Page 1

Page 2

TABLE OF CONTENTS

DESIGN FEATURES

Page No

Design Features ..................................2-3

Optional Accessories...........................3

Hub & Blade Combinations .................4

Typical Specifications..........................4

AVD Performance Diagrams ...............5-8

AVD Dimensions ................................. 9

AVD Fan Weight..................................10

Metric Conversion Table......................10

Typical Installation...............................11

Warranty.............................................. 12

The VANEMASTER

™

impeller consists of two assembled hub discs with cavities to house the blades at preset

.

Acme Axial Flow Fans

™

The VANEMASTER

fans are compact, rugged, and precisely

constructed for your airflow-pressure conditions with adjustable

pitch blades (at rest).

VANEMASTER

™

fans are suited for a large number of air

handling applications in commercial, industrial and process

ventilation.

Distinguishing features of the VANEMASTER

™

fans are space

savings, ease of installation and high reliability.

angles. The blades of the rotor can be factory set to any angle between 25° and 60°, dependent on size and

speed. The rotor is provided with a hub boss for mounting onto the motor shaft.

Aluminum Blades: Special Operating

Ranges

Normal Operating Temperature -4 to 104°F

•

(-20 to 40°C) for standard fans.

• Maximum Temperature Range of the fan is

-40 to 302°F (-40 to 150°C) with special

motors and/or reduced speeds.

Motors

Standard motors are NEMA frame, flange

mounted type.

BLADE

MOTOR/BLADE ASSEMBLY

Adjustment Of Blade Angles

The blade pitch may be manually adjusted to obtain different performances. The rotor must be aligned and

balanced before starting. Care must be taken to not exceed the motor output power.

AVD For Duct Installations

™

The VANEMASTER

1600mm) and 7 hub diameters from 6 to 23 inches (152 mm to 584 mm). Air volumes from 212 to 116,500 CFM

(0.01 m

3

/s to 54.98 m3/s). The fan consists of a cylindrical casing with connecting flanges at both ends.

fan line comprises 14 sizes with impeller diameters ranging from 10 to 63 inches (254mm to

The mounting for the rotor serves as a downstream guide vane arrangement ensuring extremely high fan

efficiency.

The motor is flange-mounted and is provided with extended leads through the fan casing to a terminal box for

electrical connection.

Variable Frequency Controls

™

When designing ventilation and air conditioning systems, the VANEMASTER

fans with frequency convertors are

an excellent alternative to centrifugal fans with inlet vane controls for systems requiring varying air quantity

requirements.

Acme Engineering & Manufacturing Corporation certifies that the

models shown herein are licensed to bear the AMCA seal. The ratings

shown are based on tests and procedures performed in accordance

with AMCA Publication 211 and AMCA Publication 311 and comply

with the requirements of the AMCA Certified Ratings Program.

The sound ratings shown are loudness values in fan sones at 5 feet

(1.524 m) in a spherical free field calculated per AMCA Standard 301.

Values are shown are for Installation Type A: Free Inlet spherical

sone levels.

Model AVD is Listed for (UL/C-UL 705)

File No. E39982.

Consult your Acme representative for

availability.

Acme Engineering and Manufacturing Corporation Page 2

Page 3

DESIGN FEATURES

Investment, operating costs, and space requirements are lower for VANEMASTER™fans used in combination

with frequency converters that make even small installations economical.

The simple construction of VANEMASTER

™

fans provides a stable structure which minimizes vibration. Normally

there is only one or more vibration modes in which the associated speed(s) must be avoided. This is easily

accomplished by programming the variable frequency control.

As may be seen in the table, frequency control permits speeds and capacities in excess of the standard motor

rating. Care must be taken to not exceed the available motor output power or the maximum rotor speed.

Contrary to fixed speed fans, the use of speed regulation improves sound as lower speeds result in lower sound

power levels.

Max Speed (RPM) of VANEMASTER™ Rotors At 70 F (21 C)*

Hub

250 315 400 500 560 630 710 800 900 1000 1120 1250 1400 1600

5827 5080 4436 3943

160

230

280

330

380

403

578

4695 4112 3865 3676 3393 2993

4012 3755 3536 3334 3058 2571

3977 3686 3448 3215 2973 2665

3674 3388 3097 2859 2651 2324

NOMINAL WHEEL SIZE (mm)

2279 2125 1985 1833 1710

2128 1957 1804 1673 1553 1444

*Maximum allowable speeds may be adjusted for temperatures higher or lower than 70°F

