Page 1

Page 2

CONSTRUCTION FEATURES

Model PL belt drive fan is a downblast centrifugal power roof ventilator designed for exhausting clean air. Capacities

range from 635 to 31,810 CFM and up to 1 inch static pressure. The PL is built to be quieter than conventional

exhausters. In fact, they are quieter than many conventional exhausters with sound curbs. For this reason PL

exhausters are suitable for all types of commercial and institutional buildings such as schools, hospitals, office buildings

and retail stores requiring low noise levels.

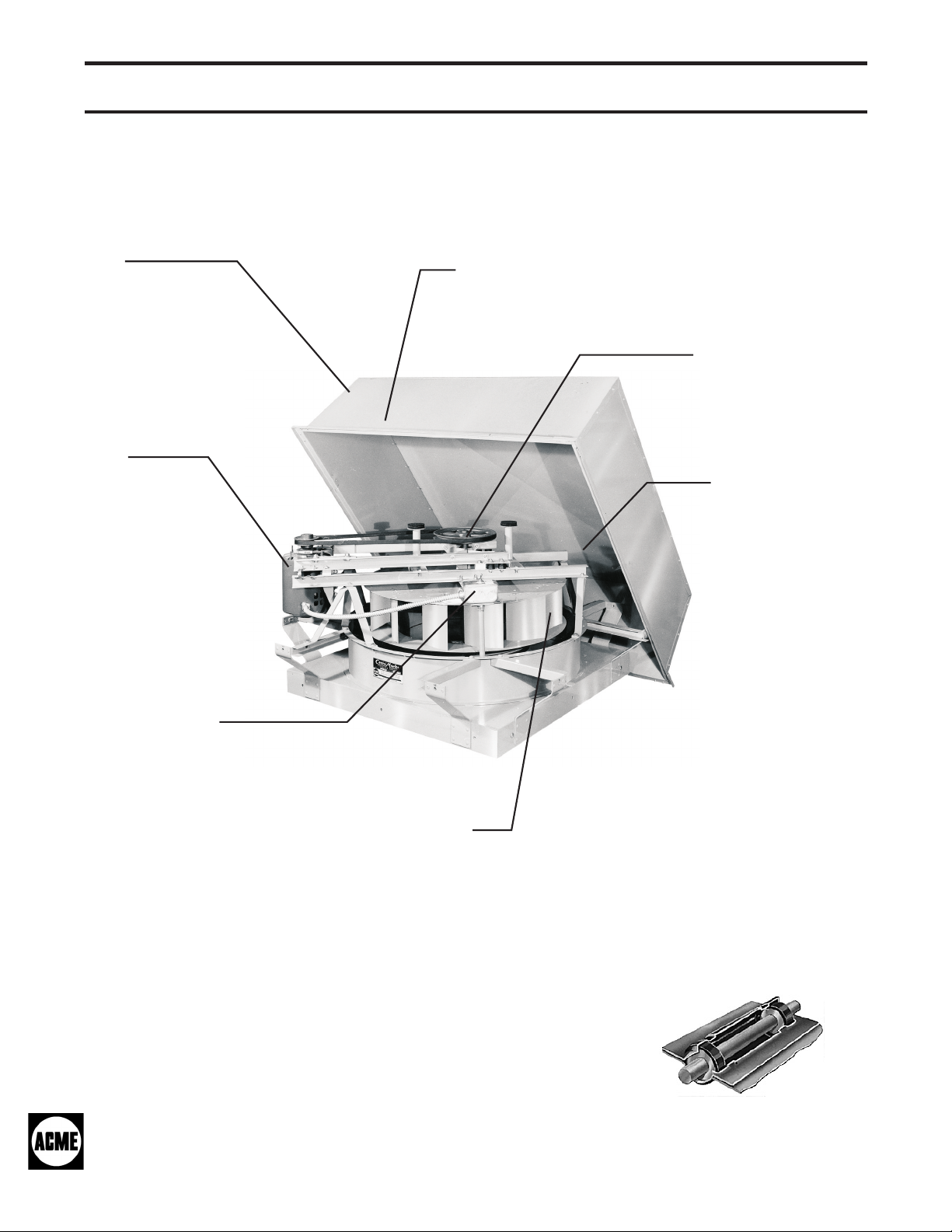

Hood

Full 360° perimeter

outlet area for efficient

performance. Hinged

to permit easy

accessibility and

servicing.

Motor

All motors are

continuous duty type

and have lubricated

shielded ball bearings.

