for each frequency

segment, irrespective whether they are for different antennas or for different environment

conditions (for example wet and dry weather on the same antenna).

N O T E

REFLECTED POWER readings and the measured VSWR depend on the load

impedance only and not on the amplier tuning. If the impedance is different

from the nominal (50 Ohm pure resistive), the REFLECTED POWER bargraph

will always indicate the reected power presence (even at actual USR-tuning).

The proper USR tuning will, however, allow you to operate with greater power

without distortions and danger to the amplier.

The real power in the load is equal to the difference between the FORWARD- and REFLECTEDbargraph readings. For instance, at indicator reading for FORWARD 1775W, and for

REFLECTED 275W, the real output power is 1500W. At very high VSWR (lack of antenna or

shortened antenna), the FORWARD and REFLECTED readings will be almost equal, while the

real output power (the difference between them) will be practically zero.

The amplier can operate safely if the following rule is obeyed: "REFLECTED POWER < 500W".

Matching can be assured for loads with VSWR up to 3:1 (for 160m - 2:1). Nevertheless, for

some loads matching is possible even at higher VSWR.

19

Page 22

C A U T I O N

Using a feeder of coaxial cable at VSWR > 3:1 on HF bands is not

recommended. At such high values of VSWR, the high voltages, high currents,

and heat associated with line losses, risk permanently damaging the coaxial

cable.

Always prefer USER- to DEFAULT-tunings and update them periodically, in particular when you

install a new antenna or when a signicant change in the environment occurs (snow, ice, newly

appeared or removed massive objects, power lines etc.) that would cause signicant changes

in the antenna impedance.

b) Procedure for preparation of USER-tunings.

We recommend that you prepare USER-tunings for the center frequencies of the segments,

but you can do them for other preferred frequencies.

N O T E

If you use more than one antenna per segment, it is necessary that you select

the proper antenna number (see S.4-1d) BEFORE the next step. Otherwise

you may "overwrite" some useful tuning for another antenna number.

The following instructions are valid if your amplier is not connected to the transceiver by CAT

(or the CAT connection is of RX only type, which is rare but possible if there are other devices

connected via Y cable).

If there is a two-way CAT connection between the transceiver and ACOM2000A, skip to para.

4-2c.

To begin AUTO TUNE while in the MAIN menu, press the TUNE button and you will see the

following display:

20

Fig.4-4 RCU display - AUTO TUNE

Page 23

The amplier will wait for you to apply between 10 and 20W continuous (CW) carrier signal on

the desired frequency. If you don’t begin transmitting within 40 seconds, the amplier will return

back to the MAIN menu.

The automatic matching process starts the moment power remains constant within the indicated

boundaries. This is shown by the bottom bar graph, which indicates the applied input power

and glows in green:

If the drive power is less than 10W or greater than 20W, the yellow arrows will remind you to

correspondingly increase or decrease the drive:

The antenna impedance matching process is completed in less than 3 seconds and “AUTO

TUNE COMPLETED PLEASE REMOVE DRIVE message is displayed as shown in gure 4-5

and the letter "S" is being sent in CW:

Fig.4-5 RCU display - end of AUTO TUNE

N O T E

If the KEY-OUT control is used (see S.2-4e), the above message will be skipped.

If for some reason matching cannot be accomplished successfully (for example excessive VSWR

or unstable drive power during tune-up), the process ends up with the choice of DEF-tuning

and you will hear “K” being sent in CW.

21

Page 24

Fig.4-6 RCU display – AUTO TUNE fail

After removing drive power, the RCU returns automatically to the MAIN menu with USER or

DEFAULT indicated

c) If you are using your ACOM2000A connected by CAT to a transceiver, the USER tuning

preparation procedure is extremely simple.

- If the transceiver is FT-450, FT-950, FT-2000, FT-3000, FT-5000, FT-9000, IC-756PROIII, IC7410, IC-7600, IC-7700, IC-7800, K3, TS-480, TS-590, TS-990, TS-2000, or another modern

CAT protocol enabled radio, you need only to push the RCU TUNE button. ACOM 2000A will

do the rest by itself.

- If your transceiver is not one of those listed above and its output power can’t be controlled

by CAT, you must set the output power to between 10 and 20W and push the TUNE button, or

reduce the power and adjust it as explained above in para 4-2b after pushing the TUNE button.

4-3. Erasing USER segments (return to DEFAULT- tunings)

If you wish to clear a USR setting for a frequency segment and/or antenna, there are two ways

this can be accomplished:

a) to clear all memorized USR-tuning settings – while in OFF MENU, select “CLEAR the USER

TUNINGS” (see S.6-5)

b) for separate segments and/or antennas:

select the segment and antenna for which you want to erase the USR-tuning (see S.4-1c,d).

enter “MANUAL MODE”, select “SETTINGS“ and choose “CLEAR THE SEGMENT TUNING”

(see S.5-5c)

22

Page 25

5. MANUAL MODES

Pushing the SET/EXIT key while in main menu will get you to the MANUAL MODE:

Fig.5-1 RCU display - MANUAL MODE

Now you have access to some functions, procedures, and settings, which are marked on the

soft key prompting labels.

