Page 1

Form 613120

Read and Save These Instructions

ASSEMBLY INSTRUCTIONS FOR MOTORIZING

WAG, WAA, WAGC & WAAC Single & Double Panel Backdraft Dampers

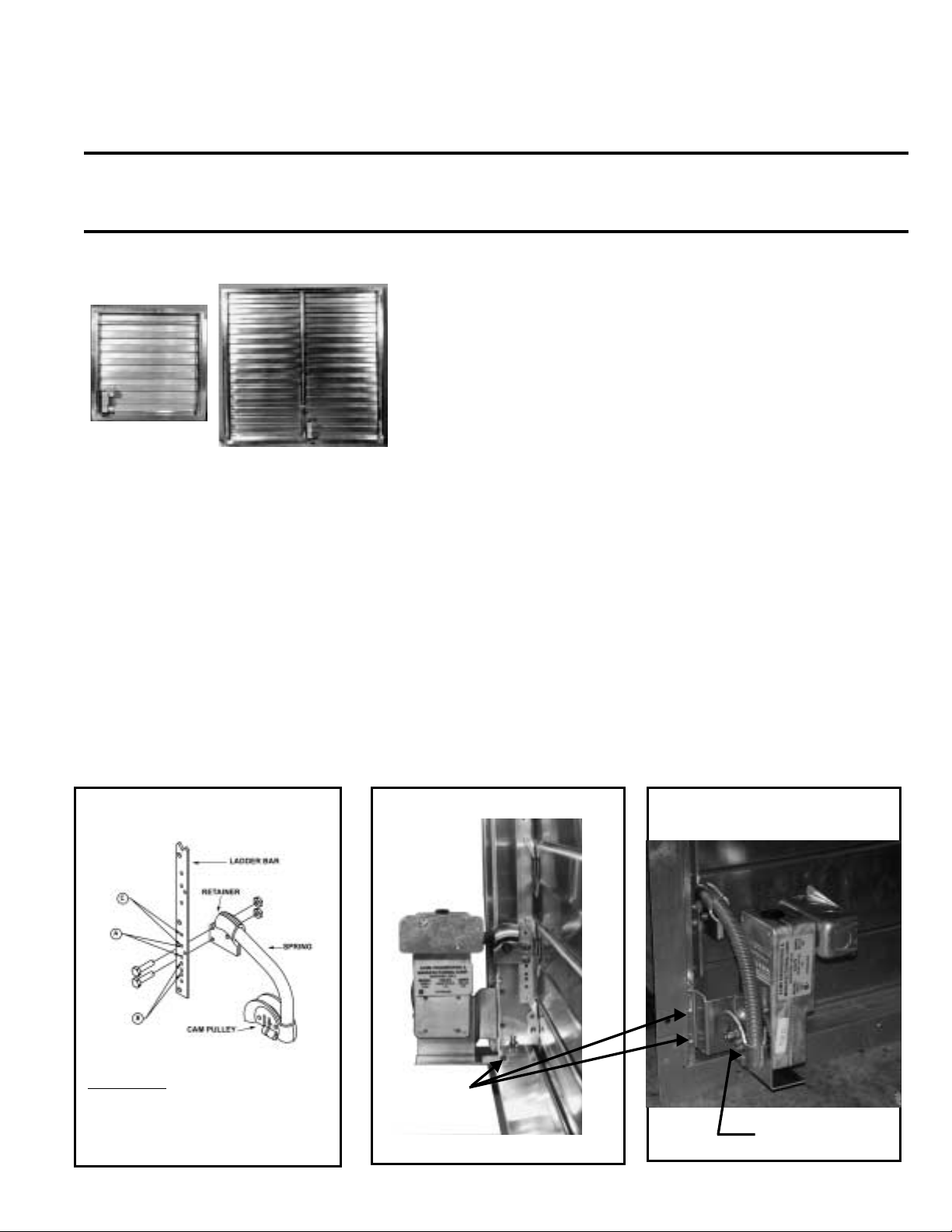

This CAM motor operation package consists of four major components;

motor with base, CAM assembly (with pull spring, CAM pulley and spring

retainer) and hardware. Follow steps in sequence for best results.