The motor is mounted

on special slide rails

that help maintain

correct belt drive

alignment. Factory

wired to junction box.

Aluminum Construction

Heavy gauge aluminum hoods, housing and

base provide durable, weather protected

construction.

Drive Assembly

Cast iron drives sized for

150% of drive horsepower

with static free, oil and

heat resistant belts.

Frame

The entire weight of

the motor, impeller,

drive assembly and

hood is carried by a

rugged structural

frame that transmits

load directly to the roof

curb.

Disconnect Switch

Factory installed disconnect

switch is standard.

Aluminum Hollow Airfoil Impeller

All exhausters have backward curved non-overloading

aluminum impellers with the hollow airfoil blades.

Impellers are precision balanced for smooth, vibration

free operation. Hollow airfoil blades produce a

centrifugal impeller having high performance with lower

air noise, and at less horsepower.

Bearings

Permanently lubricated in a duplex split pillow block housing. Bearings are resiliently

mounted in neoprene rings and rated at L

limited warranty on duplex split pillow block bearings (unitary pillow block bearings

standard on PL368-543).

life of 200,000 hours. There is a 5 year

50

Bird Screen (not shown)

Constructed of .50” x 1.00” mesh

heavy gauge galvanized steel

wire.

Page 2

Page 3

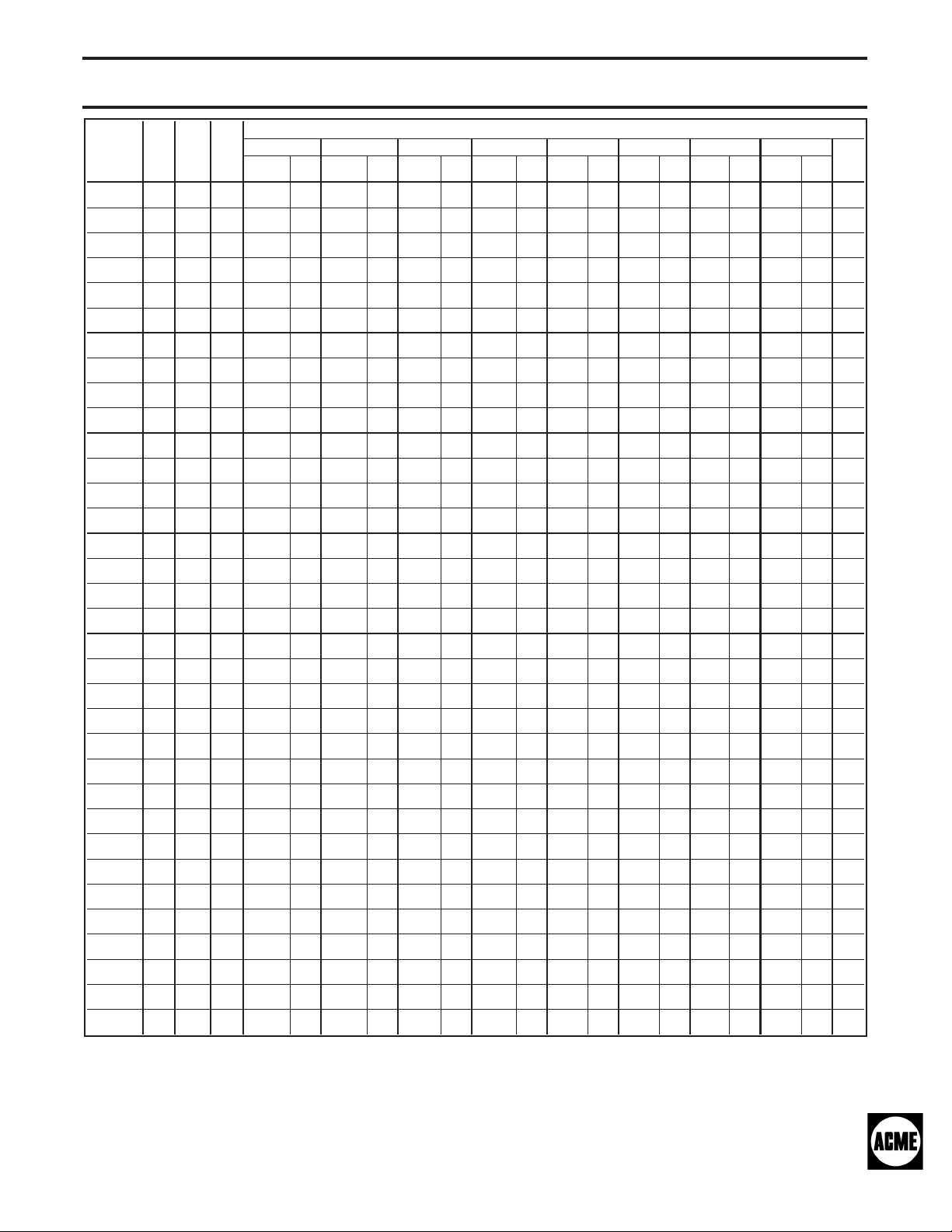

PERFORMANCE DATA

Fan

Model

PL135E1

PL135E2

PL135E3

PL135E4

PL135E5

PL135F

PL145E1

PL145E2

PL145E3

PL145F

PL163E1

PL163E2

PL163F

PL163G

PL171E1

PL171E2

PL171F

PL171G

PL200E1

PL200E2

PL200F

PL200G

PL223E1

PL223E2

PL223F

PL223G

PL245E

PL245F

PL245G

PL245H

PL270E

PL270F

PL270G

PL270H

Performance shown is for installation type A: Free inlet, Free Outlet.

Performance ratings do not include the effects of appurtenance in the airstream.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524m) in a

hemispherical free field calculated per AMCA Standard 301. Values shown are

for Installation Type A: Free Inlet fan Sone levels.