5-1. MANUAL TUNE

C A U T I O N

During the manual tune process, be certain to keep transmissions to less than

3 minutes in duration and leave pauses of 1-2 minutes between transmissions

for cooling of the tubes.

If for some reason you prefer to match the antenna impedance manually, you can do so through

the MAN TUNE procedure. The procedure starts the same as for AUTO TUNE, but you will

need to adjust the LOAD and TUNE settings yourself as described below:

23

Page 26

Fig.5-2 RCU display - MANUAL TUNE

In gure 5-2, graphical representations of the physical positions of the Tune (STEP 101) and

Load (STEP 35) capacitors are depicted above their respective TUNE and LOAD dual-arrow

adjustment buttons. The arrows indicate which way the automatic procedure would move the

motor (they are correct only at drive power of 5 to 50W).

By pressing the left and right arrow buttons you can increase or decrease the step number

which in turn moves the motors and capacitors. To end the manual tune procedure and save

the tuning as USER, remove drive power and press the SAVE button.

If you decide to leave the procedure without overwriting the current tuning, push the SET/

EXIT button.

If you adhere to the tune-up criteria following the arrow prompts, you will achieve the same

results as AUTO TUNE. Because of this, the MAN.TUNE procedure is only appropriate if

you have tune-up criteria of your own. We recommend you use the AUTO TUNE procedure

instead.

5-2. MEASURE function

The function MEASURE controls the technical state of the amplier and the parameters

associated with it. The TFT display is divided into two equal display areas, and in either you can

monitor any of the 20 parameters provided for measuring, for example GRID BIAS VOLTAGE

and DC SCREEN VOLTAGE:

24

Page 27

Fig.5-3 RCU display - MEASURE

With the up and down buttons you can select the item to be measured (listed in an alphabetic

order).

During measuring, the amplier can be used and controlled in OPR or STB modes, to transmit

and change the frequency segment and antenna if a new frequency is applied to it. Return to

the MAIN - menu is done by the SET/EXIT button.

The following is a list of parameters that can be measured:

AMPLIFIER POWER GAIN

DC POWER INPUT

DRIVE RF POWER

EXHAUST AIRFLOW TEMPERATURE - FRONT TUBE

EXHAUST AIRFLOW TEMPERATURE - REAR TUBE

FILAMENT CURRENT - FRONT TUBE

FILAMENT CURRENT - REAR TUBE

FILAMENT VOLTAGE

GRID BIAS VOLTAGE

GRID DC CURRENT

LAST FREQUENCY USED

LOAD (ANTENNA) VOLTAGE STANDING WAVE RATIO

LOAD (ANTENNA) FORWARD POWER

MAINS VOLTAGE

PLATE DC CURRENT

PLATE HIGH VOLTAGE VALUE

POWER REFLECTED FROM LOAD (ANTENNA)

PLATE RF AMPLITUDE (PEAK VALUE)

SCREEN DC CURRENT

SCREEN DC VOLTAGE

25

Page 28

5-3. SERVICE procedure

The procedure SERVICE can be selected and used only in STB mode. It is used for adjustment

of the zero-signal plate current and the optical sensors disks during repair. We recommend this

procedure to be carried out only by a trained service technician.

Fig.5-4 RCU display - SERVICE

When selecting TUNE, LOAD or BAND, the respective motor can be moved step by step CCW

or CW with the left and right arrow buttons. The positions of the motors are shown in a numerical

and in a graphical form. The status LIGHT or DARK of the respective optical sensors are also

displayed.

When the BIAS function is activated, it starts an automatic switching queue over three different

grid bias voltages. The voltages are shown along with the respective measured DC plate current.

This is used when the tube idling current adjustment is required.

If the amplier remains in the SERVICE sub-menu for more than 5 minutes without any

further RCU input, it will return automatically to the MAIN menu. For more information see the

TECHNICAL SUPPLEMENT.

5-4. CAT SETTINGS

Here you set the type of the transceiver connected by CAT to the amplier. Use the UP and DOWN

buttons to move the pointer and exit with SET/EXIT button. Pay attention to the communication

speed shown in the brackets next to each transceiver type. Set your transceiver serial port to

the same Baud rate (speed).

26

Page 29

Fig.5-5 RCU display – CAT SETTINGS

A transceiver that is not included in the list still could be CAT connected to the 2000A if its

protocol is compatible with any of the listed transceivers.

Select KENWOOD NEW if your transceiver is TS-570, TS-870, TS-480, TS-590, TS-990, TS2000 or newer.

