Page 1

Form611130

MODEL: VQ080ESBV VQ090ES

VQ110ES VQ120ES

VQ150ES

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR IN JURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning

equipment to prevent backdrafting. Follow the heating

equipment manufacturer’s guideline and safety standards

such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and

the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Acceptable for use over a tub or shower when connected to

a GFCI (Ground Fault Circuit Interrupter) - protected branch

circuit (ceiling installation only).

8. This unit must be grounded.

9. Never place a switch where it can be reached from a tub or

shower.

10. To reduce the risk of fire use only metal ductwork.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. This product is designed for installation in ceilings up to a

12/12 pitch (45 degree angle). Duct connector must point up.

DO NOT MOUNT THIS PRODUCT IN A WALL.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Please read specification label on product for further

information and requirements.

Installer: Leave this manual with the owner.

CEILING VENTILATOR

CLEANING & MAINTENANCE

For quiet and efficient operation, long life, and attractive

appearance - lower or remove grille and vacuum interior of unit

with the dusting brush attachment.

The motor is permanently lubricated and never needs oiling. If the

motor bearings are making excessive or unusual noises, replace

the motor with the exact service motor. The impeller should also

be replaced.

OPERATION

Use an on/off switch to operate this fan. See “Connect Wiring”

for details.

WARRANTY

LIMITED WARRANTY Acme Engineering and Manufacturing Corporation extends

this limited warranty to the original purchaser and warrants that products described

herein shall be free from original defects in workmanship and materials for two

years from date of shipment provided same have been properly handled, stored,

installed, serviced, maintained and operated. THIS WARRANTY DOES NOT

EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES.

MS149 for complete limited warranty terms and conditions. This form is available

to anyone at www.acmefan.com. The Company's warranty is in lieu of all other

warranties, express or implied, arising by law or otherwise, including without

limitation the implied warranties of merchantability and fitness for a particular

purpose, which are hereby expressly disclaimed claimed and waived.

Acme products are designed and manufactured to provide reliable performance but

they are not guaranteed to be 100% free of defects. Even reliable products will

experience occasional failures and this possibility should be recognized by the

Purchaser and End User. If these products are used in a life support ventilation

system where failure could result in loss or injury, the Purchaser and End User

should provide adequate back-up ventilation, supplementary natural ventilation or

failure alarm system, or acknowledge willingness to accept the risk of such loss or

injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fans electrical

system could provide ignition to combustible or flammable materials unless unit is

specifically built for hazardous environments. Comply with all local and national

safety codes including the National Electrical Code (NEC) and National Fire

Protection Act (NFPA). Guards must be installed when fan is within reach of

personnel or within eight (8) feet (2.5 m) of working level or when deemed

advisable for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe

the products in this literature accurately; however, such illustrations and

descriptions are for the sole purpose of identification, and do not express or imply a

warranty that the products are merchantable, or fit for a particular purpose.

INDEMNITY Purchaser acknowledges various warnings by the Company

regarding the products and its installation and use. If the Company incurs any

claims, lawsuits, settlements, or expenses (including attorney fees) for any loss,

injury, death or property damage including, but not limited to, claims arising out of

the Purchasers or any end users installation or use of the products, the Purchaser

shall indemnify and hold the Company harmless.

