Page 1

Page 2

CONSTRUCTION FEATURES

Models FN and FQ direct drive propeller fans are offered for commercial and industrial applications having

low noise and high pressure requirements.

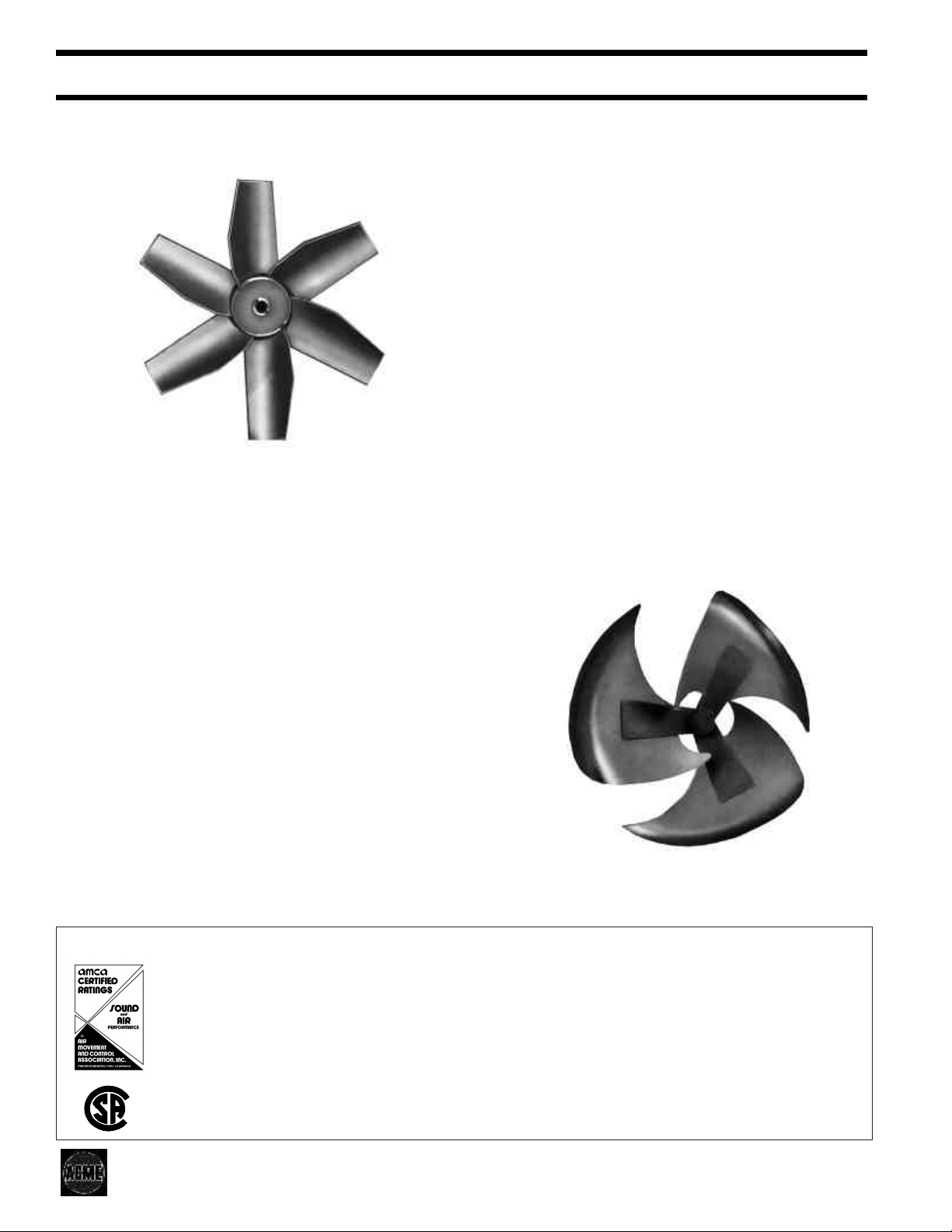

FQ FANS

These fans are designed to operate more quietly than

conventional propeller fans and are recommended for

ventilating applications desiring less fan noise. FQ fans are

available in 10 sizes, 9" through 36" with a maximum capacity

of 17,800 CFM.

