Page 1

User Manual

FPC6065: 6.5” Industrial Panel PC with AMD Geode LX

800 500MHz processor

FPC 6065 / 6084

FPC6084: 8.4” Industrial Panel PC with AMD Geode LX

800 500MHz processor

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 2

FPC 6065 / 6084

COPYRIGHT NOTICE

The information in this document is subject to change without prior notice in order to improve reliability , design and function and does not represent a commitment on the part of the manufacturer .

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential

damages arising out of the use or inability to use the product or documentation, even if

advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No

part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer .

TRADEMARKS

All registered trademarks and product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective owners.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 3

FPC 6065 / 6084

T able of Contents

CHAPTER 1 INTRODUCTION

1.1 FPC6065/ FPC6084 FLA T P ANEL PC OVERVIEW .................................................... 2

1.1.1 Model V ariations ................................................................................................ 2

1.1.2 Applications ....................................................................................................... 2

1.1.3 St andard Features ............................................................................................. 2

1.2 EXTERNAL OVERVIEW .................................................................................................. 3

1.2.1 General Description........................................................................................... 3

1.2.2 Front Panel ........................................................................................................ 3

1.2.3 Rear Panel ......................................................................................................... 4

1.2.4 T op Panel ........................................................................................................... 4

1.2.5 Bottom Panel...................................................................................................... 5

1.3 INTERNAL OVERVIEW ................................................................................................... 6

1.4 SPECIFICA TIONS ........................................................................................................... 6

1.4.1 Preinstalled Hardware Components ................................................................. 6

1.4.2 System Specifications ....................................................................................... 7

1.4.3 Motherboard Specifications .............................................................................. 8

1.4.4 Flat Panel Screen .............................................................................................. 9

1.4.4.1 FPC6065 Flat Panel Screen Specifications ...................................... 9

1.4.4.2 FPC6084 Flat Panel Screen Specifications .......................................11

1.5 DIMENSIONS................................................................................................................... 12

1.5.1 FPC6065 Dimensions ..................................................................................... 12

1.5.2 FPC6084 Dimensions ..................................................................................... 13

CHAPTER 2 WAFER-LX MOTHERBOARD

2.1 INTRODUCTION.............................................................................................................. 15

2.2 CPU SUPPORT .............................................................................................................. 15

2.2.1 AMD® Geode™ LX 800 500MHz S pecifications............................................ 15

2.2.2 AMD® Geode™ LX 800 500MHz Power Management.................................. 16

2.3 SYSTEM CHIPSET .......................................................................................................... 16

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 4

FPC 6065 / 6084

2.4 ETHERNET CONTROLLER SPECIFICA TIONS........................................................... 17

2.4.1 Overview ........................................................................................................... 17

2.4.2 Features ........................................................................................................... 17

2.5 PERIPHERAL DEVICE INTERF ACES, CONNECT ORS, AND SLOTS .................... 18

2.5.1 OEM Options ................................................................................................... 18

2.5.2 Internal Slots .................................................................................................... 18

2.5.3 Internal Peripheral Device Connectors ........................................................... 18

2.5.4 External Peripheral Device Connectors ......................................................... 19

CHAPTER 3 INSTALLATION AND CONFIGURATION

3.1 INST ALLA TION PRECAUTIONS ................................................................................... 21

3.2 PREINST ALLED COMPONENTS.................................................................................. 21

3.3 INST ALLA TION AND CONFIGURA TION STEPS ......................................................... 21

3.4 UNP ACKING .................................................................................................................. 22

3.4.1 Packing List ..................................................................................................... 23

3.5 REMOVE THE BACK COVER ...................................................................................... 23

3.5.1 FPC6065 Back Cover Removal ..................................................................... 23

3.5.2 FPC6084 Back Cover Removal ..................................................................... 24

3.6 JUMPER SETTINGS ..................................................................................................... 25

3.6.1 JP1: A T Power Select Jumper Settings ......................................................... 26

3.6.2 CN7: Clear CMOS Setup ................................................................................ 26

3.6.3 JP2: COM3 Setup Jumper Settings................................................................ 27

3.7 SYSTEM F AN INSTALLATION ...................................................................................... 27

3.7.1 FPC6065System Fan Installation................................................................... 27

3.7.2 FPC6084 System Fan Installation.................................................................. 30

3.8 HDD INST ALLA TION................................................................................................. 31

3.8.1 FPC6065 HDD Installation............................................................................ 31

3.8.2 FPC6084 HDD Installation............................................................................ 32

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 5

FPC 6065 / 6084

3.9 COMP ACTFLASH® CARD INST ALLA TION .............................................................. 34

3.9.1 FPC6065 CF Card Installation ...................................................................... 34

3.9.2 FPC6084 CF Card Installation ...................................................................... 36

3.10 MEMORY MODULE INST ALLA TION ......................................................................... 37

3.1 1 SA T A - ALI RAID DRIVER INST ALLA TION ............................................................... 38

3.1 1.1 Installation S teps During Windows XP Installation ..................................... 39

3.1 1.2 Installation S teps under Existing Windows XP ............................................ 40

3.12 MOUNTING THE SYSTEM ........................................................................................ 41

3.12.1 Wall Mounting ............................................................................................... 41

3.12.2 Panel Mounting.............................................................................................. 43

3.12.2.1 FPC6065 Panel Mounting ............................................................. 43

3.12.2.2 FPC6084 Panel Mounting ............................................................. 45

3.12.3 Arm Mounting ................................................................................................ 46

3.12.4 Cabinet and Rack Installation ....................................................................... 48

3.12.4.1 FPC6065 Cabinet and Rack Installation........................................ 48

3.12.4.2 FPC6084 Cabinet and Rack Installation......................................... 50

3.12.5 DIN Mounting .................................................................................................. 51

3.13 REAR P ANEL CONNECT ORS ................................................................................... 53

3.13.1 LCD Panel Connection .................................................................................. 53

3.13.2 Ethernet Connection ...................................................................................... 54

3.13.3 USB Connection............................................................................................. 54

3.13.4 Keyboard and Mouse Connection ................................................................. 54

3.14 SYSTEM MAINTENANCE ........................................................................................... 54

CHAPTER 4 GASKET REPLACEMENT

4.1 GASKET REPLACEMENT ........................................................................................... 56

CHAPTER 5 AMI BIOS SETUP

5.1 INTRODUCTION.............................................................................................................. 58

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 6

FPC 6065 / 6084

5.1.1 Starting Setup ................................................................................................... 58

5.1.2 Using Setup ...................................................................................................... 58

5.1.3 Getting Help ..................................................................................................... 59

5.1.4 Unable to Reboot Af ter Configuration Changes.............................................. 59

5.1.5 Main BIOS Menu ............................................................................................. 59

5.2 ST ANDARD CMOS FEA TURES .................................................................................. 62

5.2.1 IDE Primary Master/Slave .............................................................................. 64

5.3 ADV ANCED BIOS FEATURES .................................................................................... 66

5.4 ADV ANCED CHIPSET FEATURES ............................................................................. 72

5.4.1 Flat Panel Configuration .................................................................................. 75

5.5 INTEGRA TED PERIPHERALS...................................................................................... 77

5.5.1 IT8888 ISA Decode IO ..................................................................................... 83

5.5.2 IT8888 ISA Decode Memory ............................................................................ 86

5.6 POWER MANAGEMENT SETUP ................................................................................. 87

5.7 PNP/PCI CONFIGURA TIONS ........................................................................................ 91

5.8 PC HEAL TH ST A TUS .................................................................................................... 95

A. INTERFACE CONNECTORS

A.1 PERIPHERAL INTERF ACE CONNECTORS ............................................................... 99

B. BIOS CONFIGURATION OPTIONS

B.1 BIOS CONFIGURA TION OPTIONS .............................................................................. 107

C. SAFETY PRECAUTIONS

C.1 SAFETY PRECAUTIONS ..............................................................................................1 1 1

C.1.1 General Safety Precautions ........................................................................... 1 1 1

C.1.2 Anti-st atic Precautions .....................................................................................1 12

C.1.3 Product Disposal .............................................................................................1 13

C.2 MAINTENANCE AND CLEANING PRECAUTIONS ....................................................1 13

C.2.1 Maintenance and Cleaning .............................................................................1 13

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 7

FPC 6065 / 6084

C.2.2 Cleaning Tools................................................................................................114

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 8

FPC 6065 / 6084

CHAPTER 1 INTRODUCTION

1.1 FPC6065/ FPC6084 FLAT PANEL PC OVERVIEW

The FPC 6065/ FPC6084 flat panel PC is a flexible, multi-functional flat panel PC that can be applied

in diverse operational environments and implemented in multi-faceted applications. The FPC6065/

FPC6084 Comes fully kitted with a high-performance motherboard and a host of other peripheral

interface connectors. The FPC6065/ FPC6084 is designed for ease of use and easy installation.

1.1.1 MODEL VARIATIONS

Three IEI FPC series models are available. All models come with anAMD® Geode LX800 CPU and

touch screen.

FPC6065 FPC6084

CPU: AMD® Geode LX80 CPU: AMD® Geode LX80

LCD: 6.5” LCD: 8.4”

Brightness: 800 cd/m2 Brightness: 450 cd/m2

Memory: 256MB Memory: 256MB

1.1.2 APPLICATIONS

The FPC6065/ FPC6084 flat panel PC is designed for rigorous industrial environments where it may

be exposed to both heat and moisture. Its durability and strength also makes it an ideal choice for

public access computers. Some possible applications include:

-Automated manufacturing processes

-Public information gathering point

1.1.3 STANDARD FEATURES

Some of the standard features of the FPC6065 and FPC6084 flat panel PC include:

-Low power consumption and thermal distribution

-AMD® Geode LX800 processor

-DDR 333/400 MHz SO-DIMM memory support up to 1GB

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 9

FPC 6065 / 6084

-Aluminum die-casting IP65 industrial panel

-Dual 10/100Mbps Ethernet support

-One CompactFlash® Type I/II socket support

-Simplified installation process

-RoHS compliance

1.2 EXTERNAL OVERVIEW

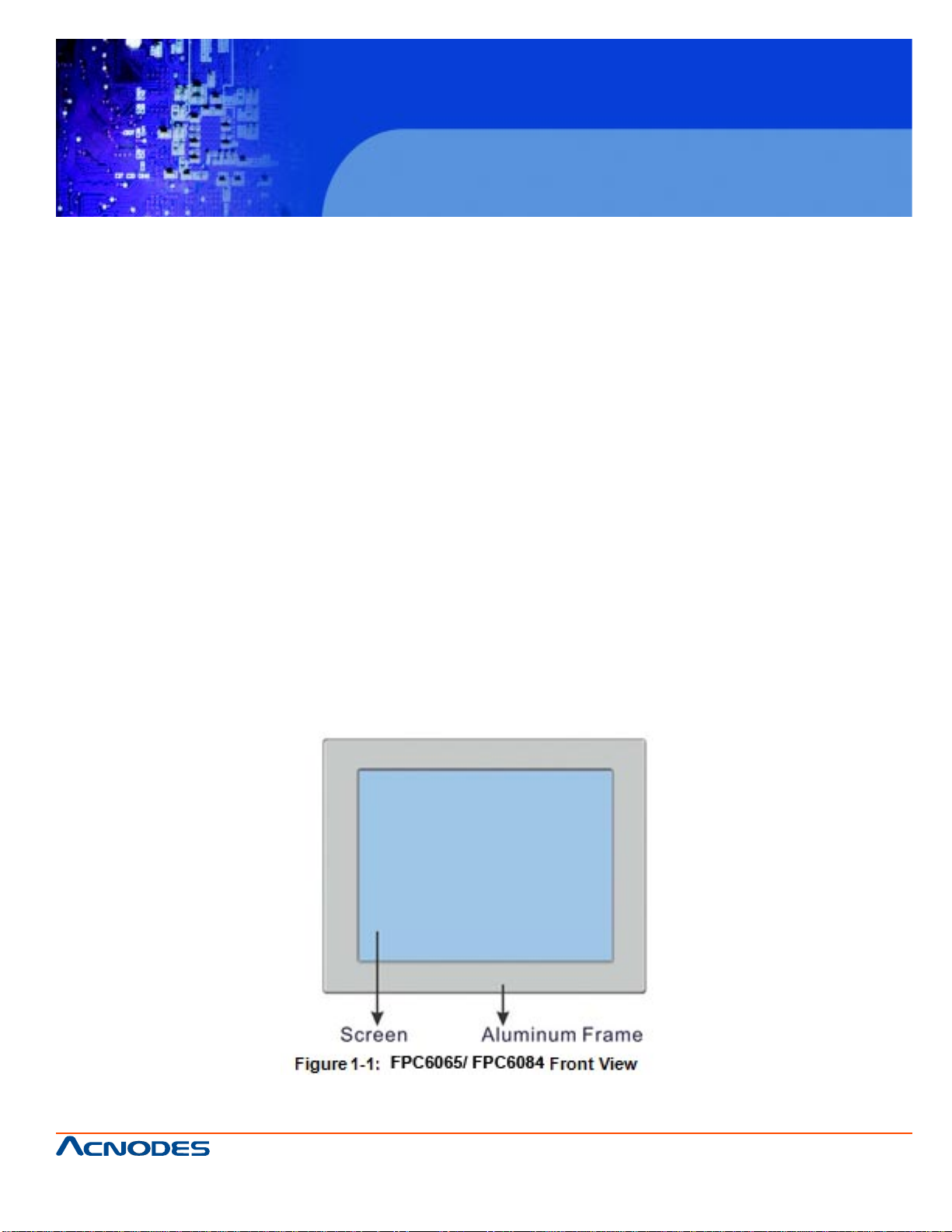

1.2.1 GENERAL DESCRIPTION

The FPC6065/FPC6084 flat panel PC is a rectangular cubic structure that comprises of a screen, rear

panel, top panel, bottom panel and two side panels (left and right). An aluminum frame surrounds the

front screen. The rear panel provides screw holes for a wall-mounting bracket, and a DIN rail mounting

bracket. The bottom panel provides access to external interface connectors that include LAN, USB

2.0, audio, VGA port, serial port, keyboard/mouse connectors and power switch.

