Page 1

FORM 613095

Read and Save These Instructions

INSTALLATION & MAINTENANCE INSTRUCTIONS

Models XB, XD, USB and USD

RECEIVING AND INSPECTION

humidity indicators at several points and maintain the

atmosphere at 40% relative humidity, or lower.

Immediately upon receipt of a shipment, carefully inspect for

damage and shortage. Turn the impeller by hand to see that it

turns freely and does not bind. If any damage and/or shortage

is detected or suspected, the carrier must be asked to

conduct an inspection. The consignee’s representative should

not accept a shipment without a notation on the delivery

receipt indicating items not delivered or the apparent extent of

damage.

When a shipment is opened and damage is found which was

not evident externally (concealed damage), it is mandatory

that the consignee request an immediate inspection by the

carrier. Report any damage to the carrier within 15 days.

Failure to report damage within the above time limit will result

in rejection of a claim.

HANDLING

When handling fans and their accessories, always use

equipment and methods that will not cause damage. Fans

should be lifted using slings and padding or spreaders to

avoid damage.

CAUTION! Always make sure that all lifting and handling

equipment and techniques conform to current safety

standards.

Avoid lifting fans in a way that will bend or distort fan parts.

Never pass slings or timbers through the orifices of fan.

CAUTION! Do not lift by the fan hood. Fans with special

coatings or paints must be protected in handling to prevent

damage.

STORAGE

Fans are protected against damage during shipment. If they

cannot be installed and put into operation immediately upon

receipt certain precautions are necessary to prevent

deterioration during storage. Responsibility for integrity of

fans and accessories during storage must be assumed by the

user. The manufacturer will not be responsible for damage

during storage. These suggestions are provided solely as a

convenience to the user, who shall make his own decision as

to whether to use any or all of them.

INDOOR: The ideal storage environment for fans and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of blowing

dust, rain, or snow. Temperatures should be evenly

maintained at between 70°F and 105°F (wide temperature

swings may cause condensation and "sweating" of metal

parts). Windows should be covered to prevent temperature

variations caused by sunlight. Provide thermometers and

It may be necessary to use trays of renewable desiccant or

portable dehumidifier to remove moisture from the air in the

storage enclosure.

Thermostatically controlled portable heaters (vented to

outdoors) may be required to maintain even temperatures

inside the enclosure.

CAUTION! Provide fire extinguishers, or fire alarms, or

emergency response communication to protect building and

equipment against fire damage. Be sure that building and

storage practices meet all local, state and federal fire and

safety codes.

The following fans or accessories must be stored indoors, in

a clean dry atmosphere:

a. Propeller wall fans not in wall housings.

b. Any fan protected by a cardboard carton.

c. Motors dismounted from fans.

d. Spare wheels or propellers.

e. Belts, sheaves, bushings and other parts when not

mounted on fan.

f. Boxes, bags or cartons of hardware.

g. Curbs

h. Dampers

Remove any accumulations of dirt, water, ice or snow and

wipe dry before moving indoor storage. Allow cold parts to

reach room temperature to avoid “sweating” of metal parts.

Open boxes or cartons. Remove any accumulated moisture;

if necessary use portable electric heaters to dry parts and

packages. Leave coverings loose to permit air circulation and

to permit periodic inspection.

Rotate wheels or propellers by hand to distribute bearing

grease over the entire bearing surfaces.

Store at least 3 ½” off the floor on wooden blocks covered

with moisture proof paper or polyethylene sheathing. Provide

aisles between parts and along all walls, to permit air

circulation and space for inspection.

OUTDOOR: Fans designed for outdoor use may be stored

outdoors, if absolutely necessary. The storage area should

be reasonably level and drained or ditched to prevent

accumulation of water. Fencing and lighting for security are

desirable. Roads or aisles for portable cranes and hauling

equipment are needed. Consider the use of drift fencing to

minimize accumulation of blowing snow or dirt.

The following fans may be stored outdoors, if dry indoor

storage space is not available:

a. Fans intended for outdoor use that are crated in wood.

b. Wall fans installed in wall housings.

Page 2

All fans must be supported on wooden blocks or timbers

above water or normal snow levels. Provide enough blocking

to prevent settling into soft ground. Fans should be set in

place using the directional arrow markings on the crate as a

guide.

Locate pieces far enough apart to permit air circulation,

sunlight, and space for periodic inspection. Place all parts on

their supports so that rain water will run off, or to minimize

water accumulation. Do not cover parts with plastic film or

tarps - these cause condensation of moisture from the air

passing through heating and cooling cycles.

