Page 1

User Manual

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

KD 9170N: 17” Short Depth Monitor Keyboard Drawer

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 2

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

LEGAL INFORMA TION

Information in this document has been carefully checked for accuracy; however, no guarantee is

given to the correctness of the contents. The information in this document is subject to change

without notice. We are not liable for any injury or loss that results from the use of this equipment.

Safety Instructions

Please read all of these instructions carefully before you use the device. Save this manual for future

reference.

? Unplug equipment before cleaning. Don't use liquid or spray detergent; use a moist cloth.

? Keep equipment away from excessive humidity and heat. Preferably , keep it in an air-conditioned

environment with

temperatures not exceeding 40º Celsius (104º Fahrenheit).

? When installing, place the equipment on a sturdy , level surface to prevent it from accidentally

falling and causing dam

age to other equipment or injury to persons nearby .

? When the equipment is in an open position, do not cover , block or in any way obstruct the gap

between it and the

power supply . Proper air convection is necessary to keep it from overheating.

? Arrange the equipment's power cord in such a way that others won't trip or fall over it.

? If you are using a power cord that didn't ship with the equipment, ensure that it is rated for the

voltage and current

labeled on the equipment's electrical ratings label. The voltage rating on the cord should be higher

than the one listed

on the equipment's ratings label.

? Observe all precautions and warnings attached to the equipment.

? If you don't intend on using the equipment for a long time, disconnect it from the power outlet to

prevent being dam

aged by transient over-voltage.

? Keep all liquids away from the equipment to minimize the risk of accidental spillage. Liquid

spilled on to the power

supply or on other hardware may cause damage, fire or electrical shock.

? Only qualified service personnel should open the chassis. Opening it yourself could damage the

equipment and invali

date its warranty .

? If any part of the equipment becomes damaged or stops functioning, have it checked by qualified

service personnel.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 3

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

WHAT THE WARRANTY DOES NOT COVER

Any product, on which the serial number has been defaced, modified or removed.

? Damage, deterioration or malfunction resulting from:

? Accident, misuse, neglect, fire, water , lightning, or other act s of nature, unauthorized product

modification, or failure to follow instructions supplied with the product.

? Repair or attempted repair by anyone not authorized by us.

? Any damage of the product due to shipment.

? Removal or installation of the product.

? Causes external to the product, such as electric power fluctuation or failure.

? Use of supplies or parts not meeting our specifications.

? Normal wear and tear .

? Any other causes which does not relate to a product defect.

? Removal, installation, and set-up service charges.

Regulatory Notices Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference in a residential instal- lation.

Any changes or modifications made to this equipment may void the user's authority to operate this

equipment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio

communications.

However, there is no guarantee that interference will not occur in a p articular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

? Re-position or relocate the receiving antenna.

? Increase the separation between the equipment and receiver.

? Connect the equipment into an outlet on a circuit different from that to which the receiver is con-

nected.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 4

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

T able of Contents

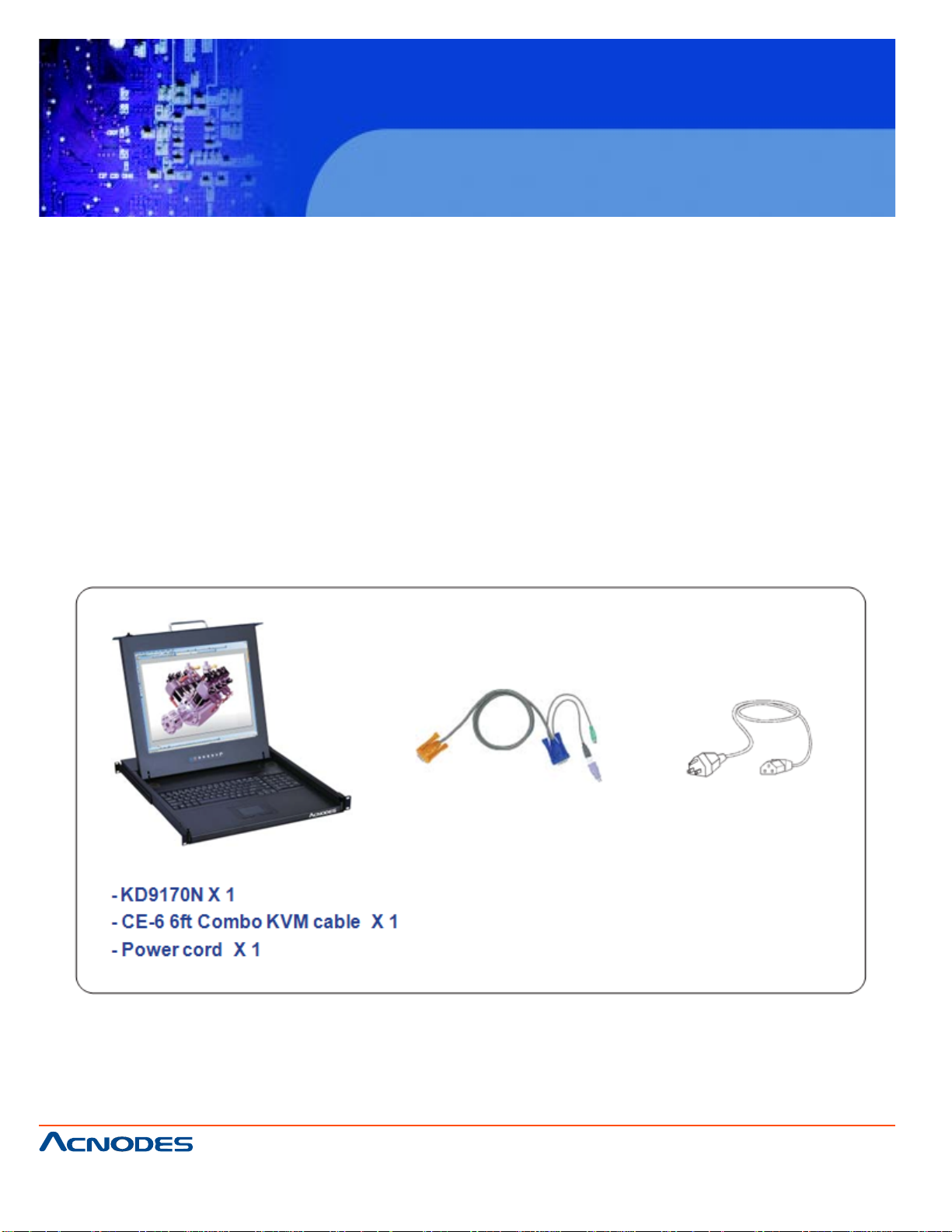

1.1 Package Contents P.1

1.2 Structure Diagram & Dimension P.2

1.3 Installation P.3-5

1.4 Connection to External KVM Switch or Server P.6

1.5 On-screen Display Operation ( OSD ) P.7

1.6 LCD / Keyboard / Mouse Specification P.8-9

1.7 Audio P.10

Package Content

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 5

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

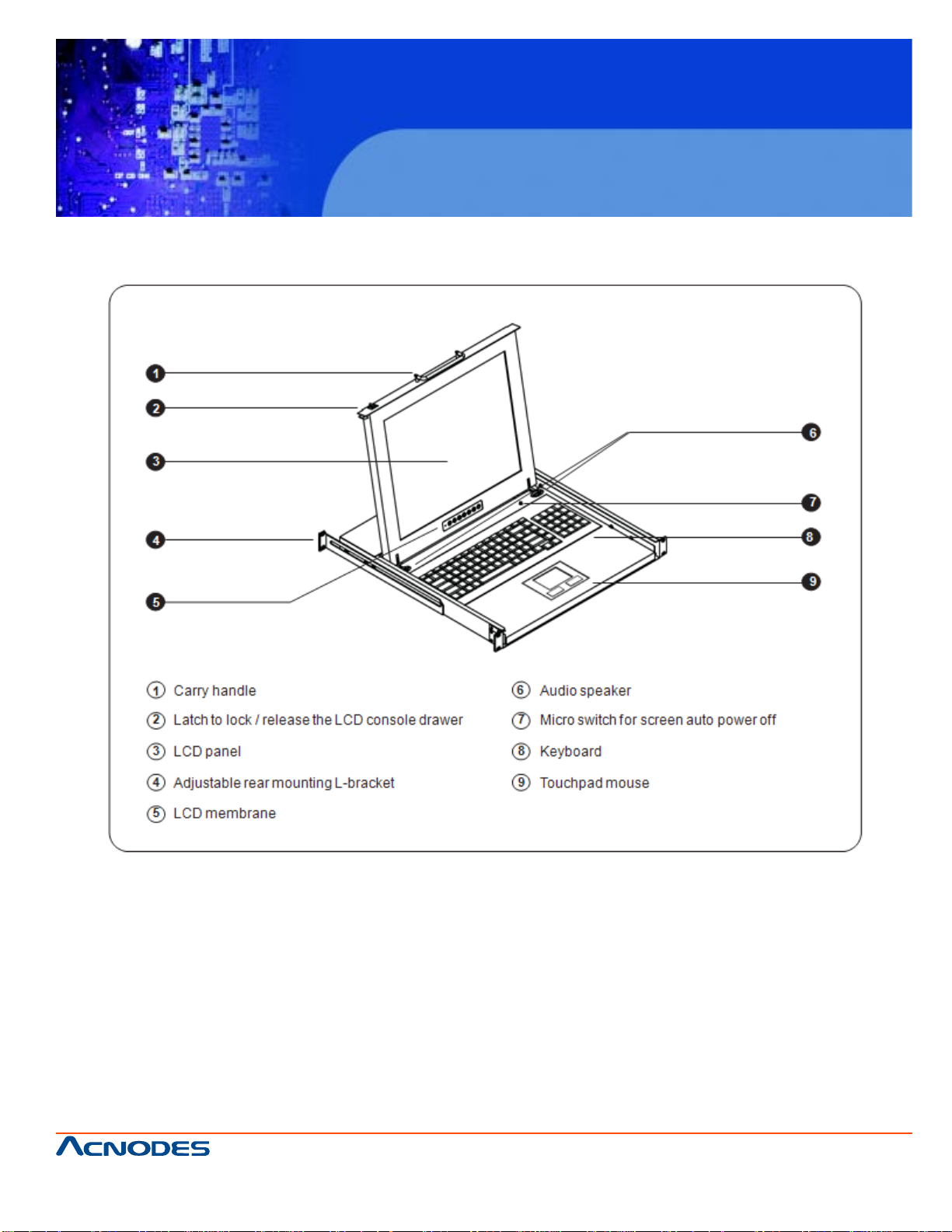

Structure Diagram & Dimension

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 6

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.8 PCIE EXP ANSION CARD INST ALLA TION (OPTIONAL) ................................................ 51

4.9 A T/ATX MODE SELECTION ............................................................................................. 53

4.10 ACTIVATING THE FRONT USB CONNECTORS (WIDS SERIES ONL Y) .................... 53

4.1 1 MOUNTING THE SYSTEM ............................................................................................... 55

4.1 1.1 WALL MOUNTING .............................................................................................. 55

CHAPTER 5 BIOS SETUP

5.1 INTRODUCTION.................................................................................................................. 67

5.1.1 Starting Setup ...................................................................................................... 67

5.1.2 Using Setup .......................................................................................................... 67

5.1.3 Getting Help .......................................................................................................... 68

5.1.4 Unable to Reboot after Configuration Changes ................................................. 68

5.1.5 BIOS Menu Bar .................................................................................................... 68

5.2 MAIN.................................................................................................................................... 69

5.3 ADV ANCED ...................................................................................................................... 70

5.3.1 CPU Configuration .............................................................................................. 71

5.3.2 IDE Configuration ................................................................................................ 72

5.3.2.1 IDE Master , IDE Slave .......................................................................... 74

5.3.3 Super IO Configuration ....................................................................................... 77

5.3.4 Hardware Health Configuration .......................................................................... 83

5.3.5 Power Configuration ........................................................................................... 86

5.3.5.1 ACPI Settings......................................................................................... 87

5.3.5.2 APM Configuration................................................................................. 87

5.3.6 Remote Access Configuration ........................................................................... 90

5.3.7 USB Configuration............................................................................................... 93

5.4 PCI/PNP .................................................................................................................... .......... 95

5.5 BOOT ................................................................................................................................... 97

. 5.5.1 Boot Settings Configuration................................................................................. 98

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 7

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

5.6 SECURITY ...................................................................................................................... 100

5.7 CHIPSET ........................................................................................................................ 101

5.7.1 North Bridge Configuration.............................................................................. 102

5.7.1.1 Video Function Configuration ........................................................... 103

5.7.2 South Bridge Configuration ............................................................................ 104

5.8 EXIT ................................................................................................................................ 105

