Page 1

Page 2

S

ervice

SYMBOL

Q

UAL ITY

OF

Blowyou Aw a y!

thatwill

Quality

and

Industry Leadership

Founded in 1938, Acme Engineering and Manufacturing

Corporation is known worldwide as a leader in the

manufacture of fans, blowers, and ventilation equipment.

Acme’s growth over the past half century is a tribute to

superior quality, customer loyalty, and dedicated employees

and sales representatives.

Today, from its headquarters in Muskogee, Oklahoma, Acme

serves customers worldwide with high quality air movement

and control products.

Manufacturing

With approximately 350,000 square feet of manufacturing

space, Acme produces one of the broadest lines of air

moving equipment in the industry. State-of-the-art

manufacturing equipment and a well trained, experienced

workforce is the key to Acme’s timely delivery of

quality air moving products.

Engineering

The Acme Research and Engineering Center operates both

air and sound laboratories. The Center houses four wind

tunnels with a data acquisition system, a reverberant sound

room with the latest sound analyzer equipment, and a

structural laboratory for stress and vibration analysis.

Solid modeling, and finite element analysis support

product research and development. The Center also

houses a fully equipped prototype facility enabling Acme to

develop and introduce new products to the market in the

shortest time possible.

Sales & Service

A factory trained, knowledgeable sales organization

addresses the needs of many diverse and distinct

markets. Customers around the world are serviced by a

complete system of sales representatives, equipment

distributors and local dealers supported by nationwide

distribution centers and backed by a staff of sales and

marketing professionals.

Quality

A highly trained engineering and production staff set the

standard for dependable, quality air moving products. By

using the latest computer techniques for research and

design, and rigorous quality control standards Acme can

offer one of the best warranty programs in the industry. Our

exclusive 2/5 year limited warranty provides our customers

with confidence…Year After Year.

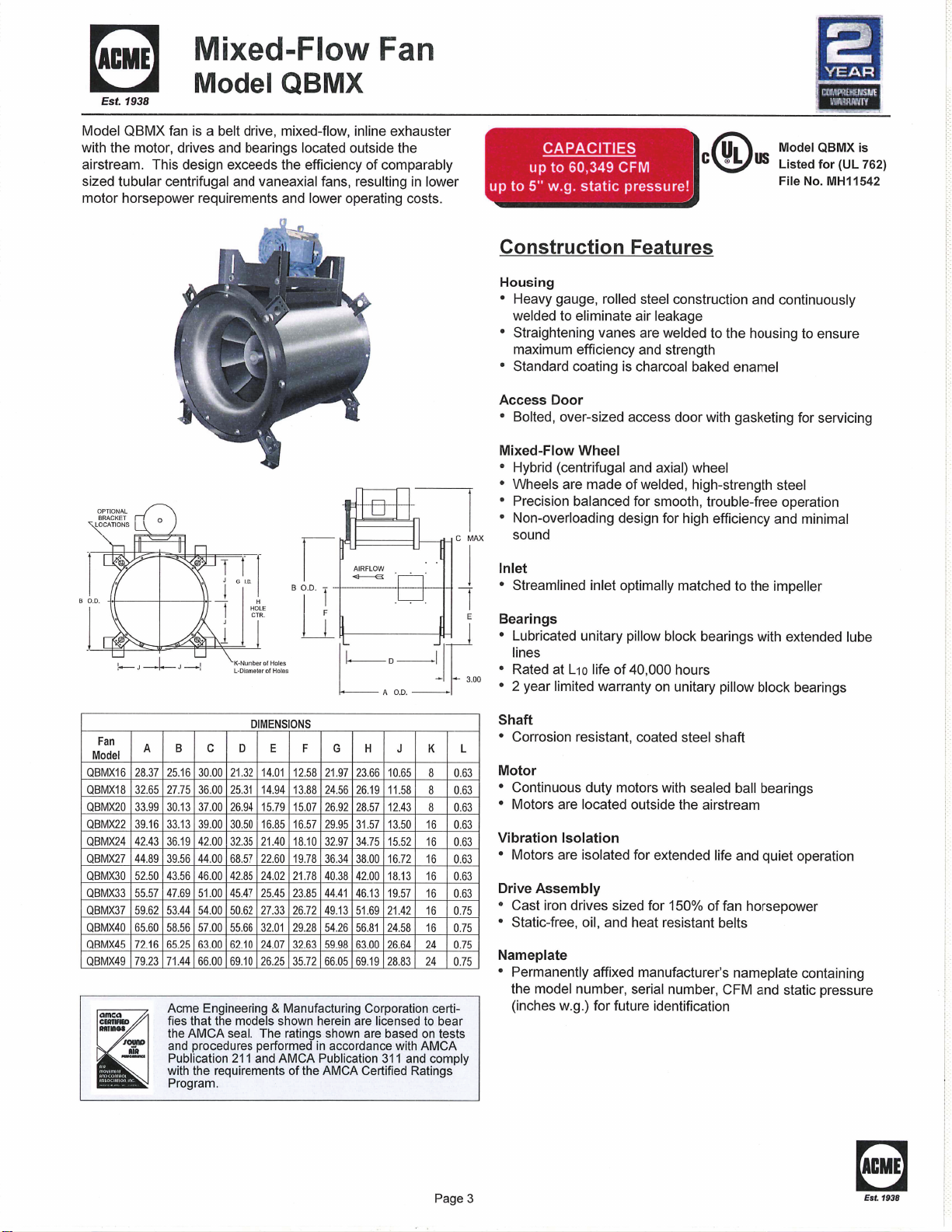

Page 3

Page 4

Options/Accessories

Disconnect Switch

• Nema 3R

• Factory wired and externally mounted (except

explosion proof motors)

Inlet and Outlet Companion Flanges

• Heavy gauge, coated galvanized steel

• Factory mounted

Inlet and Outlet Screens

• Factory mounted, heavy gauge galvanized steel

Weather Cover

• Enclosed, removable motor and belt guard

• Factory mounted

Drain

• 1.5” Drain and drain plug

Isolators

• Hanging Spring

• Hanging Rubber

• Floor Spring

• Floor Rubber

Optional Wheel Material

• Aluminum wheel

Spark Resistant Construction

• AMCA B

Shaft Seal

• Factory mounted

Stainless Steel Tag

• 4” x 2” with model, order number, and tag

information

Optional Coatings

• Acrylic Epoxy

• Decorative Coatings

• Heresite

• Insulmastic

• Special Coatings

Smoke Exhaust Option

The QBMX-SE mixed-flow inline smoke exhauster combines

superior energy efficiency with emergency smoke management

technology. Under severe temperatures, the QBMX-SE is designed

to exhaust life-threatening smoke to provide extra evacuation time.

