Page 1

®

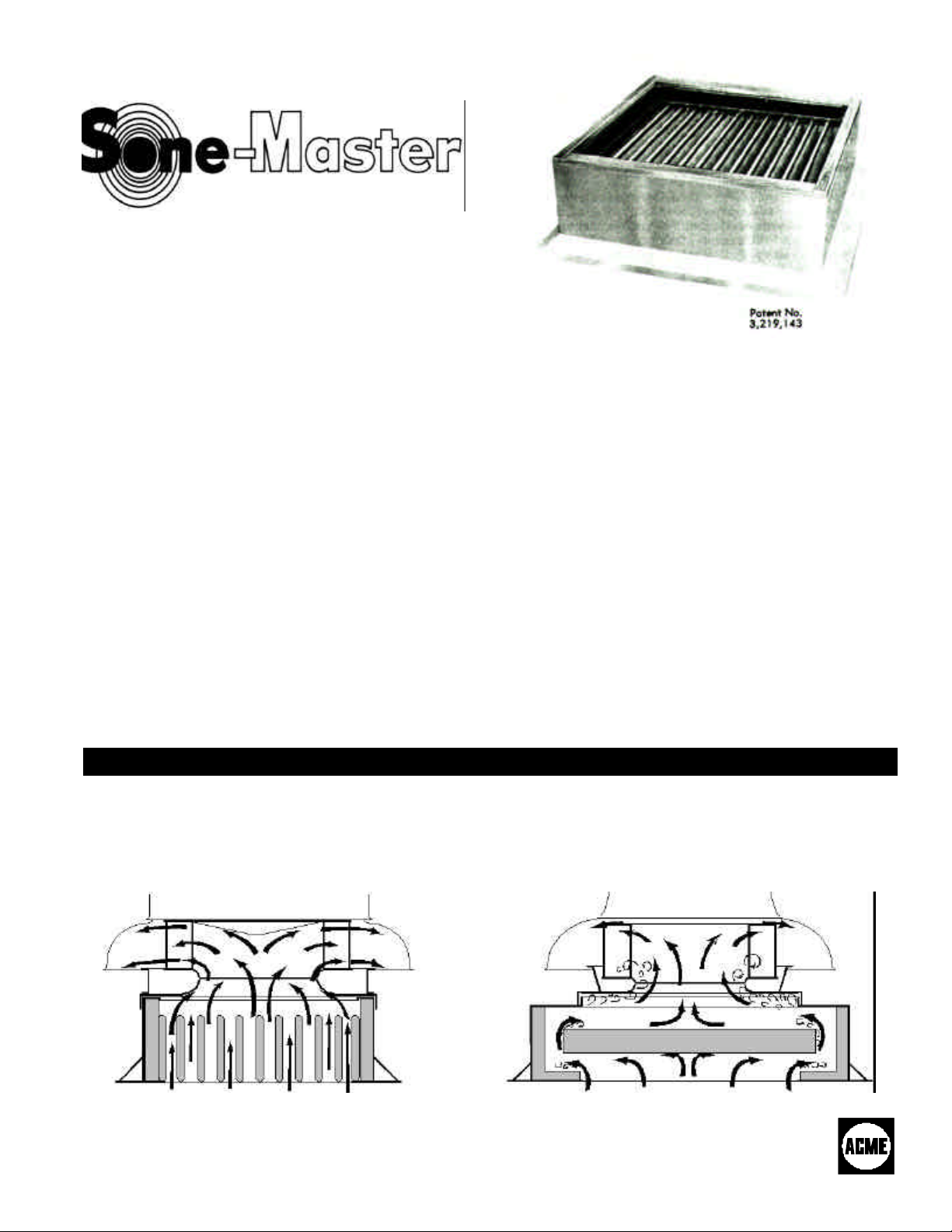

Sound Attenuating Curbs

An engineering concept that provides effective sound absorption with

lower airflow interference than the center baffle sound attenuating curbs.

For use with Centri Master® ® and Skymaster®® power roof

exhausters on exceptionally quiet ventilating applications or

where the specifications require sound attenuating curbs.

Therefore, when working with sones, use 0.60 as the sound

transmission coefficient in attenuation calculations and to

make the proper power roof ventilator selections.

This Acme development utilizes a core of modular type

sound absorbing cells that exposes a very large sound

absorbing surface to the sound transmitted to the curb from

the power roof ventilator.

The sound absorbing material consists of special

acoustical-type glass fibers held in galvanized framework.