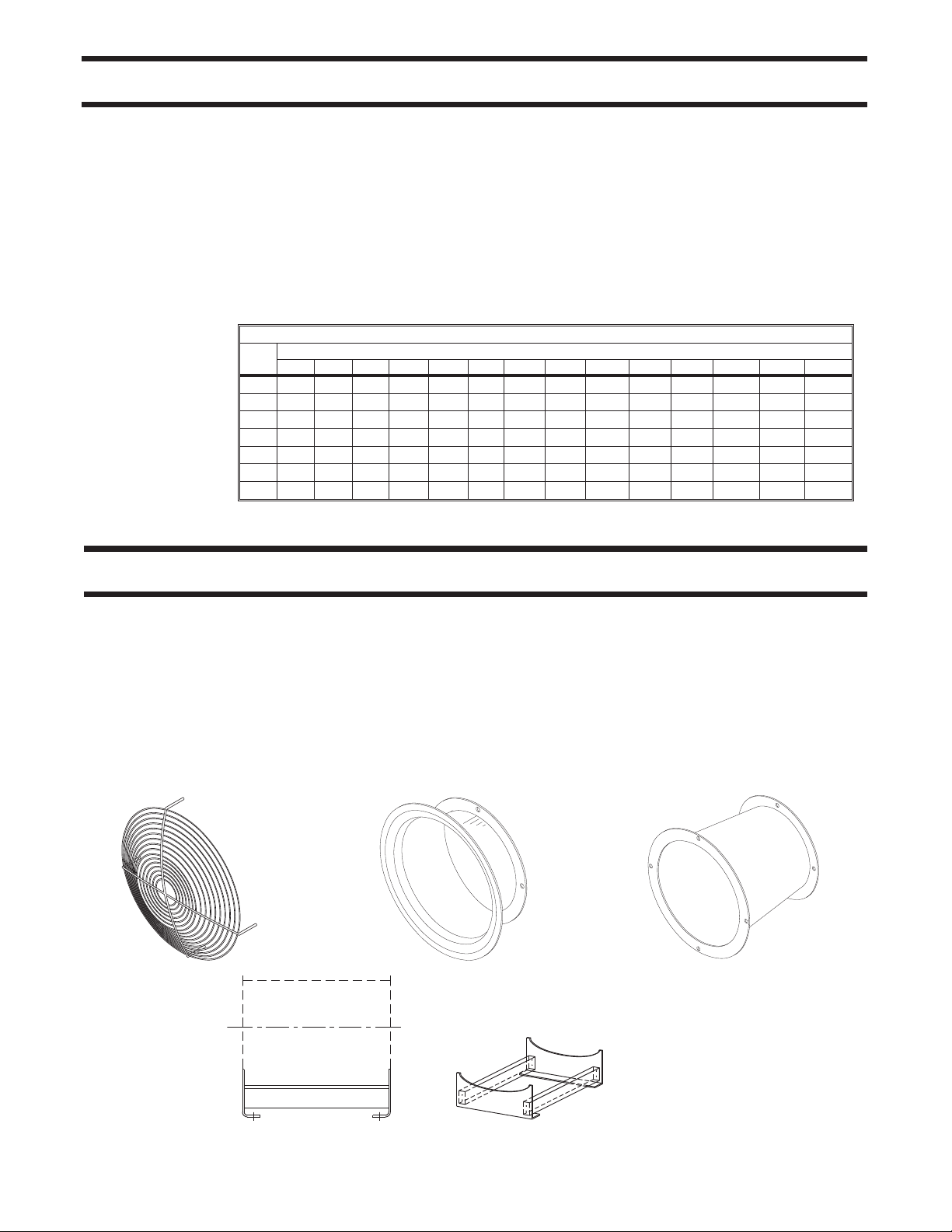

OPTIONAL ACCESSORIES

Mounting feet

Curb Cap(Sizes 400-1250)

Inlet/Guard

Inlet Bell

Outlet Guard

Discharger Hood

(Sizes 250-900)

Outlet Diffusers

(Sizes 800-1600)

Vibration Isolation mountings

Diffuser for outlet (short & long)

For sizing or details of these

accessories please review the

appropriate drawings.

Diffusers create lower discharge velocity

thus recovering some static pressure.

Diffuser can also be used on the inlet for

duct size differences.

Mounting Feet, Horizontal Air Flow.