These power ventilators are intended for installation in buildings in

accordance with requirements contained in the Recommended

Practice for Smoke Control System, NFPA 92A; and are intended to

be connected to and controlled by Listed Smoke Control System

Equipment (UUKL).

Page 4

QBMX-SE

Maximum Temperatures

500°F for 4 hours

1000°F for 15 minutes

Page 5

QBMX16

RPM

903

990

1137

1302

1433

1640

1805

2066

2450

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 2597 2319 1887

BHP 0.18 0.22 0.25

LwA 69 67 65

CFM 2847 2600 2264 1672

BHP 0.23 0.29 0.32 0.33

LwA 71 70 67 67

CFM 3270 3061 2806 2454 1888

BHP 0.35 0.42 0.46 0.50 0.49

LwA 74 73 72 70 70

CFM 3745 3565 3362 3116 2784 2314

BHP 0.53 0.60 0.67 0.71 0.75 0.75

LwA 78 78 76 75 74 73

CFM 4122 3961 3781 3577 3332 3009 2576

BHP 0.70 0.79 0.86 0.92 0.97 1.00 1.00

LwA 80 81 79 78 77 76 76

CFM 4717 4578 4427 4264 4080 3868 3614 3290 2884

BHP 1.05 1.15 1.24 1.32 1.38 1.43 1.48 1.50 1.49

LwA 84 85 83 82 81 80 80 79 79

CFM 5192 5066 4931 4788 4634 4462 4269 4043 3769 3444 3036

BHP 1.40 1.52 1.62 1.71 1.78 1.85 1.91 1.96 1.99 2.00 1.97

LwA 86 87 86 85 84 84 83 82 82 81 82

CFM 5942 5832 5720 5599 5471 5339 5192 5035 4861 4664 4436 4174 3873 3517

BHP 2.10 2.23 2.36 2.47 2.56 2.65 2.74 2.81 2.87 2.93 2.98 2.99 2.99 2.96

LwA 89 91 90 89 88 88 87 87 86 85 85 85 85 85

CFM 7047 6954 6861 6764 6662 6558 6447 6335 6211 6086 5949 5804 5648 5469 5273 5057 4821 4559 4264 3888

BHP 3.50 3.66 3.81 3.96 4.09 4.22 4.32 4.42 4.52 4.62 4.70 4.77 4.85 4.91 4.96 4.99 5.00 4.99 4.96 4.88

LwA 93 95 95 94 93 92 92 92 92 91 91 90 90 90 89 89 89 89 89 90

Static Pressure (inches water gauge)

QBMX18

RPM SP

745

818

939

1075

1183

1354

1491

1706

2023

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 3024 2634 1933

BHP 0.18 0.23 0.25

LwA 67 65 63

CFM 3320 2977 2460

BHP 0.23 0.29 0.33

LwA 70 68 66

CFM 3811 3522 3154 2576

BHP 0.35 0.42 0.48 0.50

LwA 73 72 70 69

CFM 4363 4116 3826 3454 2905

BHP 0.53 0.61 0.68 0.73 0.75

LwA 76 76 74 73 72

CFM 4802 4579 4330 4032 3645 3096

BHP 0.7 0.80 0.88 0.94 0.99 1.00

LwA 79 79 77 76 75 74

CFM 5496 5305 5096 4862 4595 4264 3835 3269

BHP 1.05 1.17 1.27 1.35 1.42 1.47 1.5 1.48

LwA 82 83 81 80 79 78 78 78

CFM 6052 5879 5695 5494 5273 5019 4716 4339 3873 3191

BHP 1.40 1.53 1.65 1.75 1.83 1.90 1.96 2.00 1.99 1.93

LwA 85 86 84 83 82 82 81 80 80 80

CFM 6924 6774 6617 6453 6273 6080 5867 5629 5355 5024 4640 4179

BHP 2.10 2.25 2.39 2.52 2.62 2.72 2.80 2.88 2.95 2.99 3.00 2.98

LwA 88 90 88 87 87 86 85 85 84 84 84 84

CFM 8211 8084 7957 7820 7683 7533 7381 7214 7039 6852 6641 6410 6148 5852 5522 5148 4707

BHP 3.50 3.68 3.87 4.02 4.17 4.29 4.41 4.53 4.63 4.73 4.82 4.90 4.96 4.98 4.99 4.97 4.91

LwA 92 94 93 92 91 91 91 90 90 89 89 88 88 88 88 88 88

Static Pressure (inches water gauge)