Make all electric connections using good wiring practices and in

accordance with National Electric Code and any local codes.

HINTS (A) On new installations, assembly of the motorizing kit would be

(B) DO NOT ATTACH THE CAM OPERATOR TO THE MOTOR

Single Panel Instructions

1. Refer to Chart 2 on page 5 for proper retainer hole location. Attach the pull spring retainer to the backdraft

damper ladder bar using two (2) bolts and lock nuts.

Opening the unit will give easy access to the ladder

bar.

2. Mount the motor and base using three (3) No. 8

screws (and three (3) speed nuts on aluminum

frames) by aligning the slots in the motor with the three

(3) holes in the frame. (Note: On some models the

backdraft damper frame is not pre-drilled. In this case,

use the motor base as a template to locate the proper

locations. For single panel units, the motor base

should fit in the lower left corner of the backdraft

damper as viewed from the inlet side. The motor base

Step 1 TOP VIEW

more easily done prior to installing the damper.

UNTIL THE CAM ASSEMBLY IS ATTACHED TO THE

BACKDRAFT DAMPER LADDER BAR AND THE MOTOR IS

ATTACHED TO THE BACKDRAFT DAMPER FRAME.

should be square to the backdraft damper. Self drilling

screws can be used to secure the motor base to the

backdraft damper frame. As an alternate to the self

drilling screws, .125" diameter holes can be pre-drilled

to use the #8 screws provided in the motor kit.

3. Attach the CAM pulley to the motor shaft. Position the

CAM assembly so that approximately 1/8" of the motor

shaft is showing through the CAM pulley, then tighten

the cam clamp bolt.

4. Check to see that all other bolts in the assembly are

tight.

IMPORTANT

ASSEMBLE IN THIS MANNER:

Bolt through ladder bar first, then

retainer, then lock nut.

