Page 1

FORM 613107

Read and Save These Instructions

ASSEMBLY INSTRUCTIONS FOR MOTORIZING

AR or AW Single and Double Panel Dampers

Final assembly of the motor operating mechanism on AR or AW damper may be accomplished by the following

instructions:

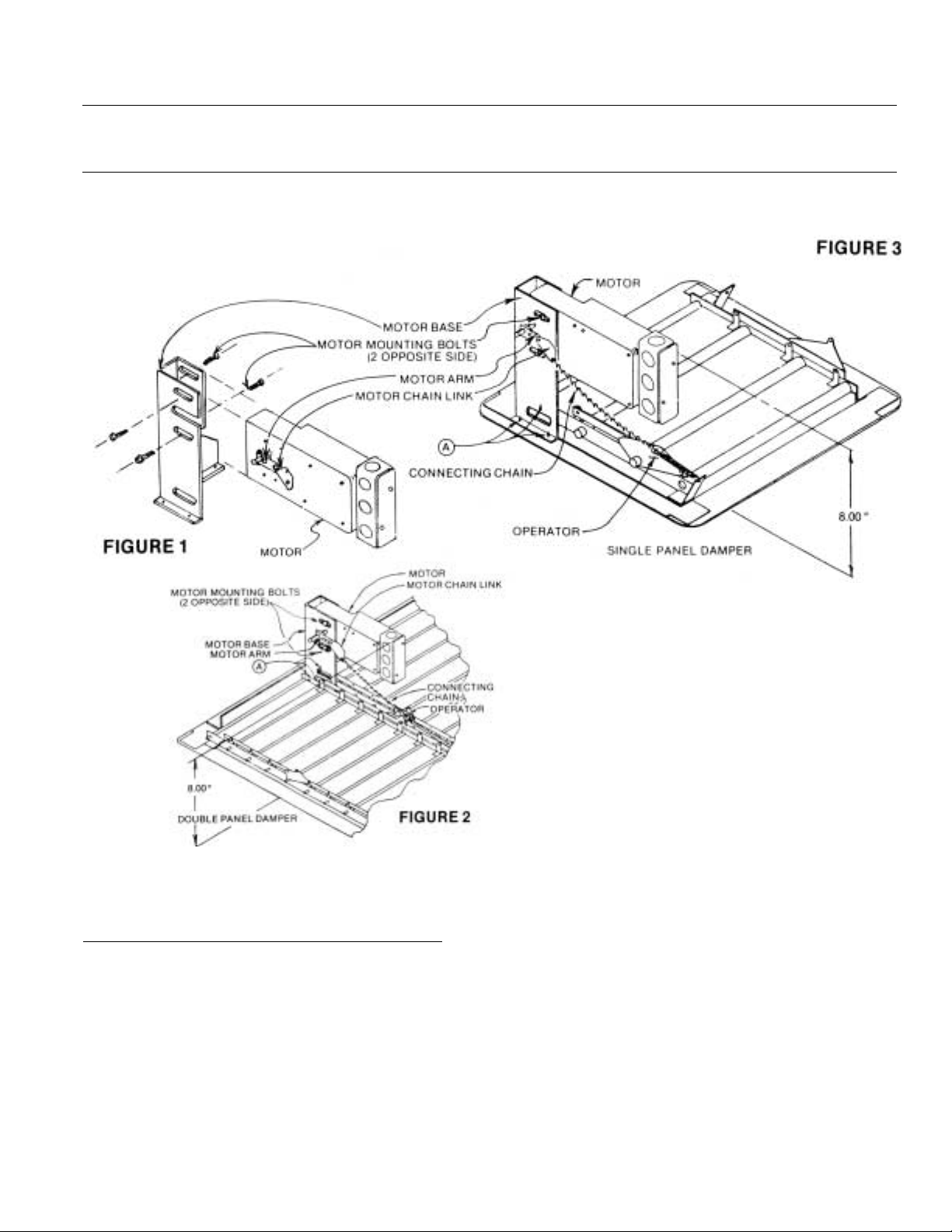

1. Attach the Motor to the Motor Base as shown in

Figure 1 using four 5/32” x 3/8” bolts. Do not

tighten bolts.