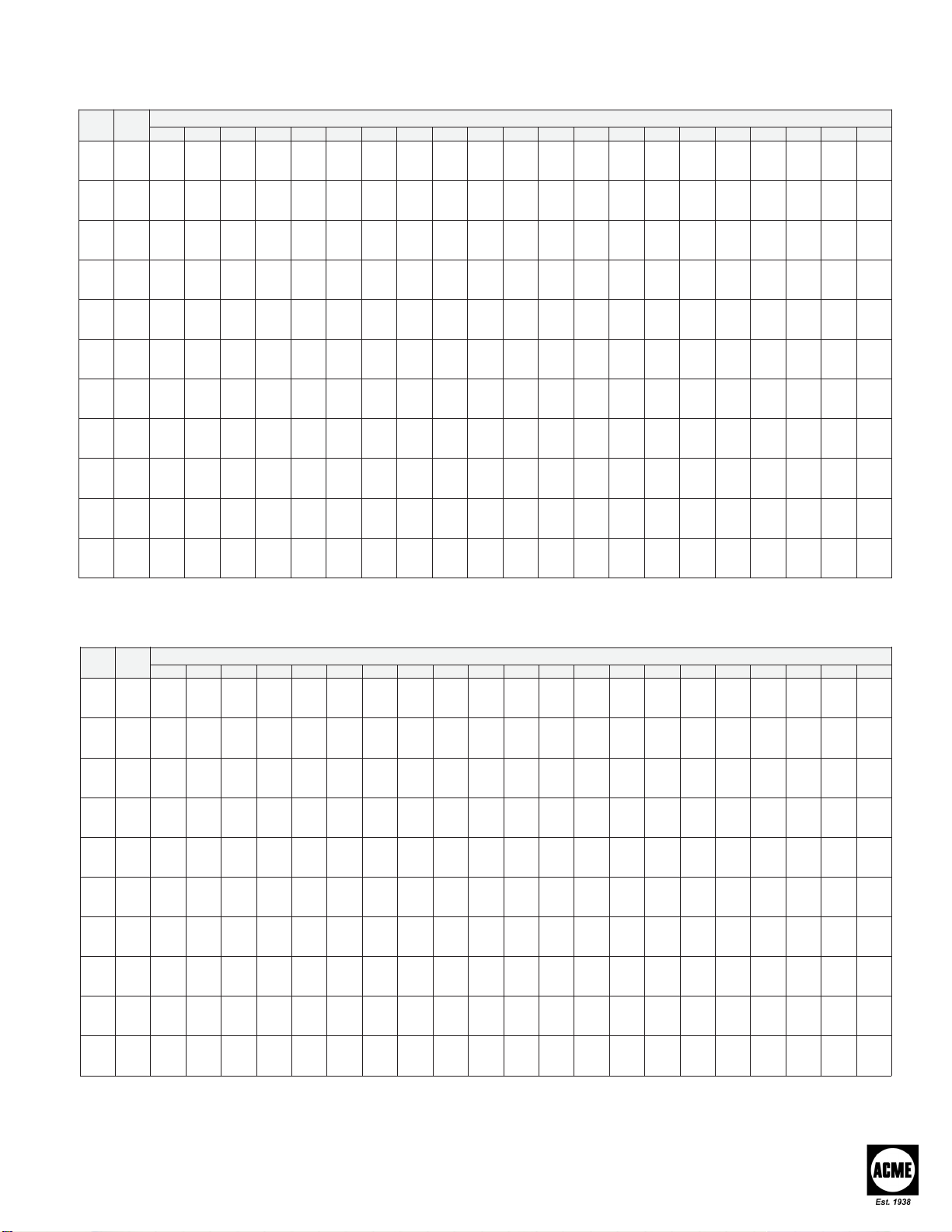

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

Page 5

Page 6

QBMX20

RPM

634

696

799

915

1007

1152

1268

1452

1721

1970

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 3434 2948 1797

BHP 0.18 0.23 0.23

LwA 62 63 62

CFM 3769 3344 2638

BHP 0.23 0.29 0.33

LwA 64 66 64

CFM 4327 3972 3494 2607

BHP 0.35 0.43 0.48 0.49

LwA 68 70 68 67

CFM 4955 4654 4290 3791 2893

BHP 0.53 0.61 0.69 0.74 0.73

LwA 72 74 73 72 71

CFM 5454 5182 4871 4484 3945 2947

BHP 0.71 0.80 0.88 0.96 1.00 0.95

LwA 74 77 76 75 74 73

CFM 6239 6005 5748 5455 5100 4644 3979

BHP 1.06 1.16 1.26 1.36 1.44 1.49 1.48

LwA 78 81 80 79 78 77 76

CFM 6867 6656 6431 6181 5895 5559 5139 4578 3595

BHP 1.41 1.53 1.64 1.75 1.85 1.93 1.98 2.00 1.87

LwA 80 84 83 82 81 80 80 79 79

CFM 7864 7679 7487 7284 7063 6818 6539 6217 5830 5340 4656

BHP 2.11 2.25 2.38 2.51 2.64 2.75 2.85 2.93 2.98 2.99 2.93

LwA 83 87 86 86 85 84 84 83 83 82 82

CFM 9321 9165 9009 8843 8674 8488 8292 8086 7853 7600 7317 6993 6615 6156 5556 4370

BHP 3.52 3.68 3.83 4.00 4.15 4.29 4.44 4.57 4.69 4.80 4.89 4.95 4.99 4.98 4.89 4.46

LwA 88 92 92 91 90 90 89 89 88 88 88 87 87 86 87 86

CFM 10669 10533 10397 10258 10112 9966 9805 9643 9468 9287 9088 8883 8652 8404 8132 7826 7475 7062 6560 5882

BHP 5.28 5.45 5.64 5.83 6.00 6.18 6.35 6.52 6.69 6.83 6.97 7.12 7.23 7.33 7.40 7.46 7.50 7.47 7.39 7.16

LwA 91 95 95 95 94 94 94 93 93 92 92 92 92 91 91 91 90 90 90 90

Static Pressure (inches water gauge)