1.2.1 FRONT PANEL

The front side of the FPC6065/FPC6084 is a flat panel TFT LCD screen surrounded by an aluminum

frame.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 10

FPC 6065 / 6084

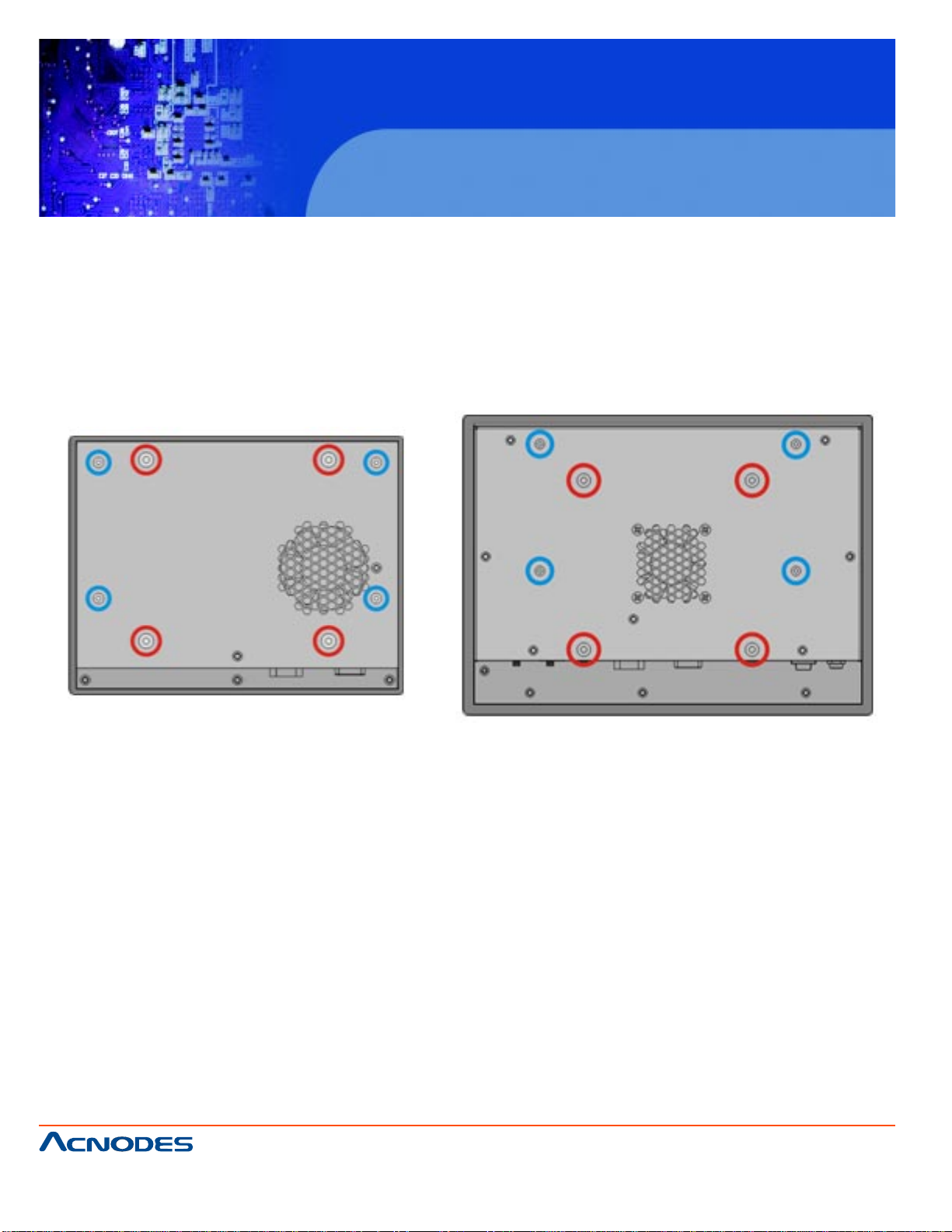

1.2.3 REAR PANEL

The rear panel provides access to a fan ventilation vent and retention screw holes that support the wall

mounting (circled in red) and DIN rail mounting (circled in blue). Refer to Figure 1-2 and Figure 1-3.

FIGURE 1-2: FPC6065 REAR VIEW FIGURE 1-3: FPC6084 REAR VIEW

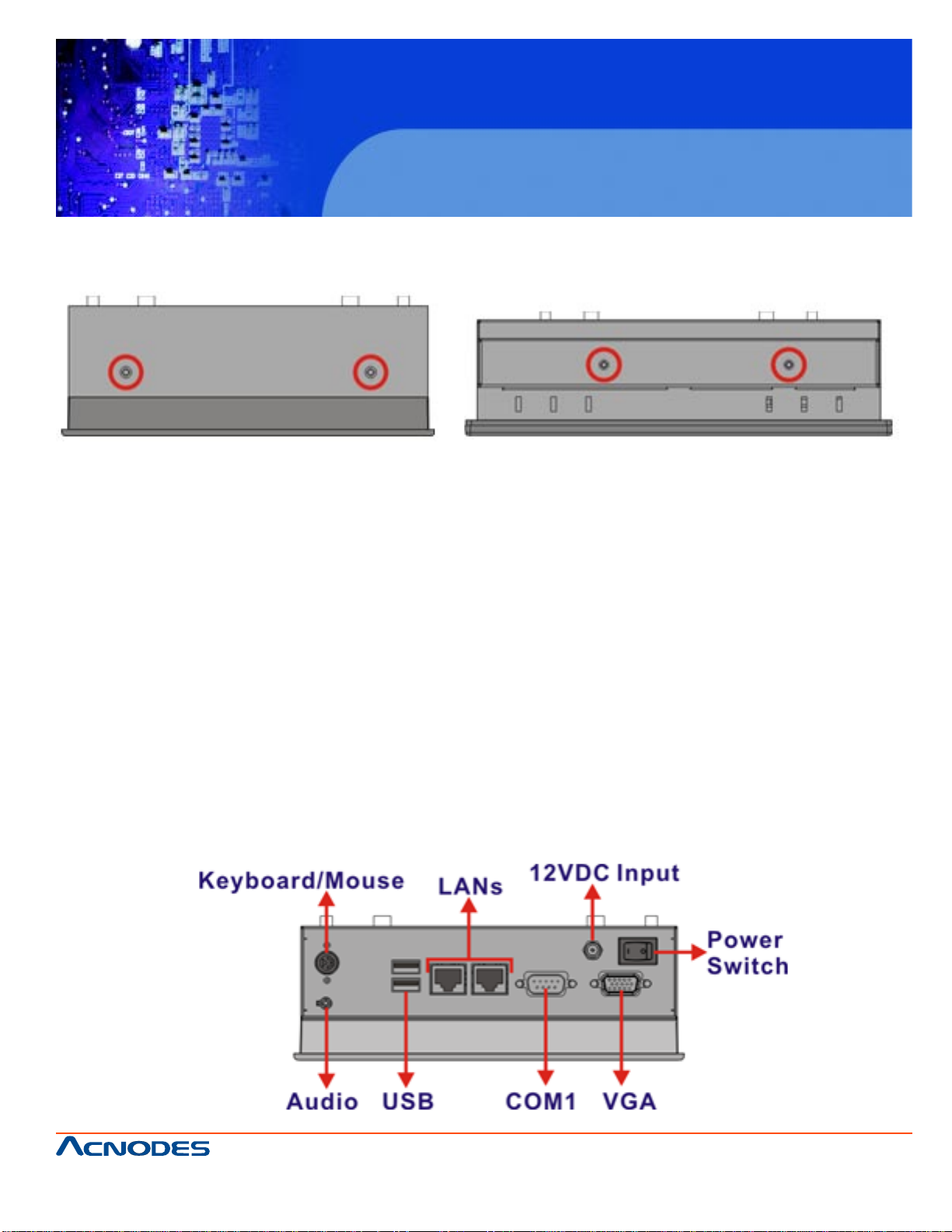

1.2.4 TOP PANEL

The top panel of FPC6065 provides access to two retention screw holes that support to secure the

back cover to the chassis. The retention screw holes are circled in Figure 1-4 below .

The top panel of FPC6084 provides access to two retention screw holes that support to secure the

power module to the chassis. The retention screw holes are circled in Figure 1-5 below .

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 11

FPC 6065 / 6084

FIGURE 1-4: FPC6065 TOP VIEW FIGURE 1-5: FPC6084 TOP VIEW

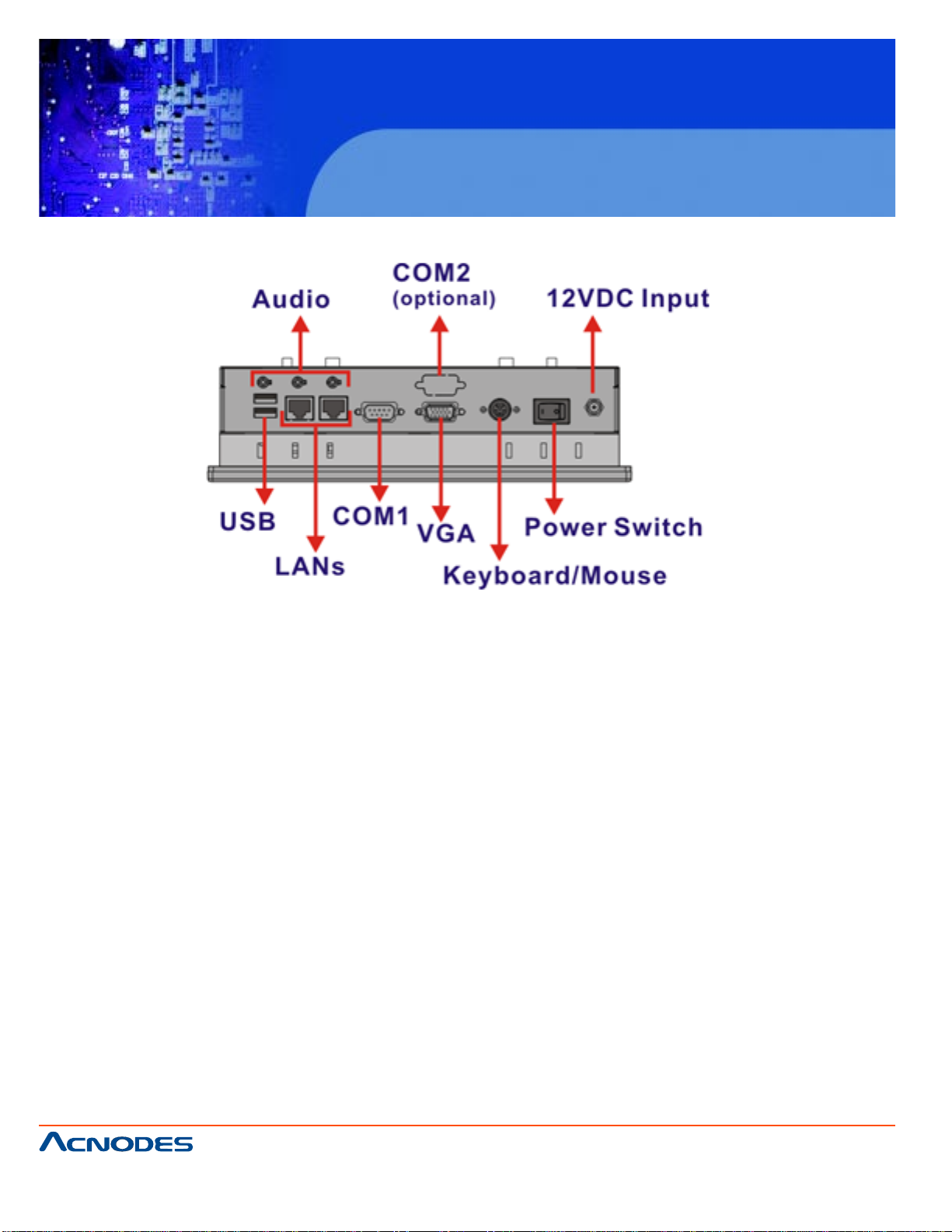

1.2.5 BOTTOM PANEL

The bottom panel of the FPC6065/FPC6084 has the following I/O interfaces (Figure 1-6 and

Figure 1-7):

1 x Serial port (COM) connector

1 x PS/2 keyboard/mouse connector

1 x AC power adapter connector

1 x VGA connector

2 x RJ-45 10/100Mbps Ethernet connectors

2 x USB 2.0 connectors

1 x Power switch

Audio jacks

FIGURE 1-6: FPC6065 BOTTOM VIEW

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 12

FIGURE 1-7: FPC6084 BOTTOM VIEW

FPC 6065 / 6084

1.3 INTERNAL OVERVIEW

The FPC6065/FPC6084 internal components are configured in a two level format. The

motherboard and 2.5" HDD are installed on a metal sheet that protects the rear of the TFT

LCD screen. Below the metal sheet is a circuit board that is connected to the screen and the

motherboard.

