Page 1

Page 2

Quality

and

ervice

S

thatwill

Blowyou Aw a y!

Industry Leadership

Founded in 1938, Acme Engineering and Manufacturing

Corporation is known worldwide as a leader in the

manufacture of fans, blowers, and ventilation equipment.

Acme’s growth over the past half century is a tribute to

superior quality, customer loyalty, and dedicated employees

and sales representatives.

Today, from its headquarters in Muskogee, Oklahoma, Acme

serves customers worldwide with high quality air movement

and control products.

Manufacturing

With approximately 350,000 square feet of manufacturing

space, Acme produces one of the broadest lines of air

moving equipment in the industry. State-of-the-art

manufacturing equipment and a well trained, experienced

workforce is the key to Acme’s timely delivery of

quality air moving products.

Research and Testing

The Acme Research and Development Center operates both

air and sound laboratories. The Center houses four wind

tunnels with a data acquisition system, a reverberant sound

room with the latest sound analyzer equipment, and a

structural laboratory for stress and vibration analysis.

Solid modeling, and finite element analysis support

product research and development. The Center also

houses a fully equipped prototype facility enabling Acme to

develop and introduce new products to the market in the

shortest time possible.

Sales & Service

A factory trained, knowledgeable sales organization

addresses the needs of many diverse and distinct

markets. Customers around the world are serviced by a

complete system of sales representatives, equipment

distributors and local dealers supported by nationwide

distribution centers and backed by a staff of sales and

marketing professionals.

Quality

A highly trained production staff sets the standard for

dependable, quality air moving products. By using the

latest computer techniques for research and design,

and rigorous quality control standards Acme can offer

one of the best warranty programs in the industry. Our

exclusive 2/5 year limited warranty provides our customers

with confidence…Year After Year.