Page 3 Acme Engineering and Manufacturing Corporation

Page 4

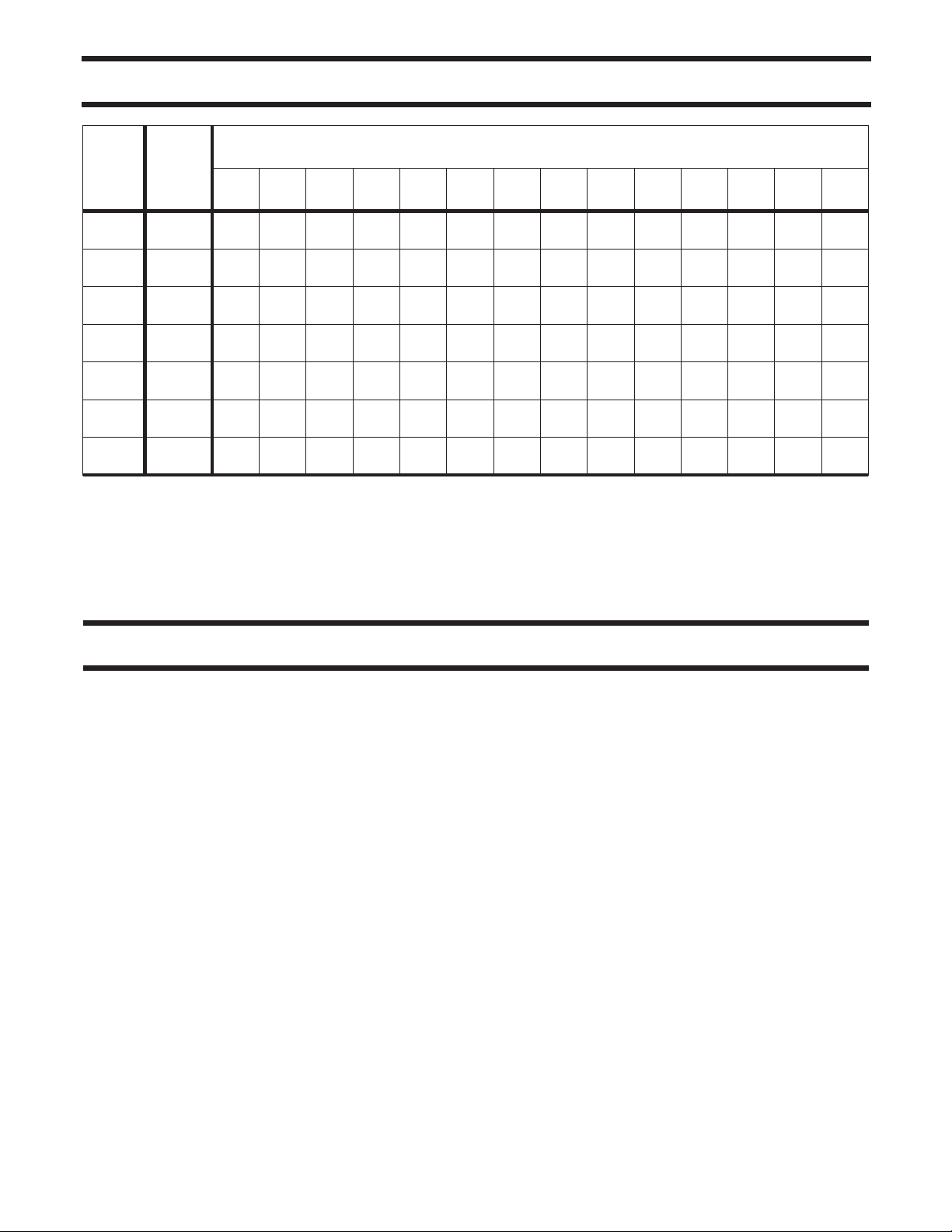

HUB AND BLADE COMBINATIONS

Hub

dia.

(mm)

160 4

230 6

280 8

330 10

380 12

403 6

578 10

AVD VANEMASTER™fans should be specified by giving both the fan diameter and the hub diameter. A typical

fan selection example would be AVD 1000/403. Additional data concerning motor RPM, voltage, Hz and

accessories are required to create the proper fan selection for each application.

Number

of

Blades

250 315 400 500 560 630 710 800 900 1000 1120 1250 1400 1600

••••

••••••

••••••

••••••

FAN DIAMETER (mm)

••••••

•••••

••••••

TYPICAL SPECIFICATIONS

Vane Axial fans shall be Direct Driven, Arrangement 4, with the motor located downstream from the impeller.

Impeller blades are to be made of a high strength, corrosion resistant, aluminum alloy. Blades are to be die cast

for maximum efficiency and low noise levels. The impeller hubs are to be die-formed of galvanized steel with

angle location marks to allow accurate blade setting at the factory or in the field.

The impeller shall be positively secured to the motor shaft. The impeller is to be statically and dynamically

balanced.

Fan housings shall be constructed of heavy gauge steel with integral prepunched flanges for leak-free

performance. High efficiency, straightening vanes of heavy gauge steel are to be installed to eliminate air swirl

and regain static pressure. The vanes are to be designed to support the motor and welded to the housings in a

manner designed to reduce air turbulence. Fans to be supplied with limited two year warranty.

Vane Axial fans shall be model AVD as manufactured by Acme Engineering & Manufacturing Corporation of

Muskogee, Oklahoma. Sizes and performance as shown on the plans.