The Sone-Master®® curb reduces the audible sound

produced by the power roof ventilator by approximately

40%. In other words, it transmits approximately 60% of the

sound entering the curb.

Sone-Master®® Curb vs. Center Baffle Type

The Sone-Master®® curbs, as previously explained, have a

very low airflow interference. The center baffle type sound

curbs, on the other hand, reduce the roof fan performance

much more than their resistance charts show. A typical

center baffle type curb resistance chart will indicate only 8

to 10% loss in roof fan performance.

The amount of attenuation in decibels of Lw(A) is

dependent upon the eight octave band sound spectrum of

the specific fan being used. The Centri Master®® spectrum

differs substantially from that of the Skymaster®® . In

addition, there are other dissimilarities in sound spectra due

to differences in motor horsepower. The factory should be

consulted when attenuation in Lw(A) is needed.

Low Airflow Interference

Since airflow is the first consideration in ventilation, a “low

loss” sound curb is essential. The Sone-Master®® sound

curb provides a straight-through streamlined air passage

that has an absolute airflow interference of only 2 to 4% for

most all applications.

The center baffle disturbs the airflow pattern at the fan

wheel inlet in a manner similar to an elbow at a blower inlet.

Wind tunnel tests repeatedly show this disturbance reduces

fan performance by as much as 3 times that caused by the

resistance. The result is a total fan performance loss of 20

to 35%. This total loss is called interference.

Form C16L

Section 11

Sone-Master®® Curb Center Baffle Type

Specify Quality.