1.4 SPECIFICATIONS

1.4.1PREINSTALLED HARDWARE COMPONENTS

The FPC6065/FPC6084 flat panel PC has the following preinstalled components:

1 x Motherboard

1 x TFT LCD screen

The technical specifications for these components and the system are shown in the sections

below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 13

FPC 6065 / 6084

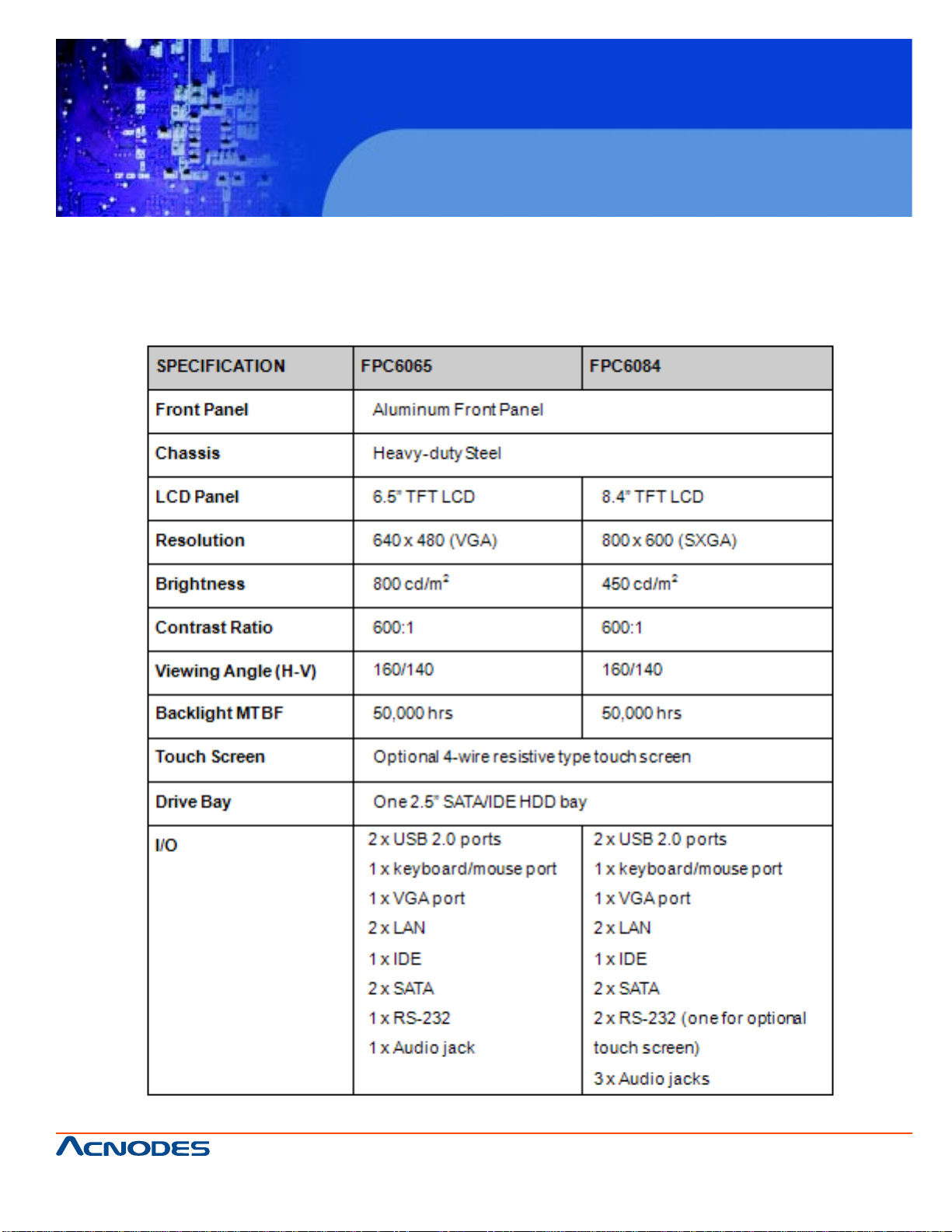

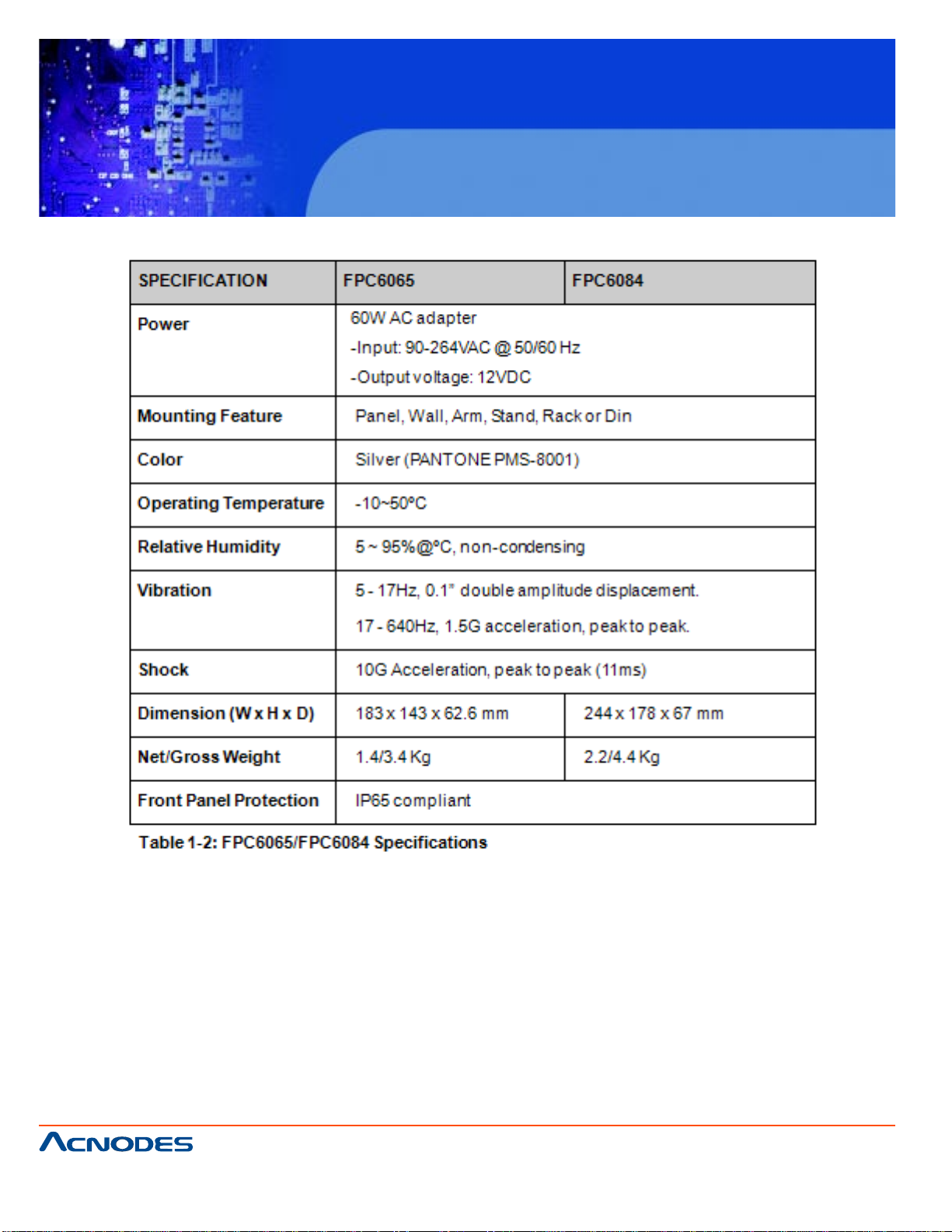

1.4.2 SYSTEM SPECIFICATIONS

The technical specifications for the FPC6065 and FPC6084 systems are listed in Table

