Acme Electric DRIVE ISOLATION TRANSFORMERS General Product Line Information

SECTION

4

D RIVE ISOLA TION TRANSFORMERS

Drive Isolation Transformers

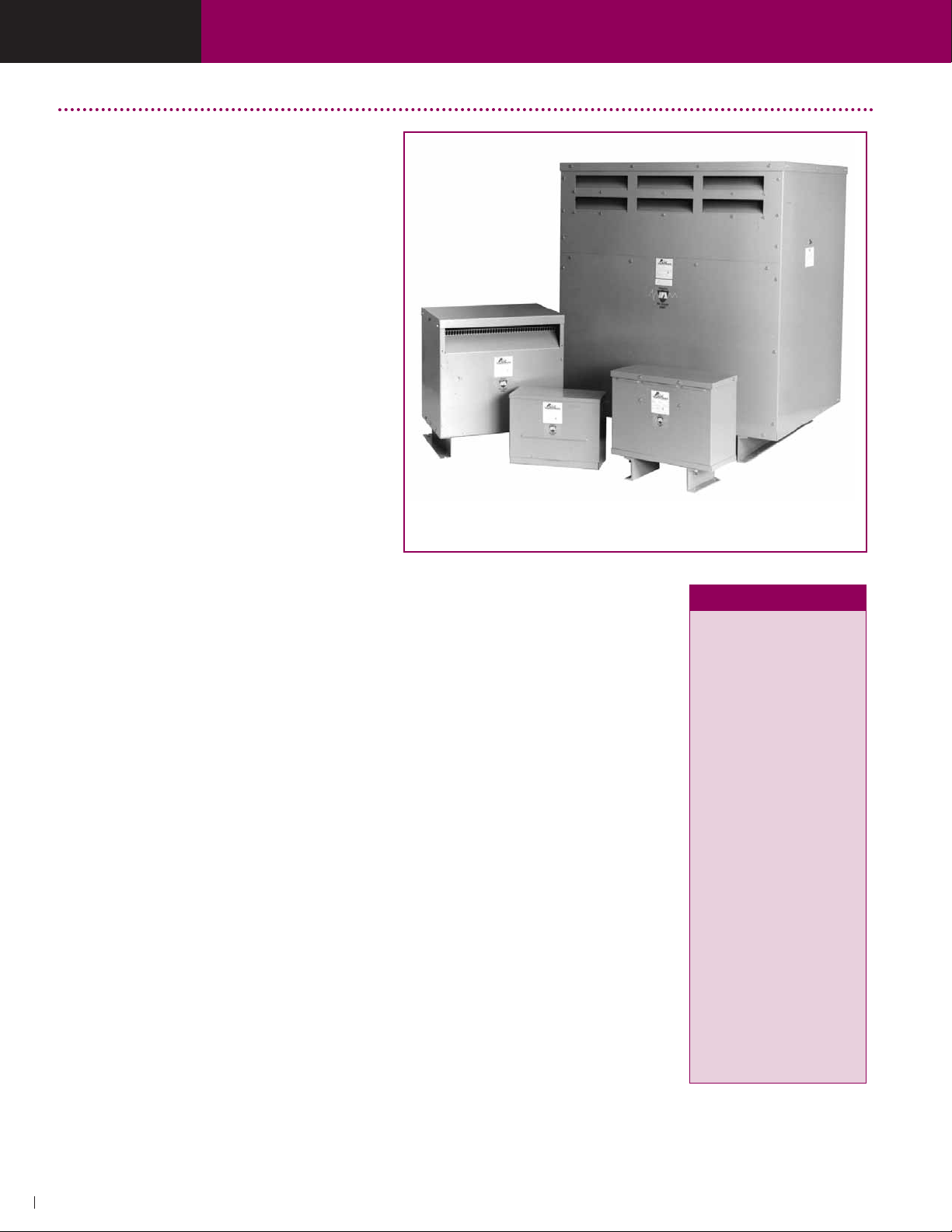

The Acme Drive Isolation Transformers are

specifically designed to accommodate the

special voltages and KV A sizes unique to AC

and DC motor drive applications.

FEA TURES

■

UL T ype 3R Enclosures with Weather Shield

on V entilated Units (above 20 KV A).Type 2

Enclosure without weather shield. UL Listed and

CSA certified. 7.5–20.0 KVA are encapsulated,

UL 3R.

■

3-Phase 60 Hertz.

■

180°C and 220°C insulation systems.

■

Encapsulated and ventilated designs. All

ventilated units, are of strip wound construction.

Acme’ s reinforced core assemblies enhance

quiet operation.

■

Nominally 6% impedance.

■

Designed for use with AC, adjustable frequency

or DC drives.

■

Full capacity taps are featured on all units. On

7.5 through 20 KV A units, taps are 1-5% ANFC

and 1-5% BNFC. On 27 through 660 KVA units,

taps are 2-2

■

Full range of KV A ratings cover all standard

drive systems.

■

Ample wiring compartment for easy cable entry.

■

Optional wall mounting brackets for certain sizes.

1

/2% ANFC and 2-21/2% BNFC.

Stress relief

Acme uses strip conductors (above 7.5 KVA) instead

of wire for a DIT series that easily accommodates

the severe electrical and mechanical stresses

found in today’ s AC & DC motor drives. The inherent

excellent line isolation of these transformers is

further enhanced with the extra protection of

Acme’ s Electrostatic Shield — free in all DIT’s.

Lower losses

The harmonic currents generated by AC & DC

drives increase eddy current losses (heat) in

transformer windings. The thicker the winding

conductor , the greater the losses. Acme uses one

turn per layer of thin strip conductor which provides

lower eddy current losses than comparable wire

wound units. Lower losses = cooler operation

and longer transformer life.