Fan wheels and propellers should be blocked to prevent

spinning caused by strong winds.

INSPECTION AND MAINTENANCE DURING STORAGE

Inspect fans and accessories at least once per month, while

in storage. Log results of inspection and maintenance

performed. A typical log entry should include the following:

a. Date

b. Inspector’s Name

c. Name of Fan

d. Location

e. Condition of Paint or Coating

f. Is moisture present?

g. Is dirt accumulated?

h. Corrective steps taken?

If moisture or dirt accumulations are found on parts, the

source should be located and eliminated. Fans should be

rotated at each inspection by hand ten to fifteen revolutions to

redistribute the motor and bearing lubricant.

If paint deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust occur. The

most critical items are pulleys, shafts and bearing locking

collars. At the first sign of rusting on any of the above parts,

remove the original rust preventive coating with petroleum

solvent and clean lint-free cloths. Polish any remaining rust

from surfaces with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe clean

with lint-free cloths and recoat surfaces evenly and thoroughly

with Tectly 506 (Ashland Oil Company) or equal. For hard to

reach internal surfaces or for occasional use, consider using

Tectly 511M Rust Preventive or WD40 or equal.

2. WARNING! Do not use in hazardous environments where

the fan’s electrical system could provide ignition to

combustible or flammable materials, unless the unit is

specifically built for hazardous environments.