CHAPTER 6 SYSTEM MAINTENANCE

6.1 SYSTEM MAINTENANCE INTRODUCTION ................................................................ 108

6.2 MOTHERBOARD REPLACEMENT ............................................................................. 108

6.3 BACK COVER REMOV AL ............................................................................................ 108

6.4 DIMM REPLACEMENT ................................................................................................. 109

6.5 ELEV A TED PLA TFORM REMOVAL .............................................................................110

6.6 PSU MODULE REPLACEMENT ...................................................................................1 12

6.6.1 Remove the Old PSU.........................................................................................1 12

6.6.2 Install the New PSU ...........................................................................................1 14

6.7 SYSTEM COOLING F AN REPLACEMENT ....................................................................115

6.7.1 Remove the Old System Cooling Fans ............................................................1 15

6.7.2 Install the New System Cooling Fans ...............................................................1 16

A. BIOS OPTIONS

B. DIGITAL I/O INTERFACE

B.1 INTRODUCTION ............................................................................................................ 126

B.2 DIO CONNECTOR PINOUTS ....................................................................................... 126

B.3 ASSEMBLY LANGUAGE SAMPLES ........................................................................... 127

B.3.1 Enable the DIO Input Function..................................................................................... 127

B.3.2 Enable the DIO Output Function ................................................................................. 127

C. WATCHDOG TIMER

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 8

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

D. HAZARDOUS MATERIALS DISCLOSURE

D.1 HAZARDOUS MA TERIALS DISCLOSURE TABLE FOR IPB PRODUCTS CERTIFIED AS

ROHS COMPLIANT UNDER 2002/95/EC WITHOUT MERCURY ......................................152

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 9

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

CHAPTER 1 INTRODUCTION

1. 1 OVERVIEW

The PC5153/ PC5173 flat panel PC is for industrial environments like production lines and machine automation. The PC5153/ PC5173 provides all the features of a PC, combined with a touch

panel screen for mouse and keyboard free data input. The PC5153/ PC5173 provides wired

networking for integration into company networks and PC5153/ PC5173 also provides wireless

network via PIF A antenna on the front panel. All major external device connections including

USB, serial and parallel port connectors. Storage options include a

2.5" hard drive and a CompactFlash® slot, allowing for flexibility in choosing solid state drives or

traditional hard drives. A VGA output on the rear panel allows the PC5153/ PC5173 to connect

to a second screen for duplicating the screen contents or extending the user interface.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 10

1.1.1 MODEL VARIATIONS

15” PC 5153

CPU: 2.2GHz Intel Celeron E1500

Power: AC input, 18~36V DC input

17” PC 5173

CPU: 2.2GHz Intel Celeron E1500

Power: AC input, 18~36V DC input

1.1.2 APPLICATIONS

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

The PC5153/ PC5173 flat panel PC is designed for rigorous industrial environments where it may be

exposed to both heat and moisture. Its durability and strength also makes it an ideal choice for public

access computers. Some possible applications include:

ƒ Automated manufacturing processes

ƒ Public information gathering point

ƒ Plant environment monitoring system

ƒ Factory automation

ƒ Manufacturing shop flow

ƒ Equipment and device control

1.1.3 FEATURES

Some of the features of the PC5153/ PC5173 flat panel PC include:

ƒ Mainstream panel PC design with dual display function.

ƒ Aluminum die-casting front panel meet IP 65 water proof standard

ƒ Support LGA755 Intel® Core™2 Extreme/Quad/Duo, Celeron® processors with 800/1066/

1333 MHz FSB

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 11

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

ƒ Dual DDR3 memory DIMM (system max. 4 GB SDRAM)

ƒ SA T A connectors

ƒ High brightness industrial grade LCD panel

ƒ The following I/O ports

o Five COM (one RS-232/422/485)

o One CompactFlash® slot

o One VGA port

o One Parallel port

o USB 2.0 ports

ƒ Dual 10/100/Gigabit Ethernet supported

ƒ RoHS compliant

1.2 EXTERNAL OVERVIEW

The PC5153/ PC5173 flat panel PC is comprised of an LCD screen, aluminum front panel and heavy

duty steel rear and side panels. The rear panel provides screw holes for wall and an arm mounting.

The right panel provides access to a slim type CD drive bay . The bottom p anel provides access to

external interface connectors that include GbE, USB 2.0, audio, parallel port, serial port connectors,

VGA port and a CompactFlash® card slot.

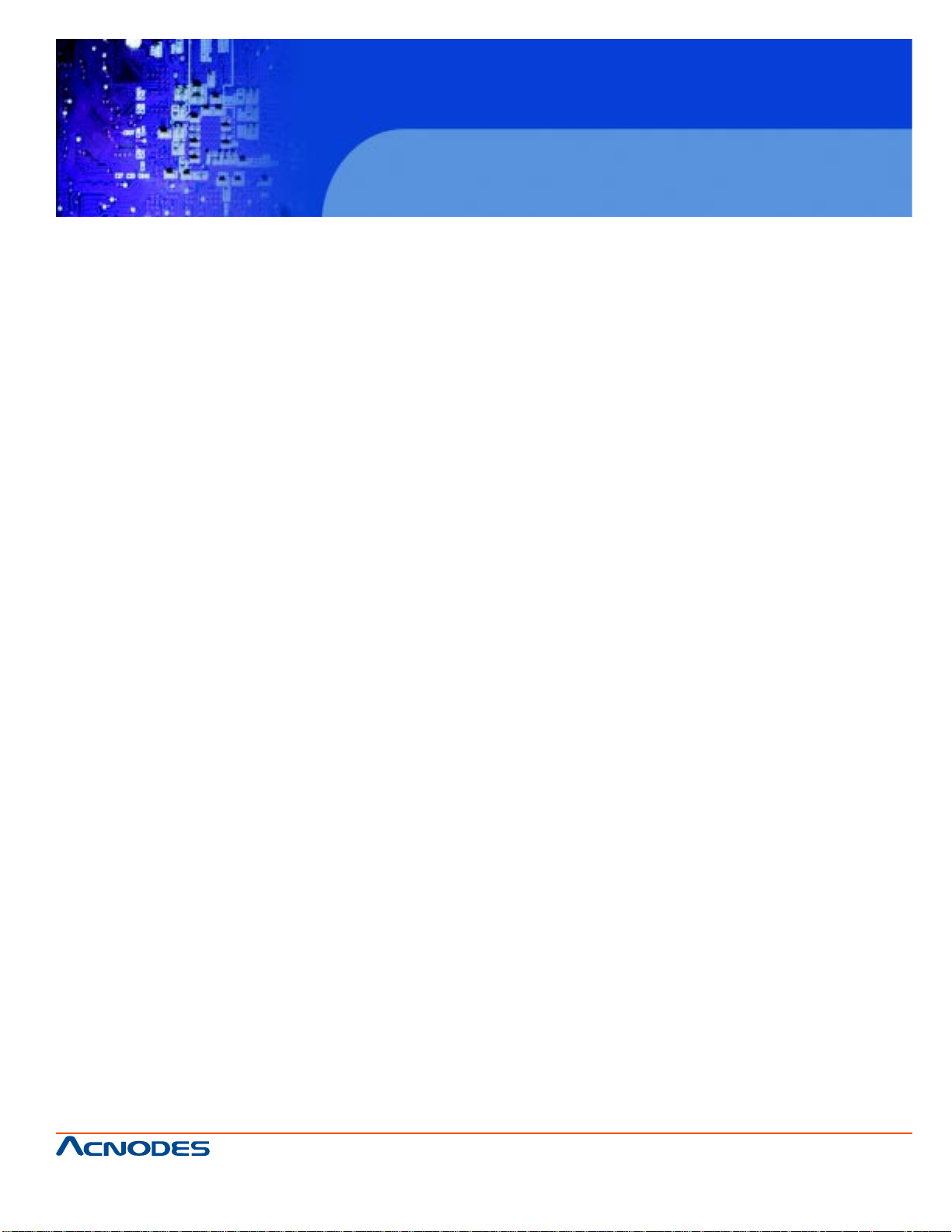

1.2.1 FRONT PANEL

The front panel of the PC5153/ PC5173 (Figure 1-2) is a flat panel TFT LCD screen surrounded by an

aluminum frame. The PC5153/ PC5173 also has wireless antenna and two USB ports protected

by waterproof cover on the front panel.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 12

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

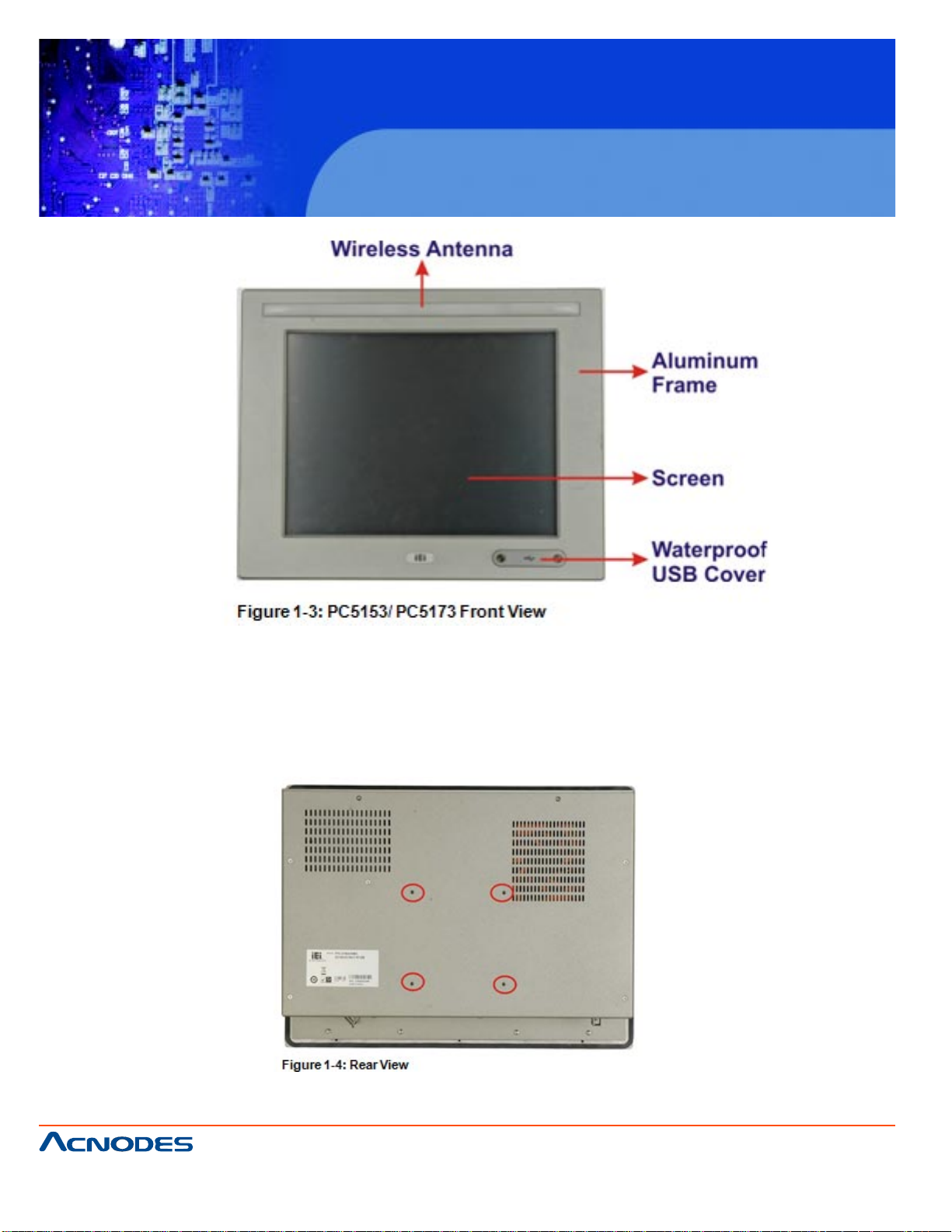

1.2.2REAR PANEL

The rear panel has a fan vent, four VESA standard mounting holes and several retention screw holes.