KENWOOD TS-850 covers also TS-950 as well as TS-440, TS-940 with optional units.

YAESU FT-1000D can be selected for some FT-1000 and FT-990 versions.

YAESU FT-897 covers also FT-847, FT-857 and FT-817.

YAESU NEW includes FT-450, FT-950, FT-2000, FT-3000, FT-5000 and FT-9000 or newer.

5-5. MORE SETTINGS

Some more items can be set through this menu.

Fig.5-6 RCU display – MORE SETTINGS

27

Page 30

a) LOCK

Once locked through this option, the amplier can be switched on, but it will not turn into

OPERATE state until entering the same menu and choosing UNLOCK. This feature is intended

to protect the amplier from children, or from other persons, not familiar with the equipment.

The locked state is indicated by a displayed image of a key.

b) GAIN

N O T E

Inappropriate use of this function may reduce the gain or the maximum

undistorted output power.

In fact, this selection controls the tubes plate load resistance achieved by AUTO TUNE procedure.

When HIGH is selected, a next AUTO TUNE will result in a higher than nominal load resistance,

thus there will be more gain, but less maximum attainable output power. When available drive

power is insufcient or when less output but better efciency are needed, e.g., for RTTY and

SSTV, this may be desirable and you may select HIGH also at a nominal mains voltage condition.

Selecting LOW would lead to the opposite result, i.e., lower than nominal load resistance, less

gain, and more power attainable. Of course, this requires more drive power, more plate current,

and more plate heat, which shortens tubes expected life. We do not recommend this selection

at normal mains voltage and never at increased mains voltage. You may use it in conditions

with lower than nominal mains voltage.

Departure from NORMAL selection should be mainly used to compensate for small line (mains)

voltage variations in order to maintain tubes efciency and linearity at deviated mains voltage.

However, when there is more than plus or minus 5% deviation from the nominal line (mains)

voltage, the voltage selector inside the amplier should be changed (see S2-2).

A LOW-NORMAL-HIGH change requires refreshing the USER tunings in order to take place.

c) CLEAR THE SEGMENT TUNING

Use this entry if you want to erase a single USER tuning. Choosing YES will restore the

DEFAULT tuning for the current segment and antenna at leaving the menu.

d) DISPLAY BRIGHTNESS

The display brightness can be adjusted through the left and right arrow buttons.

e) SOUND

You can turn ON and OFF the RCU internal beeper. When turned ON, the amplier will alert

you with a beep, or CW characters at the start and at end of some procedures, as warmup

and autotune. Every fault that would trip the protection also will be indicated by letter “F” in

CW.

f) ANTENNAS

To enter the antenna list, press the down button one more time when the marker is on the

last line.

28

Page 31

Fig.5-7 RCU display – MORE SETTINGS – ANTENNAS

Here you can give a name to each antenna, which will be displayed next to its number on

the screen. First select the antenna number with up and down buttons. Use the left and right

arrow buttons to choose the character position. Then select the character with up and down

keys. The name can consist of up to 8 characters. When nished, return to the antenna

number with the left arrow button. You can return to the rst page of MORE SETTINGS menu

with the up key, or you can exit to MANUAL MODE by pressing the SET/EXIT button.

5-6. HELP

When HELP is selected, you can choose one of the help topics by means of the up, down

and select keys. The help topics have the same titles as the sections in this manual. Under

the title AMPLIFIER INFO you may see the Revision Code of the rmware, the Running

Time of tubes, the Serial Numbers of Amplier and Tubes (front and rear).

During normal operation of the amplier, information is stored in the nonvolatile memory

about the 12 most recent protection trips or irregularities and the time when they have

occurred (indicated as tube working hours). This information can be read if you select LAST

12 PROTECTION TRIPS.

6. OFF MENU

When the main power switch on the front panel is turned ON but the amplier is still in OFF

state, a number of settings can be changed by means of the OFF MENU – (Fig 3-3). You can

enter it by pushing the SET/EXIT button.

Use the up and down buttons to select an item, then push left or right arrow buttons to choose

the value.

6-1 CALL SIGN

You can select any 9-character text to appear in the OFF-MENU (for example your own

CALL SIGN). The up and down buttons select the character in the position indicated by the

cursor (the characters are in an alphabetic order by the ASCII-code). The left and right arrow

buttons move the cursor left or right to select different character positions. When nished,

29

Page 32

return to the CALL SIGN label with the left arrow button.

Erasing the nonvolatile memory (see S.6-6) will blank the CALL sign message until the text is

reprogrammed following the procedure described above.

6-2 AUTO ANTENNA CHANGE

When YES is selected, changing frequency segments (manually or following the transceiver

frequency or by CAT - S.4-1c), will cause the antenna last used in the respective segment

and the tuning settings for it to be selected. This is convenient when you have 1 or 2

antennas for each band. With more antennas you would have to keep track of which

antenna you used last.