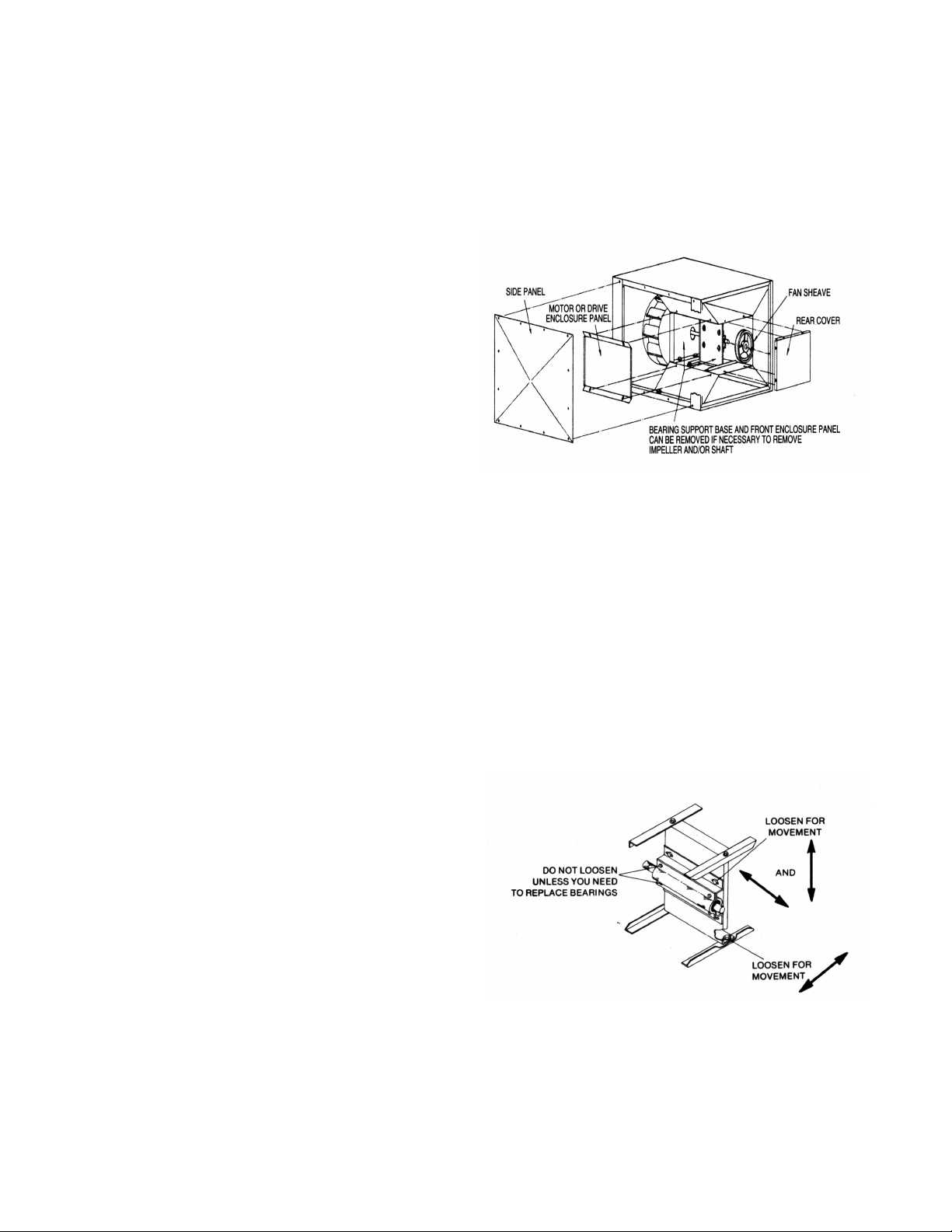

3. Impeller Adjustment: Turn centrifugal impeller by hand to

make sure it rotates freely. If impeller hits orifice, remove

side panel (both sides are removable) and motor or drive

enclosure panel as in shown Figure1.

Figure 1

Adjustment is made as follows:

4.

Direct Driven Units

Loosen bolts holding the motor to the mounting frame.

This will allow free movement of the impeller in all

directions for adjustment. Do not loosen the set screws in

the impeller hub since this will only allow movement in or

out on the motor shaft. Tighten all bolts before operating

the unit.

Belt Driven Unit

The bearing support base and the bearing lower housing

are slotted for adjustment. Loosen the bolts indicated in

Figure 2 and center the impeller over the orifice. Tighten

all bolts before operating the unit.

REMOVING FROM STORAGE

As fans are removed from storage to be installed in their final

location, they should be protected and maintained in similar

fashion, until the fan equipment goes into operation.

INSTALLATION

1. These units are not air tight and should not be used where

escape of contaminated air would cause problems.

CAUTION! This unit has rotating parts and safety

precautions should be exercised during installation,

operation and maintenance.

Page 2

Figure 2

Belt drive units are shipped without the sheaves mounted.

5.

Remove the sheaves from the drive package and install

on the fan. The rear cover is removable if required.

6. Check the pulley alignment and belt tension. Adjust the

belt tension using motor base jack screws. Belt should

depress its width when pressed firmly inward at midway

point between the pulleys. Replace all panels and tighten

corresponding bolts.

Page 3

7. If unit is to be equipped with isolators and/or support

brackets they should be attached at this time using the

mounting instructions (Form 613101) included with them.

8. Securely support the unit and attach the duct work.

9. Units used outdoors should be installed to provide

maximum weather protection. Direct driven units should

be positioned so that the breather tube to the motor

compartment will not let moisture enter. Belt driven units

should include a motor cover to protect the motor and belt

enclosure opening from moisture.

10. CAUTION! Before proceeding, make sure electrical

service to the fan is locked in the “OFF” position.

11. All wiring should be in accordance with local ordinances

and the National Electric Code.

12. WARNING! Check the voltage at the fan to see if it

corresponds with the motor nameplate. High or low

voltage can seriously damage the motor. Extra care

should be taken when wiring two speed motors since

improper connections will damage the motor and void the

motor warranty. On belt driven units, leave enough slack

in wiring to allow for motor movement when adjusting belt

tension.

13. Apply power momentarily and compare the rotation of the

impeller with the directional arrow on fan. WARNING!

Operation in the wrong direction will deliver air but will

overload the motor to the extent of blowing fuses and

seriously damaging the motor. In the case of three phase

motors, the direction can be changed by interchanging

any two of the three motor leads. In the case of single

phase motors, the reversing instructions will appear on the

wiring diagram in the motor wiring compartment.

14. CAUTION! Guards must be installed when the fan is

within reach of personnel or within eight (8) feet (2.5m) of

working level or when deemed advisable for safety.

MAINTENANCE

1. Under normal usage, no spare parts are recommended for

one year of operation. Recommended spare parts are

shown on Pages 6 and 7.

2. CAUTION! Before proceeding, make sure electrical

service to the fan is locked in the “OFF” position.

WINDMILLING: Even when the power supply is locked

out, fans may cause injury or damage if the impeller is

subject to “windmilling” which is the turning of the impeller

and drive components due to a draft in the system. To

guard against this hazard, the impeller should be secured

to physically restrict rotational movement.

3. Acme Duplex Split pillow block bearings are prelubricated

and do not require relubrication. Units with pillow block

bearings have grease fittings and, under normal operating

conditions, will need no relubrication for 3 to 5 years. If

relubrication is required, use a grease conforming to NLGI

No. 2. CAUTION! Lubricating bearings with a high

pressure gun can blow bearing seals and overfill the

bearing with grease. This condition can result in excessive

churning and overheating. For normal operating conditions

it is standard practice to fill only 30% of the bearing void

with grease. Do not over lubricate.