QBMX22

RPM

524

575

661

756

832

953

1049

1200

1423

1629

1793

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 3996 3305

BHP 0.18 0.24

LwA 61 61

CFM 4385 3791 2521

BHP 0.23 0.30 0.32

LwA 63 64 62

CFM 5041 4551 3822

BHP 0.35 0.44 0.49

LwA 67 68 66

CFM 5766 5350 4822 3993

BHP 0.53 0.62 0.71 0.75

LwA 70 73 71 70

CFM 6345 5973 5532 4937 3950

BHP 0.70 0.81 0.91 0.98 0.98

LwA 73 76 74 73 72

CFM 7268 6948 6591 6163 5616 4809

BHP 1.06 1.18 1.30 1.40 1.48 1.49

LwA 76 80 78 77 76 75

CFM 8000 7713 7399 7043 6622 6089 5349 3749

BHP 1.41 1.55 1.68 1.80 1.91 1.98 1.99 1.78

LwA 79 82 81 80 79 78 78 78

CFM 9152 8902 8638 8350 8031 7669 7238 6709 5992 4794

BHP 2.11 2.26 2.42 2.57 2.70 2.83 2.93 2.98 2.98 2.81

LwA 82 86 85 84 83 83 82 82 81 81

CFM 10853 10642 10427 10200 9957 9699 9419 9104 8753 8351 7871 7283 6497

BHP 3.52 3.71 3.89 4.07 4.25 4.42 4.57 4.71 4.84 4.92 4.99 4.99 4.89

LwA 86 90 90 89 89 88 88 87 87 86 86 85 85

CFM 12424 12240 12056 11861 11664 11452 11232 10994 10747 10470 10172 9846 9480 9061 8566 7968 7190

BHP 5.28 5.49 5.71 5.91 6.13 6.33 6.53 6.71 6.89 7.05 7.19 7.32 7.40 7.48 7.48 7.44 7.28

LwA 90 94 94 93 93 92 92 91 91 91 90 90 90 89 89 88 89

CFM 13675 13508 13340 13169 12990 12810 12615 12416 12206 11985 11751 11500 11228 10943 10617 10261 9864 9409 8872 8224 7297

BHP 7.04 7.28 7.51 7.74 7.98 8.21 8.41 8.63 8.84 9.05 9.23 9.42 9.56 9.70 9.83 9.91 9.98 10.00 9.95 9.80 9.46

LwA 92 96 96 96 95 95 95 94 94 94 93 93 93 92 92 92 92 91 91 91 91

Static Pressure (inches water gauge)

Page 6

Page 7

QBMX24

RPM

441

483

555

635

699

801

881

1009

1196

1369

1507

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 4556 3555

BHP 0.18 0.25

LwA 60 60

CFM 4991 4152

BHP 0.24 0.32

LwA 62 62

CFM 5735 5067 3881

BHP 0.37 0.46 0.50

LwA 66 67 65

CFM 6563 6016 5187

BHP 0.55 0.65 0.74

LwA 69 71 69

CFM 7224 6747 6082 5114

BHP 0.73 0.85 0.96 1.00

LwA 72 74 72 71

CFM 8279 7870 7363 6683 5792

BHP 1.10 1.24 1.37 1.47 1.50

LwA 75 78 77 76 75

CFM 9106 8741 8311 7769 7097 6202

BHP 1.46 1.61 1.76 1.90 1.98 2.00

LwA 78 81 80 78 78 77

CFM 10430 10117 9769 9359 8865 8272 7603 6628

BHP 2.20 2.37 2.54 2.70 2.86 2.96 3.00 2.99

LwA 81 85 84 83 82 81 81 80

CFM 12363 12099 11820 11520 11173 10773 10343 9817 9286 8585 7668

BHP 3.66 3.87 4.07 4.26 4.46 4.66 4.82 4.93 4.98 4.99 4.96

LwA 85 89 88 88 88 87 86 86 85 85 84

CFM 14152 13921 13689 13431 13165 12862 12528 12166 11784 11310 10881 10345 9687 8881

BHP 5.50 5.73 5.96 6.19 6.41 6.64 6.86 7.07 7.25 7.38 7.46 7.49 7.49 7.45

LwA 89 92 92 92 91 91 90 90 90 89 89 88 88 87

CFM 15578 15369 15158 14935 14699 14450 14175 13878 13555 13214 12840 12414 12024 11555 10992 10381 9547

BHP 7.33 7.59 7.85 8.10 8.34 8.59 8.84 9.09 9.33 9.54 9.72 9.85 9.94 9.98 9.99 9.99 9.90

LwA 91 95 95 94 94 94 93 93 92 92 92 92 91 91 90 90 90

Static Pressure (inches water gauge)

QBMX27

RPM

424

487

558

614

703

774

886

1050

1202

1323

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 5517 4505

BHP 0.22 0.31

LwA 63 60

CFM 6337 5523 4060

BHP 0.33 0.45 0.50

LwA 67 65 63

CFM 7261 6585 5632

BHP 0.49 0.64 0.73

LwA 70 70 67

CFM 7989 7391 6616 5441

BHP 0.66 0.82 0.94 0.99

LwA 73 73 70 69

CFM 9147 8637 8028 7256 6135

BHP 0.99 1.17 1.32 1.45 1.49

LwA 76 78 75 73 72

CFM 10071 9615 9092 8465 7679 6532

BHP 1.32 1.52 1.70 1.86 1.96 2.00

LwA 79 81 78 77 76 75

CFM 11528 11139 10704 10211 9649 8973 8118 6703

BHP 1.98 2.21 2.44 2.62 2.80 2.92 2.99 2.94

LwA 82 85 83 81 80 79 79 79

CFM 13662 13334 12984 12608 12196 11741 11230 10647 9962 9088 7505

BHP 3.29 3.56 3.83 4.10 4.32 4.54 4.72 4.86 4.96 5.00 4.80

LwA 87 90 89 87 86 85 84 84 83 83 83

CFM 15640 15353 15061 14744 14409 14056 13667 13247 12789 12282 11709 11044 10201 8890

BHP 4.93 5.24 5.56 5.87 6.15 6.43 6.67 6.91 7.10 7.26 7.39 7.48 7.47 7.31

LwA 90 93 93 92 91 89 89 88 88 87 87 87 87 87

CFM 17214 16954 16694 16411 16123 15810 15491 15138 14769 14376 13940 13470 12951 12362 11671 10792 8876

BHP 6.57 6.92 7.29 7.61 7.95 8.25 8.56 8.84 9.08 9.31 9.50 9.68 9.82 9.92 9.99 9.95 9.35

LwA 92 95 96 95 94 93 92 91 91 91 90 90 90 89 89 89 89

Static Pressure (inches water gauge)