1-2.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 14

FPC 6065 / 6084

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 15

FPC 6065 / 6084

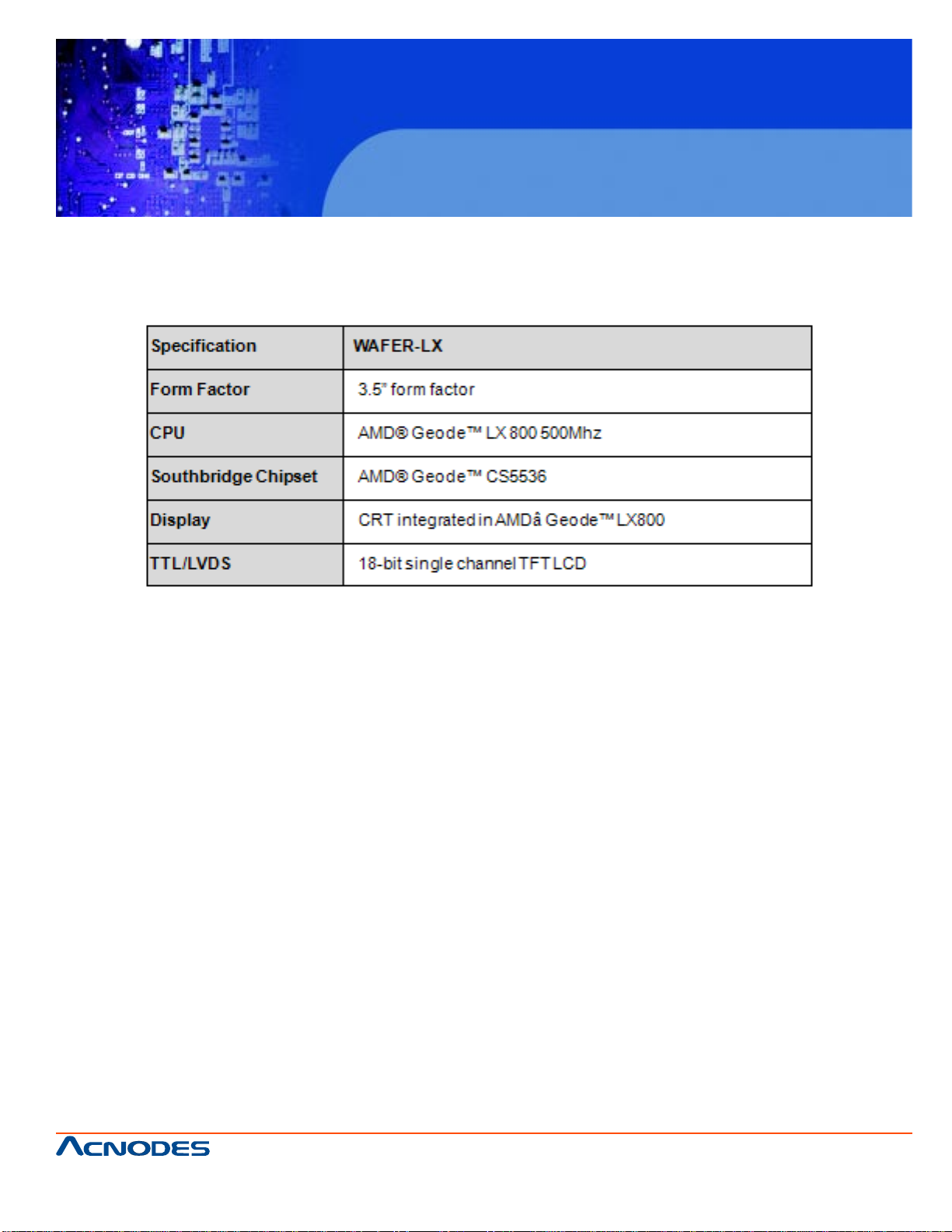

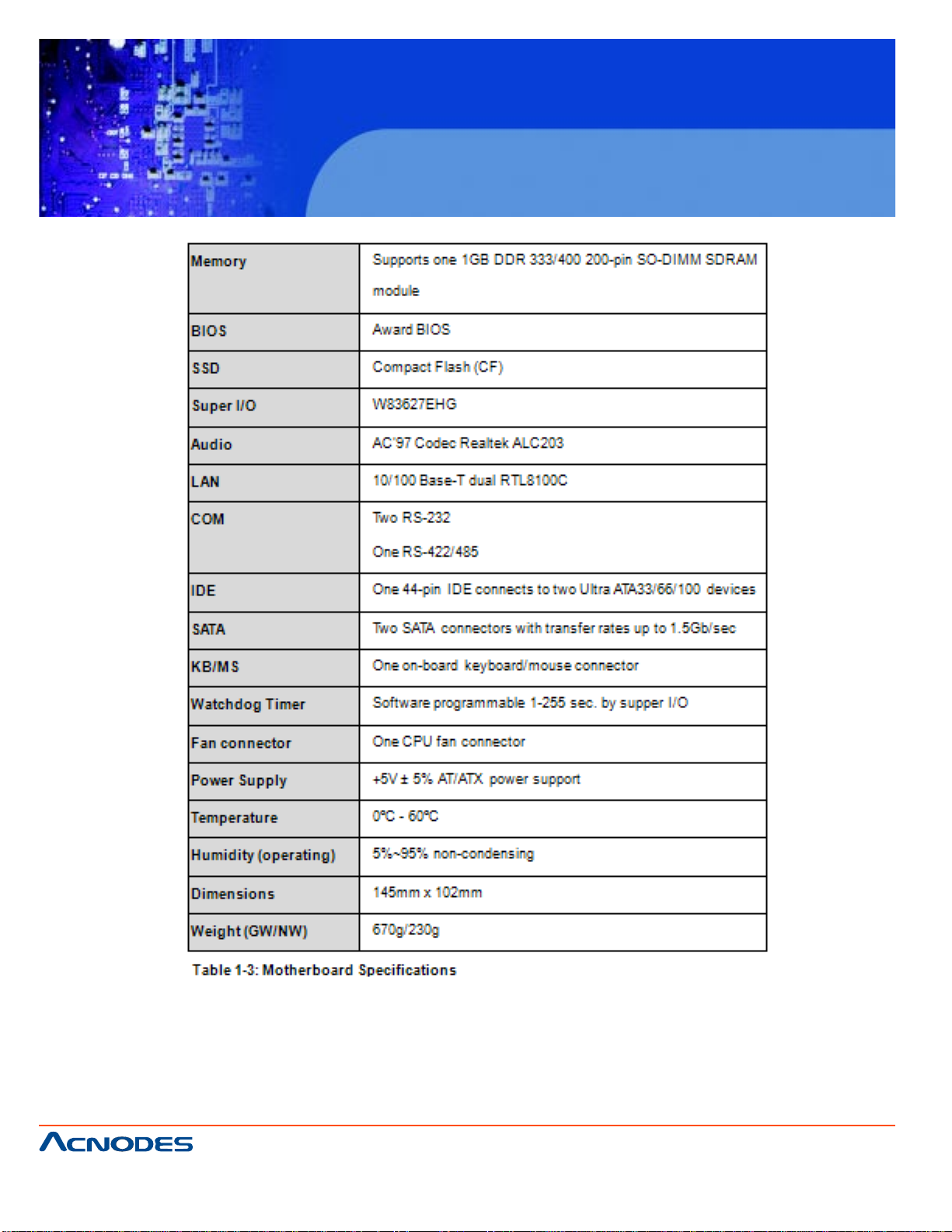

1.4.3 MOTHERBOARD SPECIFICATIONS

The FPC6065 and FPC6084 both come with a WAFER-LX motherboard. The technical specifications of the motherboard are listed in Table 1-3.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 16

FPC 6065 / 6084

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 17

FPC 6065 / 6084

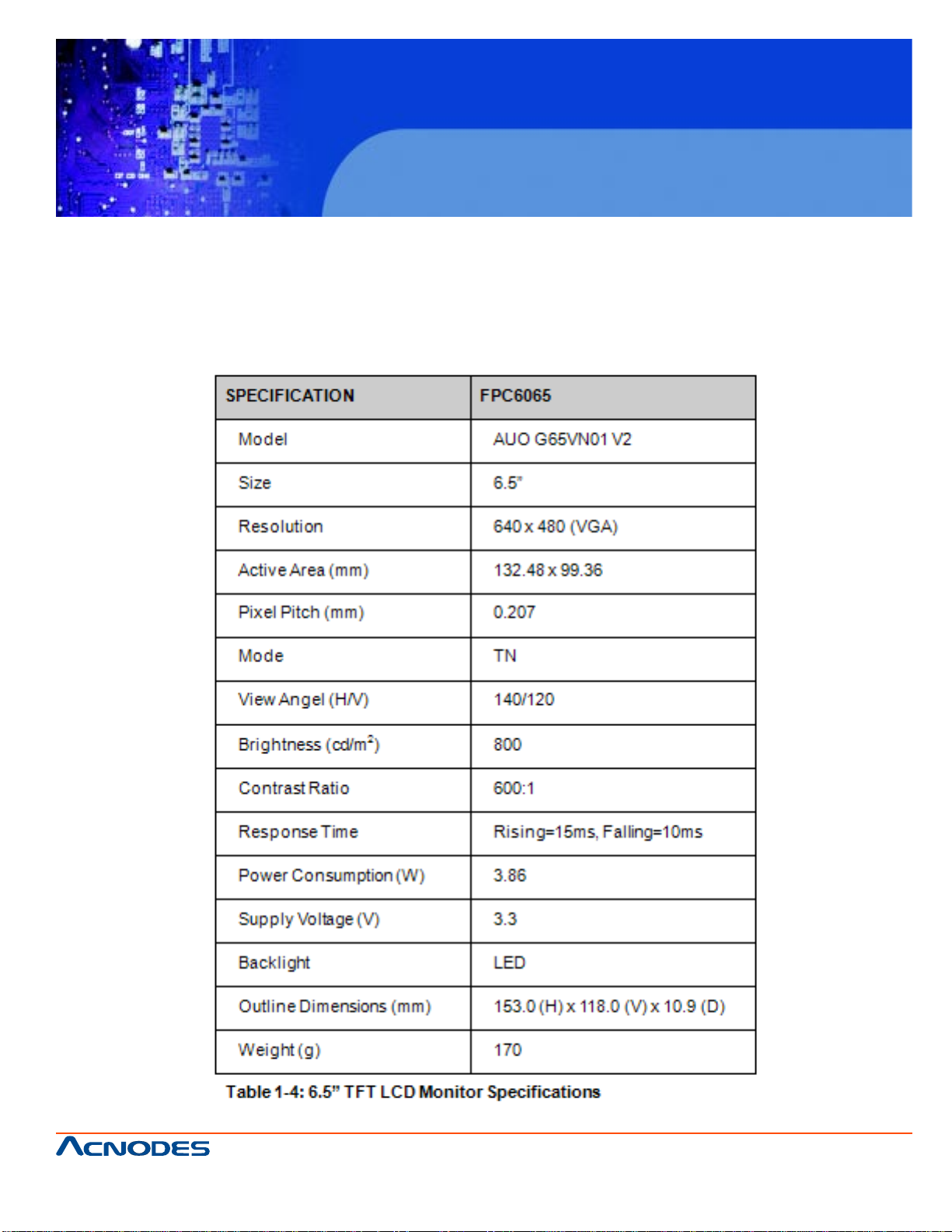

1.4.4 FLAT PANEL SCREEN

1.4.4.1 FPC6065 FLAT PANEL SCREEN SPECIFICATIONS

The FPC6065 comes with a 6.5" TFT LCD monitor at the front of the flat panel PC (see Figure

1-1). The specifications for the LCD monitor are shown in Table 1-4 below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 18

FPC 6065 / 6084

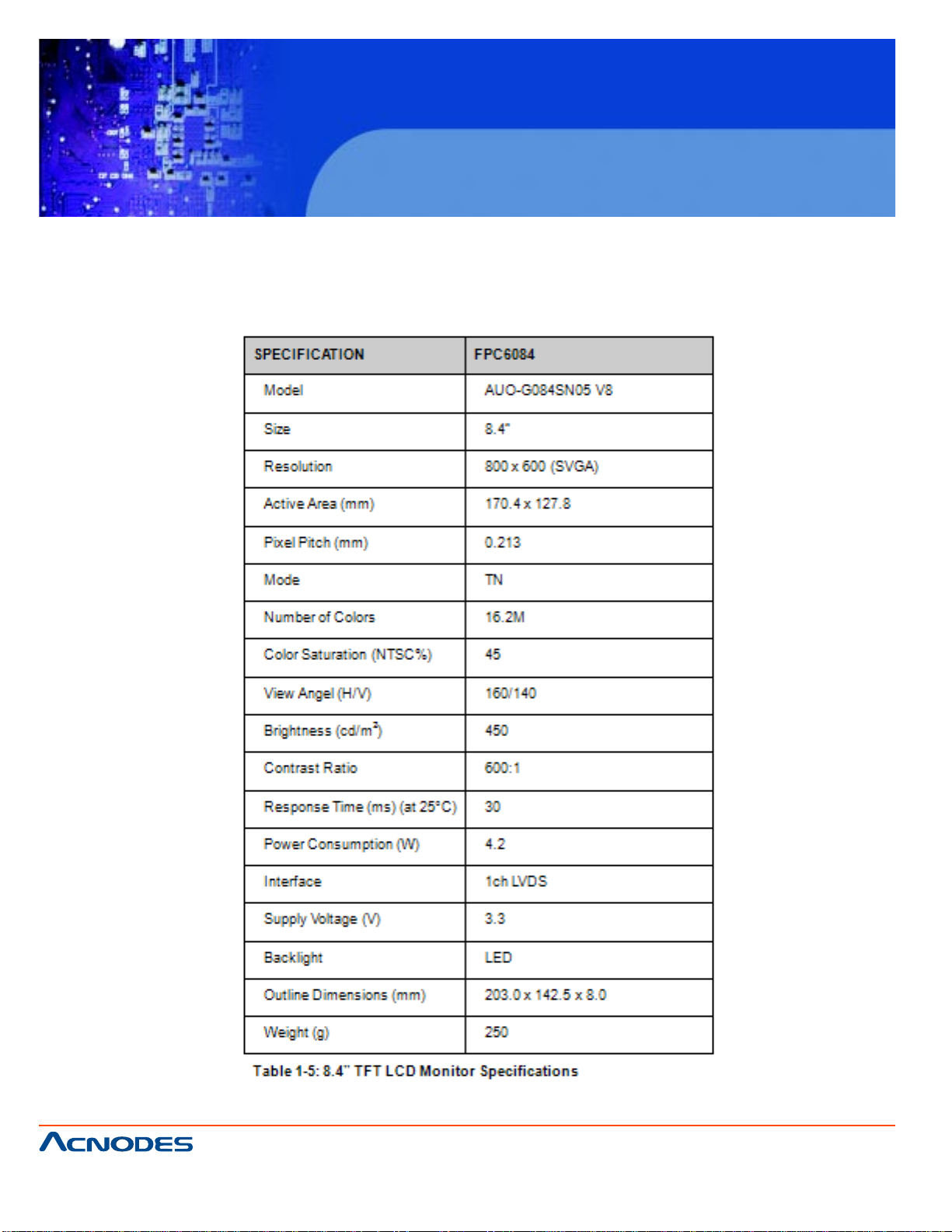

1.4.4.2 FPC6084 FLAT PANEL SCREEN SPECIFICATIONS

The FPC6084 comes with a 8.4" TFT LCD monitor at the front of the flat panel PC (see Figure