4. Motor bearings are prelubricated. Consult information

printed on the motor for lubrication instructions.

5. On belt driven units, check belt tension after the first 48

hours of operation and thereafter annually. Belt should

depress its width when pressed firmly inward at midway

point between the pulleys. Too much tension will damage

the bearings. The belt should be tight enough to prevent

slippage. When replacing a worn belt, replace the motor

pulley if “shoulder” is worn in groove. WARNING! Do not

replace the motor pulley with a larger diameter pulley. Do

not replace the fan pulley with one smaller in diameter.

The pulley ratios are set so that the motor will not be

overloaded. Do not operate at higher speeds than that

cataloged for this equipment.

6. If it should become necessary to remove the impeller, first

remove the motor and impeller or shaft, bearing and

impeller assembly.(See Figure 1) On model sizes 120,

137 and 161 there is a sleeve which fits inside the impeller

hub. To remove the impeller from the shaft, completely

remove the two socket head cap screws that go through

the sleeve. The impeller will then slide off the sleeve and

the set screws attaching the sleeve can be loosened

allowing its removal. The impellers on larger size units are

attached with a roll pin. Remove the roll pin by driving it

out with a drift pin.

7. On belt driven units: If impeller shaft bearings need

replacement, replace with bearing comparable to the

original equipment. If Acme Duplex Split pillow block

bearings are used, install new bearings into neoprene

rings, check correct position of impellers with orifice,

position bearings in the die-formed recess and tighten the

set screws. Replace the die-formed bearing cap and

tighten the four bolts.

NOTE: If locking collar type bearing is used, collar must

first be positioned against the inner race on the bearing

nearest the impeller and turned in the direction of impeller

rotation with a drift pin and hammer until it locks. Locking

collars must be on the inboard (facing) sides of the

bearings. Secure the bearing to the shaft with set screws.

Lock and secure the other bearing to the shaft in the same

manner.

NOTE: If pillow block type bearings are used, slide

bearings onto shaft to desired location and bolt bearing

block securely to support base. Slide shaft back and forth

in secured bearing (do not drive with hammer) and rotate

to make certain it turns freely. Check correct position of

propeller with inlet orifice. Then secure bearings to shaft

by tightening set screws.

Page 3

Page 4

SET SCREW TIGHTENING SCHEDULE

1. Before initial operation of the fan, tighten set screws

according to the procedure outlined below.

2. After 500 operating hours or three months, whichever

comes first, tighten set screws to the full recommended

torque.

PROCEDURE FOR TIGHTENING SET SCREWS IN

BEARINGS AND HUBS

One Set Screw Application

Using a torque wrench, tighten the set screw to the torque

recommended in Table 1.

3. At least once a year, tighten set screws to the full

recommended torque.

Table 1. Recommended Tightening

Torque for Set Screws

Set Screw Diameter Torque (in-lbs)

#10 35

1/4 80

5/16 126

3/8 240

7/16 384

1/2 744

9/16 1080

5/8 1500

3/4 2580

7/8 3600

1 5400

Two Set Screw Application

1. Using a torque wrench, tighten one set screw to half of the

torque recommended in Table 1.

2. Tighten the second set screw to the full recommended

torque.

3. Tighten the first set screw to the full recommended torque.

VARIABLE FREQUENCY

DRIVES AND MOTORS

There are occasions when a Variable Frequency Drive (VFD)

will cause poor motor performance and possible damage. To

avoid these problems, the Company recommends the

following:

1. Select compatible motor and VFD inverter; if possible, the

motor and the inverter should be from the same

manufacturer or at least the inverter selected should be

recommended by the motor manufacturer.

2. A motor shaft grounding system should be used to prevent

motor bearing damage from eddy currents.

NOTE: The Company will not honor motor warranty

claims if the customer fails to follow these recommendations.

Wiring Diagram for EC Motors

When XD fans are used with EC Motors and the optional remote speed control, the following wiring diagram should be

observed. A 120/24 VAC transformer will be added to the fan assembly for the purpose of powering the logic circuits in both

the motor and the remote speed control. The remote speed control will output a DC signal that varies from 0 to 10V. This

signal will vary the motor speed. All 120V connections will be made in the supplied junction box. Wire to the remote speed

control is to be supplied by others and must meet all applicable codes. The remote speed control location is limited by a

maximum wire length of 100 feet. Up to 6 fans can be operated from one remote control. Only one transformer should be

used. The 0-10 VDC (red) wires should be connected together, the common (white) wires should be connected together, and

the 24 VAC (black) should be connected together.