SYMBOL

OF

UAL ITY

Q

Page 3

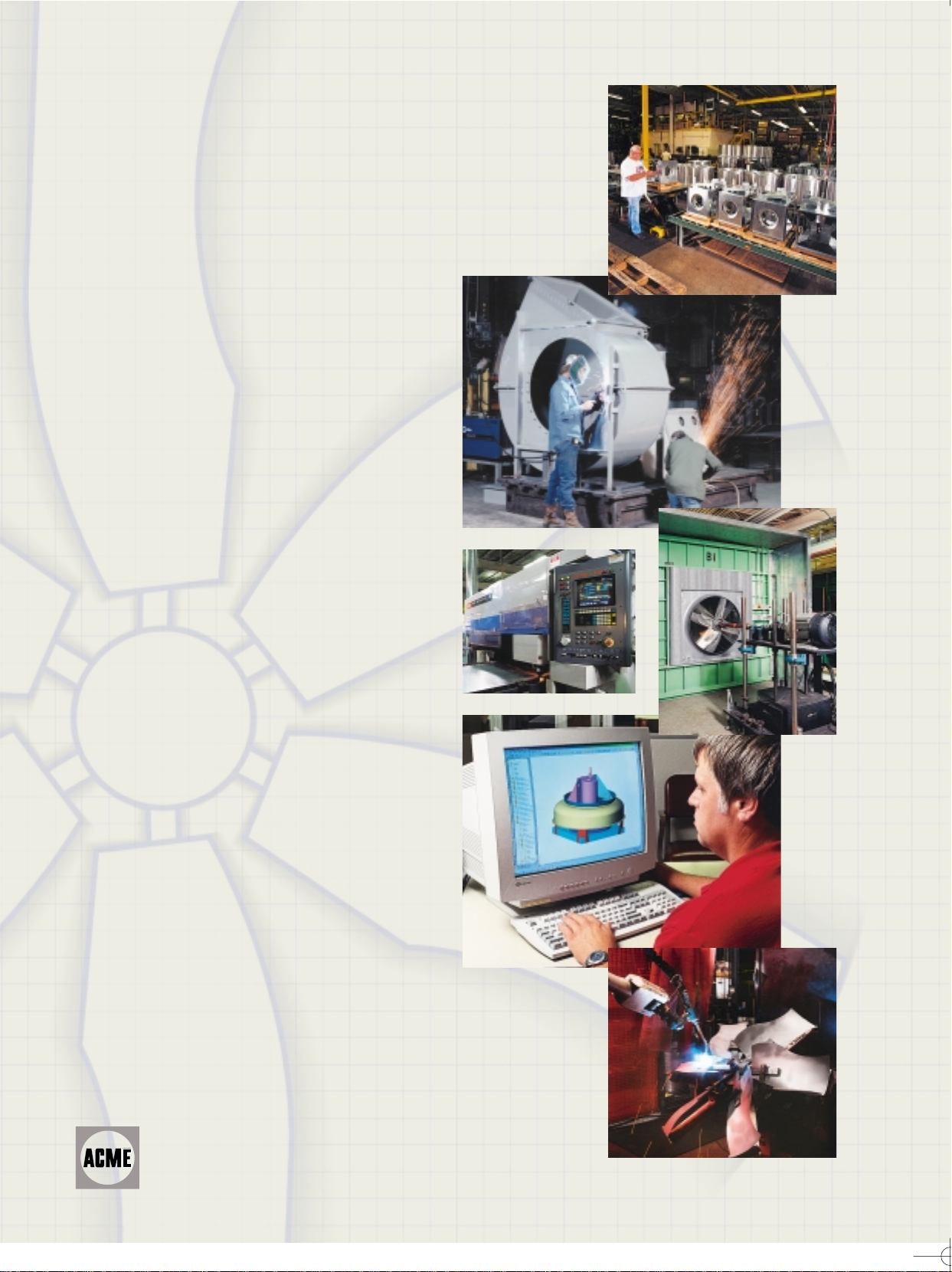

UBG CONSTRUCTION FEATURES

REMOVABLE WINDBAND

Constructed of heavy gauge

galvanized steel. Removable

panels for easy access to fan

and dampers. (Size 72

windband shipped knocked

down; requires field assembly.)

Model UBG low silhouette belt drive exhausters are

ideally suited for moving large volumes of air.

Capacities range from 3,770 to 83,370 CFM and up

to ¾ inch static pressure. The UBG is a high

velocity exhauster design to discharge air up and

away from the building. Typical applications

includes all types of commercial and industrial

facilities such as warehouses, foundries, mills and

manufacturing plants.

BUTTERFLY DAMPERS

Constructed of aluminum for

ease of opening at low

velocities. Dampers provide

weather protection and

prevents backdrafts when fan

is not in operation.

LIFTING EYES

For ease in lifting onto the

roof deck.

BASE

Constructed of heavy

gauge galvanized

steel for weather

resistance.

HEAVY DUTY ALUMINUM

PROPELLER

Heavily reinforced, highly

efficient, cambered airfoil

blades, welded to hub and

precision balanced on

corrosion resistant coated fan

shaft.

MOTORS

Heavy-duty type with

prelubricated ball bearings

requiring minimum

maintenance.

DRIVE ASSEMBLY

Designed for 150% of driven

horsepower. Sheaves are

machined cast iron. Belts are

static free and heat and oil

resistant. Shafts have corrosion

resistant coating.

Variable speed drives are

standard for 5 HP and smaller.

Fixed speed drives are

standard for 7 ½ and 10 HP.

Pulleys have split taper bushing.

BEARINGS

Permanently lubricated bearings are

used in duplex split pillow block housing.

Bearings are resiliently mounted in

neoprene rings, providing extra

protection and vibration isolation. The

bearing assembly is rated at an L-50 life

of 200,000 hours and features Acme’s 5 year

limited warranty.