Acme Engineering and Manufacturing Corporation Page 4

Page 5

AVD 560/330-10

1470 RPM

37° Blade Angle

AVD PERFORMANCE

CFM

Static

Pressure

Total

Pressure

Max HP

4958 4388 3901 3432 2925 2442

0.000 0.486 0.854 1.099 1.247 1.217

0.219 0.656 0.988 1.202 1.322 1.269

AVD 710/280-8

1470 RPM

43° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

10954 9854 8760 7672 6642 5485 4320 3345

0.000 0.398 0.722 0.945 1.068 1.143 1.232 1.439

0.160 0.521 0.819 1.019 1.124 1.181 1.256 1.453

Air Performance

.92

Air Performance

2.09

Sound Data

Static

Pressure

0.00 14.1 81

0.47 12.9 80

0.89 13.9 81

1.21 21 88

Spherical

Sones

Sound Data

Static

Pressure

0.00 20 87

0.31 20 87

0.58

0.86 26 92

Spherical

Sones

21 87

LwA

LwA

AVD 710/330-10

1470 RPM

45° Blade Angle

Air Performance

CFM

Static

Pressure

Total

Pressure

Max HP

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 ft) in a spherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type B: free inlet spherical sone levels.

11913 10738 9568 8388 7155

0.000 0.518 0.966 1.334 1.536

0.493 0.914 1.280 1.575 1.711

3.03

Static

Pressure

0.00 21 87

0.64 20 87

1.24 26 92

1.39 31 95

Sound Data

Spherical

Sones

LwA

Page 5 Acme Engineering and Manufacturing Corporation

Page 6

AVD PERFORMANCE

AVD 800/380-12

1470 RPM

39° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

13886 12535 11169 9804 8383 7019 5543 4130

0.000 0.620 1.169 1.589 1.827 2.012 2.122 2.260

0.426 0.966 1.443 1.800 1.980 2.120 2.189 2.297

AVD 900/380-12

1470 RPM

43° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

20368 18349 16355 14345 12373 10113 8273 6168 3426

0.000 0.647 1.205 1.645 1.911 2.111 2.214 2.391 2.774

0.541 1.085 1.552 1.911 2.109 2.243 2.302 2.440 2.789

Air Performance

3.62

Air Performance

5.78

Sound Data

Static

Pressure

0.00 27 91

0.80 26 91

1.40 37 98

1.70 44 101

Static

Pressure

0.10 34 95

0.70 33 95

1.30 46 101

1.90 62 106

Spherical

Sones

Sound Data

Spherical

Sones

LwA

LwA

AVD 1000/403-6

1470 RPM

39° Blade Angle

Air Performance

CFM

Static

Pressure

Total

Pressure

Max HP

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 ft) in a spherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type B: free inlet spherical sone levels.

27190 24566 21776 19088 16426 13396 10909 8188 3768

0.00 0.697 1.416 1.990 2.377 2.758 2.919 3.016 3.808

0.627 1.203 1.813 2.294 2.602 2.908 3.018 3.072 3.820

8.79

Static

Pressure

0.00 40 97

1.00 37 97

2.00 47 102

3.00 66 107

Sound Data

Spherical

Sones

LwA

Acme Engineering and Manufacturing Corporation Page 6

Page 7

AVD 1000/578-10

1470 RPM

29° Blade Angle

AVD PERFORMANCE DIAGRAMS

CFM

Static

Pressure

Total

Pressure

Max HP

17372 15659 13986 12212 10438 8732 6974 5213 2551 0

0.00 0.911 1.720 2.433 2.904 3.246 3.638 4.164 4.976 6.276

0.265 1.122 1.888 2.561 2.997 3.312 3.679 4.188 4.981 6.276

AVD 1000/380-12

1470 RPM

47° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

30227 27320 24351 21308 18232 15168 12153 9040 4623

0.00 0.71 1.34 1.85 2.20 2.41 2.43 2.65 2.99

0.79 1.35 1.84 2.24 2.49 2.60 2.56 2.72 3.00

Air Performance

8.67

Air Performance

10.72

Sound Data

Static

Pressure

0.00 48 99

1.50 49 102

3.00 62 106

4.00 63 105

Static

Pressure

0.00 41 99

0.63 42 99

1.27 52 102

1.90 68 107

Spherical

Sones

Sound Data

Spherical

Sones

LwA

LwA

AVD 1120/403-6

1470 RPM

42° Blade Angle

Air Performance

CFM

Static

Pressure

Total

Pressure

Max HP

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 ft) in a spherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type B: free inlet spherical sone levels.