Fan panels are constructed of steel and range from 18 to 16

gauge.

Aluminum blade thickness is from .050 to .125.

ADVANCED PROPELLER DESIGN

These propellers feature an advanced teardrop shape blade

designed for exceptionally low noise level performance.

Aluminum blades are fastened to a formed steel hub with

heavy duty oversize rivets. Propeller is precision balanced for

smooth operation.

FN FANS

FN fans are designed to operate up to 1" static pressure with

capacities to 22,400 CFM. Available in 9 sizes, 14" through

48”, these heavy duty fans are designed for industrial type

applications where extra strength and durability are desired.

Fan panels are constructed of steel and range from 18 to 14

gauge.

Aluminum blade thickness is from .080” to .125”.

The swept-back teardrop blade shape with its aerodynamic

leading edge propels the air through the streamlined orifice

with a minimum of air turbulence.

FQ not available with steel propeller.

HIGH PRESSURE PROPELLERS

For increased pressure requirements, FN propellers,

depending on size and horsepower, have four or six tapered

circular-arc airfoil blades. Standard construction is all welded

heavy duty aluminum that is precision balanced.

Non-overloading design prevents motor overload when

operated within cataloged static pressure ranges. Optional

steel prop is available for all FN fans, except size 48".

LICENSED RATINGS FOR SOUND AND AIR

Acme Engineering & Manufacturing Corp. certifies that the FQ and FN Propeller Fans shown herein are licensed to bear the

AMCA Seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and

AMCA Publication 311 and comply with the requirements of the AMCA Certified Ratings Program.

The sound ratings shown are loudness values in fan sones at 5 feet in a hemispherical free field calculated per AMCA Standard

301. Values shown are for installation Type A: Free Inlet fan sone levels.

Most Acme FQ and FN fans are listed by the Canadian Standards Association Testing Laboratory as approved.

Page 2

Page 3

CONSTRUCTION FEATURES

FAN PANEL - Construction of heavy

gauge steel. Wide flange on all four

sides provides extra strength and rigidity

to reduce the possibility of vibration and

for a more secure installation. Standard

finish is acrylic epoxy.

FQ09 AND 10

FQ12 THRU 18

EXHAUST MODELS FQ09 and 10

utilize the rugged motor side wire guard

as the motor support means thereby

making this guard standard equipment.

Front (propeller side) guard is optional.

FQ09 and FQ10 are not available in

reverse flow (supply).

STREAMLINED ORIFICE - Die formed

for uniformity, the deep streamlined

orifice provides for high efficiency airflow

throughout the propeller.

FN14 THRU 18

FQ21 THRU 36

EXHAUST MODELS FQ12 to 36 have

the motor mounted on an all welded

steel plate and formed pipe frame

assembly for extra strength and rigidity.

Front and back guards are optional on

these sizes. FQ1210 and FQ129 are

not available in reverse flow (supply).

EASY TO INSTALL - Prepunched holes

in flange saves on installation time and

cost.

MOUNT IN ANY POSITION - All motors

are equipped with all-angle thrust ball

bearings.

FN21 THRU 48

EXHAUST MODELS FN14 to 48 have

the motor mounted on an all welded

steel plate and formed pipe frame

assembly for extra strength and rigidity.

Front and back guards are optional on

all sizes.

Supply fans are available in all models

except FQ09, 10, 1210 and 129. The

airflow capacity is the same as for

exhaust type fans as shown on page 4.

REVERSE FLOW (SUPPLY) FANS

Only circular basket type guards are

available with these fans.

When supply type fans are used with

motorized wall dampers, it is

recommended to use WAGC and

RESERVE MOTOR POWER - Fans are

designed with conservative motor

loadings and efficient motor cooling to

obtain longer motor life under

continuous duty operation.

All motors are totally enclosed type with

lubricated sealed ball bearings. All

single phase motors have automatic

resetting thermal overloads for low

voltage protection.

Models FQ09, 10, 1210 & 129 use two

speed tapped winding, single phase,

shaded pole type ball bearing motors

only.

WAGCH center pivot dampers. A

time delay is recommended in the fan

motor’s starter control circuit to

allow the damper to fully open before

the fan is activated.