If "NO" is selected, this function is disabled and the currently used antenna is changed only

after an intentional command is given for an antenna change (manually or via the local

network - see S.4-1d). When changing frequency segments, the tuning settings for the

antenna currently used will be selected in the new segment. This mode is preferred when

you have multiple antennas per band.

Selection of YES or NO does not change any contents for tuning settings in the nonvolatile

memory.

6-3 AUTO OPERATE

Set to "OFF" by default.

When “ON” is selected, the amplier will remain ready to operate, even automatically

returning from standby after a soft-fault protection trip. That is, after a protection trip, e.g.

from an overdrive event, the amplier will normally shift to the STB mode for about four

seconds, but it will automatically return to the OPR mode after that. Even with ON selected

however, you still may depress the OPR hardware button manually to go to and remain in the

STB (Stand By) mode at any time, such as when you leave the station for a while.

If “OFF” is selected for AUTO OPERATE, the amplier will go and remain in the STB mode

after a soft fault until switched over to the OPR mode manually by the operator or an

intended command is received via the local network.

6-4 SELF ADDRESS

Here you can set the amplier self address for operation in a network with other systems.

When the amplier is not used in a network, this address is meaningless.

6-5 CLEAR THE USER TUNINGS

N O T E

If you use this function, it is advisable that you update the USR tunings (see

S.4-1).

When selected “YES”, this function clears all USR-tunings from the nonvolatile memory but

does not change anything else in the INFO-BOX.

The use of CLEAR THE USER TUNINGS is convenient when the amplier is moved to

another operating place to prevent from mixing with the remaining USR-tunings which are

valid for the antennas at the old location. Of course, if the total number of antennas is less

than 10 per segment, you can do USR-tunings with new antenna numbers and thus preserve

30

Page 33

the USR-tunings for the antennas at the old location as well.

6-6 CLEAR THE MEMORY

N O T E

Erasing Nonvolatile Memory erases all user data for the amplier stored in its

nonvolatile memory and the INFO-BOX. This includes the following:

• the elapsed hours on is set to zero;

• the text set for CALL is deleted;

• the information stored for recent 12 protection trips is cleared;

• selection for LOW-NORMAL-HIGH of GAIN is set to NORMAL;

• the amplier self-address in local network is set to 01;

• the last segment and antenna in use is set to 1800-1825 ANT1;

• all USR-tuning settings for all segments and antennas are set to DEFAULT;

• the auto antenna change mode is set to ON.

• the AUTO OPERATE selection is set to OFF.

If you are fully convinced that you want all of these actions to take place, choose “YES” and

then leave the menu pressing the SET/EXIT button.

The procedure is now completed and the amplier remains in OFF state with no user data in

it. The serial numbers of the RCU, amplier and its tubes as well as the rmware revision code

and DEFault tuning settings, however, are preserved.

N O T E

After this procedure set new data in OFF-menu and update the USR-tunings

for the frequency segments and antennas to be used (see S.4-1).

7. CAT OPERATION AND CONNECTIONS

Most of the modern transceivers that have the operating frequency data available on an auxiliary

serial port could be connected to Acom2000A by means of a CAT connection. This will enable

the amplier to track the frequency of the transceiver and to tune up automatically when entering

a new segment without transmitting.

Because of the variety of CAT protocols, the amplier response could vary when used with

different transceivers.

Some older transceivers use very slow protocol and send the frequency data with delay up to

few seconds. The amplier’s response will also be delayed. In some cases when the transceiver

is turned ON after the amplier you may need to actuate the RCU CAT/FREQ button in order

for the radio to announce its frequency.

In other cases the transceiver sends the frequency data only when the frequency changes.

You may have to move its main dial, or change its frequency by another way to let the amplier

31

Page 34

know the transceiver frequency after the initial power ON.

Not all transceivers correctly report VFO A and VFO B when in split mode. If your transmit and

receive frequencies are in different band segments and the amplier retunes on every RX/TX

transition, turn off the CAT until the end of the split operation.

The CAT connector is located on the RCU rear panel. Besides the RS232 and TTL compatible

serial interface, the CAT connector also carries the KEY IN and KEY OUT lines, which can be

used instead of using separate cables for those functions from the transceiver to the sockets

of the same names. See Figure 7-1 below:

Pin 1 – RX RS232

Pin 2 – RX TTL

Pin 3 – TX TTL

Pin 4 – TX RS232

Pin 5 – GROUND

Fig. 7-1 CAT Connector pin-out front view

Many transceivers have different connectors and different signal levels. To be sure that your radio

will interface properly with the 2000A, the connection cable should be prepared according to

Fig.7-1 and the corresponding information from your transceiver’s user manual. Here are some

examples. Please note that the front view of the cable connectors is shown in these pictures.