3

Page 4

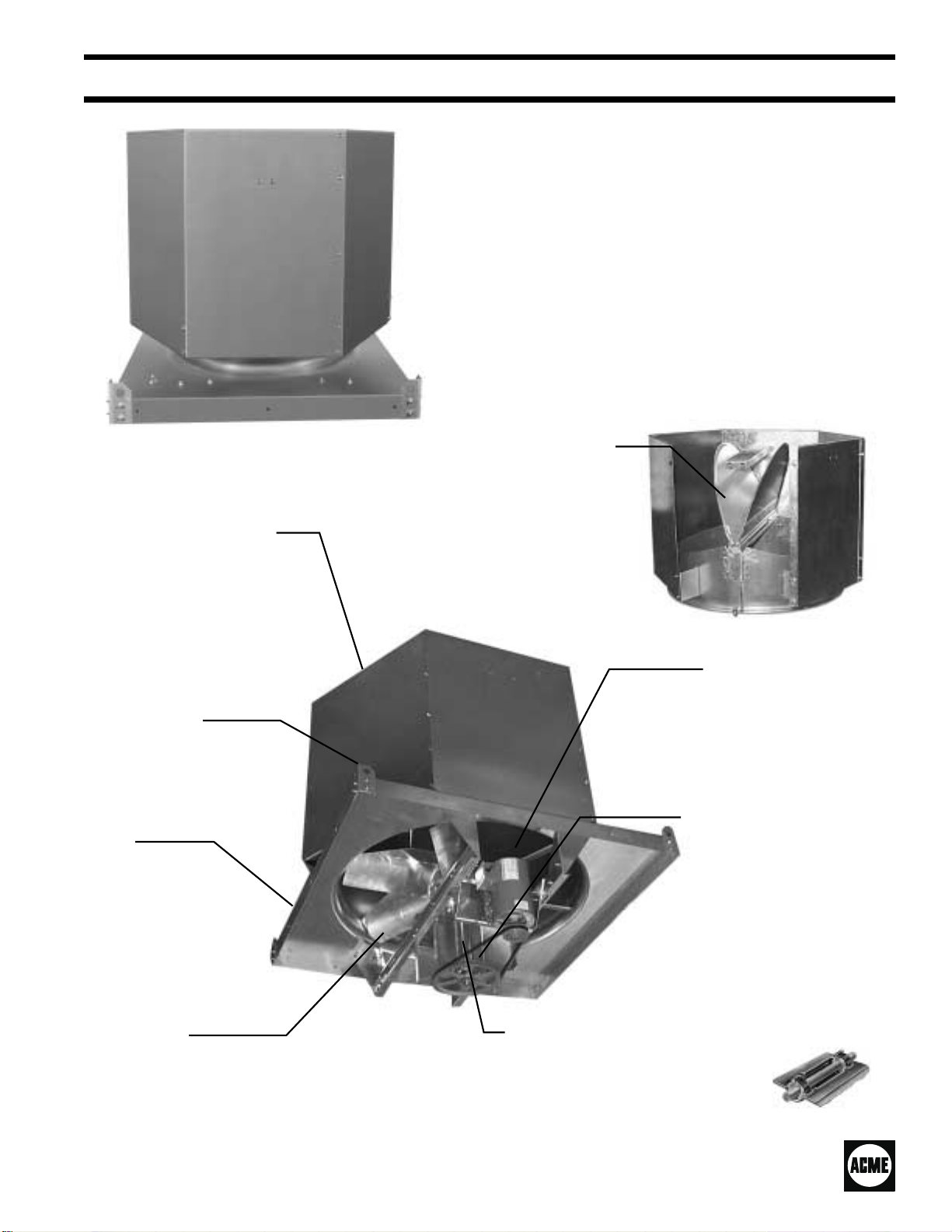

UBGMX CONSTRUCTION FEATURES

Motor Out of Airstream

The UBGMX offers all of the standard construction

features of the UBG in addition to the motor out of the

airstream for ease of servicing and inspection.

Removable motor cover allows quick and easy

access to the motor, belt and drives without removing

the fan.

High Temperature Options

UBGMX exhausters are available with special

features for emergency high temperature exhaust

and smoke removal applications. The table below

lists the specific options and the high temperature

features.

UF Option

500° F for 4 hours

•

1000° F for 15 minutes

•

Construction Features

Hi-Temperature Bearings ··

Copper Lubrication Lines ··

Dual Heat Resistant Belts ··

Heat Slinger ··

Steel Propeller ··

Motor Outside Airstream ··

Ventilated Belt and Bearing Enclosure ··

Fusible Link Damper Lifters ··

Fusible Link Damper Lifters Capable of

Lifting 10 lbs./sq. ft., meets UL793.

UL Listed “Power Ventilator for Smoke

Control Systems”

Note: Exhausters with UF and SE options are constructed to operate

in temperature and time limits stated. Some parts of the fan may be

destroyed when exposed to unusually high temperatures for prolonged

periods.

OptionUFOption

SE

·

·

SE Option

500° F for 4 hours

•

1000° F for 15 minutes

•

Meets UL793 requirements

•

UBGMX exhausters with UF and SE options are designed and constructed to remove high temperature exhaust and smoke.