Step 2

Step 3

Page 2

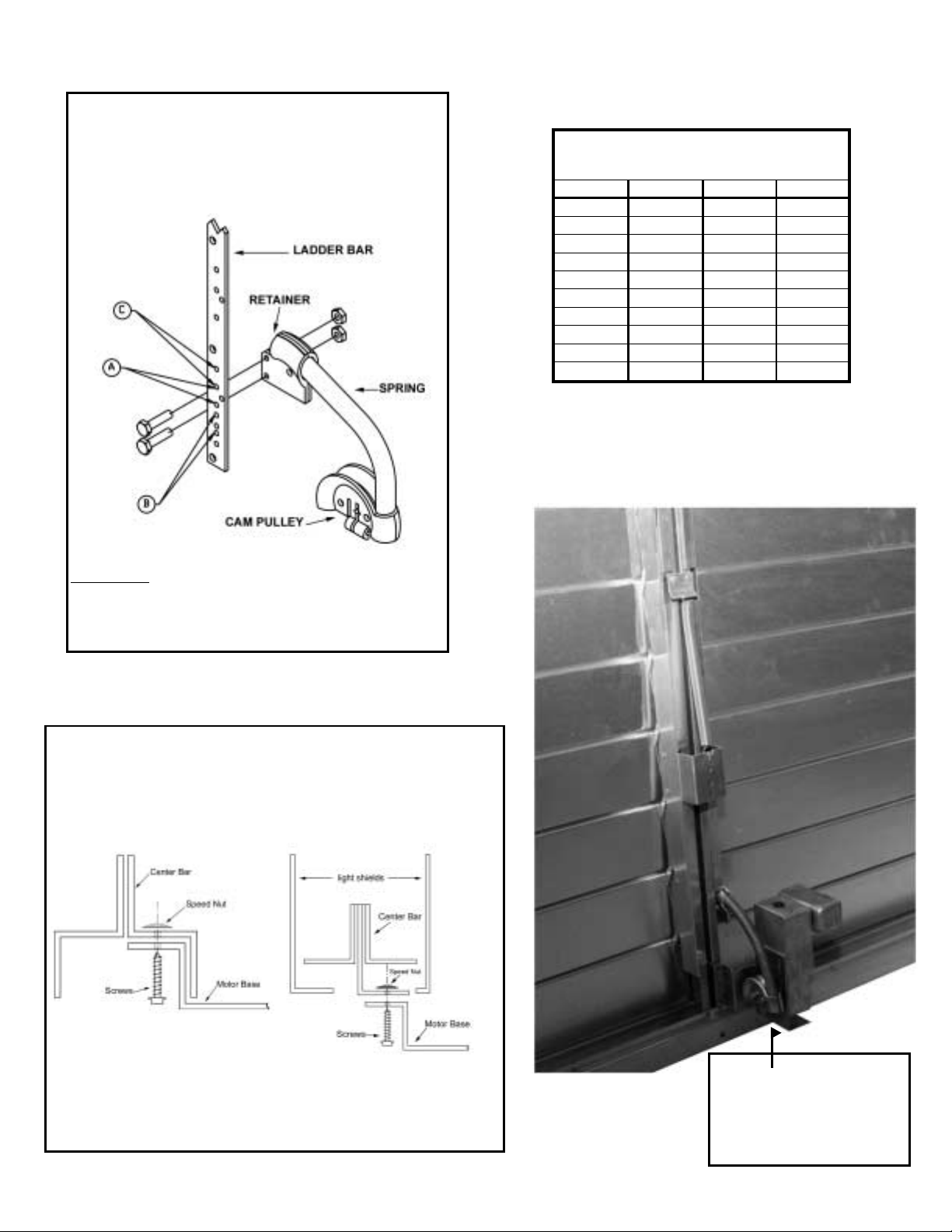

Backdraft Damper Double Panel Installation - WAGC & WAAC

Step 1

Refer to chart 1 for proper retainer hole location. Attach the pull

spring retainer to the backdraft damper ladder bar using two (2)

bolts and lock nuts. Opening the unit will give easy access to the

ladder bar.

CHART 1

MATCH RETAINER HOLE LOCATION TO BACKDRAFT

DAMPER MODEL SIZE BELOW

ABCC

4040 4141 4242

4343 4444 4545 4646

4747 4848 4949 5050

5151 5252 5353 5454

5555 5656 5757 5858

5959 6060 6161 6318

6363 6340 6565 6362

6767 6464 6969 6262

7171 6868 6666

7272 7070

IMPORTANT

ASSEMBLE IN THIS MANNER:

Bolt through the ladder bar first, then retainer, then lock

nuts.

Step 2

Mount the motor and base as shown using three (3) No. 8 screws (and three (3)

speed nuts onaluminum frames) by aligning the slots in the base with the three

(3) holes in the frame and center bar.

WAAC

WAAC With Light Shields

Step 3

Attach the CAM pulley to the

motor shaft. Position the CAM

assembly so that approximately

1/8" of the motor shaft is showing

through the CAM pulley then

tighten the Cam clamp bolt.