All other models have split phase,

capacitor start, capacitor run, or

permanent split capacitor single phase

motors. Some are available in two

speed types.

Explosion resistant and three phase

single speed motors are also available

for some models. Consult your Acme

Representative for more details plus

availability of motors.

Single phase motors are resilient

mounted in circular neoprene vibration

isolators integral with the motor base.

Page 3

Page 4

PERFORMANCE DATA

FAN

MODEL

FQ098LO

FQ098HI

FQ108LO

FQ108HI

FQ1210LO

FQ1210HI

FQ129LO

FQ129HI

FQ12D4

FQ14C6

FQ14F4

FN14D4

FN14E4

FQ16C6

FQ16F4

FQ16H4

FN16F4

FQ18E6

FQ18G6

FQ18H4

FN18G4

FQ21G6

FQ21K4

FN21J4

FN21K4

FQ24F8

FQ24H6

FN24J6

FN24J4

FN24L4

FQ30H8

FQ30K8

FQ30M6

FN30L6

FN30M6

FQ36K8

FQ36L8

FN36K8

FN36L6

FN36M6

FN42K8

FN42L8

FN42M8

FN48K8

FN48L8

FN48M8

TIP

RPM

SPEED

Ft/Min

1500

3435

1650

3780

1500

3925

1650

4320

3030

980

3280

1060

4180

1350

4795

1550

5445

1760

1160

4150

1760

6295

1760

6450

1760

6450

1160

4800

1760

7280

7280

1760

1760 7370 1/3 17 3200 3030 2980 2740 2480 2170 1500 1350 .393 36

1160

5505

1160

5505

8350

1760

1760 8290 1/2 21 4170 4000 3960 3760 3520 3250 2950 2520 2040 .571 33

1160

6325

1760

9595

1760

9670

1760

9670

860

5430

1160

7325

1160

7280

1760

11050

11050

1760

860

6700

6700

860

9035

1160

1160

9110

1160

9110

860

8020

860

8020

8100

860

10930

1160

10930

1160

860

9456

860

9456

9456

860

860

10800

860

10800

10800

860

SONES

HP

1/28

1/28

1/28

1/2866

1/28

1/28

1/8

1/8

1/6

1/8

1/3

1/6

1/4

1/6

1/3

3/4

1/4

1/2

3/4

1/2

1 1/21324

1 1/23030

1/3

3/4

1 1/2

1 1/2

1 1/2

1 1/2

1 1/2

1

1

1

2

3/4

3

2

3

2

2

3

2

3

2

3

@

.100”SP

10

14141880

16

17

12

17

10145550

23

39

40

18

14

21

303112450

212214450

27

43

43

32

33

43

36

39

41

CFM vs. STATIC PRESSURE

.000” .100” .125” .250” .375” .500” .625” .750” .875” 1.000” Lbs.