TABLE 1

AR&AW

SIZE

11-17

18-82

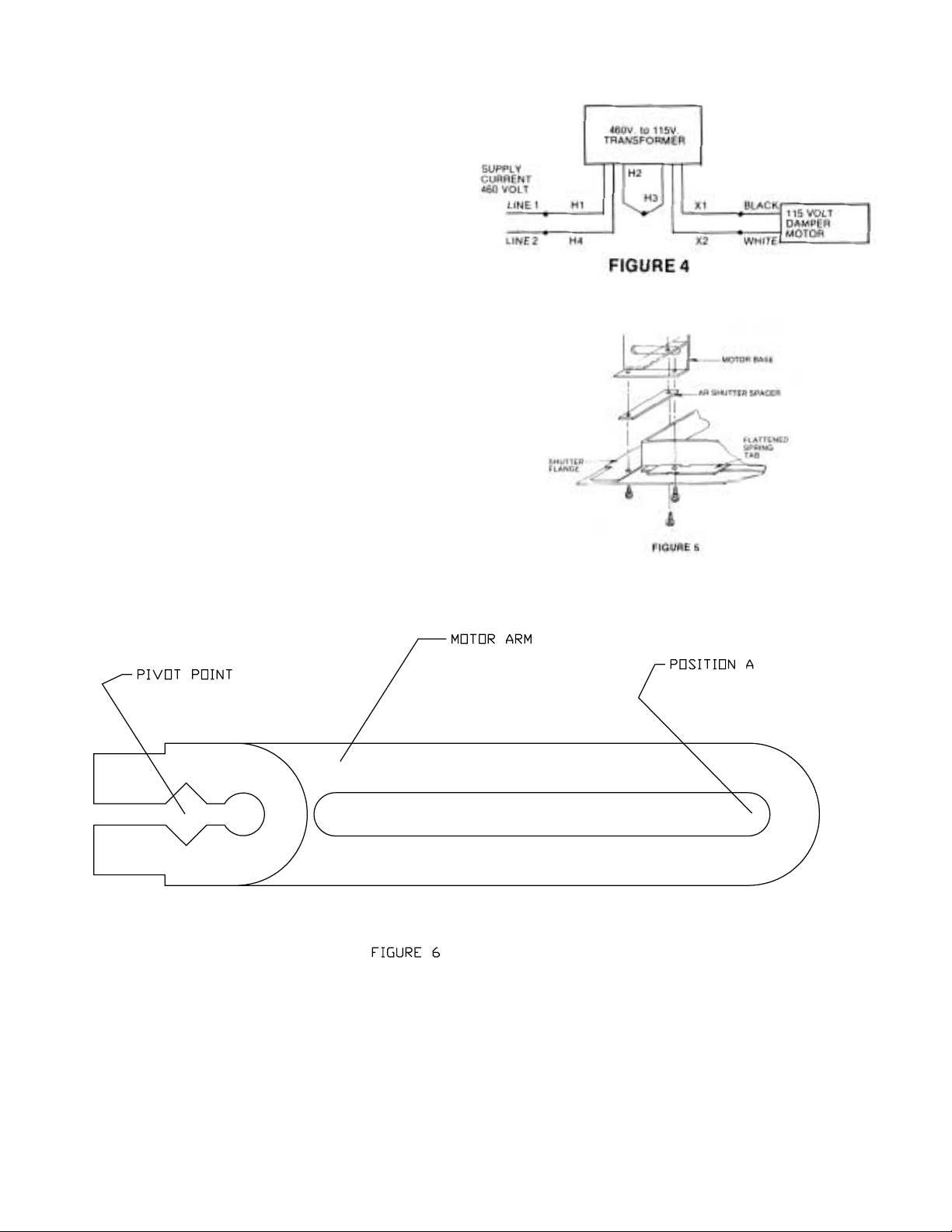

2. Remove all springs supplied on the unmotorized

version and discard. Flatten the spring tab to the

position shown in Fig. 5.

3. Place the motor assembly as shown in Fig. 2 for

double panel damper and Fig. 3 for a single panel

damper.