To use the remote variable speed control the speed control on the motor (if present) should be set full clockwise.

Page 4

Page 5

BELT DRIVE CENTRIFUGAL INLINE FAN RPM SELECTION TABLE

Model

Size

Power

HP 0

1

2

Fan RPM vs. Number of Turns from Full Closed

11

1

2

22

1

2

33

1

2

44

1

2

5

090E1 .25 2177 2118 2058 1999 1939 1880 1821 1761 1702 1642 1583

090E2 .25 2492 2428 2363 2299 2234 2170 2105 2041 1976 1912 1847

090F .33 2717 2637 2558 2478 2398 2319 2239 2159 2079 2000 1920

090G .50 3196 3110 3023 2937 2851 2765 2678 2592 2506 2419 2333

120E1 .25 1375 1317 1259 1201 1143 1084 1026 968 910 —— ——

120E2 .25 1570 1520 1470 1420 1370 1320 1270 1220 1170 1120 1070

120F .33 1725 1667 1608 1550 1491 1433 1374 1316 1257 1199 1140

120G .50 2060 1994 1928 1862 1796 1730 1664 1598 1532 1466 1400

120H .75 2335 2261 2186 2112 2037 1963 1888 1814 1739 1665 1590

120J 1.00 2570 2507 2443 2380 2316 2253 2189 2126 2062 1999 1935

137F .33 1365 1322 1278 1235 1191 1148 1104 1061 1017 974 930

137G .50 1605 1551 1496 1442 1387 1333 1278 1224 1169 1115 1060

137H .75 1830 1780 1729 1679 1628 1578 1527 1477 1426 1376 1325

137J 1.00 2060 1994 1928 1862 1796 1730 1664 1598 1532 1466 1400

137K 1.50 2310 2247 2183 2120 2056 1993 1929 1866 1802 1739 1675

137L 2.00 2490 2437 2383 2330 2276 2223 2169 2116 2062 2009 1955

161F .33 1055 1019 983 947 911 875 839 803 767 731 695

161G .50 1210 1172 1133 1095 1056 1018 979 941 902 864 825

161H .75 1365 1322 1278 1235 1191 1148 1104 1061 1017 974 930

161J 1.00 1570 1520 1470 1420 1370 1320 1270 1220 1170 1120 1070

161K 1.50 1710 1672 1634 1596 1558 1520 1482 1444 1406 1368 1330

161L 2.00 1865 1819 1773 1727 1681 1635 1589 1543 1497 1451 1405

161M 3.00 2210 2163 2115 2068 2020 1973 1925 1878 1830 1783 1735

200H .75 985 954 922 891 859 828 796 765 733 702 670

200J 1.00 1055 1023 990 958 925 893 860 828 795 763 730

200K 1.50 1250 1211 1172 1133 1094 1055 1016 977 938 899 860

200L 2.00 1410 1371 1332 1293 1254 1215 1176 1137 1098 1059 1020

200M 3.00 1525 1492 1459 1426 1393 1360 1327 1294 1261 1228 1195

200N 5.00 1885 1854 1822 1791 1759 1728 1696 1665 1633 1602 1570

245H .75 645 625 604 584 563 543 522 502 481 461 440

245J 1.00 735 712 688 665 641 618 594 571 547 524 500

245K 1.50 855 829 802 776 749 723 696 670 643 617 590

245L 2.00 965 935 905 875 845 815 785 755 725 695 665

245M 3.00 1100 1076 1052 1028 1004 980 956 932 908 884 860

245N 5.00 1295 1271 1246 1222 1197 1173 1148 1124 1099 1075 1050

300J 1.00 520 504 487 471 454 438 421 405 388 372 355

300K 1.50 595 577 558 540 521 503 484 466 447 429 410

300L 2.00 670 652 633 615 596 578 559 541 522 504 485

300M 3.00 775 759 742 726 709 693 676 660 643 627 610

300N 5.00 875 859 842 826 809 793 776 760 743 727 710

300P 7.50 1010 992 973 955 936 918 899 881 862 844 825

300R 10.00 1135 1114 1093 1072 1051 1030 1009 988 967 946 925

365K 1.50 450 436 422 408 394 380 366 352 338 324 310

365L 2.00 505 491 477 463 449 435 421 407 393 379 365

365M 3.00 555 543 531 519 507 495 483 471 459 447 435

365N 5.00 675 663 650 638 625 613 600 588 575 563 550

365P 7.50 760 746 732 718 704 690 676 662 648 634 620

365R 10.00 815 803 790 778 766 754 741 729 717 705 692

425K 1.50 380 369 359 348 338 328 318 307 296 285 255

425L 2.00 415 403 391 379 368 356 345 333 322 310 300

425M 3.00 475 463 451 439 427 415 403 391 379 367 355

425N 5.00 565 553 541 529 517 505 493 481 469 457 445

425P 7.50 645 633 621 609 597 585 573 561 549 537 525

425R 10.00 690 675 660 646 631 617 602 588 573 559 545

Actual speeds may vary as much as ±5%. Based on motor RPM of 1725.