The VESA mounting holes are circled in Figure 1-4.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 13

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

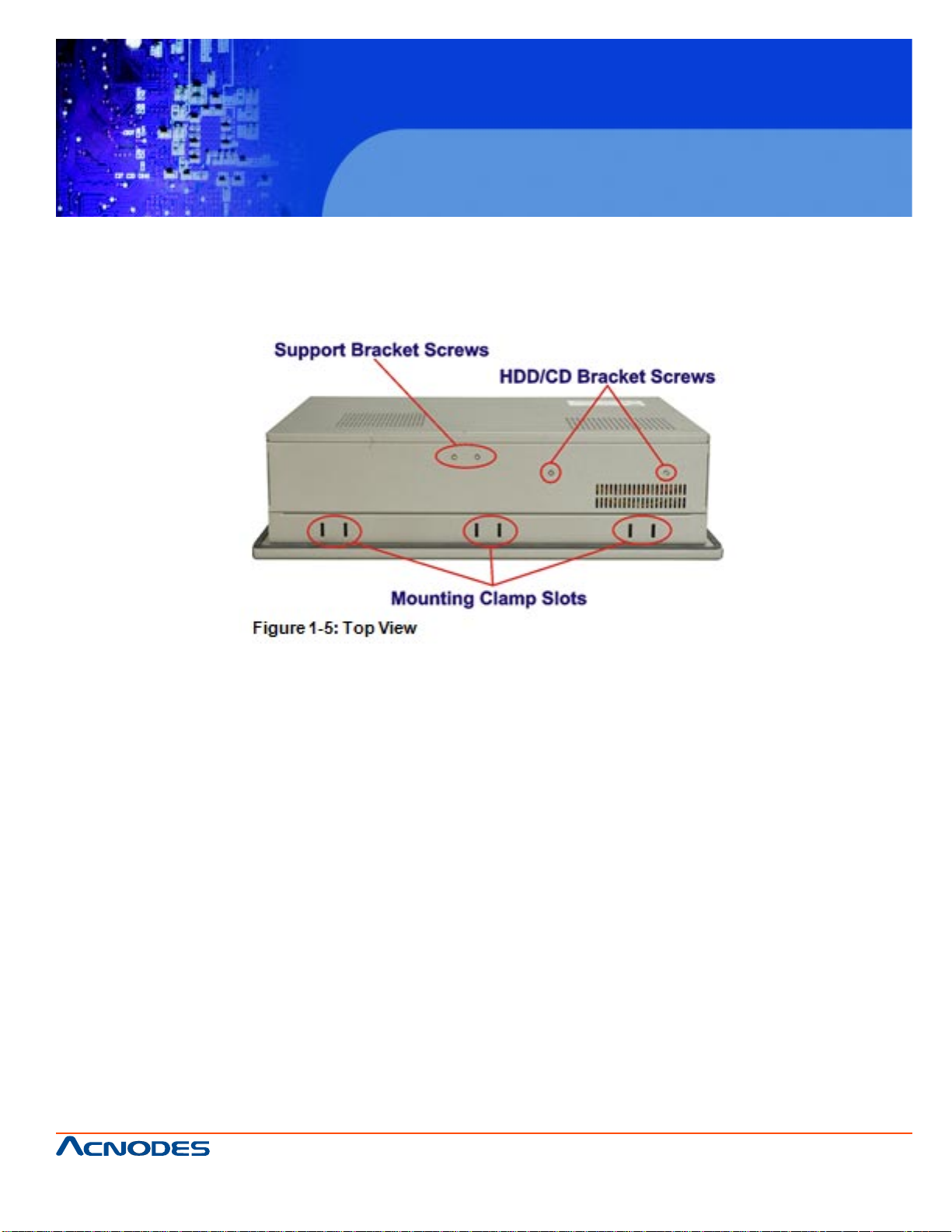

1.2.3 TOP PANEL

The top panel has three sets of mounting clamp slot, fan vents and retention screws for

securing the drive bay bracket. The retention screws are circled in Figure 1-5 below.

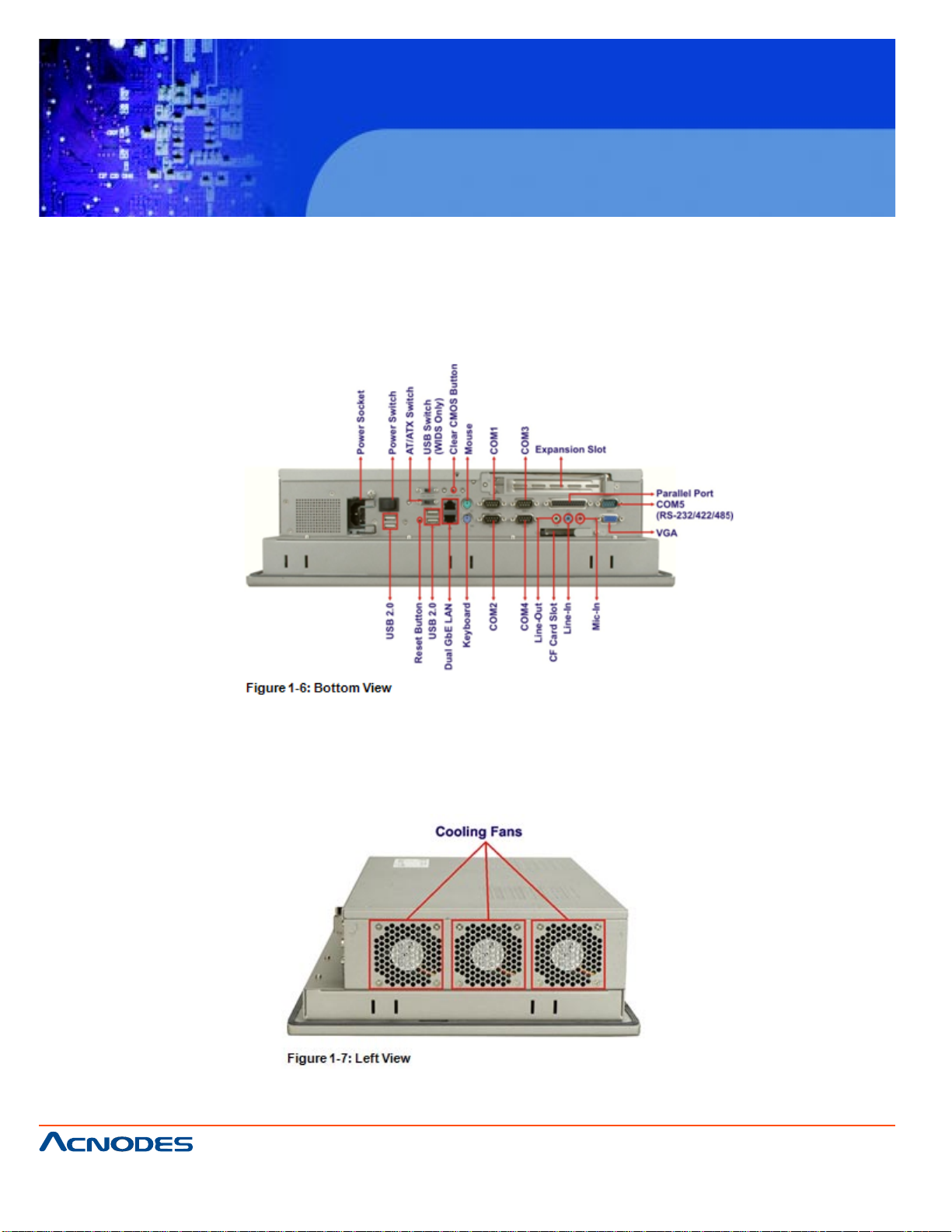

1.2.4 BOTTOM PANEL

The bottom panel shown in Figure 1-6 has the following interfaces:

ƒ 1 x Power input connector

ƒ 1 x Power switch

ƒ 4 x USB connectors

ƒ 1 x Reset button

ƒ 2 x RJ-45 GbE connectors

ƒ 1 x PS/2 mouse connector

ƒ 1 x PS/2 keyboard connector

ƒ 4 x RS-232 connectors (COM1, COM2, COM3 and COM4)

ƒ 1 x RS-232/422/485 connector (COM5)

ƒ 1 x PCI/PCIe x1 add-on card slot

ƒ 1 x Parallel port connector

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 14

ƒ 3 x Audio jacks

ƒ 1 x VGA connector

ƒ 1 x CompactFlash® slot

ƒ 1 x AT/ATX switch

ƒ 1 x USB switch

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

1.2.5 LEFT PANEL

The left side panel hosts three cooling fans that cool the interior of the system (Figure 1-7).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 15

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

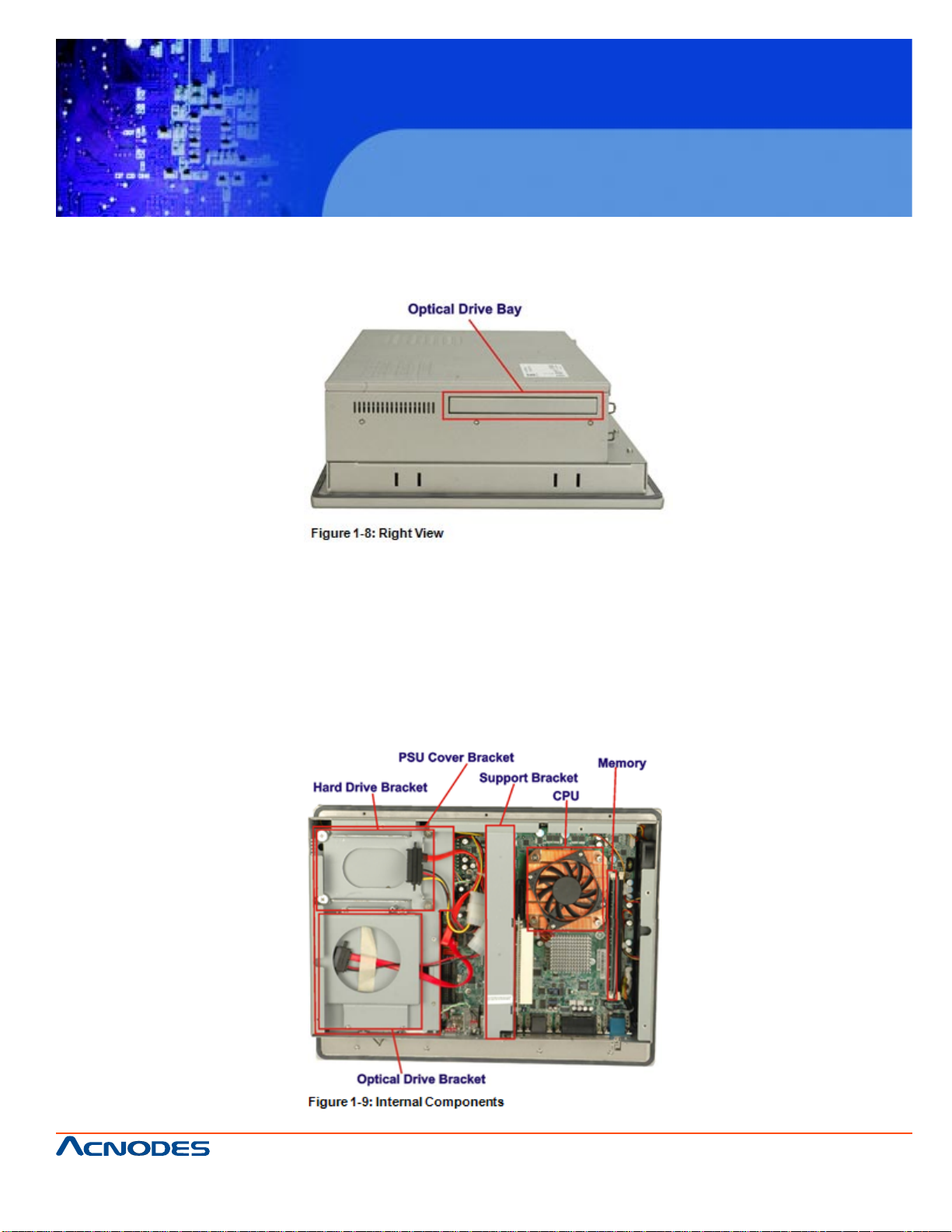

1.2.6 RIGHT PANEL

The right panel has a CD-ROM drive bay for CD-ROM drive installation (Figure 1-8).