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

Page 7

Page 8

QBMX30

RPM

407

466

515

587

647

740

877

1004

1106

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 7318 6191

BHP 0.33 0.46

LwA 65 63

CFM 8378 7455 6019

BHP 0.49 0.65 0.75

LwA 69 67 65

CFM 9259 8450 7340 4966

BHP 0.67 0.85 0.97 0.96

LwA 72 71 68 68

CFM 10554 9868 9009 7843

BHP 0.99 1.19 1.36 1.47

LwA 75 76 73 72

CFM 11633 11018 10292 9388 8146

BHP 1.32 1.55 1.76 1.91 1.99

LwA 77 80 76 74 74

CFM 13305 12778 12182 11497 10671 9613 7918

BHP 1.97 2.24 2.49 2.70 2.88 2.98 2.96

LwA 81 84 81 79 78 78 78

CFM 15768 15330 14856 14335 13757 13102 12335 11416 10174

BHP 3.28 3.60 3.91 4.19 4.46 4.66 4.84 4.94 4.98

LwA 85 88 87 85 84 83 82 82 82

CFM 18051 17669 17270 16847 16379 15875 15323 14711 14023 13232 12241 10842

BHP 4.93 5.30 5.67 6.00 6.31 6.62 6.86 7.09 7.29 7.43 7.46 7.38

LwA 89 92 91 90 88 88 87 86 86 86 85 86

CFM 19885 19538 19187 18805 18407 17982 17519 17027 16496 15911 15256 14510 13618 12475

BHP 6.58 7.00 7.39 7.79 8.17 8.52 8.81 9.10 9.39 9.61 9.78 9.94 9.98 9.94

LwA 91 94 94 93 92 91 90 90 89 88 88 88 88 88

Static Pressure (inches water gauge)

QBMX33

RPM

346

396

436

499

550

629

716

854

940

1076

1184

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 8330 6809

BHP 0.33 0.47

LwA 64 60

CFM 9533 8303 6083

BHP 0.49 0.66 0.74

LwA 67 65 64

CFM 10496 9422 7822

BHP 0.66 0.86 0.98

LwA 70 68 66

CFM 12013 11108 9934 8149

BHP 0.98 1.22 1.40 1.50

LwA 74 74 71 70

CFM 13241 12436 11456 10166 7988

BHP 1.32 1.58 1.80 1.96 1.97

LwA 76 78 74 73 72

CFM 15143 14452 13663 12713 11518 9769

BHP 1.97 2.28 2.56 2.78 2.93 2.99

LwA 80 82 79 77 76 76

CFM 17237 16644 15980 15229 14370 13328 11990 9520

BHP 2.91 3.26 3.58 3.87 4.11 4.31 4.39 4.26

LwA 83 86 84 82 81 80 79 80

CFM 20559 20063 19536 18967 18344 17656 16883 16002 14962 13632 11134

BHP 4.93 5.34 5.77 6.15 6.48 6.79 7.05 7.29 7.44 7.50 7.15

LwA 87 90 90 88 86 86 85 84 84 84 84

CFM 22630 22179 21713 21216 20676 20098 19473 18787 18022 17149 16131 14856 12810

BHP 6.58 7.02 7.48 7.95 8.35 8.70 9.04 9.34 9.62 9.79 9.96 9.96 9.70

LwA 90 93 93 92 90 89 88 88 87 87 87 86 87

CFM 25904 25510 25116 24690 24256 23783 23300 22766 22209 21616 20958 20245 19457 18563 17514 16161

BHP 9.86 10.37 10.91 11.45 11.95 12.42 12.84 13.24 13.65 14.00 14.26 14.56 14.77 14.88 14.99 14.87

LwA 94 96 96 96 95 94 93 92 92 92 91 91 90 90 90 90

CFM 28504 28146 27789 27418 27023 26628 26193 25756 25282 24797 24269 23728 23127 22492 21814 21051 20200 19222 18037 16226

BHP 13.14 13.70 14.33 14.91 15.46 15.97 16.48 16.97 17.43 17.87 18.31 18.69 19.01 19.26 19.58 19.77 19.86 19.92 19.87 19.43

LwA 96 98 99 99 98 98 96 95 95 95 94 94 94 93 93 93 93 92 93 93

Static Pressure (inches water gauge)

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

Page 8

Page 9

QBMX37

RPM

335

369

422

465

532

631

722

795

910

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 10910 9245

BHP 0.49 0.68

LwA 66 63

CFM 12017 10574 8176

BHP 0.66 0.88 1.00

LwA 68 66 65

CFM 13743 12537 10886 7133

BHP 0.99 1.25 1.44 1.40

LwA 72 72 69 68

CFM 15143 14079 12721 10777

BHP 1.32 1.62 1.85 1.98

LwA 75 76 72 71

CFM 17325 16414 15338 14002 12174

BHP 1.97 2.32 2.62 2.85 2.99

LwA 78 80 77 75 75

CFM 20549 19801 18961 18004 16883 15509 13652

BHP 3.29 3.70 4.11 4.43 4.70 4.90 5.00

LwA 83 86 83 81 80 80 79

CFM 23513 22865 22162 21392 20538 19577 18447 17102 15296

BHP 4.93 5.42 5.86 6.28 6.69 7.01 7.27 7.41 7.46

LwA 86 89 88 86 85 84 83 83 83

CFM 25890 25301 24680 24015 23293 22494 21613 20616 19462 18089 16190

BHP 6.58 7.09 7.64 8.13 8.55 8.96 9.31 9.60 9.82 9.95 9.92

LwA 89 92 91 90 88 87 87 86 86 85 85

CFM 29635 29121 28603 28034 27445 26815 26133 25407 24625 23760 22795 21706 20402 18761

BHP 9.87 10.49 11.10 11.64 12.19 12.71 13.23 13.62 14.06 14.39 14.63 14.84 14.99 14.91

LwA 92 95 95 94 93 92 91 91 90 89 89 89 89 89

Static Pressure (inches water gauge)