Page 5

Page 6

Belt Drive

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

8

No. Description Qty. No. Description Qty.

1 Motor Cover 1 15 Shaft and Bearing Assembly* 1

2 Disconnect Switch 1 16 Bearing Compartment Bottom 1

3 Motor Base 1 17 Bottom Panel 1

4 Motor Base Rails 2 18 Motor Compartment Back 1

5 Motor Rail Supports 2 19 Outlet Frame 1

6 Motor Support Brackets 2 20 Fan Sheave* 1

7 Impeller* 1 21 Bearing Base 1

8 Bearing Compartment Top 1 22 Rain Shield 1

9 Inlet Orifice 1 23 Bearing Compartment Top 1

10 Bearing Compartment Front 1 24 Belt Tube 1

11 Side Panels 4 25 Top Panel 1

12 Access Panels 2 26 Belt* 1

13 Bearing Compartment Side 2 27 Motor Sheave* 1

14 Bearing Cap 1 28 Motor* 1

*Recommended spare parts.

PARTS LIST LEGEND

Page 6

Page 7

Direct Drive

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

No. Description Qty. No. Description Qty.

1 Motor Base 1 10 Motor Compartment Front 1

2 Motor* 1 11 Access Panels 2

3 Breather Tube 1 12 Side Panels 4

4 Wiring Post 1 13 Motor Compartment Side 2

5 Disconnect Switch 1 14 Bottom Panel 1

6 Top Panel 1 15 Motor Compartment Bottom 1

7 Motor Compartment Top 1 16 Outlet Frame 1

8 Impeller* 1 17 Motor Compartment Back 1

9 Inlet Orifice 1

*Recommended spare parts.

PARTS LIST LEGEND

Page 7

Page 8

ACCEPTANCE All orders and sales are subject to

written approval and acceptance by an executive offi

cer of the Company at Muskogee, Oklahoma, and are

not binding on the Company until so approved.

DELIVERY All shipping and delivery dates are esti

mated only. No delays in delivery will subject the

Company to any costs, damages or fees for late deliv

ery. Delivery of the products herein specified shall be

made F.O.B. point of shipment, unless otherwise

stated. The Company shall not be liable for delay due

to causes beyond its reasonable control, such as Acts

of God, acts of the purchaser, acts of civil or military

authorities, priorities, fires, strikes, floods, epidemics,

war, riots, delays in transportation, car shortages, and

inability, due to reasons beyond its reasonable control,

to obtain necessary labor, material, or manufacturing

facilities. In the event of such a delay, the date of deliv

ery shall be extended for a period equal to the time lost

by reason of the delay.

TERMS OF PAYMENT If, in the judgment of the Com

pany, the financial condition of the purchaser at any

time does not justify continuation of manufacture or

shipment on the terms of payment specified, the Com

pany may require full or partial payment in advance.

Pro rata payments shall become due as shipments are

made. Each shipment or delivery shall constitute a

separate sale, and the default of any shipment or deliv

ery shall constitute a separate sale, and the default of

any shipment or delivery shall not vitiate the contract

as to other shipments or deliveries.

SALES AND SIMILAR TAXES The Company’s prices

do not include sales, use, excise, or similar taxes.

Consequently, in addition to the price specified herein,

the amount of any present or future sales, use, excise,

or other similar tax applicable to the sale of the product

herein shall be paid by the Purchaser, or in lieu thereof

TERMS AND CONDITIONS OF SALE

the Purchaser shall provide the Company with a tax

exemption certificate acceptable to the taxing authori

ties.

CANCELLATION Any contract resulting from the Pur

chaser’s order may be canceled by the Purchaser only

by negotiations and upon payments of reasonable can

cellation charges which will take into account expenses

already incurred and commitments made by the Com

pany.

DESIGN CHANGES The Company reserves the right

to make changes in design, improvements and addi

tions in and to its products any time without imposing

any liability or obligations to itself to apply or install the

same in any product manufactured by it.