Acme Engineering and Manufacturing Corporation

1820 N. York St., Muskogee, OK 74403

918-682-7791

Refer to Form

Page 2

CEILING VENTILATOR

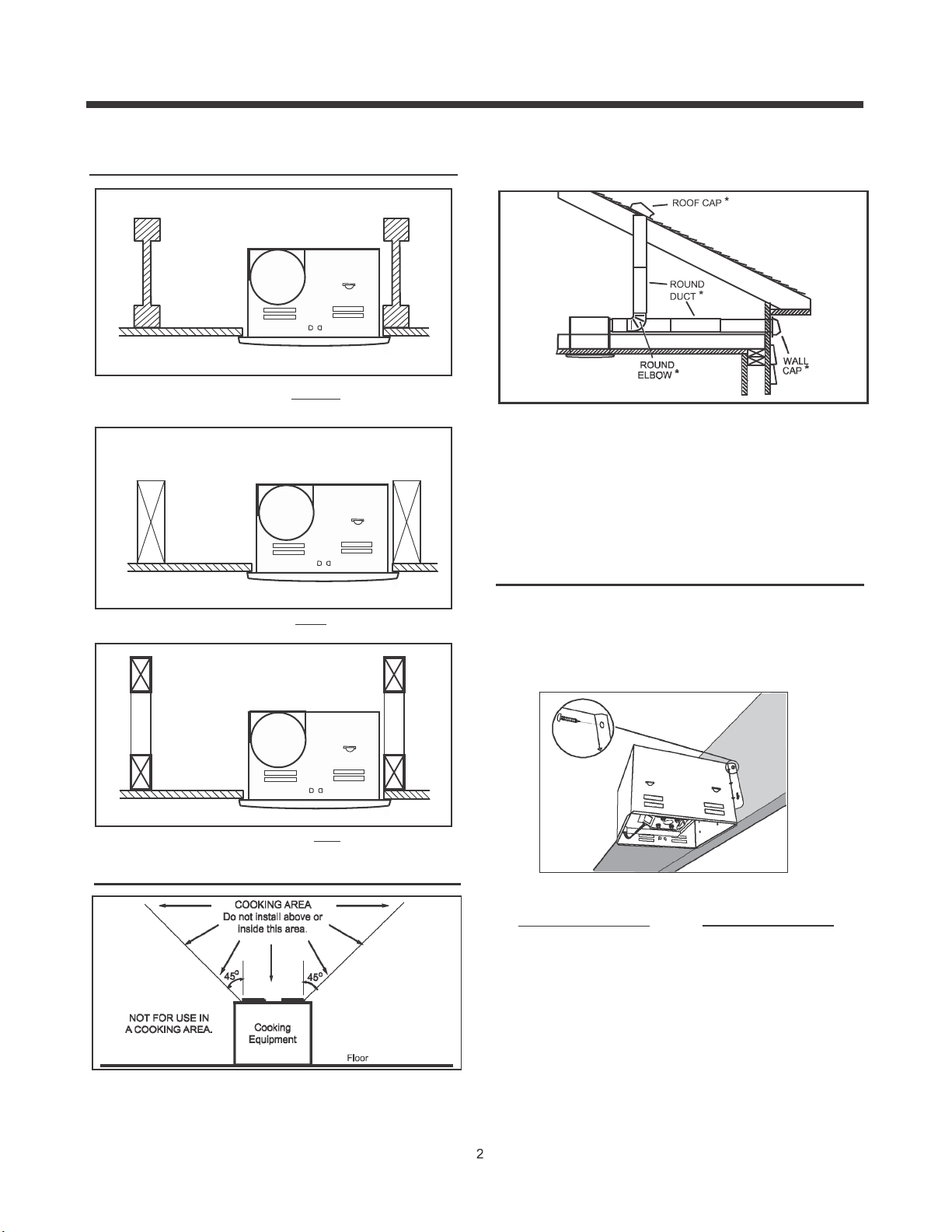

TYPICAL INSTALLATIONS

6”

Housing

mounted

to I -joists

.

For a more quiet and efficient fan locate fan where the shortest

duct run and a minimum number of elbows will be needed.

Use a roof cap or wall cap that has a built-in damper to reduce

backdrafts.

NOTE: Model VQ080ESB4 uses a 4” duct.

Housing mounted

Housing mounted

to

joists

to truss.

.

INSTALL HOUSING

1a. Mount housing to joist or I-joist. Hold housing in

place so that the housing contacts the bottom of the joist.

The housing mounts with two(2) screws or nails. Screw or

nail housing to joist through the holes in each mounting

flange.

6”

PLAN THE INSTALLATION

OR

1b. Mount housing anywhere between

trusses, joists, or I -joists using hanger

bars.

Sliding hanger bars are provided to allow for accurate

positioning of housing anywhere between framing. They

can be used on all types of framing (I-joist, standard joist,

and truss construction) and span up to 24”.

