Page 1

Acme Engineering & Manufacturing Corp.

P.O. Box 978

Muskogee, Oklahoma 74402

Phone 918/682-7791 Fax 918/682-0134

www.acmefan.com acmefan@acmefan.com

VANEMASTER FANS

SERIES AVD VANEAXIAL FAN

INSTALLATION/MAINTENANCE INSTRUCTIONS

Form 690016

I. Introduction

Your vaneaxial fan is a carefully engineered and

constructed piece of machinery which will give

long, satisfactory service provided correct

installation and proper maintenance practices

are observed. DO NOT DESTROY THIS

DOCUMENT AFTER INSTALLATION - RETAIN

WITH THE UNIT FOR MAINTENANCE.

Preventative maintenance including periodic

inspection, testing, cleaning, lubrication and

replacement of worn parts will forestall

equipment breakdowns and minimize equipment

shut-downs.

In addition to this manual, all fans are shipped

with the Air Movement and Control Association

(AMCA) Publication 410-90. “Recommended

Safety Practices for Users and Installers of

Industrial and Commercial Fans”. If you did not

receive this booklet, immediately contact the

factory to obtain a copy or contact AMCA directly.

The AMCA Safety Publication 410-90 should be

read before installing and operating the

equipment to insure safety of personnel and

equipment.