Page 2

Page 3

BACKDRAFT DAMPER INSTALLATION - WAGC, WAAC, WAA & WAG

C = Wide

D = High

MODEL

1212 12.00 12.00 9.75 10.32 1 1

1313 13.00 13.00 10.75 11.32 1 1

1414 14.00 14.00 11.75 12.32 1 1

1515 15.00 15.00 12.75 13.32 1 1

1616 16.00 16.00 13.75 14.32 1 1

1717 17.00 17.00 14.75 15.32 1 1

1818 18.00 18.00 15.75 16.32 1 1

1919 19.00 19.00 16.75 17.32 1 1

2020 20.00 20.00 17.75 18.32 1 1

2121 21.00 21.00 18.75 19.32 1 1

2222 22.00 22.00 19.75 20.32 1 1

2323 23.00 23.00 20.75 21.32 1 1

2424 24.00 24.00 21.75 22.32 1 1

2525 25.00 25.00 22.75 23.32 1 1

2626 26.00 26.00 23.75 24.32 1 1

2727 27.00 27.00 24.75 25.32 1 1

2828 28.00 28.00 25.75 26.32 1 1

2929 29.00 29.00 26.75 27.32 1 1

3030 30.00 30.00 27.75 28.32 1 1

3131 31.00 31.00 28.75 29.32 1 1

3232 32.00 32.00 29.75 30.32 1 1

3333 33.00 33.00 30.75 31.32 1 1

3434 34.00 34.00 31.75 32.32 1 1

3535 35.00 35.00 32.75 33.32 1 1

3636 36.00 36.00 33.75 34.32 1 1

3737 37.00 37.00 34.75 35.32 1 1

3838 38.00 38.00 35.75 36.32 1 1

3939 39.00 39.00 36.75 37.32 1 1

4040 40.00 40.00 37.75 38.32 2 1

4141 41.00 41.00 38.75 39.32 2 1

4242 42.00 42.00 39.75 40.32 2 1

4343 43.00 43.00 40.75 41.32 2 1

4444 44.00 44.00 41.75 42.32 2 1

4545 45.00 45.00 42.75 43.32 2 1

4646 46.00 46.00 43.75 44.32 2 1

4747 47.00 47.00 44.75 45.32 2 1

4848 48.00 48.00 45.75 46.32 2 1

4949 49.00 49.00 46.75 47.32 2 1

5050 50.00 50.00 47.75 48.32 2 1

5151 51.00 51.00 48.75 49.32 2 1

5252 52.00 52.00 49.75 50.32 2 1

5353 53.00 53.00 50.75 51.32 2 1

5454 54.00 54.00 51.75 52.32 2 1

5555 55.00 55.00 52.75 53.32 2 1

5656 56.00 56.00 53.75 54.32 2 1

5757 57.00 57.00 54.75 55.32 2 1

5858 58.00 58.00 55.75 56.32 2 1

5959 59.00 59.00 56.75 57.32 2 1

6060 60.00 60.00 57.75 58.32 2 1

6161 61.00 61.00 58.75 59.32 2 1

6262 62.00 62.00 59.75 60.32 2 1

6363 63.00 63.00 60.75 61.32 2 1

The framed opening can be calculated for backdraft damper sizes not shown. For units mounted outside the wall, subtract 3 inches from the width and height

dimension of thebackdraft damper. For units mounted through the wall, subtract 2.25 inchesfrom the width and subtract 1.68 inches from the height. Be sure the

bottom blade does not rub the framing.

A BCD

IN IN IN IN

Number of

Panels

Number of

Motors

Page 3

Page 4

BACKDRAFT DAMPER DOUBLE PANEL INSTALLATION - WAG & WAA

Step 1

Refer to chart 2 for proper retainer hole location.

Attach the pull spring retainer to the backdraft

damper ladder bar using two (2) bolts and lock

nuts. Opening the backdraft damper will give

easy access to the ladder bar.

IMPORTANT

ASSEMBLE IN THIS MANNER:

Bolt through the ladder bar first, then retainer,

then lock nuts.

Step 4 (For Existing Installation)

Attach the panel connectinglink to

the two center ladder bars, at

holes provided, using four (4)

No. 8 x 5/8” bolts and lock nuts.

IMPORTANT

Assemble in this manner.

bolt through ladder bar

first, then panel link, then

lock nuts.

Step 2

Mount the motor and base as shown using three

(3) No. 8 screws (and three (3) speed nuts on

aluminum frames) by aligning the slots in the

base with the three (3) holes in the frame and

center bar.