QBMX40

RPM

288

317

363

399

457

542

620

683

781

860

926

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 12334 10133

BHP 0.50 0.70

LwA 65 62

CFM 13576 11687 7725

BHP 0.66 0.90 0.98

LwA 67 65 63

CFM 15546 13988 11692

BHP 0.99 1.28 1.47

LwA 71 69 67

CFM 17088 15703 13865 10818

BHP 1.31 1.64 1.89 1.99

LwA 73 73 70 70

CFM 19571 18400 16979 15112 12075

BHP 1.97 2.37 2.68 2.91 2.96

LwA 77 79 75 74 73

CFM 23212 22247 21152 19873 18315 16270

BHP 3.29 3.75 4.18 4.56 4.81 4.97

LwA 82 84 81 80 78 78

CFM 26552 25725 24817 23799 22640 21308 19679 17505

BHP 4.93 5.48 6.00 6.43 6.86 7.18 7.41 7.49

LwA 85 88 86 84 83 82 82 81

CFM 29250 28499 27693 26816 25851 24775 23558 22128 20378 17831

BHP 6.59 7.16 7.74 8.28 8.76 9.19 9.54 9.80 9.96 9.88

LwA 88 90 90 88 86 86 85 84 84 84

CFM 33447 32790 32113 31387 30602 29765 28863 27872 26768 25518 24057 22293 19590

BHP 9.85 10.50 11.23 11.83 12.43 12.99 13.55 14.00 14.38 14.69 14.84 14.92 14.71

LwA 91 94 94 93 91 90 89 89 88 88 88 87 88

CFM 36830 36234 35638 34983 34318 33588 32827 32019 31130 30177 29140 27988 26674 25123 23152

BHP 13.15 13.92 14.68 15.40 16.11 16.70 17.32 17.95 18.39 18.84 19.24 19.63 19.87 19.91 19.84

LwA 93 96 96 96 95 94 92 92 92 91 91 90 90 90 90

CFM 39657 39103 38549 37960 37348 36706 36028 35314 34563 33749 32898 31967 30953 29845 28602 27165 25410 22785

BHP 16.42 17.24 18.01 18.86 19.63 20.30 20.99 21.72 22.34 22.82 23.41 23.86 24.25 24.58 24.73 24.94 24.91 24.32

LwA 95 98 98 98 97 96 95 94 94 94 93 93 92 92 92 92 92 92

Static Pressure (inches water gauge)

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

Page 9

Page 10

QBMX45

RPM

268

307

338

387

458

525

578

661

728

784

833

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 15505 12944

BHP 0.66 0.93

LwA 66 63

CFM 17761 15666 12245

BHP 0.99 1.31 1.50

LwA 69 67 66

CFM 19555 17719 15116

BHP 1.32 1.70 1.94

LwA 72 71 68

CFM 22390 20844 18879 16107

BHP 1.98 2.41 2.76 2.99

LwA 75 76 73 72

CFM 26498 25222 23752 21959 19641 15845

BHP 3.28 3.80 4.30 4.65 4.93 4.89

LwA 80 82 79 77 77 76

CFM 30374 29287 28067 26681 25067 23103 20474

BHP 4.94 5.57 6.15 6.65 7.07 7.37 7.47

LwA 84 87 84 82 81 80 80

CFM 33440 32459 31390 30209 28879 27347 25561 23304 19778

BHP 6.59 7.29 7.94 8.50 9.02 9.44 9.77 9.96 9.82

LwA 86 89 88 86 84 84 83 83 83

CFM 38242 37384 36481 35516 34467 33307 32032 30610 28952 26991 24394

BHP 9.86 10.61 11.42 12.10 12.82 13.36 13.89 14.33 14.67 14.88 14.95

LwA 90 93 92 91 89 88 88 87 87 86 86

CFM 42118 41339 40545 39685 38772 37810 36753 35606 34355 32967 31396 29570 27215 23129

BHP 13.17 13.99 14.91 15.73 16.43 17.23 17.89 18.48 18.91 19.35 19.77 19.98 19.99 19.19

LwA 92 95 95 94 93 91 91 90 90 89 89 89 89 89

CFM 45358 44635 43912 43120 42320 41436 40521 39538 38473 37336 36101 34731 33180 31360 29102 25500

BHP 16.45 17.39 18.34 19.22 20.10 20.90 21.67 22.29 22.92 23.58 24.08 24.41 24.72 24.98 24.86 24.19

LwA 94 97 97 97 96 94 93 93 92 92 91 91 91 91 91 91

CFM 48193 47512 46832 46106 45354 44562 43729 42844 41919 40910 39852 38709 37444 36058 34502 32690 30448 26614

BHP 19.73 20.66 21.74 22.70 23.63 24.52 25.28 26.16 26.81 27.48 28.09 28.64 29.21 29.48 29.75 29.99 29.90 28.93

LwA 96 98 99 98 98 97 95 95 94 94 94 93 93 93 92 92 92 93

Static Pressure (inches water gauge)

QBMX49

RPM

228

261

288

329

390

447

492

563

530

667

709

781

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Power rating (BHP) does not include transmission losses.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00 4.25 4.50 4.75 5.00

CFM 17618 14147

BHP 0.66 0.94

LwA 64 60

CFM 20168 17379 11609

BHP 0.98 1.35 1.45

LwA 68 66 64

CFM 22254 19828 16089

BHP 1.32 1.75 2.00

LwA 71 69 67

CFM 25422 23381 20677 16247

BHP 1.97 2.45 2.82 2.99

LwA 74 74 71 70

CFM 30136 28473 26489 23988 20385

BHP 3.28 3.89 4.41 4.80 4.99

LwA 79 80 77 75 75

CFM 34540 33118 31504 29622 27338 24349

BHP 4.94 5.65 6.25 6.79 7.20 7.44

LwA 82 85 82 80 79 79

CFM 38017 36748 35332 33732 31905 29722 26978 22714

BHP 6.59 7.38 8.06 8.75 9.24 9.66 9.92 9.82

LwA 85 88 86 83 83 82 81 81

CFM 43503 42394 41206 39914 38492 36907 35117 33028 30483 26828

BHP 9.87 10.71 11.64 12.44 13.16 13.80 14.25 14.74 14.90 14.89

LwA 89 92 91 89 87 86 86 85 85 85

CFM 40954 39775 38494 37082 35508 33688 31579 28954 25131

BHP 8.23 9.03 9.83 10.56 11.27 11.80 12.23 12.41 12.34

LwA 87 90 89 86 85 84 84 83 83

CFM 51540 50604 49652 48618 47528 46383 45112 43750 42268 40629 38780 36637 34001 30023

BHP 16.41 17.48 18.54 19.54 20.40 21.40 22.10 22.93 23.58 24.13 24.56 24.74 24.94 24.46

LwA 93 96 96 95 94 92 91 91 90 90 90 90 89 90

CFM 54785 53904 53024 52058 51081 50004 48885 47689 46384 44987 43468 41783 39866 37610 34806 29652

BHP 19.70 20.76 21.99 22.96 24.11 25.07 26.00 26.74 27.49 28.17 28.89 29.39 29.62 29.93 29.75 28.55

LwA 94 97 97 97 96 94 93 93 93 92 92 91 91 91 91 91

CFM 60349 59549 58750 57910 57027 56125 55147 54153 53068 51947 50742 49450 48084 46577 44914 43058 40915 38308 34291

BHP 26.34 27.59 28.85 30.07 31.12 32.26 33.32 34.35 35.43 36.19 37.14 37.87 38.54 39.11 39.55 39.87 39.88 39.94 38.88

LwA 97 100 100 100 99 98 97 96 96 95 95 95 94 94 94 94 93 94 94

Static Pressure (inches water gauge)