Sones

RPM

@

HP

1/8” SP

474

5.4 1/4

712 950 .02 660 .02

657

7.3 1/4

987 1320 .05 1100 .06 900 .06 585 .06

835

9.9 1/4

1228 1640 .10 1460 .11 1295 .11 1135 .12 930 .13 575 .11

917

10.8 1/4

1376 1840 .13 1675 .14 1525 .16 1385 .17 1230 .18 1045 .18 750 .16

1032

14.1 1/4

1548 2070 .19 1925 .20 1780 .23 1655 .24 1535 .25 1395 .25 1240 .25 700 .20

1327

16.0 1/3

1720 2299 .26 2140 .28 2040 .29 1920 .30 1805 .31 1700 .33 1575 .34 1270 .35

752

9.6 1/4

1075 1760 .11 1590 .12 1395 .13 1150 .13 760 .12

786

11.3 1/4

1180 1930 .14 1770 .15 1610 .17 1410 .17 1155 .17 745 .15

918

14.4 1/4

1376 2250 .28 2120 .24 1980 .25 1830 .27 1660 .28 1455 .28 1180 .26

1130

17.1 1/3

1522 2490 .31 2370 .32 2250 .33 2120 .35 1970 .36 1810 .37 1630 .37 1090 .32

658

9.9 1/4

988 2325 .15 2100 .17 1850 .18 1560 .19 1145 .17 385 .12

741

11.3 1/4

1110 2610 .21 2420 .23 2200 .24 1960 .26 1690 .26 1305 .25 700 .20

835

13.9 1/3

1229 2890 .29 2720 .31 2530 .32 2325 .34 2100 .35 1855 .36 1505 .34 290 .20

934

16.6 1/2

1425 3350 .45 3210 .47 3045 .49 2875 .51 2695 .53 2505 .54 2290 .55 1745 .53

609

9.5 1/4

896 2450 .15 2185 .17 1935 .18 1590 .18 1030 .16

700

9.8 1/4

1029 2815 .22 2585 .25 2360 .27 2130 .28 1815 .28 1370 .27 550 .18

742

11.4 1/3

1110 3035 .28 2825 .31 2610 .33 2410 .34 2155 .35 1835 .34 1370 .31

817

14.3 1/2

1247 3410 .40 3220 .43 3025 .45 2845 .48 2660 .49 2435 .50 2160 .49 1280 .41

499

8.6 1/4

727 2605 .16 2290 .17 2025 .18 1750 .19 1410 .19

530

9.3 1/4

820 2940 .23 2660 .24 2410 .25 2170 .27 1930 .28 1630 .28 1115 .24

632

10.8 1/3

906 3245 .31 2980 .32 2750 .33 2540 .35 2325 .36 2110 .37 1850 .37

710

16.4 1/2

1049 3584 .47 3380 .49 3205 .51 3030 .52 2880 .54 2715 .55 2530 .57 2080 .58

393

6.8 1/4

590 2870 .15 2490 .16 2128 .17 1585 .17

430

8.0 1/4

674 3280 .22 2940 .23 2635 .25 2280 .26 1740 .25

478

9.8 1/3

749 3645 .30 3335 .31 3055 .34 2775 .35 2440 .36 1885 .35

574

12.1 1/2

860 4183 .45 3910 .47 3660 .50 3425 .50 3170 .53 2880 .54 2500 .54

368

7.3 1/4

577 3920 .21 3450 .23 3020 .25 2580 .26 1945 .25

442

9.3 1/3

638 4335 .29 3900 .31 3510 .33 3130 .35 2710 .36 2010 .34

466

10.8 1/2

713 4845 .40 4455 .43 4095 .44 3750 .47 3415 .49 3045 .50 2505 .49

545

14.8 3/4

831 5650 .64 5300 .67 4980 .69 4680 .72 4400 .74 4110 .77 3800 .79 3020 .78

327

6.9 1/4

491 4225 .21 3695 .24 3210 .26 2535 .26

368

8.0 1/3

532 4580 .27 4090 .30 3635 .32 3125 .33 1855 .29

405

9.8 1/2

606 5215 .40 4785 .43 4370 .46 3980 .48 3505 .49 2625 .46

486

12.7 3/4