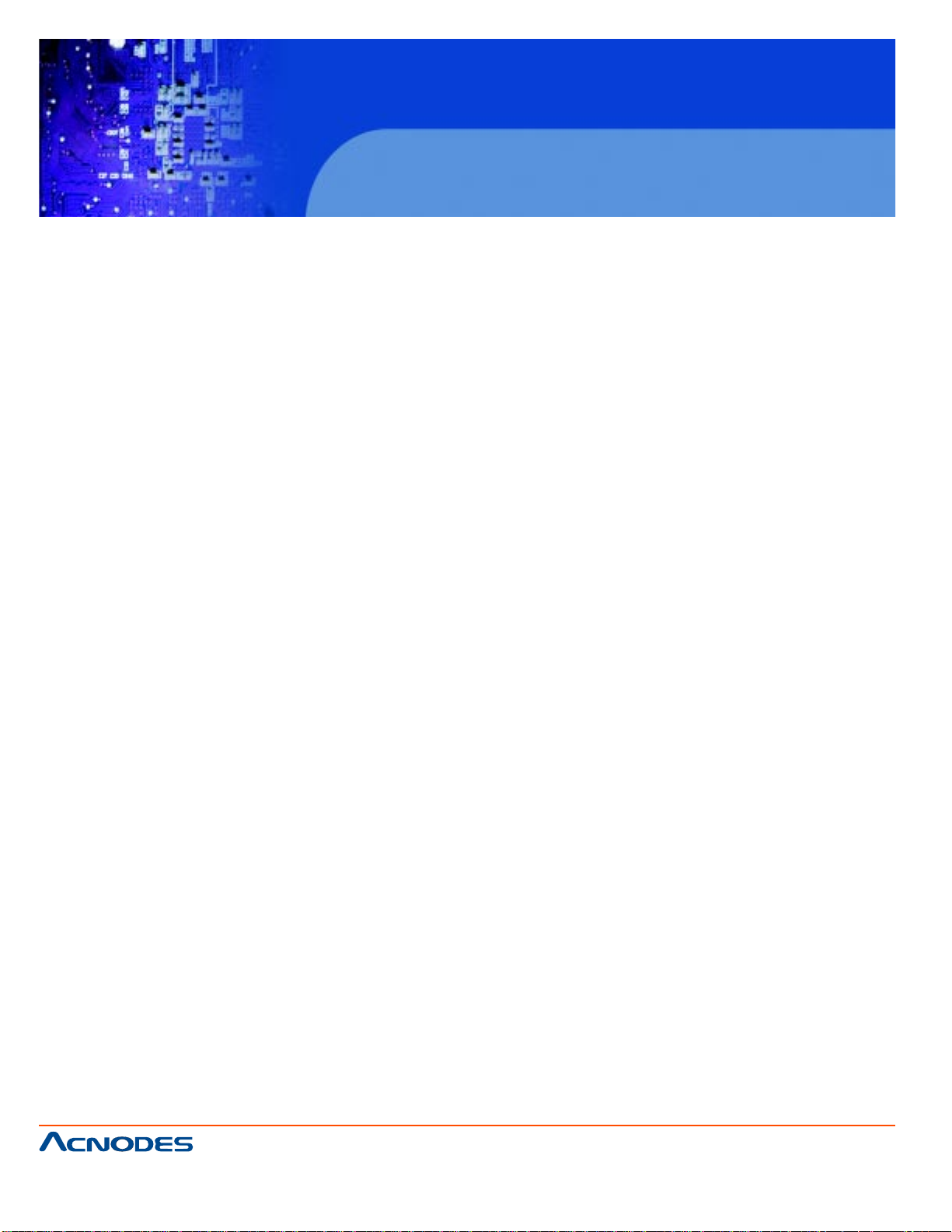

1.3 INTERNAL OVERVIEW

The PC5153/ PC5173 internal components are configured in three levels. The PSU cover

bracket to the left (Figure 1-9) supports the hard drive and optical drive brackets. Below

the PSU cover bracket is the power supply. On the same level as the power supply is the

motherboard. Below the motherboard and PSU level is an LCD panel. An overview picture

of the internal components is shown in Figure 1-9 below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 16

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

CHAPTER 2 SPECIFICA TIONS

2.1 INTRODUCTION

The PC5153/ PC5173 flat panel PC has the following preinstalled components:

ƒ 1 x Motherboard

ƒ 1 x TFT LCD screen

ƒ 1 x Power supply

ƒ 2 x Cooling fans

The technical specifications for these components and the system are shown in the sections

below.

2.1.1 SYSTEM SPECIFICATIONS

PC5153 PC5173

LCD Specs.Size 15" 17”

Resolution 1024 x 768 (XGA) 1280 x1024 (SXGA)

Brightness 350 cd/m2 380 cd/m2

Contrast Ratio 700:1 1000:1

Pixel Pitch (mm) 0.297 x 0.297 0.264 x 0.264

Viewing Angle (V-H) 125/140 160/ 170

LCD Color 16.2M 16.7M

Backlight MTBF 50,000 hours 50,000 hours

CPU:

2.66GHz Intel® Core™2 Quad Q9400 or 2.20GHz Intel® Celeron® dual-core E1500

CPU Socket: LGA775

Front Side Bus: 800 MHz, 1066 MHz or 1333 MHz

Northbridge Chipset: Intel® G41

Southbridge Chipset: Intel® ICH7

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 17

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Memory:

Two 2.0 GB 800/1066 MHz DDR3 SDRAM DIMM (system max. 4.0 GB)

Solid State Drive (SSD):

One CompactFlash® Type II socket

Drive Bay:

One 2.5" SATA 3Gb/s or IDE anti-shock drive bay,

One slim type CD-ROM bay

Ethernet: Two PCIe GbE controllers

Audio: RealTek ALC888 HD audio codec

I/O ports:

1 x RS-232/422/485 2 x LAN connectors

4 x RS-232 3 x Audio connectors (line-in, line-out and mic-in)

6 x USB 2.0 (two on front panel are waterproof) 1 x CMOS reset button

2 x PS/2 for keyboard and mouse 1 x AT/ATX switch

1 x Parallel port connector 1 x USB switch

1 x VGA-out connector 1 x Power switch

Wireless:

802.11 b/g/n wireless PCIe Mini module,

Wireless antenna embedded in front panel

Touch Screen: Resistive Type 5-wire (touch controller IC is on board)

Mounting: VESA 100 mm x 100 mm (panel, wall, rack, stand and arm)

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 18

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Expansion Slots:

Optional riser card: One PCI slot or One PCIe x4 with PCIe x1 signal

Chassis Construction: Heavy-duty steel

Front Panel Construction: Aluminum

Operating Temperature: -10ºC ~ 50ºC

Storage Temperature: -20ºC ~ 60ºC

Vibration: 5 Hz ~ 17 Hz 0.1" double amplitude displacement

17 Hz ~ 640 Hz 1.5G acceleration peak-to-peak

Shock: 10G acceleration peak-to-peak (11 ms)

Net/Gross Weight:

7 kg/11 kg 8 kg/12 kg

Dimensions (W x H x D):

410 x 309 x 110.5 452 x 356 x 115

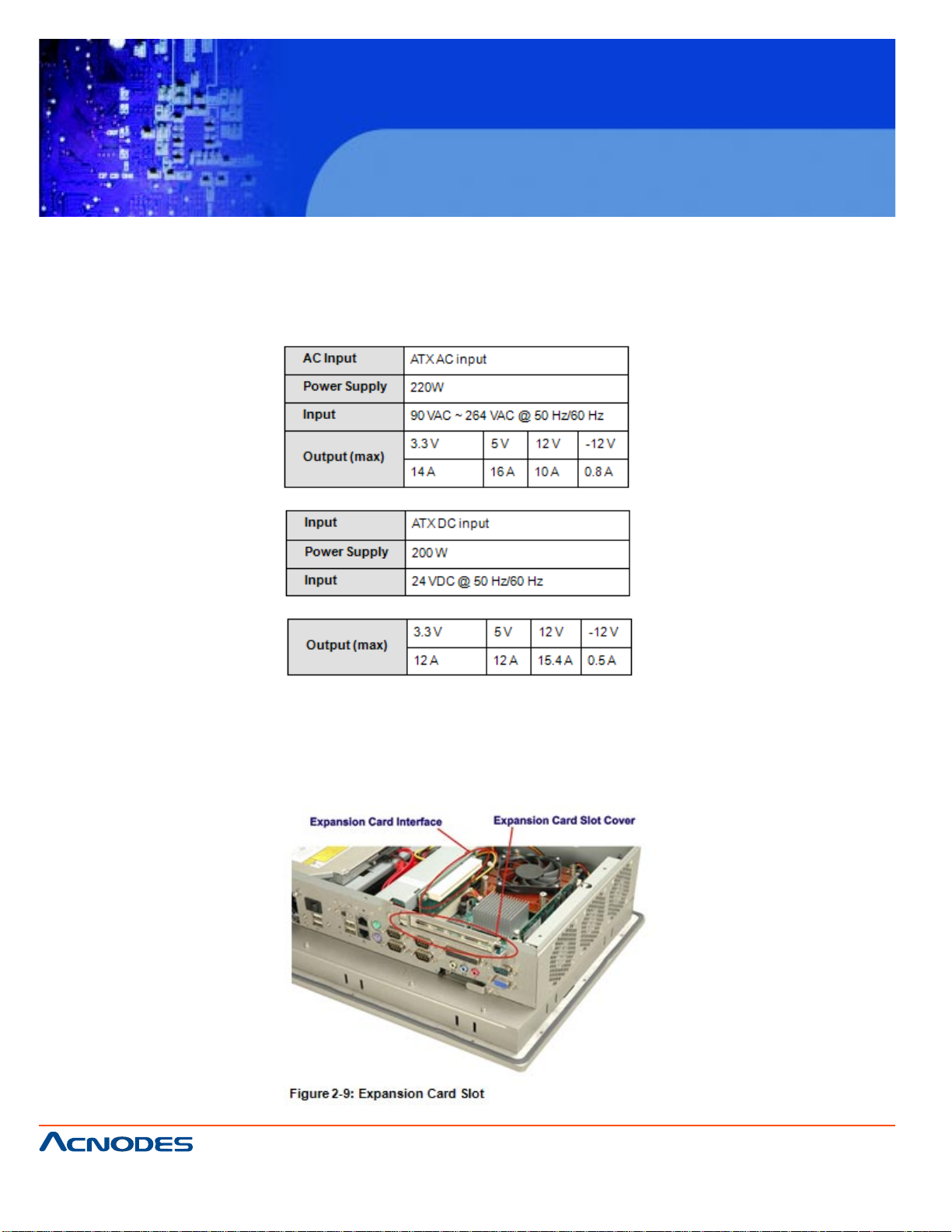

Power Supply:

AC Input ATX (A Model)

ƒ 220 W

ƒ Input: 90 V AC~264 V AC, 50/60 Hz

ƒ Output(max.): 3.3 A@14 A, 5 V@16 A, 12 V@10 A, -12 V@0.8 A

DC Input ATX (AD Model)

ƒ 200 W

ƒ Input: 24 V DC (18~36 V DC), 50/60 Hz

ƒ -Output(max.): 3.3 A@12 A, 5 V@12 A, 12 V@15.4 A, -12 V@0.5 A

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 19

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

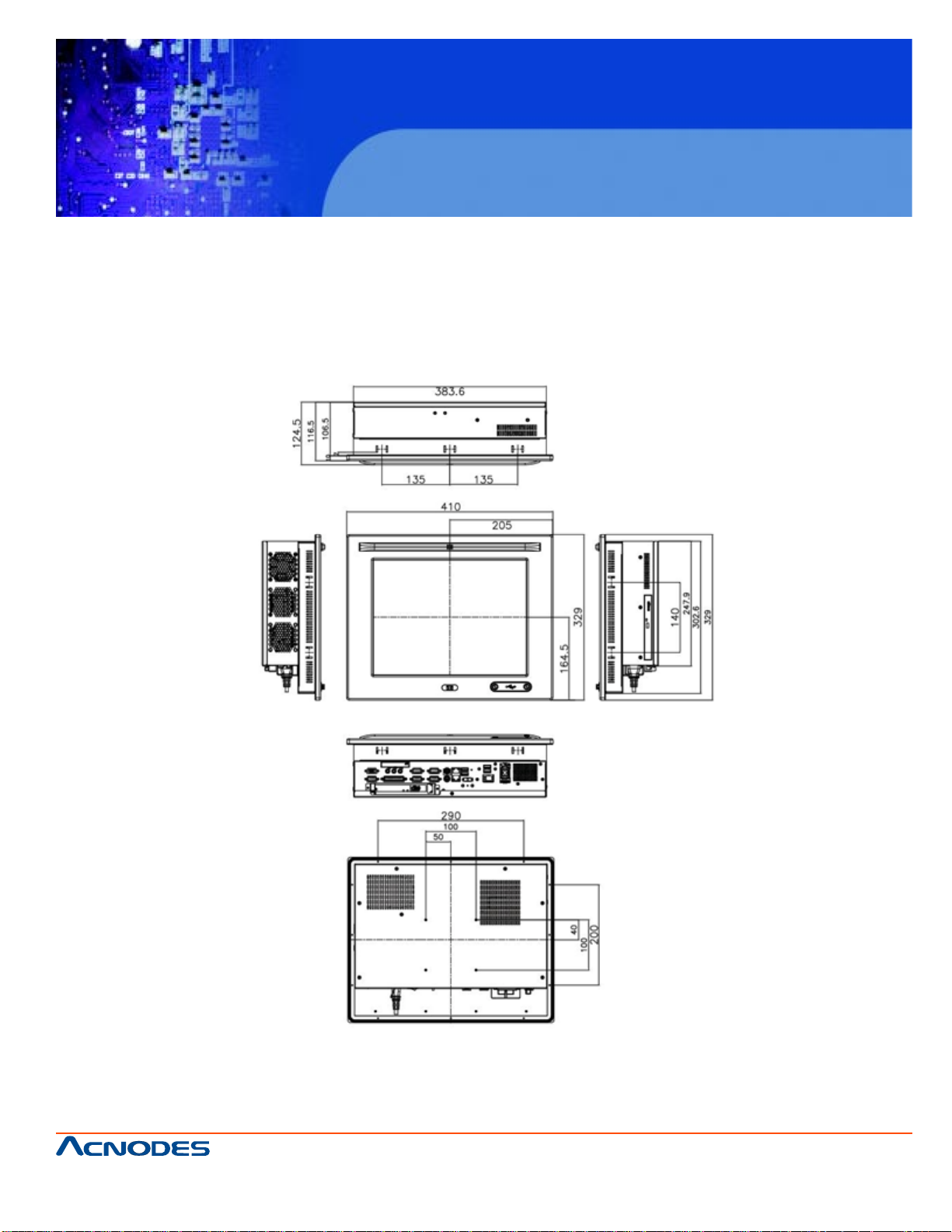

2.2 DIMENSION

The dimensions of the PC5153/ PC5173 are shown in the sections below.