- Y serial cable. When the CAT port of the transceiver is used for another device such

as a computer or an antenna controller, a Y cable should be used. An example is shown on

Fig. 7-2. Use only shielded cables for all connections. Note that the amplier will receive correct

data only when the CAT connection between the transceiver and the other device (for example,

a computer with running logging software) is active.

Fig. 7-2 CAT Connection by RS-232 Y cable

- ICOM CI-V Interface: A 3.5mm audio stereo plug, a two conductor shielded cable

and two 510 Ohm resistors are required. The wiring is shown on Fig. 7-3.

32

Page 35

Fig. 7-3 CAT Connection to ICOM CI-V interface

- KENWOOD TS480, TS570, TS590, TS870, TS2000, TS..40 with optional unit

or TS..50 with optional unit. You need a female DB9 connector and a three conductor

shielded cable. The wiring should follow Fig 7-4, including the connection between pins 7 and

8 of the DB9 connector. If the same port of the transceiver is used for computer control, you

can use Y cable shown on Fig 7-2 with an addition of a connection between pins 7 and 8 at

the transceiver side.

Fig. 7-4 CAT Connection to KENWOOD RS-232 interface

- KENWOOD TS450, TS850, and TS950. If an optional RS-232 interface is present

you may use the cable of Fig.7-4. Otherwise, the built-in TTL serial interface can be used, as

shown on Fig 7-5. Use shielded cable and universal low power NPN transistors.

Fig. 7-5 CAT Connection to KENWOOD TTL interface

- Elecraft K3. You can use a shielded cable, wired according to Fig 7-6. The RS-232

connector at the transceiver side is a male DB9. If the same port of the transceiver is used

for computer control, you can use Y cable shown on Fig 7-2.

33

Page 36

Fig. 7-6 CAT Connection to Elecraft K3

- YAESU FT450, FT847, FT920, FT950, FT1000MP, FT2000, FT5000, and FT9000

You need female DB9 connector and a three conductor shielded cable. The wiring should be

as shown in Fig 7-7. If the same port of the transceiver is used for computer control, you can

use Y cable shown on Fig 7-2.

Fig. 7-7 CAT Connection to Yaesu transceiver with RS-232 interface

- YAESU FT-990, FT-1000, and FT-1000D You will need a 6-pin DIN connector, 3

wire shielded cable and a 10k pull-down resistor as shown on Fig 7-8.

Fig. 7-8 CAT Connection to YAESU FT-1000D

- YAESU FT-817, FT-857 and FT-897 The cable is shown in Fig. 7-9. Besides the

serial interface wires, also the amplier control lines are included in the same connector. This

makes possible using of a single cable between the transceiver and ACOM2000A as shown

on Fig. 7-9. The connector at the transceiver side is a Mini 8 pin DIN. You will also need a

5 wire shielded cable and a 10k pull-up resistor. In case of using this cable, you should not

connect separate cables to the KEY-IN and KEY-OUT sockets described in s.2-4 d,e.

34

Page 37

Fig. 7-9 CAT Connection to YAESU FT-897

8. MAINTENANCE

W A R N I N G HIGH VOLTAGE!

The amplier works with high voltages up to 3000V which are LETHAL!

For your safety, pull the amplier power plug out of the mains wall outlet

and WAIT AT LEAST 30 minutes EACH TIME BEFORE you remove the

cover of the amplier. Do not touch any part inside while the amplier

is open as some residual voltages may still be present.

8-1. Cleaning

W A R N I N G

Do not use solvents for cleaning - they may be dangerous both for you

and for the amplier paint.

Do not open the amplier. Cleaning of the amplier and RCU outer surfaces can be done with

a piece of soft cotton cloth lightly moistened with clean water.

8-2. Backup Battery Replacement

If the RCU displays a message: LOW BATTERY-DATA IS IN DANGER or LOSS OF STORED

DATA-CHECK BATTERY PLEASE, it is necessary that the nonvolatile memory battery for

USR-TUNINGS be replaced. This is a 3V/38mAh "coin - type" lithium battery with a diameter

of 12mm (~1/2inch) with leads for soldering. The following types are suitable:

- BR1225T2-1 made by RAYOVAC USA

- BR1225-1HC made by PANASONIC

This is a complex and possibly dangerous operation. For this reason, Acom recommends that

this work be carried out by a trained service technician. See the TECHNICAL SUPPLEMENT

for details. The expected life of a new battery is at least 5 years.

8-3. Fuse Replacement

If circumstances require replacement of the mains fuses, use only standard ones.

The two Primary Mains Fuses of the amplier are located on the rear panel (Fig. 2-2).

They are 20A/250V Quick blow, 1-1/4 x 1/4 inch Cartridge Fuses, Size "0" Ceramic.