688 5922 .59 5540 .62 5160 .65 4820 .68 4470 .71 4050 .72 3470 .72

.000” .125” .250” .375” .500” .625” .750” 1.000” Est.

CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP

635 .01

878 .01 545 .02

1115 .03 865 .04 575 .04

1225 .04 990 .05 755 .05 250 .04

1380 .06 1165 .06 975 .07 725 .07

1775 .12 1605 .13 1450 .14 1310 .15 1140 .16 920 .16 545 .13

1230 .04 970 .04 500 .04

1285 .04 1040 .05 650 .05

1500 .07 1300 .08 1040 .08 600 .07

1850 .13 1690 .14 1510 .15 1290 .15 990 .14 440 .11

1545 .04 1185 .05 540 .05

1740 .06 1430 .07 950 .08

1965 .09 1695 .10 1370 .11 865 .10

2195 .13 1960 .14 1685 .15 1355 .16 800 .13

1665 .05 1280 .06 470 .04

1915 .06 1580 .07 1150 .06

2030 .08 1715 .10 1345 .11 570 .08

2235 .11 1945 .13 1650 .14 1190 .12 130 .07

1790 .05 1370 .06 815 .06

1900 .06 1500 .07 1100 .08

2265 .10 1910 .11 1610 .12 1225 .13

2545 .15 2230 .16 1960 .17 1675 .18 1260 .17

1910 .04 1345 .05

2090 .06 1585 .07

2325 .08 1865 .09 1250 .09

2790 .13 2400 .15 2025 .16 1375 .16

2500 .06 1805 .07

3005 .10 2410 .11 1820 .12

3170 .11 2600 .13 2060 .14

3705 .18 3200 .20 2770 .21 2265 .22

2815 .06 2045 .08

3170 .09 2490 .11 835 .06

3485 .12 2855 .14 2130 .15

4183 .21 3645 .23 3151 .25 2437 .25

CFM and BHP vs. Static Pressure

The brake horsepower capability of an exhauster motor is dependent on the

degree of cooling the motor receives from the air moving through the motor.

The motor loading beyond the motor nameplate rating does not overheat

the motor and is in accordance with the motor manufacturer’s

recommendations. It is therefore not detrimental to the motor and is

economically desirable. Power rating (BHP) does not include drive losses.

Ship

Wt.

83

83

83

83

84

87

83

83

84

87

100

101

104

111

100

101

104

111

194

195

198

203

196

197

200

205

210

213

220

223

213

216

223

226

Page 3

Page 4

PERFORMANCE DATA

Fan

Model

PL300F

PL300G

PL300H

PL300J

PL300K

PL330F

PL330G

PL330H

PL330J

PL330K

PL330L

PL365G

PL365H

PL365J

PL365K

PL365L

PL365M

PL403H

PL403J

PL403K

PL403L

PL403M

PL490H

PL490J

PL490K

PL490L

PL490M

PL490N

PL543J

PL543K

PL543L

PL543M

PL543N

PL543P

Performance shown is for installation type A: Free inlet, Free Outlet.

Performance ratings do not include the effects of appurtenance in the airstream.

The sound ratings shown are loudness values in fan sones at 5 feet (1.524m) in a

hemispherical free field calculated per AMCA Standard 301. Values shown are

for Installation Type A: Free Inlet fan Sone levels.