Page 3

HANGER

BAR

Insert hanger bars in slots provided in housing. Make sure

TABS face “up” as shown. Use the set of channel mounting

holes to mount the housing flush with the bottom of the drywall.

Use the other set of holes (not marked) to mount the housing

flush with the top of the drywall.

SCREW

Extend HANGER BARS to the width of the framing.

Hold ventilator in place with the hanger bar tabs wrapping

around the BOTTOM EDGE OF THE FRAMING.

NAIL ventilator to framing or fasten with screws (not provided)

through HOLES near nails.

To ensure a noise-free mount: Secure hanger bars together

*

with SCREWS or use p l i e r s to crimp mounting channels

tightly around hanger bars.

NAIL

INSTALL DUCTWORK

1. Attach

damper/duct

connector.

Snapthe

damper/duct

connectoronto

housing.Makesure

thetabsonthe

connectorlockinto

slotsinthehousing.

Ensuretheconnector

sitsflushwiththetop

ofthehousingand

thedamperflapfalls

closed.

DUCT

CEILING VENTILATOR

2

. Install 6”

round duct

work.

CAUTION: ALL

DUCTING MUST

COMPLY WITH

LOCAL AND

NATIONAL

BUILDING CODES

Connect ductwork to

fans damper/duct

connector. Secure

with tape or screw

clamp. Connect ductwork to outside through a roof or

wall cap. Check damper to make sure it opens freely.

Tape all duct connections.

CONNECT WIRING

Connect electrical wiring.

Lock off and test all power sources before unit is wired. All

wiring should be in accordance with local ordinances and

National Electrical Code, NFPA70. Use proper UL

approved connectors to secure wiring to wire plate. Ensure

power supply (voltage, frequency, and current capacity of

wiring) is in accordance with the motor nameplate. Connect

all wiring as shown in wiring diagram.

Page 4

1. Finish ceiling.

Install ceiling material. Cut out around housing.

2. Attach grille to housing.

Squeeze grille springs and insert them into slots on

each side of housing.

3. Push grille against ceiling.

CEILING VENTILATOR

USE AND CARE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND LOCK OUT SERVICE PANEL BEFORE CLEANING OR SERVICING

THIS UNIT.

The motor is permanently lubricated. Do not oil or disassemble motor.

TO CLEAN GRILLE:

CAUTION: Plastic parts can be cleaned with mild, soapy water (use a mild detergent, such as dishwashing liquid) and dried with a soft

cloth. Do not use abrasive cloth, steel wool pads, or scouring powders.

TO CLEAN FAN ASSEMBLY:

Unplug fan assembly. To remove motor plate: Find the screw (#15) on the motor plate (located next to the receptacle). Push up near

motor plate tab while pushing out on side of housing. Or insert a straight-blade screwdriver into slot in housing (next to tab) and twist

screwdriver. Gently vacuum fan, motor and interior of housing. METAL AND ELECTRICAL PARTS SHOULD NEVER BE IMMERSED

IN WATER.

SERVICE PARTS

Key No. Description

1

2

3

4

5

6

7

8

9

10

11

*

12

13

14

15

Product specifications subject to change without

SERVICE NOTE To remove Blower Assembly: Unplug motor (7). Remove

thumbscrew (15) from motor plate (9) flange. Find the single TAB on the motor plate (located

next to the receptacle). Push up near motor plate tab while pushing out on side of housing.

Or insert a straight-blade screwdriver into slot in housing (next to tab) and twist screwdriver.

Housing

Damper/Duct Connector

Wiring Plate

Screw

Wire Panel/Harness Assembly

Blower Wheel

Motor

Isolator (4 req’d)

Motor Plate

Washer (4 req’d)

Nut, Hex Lock (4 req’d)

Blower Assembly

(includes key nos. 6 thru 11)

Grille Assembly

(includes key nos. 13)

Grille Spring (2 req’d)

Hanger Bar Kit

Screw

notice.

January2013 611130

Loading...

Loading...