1-1). The specifications for the LCD monitor are shown in Table 1-5 below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 19

FPC 6065 / 6084

1.5 DIMENSIONS

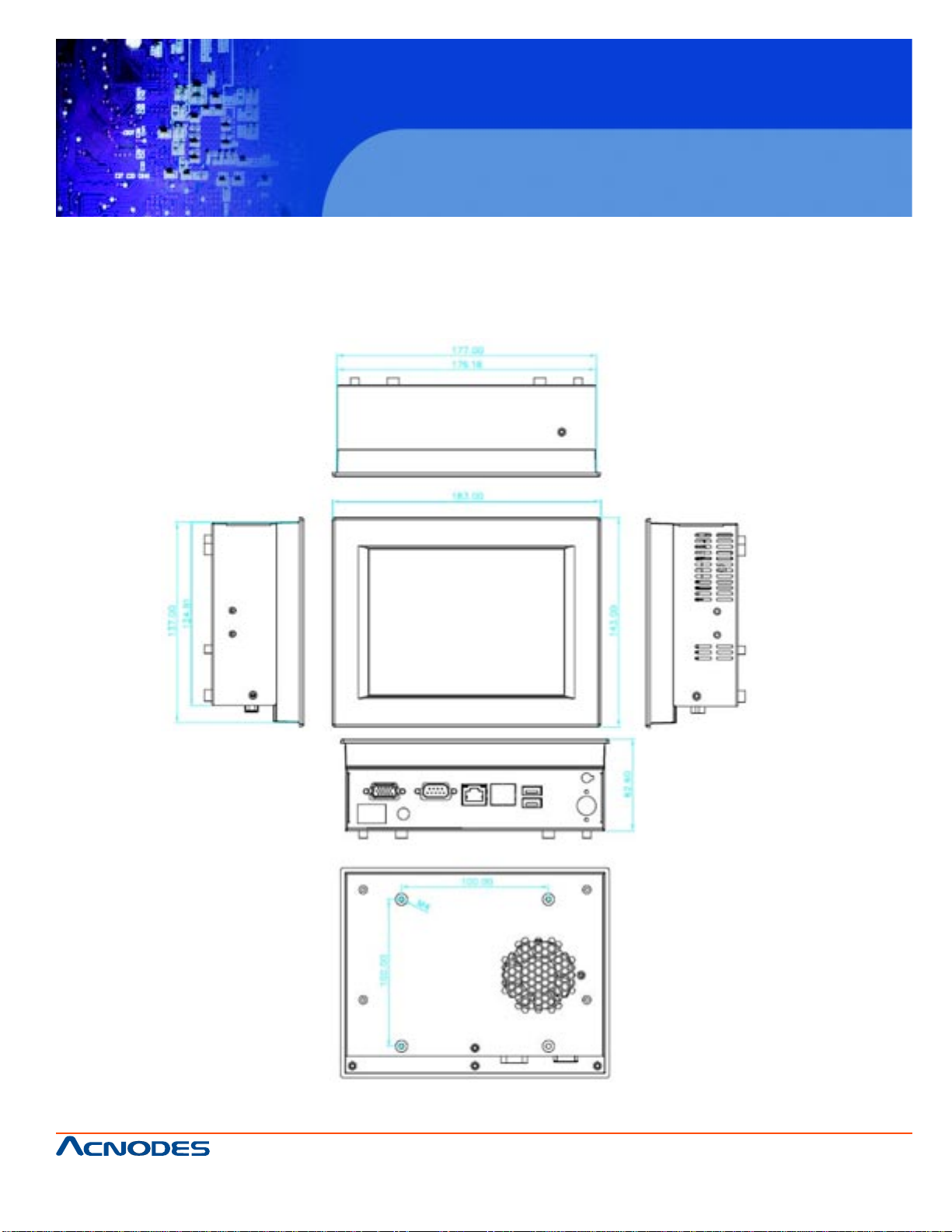

1.5.1 FPC6065 DIMENSIONS

The dimensions of the FPC6065 flat panel PC are shown in Figure 1-8 below .

FIGURE 1-8: FPC6065 DIMENSIONS (UNITS IN MM)

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 20

FPC 6065 / 6084

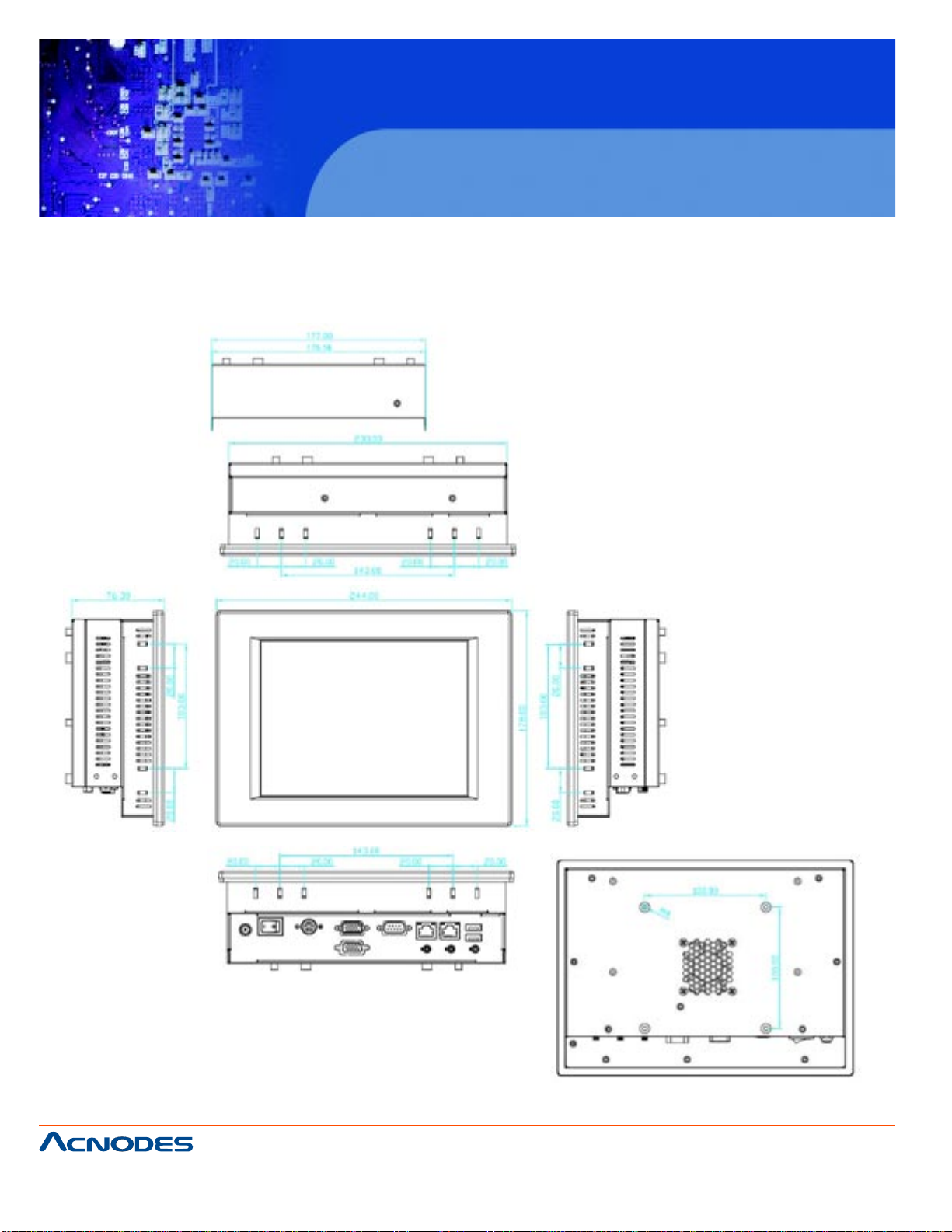

1.5.2 FPC6084 DIMENSIONS

The dimensions of the FPC6084 flat panel PC are shown in Figure 1-9 below .

FIGURE 1-9: FPC6084 DIMENSIONS (UNITS IN MM)

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 21

FPC 6065 / 6084

CHAPTER 2 WAFER-LX MOTHERBOARD

2.1 INTRODUCTION

The FPC6065 and FPC6084 flat screen PC both contain the WAFER-LX motherboard. The

motherboard is the heart of any computer and is responsible for transmitting, receiving and

processing data as well as driving the different onboard devices. This chapter gives a brief introduction to the WAFER-LX motherboard. For more complete details on the connectors and the different

implementations of the WAFER-LX, please refer to the W AFER-LX user guide.

2.2 CPU SUPPORT

The WAFER-LX series motherboards all come with a preinstalled AMD® Geode™ LX 800 500MHz

CPU.

2.2.1AMD GEODE LX 800 500MHz SPECIFICATIONS

The specifications for the 500MHz AMD® Geode™ LX 800 are listed below

x86/x87-compatible core

Processor frequency up to 500 MHZ

64K I/64K D L1 cache and 128K L2 cache

Split I/D cache/TLB (T ranslation Look-Aside Buffer)

64-bit DDR Memory interface up to 400MHz (LX 800), up to 333MHz (LX 700)

Integrated FPU that supports the Intel MMX® and AMD 3DNow!™ Technology instruction sets

9 GB/s internal GeodeLink™ Interface Unit (GLIU)

Security Block

o 128-bit AES (CBC/ECB)

o True Random Number Generator

High-resolution CRT and TFT outputs (simultaneous operation)

o Support for High Definition (HD) and St andard Definition (SD) standards

o Support 1920x1440 in CRT mode and 1600x1200 in TFT mode

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 22

FPC 6065 / 6084

VESA 1.1 and 2.0 VIP/VDA support

0.13 micron process

481-terminal PBGA (Plastic Ball Grid Array) with internal heatspreader

2.2.2 AMD® Geode™ LX 800 500MHz Power Management

The power management for the 500MHz AMD® Geode™ LX 800 is listed below:

1.8W T ypical (3.9W TDP) @ 500MHz

GeodeLink active hardware power management

Hardware support for standard ACPI software power management

I/O companion SUSP#/SUSP A# power controls

Lower power I/O

Wakeup on SMI/INTR

2.3 SYSTEM CHIPSET

The WAFER-LX series motherboards all have a preinstalled AMD® Geode™

CS5536 system chipset. The system chipset features are listed below.

GeodeLink™ Interface Unit

o 64-bit, 66MHz operation

o PCI VSM (Virtual System Module) that makes the interface transparent to

applications software and BIOS

o Programmable routing descriptors, use and activity monitors, and SSMI

(Synchronous System Management Interrupt)

ATA-6 Controller

o 100 MB/second IDE Controller in UDMA mode per the ATA-6 specification

o 5V interface

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 23

FPC 6065 / 6084

Flash Interface

o Multiplexed with IDE interface Connects to an array of industry standard

NAND Flash and/or NOR Flash

USB Controller

o 4 USB ports

o Supports both USB 1.1 and USB 2.0

o 3 host ports

o 1 host/device

Audio Codec 97 (AC97) Controller

o AC97 specification v2.3 compliant interface to multiple audio codecs:

Serial In, Serial Out, Sync Out, Bit Clock In

o Legacy "PC Beep" support

Diverse Device

o 82xx Legacy Devices

o IR Communication Port

o System Management Bus (SMB) Controller

o LPC (Low Pin Count) Port

o General Purpose I/Os (GPIOs)

o 8 Multi-Function General Purpose Timers (MFGPTs)

o Real-Time Clock (RTC) with CMOS RAM

o Power Management Controller

o ACPI v2.0 compliant

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 24

FPC 6065 / 6084

2.4 ETHERNET CONTROLLER SPECIFICATIONS

2.4.1 OVERVIEW

The Realtek RTL8100C(L) is a highly integrated and cost-effective single-chip Fast Ethernet

controller . It is enhanced with an ACPI (Advanced Configuration Power Interface) management function

for PCI in order to provide efficient power management for advanced operating systems

with OSPM (Operating System Directed Power Management).

The RTL8100C(L) also supports remote wake-up (including AMD Magic Packet™ and Microsoft®

Wake-up frame) to increase cost-efficiency in network maintenance and management. It is an

ideal solution for notebook/motherboard-embedded network designs.

2.4.2 FEATURES

Integrates Fast Ethernet MAC, physical chip, and transceiver onto a single chip

10Mbps and 100Mbps operation

Supports 10Mbps and 100Mbps N-way auto-negotiation

Supports 25MHz Crystal or 25MHz OSC as the internal clock source

Complies with PC99/PC2001 standards

Supports ACPI power management

Provides PCI bus master data transfer

2.5 PERIPHERAL DEVICE INTERFACES, CONNECTORS, AND SLOTS

The peripheral device connectors, interfaces and slots on the WAFER-LX motherboard are listed in the

sections below.