Step 3

Attach the CAM pulley to the motor shaft.

Position the CAM assembly so that

approximately 1/8" of the motor shaft is

showing through the CAM pulley then tighten

the CAM clamp bolt.

NOTE: Return Spring is not required on this unit.

Page 4

Page 5

BACKDRAFT DAMPER - WAG & WAA

Preparing Backdraft Damper For Existing Installations

Mounting holes need to be provided to the motor base in the backdraft damper frame and center bar (double panel) and for the spring

retainer in the ladder bar.

1. USING THE MOTOR BASE AS A TEMPLATE.

A. On single panel units, drill (3) holes in the lower left hand corner of the backdraft damper frame:

B. On double panel units, drill (2) holes inthe centerbar onthe righthand leg and(1) holein thebackdraft damper

frame. Be sure to locate the motor base inside the channel of the center bar. (See step 2, Page 2)

2. Locate the backdraft damper size (outside dimensions) on the chart below and select the proper retainer hole lo

cations. Mark the ladder bar and drill (2) 11/16” holes.

3. Follow assembly instructions on page 1 (single panel) or page 2 (double panel) to complete the installation.

-

SINGLE PANEL

CHART 2

MATCH RETAINER HOLE LOCATION TO

BACKDRAFT DAMPER MODEL SIZE BELOW

AB C C

2 9/32” 1 1/4” 2 15/16 2 15/16

1212 1313 1414

1515 1616 1717 1818

1919 2020 2121 2222

2323 2424 2525 2626

2727 2828 2929 3030

3131 3232 3333 3434

3535 3636 3737 3838

3939 4040 4141 4242

4343 4444 4545 4646

4747 4848 4949 5050

5151 5252 5353 5454

5555 5656 5757 5858

5959 6060 6161 6318

6363 6340 6565 6362

6767 6464 6969 6262

7171 6868 6666

7272 7070

Sizes 12-39 are single panel units and the

remaining sizes are double panel units.