39677 35905 32052 28135 24129 20172 16078 12016 5680

0.00 0.76 1.47 2.11 2.55 2.87 3.04 3.34 4.05

0.86 1.46 2.03 2.54 2.87 3.09 3.18 3.41 4.07

14.75

Static

Pressure

0.00 51 101

0.82 45 100

1.65 49 101

2.47 83 111

Sound Data

Spherical

Sones

LwA

Page 7 Acme Engineering and Manufacturing Corporation

Page 8

AVD PERFORMANCE DIAGRAMS

AVD 1120/578-10

1470 RPM

34° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

33430 30372 27183 23835 20388 16946 13544 10234 5046

0.00 1.22 2.33 3.23 3.82 4.21 4.50 4.82 5.76

0.61 1.72 2.73 3.54 4.05 4.36 4.60 4.87 5.77

AVD 1250/403-6

1470 RPM

46° Blade Angle

CFM

Static

Pressure

Total

Pressure

Max HP

55837 50530 45064 39456 33871 28266 22529 16786 8095

0.00 0.82 1.63 2.31 2.84 3.23 3.31 3.69 4.42

1.08 1.71 2.33 2.85 3.23 3.50 3.48 3.79 4.44

Air Performance

18.04

Air Performance

22.59

Sound Data

Static

Pressure

0.00 62 103

1.13 56 102

2.26 63 105

3.38 81 110

Static

Pressure

0.00 65 106

0.94 60 105

1.89 63 105

2.84 114 115

Spherical

Sones

Sound Data

Spherical

Sones

LwA

LwA

Performance certified is for Installation Type B: Free inlet, ducted outlet.

Performance ratings do not include the effects of appurtenances (accessories).

The A-weighted sound power ratings shown have been calculated per AMCA Standard 301.

Values shown are for (Inlet LwA) sound power levels for: Installation Type B: free inlet, ducted outlet.

The sound ratings shown are loudness values in fan sones at 1.5 m (5 ft) in a spherical free field calculated per AMCA Standard 301.

Values shown are for Installation Type B: free inlet spherical sone levels.