2.5.1 OEM OPTIONS

Many of the peripheral device connectors listed below are not connected to any devices. These connectors are reserved for OEM customizations. For a customized

option, please contact the vendor, reseller or IEI sales representative.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 25

FPC 6065 / 6084

2.5.2 INTERNAL SLOTS

The slots listed below can all be found on the WAFER-LX motherboard.

1 x 200-pin DDR SO-DIMM socket

1 x CFII slot

2.5.3 INTERNAL PERIPHERAL DEVICE CONNECTORS

The peripheral device connectors listed below are located on the WAFER-LX

motherboard. Pinouts for these connectors can be found in Appendix A.

1 x AT power connector

1 x ATX power function connector

1 x Audio connector

1 x Battery connector

1 x Compact Flash (CF) connector (solder side)

1 x External LED connector

1 x Fan connector

1 x Floppy disk drive (FDD) connector

1 x General purpose input/output (GPIO) connector

1 x IDE Interface connectors (44-pin)

1 x Inverter power connector

1 x Keyboard/mouse connector

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 26

1 x Parallel port connector

1 x Reset button connector

1 x RS-232/422/485 serial port connector

2 x SATA connectors

1 x Suspend power input connector

1 x TFT LCD LVDS interface connector

1 x TFT LCD TFT interface connector

1 x USB connector

1 x SO-DIMM socket

FPC 6065 / 6084

2.5.4 EXTERNAL PERIPHERAL DEVICE CONNECTORS

The peripheral device connectors listed below are located on the rear panel of the

WAFER-LX motherboard. Pinouts for these connectors can be found in Appendix A.

2 x Ethernet connectors

2 x USB connectors

1 x Serial port connector

1 x VGA connector

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 27

FPC 6065 / 6084

CHAPTER 3

INSTALLATION AND CONFIGURATION

3.1 INSTALLATION PRECAUTIONS

When installing the flat panel PC, please follow the precautions listed below:

Power turned off:

When installing the flat panel PC, make sure the power is off. Failing to turn off the power may cause severe injury to the body and/or damage to the system.

Certified Engineers:

Only certified engineers should install and modify onboard functionalities.

Mounting:

The flat panel PC is a heavy device. When mounting the system onto a rack, panel, wall or arm please

make sure that at least two people are assisting with the procedure.

Anti-static Discharge:

If a user open the rear panel of the flat panel PC, to configure the jumpers or plug in added peripheral

devices, ground themselves first and wear and anti-static wristband.

3.2 PREINSTALLED COMPONENTS

The following components are all preinstalled.

Motherboard

TFT LCD screen

Power module

Power switch

Preinstalled OEM customizations may include the following.

Hard disk drive (HDD)

Resistive type touch screen

Installation of some of the components are described in the following sections.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 28

FPC 6065 / 6084

3. 3 INSTALLATION AND CONFIGURATION STEPS

The following installation steps must be followed.

Step 1: Unp ack the flat panel PC

Step 2: Set the jumper settings

Step 3: Inst all system fan

Step 4: Inst all HDD

Step 5: Inst all the SO-DIMM memory module

Step 6: Mount the flat panel PC

Step 7: Connect peripheral devices to the bottom panel of the flat p anel PC

Step 8: Configure the system

3.4 UNPACKING

T o unpack the flat panel PC, follow the step s below:

WARNING!

The front side LCD screen has a protective plastic cover stuck to the screen. Only remove the plastic cover

after the flat panel PC has been properly installed. This ensures the screen is protected during the

installation process.

Step 1: Use box cutters, a knife or a sharp p air of scissors that seals the top side of the external (second)

box.

Step 2: Open the external (second) box.

Step 3: Use box cutters, a knife or a sharp p air of scissors that seals the top side of the internal (first) box.

Step 4: Lift the monitor out of the boxes.

Step 5: Remove both polystyrene ends, one from each side.

Step 6: Pull the plastic cover of f the flat panel PC.

Step 7: Make sure all the component s listed in the packing list are present.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 29

FPC 6065 / 6084

3.4.1 PACKING LIST

The FPC6065/FPC6084 flat panel PC is shipped with the following components:

1 x IDE HDD cable

1 x SA TA HDD cable

1 x PS/2 cable

1 x Screw kit

1 x Jumper pack

1 x Power cord

1 x Power adapter

1 x System fan module

1 x Fan bracket (FPC6084 only)

1 x Cable tie or cable clip for fan installation

1 x Panel mounting kit

1 x Wall mounting kit

1 x User Manual and Driver CD

1 x T ouch screen driver CD and touch pen

If any of these items are missing or damaged, contact the distributor or sales representative immediately .

3.5 REMOVE THE BACK COVER

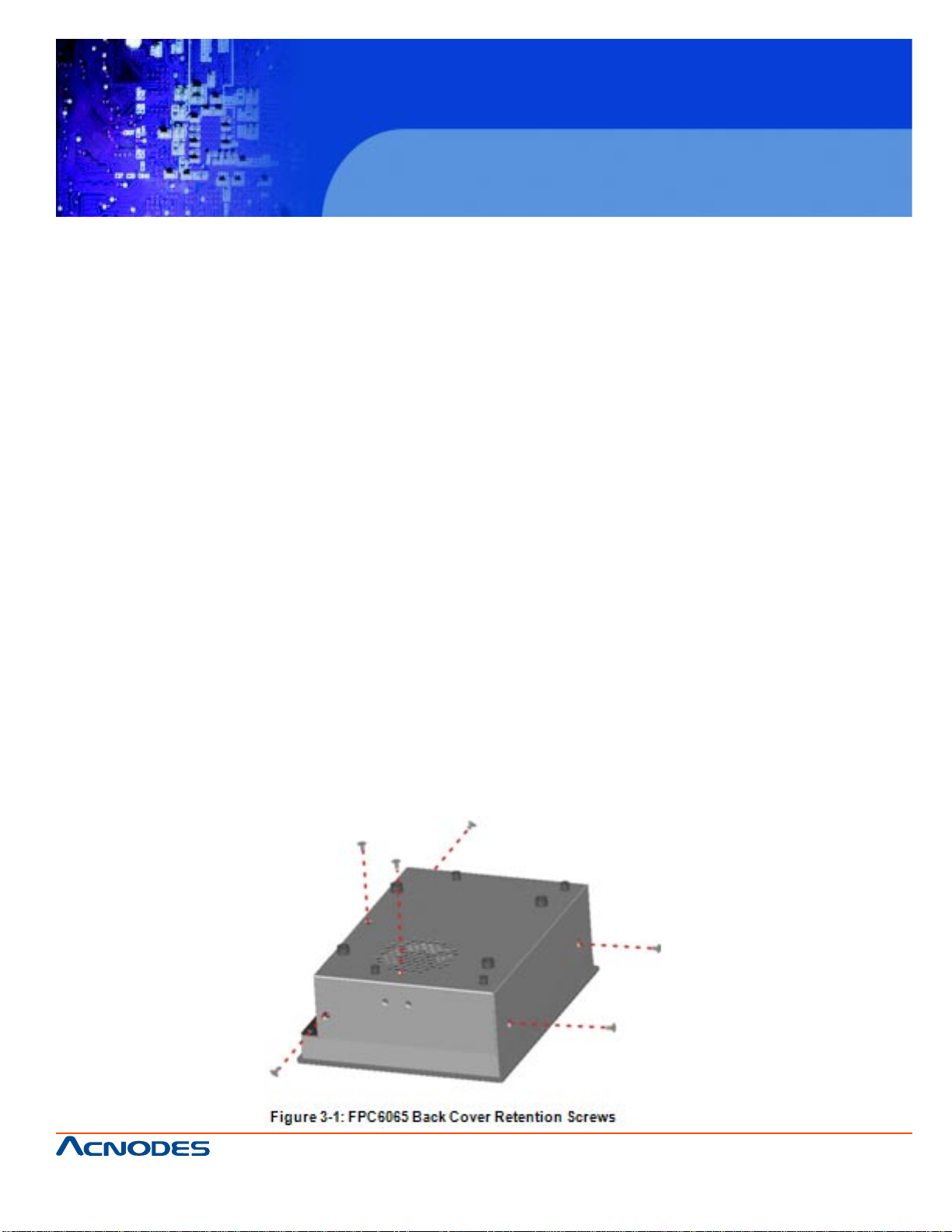

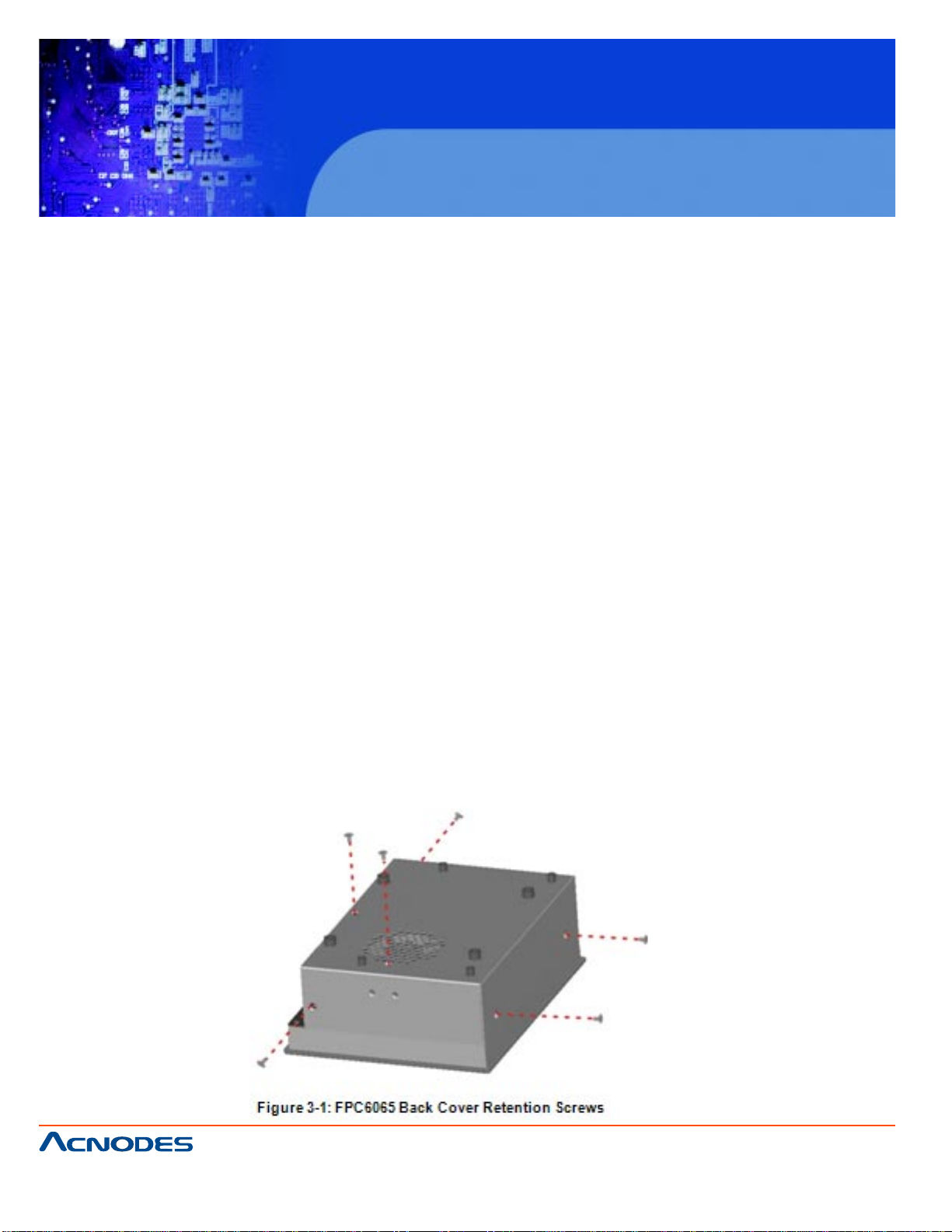

3.5.1 FPC6065 BACK COVER REMOVAL

The back cover is secured to the chassis with six retention screws, two on the top panel, two on the rear

panel, one on the right panel and one on the left panel (Figure 3-1). Remove the six retention screws and

lift the cover off the FPC6065.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 30

FPC 6065 / 6084

3.4.1 PACKING LIST

The FPC6065/FPC6084 flat panel PC is shipped with the following components:

1 x IDE HDD cable

1 x SA TA HDD cable

1 x PS/2 cable

1 x Screw kit

1 x Jumper pack

1 x Power cord

1 x Power adapter

1 x System fan module

1 x Fan bracket (FPC6084 only)

1 x Cable tie or cable clip for fan installation

1 x Panel mounting kit

1 x Wall mounting kit

1 x User Manual and Driver CD

1 x T ouch screen driver CD and touch pen

If any of these items are missing or damaged, contact the distributor or sales representative immediately .