Page 2

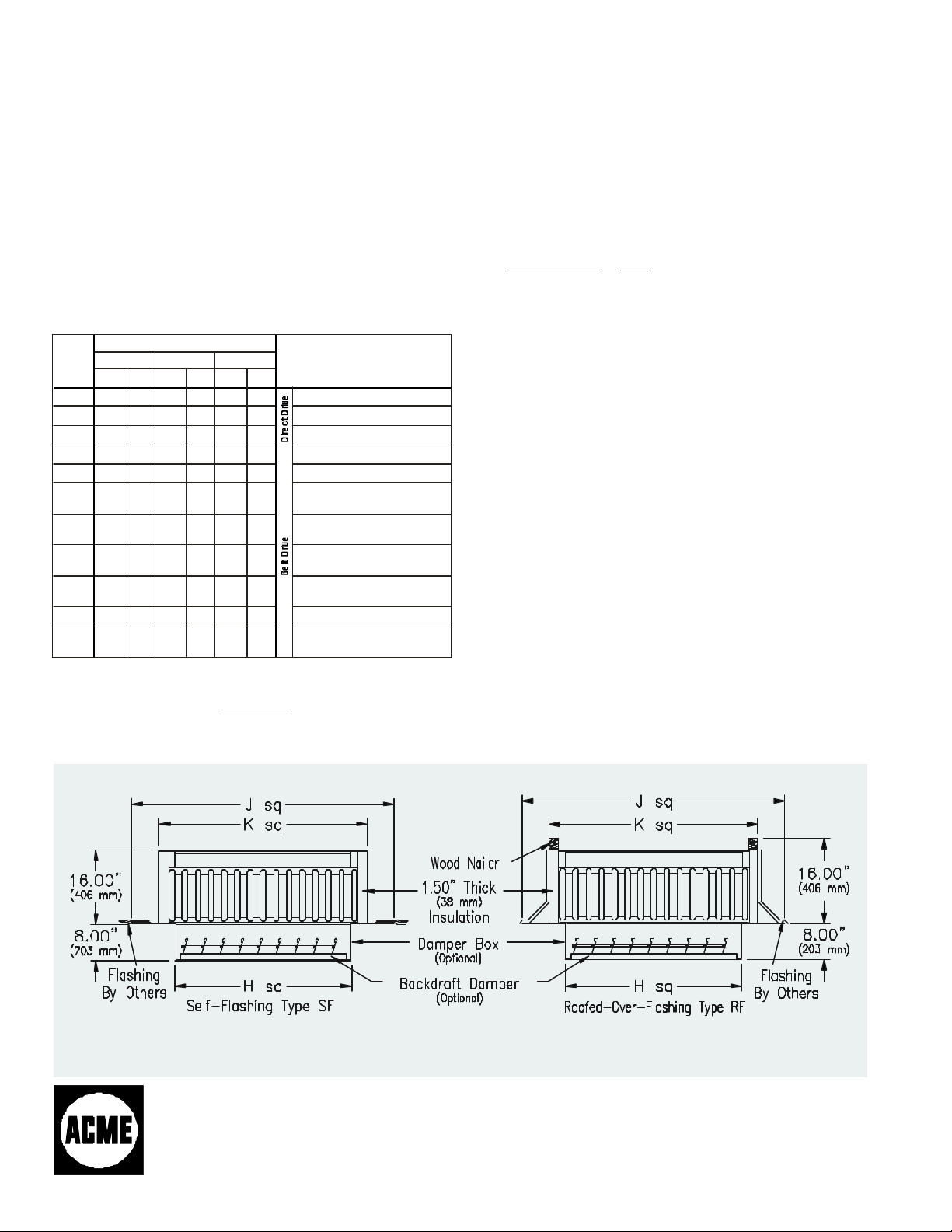

Construction

Heavy gauge galvanized steel sound curb has continuous

welded watertight corners. Curb is available as

Self-Flashing type (SF) or as Roofed-Over Flashing type

with built-in cant strip (RF).

All acoustical and thermal insulation materials are fire

resistant glass fiber. Internal sound absorbing cells have

galvanized framework. SF curb includes foam rubber

gasket for field installation to curb top. This gasket reduces

the transmission of any vibration or metal-to-metal

conducted noise. RF curb has a wood nailer as standard.

When used, the backdraft damper may be installed in the

mounting frame opening below the curb or attached to the

sound curb with a damper box.

Curb

Model

IN mm IN mm IN mm

CS14.5 11.00 279 22.50 572 14.50 368 PRN100-110

CS19.5 16.00 406 27.50 699 19.50 495 PRN118-145

CS22.5 16.00 406 30.50 775 22.50 572 PRN163-171

CS19.5 16.00 406 27.50 699 19.50 495 PNN100-135

CS22.5 16.00 406 30.50 775 22.50 572 PL & PU135-145; PNN163

CS26.5 20.00 508 34.50 876 26.50 673

CS32.5 26.00 660 40.50 1029 32.50 826

CS38.5 32.00 813 46.50 1181 38.50 978

CS44.5 38.00 965 52.50 1334 44.50 1130

CS52.5 46.00 1168 60.50 1537 52.50 1334 EC & ECH42

CS58.5 52.00 1321 66.50 1689 58.50 1486

Dimensions

H J K

Fan

Size

PL & PU163-171-200-223;

PNN200

ECH24; PL & PU245-270;

PNN245

EC30; PL & PU300-330;

PNN300

PL & PU365-403; PNN365; EC

& ECH36

PNN425; PNN, PL &

PU440-543; EC & ECH48

transmission factor (0.60) to determine the maximum

allowable sone level of the ventilator to be selected. Then

refer to the Acme catalog to select the model that fulfills the

airflow requirements and that does not exceed the

maximum allowable sone level just determined.

Example: Furnish a power roof ventilator providing

2800 CFM (1.321 m3 /s) at .125" S.P. (31 Pa) that will not

produce over 7.0 sones with a sound curb.

1. Maximum allowable ventilator sones =

desired sones

0 60

.

7 0

.

0 60

.

117

sones

.= =

2. Since in most ventilating applications the

Sone-Master®® curb interference is about 4%,

compensate for this by selecting an airflow capacity of

4% more than desired.

Selected CFM = Required CFM x 1.04

= 2800 CFM (1.321 m3/s) x 1.04

= 2912 CFM (1.374 m3/s)

3. Refer to the appropriate Acme catalog and select an

exhauster providing 2912 CFM (1.374 m3/s) at .125"

S.P. (31 Pa) having no more than 11.7 sones. In

catalog C14, PNN200E will meet the airflow

requirements. The performance curve shows this model

will produce 11.1 sones.

4. Desired sones = 0.60 x ventilator sones

= 0.60 x 11.1 (from catalog performance curves)

= 6.7 sones

Limited Warranty

To select the proper power roof ventilator when using

sones, divide the desired attenuated sone by the sound

Acme Engineering & Manufacturing Corporation reserves the right to change specifications without notice.

These are typical drawings for dimensional purposes only. They are correct within limits suitable for normal installation and do not necessarily show actual construction.

Acme Engineering &

Manufacturing Corporation

P.O. Box 978

Muskogee, OK 74402

Telephone 918/682-7791

Fax 918/682-0134

The Sone-Master®® curbs are subject to the same Warranty

and Terms and Conditions as listed in Acme catalogs C14,

C3, C23 and C13.

Mem ber Air Move ment and Con trol As so ci a tion Au gust 1994 Form C16L

Loading...

Loading...