These specially equipped ventilators meet IRI (Industrial Risk Insurers) requirements for exhausting 500° F air for 4 hours

and SBCCI’s “Standard Fire Prevention Code” requirements for exhausting 1000° F air for 15 minutes. The Butterfly

Damper on the SE option meets the requirements of UL 793 for automatically opening under snow or dust load in an

emergency situation.

4

Page 5

Model RPM

745

780

UBG24

UBG30

UBG36

UBG42

896

1025

1128

593

608

696

729

766

877

965

503

523

529

582

644

667

733

839

406

447

500

512

563

639

645

764

UBG PERFORMANCE DATA

CFM vs. STATIC PRESSURE

.000” .125” .250” .375” .500” .625” .750”

Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP

5059 3769

13.5 0.30 13.5 0.31

5296 4175

14.7 0.35 14.6 0.36

6084 5175

17.3 0.53 17.1 0.54

6960 6222

20 0.79 19.7 0.81

7659 6998 6145

24 1.05 24 1.08 24 1.08

8109 6543

15.8 0.48 16.0 0.51

8314 6795

16.6 0.51 16.8 0.55

9517 8238

19.5 0.77 19.2 0.82

9968 8766

21 0.88 21 0.94

10474 9351

24 1.02 22 1.08

11992 11038 9896

27 1.53 27 1.61 26 1.65

13195 12328 11339 9762

31 2.04 31 2.12 31 2.18 34 2.16

11784 9343

16.8 0.64 16.7 0.70

12253 9958

24 0.72 21 0.78

12393 10133

23 0.74 22 0.81

13635 11650

22 0.99 22 1.06

15087 13375

23 1.34 22 1.42

15626 14004 11605

24 1.49 24 1.58 24 1.62

17172 15711 13890

28 1.97 28 2.07 28 2.16

19656 18379 16924 15022

34 2.96 34 3.07 34 3.18 34 3.24

15263 12295

15.2 0.70 14.9 0.79

16804 14152

18.1 0.94 17.8 1.04

18797 16480 13882

23 1.31 22 1.42 22 1.51

19248 16999 14462

23 1.41 22 1.52 23 1.61

21165 19160 16871

27 1.87 26 2.00 27 2.11

24022 22256 20319 18285

32 2.73 33 2.88 32 3.02 34 3.13

24248 22498 20585 18571

32 2.81 34 2.96 33 3.10 34 3.21

28721 27244 25750 24054 22354 20648

44 4.67 44 4.85 50 5.03 51 5.18 46 5.31 43 5.42

HP

1/3

1/2

3/4

1

1/2

3/4

1

11/2

2

3/4

1

11/2

2

3

1

11/2

2

3

5

Variable speed range shown by arrows.

Performance shown is for Installation Type A: Free Inlet, Free Outlet.

Performance ratings include the effects of the damper in the airstream. Power

rating (BHP) does not include drive losses.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524 m)

in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type A: Free Inlet fan sone levels.

Brake horsepower capability of an exhauster motor is dependent on the degree of

cooling the motor receives from the air moving through the motor. Motor loading

beyond the motor nameplate rating on Acme built exhausters does not overheat the

motor and is in accordance with the motor manufacturer’s recommendations. It is

therefore not detrimental to the motor and is economically desirable.

5

Page 6

Model RPM

409

420

462

524

UBG48

530

583

628

719

346

388

414

444

UBG54

487

526

603

664

322

362

414

UBG60

429

491

541

207

275

322

UBG72

368

406

464

UBG PERFORMANCE DATA

CFM vs. STATIC PRESSURE

.000” .125” .250” .375” .500” .625” .750”

Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP

21976 18492

21 1.31 21 1.45

22567 19177

22 1.42 22 1.57

24824 21753 18275

26 1.89 25 2.06 26 2.18

28155 25464 22649

32 2.76 32 2.98 30 3.10

28477 25818 23061

32 2.86 32 3.08 30 3.20

31325 28908 26438 23619

38 3.80 38 4.05 35 4.20 36 4.35

33743 31500 29218 26788

44 4.75 44 5.02 40 5.21 40 5.35

38633 36673 34704 32690 30504 27583

53 7.13 53 7.43 53 7.71 49 7.87 52 8.05 55 8.15

24877 20434

21 1.41 21 1.54

27897 24016

25 1.99 24 2.16

29767 26190 21882

27 2.42 26 2.59 27 2.66

31924 28659 24831

31 2.98 29 3.17 30 3.27

35015 32139 28697 24718

36 3.94 36 4.14 34 4.30 34 4.31

37819 35165 32037 28686

39 4.96 39 5.18 37 5.41 37 5.46

43356 41040 38487 35713 32696

52 7.47 52 7.72 47 7.98 48 8.17 48 8.23

47742 45639 43461 40918 38428 35553

59 9.97 59 10.25 59 10.53 53 10.83 57 10.92 58 11.01

33408 27995

22 2.09 22 2.27

37558 32901 25971

27 2.97 27 3.19 27 3.19

42953 38881 34284

32 4.45 32 4.70 31 4.88

44509 40580 36228

36 4.95 34 5.21 34 5.41

50941 47509 44040 39884

47 7.41 44 7.71 44 8.01 44 8.18

56129 53013 49898 46367 42292

52 9.91 52 10.24 48 10.58 48 10.82 48 10.97

37195

14 1.27

49413 41808

24 2.98 24 3.29

57858 51360 43496

32 4.79 32 5.21 31 5.52

66124 60386 54633 46908

40 7.15 40 7.68 40 7.95 39 8.25

72952 67723 62678 56237 49707

47 9.60 47 10.22 47 10.55 46 10.98 45 10.89

83373 78777 74343 69799 63709 57978 36954

59 14.32 59 15.07 59 15.57 58 15.87 58 16.45 58 16.42 58 15.57

1 1/2

HP

2

3

5

71/2

2

3

5

71/2

10

3

5

71/2

10

3

5

71/2

10

15

Variable speed range shown by arrows. Shaded lines represent fixed speed

for 7 ½ HP, 10 HP and 15 HP.

Performance shown is for Installation Type A: Free Inlet, Free Outlet.

Performance ratings include the effects of the damper in the airstream. Power

rating (BHP) does not include drive losses.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524 m)

in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type A: Free Inlet fan sone levels.

Brake horsepower capability of an exhauster motor is dependent on the degree of

cooling the motor receives from the air moving through the motor. Motor loading

beyond the motor nameplate rating on Acme built exhausters does not overheat

the motor and is in accordance with the motor manufacturer’s recommendations. It

is therefore not detrimental to the motor and is economically desirable.

6

Page 7

Model RPM

781

UBGMX24

UBGMX30

UBGMX36

UBGMX42

UBGMX48

UBGMX54

897

1027

1130

629

720

792

907

998

525

578

662

728

834

452

518

570

652

773

413

454

520

616

705

374

428

507

581

639

UBGMX PERFORMANCE DATA

CFM vs. STATIC PRESSURE

.000” .125” .250” .375” .500” .625” .750”

Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP

4715 4166

13.1 0.35 13.1 0.36

5416 4971 3864

16.7 0.53 16.6 0.55 18.0 0.51

6200 5824 5303

21 0.80 21 0.82 23 0.82

6822 6484 6076 5281

24 1.07 24 1.08 25 1.09 25 1.07

7309 6281

14.3 0.52 13.4 0.54

8366 7557

18.1 0.78 17.3 0.81

9203 8492 7180

21 1.04 20 1.07 20 1.09

10539 9935 9144

26 1.57 25 1.60 25 1.63

11596 11053 10416 9348

30 2.09 29 2.12 29 2.14 30 2.16

11214 9556

15.4 0.78 14.8 0.81

12346 10956

18.1 1.04 18.3 1.08

14140 12991 10977

23 1.57 23 1.61 24 1.64

15550 14525 13101

26 2.09 26 2.13 27 2.18

17814 16934 15909 14246 9332

33 3.15 33 3.19 34 3.25 34 3.30 34 2.86

15425 12282

15.4 1.03 16.5 1.09

17677 15110

22 1.55 21 1.62

19452 17176 13869

24 2.07 25 2.17 24 2.14

22250 20302 17950 14380 11811

30 3.09 32 3.21 30 3.29 31 3.12 31 3.26

26379 24757 22992 20815 17736 15149 13337

41 5.16 42 5.30 41 5.43 41 5.47 41 5.24 40.0 5.25 39.0 5.58

21355 17356

17.7 1.53 19.0 1.63

23475 19959

21 2.03 23 2.15

26888 23901 19996

27 3.06 30 3.20 27 3.25

31852 29372 26602 22751 17193

35 5.09 39 5.27 36 5.40 42 5.40 42 5.43

36454 34302 32018 29376 25710 20563 17637

43 7.60 50 7.84 45 8.02 53 8.12 53 8.08 53 8.08 53 8.46

27417 22493

18.2 2.03 19.4 2.16

31375 27242 20771

23 3.05 24 3.22 23 3.22

37166 33761 29755 22907

29 5.07 35 5.29 32 5.40 39 5.34

42591 39648 36444 32440 25817 21024

40 7.60 46 7.89 41 8.08 48 8.10 48 8.03 48 8.40

46843 44177 41361 38146 33863 27411 23264

46 10.16 53 10.44 47 10.68 55 10.81 55 10.79 55 10.71 55 11.10

1/2

3/4

1

1 1/2

2

1/3

3/4

1

1 1/2

2

71/2HP

3

HP

1/2

11/2

71/2

3/4

1

1

11/2

2

2

3

2

3

5

3

5

5

10

Variable speed range shown by arrows. Shaded lines represent fixed speed

for 7 ½ HP, and 10 HP.

Performance shown is for Installation Type A: Free Inlet, Free Outlet.

Performance ratings include the effects of the damper in the airstream. Power

rating (BHP) does not include drive losses.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524 m)

in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type A: Free Inlet fan sone levels.

The brake horsepower capability of an exhauster motor is dependent on the

degree of cooling the motor receives from the air moving through the motor.

The motor loading beyond the motor nameplate rating on Acme built

exhausters does not overheat the motor and is in accordance with the motor

manufacturer’s recommendations. It is therefore not detrimental to the motor

and is economically desirable.

7

Page 8

Model RPM

360

UBGMX60

UBGMX72

426

488

537

266

315

361

397

455

UBGMX PERFORMANCE DATA

CFM vs. STATIC PRESSURE

.000” .125” .250” .375” .500” .625” .750”

Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP Sone BHP

36221 30668

21 3.08 22 3.26

42861 38323 32586

28 5.10 31 5.30 28 5.40

49099 45189 40793 34516 25988

35 7.67 40 7.96 37 8.15 44 8.13 44 8.24

54029 50495 46686 42077 34729 27836 24327

43 10.23 49 10.54 43 10.70 52 10.89 49 10.76 49 11.00 50 11.70

46093 36622

21 3.07 19.0 3.27

54583 47070 34659

26 5.10 24 5.30 24 5.37

62554 56147 48207 34558

31 7.69 31 8.04 32 8.19 31 8.17

68792 63019 56433 46332 34907

35 10.22 37 10.62 34 10.87 34 10.79 34 11.12

78842 73846 68488 62107 52336 41703 36304

45 15.39 51 15.86 46 16.23 46 16.40 46 16.23 49 16.52 40 17.60

HP

71/2

71/2

10

3

5

10

3

5

15

Variable speed range shown by arrows. Shaded lines represent fixed speed

for 7 ½ HP, 10 HP and 15 HP.

Performance shown is for Installation Type A: Free Inlet, Free Outlet.

Performance ratings include the effects of the damper in the airstream. Power

rating (BHP) does not include drive losses.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524 m)

in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type A: Free Inlet fan sone levels.

The brake horsepower capability of an exhauster motor is dependent on the

degree of cooling the motor receives from the air moving through the motor.

The motor loading beyond the motor nameplate rating on Acme built

exhausters does not overheat the motor and is in accordance with the motor

manufacturer’s recommendations. It is therefore not detrimental to the motor

and is economically desirable.