3.5 Remove the Back Cover

3.5.1 FPC Back Cover Removal

The back cover is secured to the chassis with six retention screws, two on the top

panel, two on the rear panel, one on the right panel and one on the left panel (Figure 3-

1). Remove the six retention screws and lift the cover off the FPC6065.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 31

FPC 6065 / 6084

3.5.2 FPC6084 BACK COVER REMOVAL

The back cover is secured to the chassis with seven retention screws on the rear panel (Figure 3-2). Remove the seven retention screws and lift the cover off the FPC6084.

3.6 JUMPER SETTINGS

A jumper is a metal bridge that is used to close an electrical circuit. It consists of two metal pins and a

small metal clip (often protected by a plastic cover) that slides over the pins to connect them.

T o CLOSE/SHORT a jumper means connecting the pins of the jumper with the plastic clip and to OPEN a

jumper means removing the plastic clip from a jumper.

The WAFER-LX comes with three jumpers. They are listed below .

AT power select (JP1)

COM 2 mode setup (JP2)

Clear CMOS (CN7)

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 32

FPC 6065 / 6084

3.6.1 JP1: AT POWER SELECT JUMPER SETTINGS

The A T/A TX Power Mode Select jumper specifies the systems power mode.

3.6.2 CN7: CLEAR CMOS SETUP

NOTE:

The battery connector (CN7) is used as the clear CMOS jumper on the motherboard.

If the motherboard fails to boot due to improper BIOS settings, use this jumper to clear the CMOS data and

reset the system BIOS information. T o do this, use the jumper cap to close pins 2 and 3 for a few seconds

then reinstall the jumper clip back to pins 1 and 2.

If the "CMOS Settings Wrong" message displays during the boot up process, try to correct the fault by

pressing the F1 to enter the CMOS Setup menu. Then do one of the following:

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 33

FPC 6065 / 6084

Enter the correct CMOS setting

Load Optimal Defaults

Load Failsafe Defaults.

After one of the above has been done, save the changes and exit the CMOS Setup menu.

3.6.3 JP2: COM3 SETUP JUMPER SETTINGS

The COM3 port can be configured as an RS-422 serial port or as an RS-485 serial port.

3.7 SYSTEM FAN INSTALLATION

3.7.1 FPC6065 SYSTEM FAN INSTALLATION

Step 1: The fan bracket of the FPC6065 is secured to the chassis with three retention screws inside the

chassis (Figure 3-4). Remove the three retention screws. Lift the fan bracket off the FPC6065 flat panel

PC.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 34

FPC 6065 / 6084

Step 2: Inst all the system fan module to the fan bracket with four retention screws (Figure 3-1 1).

Step 3: Use a cable tie to tie the system fan module cables as shown in Figure 3-6.

Step 4: Locate the fan connector (CN4) on the motherboard (Figure 3-7). Insert the fan connector of the

fan module to the fan connector on the motherboard.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 35

FPC 6065 / 6084

Step 5:Reinstall the fan bracket into the system using the three previously removed retention screws.

3.7.2 FPC6084 SYSTEM FAN INSTALLATION

Step 1: Inst all the system fan module to the fan bracket with four retention screws (Figure 3-1 1).

Step 2: Attach the cable clip on the fan bracket as shown in Figure 3-6. Secure the fan cable with the

cable clip.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 36

FPC 6065 / 6084

Step 3: Locate the fan connector (CN4) on the motherboard (Figure 3-7). Insert the fan connector of the

fan module to the fan connector on the motherboard.

Step 4: Install the fan bracket into the system with two retention screws.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 37

FPC 6065 / 6084

3.8 HDD INSTALLATION

3.8.1 FPC6065 HDD INSTALLATION

T o install the HDD into the FPC6065, please follow the steps below:

Step 1: Remove the back cover . See Section 3.5.1 above.

Step 2: Remove HDD bracket from the plat form. See Section 3.7.1 Step 1.

Step 3: Attach the HDD brackets to the HDD. T o do this, align the four retention screw holes in the both

sides of the HDD bracket with the retention screw holes on the sides of the HDD. Insert four retention

screws into the HDD bracket (Figure3-12). Figure 3-12: FPC6065 HDD Bracket Retention Screws

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 38

FPC 6065 / 6084

Step 4: Connect the IDE/SATA cable from the IDE/SATA connector on the otherboard

to the rear of HDD. Reconnect the fan cable to the motherboard.

Step 5: Install the HDD into the FPC6065 by aligning the retention screw holes in the

HDD brackets with the retention screw holes on the chassis. Insert the three retention

screws.

3.8.2 FPC6084 HDD INSTALLATION

T o install the HDD into the FPC6084, please follow the steps below:

Step 1: Remove the back cover . See Section 3.5.2 above.

Step 2: The HDD bracket is attached to the platform by four retention screws. Remove the four retention

screws from the platform (Figure 3-13).

Step 3: Attach the HDD brackets to the HDD. T o do this, align the four retention screw holes in the base of

the HDD bracket with the retention screw holes on the bottom of the HDD. Insert four retention screws into

the HDD bracket from the bottom (Figure 3-14).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 39

FPC 6065 / 6084

Step 4:Connect the IDE/SATA cable from the IDE/SATA connector on the motherboard

to the rear of HDD.

Step 5: Install the HDD into the FPC6084 by aligning the retention screw holes in the

base of the HDD brackets with the retention screw holes on the platform. Insert the four

retention screws.

3.9 COMPACTFLASH CARD INSTALLATION

3.9.1 FPC6065 CF CARD INSTALLATION

The FPC6065 embedded motherboard has one CF T ype II slot on the solder side. T o inst all the CF card,

follow the instructions below.

Step 1: Remove the back cover . See Section 3.5 above.

Step 2: Remove HDD bracket from the chassis. See Section 3.7.1 above.

Step 3: Remove the three retention screws on the bottom p anel (Figure 3-15).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 40

FPC 6065 / 6084

Step 4: Remove the four retention screws that secure the motherboard to the chassis

(Figure 3-16).

Step 5: Remove the copper pillar that secures the motherboard to the chassis (Figure 3-17).

Step 6: Lif t the chassis up and locate the CF slot. Insert a CF card into the slot (Figure 3-18).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 41

FPC 6065 / 6084

Step 7: Secure the motherboard with the copper pillar first. Then, Insert all previously

removed retention screws into the FPC6065 to secure the motherboard and the chassis. Remember to connect the grounding cable when inserting the retention screw to

the copper pillar (Figure 3-19).

Step 8: Inst all the previously removed HDD bracket and reconnect the fan cable.

Step 9: Replace the top cover . Once replaced reinsert the six previously removed retention screws.

3.9.2 FPC6084 CF CARD INSTALLATION

The FPC6084 embedded motherboard has one CF T ype II slot on the solder side. T o inst all the CF card,

follow the instructions below.

Step 1: Remove the back cover . See Section 3.5.2 above.

Step 2: Remove HDD bracket from the chassis. See Section 3.8.2 above.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 42

FPC 6065 / 6084

Step 3: Remove the four retention screws on the bottom panel (Figure 3-15).

Step 4: Remove the six retention screws inside the chassis (Figure 3-16).

Step 5: Lif t the chassis up and locate the CF slot. Insert a CF card into the slot (Figure 3-18).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 43

FPC 6065 / 6084

Step 6: Insert all previously removed retention screws into the FPC6084 to secure the chassis.

Step 7: Inst all the previously removed HDD bracket.

Step 8: Replace the top cover . Once replaced reinsert the six previously removed retention screws.

3.10 MEMORY MODULE INSTALLATION

The flat panel PC embedded motherboard has one 200-pin SO-DIMM socket. To install the SO-DIMM

module, follow the instructions below .

Step 1: Remove the back cover . See Section 3.5 above.

Step 2: Locate the SO-DIMM socket on the motherboard of the flat p anel PC.

Step 3: Push the SO-DIMM chip into the socket at an angle. (See Figure 3-23)

Step 4: Gently pull the arms of the SO-DIMM socket out and push the rear of the SO-DIMM module down.

(See Figure 3-23)

Step 5: Release the arms on the SO-DIMM socket. They clip into place and secure the SO-DIMM module

in the socket.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 44

FPC 6065 / 6084

3.11 SATA-ALi RAID DRIVER INSTALLATION

CAUTION!

Because of the inherent limitations by AMD Geode CS5536 chipset, the ALi M5283 SA TA and RAID

controller is implemented as a device that requires device driver during the Windows installation process.

T o successfully install the device driver , please carefully read the following instructions.

The ALi driver is especially required if SA T A drives are the only hard disk drives in the FPD6065/FPC6084

system. Otherwise, the Windows installation program may fail to locate the hard drives whether configuring

the SA T A disk drives into RAID volumes or using them as individual disk drives.

The system BIOS can identify SA T A disk drives, but cannot control their operation. The separately installed

driver therefore is necessary .

3.11.1 INSTALLATION STEPS DURING WINDOWS XP INSTALLATION

Step 1: Enable SA T A ROM using the BIOS configuration utility . The process has been det ailed in Appendix E.

Step 2: Locate the ALi installation driver folder within the Utility CD that came with the motherboard.

Step 3: Copy files under a sub-directory named "SAT A50XX" (taking Windows XP inst allation as the

example) to the root directory of floppy diskette (labeled driver diskette). The file names are listed below:

disk1

5283096D.bin

txtsetup.oem

Step 4: Also copy the OS option directory "win98_me", "win_nt", or "win_xp", and related driver files in

each directory .

Step 5: Boot from Windows installation CD-ROM (set CD-ROM as the 1st Boot Device), when the W indows XP Setup blue screen appears and prompts users to Press F6. Please press the F6 key , if thirdparty SCSI or RAID driver installation is needed.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 45

FPC 6065 / 6084

Step 6: The setup program continues, later when the setup program prompts users to specify additional

adapters, please press the S key .

Step 7: The setup program prompt s user to insert the driver diskette. Please insert the driver diskette, and

press ENTER to continue.

Step 8: The follow-up window lists out the installation choices, please select ALi SA T A/RAID Controller for

Windows XP and press ENTER to continue.

Step 9: The follow-up window lists out the devices to be installed, in which selected ALi controller(s) should

be included.

Step 10: Repeat step 5, but select ALi A T A/RAID Controller at step 7. If both controllers are installed, go to

next step.

Step 1 1: If users want to inst all other devices, please operate at this time. If all devices have been successfully installed, please go to next step.

Step 12: Press ENTER to continue Windows XP setup.

3.11.2 INSTALLATION STEPS UNSER EXISTING WINDOWS XP

After Windows XP is started, Windows system automatically finds the newly installed adapter and prompts

user to install its driver . Please follow these steps to install the driver:

Step 1: When the Found New Hardware Wizard windows appear (Mass S torage Controller), select Install

from a list or specify location (Advanced) and click Next to continue.

Step 2: In the follow-up window , please select "Don't search, I will choose the driver to install", then click

Next to continue.

Step 3: In the follow-up window , please select SCSI and RAID controllers, and then click Next to continue.

Step 4: In the follow-up window , click Have Disk, then insert the driver diskette and type in the driver loca-

tion: e.g., a CD-ROM, then click OK to continue.

Step 5: In the follow-up window , select ALi SA T A/RAID Controller, then click Next to continue.

Step 6: Confirm the follow-up windows and click the Finish button to continue.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 46

FPC 6065 / 6084

Step 7: Please "confirm" the Digital Signature Not Found window when it appears, when finished, please

restart the computer .

Step 8: Repeat step 1, but select ALi A TA/RAID Controller at step 4.

3.12 MOUNTING THE SYSTEM

WARNING!

When mounting the flat panel PC onto an arm, onto the wall or onto a panel, it is better to have more than

one person to help with the installation to make sure the panel PC does not fall down and get damaged.

The five methods of mounting the FPC6065/FPC6084 are listed below .

Wall mounting

Panel mounting

Arm mounting

Rack mounting

DIN mounting

The four mounting methods are described below.

3.12.1 WALL MOUNTING

T o mount the flat panel PC onto the wall, please follow the step s below.

Step 1: Select the location on the wall for the wall-mounting bracket.

Step 2: Carefully mark the locations of the four bracket screw holes on the wall.