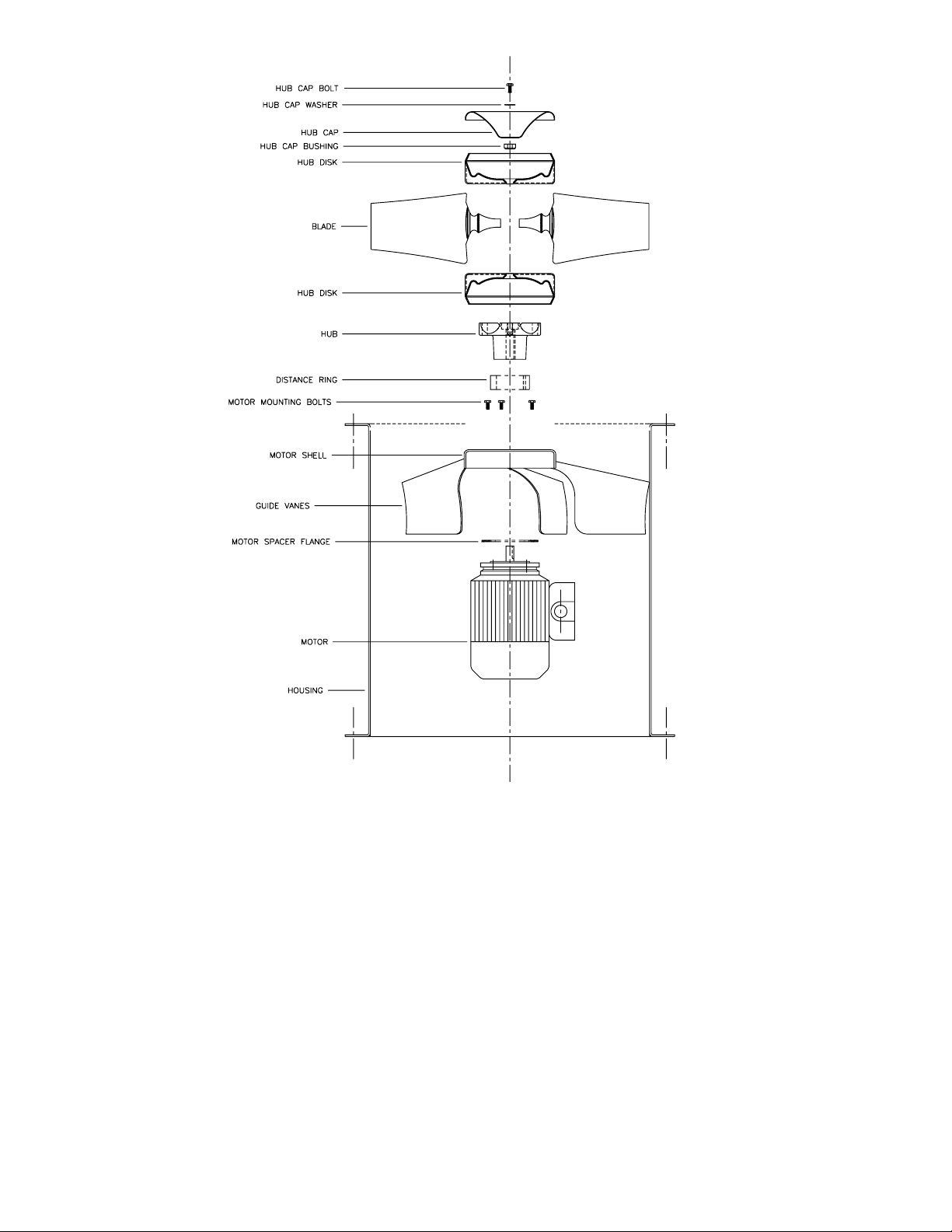

AMCA ARRANGEMENT 4 - DIRECT DRIVE

The basic AVD fan consists of a housing,

impeller, guide vanes, motor shell and a motor.

The AVD impeller consists of two assembled, die

formed, galvanized steel hub disks with cavities

to house the blades at preset angles. The

impeller blades are cast aluminum. The AVD

blades can be set at an angle between 25 and 60

degrees to allow precise performance selection.

The impellers are statically and dynamically

balanced at the blade angle required to obtain

the specified point of operation. The AVD fan

housing is accurately formed from plate steel with

integrally rolled inlet and outlet flanges. High

efficiency straightening vanes of heavy gauge

steel are installed downstream of the impeller to

eliminate swirl and regain static pressure. The

AVD straightening vanes are structurally

designed to support the weight of the motor and

impeller. TEFC, flange mounted motors are

provided as standard. The completely

assembled fan is given a running check test and

inspection before final shipment.

Page 2

II. AVD ACCESSORIES

A wide range of accessories and options are

available for the AVD fan:

1. Safety Guards are utilized to prevent

contact with rotating parts and prohibit

foreign objects from being drawn into the

fan. The wire guard is designed as a

heavy gauge wire screen which can be

supplied on the flanged fan housing or inlet

bell.

2. Inlet Bells are recommended whenever

the fan is intended for operation with an

open inlet. Inlet bells are formed from

heavy gauge steel to provide a smooth

entrance condition to the fan inlet and

minimize performance losses.

3. Housing Support Options fabricated of

heavy steel plate include: horizontal

mounting feet for floor mounting or ceiling

suspension.

4. Outlet Cones (Diffusers) are generally

used on the fan outlet to increase

pressure. These diffusers are sometimes

used on the inlet of the fan. The cones are

fabricated of heavy gauge steel and are

available in a short and long version.

2

Page 3

5. Roof Curb Mounting Base is designed for

vertical roof mounted units consisting of a

one piece, heavy gauge, reinforced steel

mounting platform for bolting to the fan

flange.

6. Discharge Hood for vertical mounted units

is designed for weather protection on either

the inlet or outlet side of the fan. The

discharge hood is constructed of heavy

gauge steel.

7. Other Available Options

· Access Doors in Housing

· Sound Attenuation

· Vibration Isolators

· Variable Frequency Drives

III.Installation and Start-Up

A. Receiving

Acme Eng. & Mfg. Corp.’s equipment is

thoroughly inspected and packaged at the

factory. When a carrier signs the Acme

Engineering & Manufacturing Corporation’s bill

of lading, the carrier accepts the responsibility for

any subsequent shortages or damage, evident

or concealed, and any claim must be made

against the carrier by the purchaser within 15

days after receipt. Evident shortage or damage

should be noted on the carrier’s delivery

document before signature of acceptance.

Inspection by the carrier of damage evident or

concealed must be requested. After inspection,

issue a purchase order for necessary parts or

arrange for return of the equipment to the Acme

factory for repair.

B. Handling

Acme Engineering & Manufacturing Corporation

fans are shipped completely assembled and

packaged. The units may be handled and

moved using good rigging techniques, being

careful to avoid concentrated stresses that will

distort any of the parts.