2.2.1 PC5153 DIMENSIONS

The dimensions of the PC5153 flat panel PC are shown below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

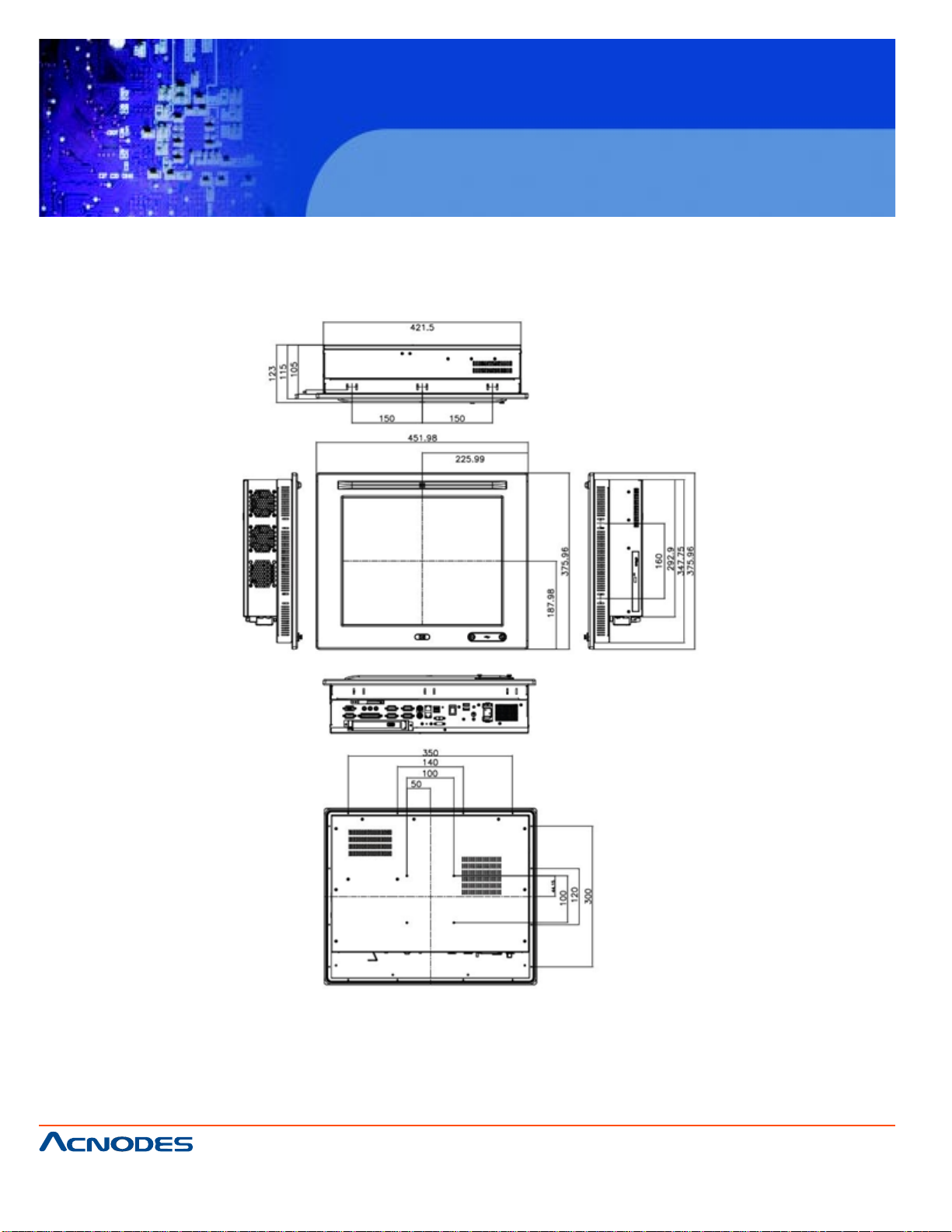

Page 20

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

2.2.2 PC5173 DIMENSIONS

The dimensions of the PC5173 flat panel PC are shown below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 21

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

2.3 GRAPHICS SUPPORT

The Intel® G41 chipset has an integrated graphics engine, Intel® Graphics

Media Accelerator X4500 that supports analog CRT display devices. The VGA port

on the external peripheral interface connector panel connects a peripheral

monitor to the PC5153/ PC5173 system.

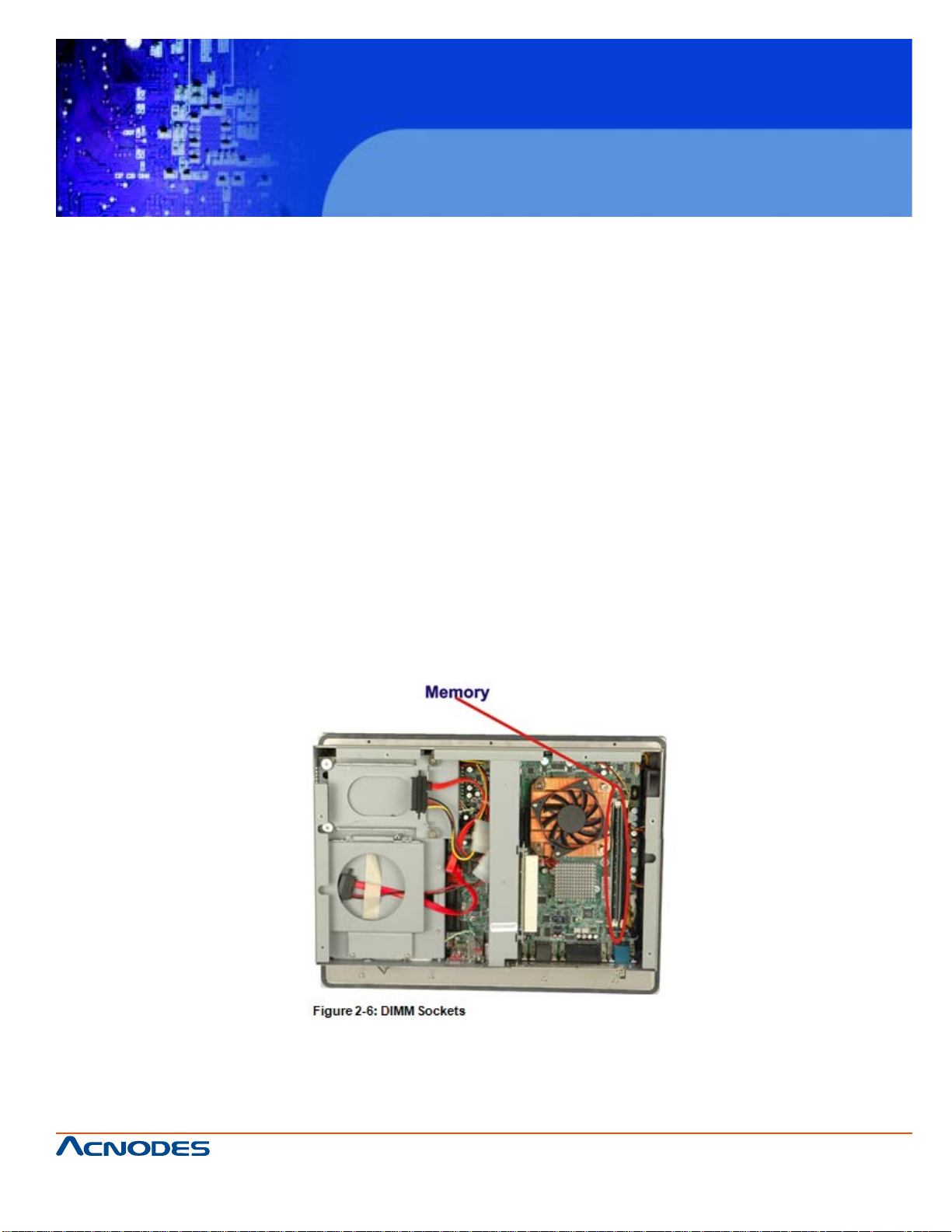

2.4 MEMORY

All processors supported by the PC5153/ PC5173 have their own internal DDR3

memory controller. The DDR3 controller has the following features:

ƒ Low-latency, high-bandwidth

ƒ Supports two 800 MHz, 1066 MHz or 1333 MHz DDR3 DIMMs

ƒ Each DIMM has a maximum capacity of 2.0 GB

The DDR3 controller on the processor is interfaced to two DIMM sockets on

the PC5153/ PC5173.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 22

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

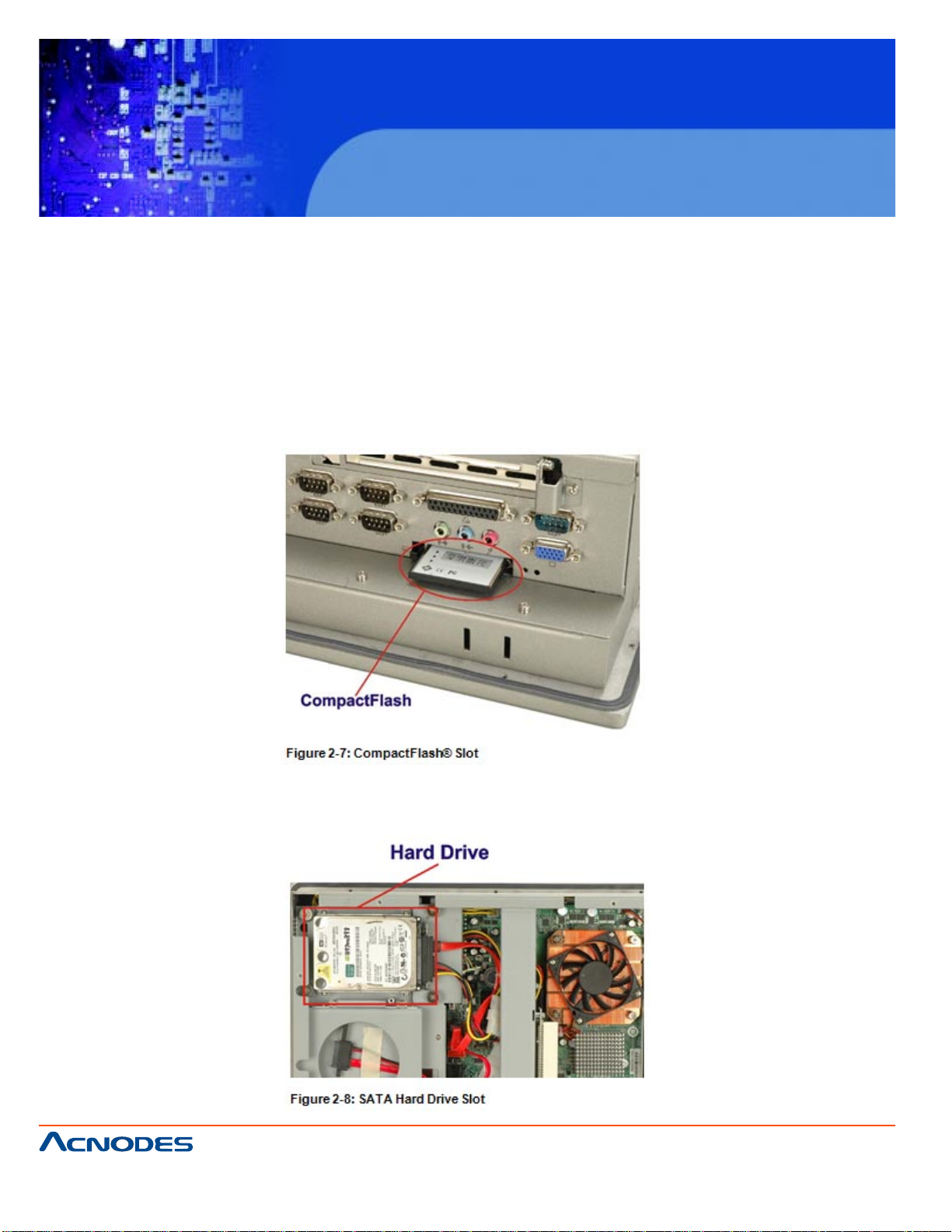

2.5 STORAGE

There following storage options are available: CompactFlash® SATA hard drive

2.5.1 COMPACTFLASH

The CompactFlash® socket supports standard CompactFlash® Type II cards. The

chipset flash interface is multiplexed with an IDE interface and can be connected to an

array of industry standard NAND Flash or NOR Flash devices. The CompactFlash® slot

location is shown below.