Page 10

Page 11

Page 12

TERMS AND CONDITIONS OF SALE

ACCEPTANCE All orders and sales are subject to

written approval and acceptance by an executive offi

cer of Acme Engineering & Manufacturing Corporation

at Muskogee, Oklahoma, (the "Company") and are not

binding on the Company until so approved.

DELIVERY All shipping and delivery dates are esti

mated only. No delays in delivery will subject the

Company to any costs, damages or fees for late deliv

ery. Delivery of the products herein specified shall be

made F.O.B. point of shipment, unless otherwise

stated. The Company shall not be liable for delay due

to causes beyond its reasonable control, such as Acts

of God, acts of the purchaser, acts of civil or military

authorities, priorities, fires, strikes, floods, epidemics,

war, riots, delays in transportation, car shortages, and

inability, due to reasons beyond its reasonable control,

to obtain necessary labor, material, or manufacturing

facilities. In the event of such a delay, the date of deliv

ery shall be extended for a period equal to the time lost

by reason of the delay.

TERMS OF PAYMENT If, in the judgment of the Com

pany, the financial condition of the purchaser at any

time does not justify continuation of manufacture or

shipment on the terms of payment specified, the Com

pany may require full or partial payment in advance.

Pro rata payments shall become due as shipments are

made. Each shipment or delivery shall constitute a

separate sale, and the default of any shipment or delivery shall constitute a separate sale, and the default of

any shipment or delivery shall not vitiate the contract

as to other shipments or deliveries.

SALES AND SIMILAR TAXES The Company’s prices

do not include sales, use, excise, or similar taxes.

Consequently, in addition to the price specified herein,

the amount of any present or future sales, use, excise,

or other similar tax applicable to the sale of the product

herein shall be paid by the Purchaser, or in lieu thereof

WARNING Acme products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of defects. Even reliable products will

experience occasional failures and this possibility should be recognized by the Purchaser and all End Users. If these products are used in a life support ventilation system

where failure could result in loss or injury, the Purchaser and all End Users should provide adequate back-up ventilation, supplementary natural ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials unless unit is specifically built for hazardous environments. Comply with all local and national safety codes including the National Electrical Code (NEC) and National Fire Protection Act (NFPA).

CAUTION Guards must be installed when fan is within reach of personnel or within eight (8) feet (2.5 m) of working level or when deemed advisable for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products accurately in all Company literature; however such illustrations and descriptions

are for the sole purpose of identification and do not express or imply any warranty.

the Purchaser shall provide the Company with a tax

-

exemption certificate acceptable to the taxing authori

ties.

CANCELLATION Any contract resulting from the Pur

chaser’s order may be canceled by the Purchaser only

-

by negotiations and upon payments of reasonable can

cellation charges which will take into account expenses

-

already incurred and commitments made by the Com

pany.

DESIGN CHANGES The Company reserves the right

to make changes in design, improvements and addi

tions in and to its products any time without imposing

any liability or obligations to itself to apply or install the

same in any product manufactured by it.

TITLE The title and right of possession of the products

sold herein shall remain with the Company and such

products shall remain personal property until all

payments herein (including deferred payments whether

evidenced by notes or otherwise) shall have been

made in full in cash and the Purchaser agrees to do all

acts necessary to perfect and maintain such right and

title in the Company.

PRICE ADJUSTMENTS Prices are subject to change

upon notice by the Company. Prices on existing or

ders are subject to surcharges in the event of cost in

creases of metals and transportation. All complete

component accessory material manufactured by others

and furnished with the Company’s products such as

motors, drives, vibration equipment, controls or other

completely assembled component structures, are subject to adjustment to the price at time of shipment regardless of the date of original order entry.

SAFETY ACCESSORIES The Company manufactures

products designed to serve multiple applications and

offers a wide range of safety equipment, including

guards and other devices, as may be required to meet

customer specifications. Without exception, the Com

pany recommends that all orders include applicable

safety devices. Products ordered without applicable

safety devices is clearly the responsibility of the Pur

chaser. Further, the Purchaser warrants that it has de

termined and acquired any and all safety devices re

quired for products sold by the Company. Weather

covers and guards for motor and V-belt drives, cou

plings, shafts and bearings, along with inlet and outlet

screens, are optional accessories noted in the price

list.

GOVERNING LAW The rights, obligations and reme

dies of Purchaser and the Company, the interpretation

of these terms and conditions and the sale of products

by the Company shall be governed by Oklahoma law,

without regard to any principles of conflict of laws.

ARBITRATION Any dispute arising under or in con

nection with these terms and conditions or the sale of

products shall be settled by binding arbitration admin

istered by the American Arbitration Association under

its Commercial Arbitration Rules, and judgment on the

award rendered by the arbitrator may be entered in

any court having jurisdiction thereof. The dispute shall

-

be resolved by one neutral arbitrator who shall have no

-

affiliation with either Purchaser or the Company and

shall be selected by the American Arbitration Association office in Dallas, Texas. The arbitration proceedings shall be held in Muskogee, Oklahoma.