8

Page 9

DIMENSIONAL DATA

Fan

Model

UBG24 36.00 31.40 37.18 12.07 27.72 C34.5 157 245

UBG30 42.00 38.08 43.14 13.95 34.25 C40.5 230 332

UBG36 48.00 39.37 49.12 13.95 41.89 C46.5 273 396

UBG42 54.00 38.49 56.11 14.59 47.65 C52.5 326 452

UBG48 60.00 45.72 62.21 20.45 53.65 C58.5 473 602

UBG54 66.00 52.96 69.31 22.07 59.73 C64.5 612 744

UBG60 72.00 58.09 79.15 22.03 65.84 C70.5 674 824

UBG72 90.00 63.25 95.68 29.34 79.61 C88.5 828 1125

Fan

Model

UBGMX24 36.00 55.06 37.18 23.71 14.21 C34.5 312 401

UBGMX30 42.00 62.01 43.17 24.65 14.20 C40.5 427 528

UBGMX36 48.00 63.50 49.14 24.65 14.38 C46.5 530 674

UBGMX42 54.00 67.02 56.45 28.30 15.76 C52.5 601 744

UBGMX48 60.00 74.03 62.40 29.18 16.56 C58.5 781 954

UBGMX54 66.00 86.40 69.68 33.73 18.71 C64.5 965 1157

UBGMX60 72.00 91.65 79.46 33.73 18.79 C70.5 1065 1264

UBGMX72 90.00 102.40 95.68 39.17 21.78 C88.5 1343 1675

ABCFG

ABCRS

Curb

Model

Curb

Model

Est. Unit

Wt. Lbs.

Est. Unit

Wt. Lbs.

Est. Ship

Wt. Lbs.

Est. Ship

Wt. Lbs.

UBGMXUBG

Typical drawings are for dimensional purposes only which are correct within limits suitable for normal installation requirements and do not

necessarily show actual construction. All dimensions are in inches.

9

Page 10

OPTIONAL ACCESSORIES

Fusible Link Damper Lifters automatically open the

dampers when the air temperature exceeds 165°F.

Prefabricated Roof Curbs lined with fiberglass insulation

to reduce condensation and sound levels. Insures

compatibility between the fan and mounting curb.

Disconnect Switches for positive electrical shut-off and

safety when servicing fans. Switch is factory mounted on

bottom side of exhauster base housing through 1.50 HP

single phase and 2 HP three phase. Switch extends through

base and is operated from outside of exhauster for

maximum safety when servicing. For 3 HP and above,

NEMA 3R raintight switches mounted above curbcap.

Aluminum Construction is available for windbands and

curbcaps.

Energy Efficient Motors are available for most sizes.

Contact the factory for specific efficiency data.

Outlet Guards of heavy gauge steel mesh shield the fan

discharge from debris.

Steel Propellers are available with an acrylic epoxy finish.

Unitary Pillow Block Bearings are available with external

lube fitting when relubricatable bearings are required.

Magnetic Latches are available to minimize damper flutter

when fan is not in operation.

Coatings Aluminum and galvanized components remain

unpainted as a standard finish, but when required, are

processed through the finishing system to apply decorative

or special coatings. A high turbulence oven is used to

produce a baked on finish for most special coatings.

Decorative coatings are not baked on.

Decorative Coating Acme offers 16 popular colors for

decorative finishes utilizing an industrial grade enamel

applied to the exterior of the fan.

Note: For any coating selected, the user assumes

responsibility for the ultimate effect on the coating and

equipment due to the corrosive agent, its concentration,

temperature and moisture content.

Belt Cover is available with UBGMX to isolate the belt and

drive components from airstream contaminants (standard

with UF and SE options). Performance can be estimated

by applying a 7.5% reduction on the system curve when

using the belt cover.

Special Coatings Products receiving special coatings

have components painted before assembly. Fasteners are

not painted.

Acrylic Epoxy This product provides a more durable

•

surface.

Carboline Sanitile (Eisenheiss) This air dry synthetic

•

polyester forms a black coating that offers greater

resistance to most organic and inorganic acids.

Heresite (Air Dry) A phenolic coating with greater

•

resistance to most organic and inorganic acids.

Insulmastic A black asphalt based mastic that provides

•

some condensation control, sound deadening and

corrosion resistance.

10

Page 11

TYPICAL SPECIFICATIONS

The upblast roof exhaust ventilators shall be belt driven axial

type. Motors shall be heavy duty, ball bearing type, matched

to the fan load.

Propellers shall be constructed of die-formed aluminum

blades welded to an aluminum hub. Propellers shall be

statically and dynamically balanced. Propellers shall be

mounted securely to shaft. Shafts shall be coated for

corrosion resistance.

Windband shall be hexagonal in shape with removable

panel(s) for easy access to motor, drives and propeller.

Pre-lubricated ball bearings shall be mounted in a duplex split

pillow block housing for accurate alignment and rated at L-50

life of 200,000 hours. Bearings shall be resilient mounted in

neoprene rings providing protection and vibration isolation

(Size 72 standard with unitary pillow block bearings).

The drive frame, windband and curbcap shall be fabricated of

heavy duty galvanized material.