2.5.2 HARD DRIVE

The PC5153/ PC5173 comes has a single drive bay for 2.5" SATA 3Gb/s hard drive or

IDE hard drive.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 23

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

2.6 FRONT PANEL

The front panel of the PC5153/ PC5173 consists of an LCD monitor and a touch

screen panel.

2.6.1 FLAT SCREEN

The PC5153/ PC5173 comes with a TFT LCD monitor. The tough construction of

the TFT monitor allows the PC5153/ PC5173 to withstand the conditions it is likely to be

exposed to during regular use. Some of the specifications of the TFT monitors are

shown below:

ƒ Pixel pitch of 0.297 mm or less

ƒ 700:1 contrast ratio or better

ƒ 350 cd/m2 or greater

ƒ 0oC to 50oC operating temperature

2.6.2 TOUCH SCREEN

The touch screen panel on the PC5153/ PC5173 allows complete user interaction without the need for a keyboard or mouse. Some of the features of the touch panel are

listed below.

ƒ 5-wire analog resistive type

ƒ 78% transmission

ƒ Control chipset built onto the motherboard

ƒ -10oC to 50oC operating temperature

ƒ 7 V maximum voltage

2.7 POWER SUPPLY

The PC5153/ PC5173 flat panel PC comes with either an AC input 220 W AC 1U, or

DC input 200 W DC 1U RoHS compliant ATX power supply. The PSUs have an MTBF

greater than 100,000 hours.

W ARNING:

Under no circumstances is the PSU case to be opened. The PSU module is not user

serviceable and there are dangerous high-voltages inside the case. If there are any

problems with the PSU module, please contact the dealer or reseller immediately.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 24

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

2.7.1.1 AC INPUT/ DC INPUT SPECIFICATIONS

There are three connector for two kinds of expansion modules, Type A module and

Type B module. Slot 1 and Slot 2 are for installing Type A module and Slot 3 is for Type

B module. The pinouts of these slots are listed below.

2.8 EXPANSION SLOTS

The riser card with either a PCI or PCIe x1 expansion card slot can be separately purchased and installed in the PC5153/ PC5173. The expansion card slots add additional

functionality to the PC5153/ PC5173.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 25

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

2.9 WIRELESS LAN

The PC5153/ PC5173 panel PC preinstalled an 802.11 b/g/n wireless LAN (WLAN)

module in the Mini-PCIe socket and interfaced to the Intel® ICH7 through the PCIe x1

bus.

The wireless module is then connected directly to the front panel PIFA antenna.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 26

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

CHAPTER 3 UNPACKING

3.1 ANTI-STATIC PRECAUTIONS

WARNING!

Failure to take ESD precautions during the installation of the PC5153/ PC5173

may result in permanent damage to the PC5153/ PC5173 and severe injury to the user.

Electrostatic discharge (ESD) can cause serious damage to electronic components, including the PC5153/ PC5173. Dry climates are especially susceptible to ESD.

It is critical that the following anti-static precautions are strictly adhered to whenever

handling the PC5153/ PC5173 or any other electrical component.

ƒ Wear an anti-static wristband - Wearing a simple anti-static wristband can help to

prevent ESD from damaging the PC5153/ PC5173.

ƒ Self-grounding - Touch a grounded conducting material before handling and peri

odically while handling the PC5153/ PC5173.

ƒ Use an anti-static pad - When configuring the PC5153/ PC5173, place it on an

antic-static pad to reduce the possibility of ESD damage.

ƒ Only handle the edges of the PC5153/ PC5173 - When handling the PC5153/

PC5173, hold it by its edges.

3.2 UNPACKING PRECAUTIONS

When the PC5153/ PC5173 is unpacked, please do the following:

ƒ Follow the anti-static precautions outlined in Section 3.1.

ƒ Make sure the packing box is facing upwards so the PC5153/ PC5173 does not

fall out of the box.

ƒ Make sure all the components shown in Section 3.3 are present.

3.3 PACKAGE CONTENTS

1 x PC5153/ PC5173

1 x SATA CD-ROM cable

1 x Panel Mount Kit

1 x Wall Mount Kit

1 x Power cord

1 x Screw set

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 27

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

CHAPTER 4

INSTALLATION AND CONFIGURATION

4.1 INSTALLATION PRECAUTIONS

When installing the PC5153/ PC5173, please follow the precautions listed below:

ƒ Turn power off: When installing the PC5153/ PC5173 make sure the power is off.

Failing to turn off the power may cause severe injury to the body and/or damage

to the system.

ƒ Certified Engineers: Only certified engineers should install and modify on-board

functions.

ƒ Mounting: The PC5153/ PC5173 is a heavy device. When mounting the system

onto a rack, panel, wall or arm please make sure that at least two people are as

sisting with the procedure.

ƒ Anti-static Discharge: If a user open the rear panel of the PC5153/ PC5173, to

configure the jumpers or plug in added peripheral devices, ground themselves

first and wear and anti-static wristband.

4.2 PREINSTALLED COMPONENTS

The following components are all preinstalled.

ƒ Motherboard

ƒ TFT LCD

ƒ Touch screen

ƒ Power switch

ƒ Power supply

ƒ Inverter board

ƒ DIMM

ƒ System cooling fans

Preinstalled OEM customizations may include the following.

ƒ CPU

ƒ HDD

ƒ CD drive

ƒ PCI/PCIe x4 riser card

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 28

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Removal and reinstallation of some of the components are described in Chapter 4.

4.3 INSTALLATION AND CONFIGURATION STEPS

The following installation steps must be followed.

Step 1: Unpack the PC5153/ PC5173.

Step 2: Set the jumper settings.

Step 3: Install HDD, CompactFlash® and CD drive.

Step 4: Mount the PC5153/ PC5173 flat panel PC.

Step 5: Connect peripheral devices to the bottom panel of the PC5153/ PC5173.

Step 6: Configure the system.

4.4 REMOVE THE BACK COVER

Remove all the retention screws on the back cover. Lift the cover up to remove

(Figure 4-1).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 29

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

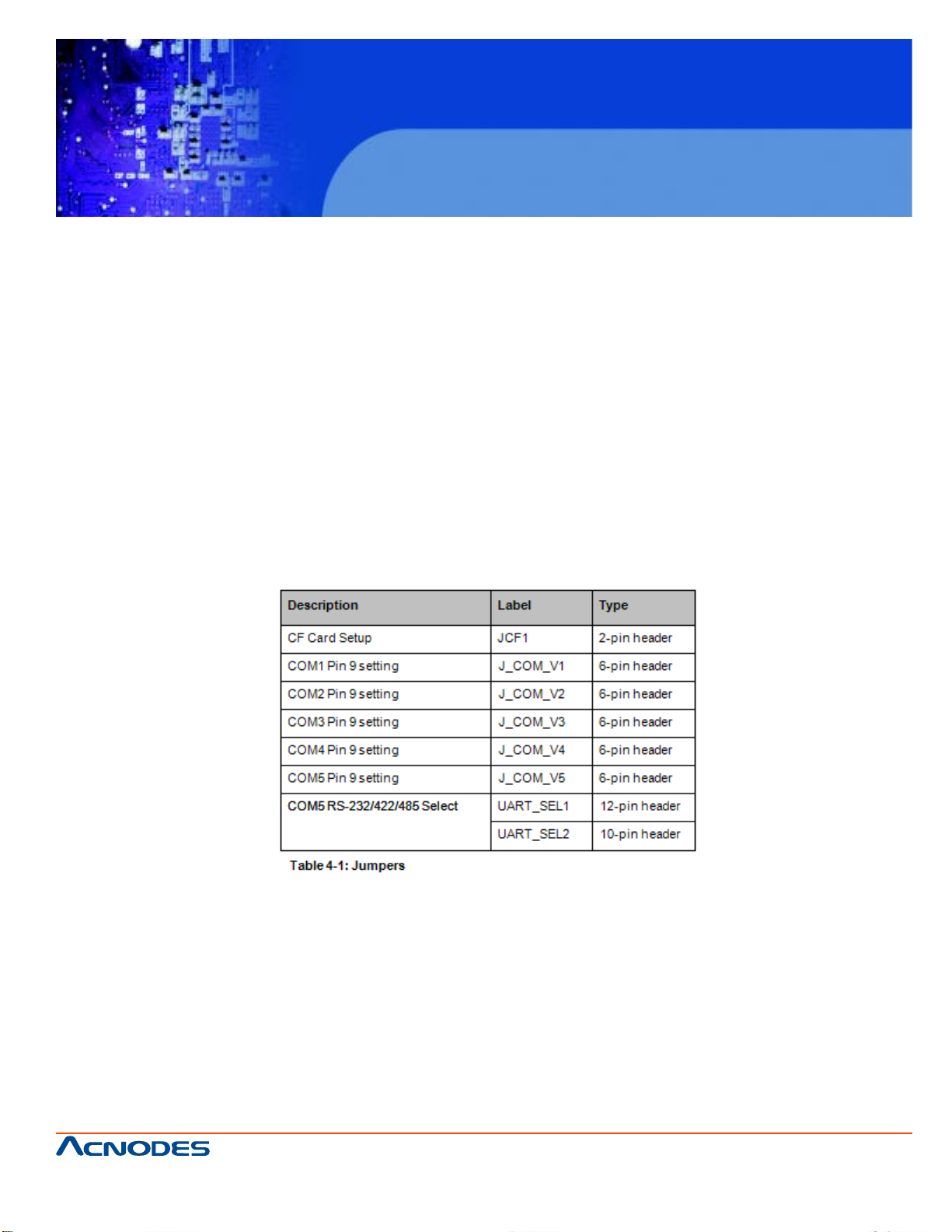

4.5 JUMPER SETTINGS

NOTE:

A jumper is a metal bridge that is used to close an electrical circuit. It consists of two

metal pins and a small metal clip (often protected by a plastic cover that slides over

the pins to connect them. To CLOSE/SHORT a jumper means connecting the

pins of the jumper with the plastic clip and to OPEN a jumper means removing the plastic clip from a jumper.

The following jumpers can be found on the motherboard installed in the PC5153/

PC5173. Before thePC5153/ PC5173 is installed, the jumpers must be set in accordance with the desired configuration. The jumpers on the PC5153/ PC5173

motherboard are listed in Table 4-1.