DOUBLE PANEL

Page 5

Page 6

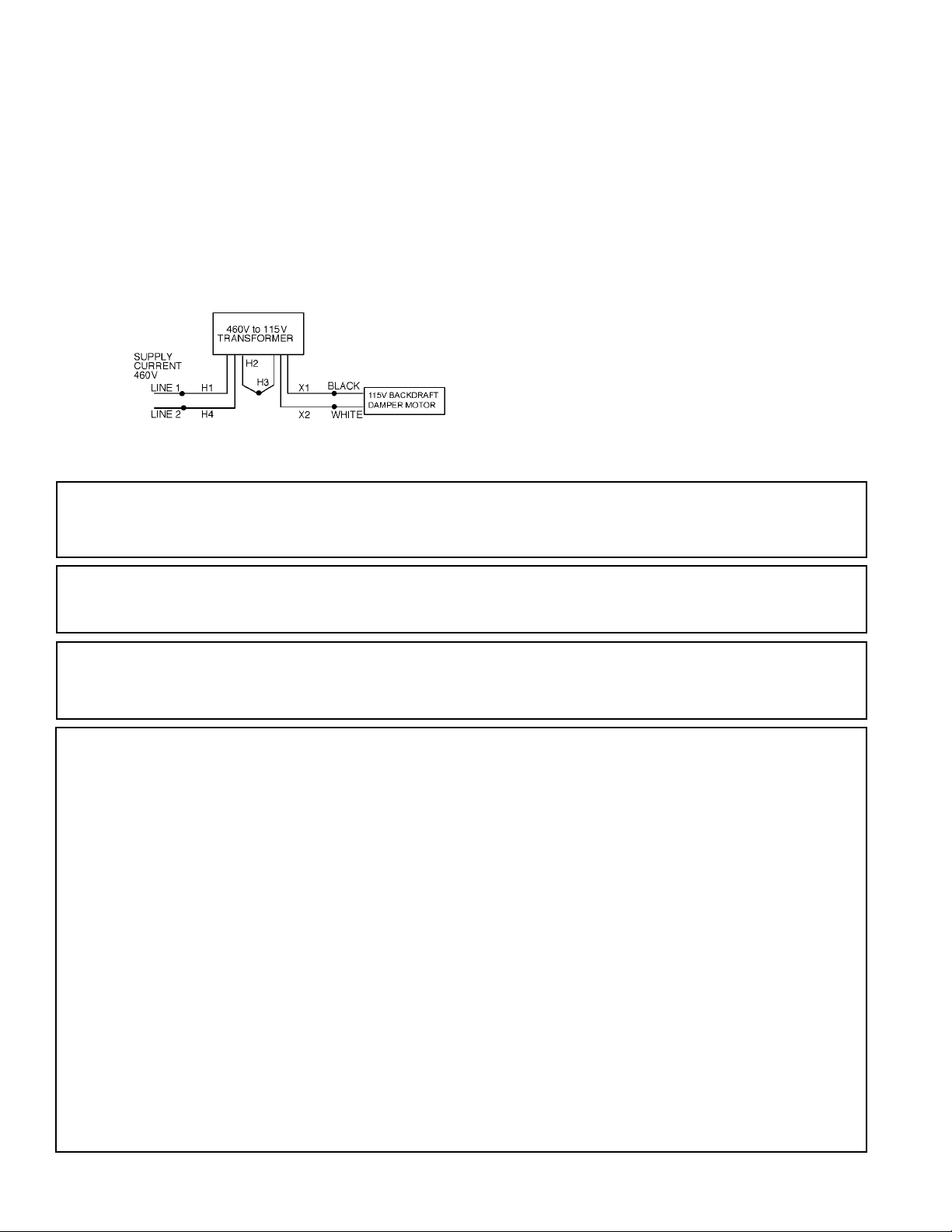

ELECTRICAL CONNECTIONS

Make all electrical connections using good wiring practices

and in accordance with National Electric Code and any local

code.

When using this motor in a moist environment, incorporate a

drip loop in the wiring and/or conduit to prevent water from

tracking into the junction box.

When wiring is complete, caulk the wire passage from the

junction box into the motor. This will extend the life of the

motor.

WARNING

To prevent excessive gaps or binding between the

backdraft damper frame and the blades, the following

must be observed.

1. Backdraft Damper mounting frame surface must be

flat and parallel to the mounting surface of the unit.

2. Backdraft Damper sides, top and bottom must be

straight and parallel when mounted to the framed

mounting surface.

NOTE: If this motorizing kit is to be used in an application

requiring 460 volt single phase, a 115 volt backdraft

damper motor and a 460 volt to 15 volt transformer will

be supplied and must be wired as shown.

These instructions cover the usual installation, operation and maintenance methods for which the product(s) was designed. They do not purport to cover all details or

variations in the product(s) norto provide for everypossible contingency that might bemet in connection withthe installation, operation and maintenance.For any depar

tures from these instructions, or should particular problems arise which are not covered sufficiently for the purchaser’s purpose, the matter should be referred to the

Company.

The Company has made a diligent effort to illustrate and describe the products in this literature accurately; however such illustrations and descriptions are for the sole

purpose of identification and do not express or imply a warranty that the products are merchantable or fit for a particular purpose, or that the products will necessarily

conform to the illustrations or descriptions or dimensions.

The Companyproducts are designed and manufactured to provide reliable performance, but they are not guaranteed to be 100% freeof defects.Even reliableproducts

will experience occasional failures and this possibilityshould be recognized by the User.If theseproducts are used in a lifesupport ventilation support system where fail

ure could result in loss or injury, the user should provide adequate back-up ventilation, supplementarynatural ventilationor failurealarm system or acknowledge willing

ness to accept the risk of such loss or injury.

