Page 1

Utility

Smoke Exhaust

NEW

Blowers

U.L. 705 Listed

500°F for 4 hours

1000°F for 15 minutes

The QBR-SE and 8100-SE smoke exhaust blowers are designed

for life-saving smoke exhaust management under severe temperatures in a

utility setting with high volume and extended pressures.

These blowers are intended for installation in buildings in accordance with

requirements contained in the Recommended Practice for Smoke Control

System, NFPA 92A; and are intended to be connected to and controlled by

Listed Smoke Control System Equipment (UUKL).

Acme Engineering & Manufacturing Corporation

P.O. Box 978

Muskogee, OK 74402

918/682-7791

Fax 918/682-0134

www.acmefan.com

Est. 1938

Page 2

Utility

Smoke Exhaust

Blowers

Utility Smoke

Exhaust Fans

Max Performance (CFM) 23,230 61,128 74,712

Max SP (inches w.g.) 3.50 5.50 9.00

UL 705 Electrical

UL Listed Power Vents for

Smoke Control Systems

Smoke Exhaust Rating

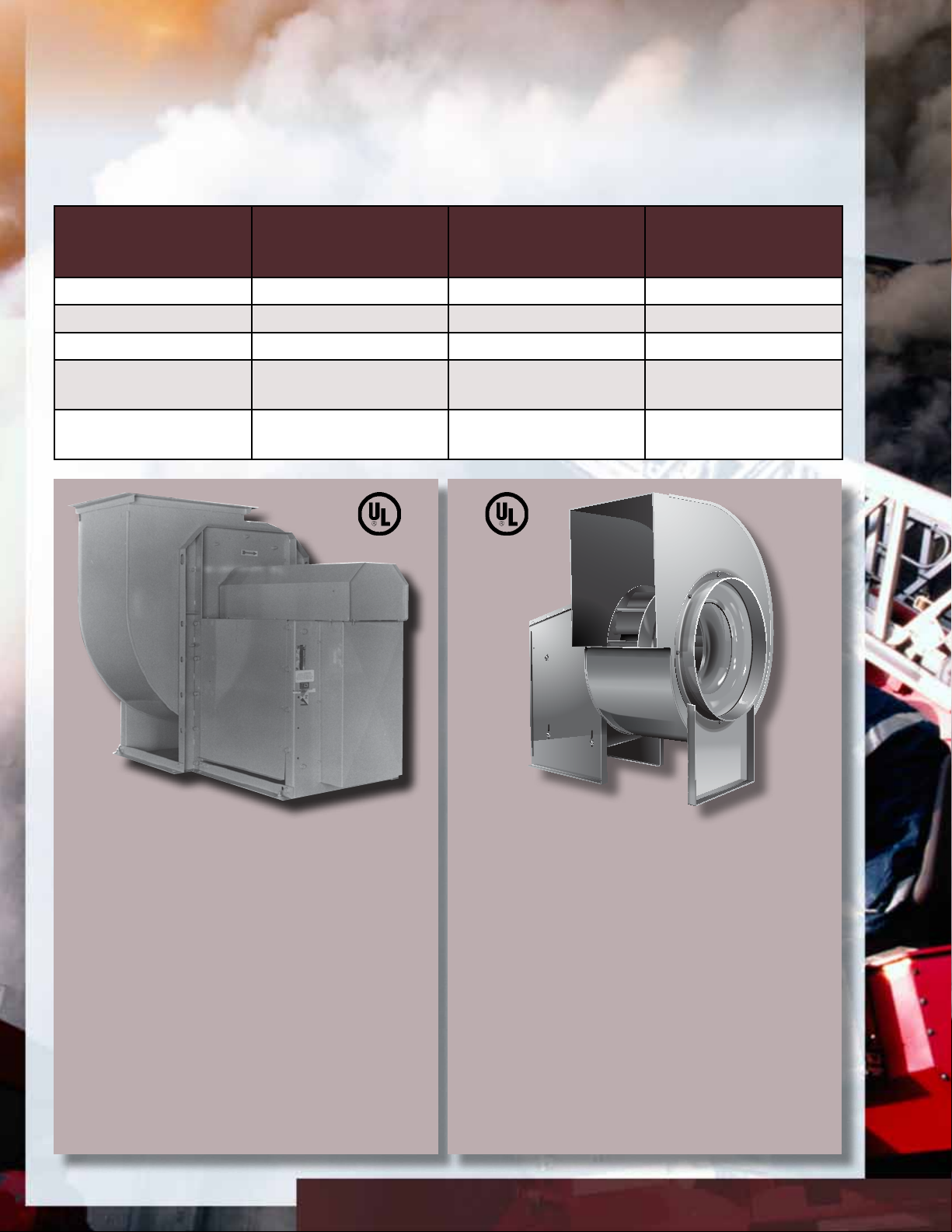

QBR-SE: Belt Drive

Utility Smoke Exhaust

Centrifugal Blower

✔ ✔ ✔

Pending Documentation Pending Documentation Pending Documentation

500°F for 4 hours

1000°F for 15 minutes

U.L. 705 Listed

8100-SE C1: Belt Drive

Utility Smoke Exhaust

Centrifugal Blower

500°F for 4 hours

1000°F for 15 minutes

U.L. 705 Listed

8100-SE C2: Belt Drive

Utility Smoke Exhaust

Centrifugal Blower

500°F for 4 hours

1000°F for 15 minutes

8100-SE Utility Smoke Exhaust

Blower is standard with…

■ Class 1 and Class 2 Construction

■ 2 year limited warranty

■ Heavy-gauge, enamel coated, steel housing

and weather cover

■ Airfoil steel wheel and fully streamlined inlet

■ Added insulation and heat slinger for high

heat resistance

■ Dual belt, variable pitch drives designed for

1.5 service factor

■ Flush, bolted access door

■ Unitary pillow block bearings rated at an

L-50 life of 200,000 hours

QBR-SE Utility Smoke Exhaust

Blower is standard with…

■ Field rotatable housing in 7 discharge

arrangements

■ 2 year limited warranty

■ Heavy-gauge, enamel coated, steel housing

and weather cover

■ Airfoil steel wheel and fully streamlined inlet

■ Added insulation and heat slinger for high

heat resistance

■ Dual belt, variable pitch drives designed for

1.5 service factor

■ Flush, bolted access door

■ Unitary pillow block bearings rated at an L-50

life of 200,000 hours

JANUARY 2011 PM235A

Loading...

Loading...