APPLICABLE DOCUMENTS The

tween the Company and the Purchaser relating to the

products includes these terms and conditions of sale,

any applicable installation and maintenance instructions provided by the Company and any terms appearing on the Company’s quotation, sales order acknowledgment and invoice.

agreement be-

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: the Company ex-

tends this limited warranty to the original purchaser

and warrants that products supplied by the Company,

shall be free from original defects in workmanship and

materials for two years from date of shipment (except

for the warranty periods noted for products listed below), provided same have been properly handled,

stored, installed, serviced, maintained and operated.

This warranty shall not apply to products which have

been altered or repaired without the Company’s express authorization, or altered or repaired in any way

so as, in the Company’s judgment, to affect its performance or reliability, nor which have been improperly

installed or subjected to misuse, negligence, or accident, or incorrectly used in combination with other substances. The Purchaser assumes all risks and liability

for results of use of all products.

Evaporative cooling pads are warranted to be free of

defects in materials and workmanship for a period of

two years from date of shipment provided same have

been properly handled, stored, installed, serviced,

maintained and operated; and further, not subjected to

excessive heat, corrosive agents or chemicals, or mechanical abuse that may cause tearing, crushing or undue deterioration, nor used on a system or in a manner

other than that for which it was designed as explained

in the product literature.

The following products are warranted to be free of de

fects in materials and workmanship for the periods

shown from date of shipment: Acme’s exclusive du

plex split pillow block bearings and shaft five years,

belts one year, Polyethylene tubing 90 days, AIR40

Heater warranty one year, AIR40 Emitter warranty

three years and DDP fan lifetime warranty on its pro

peller, cone, and housing.

LIMITATION OF REMEDY AND DAMAGES: All

claims under this warranty must be made in writing and

delivered to P. O. Box 978, Muskogee, Oklahoma,

74402, within 15 days after discovery of the defect and

prior to the expiration of two years from the date of

shipment by the Company of the product claimed de

fective, and Purchaser shall be barred from any

ACME ENGINEERING AND

MANUFACTURING CORPORATION

P.O. Box 978

Muskogee, Oklahoma 74402

Telephone 918/682-7791

Fax 918/682-0134

www.acmefan.com

Member Air Movement and Control Association International, Inc. January 2016 C230B

remedy if Purchaser fails to make such claim within

such period.

Within 30 days after receipt of a timely claim, the Company shall have the option either to inspect the product

while in Purchaser's possession or to request Purchaser to return the product to the Company at Purchaser's expense for inspection by the Company. The

Company shall replace, or at its option repair, free of

charge, any product it determines to be defective, and

it shall ship the repaired or replacement product to

Purchaser F.O.B. point of shipment; provided, however, if circumstances are such as in the Company’s

judgment to prohibit repair or replacement to remedy

the warranted defects, the Purchaser's sole and exclusive remedy shall be a refund to the Purchaser of any

part of the invoice price, paid to the Company, for the

defective product or part.

The Company is not responsible for the cost of removal of the defective product or part, damages due to

removal, or any expenses incurred in shipping the

product or part to or from the Company’s plant, or the

installation of the repaired or replaced product or part.

The warranties set forth above do not apply to any

components, accessories, parts or attachments manufactured by other manufacturers; such being subject to

the manufacturer’s warranty, if any. To the extent not

prohibited by the manufacturer’s warranty, the Com

pany shall pass through to Purchaser such manufac

turer’s warranty.

THE COMPANY’S WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED,

ARISING BY LAW OR OTHERWISE, INCLUDING

WITHOUT LIMITATION THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PAR

TICULAR PURPOSE, WHICH ARE HEREBY EX

PRESSLY DISCLAIMED AND WAIVED. THIS WAR

RANTY CONSTITUTES THE COMPANY’S SOLE

AND EXCLUSIVE WARRANTY FOR DEFECTIVE

GOODS AND PURCHASER’S SOLE AND EXCLU

SIVE REMEDY FOR DEFECTIVE PRODUCTS.

-

No employee, agent, dealer, or other person is

authorized to give any warranties on behalf of the

Company or to assume for the Company any

other liability in connection with any of its products

except in writing and signed by an officer of the

Company.

REPLACEMENT PARTS If replacement parts are

ordered, purchaser warrants that the original com

ponents in which these replacement parts will be

placed are in satisfactory working condition, and

when said replacement parts are installed, the resultant installation will operate in a safe manner, at

speeds and temperatures for which the original product was purchased.

TECHNICAL ADVICE AND RECOMMENDATIONS,

DISCLAIMER: Notwithstanding any past practice or

dealings or any custom of the trade, sales shall not include the furnishing of technical advice or assistance

or system design. Any such assistance shall be at the

Company’s sole option and may be subject to additional charge.

The Company assumes no obligation or liability on account of any recommendations, opinions or advice as

to the choice, installation or use of products. Any such

recommendations,

shall be accepted at Purchaser's and End User's risk

and shall not constitute any warranty or guarantee of

such products or their performance.

LIMITATION OF LIABILITY The cumulative liability of

the Company to the Purchaser and any other persons

for all claims in any way relating to or arising out of the

products, including, but not limited to, any cause of action sounding in contract, tort, or strict liability, shall not

exceed the total amount of the purchase price paid for

those products which are the subject of any such

claim. This limitation of liability is intended to apply

without regard to whether other provisions of this

agreement have been breached or have proven inef

fective even if the Company has been advised of the

possibility of such claims or demands. In no event

shall the Company be liable to the Purchaser or any

other person for any loss of profits or any incidental,

special, exemplary, or consequential damages for any

claims or demands brought by the Purchaser or such

other persons.

-

INDEMNITY The Company’s maximum liability to Pur

chaser and to any end user is as set forth above. The

Company makes no warranty to anyone for any prod

ucts not manufactured by the Company and shall have

no liability for any use or installation of any products

(whether manufactured by the Company or other man

ufacturers) not specifically authorized by this sale.

Purchaser acknowledges various warnings by the

Company regarding the products and its installation

and use. If the Company incurs any claims, lawsuits,

settlements, or expenses (including attorney fees) for

any loss, injury, death or property damage including,

but not limited to, claims arising out of the Purchaser’s

or any end user’s installation or use of the products,

the Purchaser shall indemnify and hold the Company

harmless.

opinions or advice are given and

-

-

-

-

-

-

-

-

-

-

-

-

Loading...

Loading...