Sones

RPM

@

HP

1/8” SP

311

9.0 1/3

457 5785 .30 4990 .33 4385 .35 3720 .37 2325 .33

337

9.7 1/2

514 6505 .43 5775 .46 5220 .49 4660 .51 4050 .53 2860 .48

395

13.2 3/4

593 7505 .66 6860 .70 6315 .73 5860 .76 5375 .79 4855 .81 4240 .81

481

15.1 1

653 8265 .88 7660 .93 7147 .97 6730 1.00 6305 1.03 5850 1.06 5380 1.08 3800 1.01

553

17.3 1 1/2

751 9505 1.34 8980 1.39 8500 1.44 8100 1.48 7720 1.52 7370 1.55 6980 1.59 6160 1.65

248

8.5 1/3

384 6077 .31 5240 .34 4475 .37 3211 .37

301

9.8 1/2

427 6758 .43 5995 .46 5293 .49 4568 .52 2398 .44

327

12.8 3/4

499 7897 .67 7246 .72 6621 .75 6031 .79 5421 .82 4340 .81

386

15.0 1

546 8641 .88 8050 .93 7463 .97 6909 1.01 6386 1.05 5767 1.08 4717 1.06

450

16.4 1 1/2

611 9670 1.23 9148 1.28 8601 1.33 8106 1.37 7618 1.42 7150 1.46 6636 1.50 4170 1.38

531

21 2

688 10889 1.75 10432 1.81 9942 1.87 9481 1.92 9041 1.97 8608 2.01 8192 2.07 7229 2.14

246

9.2 1/2

369 8365 .44 7280 .47 6340 .52 5155 .53

279

11.6 3/4

426 9655 .67 8670 .71 7880 .77 7000 .82 5945 .82 3990 .73

313

12.9 1

469 10630 .90 9735 .93 8965 1.00 8245 1.06 7400 1.10 6375 1.09 4620 .97

375

15.7 1 1/2

532 12060 1.31 11250 1.35 10540 1.41 9915 1.49 9255 1.56 8425 1.60 7645 1.60 4140 1.32

395

18.9 2

593 13440 1.81 12700 1.86 12045 1.92 11450 2.00 10905 2.10 10290 2.16 9635 2.21 8058 2.21

494

21 3

677 15345 2.70 14700 2.70 14100 2.80 13540 2.90 13040 3.00 12560 3.10 12040 3.20 10890 3.30

234

9.9 3/4

357 10595 .67 9335 .74 8165 .78 6895 .79 2950 .58

265

11.5 1

397 11785 .92 10650 1.00 9550 1.06 8510 1.08 7195 1.09 2540 .72

318

13.7 1 1/2

450 13355 1.35 12340 1.44 11390 1.51 10455 1.55 9520 1.58 8390 1.58 6355 1.48

377

16.5 2

498 14780 1.82 13870 1.92 12975 2.01 12125 2.07 11315 2.12 10445 2.15 9430 2.15 2565 1.29

406

18.6 3

563 16710 2.64 15900 2.75 15100 2.85 14340 2.94 13600 3.00 12860 3.05 12110 3.09 10300 3.10

168

8.9 3/4

265 14155 .65 11905 .69 10025 .76 7465 .74

191

9.9 1

287 15950 .91 13900 .95 12145 1.04 10390 1.08 7155 .98

229

11.8 1 1/2

325 18060 1.32 16210 1.36 14580 1.46 13125 1.51 11530 1.51 8890 1.48

268

13.0 2

363 20170 1.84 18485 1.87 16965 1.97 15600 2.10 14310 2.17 12860 2.19 10725 2.12

298

18.7 3

413 22950 2.72 21450 2.72 20080 2.82 18800 2.96 17650 3.10 16500 3.18 15250 3.21 11600 3.07

410

28 5

505 28060 4.95 26880 4.97 25700 5.03 24500 5.21 23500 5.40 22450 5.56 21700 5.72 19450 5.88

169

8.3 1

239 16525 .89 14290 .97 11900 1.02 7840 .95

185

10.2 1 1/2

273 18880 1.33 16905 1.42 14945 1.50 12626 1.53 8110 1.36

200

11.0 2

296 20470 1.69 18650 1.86 16910 1.88 14875 1.94 12505 1.92 4960 1.32

243

15.5 3

341 23580 2.59 21995 2.71 20460 2.81 18925 2.91 17110 2.97 15115 2.97 11935 2.83

305

18.8 5

400 27660 4.17 26300 4.30 24950 4.46 23650 4.58 22350 4.68 20850 4.77 19250 4.80 14950 4.64

350

25 7 1/2

460 31810 6.35 30600 6.49 29400 6.67 28300 6.80 27150 6.95 26000 7.09 24800 7.15 22050 7.26

.000” .125” .250” .375” .500” .625” .750” 1.000” Est.

CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP

3935 .09 2900 .11

4265 .12 3310 .14 2300 .15

5000 .19 4140 .22 3400 .24 1930 .21

4810 .35 5320 .38 4740 .41 4130 .43 3380 .43

7000 .53 6320 .57 5765 .60 5265 .63 4720 .65 4125 .66 2135 .50

3925 .09 2674 .11

4764 .16 3725 .18 1505 .15

5175 .20 4208 .22 3184 .24

6109 .32 5276 .35 4514 .38 3330 .38

7122 .50 6395 .54 5719 .57 5083 .60 4101 .61

8404 .81 7795 .85 7196 .90 6632 .93 6094 .97 5391 .99 3745 .92

5575 .13 4050 .16

6325 .19 4985 .22 3225 .22

7095 .27 5871 .30 4625 .33

8500 .46 7420 .50 6510 .55 5365 .56

8955 .61 7920 .65 7060 .72 6045 .74 4600 .71

11195 1.05 10340 1.09 9595 1.15 8925 1.23 8160 1.27 7280 1.28 6135 1.24

6945 .19 5100 .22

7865 .27 6215 .32 4150 .31

9440 .51 8035 .53 6720 .56 4485 .52

11190 .79 9990 .86 8870 .91 7750 .93 6045 .91

12050 .99 10950 1.07 9880 1.13 8860 1.16 7660 1.16 4905 1.02

9335 .18 6185 .22

10615 .27 7805 .31

12725 .46 10260 .51 8095 .55

14890 .74 12720 .79 10900 .86 8825 .88

16560 1.02 14575 1.06 12865 1.16 11220 1.21 8985 1.19

22780 2.66 21300 2.70 19850 2.81 18600 2.93 17350 3.03 16080 3.10 14800 3.14 11100 2.91

11685 .31 8416 .36

12795 .41 9920 .47 2220 .26

13830 .52 11180 .59 7450 .58

16805 .94 14590 1.02 12270 1.07 3280 .62

21090 1.85 19315 1.95 17615 2.04 15710 2.12 13520 2.12 9000 1.88

24200 2.77 22600 2.90 21050 3.00 19550 3.12 17900 3.18 16050 3.20 13500 3.11

CFM and BHP vs. Static Pressure

The brake horsepower capability of an exhauster motor is dependent on the

degree of cooling the motor receives from the air moving through the motor.

The motor loading beyond the motor nameplate rating does not overheat

the motor and is in accordance with the motor manufacturer’s

recommendations. It is therefore not detrimental to the motor and is

economically desirable. Power rating (BHP) does not include drive losses.

Ship

Wt.

340

348

351

354

366

346

353

356

359

371

380

463

466

469

480

488

540

473

476

488

495

550

687

690

702

709

765

779

704

716

725

778

783

834

Page 4

Page 5

OPTIONAL ACCESSORIES

Backdraft Dampers

All aluminum multiple blade construction. Precision

balanced full opening

blades have nylon

bearings. Wide damper

frame for installing flush to

ceiling opening or to

mounting frame in roof

openings. Mounts inside

Acme prefabricated curb.

Available as automatic or

motor operated.

Damper Box

For easy mounting of damper inside field constructed roof

curb. Required for Acme sound curbs, but not required

when Acme prefabricated curbs are used.

Prefabricated Curbs

Heavy gauge galvanized steel or aluminum curbs for

easy installation of exhauster over roof opening.

Replaces conventional field constructed curb for steel,

concrete or wood roof.

Type RF - Roofed-over type features built-in cant strip to

accommodate roofing materials for flashing up over top of

curb. Wood nailer is standard.

Type SF - Self-flashing type features wide base flange for

easy flashing to roof. This eliminates need for extending

roofing material up over top of curb. ¼" polystyrene

gasket is standard.