Besides these primary fuses, there are six small glass fuses (5x20mm) on the MAINS CONTROL

35

Page 38

BOARD which are not to be replaced by the user. Should one of these fuses be blown, it may be

indicative of other more serious failures. This is a complex and possibly dangerous operation.

For this reason we recommend this work be carried out by a trained service technician. See

the TECHNICAL SUPPLEMENT for details.

8-4. Tube Replacement

New tubes must be supplied as a Matched Pair with close electrical characteristics. Otherwise

there may be an imbalance and one of the tubes will bear an excessive share of the operating

current, which can lead to overheating and reduced tube life.

Two 4CX800A (GU74B / ГУ74Б) high performance ceramic-metal tetrodes manufactured by

Svetlana (Светлана) are employed in the amplier. Tube replacement is a complex and possibly

dangerous operation. For this reason, we recommend that this work be carried out by a trained

service technician. See the TECHNICAL SUPPLEMENT for details.

8-5. The ACOM2000A Simplied Schematic Diagram

See Fig.6-1 ACOM2000A Simplied Schematic Diagram.

The two 4CX800A (GU74B / ГУ74Б) Svetlana (Светлана) high performance ceramic-metal

tetrodes (V1 and V2) with plate dissipation of 800W each are grid-driven. The input signal from

the RF INPUT jack is passed through a broadband input matching circuit which is comprised

of components in the PHASE DETECTOR PCB and also L1, L2, C2, C3 and R1. This circuit

tunes out the input capacitance of the tubes. The resistor R1 is a termination load of this circuit

and can dissipate up to 100W of drive power.

Cathode resistors R2 and R5 create DC and RF negative feedback and equalize the gain of

the tubes. The varistor RV1 in the screen grid circuit protects the tube screen grid, and voltage

regulator in the events of a ashover.

The combinations of L3-R3 and L4-R6 in the plate circuits are the VHF/UHF parasitic suppressors.

DC plate voltage is fed through chokes RFC2-RFC3 and the capacitor C10 blocks it from the

output. The output circuit is comprised of L5-L6 and C12-C16, which form a classic Pi-L network

and suppresses harmonic frequency emissions. It is switched and tuned over the bands by

S1A-S1D and the stepping motors M3-M5 via the MOTOR DRIVER PCB. The output signal is

fed through the vacuum antenna relay K1, wattmeter current transformer TA1 and high-pass

lter RFC5-C20 and nally to the antenna output. The chokes RFC4 and RFC5 keep track of the

antenna relay contact condition and together with C20 prevent the plate supply from reaching

the antenna and RFC5 shunts it to ground if the DC blocking capacitor C10 fails. The resistor

R9 and FV1 protect the amplier from static discharge via the RF OUT connector.

The PHASE DETECTOR together with the PLATE CAPACITIVE DIVIDER, RF WATTMETER

and three OPTOSENSOR circuits are the main sources of information for the control circuit

of the amplier during the autotune process. The control circuit consists of the CENTRAL

PROCESSOR UNIT, based on the 80C31 microprocessor as the main system and the Z86E04

Zilog single chip microprocessor which is used as the antenna relay QSK controller. They are

interfaced through the INTERFACE PCB to all other circuits.

All voltages delivered from the LOW VOLTAGE and HIGH VOLTAGE SUPPLY PCBs, tube

currents, temperatures and airow cooling capability are permanently monitored. Numerous

software-derived protection limits are based on this information.

The SIGNAL FILTER PCB and RFC1 eliminate RF feedback from incoming cables, including the

36

Page 39

mains power cord. The Remote Control Unit (RCU) is based on the ATmega64 microcontroller

and uses a 7” color TFT display.

Detailed electrical schematic diagrams are available in the TECHNICAL SUPPLEMENT. Contact

your dealer for details.

8-6. Troubleshooting

Should the RCU display indicate a problem, look up the message in the list below and before

you contact the service of your dealer (see S.1-2 and S.5-3), try the recommendations. The

messages are listed in an alphabetic order. The abbreviations used for some recommendations

are decoded after the list.

In case of necessity of transportation see S.9-3.

MESSAGE RECOMMENDATION

ADC - OVERFLOW OFF5*

ANTENNA CONTROL UNIT MALFUNCTION check the control cable from the amplier

INTERFACE connector to ACU (Antenna

Control Unit, if there is one).