C. Safety Precautions

receive this booklet, immediately contact the

factory to obtain a copy or contact AMCA

directly. The AMCA Safety Publication 410-90

should be read before installing and operating

the equipment to promote safety of personnel

and equipment. This unit has rotating parts and

safety precautions should be exercised during

installation, operation and maintenance.

The maximum operating speed for which this fan

is designed must not be exceeded. These limits

are available through Acme Engineering &

Manufacturing Corporation’s Applications

Group.

The maximum operating temperatures are given

in “Installation” Section B.5, Item 9 below.

Do not use fans in hazardous environments

where fan’s electrical system could provide

ignition to combustible or flammable materials

unless built specifically for the environment.

D. Storage

Acme provides sufficient protection for shipping

the equipment to the jobsite. If the equipment is

not installed immediately, additional precautions

are necessary. For storage:

1. Equipment shall be kept in a dry area, free

from rigid and extreme changes in humidity

and protected from low temperature. The

unit should not be exposed to vibration.

2. Rotor should be blocked to prevent

windmilling.

3. The impeller should be rotated several

revolutions every 90 days to re-coat the

motor bearings with grease and to minimize

brinelling of the motor bearings.

4. Every 6 months, add high quality grease to

bearings to purge and replace old grease.

5. Upon removal from storage, bearings

should be supplied with an ample supply of

fresh grease to purge and replace the old

grease. High quality ball bearing grease

should be used per the motor

manufacturers recommendations.

In addition to this manual, all fans are shipped

with the Air Movement and Control Association

(AMCA) Publication 410-90, Recommended

Safety Practices of Users and Installers of

Industrial and Commercial Fans. If you did not

6. Acme does not recommend use of any

plastic to cover the fan equipment as this

can create condensation, rusting and

equipment damage.

3

Page 4

E. Installation

1. The basic fan consists of a housing,

impeller, guide vanes and a motor. The

motor is factory installed. The impeller

is supplied from the factory with the

blades set to the angle that

corresponds to the specified point of

operation (volume flow rate and

pressure) for the fan speed. The

impeller has been statically and

dynamically balanced with the blade

angle set to this position.

hole(s) are at the lowest point of the

motor.

5. The fan can be installed in a number of

ways, either horizontally or vertically:

· The fans can be supplied with

mounting feet (optional)

· Supported by ductwork if

sufficiently braced to support

the weight of the fan

· Ceiling suspended by specially

designed supports or hangers

The impeller design permits adjustment

of the blade angle over the full

performance range (25 to 60 degrees).

The quadrant at the base of the blade

covers an angular adjustment range

from 70 to 0 degrees in 5 degree

increments. An increase in the blade

angle will increase the motor load,

therefore, it must be determined that

the motor is capable of handling the

additional load. Changes in blade

angle (increase or decrease) may also

disrupt the balance of the impeller

causing increased vibration levels.

Please contact Acme’s Application

Engineering group before making any

adjustment of the blade angle.

2. Before installing the fan, check all

fasteners for tightness; particularly the

impeller and motor.

Turn the impeller by hand to make sure

it does not strike the fan housing. The

tip clearance of the impeller should be

close to the same along the entire

circumference of the housing. If this is

not the case, adjust the motor location

in the suspension arrangement. (See

the maintenance instructions for

dismantling and re-assembly of the fan

for motor servicing).

3. The fan is provided with an arrow label

showing the rotation and direction of air

flow through the fan. The fan should be

so installed that the required air flow

direction in the system is achieved.

4. If the motor is provided with

condensation drain holes, the fan

should be so installed that the drain

When the fan is finally secured in place,

make sure that the impeller rotates

freely in the fan housing. The tip

clearance between the impeller and the

fan housing should be close to the

same along the entire housing

circumference.

6. Ducts on the inlet and outlet side should

be so arranged that the airflow to and

away from the fan is straight and

unobstructed; i.e. there must be no

sharp bends immediately in front of the

inlet or outlet opening for at least three

(3) duct diameters.

Sharp ends or other obstructions at the

inlet or outlet of the fan can result in

reduced fan performance and/or

increased sound levels.

7. To prevent vibration from being

transmitted to the surroundings, the

fans can be furnished with optional

vibration isolation and flexible duct

connections (by others).