TITLE The title and right of possession of the products

-

sold herein shall remain with the Company and such

products shall remain personal property until all

payments herein (including deferred payments whether

evidenced by notes or otherwise) shall have been

made in full in cash and the Purchaser agrees to do all

acts necessary to perfect and maintain such right and

title in the Company.

PRICE ADJUSTMENTS Prices are subject to change

upon notice by the Company. Prices on existing or

ders are subject to surcharges in the event of cost in

creases of metals and transportation. All complete

-

component accessory material manufactured by others

and furnished with the Company’s products such as

motors, drives, vibration equipment, controls or other

completely assembled component structures, are sub

ject to adjustment to the price at time of shipment re

gardless of the date of original order entry.

SAFETY ACCESSORIES The Company manufactures

products designed to serve multiple applications and

offers a wide range of safety equipment, including

guards and other devices, as may be required to meet

customer specifications. Without exception, the Com

pany recommends that all orders include applicable

safety devices. Products ordered without applicable

safety devices is clearly the responsibility of the Pur

chaser. Further, the Purchaser warrants that it has de

termined and acquired any and all safety devices re

quired for products sold by the Company. Weather

covers and guards for motor and V-belt drives, cou

plings, shafts and bearings, along with inlet and outlet

screens, are optional accessories noted in the price

list.

GOVERNING LAW The rights, obligations and reme

dies of Purchaser and the Company, the interpretation

of these terms and conditions and the sale of products

by the Company shall be governed by Oklahoma law,

without regard to any principles of conflict of laws.

ARBITRATION Any dispute arising under or in con

nection with these terms and conditions or the sale of

products shall be settled by binding arbitration admin

istered by the American Arbitration Association under

its Commercial Arbitration Rules, and judgment on the

award rendered by the arbitrator may be entered in

any court having jurisdiction thereof. The dispute shall

-

be resolved by one neutral arbitrator who shall have no

-

affiliation with either Purchaser or the Company and

shall be selected by the American Arbitration Associa

tion office in Dallas, Texas. The arbitration proceed

ings shall be held in Muskogee, Oklahoma.

APPLICABLE DOCUMENTS The agreement be

tween the Company and the Purchaser relating to the

products includes these terms and conditions of sale,

any applicable installation and maintenance instruc

tions provided by the Company and any terms appear

ing on the Company’s quotation, sales order acknowl

edgment and invoice.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

WARNING The Company products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of defects. Even reliable prod

ucts will experience occasional failures and this possibility should be recognized by the Purchaser and all End Users. If these products are used in a life support ventilation sys

tem where failure could result in loss or injury, the Purchaser and all End Users should provide adequate back-up ventilation, supplementary natural ventilation or failure alarm

system, or acknowledge willingness to accept the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials unless unit is specifically built for hazardous environments. Comply with all local and national safety codes including the National Electrical Code (NEC) and National Fire Protection Act (NFPA).

CAUTION Guards must be installed when fan is within reach of personnel or within eight (8) feet (2.5 m) of working level or when deemed advisable for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products accurately in all Company literature; however such illustrations and descriptions

are for the sole purpose of identification and do not express or imply any warranty.

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: the Company ex-

tends this limited warranty to the original purchaser

and warrants that products supplied by the Company,

shall be free from original defects in workmanship and

materials for two years from date of shipment (except

for the warranty periods noted for products listed be

low), provided same have been properly handled,

stored, installed, serviced, maintained and operated.

This warranty shall not apply to products which have

been altered or repaired without the Company’s ex

press authorization, or altered or repaired in any way

so as, in the Company’s judgment, to affect its perfor

mance or reliability, nor which have been improperly

installed or subjected to misuse, negligence, or acci

dent, or incorrectly used in combination with other sub

stances. The Purchaser assumes all risks and liability

for results of use of all products.

Evaporative cooling pads are warranted to be free of

defects in materials and workmanship for a period of

two years from date of shipment provided same have

been properly handled, stored, installed, serviced,

maintained and operated; and further, not subjected to

excessive heat, corrosive agents or chemicals, or me

chanical abuse that may cause tearing, crushing or un

due deterioration, nor used on a system or in a manner

other than that for which it was designed as explained

in the product literature.

The following products are warranted to be free of de

fects in materials and workmanship for the periods

shown from date of shipment: the Company’s exclu

sive duplex split pillow block bearings and shaft five

years, belts one year, Polyethylene tubing 90 days,

AIR40 Heater warranty one year, AIR40 Emitter war

ranty three years and DDP fan lifetime warranty on its

propeller, cone, and housing.