Step 3: Drill four pilot holes at the marked locations on the wall for the bracket retention screws.

Step 4: Align the wall-mounting bracket screw holes with the pilot holes.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 47

FPC 6065 / 6084

Step 5: Secure the mounting-bracket to the wall by inserting the retention screws into the four pilot holes

and tightening them (Figure 3-24).

Step 6: Insert the four monitor mounting screws provided in the wall mounting kit into the four screw holes

on the real panel of the flat panel PC and tighten until the screw shank is secured against the rear panel

(Figure 3-25).

Step 7: Align the mounting screws on the monitor rear panel with the mounting holes on the bracket.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 48

FPC 6065 / 6084

Step 8: Carefully insert the screws through the holes and gently pull the monitor downwards until the monitor rests securely in the slotted holes (Figure 3-26). Ensure that all four of the mounting screws fit snuggly

into their respective slotted holes.

NOTE: In the diagram below the bracket is already installed on the wall.

3.12.2 PANEL MOUNTING

3.12.2.1 FPC6065 PANEL MOUNTING

T o mount the FPC6065 flat panel PC into a panel, please follow the step s below.

Step 1: Select the position on the p anel to mount the FPC6065.

Step 2: Cut out a section from the p anel that corresponds to the rear panel dimensions of the FPC6065.

T ake care that the panel section that is cut out is smaller than the overall size of the met al frame that surrounds the FPC6065 but just large enough for the rear panel of the FPC6065 to fit through (Figure 3-27).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 49

FPC 6065 / 6084

Step 3: Slide the FPC6065 through the hole until the aluminum frame is flush against the panel.

Step 4: Secure the panel mounting clip s to either side of the monitor using the retention screws supplied

in the mounting kit pack (Figure 3-28).

Step 5: Tighten the panel retention screws that pass through the panel mounting clip s until the plastic caps

at the front of all the screws are firmly secured to the panel (Figure 3-28).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 50

FPC 6065 / 6084

3.12.2.2 FPC6084 PANEL MOUNTING

T o mount the FPC6084 flat panel PC into a panel, please follow the step s below.

Step 1: Select the position on the p anel to mount the FPC6084.

Step 2: Cut out a section from the p anel that corresponds to the rear panel dimensions of the FPC6084.

T ake care that the panel section that is cut out is smaller than the overall size of the met al frame that surrounds the FPC6084 but just large enough for the rear panel of the FPC6084 to fit through (Figure 3-29).

Step 3: Slide the FPC6084 through the hole until the aluminum frame is flush against the p anel.

Step 4: Insert the p anel mounting clamps into the pre-formed holes along the edges of the chassis, behind

the aluminum frame. There are a total of 8 panel mounting clamps.

Step 5: Tighten the screws that pass through the panel mounting clamps until the plastic caps at the front

of all the screws are firmly secured to the panel (Figure 3-30).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 51

3.12.3 ARM MOUNTING

FPC 6065 / 6084

The FPC6065/FPC6084 is VESA (V ideo Electronics S t andards Association) compliant and can be

mounted on an arm with a 100mm interface pad. To mount the FPC6065/FPC6084 on an arm,

please follow the steps below .

Step 1: The arm is a sep arately purchased item. Please correctly mount the arm onto the surface it uses

as a base. To do this, refer to the installation documentation that came with the mounting arm.

NOTE: When purchasing the arm please ensure that it is VESA compliant and that the arm has a 100mm

interface pad. If the mounting arm is not VESA compliant it cannot be used to support the FPC6065/

FPC6084 flat panel PC.

Step 2: Once the mounting arm has been firmly attached to the surface, lif t the flat panel PC onto the

interface pad of the mounting arm.

Step 3: Align the retention screw holes on the mounting arm interface with those in the flat panel PC. The

flat panel PC arm mount retention screw holes are shown in Figure 3-31.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 52

FPC 6065 / 6084

Step 4: Secure the flat p anel PC to the interface pad by inserting four retention screws through the bottom

of the mounting arm interface pad and into the flat panel PC.

3.12.4 CABINET AND RACK INSTALLATION

The FPC6065/FPC6084 flat panel PC can be installed into a cabinet or rack. The installation procedures

are similar to the panel mounting installation. To do this, please follow the steps below:

NOTE: When purchasing the cabinet/rack installation bracket, make sure it is compatible with both the

FPC6065/FPC6084 flat panel PC and the rack/cabinet into which the FPC6065/FPC6084 is installed.

3.12.4.1 FPC6065 CABINET AND RACK INSTALLATION

Step 1: Slide the rear chassis of the FPC6065 flat p anel PC through the rack/cabinet bracket until the

aluminum frame is flush against the front of the bracket (Figure 3-32).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 53

FPC 6065 / 6084

Step 2: Secure the mounting clips to either side of the flat p anel PC using the retention screws supplied in

the mounting kit pack (Figure 3-33).

Step 3: Tighten the panel retention screws that pass through the mounting clip s until the plastic caps at the

front of all the screws are firmly secured to the rack/cabinet bracket (Figure 3-33).

Step 4: Slide the FPC6084 flat p anel PC with the attached rack/cabinet bracket into a rack or cabinet

(Figure 3-34).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 54

FPC 6065 / 6084

Step 5: Once the FPC6084 flat p anel PC with the attached rack/cabinet bracket has been properly inserted into the rack or cabinet, secure the front of the rack/cabinet bracket to the front of the rack or cabinet

(Figure 3-34).

3.12.4.2 FPC6084 CABINET AND RACK INSTALLATION

Step 1: Slide the rear chassis of the FPC6084 flat p anel PC through the rack/cabinet bracket until the

aluminum frame is flush against the front of the bracket (Figure 3-35).

Step 2: Insert the rack mounting clamps into the pre-formed holes along the edges of the FPC6084,

behind the metal frame. Refer to the mounting kit packing list for the required number of mounting clamps.

Step 3: Tighten the screws that pass through the rack mounting clamps until the plastic cap s at the front of

all the screws are firmly secured to the bracket (Figure 3-36).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 55

FPC 6065 / 6084

Step 4: Follow the S tep 4 and S tep 5 of the FPC6065Cabinet and Rack Installation procedures to complete the whole installation process.

3.12.5 DIN MOUNTING

T o mount the FPC6065/FPC6084 flat panel PC onto a DIN rail, please follow the step s below.

Step 1: Attach the DIN rail mounting bracket to the rear of the panel PC. Secure the bracket to the p anel

PC with the supplied retention screws (Figure 3-37).

Step 2: Make sure the inserted screw in the center of the bracket is at the lowest position of the elongated

hole (Figure 3-38).

Step 3: Place the DIN rail flush against the back of the mounting bracket making sure the edges of the rail

are between the upper and lower clamps (Figure 3-39).

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 56

FPC 6065 / 6084

Step 4: Secure the DIN rail to the mounting bracket by turning the top screw clockwise.This draws the

lower clamp up and secures the monitor to the DIN rail (Figure 3-40).

3.13 REAR PANEL CONNECTORS

3.13.1 LCD PANEL CONNECTION

T o connect the FPC6065/FPC6084 flat panel PC to a second monitor , a conventional CRT VGA monitor

connector is located on the bottom panel. This panel is a 15-pin, female D-SUB connector .

3.13.2 ETHERNET CONNECTION

The two rear panel RJ-45 connectors can be connected to an external LAN and provide Internet connectivity to the flat panel PC.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 57

FPC 6065 / 6084

3.13.3 USB Connection

The rear panel USB connectors provide easier and quicker access to external USB

devices. The rear panel USB connector is a standard connector and can easily be

connected to other USB devices.

3.13.4 Keyboard and Mouse Connection

One PS/2 connector on the bottom panel facilitates the connection of a mouse and a

keyboard. To connect either device, plug the PS/2 connector at the end of the keyboard

or mouse cable into the corresponding PS/2 connector on the external peripheral interface panel.

3.14 System Maintenance

If the components of the FPC6065/FPC6084 fail they must be replaced. Please contact the system reseller or vendor to purchase the replacement parts. Replacement instructions for the above listed components are described below.

NOTE: A user cannot replace a motherboard. If the motherboard fails it must be

shipped back to IEI to be replaced. Please contact the system vendor, reseller or an

IEI sales person directly.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 58

FPC 6065 / 6084

CHAPTER 4 GASKEY REPLACEMENT

4.1 Gasket Replacement

A gasket used for a long time may gradually lose its ability to protect the monitor from

fluids and vapors; scratches or dirt may also accumulate. It is recommended that the

gasket be replaced yearly.

NOTE: If the monitor is mounted vertically, first remove it and place it on a flat, level

surface with the display screen facing down before changing the gasket.

Step 1: Remove the old gasket from the sides of the monitor.

Step 2: Attach the new gasket to the monitor. Make sure the gasket fits precisely into

the groove along the edges of the monitor's front panel (Figure 4-1).

NOTE: Compliance with the IP65 standard depends on correct installation of the

gasket. Be sure to check that the gasket is properly installed after changing it.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 59

FPC 6065 / 6084

CHAPTER 5 AMI BIOS SETUP

5.1 Introduction

A licensed copy of Phoenix Award BIOS is preprogrammed into the ROM BIOS. The

BIOS setup program allows users to modify the basic system configuration. This

chapter describes how to access the BIOS setup program and the configuration options that may be changed.

5.1.1 Starting Setup

The Phoenix Award BIOS is activated when the computer is turned on. The setup program can be activated in one of two ways.

1. Press the DELETE key as soon as the system is turned on or

2. Press the DELETE key when the "Press Del to enter SETUP" message appears on

the screen.

If the message disappears, restart the computer and try again.

5.1.2 Using Setup

Use the arrow keys to highlight items, press ENTER to select, use the PAGEUP and

PAGEDOWN keys to change entries, press F1 for help and press ESC to quit. Navigation keys are shown below.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 60

FPC 6065 / 6084

5.1.3 Getting Help

When F1 is pressed a small help window describing the appropriate keys to use and

the possible selections for the highlighted item appears. To exit the Help Window press

ESC or the F1 key again.

5.1.4 Unable to Reboot After Configuration Changes

If the system cannot be booted after changes are made, restore the CMOS defaults.

The CPU card should come with a restore CMOS settings jumper. Refer to Section

3.6.2 for more information.

5.1.5 Main BIOS Menu

Once the BIOS opens, the main menu (BIOS Menu 1) appears.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 61

FPC 6065 / 6084

NOTE: The following sections will completely describe the menus listed below and

the configuration options available to users.

The following menu options are seen in BIOS Menu 1.

Standard CMOS Features: Changes the basic system configuration.

Advanced BIOS Features: Changes the advanced system settings.

Advanced Chipset Features: Changes the chipset configuration features.

Integrated Peripherals: Changes the settings for integrated peripherals.

Power Management Setup: Configures power saving options.

PnP/PCI Configurations: Changes the advanced PCI/PnP settings.

PC Health Status: Monitors essential system parameters.

The following user configurable options are also available in BIOS Menu 1:

Load Fail-Safe Defaults

Use the Load Fail-Safe Defaults option to load failsafe default values for each BIOS

parameter in the setup menus. Press F6 for this operation on any page.

Load Optimized Defaults

Use the Load Optimized Defaults option to load optimal default values for each BIOS

parameter in the setup menus. Press F7 for this operation on any page.

Set Supervisor Password

Use the Set Supervisor Password option to set the supervisor password. By default, no supervisor

password is set. To install a supervisor password, select this field and enter the password. After this

option is selected, a red dialogue box appears with "Enter Password: ". T ype the password and

press ENTER. Retype the original password into the "Confirm Password: " dialogue box and press

ENTER. To disable the password, simply press ENTER in the "Enter Password: " dialogue box,

then press any key in the "Password Disabled !!!" dialogue box.

661 Brea Canyon Rd., Suite 3

Walnut, CA 91789

tel: 909.598.7388, fax: 909.598.0218

© Copyright 2011 Acnodes, Inc.

All rights reserved. Product description and product specifications

are subject to change without notice. For latest product information,

please visit Acnodes’ web site at www.acnodes.com.

Page 62

FPC 6065 / 6084

Set User Password

Use the Set User Password option to set the user password. By default no user password is set.

T o inst all a user password, select this field and enter the password. Af ter this option is selected, a red

dialogue box appears with "Enter Password: ". T ype the password and press ENTER. Retype the original

password into the "Confirm Password: " dialogue box and press ENTER. To disable the password, simply

press ENTER in the "Enter Password: " dialogue box, then press any key in the "Password Disabled !!!"

dialogue box.

Save & Exit Setup

Use the Save & Exit Setup option to save any configuration changes made and exit the BIOS menus.

Exit Without Saving