Acme Engineering and Manufacturing Corporation Page 8

Page 9

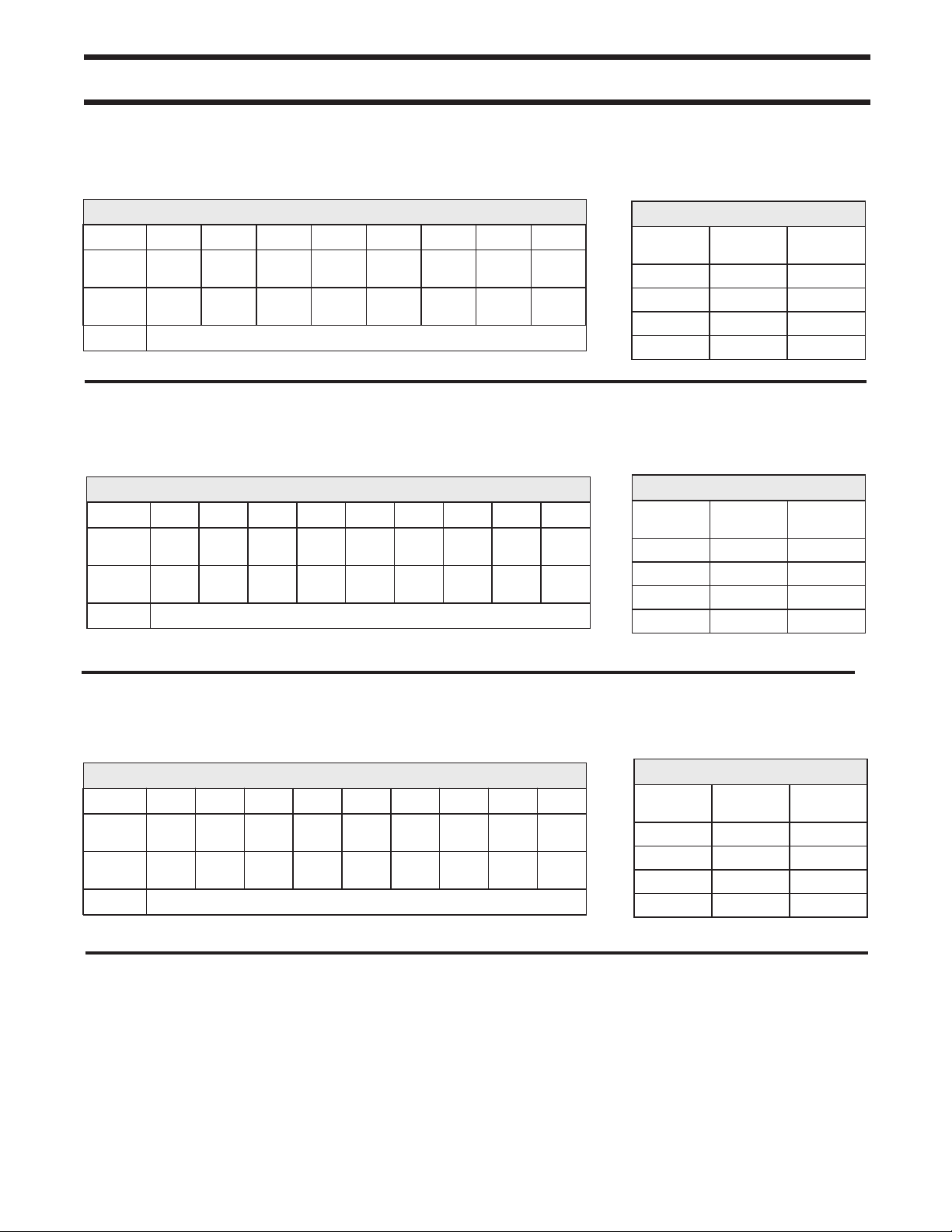

AVD DIMENSIONAL DATA

Hub Dia.

(mm)

A

B

C

160-

380

D

P

R

L 160-380

Hub Dia.

(mm)

A

B

C

230-

578

D

P

R

L 230-380

L 403

L 578

NEMA

Motor

Frame

All

Frame

Sizes

NEMA

Motor

Frame

All

Frame

Sizes

Size (Impeller Diameter)

AVD250 AVD315 AVD400 AVD500 AVD560 AVD630 AVD710

IN mm IN mm IN mm IN mm IN mm IN mm IN mm

12.20 310 15.16 385 18.90 480 23.23 590 25.59 650 28.35 720 31.50 800

11.02 280 13.98 355 17.72 450 22.05 560 24.41 620 27.17 690 30.31 770

.08 2 .08 2 .14 3 .14 3 .14 3 .14 3 .14 3

9.84 250 12.40 315 15.75 400 19.69 500 22.05 560 24.80 630 27.95 710

4.00 4 8.00 8 8.00 8 12.00 12 12.00 12 12.00 12 16.00 16

.38 10 .38 10 .50 12 .50 12 .50 12 .50 12 .50 12

14.17 360 15.75 400 20.47 520 22.05 560 24.41 620 24.41 620 28.74 730

Size (Impeller Diameter)

AVD800 AVD900 AVD1000 AVD1120 AVD1250 AVD1400 AVD1600

IN mm IN mm IN mm IN mm IN mm IN mm IN mm

35.04 890 39.37 1000 43.31 1100 48.03 1220 53.54 1360 59.45 1510 67.72 1720

33.86 860 38.19 970 42.13 1070 46.85 1190 51.97 1320 57.87 1470 66.14 1680

.14 3 .14 .75 .14 .75 .14 .75 .14 .75 .18 4 .18 4

31.50 800 35.43 900 39.37 1000 44.09 1120 49.21 1250 55.12 1400 62.99 1600

16.00 16 16.00 16 16.00 16 20.00 20 20.00 20 20.00 20 24.00 24

.50 12 .63 15 .63 15 .63 15 .63 15 .63 15 .75 19

29.53 750 33.86 860 35.43 900

25.59 650 29.53 750

33.46 850 29.53 750 25.59 650 29.53 750 33.46 850

33.46 850 29.53 750 29.53 750 29.53 750 33.46 850

35.43 900 33.46 850 33.46 850 33.46 850

29.53 750 25.59 650 29.53 750

33.46 850 29.53 750 29.53 750 29.53 750 33.46 850

33.46 850 35.43 900 33.46 850 33.46 850 33.46 850

35.43 900 37.40 950 37.40 950 37.40 950 35.43 900

37.40 950 37.40 950 37.40 950 44.09 1120

41.73 1060 44.09 1120 44.09 1120

44.09 1120 44.09 1120

Data shown on this page is for general information only and should not be used for exact installation dimensions.

Refer to a submittal drawing for detailed dimensions.

Accessory dimensions are available through your local Acme representatives.

Page 9 Acme Engineering and Manufacturing Corporation

Page 10

AVD FAN WEIGHTS

Hub

Dia.

(mm)

160-380 24 11 31 14 60 27 93 42 121 55 132 60 161 73

AVD250 AVD315 AVD400 AVD500 AVD560 AVD630 AVD700

lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg

Hub

Dia.

(mm)

160-380 181 82 216 98 295 134

403 258 117 340 154 368 167 406 184 445 202

578 337 153 423 192 441 200 593 269 725 329 807 366

AVD800 AVD900 AVD1000 AVD1120 AVD1250 AVD1400 AVD1600

lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg

Weight (Less Motors)

Weight (Less Motors)

Specific motor weights are available from your Acme representative.