WARRANTY AND DISCLAIMER. The Company

extends this limited warranty to the original buyer

and warrants that products manufactured by the

Company shall be free from original defects in

workmanship and materials for two years fromdate

of shipment, provided same have been properly

stored, installed, serviced, maintained and oper

ated. This warranty shall not apply to products

which have been altered or repaired without the

Company’s express authorization, or altered or re

paired in any way so as in the Company’sjudgment

to affect its performance or reliability, nor which

have been improperly installed or subjected to mis

use, negligence or accident, or incorrectly used in

combination with other substances. The Buyer as

sumes all risks and liability for the results of use of

the products. Warranties on purchased parts such

as electric motors, pumps and controls are limited

to the terms of warranty extended by our supplier.

LIMITATION OF REMEDY AND DAMAGES. All

claims underthis warranty must be made in writing

and delivered to Box 978, Muskogee, Oklahoma

74402 within 15 days after discovery of the defect

and prior to the expiration of two years from the

date of shipment by the Company of the product

claimed defective, and Buyer shall be barred from

any remedy if Buyer fails to make such claim within

such period.

Within 30 days after receipt of a timely claim, the

Company shall have the option either to inspect the

product while in Buyer’s possession or to request

Buyer to return the product to the Company at

Buyer’s expense for inspection by the Company.

The Company shall replace, or at its option repair,

free of charge, any product it determines to be de

fective, and it shall ship the repaired or replacement

product to Buyer F.O.B., point of shipment pro

vided, however, if circumstances are such as in the

-

Company’s judgement to prohibit repair or replace

ment to remedy the warranted defects, the Buyer’s

sole and exclusive remedy shall be a refund to the

-

Buyer of any part of the invoice price, paid to the

Company for the defective product or part.

The Company is not responsible for the cost of re

moval ofthe defectiveproduct orpart damages due

to removal, or any expenses incurred in shipping

the product or part to or from the Company’s plant,

or the installation of the repaired or replaced prod

uct or part.

Implied warranties, when applicable, shall com

mence upon the same dateas the express warranty

provided above, and shall except for warranties of

title, extend only the duration of the express war

ranty. Some states do not allow limitations on how

long an implied warranty lasts, so the above limita

tion may not apply to you. The only remedy pro

vided to you under an applicable implied warranty

and the express warranty shall be the remedy pro

vided under the express warranty. Subject to the

terms and conditions contained therein, the Com

pany shall not be liable for incidental and conse

quential losses and damages under the express

warranty, any applicable implied warranty, or

claims for negligence, except to the extent that this

NOTICE

DISCLAIMER

WARNING

LIMITED WARRANTY

limitation is found to be unenforceable under ap

plicable state law. Some states do not allow the

-

exclusion or limitation of incidental or conse

quential damages, so the above limitation or ex

-

clusion maynot applyto you.This warranty gives

you specific legal rights, and you may also have

-

other rights which vary from state to state.

No employee, agent, dealer, or other person is

authorized to give any warranties on behalf of the

Company or to assume for the Company any

other liability in connection with any of its prod

-

ucts except in writing and signed by an officer of

the Company.

TECHNICAL ADVICE AND RECOMMENDA

TIONS, DISCLAIMER. Notwithstanding any

past practice or dealings or any custom of the

trade, sales shall not include the furnishing of

-

technical advice or assistance or system design.

Any such assistance shall be at the Company’s

sole option and may be subject to additional

-

charge.

The Company assumes no obligation or liability

on account of any recommendations, opinions or

advice as to the choice, installation or use of

products. Any such recommendations, opinions

or advice are given and shall be accepted atyour

own risk and shall not constitute any warranty or

guarantee of such products ortheir performance.

GENERAL. In no event shallany claim for conse

quential damages be made by either party. The

Company will comply with all applicable Federal,

State and local laws.

Page 6 December 2000 Form 613120

-

-

-

-

-

-

-

-

-

Loading...

Loading...