8. The natural frequency of the fan

mounting structure must differ by a

minimum of 20% from the fan speed.

9. Temperature Limitations

As standard, the fans are designed for a

gas temperature range of -20° C (-4° F)

to +40° C (+104° F). The temperature

range can be increased to -40° C

(-40° F) to +150° C (+302° F) with special

motors (lubrication), reduced speed

and/or increased tip clearance.

CAUTION! For applications at elevated

temperatures, the fan must operate

4

Page 5

after the process has been shut down

until the exhaust air or gas is cooled

sufficiently to protect fan components

from overheating.

10. Electrical Connections

IV. General Operation and Maintenance

A. CAUTION! Before proceeding with any

maintenance, make sure the motor

starter or disconnect switch to the fan is

locked in the “OFF” position.

Connections with the electrical supply

main should be made directly to the

outside terminal box located on the fan

housing.

When the power supply has been

connected, make sure that the direction of

rotation of the impeller is in accordance with

the arrow label on the outside of the fan.

F. Pre-operating Check List

After the equipment has been installed

correctly and a check has been made for

tightness of all hardware and mounting bolts,

the fan will be ready to operate after these

final safety checks to prevent injury to

personnel or damage to the equipment.

1. Check for correct supply voltage.

2. Remove all foreign matter from the

vicinity of the fan inlet(s)/outlet(s),

ductwork and interior of fan.

3. Check blade angle setting for desired

air performance (blade angle setting for

specified point of operation can be

found on fan nameplate).

5. Make sure that all safety guards are in

place.

6. Momentarily energize the fan to check

the direction of rotation.

7. Start the fan and check for the

following:

· Motor amperage in each

phase for balance and correct

motor load.

· Excessive vibration (not to

exceed a peak-to-peak velocity

of 7mm/sec (0.28 ins/sec).

· Unusual noise.

B. The fan housing and impeller require no

maintenance other than ordinary

cleaning. The motor needs to be kept

clean along with the fan housing and

impeller.

Excessive vibration occurring after the fan

has been in operation for some time will

usually be due to an accumulation of dust or

dirt on the impeller and should disappear

after cleaning. Dust buildups, in general,

occur uniformly with time not creating a

balance problem until the buildup reaches a

thickness where a portion of the buildup flies

off of the impeller initiating an unbalance

condition. If dust or dirt is not the problem, a

balancing specialist should be consulted to

analyze and rectify the problem.

C. To service the motor, the following

steps are required:

1. Disconnect the electrical cables

from the motor terminal box on the

fan housing.

2. Remove any ductwork adjacent to

the fan inlet and outlet.

3. Remove the impeller center bolt,

washer and hub cover.

4. Remove the impeller by means of a

pulley remover fastened to the two

threaded holes of the hub boss.

5. The motor will need to be supported

while the retaining bolts are being

loosened and removed from the

motor shell. The motor is now

completely accessible for service.

After servicing the motor:

1. New bolts, lock washers and nuts

should be utilized in re-assembling

the fan.

2. Re-mount the motor on the motor

mounting plate. Care must be taken

to locate the motor shaft in the exact

center of the housing. Motor

mounting bolts must be tight.

5

Page 6

3. Mount the impeller on the motor

shaft by aligning impeller on the

motor shaft. Utilize the impeller

center bolt, washer, hub cover and

drilled/threaded motor shaft to pull

impeller hub boss up against the

shoulder on the motor shaft.

Tighten the impeller center bolt

securely.

4. Ensure that the tip clearance of the

impeller to the fan housing is close

to the same along the entire

circumference of the housing. If this

is not the case, loosen and adjust

the motor location on the motor

mounting plate. Re-tighten the

motor mounting bolts when the

impeller is centered in the fan

housing.

5. Re-connect the electrical cables to

the motor terminal box. Check for

proper rotation.

6. Replace all inlet and/or outlet

ductwork.

7. Start fan and check vibration levels.

Vibration levels shall not exceed a

peak-to-peak velocity of 7mm/sec

(0.28 ins/sec).

D. The following steps are required to

change fan air performance by blade

angle adjustment.