ANTENNA RELAY CLOSED

IT SHOULD BE OPEN

ANTENNA RELAY OPEN

IT SHOULD BE CLOSED

ARC FAULT try again; check antenna cable, selector,

AUTOMATIC PROTECTION

DRIVE POWER REMOVED

BAND SWITCH SYSTEM MALFUNCTION OFF5*

BIAS CONTROL MALFUNCTION OFF5*; CCC*

BIAS TOO LOW AT POWER ON OFF5*; CCC*

BIAS VOLTAGE TOO LOW OFF5*; CCC*

CAT CONNECTION FAULT Check the CAT cable, the CAT settings and

COVER INTERLOCK OPEN Check cover; OFF5*

DETECTED RF POWER AT WRONG TIME Check if there is power in the antenna

DRIVE FREQUENCY OUT OF RANGE check the transceiver frequency; OFF5*

DRIVE POWER TOO HIGH RD&T*

EXCESSIVE G2 CURRENT RD&T*

EXCESSIVE PLATE CURRENT RD&T*

FREQUENCY VIOLATION submit to your dealer your license for

CCC*

CCC*

antenna and grounding for loose contacts

or worsened insulation.

power not removed more than 10 seconds

after the message "REMOVE AND

REDUCE DRIVE POWER" appeared.

the transceiver CAT settings

induced from another nearby transmitter;

CCC;OFF5*

opera- tion in the respective frequency

band.

37

Page 40

FRONT TUBE EXHAUST TEMP TOO HIGH check if air intake (rear panel) and exhaust

(above tubes) openings are clear of

obstructions; RD&T*

G1: EXCESSIVE GRID CURRENT RD&T*

G2: CURRENT TOO HIGH RD&T*

G2 CONTROL CIRCUIT MALFUNCTION OFF5*

G2 VOLTAGE TOO HIGH OFF5*; RD&T*

G2 VOLTAGE TOO LOW OFF5*; RD&T*

HEATER CURRENT TOO HIGH CMV*

HEATER CURRENT TOO LOW CMV*

HEATER VOLTAGE TOO HIGH CMV*

HEATER VOLTAGE TOO LOW CMV*

HEATERS ON BEFORE TIMEOUT STARTED OFF5*

HIGH VOLTAGE TOO HIGH CMV*

HIGH VOLTAGE TOO LOW CMV*

HV TOO LOW AT POWER ON check if the power transformer is properly

connected (see S.2-3) ; CMV*

IG2=......mA SHOULD BE ZERO OFF5*

IG1=......mA SHOULD BE ZERO OFF5*

Ip= ......mA SHOULD BE ZERO OFF5*

Ip PRESENT: SHOULD BE ZERO OFF5*

INPUT RELAY CLOSED

IT SHOULD BE OPEN

CCC; OFF5*

LOAD CAPACITOR SYSTEM MALFUNCTION OFF5*

LOSS OF STORED DATA

CHECK BATTERY PLEASE

LOW BATTERY DATA IS IN DANGER see S.8-2.

LOW AIRFLOW check if air intake (rear panel) and exhaust

LOW GAIN RD&T*; check the coaxial cable from

MICROPROCESSOR CONFLICT OFF5*

MOTOR VOLTAGE TOO HIGH CMV*

MOTOR VOLTAGE TOO LOW check if the power transformer is properly

QSK BREAK in FAULT

PROCESSOR CONFLICT

REAR TUBE EXHAUST TEMP TOO HIGH check if air intake (rear panel) and exhaust

see S.8-2.

(above tubes) openings are clear of

obstructions; RD&T*

transceiver output to amplier input.

connected (see S.2-3) ; CMV*

OFF5*; CCC*

(above tubes) openings are clear of

obstructions; RD&T*;

38

Page 41

REFLECTED POWER TOO HIGH check antenna cable, selector, antenna and

grounding for loose contacts or worsened

insulation; trim the antenna for minimum

VSWR or use an antenna tuner; try another

antenna; check if REFLECTED POWER is

induced from another nearby transmitter.

REMOVE AND REDUCE DRIVE POWER RD&T*

RF PLATE =......V SHOULD BE ZERO OFF5*; CCC*

RF GRID =......W SHOULD BE ZERO OFF5*; CCC*

SCREEN VOLTAGE ON

BEFORE TIMEOUT OVER

TUNE CAPACITOR SYSTEM MALFUNCTION

+5V TOO HIGH (TOO LOW) CMV*

+/- 12V TOO HIGH (TOO LOW) CMV*

+24V /+48V TOO HIGH (TOO LOW) CMV*

* Abbreviations:

OFF5 - Turn the amplier off for 5 minutes and try again.

RD&T - Reduce drive power from transceiver; do AUTO TUNE - see S.4-2.

CMV - Check the mains voltage and verify that it matches the voltage selector

- see S.2-2 and table 2-1.

OFF5*

OFF5*

CCC - Check the control cable from the transceiver to KEY-IN input - see

S.2-4.

9. SPECIFICATIONS

9-1. Parameters

a) Frequency Coverage: All amateur bands 1.8-29.7MHz

b) Power Output: 1500W PEP or continuous carrier, no mode limit.