LENGTH TO

REMOVE

5.75"

Use Spring As Is

4. Mark the locations of the (3) holes in the motor base

on the flange.

5. Drill 11/64” (.172) dia. hole at each of the positions

marked.

6. Place the motorizing AR damper spacer between

the motor base and flange as shown in Figure 5.

7. Mount the motor assembly to the damper using

three No. 8 sheet metal screws marked “A” in

Figures2&3.

8. Attach the spring, supplied in the motorizing kit, to

the operator and the spring tab opposite the motor

as shown in Fig. 3. Refer to Table 1 for length.

9. Slide the Motor in the Motor Base slots toward the

center of the Damper. Rotate the motor arm to the

position shown in Fig. 1, 2 & 3.

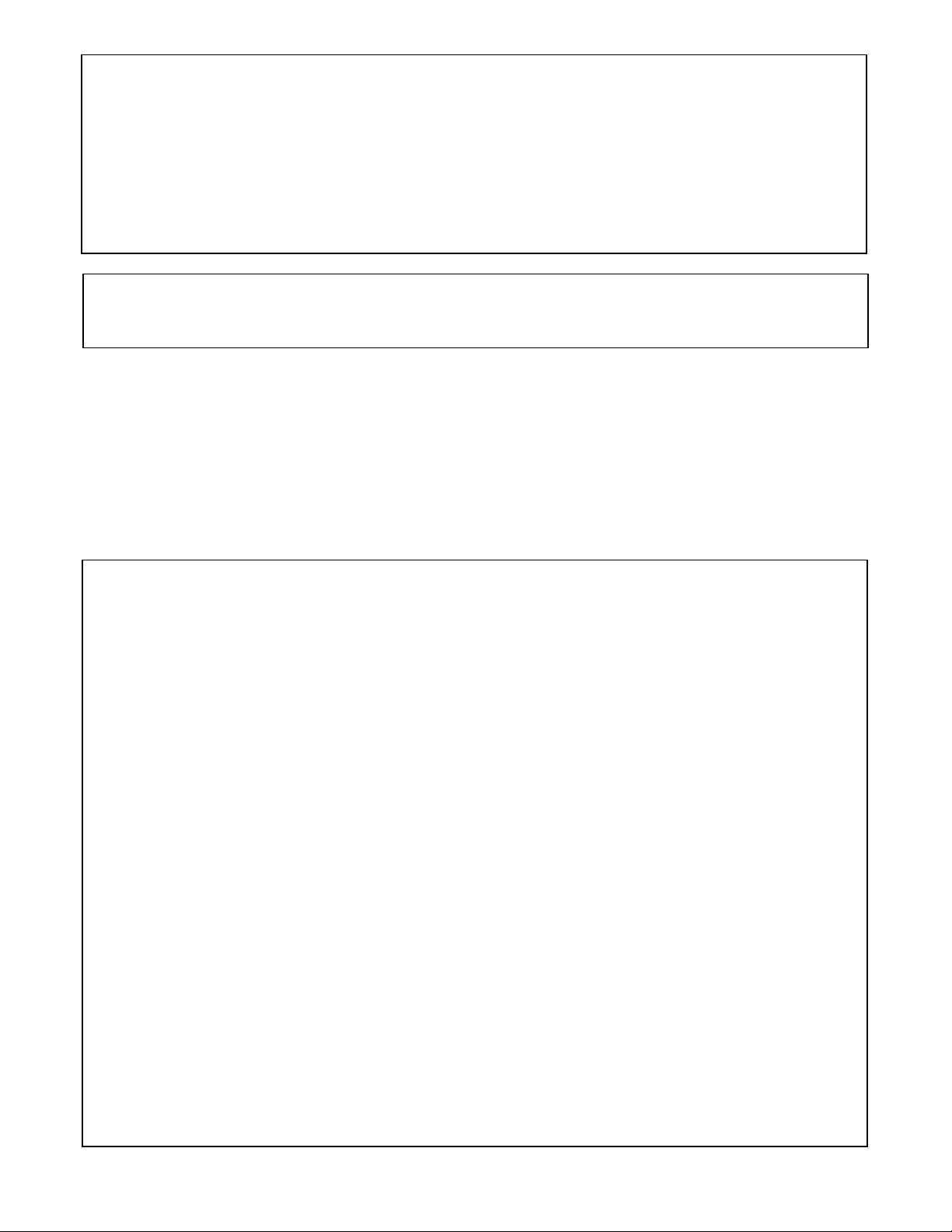

10.Connect the Motor Chain Link to the Motor Arm at

the furthest position (position A in Fig. 6) from the

Pivot Point. Remove a sufficient number of links

from the Connecting Chains such that as much

slack as possible is removed when installed. Install

the Connecting Chain from the Operator to the

Motor by hooking the end of the Connecting Chain

into the hole in the Operator. Close the end link

Page 2

around the Operator. Slide the Motor away from the

center of the damper until all slack is removed from the

Connecting Chain. Tighten Motor Mounting Bolts

thoroughly. Take care to maintain the 8 inch dimension

as shown in Figures 2 and 3.

Your damper is now ready to operate.

NOTE: The Damper Motors on this product

are stall type motors which are designed to

run continuously, in a stalled condition, when

the damper is open.

NOTE: If dampers do not open fully, the

connection between the Motor Arm and Motor

Chain Link can be slid towards the Pivot Point

(Fig. 6), to supply more torque to the operator.

NOTE: If this motorizing kit is to be used in an

application requiring 460 volt single phase

current, then a 115 volt Damper Motor and a

460 volt to 115 volt Step-Down Transformer

will be supplied and should be wired as shown

in Figure 4.

Page 2

Page 3

TERMS AND CONDITIONS

DESIGN CHANGES The Company reserves

the right to make changes in design, improve

ments and additions in and to its products any

time without imposing any liability or obligations

to itself to apply or install the same in any prod

uct manufactured by it.

TITLE The title and right of possession of the

equipment sold herein shall remain with the

Company and such equipment shall remain

personal property until all payments herein (in

These instructions cover the usual installation, operation and maintenance methods for which the product(s) was designed. They do not purport to

cover all details or variations in the product(s) nor to provide for every possible contingency that might be met in connection with the installation, oper