1. Make certain that the required air

performance adjustment will not

overload the motor. You may need

to talk with Acme’s Application

Engineering group.

2. CAUTION! Before proceeding,

make sure the electrical service to

the fan is locked in the “OFF”

position. Disconnect the electrical

cables from the motor terminal box

on the fan housing.

3. Remove any ductwork adjacent to

the fan inlet.

4. Remove the impeller center bolt,

washer and hub cover.

5. Remove the impeller by means of a

pulley remover fastened to the two

threaded holes of the hub boss. The

weight of the impeller must be

properly supported to prevent blade

damage.

6. Loosen the bolts near the outer

diameter of the hub disc to a “snug”

tightness.

7. Adjust the blade angle by hand to

obtain the desired performance. It

is critical that all blades be set at

the same blade angle.

8. Tighten the bolts near the outer

diameter of the hub disc securely.

9. Mount the impeller by aligning

impeller hub boss on the motor

shaft. Utilize the impeller center

bolt, washer, hub cover and

drilled/threaded motor shaft to pull

impeller hub boss up against the

shoulder on the motor shaft.

Tighten the center bolt securely.

10.Replace the ductwork at the fan

inlet.

11.Return the electrical service to the

fan. Check for proper rotation.

12.Start fan and check vibration levels.

Vibration levels shall not exceed a

peak-to-peak velocity of 7 mm/sec

(0.28 ins/sec).

6

Page 7

NOTES

7

Page 8

TERMS AND CONDITIONS

DESIGN CHANGES The Company reserves

the right to make changes in design, improve

ments and additions in and to its products any

time without imposing any liability or obligations

to itself to apply or install the same in any prod

uct manufactured by it.

TITLE The title and right of possession of the

equipment sold herein shall remain with the

Company and such equipment shall remain

personal property until all payments herein (in

These instructions cover the usual installation, operation and maintenance methods for which the product(s) was designed. They do not purport to

cover all details or variations in the product(s) nor to provide for every possible contingency that might be met in connection with the installation, oper

ation and maintenance. For any departures from these instructions, or should particular problems arise which are not covered sufficiently for the pur

chaser’s purpose, the matter should be referred to the Company.

cluding deferred payments whether evidenced

by notes or otherwise) shall have been made in

full in cash and the Purchaser agrees to do all

acts necessary to perfect and maintain such

right and title in the Company.

-

SAFETY ACCESSORIES The Company manu

factures equipment designed to serve multiple

applications and offers a wide range of safety

equipment, including guards and other devices,

as may be required to meet customer specifica

-

tions. Without exception, the Company recom

mends that all orders include applicable safety

devices. Equipment ordered without applicable

safety devices is clearly the responsibility of the

Purchaser. Further, the Purchaser warrants

that he has determined and acquired any and

all safety devices required for equipment sold

by the Company. Weather covers and guards

for motor and V-belt drives, couplings, shafts

and bearings, along with inlet and outlet

screens, are optional accessories noted in the

price list.

-

-

-

-

WARNING The Company products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of de

fects. Even reliable products will experience occasional failures and this possibility should be recognized by the User. If these products are used ina

life support ventilation system where failure could result in loss or injury, the User should provide adequate back-up ventilation, supplementary natural

ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury.

WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials

unless unit is specifically built for hazardous environments.

CAUTION Guards must be installed when fan is within reach of personnel or within seven (7) feet (2.134 m) of working level or when deemed advisable

for safety.

DISCLAIMER The Company has made a diligent effort to illustrate and describe the products in this literature accurately; however, such illustrations and

descriptions are for the sole purpose of identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular

purpose, or that the products will necessarily conform to the illustrations or descriptions or dimensions.

LIMITED WARRANTY

WARRANTY AND DISCLAIMER: The Com-

pany extends this limited warranty to the original buyer and warrants that products manufactured by the Company shall be free from original defects in workmanship and materials for

two years from date of shipment, unless otherwise noted (see specific product literature), provided same have been properly stored, installed, serviced, maintained and operated.