8

455

355

500

620

685

870

4

940

4

1200

5

1380

6

1565

8

7141625

2460

2160

2180

8

2580

3710

3210

9

4030

4870

5250

6750

6330

8150

7140

8150

6420

9590

8860

11600

15100

16040

17800

13160

14280

17740

17560

19400

22320

17120

19340

22400

10970

14660

12100

15500

13800

17000

12650

13920

17360

16700

18600

21650

15900

18200

21600

385 b 70

410

530

505

600

580

565

645

685

750

1030

1075

1280

1475

1440

2380

1780

2050

2020

2490

3600

2960

3720

4720

5020

6570

6150

7930

5110

6820

7760

6220

9400

8310

1245

1450

1375

2350

1750

2020

1960

2460

3570

2890

3640

4670

4950

6530

6100

7880

4990

6750

7660

6190

9360

8150

10800

14570

12000

15420

13620

16800

12520

13820

17270

16340

18220

21450

15530

17930

21440

1035

1090

1295

2170 1940

1600

1430

1850

1640

1620

2150

2320

3240

3430

2500

2730

3300

4220

4450

4550

4080

6300

6050

5860

5600

7590

7250

4200

5660 4850

6260

6350

7080

5700

5950

8870

9110

6380

7330

9000

9950

13330

13980

11500

10900

14750

14000

12580

11570

15800

14700

10950

11800

12700

13300

16200

16780

14970

16980

19000 16250

20460

12400

13950

15060

16550

18940

20360

1300 965 760

1850

2770

3010

3960

5780 5490 5160 4700

5320

6880

5450

8590

12610 11900 11130

10300

13150

13300

9900

12050

15600

10640

13360

17170

3700

5020

6440

5170

8210

9580

12050

8500

11400

15000

9025

11630

15260

3350

4690

4290 3800

5840

4870

4530

7950

7600

8720 7750

6600

5250

10700

10000

14300

6000

7420

8240

9900

11285

13110

4180

7200

4000

4300

6840

10090

MAX

BHP

b120

.027

.034

.069

.105

.158

.100

.353

.208

.300

.148

.390

.685

.253

.470

.870

.610

1.5108391

1.089

1.7126882

.389

.882

.980

1.070

2.100

.830

1.370

3.060

1.96

3.03

1.640

2.420

1.66

2.26

3.14

1.80

2.26

3.45

1.71

2.19

3.01

FAN

SHIP WT.

15

15

17

17

27

27

27

27

29

32

35

32

35

37

40

40

40

48

48

93

93

121

85

99

132

168

174

175

213

197

203

199

204

244

212

222

230

223

233

241

DAMPER

MODEL

WAG

WAG

WAG

WAG

WAG

WAG

WAG

WAG

WAG

WAGH

WAG

WAG

WAG

WAG

WAGH

WAG

WAG

WAGH

WAGH

WAG

WAGH

WAGH

WAGH

WAGH

WAG

WAGH

WAGH

WAGH

WAGH

WAG

WAGH

WAGH

WAGH

WAGH

WAGH

WAGH

WAG

WAGH

WAGH

WAG

WAGH

WAGH

WAG

WAG

WAGH

Performance shown is for Installation Type A: Free Inlet, Free Outlet.

The sound ratings shown are loudness values in fan sones at 5 ft

(1.5m) in a hemispherical free field calculated per AMCA Standard

301. Values shown are for Installation Type A: Free Inlet fan sone

levels.

Performance ratings do not include the effects of appurtenances in

the airstream; FQ12 through FQ48. Performance ratings include the

effect of a back guard (motor side) on models FQ09 and FQ10.

Model numbers shown are for Exhaust Fans with standard direction

of airflow (motor on intake side of propeller). For Supply Fans with

direction of airflow reversed (motor on discharge side of propeller)

add letter “R” to the model number; example: FN-R14.

Reverse flow (supply) not available for models FQ09, 10, 1210, and

129.

The brake horsepower (BHP) capability of a fan motor is dependent on the

degree of cooling the motor receives from the moving airstream over the

motor. The motor loading beyond the motor nameplate rating on Acme

built fans does not overheat the motor and is within NEMA recommended

limits. It is therefore not detrimental to the motor and is economically

desirable.

See Page 7 for damper model numbers and sizes.

b Watts

Page 4

Page 5

DIMENSIONAL DATA

EXHAUST FANS

FAN

MODEL

FQ09 12.00

FQ10 14.00

FQ12 16.00

FQ14 18.00

FN14 18.00

FQ16 21.00

FN16 21.00

FQ18 23.00

FN18 23.00

FQ21 26.50

FN21 26.50

FQ24 30.00

FN24 30.00

FQ30 37.50

FN30 37.50

FQ36 45.00

FN36 45.00

FN42 60.00

FN48 64.00

A B Max. C D E* F

In. In. In. In. In. In. Ga. In.