CONVERSION TABLE

I-P Equivalents of Metric Units Metric Equivalents of I-P Units

3

3

= .062428 lbm/ft

= 62.428 lbm/ft

2

3

1 ft2(square foot) = .09290 m

3

1 lbm/ft

1 lbm/ft

3

3

1 ft-lb (foot pound) = 1.3558 N-m

1 Btu (British thermal unit) = 252 cal

1 CFM (Cu. ft/min) = .00047195 m

1 CFM = .02832 m

1 CFM = 1.6990 m

1 CFM = .47195 l/s

1 lb (pound) = 4.4482 N

1 lb = .45359 kp

1 ft-lb/lbm- R* = 5.3803 J/kg-K

-K (sq. mtr per sec. sq. Kelvin) = 5.9800 ft2/s2-R

1 ft

2/s2

- R** = .16723 m2/s2-K

1 Btu/lbm - R = 1.0000 cal/g- C

*(foot-pound per poundmass degree Rankine)

**(square-foot per second-square degree Rankine)

1" (inch) = 25.4 mm

1" = 2.54 cm

1 ft (foot) = .30480 m

1 mi (mile) = 1.6093 km

1 lbm (pound mass) = .45359 kg

1 hp (horsepower) = .7457 kW

1 hp = 745.70 W

1 hp = 1.0139 mhp

2

(Newton per m2)orPa (Pascal) = .0040264" wg

1" wg (inches water gauge) = 248.66 Pa or N/m

1" wg = 1.8651 mm Hg or torr

1 psi (pounds per sq. inch) = 6894.8 Pa or N/m

1" Hg (inch Mercury) = 3386.4 Pa or N/m

(inches wg at 68 F or 20 C)

2

= 1.732" wg

1"wg = 0.5774 oz./in

1 F (degree Fahrenheit) = 5/9 C

x9/5+32

C

For temperature in C =(t

1 lb-in. (pound inch) = .11298 N-m

1 lb-ft. (pound foot) = 1.3558 N-m

1 fpm (feet per minute) = .00508 m/s

1 mph (mile per hour) = 1.6093 km/hr

1 rpm (revolution per minute) = 60 rps

1 lbm/ft-s (pound/foot second) = 1488.2 cP

2

= 16.018 kg/m

= .016018 g/cm

3

/min

3

/hr

-32) x 5/9

F

Area

Density

Energy

Flow Rate

(Volume)

Force

Gas

Constant

Length

Mass

Power

Pressure

or

Stress

Temperature

Torque

Velocity

&

Speed

Viscosity

2

(square meter) = 10.764 ft

1 m

1 kg/m

1 g/cm

1 J (Joule) or N-m (Newton-meter) = .73756 ft-lb

1 kcal (kilo calorie) = 3.9683 Btu

3

1 m

/s (cubic meter per second) CMS = 2118.9 CFM

3

1 m

/min (cubic meter per minute) CMM = 35.315 CFM

3

1 m

/hr (cubic meter per hour) CMH = .58858 CFM

1 l/s (liter per second) = 2.1189 CFM

1 N (Newton) = .22481 lb

1 kp (kilopond) = 2.2046 lb

1 J/kg-K (Joule per kilogram Kelvin) = .18586 ft-lb/lbm- R

2/s2

1 m

1 cal/g- C (calorie per gram C) = 4186.8 J/kg-K

1 mm (millimeter) = .03937 inch

1 cm (centimeter) = .39370 inch

1 m (meter) = 3.2808 ft

1 km (kilometer) = .62137 mi

1 kg (kilogram) = 2.2046 lbm

1 W (Watt) = .00134 HP

1 kW (kilo-Watt) = 1.3410 hp

1 mhp (metric horsepower) = .98632 hp

1 N/m

1 mm Hg or torr (mm Mercury) = .53616" wg

1 kPa (kilo Pascal) = .1450 psi

1 atm (atmosphere) = 29.921" Hg

(mm Hg at 0°C or 68°F)

1 oz./in

For temperature intervals and rise, For temperature intervals and

rise,

1 C (degree Celsius) = 9/5 F

For temperature in F (Fahrenheit) = t

1 N-m (Newton meter) = 8.8507 lb-in.

1 N-m (Newton-meter) = .73756 lb-ft.

1 m/s = 196.5 fpm

1 km/hr (kilometer per hour) = .62137 mph

1 rps (revolution per second) = .016667 rpm

1 cP (Centipoise) = .00067197 lbm/ft-s

3

3

3

/s

2

2

2

2

Acme Engineering and Manufacturing Corporation Page 10

Page 11

TYPICAL INSTALLATION

INLET DUCT ELBOWS

Non-uniform flow into a fan inlet is the most common cause of deficient fan performance. An elbow located at, or

in close proximity to the fan inlet will not allow the air to enter the impeller uniformly. The result is less than

catalogued air performance. It is strongly advised that inlet elbows be installed a minimum of three (3) diameters

away from any axial or centrifugal fan inlet.