4.5.1 ACCESS THE JUMPER

To access the jumpers, remove the back panel. To remove the back panel, please refer

to Section 4.4.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 30

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

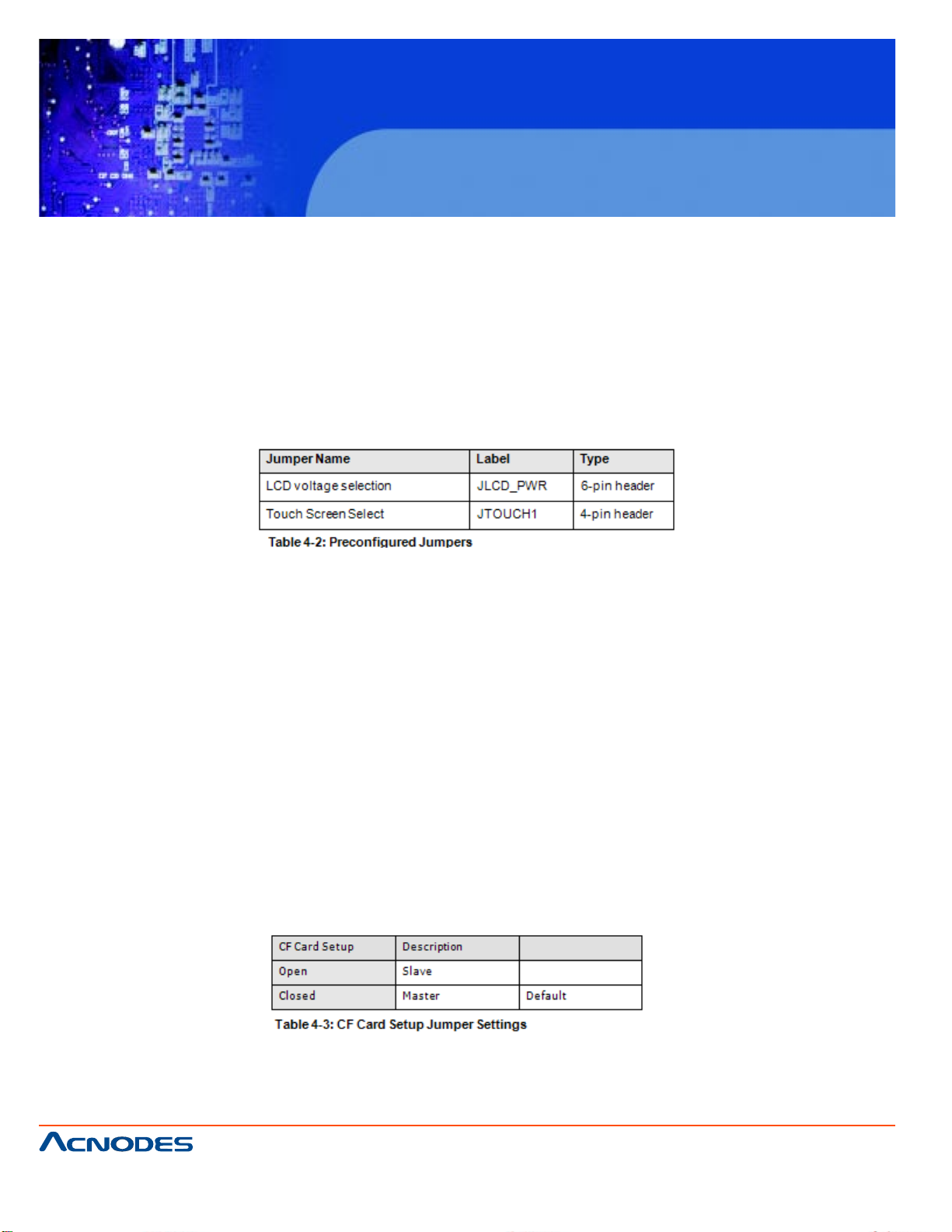

4.5.2 PRECONFIGURED JUMPERS

WARNING:

Do not change the settings on the jumpers in described here. Doing so may disable or

damage the system

The following jumpers are preconfigured for the PC5153/ PC5173. Users should no

change these jumpers.

4.5.3 CF CARD SETUP

Jumper Label: JCF1

Jumper Type: 2-pin header

Jumper Settings:See Table 4-3

Jumper Location: See Figure 4-2

The CF Card Setup jumper sets the CF Type I card or CF Type II cards as either the

slave device or the master device. CF Card Setup jumper settings are shown in Table

4-3.

The CF Card Setup jumper location is shown in Figure 4-2.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 31

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.5.4 COM1 TO COM5 PIN 9 SELECT

Jumper Label: J_COM_V1, J_COM_V2, J_COM_V3, J_COM_V4 and

J_COM_V5

Jumper Type: 6-pin header

Jumper Settings:See Table 4-4

Jumper Location: See Figure 4-3

Four jumpers configure pin 9 on the COM1, COM2, COM3 COM4 and COM5 connec-

tors. Pin 9 on these connectors can be set as either +5 V, +12 V or as the ring (RI)

signal. The COM1, COM2, COM3, COM4 and COM5 Pin 9 Setting jumper selection

options are shown in Table 4-4.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 32

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

The COM1 to COM5 Pin 9 Setting jumper locations are shown in Figure 4-3 below.

4.5.5 COM5 RS-232/422/485 SERIAL PORT SELECT JUMPER

Jumper Label: UART_SEL1 and UART_SEL2

Jumper Type: 12-pin header and 8-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-4

The COM5 RS-232/422/485 Serial Port Select jumper sets the communication protocol

used by the second serial communications port (COM5) as RS-232, RS-422 or RS-

485. The COM5 RS-232/422/485 Serial Port Select settings are shown in Table 4-5.

The COM5 RS-232/422/485 Serial Port Select jumper location is shown in Figure 4-4.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 33

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.5.5.1 COM5 RS-422 PINOUTS

The pinouts for RS-422 and RS-485 operation of external serial port COM 5 are detailed below.

4.6 DRIVE INSTALLATION

The drive installation process is shown in the sections below.

4.6.1 HARD DRIVE INSTALLATION

To install a HDD, please follow the steps below:

Step 1: Remove the back cover (Section 4.4).

Step 2: The HDD bracket is attached to the elevated platform by four retention screws.

Remove the four retention screws from the elevated platform (Figure 4-5).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 34

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 3: Attach the SATA connector cable to the bracket.

Step 4: Attach the hard drive in the bracket. To do this, slide the hard drive onto the

bracket until it connects with the SATA connector at the back. Fasten the four retention

screws on the side.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 35

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 5: Install the hard drive bracket (with hard drive and SATA cable attached) into the

PC5153/ PC5173 and fasten the four hard drive bracket screws.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 36

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.6.2 COMPACTFLASH INSTALLATION

To install the CompactFlash® card, please follow the steps below:

Step 1: Undo the CompactFlash® slot cover screw and remove the CompactFlash®

cover plate.

Step 2: Insert the CompactFlash® card into the slot.

Step 3: Fasten the CompactFlash® cover plate.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 37

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.6.3 CD DRIVE INSTALLATION

To install a CD drive, please follow the steps below.

Step 1: Remove the back cover (Section 4.4).

Step 2: Attach the CD drive adapter to the CD-ROM if it is an IDE drive (if it is a SATA

drive, proceed to Step 5:). Attach a CD drive adapter to a CD drive by aligning the two

retention screw holes in the CD drive adapter with the retention screw holes on the rear

side of the CD drive.

Step 3: Place two spacers between the CD drive and CD drive adapter.

Step 4: Insert two retention screws and secure the adapter to the CD drive

(Figure 4-12).

Step 5: Undo the optical drive bracket screws and remove the optical drive bracket.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 38

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 6: Remove the four screws from the optical drive bracket assembly. Remove the

blank drive plate.

Step 7: Install the optical drive in the same position as the previously removed blank

optical drive plate. Fasten the same four screws to attach the optical drive to the

bracket.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 39

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 8: Attach the SATA cable to the back of the optical drive and fasten the SATA

cable screws.

Step 9: Reinstall the optical drive bracket into the PC5153/ PC5173 and fasten the

optical bracket screws.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 40

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.7 PCI Expansion Card Installation (Optional)

To install a PCI expansion card, please do the following.

Step 1: Remove the back panel. See Section 4.4.

Step 2: Install the PCI riser card. Insert the PCI riser card into the PCI slot on the

motherboard of the system. Secure the PCI riser card to the system with two retention

screws.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 41

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 3: Remove the expansion slot cover. The expansion slot on the I/O panel interface is secured to the system with a single retention screw. Remove the screw.

Step 4: Insert the expansion card. Align the PCI expansion card edge connector with

the PCI expansion slot on the PCI riser card. Gently insert the PCI card into the PCI

expansion slot.

Step 5: Secure the expansion card. Once the PCI card is correctly installed in the

system, reinsert the previously removed retention screw to secure the card to the I/O

interface panel.Step 0:

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 42

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.8 PCIe Expansion Card Installation (Optional)

To install a PCI expansion card, please do the following.

Step 1: Remove the back panel. See Section 4.4.

Step 2: Install the PCIe riser card. Insert the PCIe riser card into the PCI slot and PCIe

x4 slot on the motherboard of the system. Secure the PCIe riser card to the system with

two retention screws.

Step 3: Remove the expansion slot cover. The expansion slot on the I/O panel interface is secured to the system with a single retention screw. Remove the screw.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 43

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 4: Insert the expansion card. Align the PCIe expansion card edge connector with

the PCIe expansion slot on the PCIe riser card. Gently insert the PCIe card into the

PCIe expansion slot.

Step 5: Secure the expansion card. Once the PCIe card is correctly installed in the

system, reinsert the previously removed retention screw to secure the card to the I/O

interface panel.

4.9 AT/ATX Mode Selection

AT and ATX power modes can both be used on the PPC-51xxA-G41/WIDS-51xA-G41

flat panel PC. The selection is made through an AT/ATX switch on the I/O interface

panel. The switch is shown below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 44

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.10 Activating the Front USB Connectors

A USB switch on the I/O panel of the PC5153/ PC5173 activates the two USB connectors on the front panel. To access the USB connectors and activate the connectors,

please do the following:

Step 1: Open the cover. The USB connectors are secured to the front panel of the

PC5153/ PC5173 with two retention screws. Remove these screws.

Step 2: Activate the USB connectors. To activate the USB connectors, move the USB

switch to the left.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 45

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.11 MOUNTING THE SYSTEM

WARNING!

When mounting the PC5153/ PC5173 flat panel PC onto an arm, wall or into a panel, it

is advisable to have more than one person help with the installation to prevent accidental damage to the panel and avoid personal injury.

The methods of mounting the PC5153/ PC5173 are:

ƒ Wall mounting

ƒ Panel mounting

ƒ Arm mounting

ƒ Rack mounting

The mounting methods are fully described below.

4.11.1 WALL MOUNTING

To mount the PC5153/ PC5173 flat panel PC onto a wall, please follow the steps below.

Step 1: Select the location on the wall for the wall-mounting bracket.

Step 2: Carefully mark the locations of the four bracket screw holes on the wall.

Step 3: Drill four pilot holes at the marked locations on the wall for the bracket retention

screws.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 46

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 4: Align the wall-mounting bracket screw holes with the pilot holes.

Step 5: Secure the mounting-bracket to the wall by inserting the retention screws into

the four pilot holes and tightening them (see Figure 3-11).

Step 6: Insert the four monitor mounting screws provided in the wall mounting kit into

the four screw holes on the real panel of the monitor and tighten until the screw shank is

secured against the rear panel (see Figure 3-12).

Step 7: Align the mounting screws on the monitor rear panel with the mounting holes

on the bracket.

Step 8: Carefully insert the screws through the holes and gently pull the monitor downwards until the monitor rests securely in the slotted holes (see Figure 3-12). Ensure that

all four of the mounting screws fit snuggly into their respective slotted holes.

NOTE:

In the diagram below the bracket is already installed on the wall.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 47

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 9: Secure the panel PC with the wall-mounting kit. To do this, stick the protective

cushion to the wall-mounting kit first. Then, put the wall-mounting kit on the top panel of

the panel PC. Carefully mark the location of the wall-mounting kit screw holes on the

wall. Drill a pilot hole at the marked location on the wall. Secure the wall-mounting kit to

the wall by inserting a retention screw into the pilot hole on the wall (Figure 4-30). This

step is to avoid the panel PC being pushed apart from the wall-mounting bracket accidentally.

4.11.2 Panel/ Mounting

To mount the PC5153/ PC5173 flat panel PC into a panel, please follow the steps below.

NOTE:

The maximum panel thickness should be no more than 6 mm.

Step 1: Select the position on the panel to mount the PC5153/ PC5173.

Step 2: Cut out a section of the panel that corresponds to the rear panel dimensions of

the PC5153/ PC5173. The recommended cutout sizes are shown below (Figure 4-31,

Figure 4-32 and Figure 4-33).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 48

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 3: Slide the PC5153/ PC5173 through the hole until the metal frame is flush

against the panel.

Step 4: Insert the panel mounting clamps into the pre-formed holes along the edges of

the PC5153/ PC5173, behind the metal frame (Figure 4-36). Refer to the mounting kit

packing list for the required number of mounting clamps.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 49

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Step 5: Tighten the screws that pass through the panel mounting clamps until the plastic caps at the front of all the screws are firmly secured to the panel (Figure 4-37).

4.11.3 Rack and Cabinet Installation

To mount the PC5153/ PC5173 into a rack/cabinet, please follow the steps below.

Step 1: Secure the rack mounting bracket to two sides of the monitor using the supplied retention screws (Figure 3-17). Each bracket requires four screws.

Step 2: Secure the rack mounting bracket to the rack by inserting and tightening the

supplied mounting nuts and bolts (Figure 3-17). Each bracket requires three nuts and

bolts for installation.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 50

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

4.11.4 Arm Mounting

The PC5153/ PC5173 is VESA (Video Electronics Standards Association) compliant

and can be mounted on an arm with a 100 mm interface pad. To mount the PC5153/

PC5173 on an arm, please follow the steps below.