ation and maintenance. For any departures from these instructions, or should particular problems arise which are not covered sufficiently for the pur

chaser’s purpose, the matter should be referred to the Company.

cluding deferred payments whether evidenced

by notes or otherwise) shall have been made in

full in cash and the Purchaser agrees to do all

acts necessary to perfect and maintain such

right and title in the Company.

-

SAFETY ACCESSORIES The Company manu

factures equipment designed to serve multiple

applications and offers a wide range of safety

equipment, including guards and other devices,

as may be required to meet customer specifica

-

tions. Without exception, the Company recom

mends that all orders include applicable safety

devices. Equipment ordered without applicable

safety devices is clearly the responsibility of the

Purchaser. Further, the Purchaser warrants

that he has determined and acquired any and

all safety devices required for equipment sold

by the Company. Weather covers and guards

for motor and V-belt drives, couplings, shafts

and bearings, along with inlet and outlet

screens, are optional accessories noted in the

price list.

-

-

-

-

WARNING The Company products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of de

fects. Even reliable products will experience occasional failures and this possibility should be recognized by the User. If these products are used ina

life support ventilation system where failure could result in loss or injury, the User should provide adequate back-up ventilation, supplementary natural

ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials

unless unit is specifically built for hazardous environments.

CAUTION Guards must be installed when fan is within reach of personnel or within seven (7) feet (2.134 m) of working level or when deemed advisable

for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products in this literature accurately; however, such illustrations and

descriptions are for the sole purpose of identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular

purpose, or that the products will necessarily conform to the illustrations or descriptions or dimensions.

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: The Com-

pany extends this limited warranty to the original buyer and warrants that products manufactured by the Company shall be free from original defects in workmanship and materials for

two years from date of shipment, unless otherwise noted (see specific product literature), provided same have been properly stored, installed, serviced, maintained and operated.