DTGB-040-4S

Reduced short

circuit forces

Strip windings minimize axial short

circuit forces that can cause mechanical

displacement of the windings under

fault conditions. For extra protection all

designs 7.5 KV A and above use primary

and secondary coils of equal axial

length. This feature tends to negate

axial short circuit forces, further

improving transformer life expectancy.

Selection

instructions

If you know the motor horse-power ,

simply follow the drive system manufacturer's recommendation. Or, select

the corresponding KV A from the chart

at right.

For example, a 40 Hp motor requires a

51 KV A DIT.

DTGA-7-2S

DTGA-014-2S

DTHA-0330-4S

H.P. KVA

5.0 7.5

7.5 11.0

10.0 14.0

15.0 20.0

20.0 27.0

25.0 34.0

30.0 40.0

40.0 51.0

50.0 63.0

60.0 75.0

75.0 93.0

100.0 118.0

125.0 145.0

150.0 175.0

200.0 220.0

250.0 275.0

300.0 330.0

400.0 440.0

500.0 550.0

600.0 660.0

54

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION •LUMBERTON, NC •800-334-5214 •www.acmepowerdist.com

SECTION

4

D RIVE ISOLA TION TRANSFORMERS

Acme Advantages

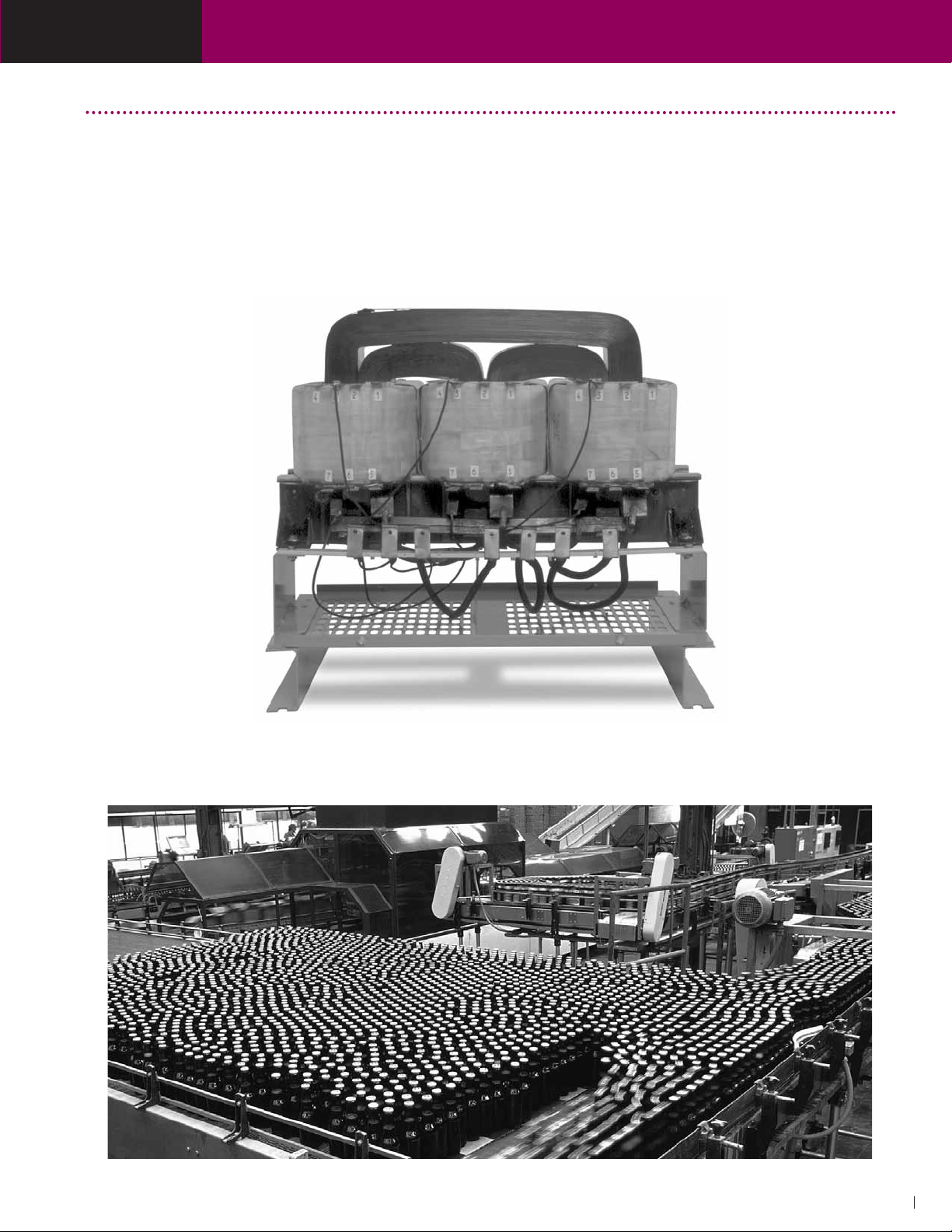

Wound Cores and Strip

Winding mean lower losses

All Acme DIT s above 7.5 KVA are wound with strip windings

to ensure the lowest possible eddy current losses. All our

DITs use a three leg wound core. This superior design has

very low losses and quiet operation. Both of these features

combine to significantly reduce losses and operating costs

compared to other types of constructions.

Copper terminations provide

trouble-free operation

All Acme DIT s up to and including 220 KVA have copper terminations. The transition from aluminum strip coil conductors

to copper terminations is accomplished by a bonding process

known as “Koldwelding

Acme for over 25 years to provide a trouble-free, permanent

bonding of the two metals.

™

”. This process has been used by

Wound core construction showing all copper terminations

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION •LUMBERTON, NC •800-334-5214 •www.acmepowerdist.com

55

Loading...

Loading...