5.75

7.00

13.25

15.00

13.67

15.50

14.76

19.00

13.82

17.50

17.71

20.00

17.78

26.25

20.13

24.75

21.38

18.62

21.00

1.50 1.50

3.00 1.50

4.00 1.50

4.50 1.50

3.75 1.50

5.00 1.50

4.00 1.50

5.50 1.50

4.50 1.50

6.00 1.75

5.00 1.75

6.50 1.75

6.00 1.75

7.50 1.75

8.00 1.75

8.00 1.75

9.00 1.75

6.37 3.06

7.50 3.06

8.00

10.00

10.00

10.00

10.00

8.00

8.00

9.00

9.00

10.00

10.00

8.00

8.00

10.00

10.00

12.00

12.00

15.00

16.00

Metal Gauges

Orifice Blades

2.00 18 .050

2.00 18 .050

3.00 18 .063

4.00 18 .080

4.00 18 .080

2.50 18 .080

2.50 18 .080

2.50 18 .080

2.50 18 .080

3.25 16 .080

3.25 16 .080

3.00 16 .080

3.00 16 .125

3.75 16 .125

3.75 16 .125

4.50 16 .125

4.50 16 .125

7.50 14 .125

8.00 14 .125

SUPPLY FANS

FAN

MODEL

FQ-R12 16.00 14.75 2.50 1.50

FQ-R14 18.00 16.75 3.25 1.50

FN-R14 18.00 13.50 1.50 1.50

FQ-R16 21.00 20.00 4.50 1.50

FN-R16 21.00 17.00 1.50 1.50

FQ-R18 23.00 21.75 4.00 1.50

FN-R18 23.00 19.00 1.50 1.50

FQ-R21 26.50 22.00 2.75 1.75

FN-R21 26.50 22.00 1.75 1.75

FQ-R24 30.00 21.00 1.50 1.75

FN-R24 30.00 25.00 1.75 1.75

FQ-R30 37.50 27.09 4.50 1.75

FN-R30 37.50 25.50 1.75 1.75

FQ-R36 45.00 25.25 5.00 1.75

FN-R36 45.00 30.00 1.75 1.75

FN-R42 60.00 30.50 2.00 3.06

FN-R48 64.00 32.25 2.50 3.06

A B Max. C D E* F

In. In. In. In. In. In. Ga. In.

10.00

10.00

10.00

8.00

8.00

9.00

9.00

10.00

10.00

8.00

8.00

10.00

10.00

12.00

12.00

15.00

16.00

*The number of holes varies depending on fan size.

FQ09 thru FN14 - 2 Holes, FQ16 thru FN21 - 3 Holes,

FQ24 thru FN48 - 4 Holes.

Typical drawings for dimensional purposes only, which are correct

within limits suitable for normal installation requirements and do not

necessarily show actual construction.

Metal Gauges

Orifice Blades

3.00 18 .063

4.00 18 .080

4.00 18 .080

2.50 18 .080

2.50 18 .080

2.50 18 .080

2.50 18 .080

3.25 16 .080

3.25 16 .080

3.00 16 .080

3.00 16 .125

3.75 16 .125

3.75 16 .125

4.50 16 .125

4.50 16 .125

7.50 14 .125

8.00 14 .125

Page 5

Page 6

SAFETY GUARDS

OPTIONAL ACCESSORIES

CIRCULAR TYPE

(SIZE 09 THRU 18)

Attractive circular type safety guards are

available for exhaust type fans through

size 18. They are constructed of heavy

gauge concentric wire rings welded to a

frame and finished with electroplated

zinc to produce attractive sturdy guards

that comply with OSHA standards.

The motor side circular guards for FQ09

and FQ10 are integral with the motor

mounting frame and are standard

equipment.

The circular type wire guards are

available for the motor and propeller

sides as optional equipment for exhaust

fan sizes 12 through 18.

COATINGS

Aluminum and galvanized components

remain unpainted as a standard finish,

but when required, are processed

through the finishing system to apply

decorative or special coatings. A high

turbulence oven is used to produce a

baked on finish for most special

coatings. Decorative coatings are not

baked on.

DECORATIVE COATINGS

Acme offers 16 popular colors for

decorative finishes utilizing an industrial

grade enamel applied to the exterior of

fan. Special colors are available upon

request. See your Acme Representative

for complete color selections.

SQUARE TYPE

(SIZE 21 THRU 48)

Extruded aluminum frame guards Model

BA for back (motor side) and Model FA

for front (propeller side) are available for

fan sizes 21 through 48. Constructed of

½” x 1” mesh heavy gauge welded

galvanized wire and are open on all

sides for maximum airflow. Guards are

shipped knocked down, easily

assembled with connecting clips which

bolt to fan frame and are easily removed

for servicing the fan.