It is strongly advised that inlet elbows be installed a minimum of three (3) diameters away from any axial

or centrifugal fan inlet.

OUTLET DUCT ELBOWS

Values for pressure losses through elbows, which are published in handbooks and textbooks, are based upon a

uniform velocity profile approaching the elbow. Any non-uniformity in the velocity profile ahead of the elbow will

result in a pressure loss greater than the published value.

The velocity profile at the outlet of a fan is not uniform and an elbow located at or near the fan outlet will,

therefore, develop a pressure loss greater than its “handbook” value.

The amount of this increased loss will depend upon the location and orientation of the elbow relative to the fan

outlet. In some cases the effect of the elbow will be to further distort the outlet velocity profile of the fan. This will

increase the losses and may result in such uneven flow in the duct that branch takeoffs near the elbow will not

deliver their designed air flow.

Wherever possible a length of straight duct should be installed at the fan outlet to permit diffusion and

development of a uniform flow profile before an elbow is inserted in the duct. If an elbow must be located near the

fan outlet then it should have a minimum radius to duct diameter ratio of 1.5.

Reprinted from AMCA Publication 201-90, FANS AND SYSTEMS, with the express written permission from the

Air Movement and Control Association International, Inc., 30 West University Drive, Arlington Heights, IL

60004-1893.

Further information on axials and centrifugal fans is provided in the above mentioned publication.

Page 11 Acme Engineering and Manufacturing Corporation

Page 12

EXHAUSTERS

CEILING AND CABINET

EXHAUSTERS

IN-LINE CENTRIFUGAL

FANS

IN-LINE AXIAL FANSCENTRIFUGAL

PROPELLER

ROOF FANS

ROOF VENTS

WALL FANS

UTILITY BLOWERS

PLENUM FANS

SUPPLY AIR FANSPROPELLER

BACKWARD

INCLINED/AIRFOIL

CENTRIFUGAL FANS

LIMITED WARRANTY Acme Engineering and Man

ufacturing Corporation extends this limited warranty

to the original purchaser and warrants that products

described hereinshallbefreefromoriginaldefectsin

workmanship and materials for two years from date

of shipment(except for Acme’s exclusiveduplexsplit

pillow block bearings and shaft 5 years from ship

ment, belts one year from shipment, and polyethyl

ene tubing at 90 days from shipping), provided

same have been properly handled, stored, installed,

serviced, maintained and operated. Refer to Form

MS149 for complete limited warranty terms andcon

ditions. This form is available to anyone at

www.acmefan.com. The Company's warranty is in

lieu ofallotherwarranties, express or implied, arising

by law or otherwise, including without limitation the

implied warranties of merchantability and fitness for

a particular purpose, whichareherebyexpressly dis

claimed claimed and waived.

ACME ENGINEERING &

MANUFACTURING CORP.

P.O. Box 978, Muskogee, Oklahoma 74402

Telephone: 918-682-7791 Fax: 918-682-0134

www.acmefan.com e-mail: acmefan@acmefan.com

Acme products are designed and manufactured to

provide reliable performance but they are not guar

anteed to be 100% free of defects. Even reliable

products will experience occasional failures and this

possibility should be recognized by the Purchaser

and End User. If these products are used in a life

support ventilation system where failure could result

in loss or injury, the Purchaser and End User should

provide adequate back-up ventilation, supplemen

tary natural ventilation or failure alarm system, or ac

knowledge willingnessto accept the risk ofsuch loss

or injury.

-

WARNING DO NOT use in HAZARDOUS ENVI

RONMENTS where fan’s electrical system could

provide ignition to combustible or flammable materi

als unless unit is specifically built forhazardous envi

ronments. Comply with all local and national safety

codes including the National Electrical Code (NEC)

and National Fire Protection Act (NFPA). Guards

Member Air Movement and Control Association International, Inc.

must be installed when fan is within reach of person

-

nel or within eight (8) feet (2.5 m) of working level or

when deemed advisable for safety.

DISCLAIMER The Company has made adiligent ef

fort to illustrate and describe the products in thisliter

ature accurately; however, such illustrations and

descriptions areforthesolepurposeofidentification,

and do not express or imply a warranty that the prod

ucts are merchantable,orfitforaparticular purpose.

-

INDEMNITY Purchaser acknowledges various

warnings by the Company regarding the products

and its installation and use. If the Company incurs

any claims, lawsuits, settlements, or expenses (in

cluding attorney fees) for any loss, injury, death or

property damage including, but not limited to, claims

arising out of the Purchaser’s or any end user ’s in

stallation or use of the products, the Purchaser shall

indemnify and hold the Company harmless.

January 2012 Form C66D

-

-

-

-

-

-

Loading...

Loading...