This warranty shall not apply to products which

have been altered or repaired without the Com

pany’s express authorization, or altered or re

paired in any way so as, in the Company’s

judgment, to affect its performance or reliability,

nor which have been improperly installed or

subjected to misuse, negligence, or accident, or

incorrectly used in combination with other sub

stances. The Buyer assumes all risks and liabil

ity for results of use of the products. Warranties

on purchased parts, such as but not limited to

bearings, sheaves, belts, couplings, electric

motors, pumps and controls are limited to the

terms of warranty extended by our supplier.

Polyethylene tubing and cooling pads are war

ranted to be free of defects in material and

workmanship for a period of 90 days from date

of shipment and a like warranty applies to the

cross fluted cellular type cooling cells for a pe

riod of two years from date of shipment pro

vided same have been properly handled,

stored, installed, serviced, maintained and op

erated. And further, not subjected to excessive

heat, corrosive agents or chemicals, or me

chanical abuse that may cause tearing, crush

ing or undue deterioration nor used on a sys

tem or in a manner other than that for which it

was designed as explained in the product litera

ture.

LIMITATION OF REMEDY AND DAMAGES:

All claims under this warranty must be made in

writing and delivered to P. O. Box 978, Musko

gee, Oklahoma, 74402, within 15 days after dis

covery of the defect and prior to the expiration

of the warranty period from the date of ship

ment by the Company of the product claimed

defective, and Buyer shall be barred from any

remedy if Buyer fails to make such claim within

such period.

Within 30 days after receipt of a timely claim,

the Company shall have the option either to inspect the product while in Buyer’s possession

or to request Buyer to return the product to the

Company at Buyer’s expense for inspection by

-

the Company. The Company shall replace, or

-

at its option repair, free of charge, any product

it determines to be defective, and it shall ship

the repaired or replacement product to Buyer

F.O.B. point of shipment; provided, however, if

circumstances are such as in the Company’s

-

judgment to prohibit repair or replacement to

-

remedy the warranted defects, the Buyer’s sole

and exclusive remedy shall be a refund to the

Buyer of any part of the invoice price, paid to

the Company, for the defective product or part.

The Company is not responsible for the cost of

removal of the defective product or part, dam

-

ages due to removal, or any expenses incurred

in shipping the product or part to or from the

Company’s plant, or the installation of the re

paired or replaced product or part.

-

-

Implied warranties, when applicable, shall com

mence upon the same date as the express war

-

ranty provided above, and shall, except for war

ranties of title, extend only for the duration of

-

the express warranty. Some states do not allow

-

limitations on how long an implied warranty

-

lasts, so the above limitation may not apply to

you. The only remedy provided to you under an

-

applicable implied warranty and the express

warranty shall be the remedy provided under

the express warranty, subject to the terms and

conditions contained therein. The Company

shall not be liable for incidental and consequen

-

tial losses and damages under the express

-

warranty, any applicable implied warranty, or

claims for negligence, except to the extent that

-

this limitation is found to be unenforceable un

der applicable state law. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation

or exclusion may not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from

state to state.

No employee, agent, dealer, or other person is

authorized to give any warranties on behalf of

the Company or to assume for the Company

any other liability in connection with any of its

products except in writing and signed by an offi

cer of the Company.

REPLACEMENT PARTS If replacement parts

are ordered, buyer warrants that the original

components in which these replacement parts

will be placed are in satisfactory working condi

tion, and when said replacement parts are in

stalled, the resultant installation will operate in

a safe manner, at speeds and temperatures for

which the original equipment was purchased.

-

TECHNICAL ADVICE AND RECOMMENDA

TIONS, DISCLAIMER: Notwithstanding any

-

past practice or dealings or any custom of the

trade, sales shall not include the furnishing of

technical advice or assistance or system de

sign. Any such assistance shall be at the Com

pany’s sole option and may be subject to addi

tional charge.

-

The Company assumes no obligation or liability

on account of any recommendations, opinions

or advice as to the choice, installation or use of

products. Any such recommendations, opinions

or advice are given and shall be accepted at

your own risk and shall not constitute any war

ranty or guarantee of such products or their

performance.

GENERAL In no event shall any claim for con

sequential damages be made by either party.

The Company will comply with all applicable

-

Federal, State, and local laws.

-

-

-

-

-

-

-

-

-

-

June 1998 Form 690016

Loading...

Loading...