Drives for belt drive fans shall have machined cast iron

pulleys with variable pitch motor and sized for 150% of driven

horsepower. Belts shall be static free and oil and heat

resistant. Fan shall have a corrosion resistant coating.

The butterfly dampers shall be of aluminum construction.

Fans shall bear the AMCA Certified Ratings Seal for Sound

and Air Performance.

Fan shall be covered with a 2 year limited warranty and a

5 year limited warranty on the duplex split pillow block

bearings and shaft.

Fans shall be model UBG as manufactured by Acme

Engineering & Manufacturing Corp.

For UBGMX insert the following additional requirements:

Motors shall be mounted outside of the airstream. Motor

cover shall be removable for servicing and vented for motor

cooling.

For UBGMX-UF and SE insert the following additional

requirements: Propellers shall be constructed of heavy

gauge galvanized steel blades welded to a steel hub.

Motors shall be mounted outside of the airstream. Motor

cover shall be removable for servicing and vented for motor

cooling.

Belt and drive components shall be enclosed in a heavy duty

galvanized steel cover.

For UBGMX-SE insert the following additional

requirements: Fans shall meet the requirements of UL 793

and UL listed “Power Ventilators for Smoke Control Systems”.

Because of constantly changing developmental research, Acme must reserve the right to change specifications without notice.

Acme Engineering & Manufacturing Corporation certifies that the Model UBG and UBGMX shown herein is licensed to

bear the AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA

Publication 211 and and AMCA Publication 311 and comply with the requirements of the AMCA Certified Ratings

Program.

Most models are available with the UL Listing mark;

consult the Acme representative for availability.

Most models are listed by the Canadian Standards

Association Testing Laboratory as approved.

11

Page 12

CENTRIFUGAL

VENTILATION FANS

DUCT FANS

PROPELLER AND

INLINE CENTRIFUGAL

CEILING, INLINE AND

CABINET FANS

CENTRIFUGAL &

PROPELLER ROOF

EXHAUST FANS

CENTRIFUGAL &

PROPELLER ROOF

SUPPLY FANS

CENTRIFUGAL AIR

HANDLING FANS

CENTRIFUGAL AND

PROPELLER UPBLAST

ROOF EXHAUSTERS

CENTRIFUGAL AND

PROPELLER

WALL FANS

CENTRIFUGAL

INDUSTRIAL

PROCESS FANS

MAKE-UP AIR SYSTEMS

CENTRIFUGAL

HEAVY DUTY

INDUSTRIAL FANS

EXHAUST &

SUPPLY VENTS

LIMITED WARRANTY Acme Engineering

and Manufacturing Corporation warrants the

products manufactured by Acme to be free

from original defects in workmanship and ma

terial for two years subject to the terms and

conditions of its published limited warranty.

Warranties on purchased products are sub

ject to the vendor’s warranty. Refer to current

Form MS149 for complete limited warranty

terms and conditions.

WARNING Acme products are designed and

manufactured to provide reliable perfor

mance but they are not guaranteed to be

100% free of defects. Even reliable products

ACME ENGINEERING &

MANUFACTURING CORP.

P.O. Box 978, Muskogee, Oklahoma 74402

Telephone: 918-682-7791 Fax: 918-682-0134

www.acmefan.com e-mail: acmefan@acmefan.com

will experience occasional failures and this

possibility should be recognized by the User.

If these products are used in a life support

-

ventilation systemwhere failure could result in

loss or injury, the User should provide ade

quate back-up ventilation, supplementary

-

natural ventilation or failure alarm system, or

acknowledge willingness to accept the risk of

such loss or injury.

WARNING DO NOT use in HAZARDOUS

ENVIRONMENTS where fan’s electrical sys

-

tem could provide ignition to combustible or

flammable materials unless unit is specifically

built for hazardous environments.

CAUTION Guards must be installed when fan

is within reach of personnel or within seven (7)

feet (2.134 m) of working level or when

deemed advisable for safety.

DISCLAIMER The Company has made a dili

gent effort to illustrate and describe the prod

ucts in this literature accurately; however, such

illustrations and descriptions are for the sole

purpose of identification, and do not express or

imply a warranty that the products are mer

chantable, or fit for a particular purpose, or that

the products will necessarily conform to the il

lustrations or descriptions or dimension.

Member Air Movement and Control Association

September 2001 Form C78B

-

-

-

-

Loading...

Loading...