In continuous carrier modes (RTTY etc.) for transmissions longer than 15 minutes (up to several

hours depending on ambient temperature), the optional auxiliary fan must be mounted.

c) Intermodulation Distortion: Better than 35dB below rated PEP output.

d) Hum and noise: Better than 35dB below rated output.

e) Harmonics Output Suppression: Better than 50dB below rated output.

f) Input and Output Impedances:

• nominal value: 50 Ohm unbalanced, UHF (SO239) type connectors;

• input circuit: broadband, VSWR less than 1.3:1, 1.8-30MHz continuously (no tunings, no

switching);

• bypass path VSWR less than 1.1:1, 1.8-30MHz continuously;

39

Page 42

• output circuit matching capability: better than VSWR 3:1 (2:1 for 160m) or greater at reduced

output levels; automated.

g) Automatic Tuning:

• Load Impedance Matching - less than 3 seconds;

• Band Change - less than one second;

• Segment Change - less than 0.2 seconds.

h) RF Gain: 14.5dB, frequency response less than 0.5dB (50 to 60W drive power for rated output).

i) ALC: grid-current derived, -11V max, rear panel adjustable.

j) Primary Power: 90-132V (100 & 120V nominal taps, 10% tol.) and 180-264V (200, 220 &

240V nominal taps, 10% tol.), 50-60Hz, single phase, 3500VA consumption at rated output. In

USA, 240v is strongly recommended.

k) Complies CE safety and electromagnetic compatibility requirements, as well as FCCregulations

l) Size & Weight (operating): W440mm x D500mm x H180mm, 36kg.

m) Operating environments:

• temperature range: 0...+50 degs.Celsius;

• humidity: up to 95% @ +35 degs.Celsius.

• altitude: up to 3000m above sea level without output deterioration.

9-2. Functions

a) Load Impedance Matching Process: automated.

b) Provides Antenna Control Interface for Automatic Antenna Selector and Tuner.

c) User tuning settings memory - nonvolatile for up to 10 antennas per frequency segment

(settings for 50 Ohm default provided).

d) Tubes: two 4CX800A (GU74B / ГУ74Б) Svetlana (Светлана) high performance ceramic-metal

tetrodes with plate dissipation of 800W each, grid driven, forced air cooling.

e) T/R System: QSK operation with built-in vacuum RF antenna relay.

f) Protections:

• cover interlock for operator's safety;

• inrush power-on current control;

• all supply voltages;

• control grid, screen grid, plate and heater currents;

40

Page 43

• cooling airow;

• exhaust air temperature - each tube separately;

• motors motion;

• T/R sequencing;

• antenna relay contacts, including RF power induced in antenna from another nearby

transmitter;

• load matching quality;

• reected power;

• RF arcs, including in antenna system;

• overdrive;

• unauthorized access to amplier.

g) INFO BOX for 12 recent protection trips, default selections, individual amplier's data and

elapsed power-on hours.

h) Up to 20 meters separation between the RCU and the main unit, on-board assistance and

troubleshooting suggestions etc. No controls on main unit (except for the ON/OFF main switch

and LED indicator).

i) All functions accessible from a computer via serial port, local network functions for more than

one (up to 15) sets of amplier / antenna units, working in a system.

j) Measurement and/or constantly monitoring of 20 most important parameters of the amplier

via RCU and/or computer.

k) RCU Beep

9-3. Storage and Shipment

C A U T I O N

Should you need to transport the amplier, use the original packing as

described below.

First pull the mains plug out of the mains outlet, afterwards disconnect all cables from the rear

panel of the amplier and RCU (remove the ground connection last) and wait 30 minutes. Then

remove the mains power transformer, observing the requirements of S.2-3, but in reverse order.

Pack the RCU in the box provided for it, and put it in the amplier in the place of the mains

transformer. Screw in the transport board to the transformer using the four shipping screws,

pack the four shorter (mounting) bolts in the polyethylene envelope. Finally mount the cover

and pack the amplier and transformer in their original cartons.

N O T E

If transporting for repair, you may not need to ship your transformer – check

with your dealer rst.

41

Page 44

a) Storage environments: the amplier can be kept packed in dry and ventilated unheated

premises without chemically active substances (acids, alkalies etc.) in the following climatic

environment:

• temperature range: -40 to +70 degs.Celsius;

• humidity: up to 75% @ +35 degs.Celsius.

b) Shipping Size and Weight:

• W390mm x D340mm x H340mm, 18.3kg - Transformer carton;

• W630mm x D590mm x H300mm, 20.7kg - Amplier carton.

c) Shipping environments: all types of transportation, including aircraft baggage section up to

12000 meters above sea level.

10. BRIEF MENU GUIDE

• POWER SWITCH -> OFF STATE:

HELP - to read serial numbers, power-on hours, suggestions

• SET/EXIT BUTON -> OFF MENU

CALL SIGN – to change display message while in OFF-state

AUTO ANTENNA CHANGE – to select the logic of the antenna change

AUTO OPERATE – to select the behaviour of the amplier after a “soft” fault