The openings for these guards comply

with OSHA standards.

Optional guards are also available for

reverse flow (supply type) fans from

sizes 12 through 48.

SPECIAL COATINGS

Products receiving special coatings have

components painted before assembly.

Fasteners are not painted.

• ACRYLIC EPOXY

This product provides a more durable

surface.

• CARBOLINE SANITILE

(Eisenheiss)

This air dry synthetic polyester forms a

black coating that offers greater

resistance to most organic and inorganic

acids.

CAUTION! Guards must be installed

when a fan is within reach of personnel or

within seven (7) feet of working level or

when deemed advisable for safety.

• HERESITE (Air Dry)

A phenolic coating with greater

resistance to most organic and inorganic

acids.

• INSULMASTIC

A black asphalt based mastic that

provides some condensation control,

sound deadening and corrosion

resistance.

NOTE: For any coating selected the user

assumes the responsibility for the

corrosive agent, its concentration,

temperature, moisture content and the

ultimate effect on the coating and

equipment.

Page 6

Page 7

OPTIONAL ACCESSORIES

DAMPER (Model WAG or WAGC)

Constructed of rigid galvanized steel frame with double tie

rods on the blades. Blades are industrial grade aluminum

reinforced with steel rods. Nylon bearings are used to

resist corrosion and prevent damper sticking making for

quieter operation.

HEAVY DUTY DAMPER

(Model WAGH or WAGCH)

Heavy duty dampers are recommended when the air

velocity exceeds 1500 FPM and up to 2500 FPM. Heavy

duty dampers are similar in construction to standard duty

dampers except each blade has a formed reinforcement

member providing extra strength and rigidity.

CENTER PIVOT

DAMPER

(Model WAGC or

WAGCH)

When a supply type

fan is used, a

motorized center

pivot type damper,

model WAGC-MT or

WAGCH-MT should

be substituted for the

WAG or WAGH. For

2 HP units and

larger, it is

recommended that a

time delay switch be

utilized. For center

pivot damper add “C”

to damper model

number.

AUTOMATIC DAMPERS

Wt.

Lbs.

Damper

11 x 11 14 x 14

13 x 13 16 x 16

15 x 15 18 x 18

18 x 18 21 x 21

20 x 20 23 x 23

23 x 23 26 x 26

27 x 27 30 x 30

34 x 34 37 x 37

42 x 42 45 x 45

57 x 57 60 x 60

57 x 57 60 x 60

FAN

MODEL

FQ09

FQ10

FQ1210 - 12 WAG1616 9 WAGH1616 10

FN/FQ14

FN/FQ16

FN/FQ18

FN/FQ21

FN/FQ24 WAG3030 17 WAGH3030 19

FN/FQ30

FN/FQ36

FN42

FN48 WAG6060 54 WAGH6060 61

Models 1212 through 3737 are single panel; 4545 through 6060 are double panel.

Maximum velocity for WAG style is 1500 FPM. Maximum velocity for WAGH style is 2500 FPM.

Use WAGC-MT or WAGCH-MT for supply (reverse) installations.

Standard Duty Heavy Duty

Model

WAG1212 6 WAGH1212 7

WAG1414 8 WAGH1414 9

WAG1818 10 WAGH1818 11

WAG2121 11 WAGH2121 12

WAG2323 12 WAGH2323 13

WAG2626 14 WAGH2626 15

WAG3737 24 WAGH3737 26

WAG4545 30 WAGH4545 33

WAG6060 54 WAGH6060 61

Wt.

Lbs.

Model

Overall

Size

In. In.

9 x 9 12 x 12

Size

WARNING! Supply type fans utilizing a motorized wall damper should

have a time relay in the fan motor’s starter control circuit to allow the

damper to fully open before the fan is activated.

Automatic, Motorized or Manual Operated.

Automatic dampers open with the airflow of the fan and are spring

closed. Not available with supply (reverse) type fans.

Motorized dampers use a stall type motor and are spring closed.

For motorized damper add “MT” to damper model number.

Manual dampers open with a pull chain and are spring closed. For

manual damper add “ML” to damper model number.

WALL COLLAR (Model WC)

For sizes 09 through 21 exhaust or

supply type. Designed for damper

to be installed flush with wall

surface. Damper is optional.