DIMENSIONS

Fan

Model

PL 135 & 145 30.5 22.5 19.5 16.5 C22.5 AR18 DB18

PL 163 & 171 34.5 26.5 23.5 20.5 C26.5 AR22 DB22

PL 200 & 223 34.5 26.5 23.5 20.5 C26.5 AR22 DB22

PL 245 & 270 40.5 32.5 29.5 26.5 C32.5 AR28 DB28

PL 300 & 330 46.5 38.5 35.5 32.5 C38.5 AR34 DB34

PL 365 & 403 52.5 44.5 41.5 38.5 C44.5 AR40 DB40

PL 490 & 543 66.5 58.5 55.5 52.5 C58.5 AR54 DB54

JKLM

Curb

Model

Damper

Model

Dimensions are shown in inches

Typical drawings for dimensional purposes only. They are correct within limits suitable for normal installation requirements and do not

necessarily show actual construction.

Damper

Box

Model

Page 5

Page 6

OPTIONAL COATINGS

Coatings

Aluminum and galvanized components remain unpainted as

a standard finish, but when required, are processed through

the finishing system to apply decorative or special coatings.

A high turbulence oven is used to produce a baked on finish

for most special coatings. Decorative coatings are not baked

on.

Decorative Coatings

Acme offers 16 popular colors for decorative finishes utilizing

an industrial grade enamel applied to the exterior of the fan.

Special colors are available upon request. See your Acme

Representative for complete color selections.

Special Coatings

Products receiving special coatings have

components painted before assembly. Fasteners are

not painted.

• Acrylic Epoxy

This product provides a more durable surface.

• Carboline Sanitile (Eisenheiss)

This air dry synthetic polyester forms a black coating

that offers greater resistance to most organic and

inorganic acids.

• Heresite (air dry)

A phenolic coating with greater resistance to most

organic and inorganic acids.

• Insulmastic

A black asphalt based mastic that provides some

condensation control, sound deadening and

corrosion resistance.

NOTE: For any coating selected the user assumes the responsibility for the corrosive agent, its concentration,

temperature, moisture content and the ultimate effect on the coating and the equipment.

DIMENSIONAL DATA

DIMENSIONS

Fan

Model

PL135 24.00 16.29 37.48 5.10 19.5 x 19.5 AR18 C22.5

PL145 24.00 16.29 37.48 5.10 19.5 x 19.5 AR18 C22.5

PL163 28.00 18.83 39.06 5.85 23.5 x 23.5 AR22 C26.5

PL171 28.00 18.82 39.06 5.85 23.5 x 23.5 AR22 C26.5

PL200 28.00 16.25 39.06 3.50 23.5 x 23.5 AR22 C26.5

PL223 28.00 16.25 39.06 3.50 23.5 x 23.5 AR22 C26.5

PL245 34.00 17.95 44.00 3.73 29.5 x 29.5 AR28 C32.5

PL270 34.00 17.95 44.00 3.73 29.5 x 29.5 AR28 C32.5

PL300 40.00 21.00 53.00 5.50 35.5 x 35.5 AR34 C38.5

PL330 40.00 21.00 53.00 5.50 35.5 x 35.5 AR34 C38.5

PL365 46.00 28.00 64.00 6.50 41.5 x 41.5 AR40 C44.5

PL403 46.00 28.00 64.00 6.50 41.5 x 41.5 AR40 C44.5

PL490 60.00 34.50 78.00 8.50 55.5 x 55.5 AR54 C58.5

PL543 60.00 34.50 78.00 8.50 55.5 x 55.5 AR54 C58.5

Dimensions are shown in inches.

* Recommended Maximum

ABCE

Roof

Opening*

Damper

Model

Curb

Model

Typical drawings for dimensional purposes only. They are correct within limits suitable for normal installation requirements and do not

necessarily show actual construction.

Page 6

Page 7

TYPICAL SPECIFICATIONS

Low silhouette roof exhaust fan shall be centrifugal belt

drive square hood type.

The fan housing shall be constructed of heavy gauge

aluminum and shall have a full perimeter stormband to aid

in protection of the orifice from blowing rain and snow.

Hood shall be hinged and permit easy accessibility and

servicing.

The fan impeller shall have centrifugal backwardly inclined

hollow airfoil blades constructed of aluminum and shall

include die-formed blades and front plate. The impeller

shall be optimally matched with a special die-formed

orifice. The impeller shall be precision balanced for

smooth vibration free operation.

The support brackets shall transmit the weight of the motor

and impeller directly to the curbcap/curb to prevent orifice

distortion.

Permanently lubricated ball bearings shall be used in a

duplex split pillow block housing for accurate alignment

and are rated at L

life of 200,000 hours. Bearings shall

50

be resilient mounted in neoprene rings providing protection

and vibration isolation.