Step 1: The arm is a separately purchased item. Please correctly mount the arm onto

the surface it uses as a base. To do this, refer to the installation documentation that

came with the mounting arm.

NOTE:

When purchasing the arm please ensure that it is VESA compliant and that the arm has

a 100 mm interface pad. If the mounting arm is not VESA compliant, it cannot

be used to support the PC5153/ PC5173 flat panel PC.

Step 2: Once the mounting arm has been firmly attached to its surface, lift the

PC5153/ PC5173 flat panel PC onto the interface pad of the mounting arm.

Step 3: Align the retention screw holes on the mounting arm interface with those in the

PC5153/ PC5173 flat panel PC. ThePC5153/ PC5173 flat panel PC arm mount retention screw.

Step 4: Secure the PC5153/ PC5173 to the interface pad by inserting four retention

screws through the mounting arm interface pad and into the

PC5153/ PC5173 flat panel PC.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 51

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

CHAPTER 5 BIOS SETUP

5.1 Introduction

The BIOS is programmed onto the BIOS chip. The BIOS setup program allows

changes to certain system settings. This chapter outlines the options that can be

changed.

5.1.1 Starting Setup

The AMI BIOS is activated when the computer is turned on. The setup program can be

activated in one of two ways.

1. Press the DELETE key as soon as the system is turned on or

2. Press the DELETE key when the "Press Del to enter SETUP" message appears on

the screen. 0.

If the message disappears before the DELETE key is pressed, restart the computer

and try again.

5.1.2 Using Setup

Use the arrow keys to highlight items, press ENTER to select, use the PAGEUP and

PAGEDOWN keys to change entries, press F1 for help and press ESC to quit. Navigation keys are shown below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 52

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

5.1.3 Getting Help

When F1 is pressed a small help window describing the appropriate keys to use and

the possible selections for the highlighted item appears. To exit the Help Window press

ESC or the F1 key again.

5.1.4 Unable to Reboot After Configuration Changes

If the computer cannot boot after changes to the system configuration is made, CMOS

defaults. Use the jumper described in Chapter 5.

5.1.5 Main BIOS Menu

The menu bar on top of the BIOS screen has the following main items:

Main Changes the basic system configuration.

Advanced Changes the advanced system settings.

PCIPnP Changes the advanced PCI/PnP Settings

Boot Changes the system boot configuration.

Security Sets User and Supervisor Passwords.

Chipset Changes the chipset settings.

Power Changes power management settings.

Exit Selects exit options and loads default settings

The following sections completely describe the configuration options found in the menu

items at the top of the BIOS screen and listed above.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 53

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

5.2 Main

The Main BIOS menu (BIOS Menu 1) appears when the BIOS Setup program is entered. The Main menu gives an overview of the basic system information.

System Overview

The System Overview lists a brief summary of different system components. The fields in System Overview

cannot be changed. The items shown in the system overview include:

-AMI BIOS: Displays auto-detected BIOS information

o Version: Current BIOS version

o Build Date: Date the current BIOS version was made

o ID: Installed BIOS ID

-Processor: Displays auto-detected CPU specifications

o T ype: Names the currently installed processor

o Speed: List s the processor speed

o Count: The number of CPUs on the motherboard

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 54

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

-System Memory: Displays the auto-detected system memory .

o Size: Lists memory size

The System Overview field also has two user configurable fields:

System Time [xx:xx:xx]

Use the System Time option to set the system time. Manually enter the hours, minutes and seconds.

System Date [xx/xx/xx]

Use the System Date option to set the system date. Manually enter the day , month and year .

5.3 Advanced

Use the Advanced menu (BIOS Menu 2) to configure the CPU and peripheral devices through the following

sub-menus:

WARNING:

Setting the wrong values in the sections below may cause the system to malfunction. Make sure that the

settings made are compatible with the hardware.

CPU Configuration

IDE Configuration

SuperIO Configuration

Hardware Health Configuration

Power Configuration

Remote Access Configuration

USB Configuration

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 55

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

5.3.1 CPU Configuration

Use the CPU Configuration menu (BIOS Menu 3) to view detailed CPU specifications and configure the

CPU.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 56

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

The CPU Configuration menu (BIOS Menu 3) lists the following CPU details:

Manufacturer: Lists the name of the CPU manufacturer

Brand String: List s the brand name of the CPU being used

Frequency: Lists the CPU processing speed

FSB Speed: List s the FSB speed

Cache L1: Lists the CPU L1 cache size

Cache L2: Lists the CPU L2 cache size

5.3.2 IDE Configuration

Use the IDE Configuration menu (BIOS Menu 4) to change and/or set the configuration of the IDE devices

installed in the system.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 57

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

A T A/IDE Configurations [Comp atible]

Use the A T A/IDE Configurations option to configure the A T A/IDE controller .

Disabled Disables the on-board A T A/IDE controller .

Compatible Configures the on-board ATA/IDE controller to be in compatible mode. In this

mode, a SA T A channel will replace one of the IDE channels. This mode sup

ports up to 4 storage devices.

Enhanced (DEFAUL T) Configures the on-board A T A/IDE controller to be in Enhanced mode.

In this mode, IDE channels and SA T A channels are sep arated. This

mode supports up to 6 storage devices. Some legacy OS do not

support this mode.

Configure SA TA as [IDE]

Use the Configure SA T A as option to configure SA T A devices as normal IDE devices.

IDE DEFAUL T Configures SA T A devices as normal IDE device.

RAID Configures SA T A devices as normal RAID device.

AHCI Configures SA T A devices as normal AHCI device.

Configure SA TA Channels [Before PATA]

Use the Configure SA T A Channels option to determine how SAT A channels and P A T A channels are

ordered.

Before PATA DEFAULT Puts SAT A channels before P A T A channels.

Behind P AT A Puts SATA channels behind PA T A channels.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 58

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

IDE Master and IDE Slave

When entering setup, BIOS auto detects the presence of IDE devices. BIOS displays the status of

the auto detected IDE devices. The following IDE devices are detected and are shown in the IDE Configuration menu:

Primary IDE Master Third IDE Master

Primary IDE Slave Third IDE Slave

Secondary IDE Master

Secondary IDE Slave

The IDE Configuration menu (BIOS Menu 4) allows changes to the configurations for the IDE devices

installed in the system. If an IDE device is detected, and one of the above listed four BIOS configuration

options are selected, the IDE configuration options shown in Section 5.3.2.1 appear.

5.3.2.1 IDE Master, IDE Slave

Use the IDE Master and IDE Slave configuration menu to view both primary and secondary IDE

device details and configure the IDE devices connected to the system.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 59

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Auto-Detected Drive Parameters

The "grayed-out" items in the left frame are IDE disk drive parameters automatically detected from

the firmware of the selected IDE disk drive. The drive parameters are listed as follows:

-Device: Lists the device type (e.g. hard disk, CD-ROM etc.)

-Type: Indicates the type of devices a user can manually select

-Vendor: Lists the device manufacturer

-Size: List the storage capacity of the device.

-LBA Mode: Indicates whether the LBA (Logical Block Addressing) is a method of address

ing data on a disk drive is supported or not.

-Block Mode: Block mode boosts IDE drive performance by increasing the amount of data

transferred. Only 512 bytes of data can be transferred per interrupt if block mode is not used. Block

mode allows transfers of up to 64 KB per interrupt.

-PIO Mode: Indicates the PIO mode of the installed device.

-Async DMA: Indicates the highest Asynchronous DMA Mode that is supported.

-Ultra DMA: Indicates the highest Synchronous DMA Mode that is supported.

-S.M.A.R.T .: Indicates whether or not the Self-Monitoring Analysis and Reporting T echnology proto

col is supported.

-32Bit Data T ransfer: Enables 32-bit data transfer .

T ype [Auto]

Use the T ype BIOS option select the type of device the AMIBIOS attempt s to boot from after the Power-On

Self-T est (POST) is complete.

Not Installed

BIOS is prevented from searching for an IDE disk drive on the specified channel.

Auto DEFAULT

The BIOS auto detects the IDE disk drive type attached to the specified channel. This setting should

be used if an IDE hard disk drive is attached to the specified channel.

CD/DVD

The CD/DVD option specifies that an IDE CD-ROM drive is attached to the specified IDE channel. The

BIOS does not attempt to search for other types of IDE disk drives on the specified channel.

ARMD

This option specifies an A T API Removable MediaDevice. These include, but are not limited to:

ZIP

LS-120

LBA/Large Mode [Auto]

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 60

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Use the LBA/Large Mode option to disable or enable BIOS to auto detects LBA (Logical

Block Addressing). LBA is a method of addressing dat a on a disk drive. In LBA mode, the maximum

drive capacity is 137 GB.

Disabled BIOS is prevented from using the LBA mode control on the specified channel.

Auto DEFAULT BIOS auto detects the LBA mode control on the specified channel.

Block (Multi Sector Transfer) [Auto]

Use the Block (Multi Sector T ransfer) to disable or enable BIOS to auto detect if the device supports

multi-sector transfers.

Disabled

BIOS is prevented from using Multi-Sector Transfer on the specified channel. The data to and from the

device occurs one sector at a time.

Auto DEFAULT

BIOS auto detects Multi-Sector T ransfer support on the drive on the specified channel. If supported

the data transfer to and from the device occurs multiple sectors at a time.

PIO Mode [Auto]

Use the PIO Mode option to select the IDE PIO (Programmable I/O) mode program timing cycles

between the IDE drive and the programmable IDE controller . As the PIO mode increases, the cycle time

decreases.

Auto

DEFAULT

BIOS auto detects the PIO mode. Use this value if the IDE disk

drive support cannot be determined.

0

PIO mode 0 selected with a maximum transfer rate of 3.3MBps

1

PIO mode 1 selected with a maximum transfer rate of 5.2MBps

2

PIO mode 2 selected with a maximum transfer rate of 8.3MBps

3

PIO mode 3 selected with a maximum transfer rate of 1 1.1MBps

4

PIO mode 4 selected with a maximum transfer rate of 16.6MBps (This setting generally works with

all hard disk drives manufactured after 1999. For other disk drives, such as IDE CD-ROM drives,

check the specifications of the drive.)

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 61

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

DMA Mode [Auto]

Use the DMA Mode BIOS selection to adjust the DMA mode options.

Auto DEFAULT

BIOS auto detects the DMA mode. Use this value if the IDE disk drive support cannot

be determined.

S.M.A.R.T [Auto]

Use the S.M.A.R.T option to auto-detect, disable or enable Self-Monitoring Analysis and

Reporting Technology (SMART) on the drive on the specified channel. S.M.A.R.T predicts impending drive failures. The S.M.A.R.T BIOS option enables or disables this

function.

Auto DEFAULT

BIOS auto detects HDD SMART support.

Disabled

Prevents BIOS from using the HDD SMART feature.

Enabled

Allows BIOS to use the HDD SMART feature

32Bit Data Transfer [Enabled]

Use the 32Bit Data Transfer BIOS option to enables or disable 32-bit data transfers.

Disabled

Prevents the BIOS from using 32-bit data transfers.

Enabled D EFAU LT

Allows BIOS to use 32-bit data transfers on supported hard disk drives.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2009 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 62

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

5.3.3 Super IO Configuration

Use the Super IO Configuration menu (BIOS Menu 6) to set or change the configurations for the FDD controllers, parallel ports and serial ports.

Parallel Port Address [Disabled]

Use the Parallel Port Address option to select the parallel port base address.

Disabled DE FAULT

No base address is assigned to the Parallel Port

378

Parallel Port I/O port address is 378

278

Parallel Port I/O port address is 278

3BC

Parallel Port I/O port address is 3BC

Parallel Port Mode [Normal]

Use the Parallel Port Mode option to select the mode the parallel port operates in.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2005 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 63

KD 9170N

17” Short Depth Monitor Keyboard

Drawer

Normal DEFAULT

The normal parallel port mode is the standard mode for parallel port operation.

Bi-directional

Parallel port outputs are 8-bits long. Inputs are accomplished by reading 4 of the

8 bits on the status register.

EPP

The parallel port operates in the enhanced parallel port mode (EPP). The EPP

mode supports bi-directional communication between the system and the parallel

port device and the transmission rates between the two are much faster than the Normal

mode.

ECP+EPP

The parallel port operates inthe extended capabilities port (ECP) mode. The ECP

mode supports bi-directional communication between the system and the parallel

port device and the transmission rates between the two are much faster than the

Normal mode The parallel port is also be compatible with EPP devices described

above

Parallel Port IRQ [IRQ7]

Use the Parallel Port IRQ selection to set the parallel port interrupt address.

IRQ5 IRQ5 is assigned as the parallel port interrupt address

IRQ7 DEFAULT IRQ7 is assigned as the parallel port interrupt address

Serial Port1 Address [3F8/IRQ4]