Constructed of galvanized steel.

(Shipped Knocked Down)

WALL COLLAR

Dimensions

FAN MODEL

FQ09 WC9FQ 12.25 10.00 15.25 10.00 2.63 18

FQ10 WC10FQ 14.25 10.00 17.25 12.00 2.63 20

FQ12 WC12FQ

FN/FQ14 WC14FQ

FN/FQ16 WC16FQ

FN/FQ16 WC18FQ

FN/FQ21 WC21FQ 26.75 13.00 29.25 24.00 2.88 35

Wall Collar

Model

A B C D E Weight

In. In. In. In. In. Lbs.

16.25 12.00 19.25 14.00 2.63 22

18.25 12.00 21.25 16.00 2.63 25

21.25 12.00 24.25 19.00 2.63 27

23.25 13.00 26.25 21.00 2.63 31

SOLID STATE SPEED

CONTROLLER Solid

state controllers are

available for selected

fans equipped with 115

volt, 60 Hz single

phase shaded pole and

smaller size permanent

split capacitor motors.

They provide a variable

speed control with

fewer parts to wear out

and eliminate the need for 2-speed

motors. Easily installed in a standard

wall box, they require a simple 2-wire

connection, but are equipped with a

third wire that maintains a constant

voltage to the damper motor in the

event a motorized wall damper is used

with the fan. Contact your Acme

Representative for 50 Hz requirements.

Page 7

Page 8

CENTRIFUGAL

VENTILATION FANS

DUCT FANS

PROPELLER AND

INLINE CENTRIFUGAL

CEILING, INLINE AND

CABINET FANS

CENTRIFUGAL &

PROPELLER ROOF

EXHAUST FANS

CENTRIFUGAL &

PROPELLER ROOF

SUPPLY FANS

CENTRIFUGAL AIR

HANDLING FANS

CENTRIFUGAL AND

PROPELLER UPBLAST

ROOF EXHAUSTERS

CENTRIFUGAL AND

PROPELLER

WALL FANS

CENTRIFUGAL

INDUSTRIAL

PROCESS FANS

MAKE-UP AIR SYSTEMS

CENTRIFUGAL

HEAVY DUTY

INDUSTRIAL FANS

EXHAUST &

SUPPLY VENTS

LIMITED WARRANTY Acme Engineering

and Manufacturing Corporation warrants the

products manufactured by Acme to be free

from original defects in workmanship and ma

terial for two years subject to the terms and

conditions of its published limited warranty.

Warranties on purchased products are sub

ject to the vendor’s warranty. Refer to current

Form MS149 for complete limited warranty

terms and conditions.

WARNING Acme products are designed and

manufactured to provide reliable perfor

mance but they are not guaranteed to be

100% free of defects. Even reliable products

ACME ENGINEERING &

MANUFACTURING CORP.

P.O. Box 978, Muskogee, Oklahoma 74402

Telephone: 918-682-7791 Fax: 918-682-0134

www.acmefan.com e-mail: acmefan@acmefan.com

will experience occasional failures and this

possibility should be recognized by the User.

If these products are used in a life support

-

ventilation systemwhere failure could resultin

loss or injury, the User should provide ade

quate back-up ventilation, supplementary

-

natural ventilation or failure alarm system, or

acknowledge willingness to accept the risk of

such loss or injury.

WARNING DO NOT use in HAZARDOUS

ENVIRONMENTS where fan’s electrical sys

-

tem could provide ignition to combustible or

flammable materials unless unit is specifically

built for hazardous environments.

CAUTION Guards must be installed when fan

is within reach of personnel or within seven (7)

feet (2.134 m) of working level or when

deemed advisable for safety.

DISCLAIMER The Company has made a dili

gent effort to illustrate and describe the prod

ucts in this literature accurately; however, such

illustrations and descriptions are for the sole

purpose of identification, and do not express or

imply a warranty that the products are mer

chantable, or fit for a particular purpose, or that

the products will necessarily conform to the il

lustrations or descriptions or dimension.

Member Air Movement and Control Association

September 2001 Form C4Q

-

-

-

-

Loading...

Loading...