Birdscreen shall be made from heavy gauge galvanized

wire and attached to the hood inlet.

A conduit post shall be provided through the orifice to the

motor compartment for ease of electrical wiring.

A disconnect device/switch shall be factory installed and

wired from the fan motor to the junction box.

Standard wiring shall comply with National Electric Code

and materials used shall be U.L. Listed.

All fans shall bear the AMCA Certified Ratings Seal for

sound and air performance.

Each fan shall have a permanently affixed

manufacturer’s nameplate containing the model number

and serial number for future identification.

Thermal overload protectors shall be standard for EP

(explosion proof) motors.

Drives shall be cast iron pulleys with variable pitch motor

pulley, static free, oil and heat resistant belts and shall be

designed for 1.5 service factor. The fan shaft shall have a

coating for resistance against corrosion.

Sealed ball bearing motors shall be mounted in the air

stream.

Acme reserves the right to change specification without notice.

Acme Engineering & Manufacturing Corporation certifies that

the PL Exhausters shown herein are licensed to bear the

AMCA seal. The ratings shown are based on tests and

procedures performed in accordance with AMCA Publication

211 and AMCA Publication 311 and comply with the

requirements of the AMCA Certified Ratings Program.

Fans shall be covered by a 2 year limited warranty with a

5 year limited warranty on duplex split pillow block

bearing and shaft.

Fans shall be Model PL as manufactured by Acme

Engineering and Manufacturing Corporation of

Muskogee, Oklahoma.

U.L. 705 Listed

CSA Certified

Consult your Acme representative for availability.

Page 7

Page 8

EXHAUSTERS

CEILING AND CABINET

EXHAUSTERS

IN-LINE CENTRIFUGAL

FANS

IN-LINE AXIAL FANSCENTRIFUGAL

PROPELLER

ROOF FANS

ROOF VENTS

WALL FANS

PLENUM FANS

UTILITY BLOWERS

BACKWARD

INCLINED/AIRFOIL

CENTRIFUGAL FANS

SUPPLY AIR FANSPROPELLER

CENTRIFUGAL

INDUSTRIAL

EXHAUSTERS

LIMITED WARRANTY Acme Engineering and

Manufacturing Corporation extends this limited

warranty to the original buyer and warrants that

products described herein shall be free from

original defectsin workmanshipand materialsfor

two years from date of shipment (except for

Acme’s exclusive duplex split pillow block bear

ings and shaft 5 years from shipment, belts one

year from shipment, and polyethylene tubing at

90 days from shipping), provided same have

been properly handled, stored, installed, ser

viced, maintained and operated. Refer to Form

MS149 for complete limited warranty terms and

conditions. This form is available to anyone at

www.acmefan.com. In order to prevent bodily in

jury, death, or destruction of livestock and prop

erty, all product safety data must be followed.

ACME ENGINEERING &

MANUFACTURING CORP.

P.O. Box 978, Muskogee, Oklahoma 74402

Telephone: 918-682-7791 Fax: 918-682-0134

www.acmefan.com e-mail: acmefan@acmefan.com

WARNING Acme products are designed and

manufactured to provide reliable performance

but they are not guaranteed to be 100% free of

defects. Even reliable products will experience

occasional failures and this possibility should be

recognized by the User. If these products are

used in a life support ventilation system where

failure could result in loss or injury, the User

should provide adequate back-up ventilation,

supplementary naturalventilation orfailure alarm

system, or acknowledge willingness to accept

the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS EN

VIRONMENTS where fan’s electrical system

-

could provide ignition to combustible or flamma

-

ble materials unless unit is specifically built for

hazardous environments. Comply with all local

Member Air Movement and Control Association International, Inc.

and national safety codes including the National

Electrical Code (NEC) and National Fire Protec

tion Act (NFPA).

CAUTION Guards must be installed when fan is

within reach of personnel or within seven (7) feet

(2.134 m) of working level or when deemed ad

visable for safety.

DISCLAIMER The Company has made a dili

gent effort to illustrate and describe the products

in this literature accurately; however, such illus

trations anddescriptions are for the solepurpose

-

of identification, and do not express or imply a

warranty that the products are merchantable, or

-

fit for a particular purpose, or that the products

will necessarily conform to the illustrations or de

scriptions or dimension.

April 2003 Form C23M

-

-

-

-

-

Loading...

Loading...