LIMITATION OF REMEDY AND DAMAGES: All

claims under this warranty must be made in writing and

delivered to P. O. Box 978, Muskogee, Oklahoma,

74402, within 15 days after discovery of the defect and

prior to the expiration of two years from the date of

shipment by the Company of the product claimed de

fective, and Purchaser shall be barred from any

remedy if Purchaser fails to make such claim within

such period.

Within 30 days after receipt of a timely claim, the Com

pany shall have the option either to inspect the product

while in Purchaser's possession or to request Pur

chaser to return the product to the Company at Pur

chaser's expense for inspection by the Company. The

Company shall replace, or at its option repair, free of

charge, any product it determines to be defective, and

it shall ship the repaired or replacement product to

Purchaser F.O.B. point of shipment; provided, how

-

ever, if circumstances are such as in the Company’s

judgment to prohibit repair or replacement to remedy

the warranted defects, the Purchaser's sole and exclu

sive remedy shall be a refund to the Purchaser of any

-

part of the invoice price, paid to the Company, for the

defective product or part.

The Company is not responsible for the cost of re

-

moval of the defective product or part, damages due to

-

removal, or any expenses incurred in shipping the

product or part to or from the Company’s plant, or the

installation of the repaired or replaced product or part.

The warranties set forth above do not apply to any

components, accessories, parts or attachments manu

factured by other manufacturers; such being subject to

the manufacturer’s warranty, if any. To the extent not

prohibited by the manufacturer’s warranty, the Com

-

pany shall pass through to Purchaser such manufac

-

turer’s warranty.

THE COMPANY’S WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

ARISING BY LAW OR OTHERWISE, INCLUDING

WITHOUT LIMITATION THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PAR

TICULAR PURPOSE, WHICH ARE HEREBY EX

PRESSLY DISCLAIMED AND WAIVED. THIS WAR

RANTY CONSTITUTES THE COMPANY’S SOLE

AND EXCLUSIVE WARRANTY FOR DEFECTIVE

GOODS AND PURCHASER’S SOLE AND EXCLU

SIVE REMEDY FOR DEFECTIVE PRODUCTS.

No employee, agent, dealer, or other person is autho

rized to give any warranties on behalf of the Company

or to assume for the Company any other liability in

connection with any of its products except in writing

and signed by an officer of the Company.

-

REPLACEMENT PARTS If replacement parts are or

dered, purchaser warrants that the original compo

nents in which these replacement parts will be placed

-

are in satisfactory working condition, and when said re

placement parts are installed, the resultant installation

-

will operate in a safe manner, at speeds and tempera

-

tures for which the original product was purchased.

TECHNICAL ADVICE AND RECOMMENDATIONS,

DISCLAIMER: Notwithstanding any past practice or

dealings or any custom of the trade, sales shall not in

clude the furnishing of technical advice or assistance

-

or system design. Any such assistance shall be at the

Company’s sole option and may be subject to addi

tional charge.

The Company assumes no obligation or liability on ac

count of any recommendations, opinions or advice as

to the choice, installation or use of products. Any such

recommendations, opinions or advice are given and

shall be accepted at Purchaser's and End User's risk

and shall not constitute any warranty or guarantee of

such products or their performance.

LIMITATION OF LIABILITY The cumulative liability of

the Company to the Purchaser and any other persons

for all claims in any way relating to or arising out of the

products, including, but not limited to, any cause of ac

tion sounding in contract, tort, or strict liability, shall not

exceed the total amount of the purchase price paid for

those products which are the subject of any such

claim. This limitation of liability is intended to apply

without regard to whether other provisions of this

agreement have been breached or have proven inef

fective even if the Company has been advised of the

possibility of such claims or demands. In no event

shall the Company be liable to the Purchaser or any

other person for any loss of profits or any incidental,

special, exemplary, or consequential damages for any

claims or demands brought by the Purchaser or such

other persons.

INDEMNITY The Company’s maximum liability to Pur

chaser and to any end user is as set forth above. The

Company makes no warranty to anyone for any prod

ucts not manufactured by the Company and shall have

no liability for any use or installation of any products

(whether manufactured by the Company or other man

ufacturers) not specifically authorized by this sale.

Purchaser acknowledges various warnings by the

Company regarding the products and its installation

-

and use. If the Company incurs any claims, lawsuits,

-

settlements, or expenses (including attorney fees) for

any loss, injury, death or property damage including,

-

but not limited to, claims arising out of the Purchaser’s

or any end user’s installation or use of the products,

-

the Purchaser shall indemnify and hold the Company

harmless.

-

-

-

-

-

-

-

-

-

-

November 2012 613095

Loading...

Loading...