This warranty shall not apply to products which

have been altered or repaired without the Com

pany’s express authorization, or altered or re

paired in any way so as, in the Company’s

judgment, to affect its performance or reliability,

nor which have been improperly installed or

subjected to misuse, negligence, or accident, or

incorrectly used in combination with other sub

stances. The Buyer assumes all risks and liabil

ity for results of use of the products. Warranties

on purchased parts, such as but not limited to

bearings, sheaves, belts, couplings, electric

motors, pumps and controls are limited to the

terms of warranty extended by our supplier.

Polyethylene tubing and cooling pads are war

ranted to be free of defects in material and

workmanship for a period of 90 days from date

of shipment and a like warranty applies to the

cross fluted cellular type cooling cells for a pe

riod of two years from date of shipment pro

vided same have been properly handled,

stored, installed, serviced, maintained and op

erated. And further, not subjected to excessive

heat, corrosive agents or chemicals, or me

chanical abuse that may cause tearing, crush

ing or undue deterioration nor used on a sys

tem or in a manner other than that for which it

was designed as explained in the product litera

ture.

LIMITATION OF REMEDY AND DAMAGES:

All claims under this warranty must be made in

writing and delivered to P. O. Box 978, Musko

gee, Oklahoma, 74402, within 15 days after dis

covery of the defect and prior to the expiration

of the warranty period from the date of ship

ment by the Company of the product claimed

defective, and Buyer shall be barred from any

remedy if Buyer fails to make such claim within

such period.

Within 30 days after receipt of a timely claim,

the Company shall have the option either to inspect the product while in Buyer’s possession

or to request Buyer to return the product to the

Company at Buyer’s expense for inspection by

-

the Company. The Company shall replace, or

-

at its option repair, free of charge, any product

it determines to be defective, and it shall ship

the repaired or replacement product to Buyer

F.O.B. point of shipment; provided, however, if

circumstances are such as in the Company’s

-

judgment to prohibit repair or replacement to

-

remedy the warranted defects, the Buyer’s sole

and exclusive remedy shall be a refund to the

Buyer of any part of the invoice price, paid to

the Company, for the defective product or part.

The Company is not responsible for the cost of

removal of the defective product or part, dam

-

ages due to removal, or any expenses incurred

in shipping the product or part to or from the

Company’s plant, or the installation of the re

paired or replaced product or part.

-

-

Implied warranties, when applicable, shall com

mence upon the same date as the express war

-

ranty provided above, and shall, except for war

ranties of title, extend only for the duration of

-

the express warranty. Some states do not allow

-

limitations on how long an implied warranty

-

lasts, so the above limitation may not apply to

you. The only remedy provided to you under an

-

applicable implied warranty and the express

warranty shall be the remedy provided under

the express warranty, subject to the terms and

conditions contained therein. The Company

shall not be liable for incidental and consequen

-

tial losses and damages under the express

-

warranty, any applicable implied warranty, or

claims for negligence, except to the extent that

-

this limitation is found to be unenforceable un

der applicable state law. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation

or exclusion may not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from

state to state.

No employee, agent, dealer, or other person is

authorized to give any warranties on behalf of

the Company or to assume for the Company

any other liability in connection with any of its

products except in writing and signed by an offi

cer of the Company.

REPLACEMENT PARTS If replacement parts

are ordered, buyer warrants that the original

components in which these replacement parts

will be placed are in satisfactory working condi

tion, and when said replacement parts are in

stalled, the resultant installation will operate in

a safe manner, at speeds and temperatures for

which the original equipment was purchased.

-

TECHNICAL ADVICE AND RECOMMENDA

TIONS, DISCLAIMER: Notwithstanding any

-

past practice or dealings or any custom of the

trade, sales shall not include the furnishing of

technical advice or assistance or system de

sign. Any such assistance shall be at the Com

pany’s sole option and may be subject to addi

tional charge.

-

The Company assumes no obligation or liability

on account of any recommendations, opinions

or advice as to the choice, installation or use of

products. Any such recommendations, opinions

or advice are given and shall be accepted at

your own risk and shall not constitute any war

ranty or guarantee of such products or their

performance.

GENERAL In no event shall any claim for con

sequential damages be made by either party.

The Company will comply with all applicable

-

Federal, State, and local laws.

-

-

-

-

-

-

-

-

-

-

April 2000 Form 613107

Loading...

Loading...