Page 1

Series 4000 MTU

DRAFT

Maintenance

and Operation

Manual

Y20456-TUM

Rev. A

www.Aclara.com

Page 2

DRAFT

Page 3

Proprietary Notice

DRAFT

Information contained in this document is private to Aclara Technologies LLC, an Ohio limited

liability company (Aclara). This information may not be published, reproduced, or otherwise

disseminated without the express written authorization of Aclara.

Any software or firmware described in this document is furnished under a license and may be

used or copied only in accordance with the terms of such license.

Disclaimer

The information in this document is subject to change without notice and should not be construed

as a commitment by Aclara. Aclara assumes no responsibility for any errors that may appear in

this document.

No responsibility is assumed for the use or reliability of software on equipment that is not

supplied by Aclara.

TWACS, STAR, and Metrum Cellular are registered trademarks of Aclara Technologies LLC.

Aclara Technologies LLC

Confidential and Proprietary

Copyright 2015. All Rights Reserved.

Series 4000 Maintenance and Operations Manual (Y20456-TUM Rev A)

Page 4

DRAFT

Page 5

WARNINGS, CAUTIONS, AND NOTES

DRAFT

Always consult and adhere to all local and national safety codes, regulations, and

standards.WARNING, CAUTION and Note statements are used throughout this

manual to emphasize important and critical information to help you ensure safety

and prevent product damage.These statements are defined below.

WARNING

CAUTION

NOTE

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious physical injury.

indicates a situation, which, if not avoided, could result in damage to

equipment, damage to software, loss of data or invalid results.

indicates important supplemental information.

FCC/IC Compliance

The following statements cover the RF exposure guide and the field calibration

procedure.

FCC/IC RF Exposure Guide

Field Calibration Procedure

Series 4000 Maintenance and Operations Manual iii

Aclara Technologies LLC low power RF devices and their antennas must be

fixed-mounted on indoor or outdoor permanent structure(s) providing a separation

distance of at least 20 cm from all persons during normal operation. This device is

not designed (and it has no external connection) to operate in conjunction with any

other antennas or transmitters. No other operating instructions for satisfying RF

exposure compliance are needed.

Aclara Technologies LLC low power RF devices have passed through extensive

testing and calibration procedures while in the factory. Therefore, no additional

calibration or adjustment is required in the field.

Page 6

Conformité FCC/IC

DRAFT

AVERTISSEMENTS, MISES EN GARDE ET REMARQUES

Toujours consulter et respecter les codes, règlements et normes de sécurité locaux

et nationaux. Des AVERTISSEMENTS, MISES EN GARDE et remarques sont

utilisés tout au long de ce guide pour souligner l'information importante et critique

qui vous aidera à assurer la sécurité et à prévenir les dommages au produit. Ces

énoncés sont définis ci-dessous.

AVERTISSEMENT

indique une situation potentiellement dangereuse qui, si elle n'était pas évitée,

pourrait entraîner la mort ou des blessures graves.

MISE EN GARDE

indique une situation qui, si elle n'était pas évitée, pourrait entraîner des

dommages à l'équipement, des dommages au logiciel, des pertes de données ou

des résultats invalides.

REMARQUE

indique des informations supplémentaires importantes.

Conformité FCC/IC

Les énoncés qui suivent portent sur le guide d'exposition aux RF et la procédure de

calibration sur place.

Guide d'exposition aux RF FCC/IC

Les appareils RF à faible puissance Aclara Technologies LLC ainsi que leurs

antennes doivent être montés de manière fixe sur des structures intérieures ou

extérieures permanentes qui se trouvent à au moins 20 cm des personnes pendant

le fonctionnement normal. Cet appareil n'est pas conçu (et il n'a aucun

branchement externe) pour être utilisé en association avec toute autre antenne ou

tout transmetteur. Aucune autre instruction d'utilisation n'est requise pour assurer

la conformité aux règles d'exposition aux RF.

Procédure de calibration sur place

Les appareils RF à faible puissance Aclara Technologies LLC ont été soumis à des

tests étendus et multi-tâches et à des procédures de calibration complexes en usine.

Par conséquent, ils ne requièrent pas de calibration ni d'ajustement supplémentaire

sur place. Les appareils RF à faible puissance Aclara Technologies LLC sont

expédiés au client dans des boîtiers scellés. Aucun ajustement ne peut donc être

effectué sur place sans briser le boîtier scellé en usine.

iv Series 4000 Maintenance and Operations Manual

Page 7

Table of Contents

DRAFT

Chapter 1: STAR Network Overview 1

Two-Way Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

MTU/DCU Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DCU/NCC Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 2: Series 4000 Operation 3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Read Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Time Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Data Encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Trend Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Read Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transmit Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 3: STAR Programmer Software 7

USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Communication LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Application Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XML File Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Read MTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Turn Off MTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Add MTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replace MTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Confirmation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replace Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 4: Hardware Installation 23

Wall Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Solid Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hollow Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pipe Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Conduit & Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MTU Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Instrument Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5: Maintenance 35

Series 4000 Maintenance and Operations Manual v

Page 8

DRAFT

Page 9

STAR NETWORK OVERVIEW

DRAFT

The STAR Network is a fixed-network, Advanced Metering Infrastructure (AMI)

that automatically reads water and gas instruments. The STAR Network uses a

3-tier configuration to read and transmit information between the measuring

instrument and the utility office. The three tiers of the STAR Network are:

1. Meter Transmission Units (MTUs)

2. Data Collection Units (DCUs)

3. Network Control Computer (NCC)

Two-Way Communications

The STAR Network two-way advanced metering infrastructure (AMI) system

allows encrypted data communications over secure, FCC licensed radio

frequencies. This wireless fixed network consists of the Meter Transmitter Unit

(MTU), Data Collector Unit (DCU), and Network Control Computer (NCC).

Communications between the MTU, DCU, and NCC are explained in greater

detail below.

MTU/DCU Communications

DCU/NCC Communications

Series 4000 Maintenance and Operations Manual 1

MTU/DCU communications occur on two FCC licensed (450-470 MHz)

frequency channels. Configuration settings, on-demand requests, and Time Sync

messages are sent from the DCU to the MTU. Instrument measurement and

configuration readings and Time Sync requests are sent from the MTU to nearby

DCUs.

DCU/NCC communications are conducted over TCP/IP protocols via the cellular,

Ethernet, or Wi-Fi

with the NCC. Configuration changes, on-demand requests, and Time Sync

messages originate in the NCC and are sent to the MTU via the DCU.

™

backhaul. The DCU initiates and maintains communications

Page 10

Two-Way Communications

DRAFT

2 Series 4000 Maintenance and Operations Manual

Page 11

SERIES 4000 OPERATION

DRAFT

The Series 4000 MTU is designed to connect with a Honeywell ERX pressure

monitor, a Honeywell Mini-AT volume corrector, or a Mini-Max volume

corrector. In addition to a 10 item audit trail, the Series 4000 allows the user to

perform on-demand reads and reconfigure the instrument and the MTU via the

NCC. It contains a replaceable battery, two LEDs, and a USB port used for

commissioning and reading information from the MTU locally.

The Series 4000 MTU is mounted to a wall or a pipe near the volume corrector or

pressure monitor. The MTU connects to the instrument via cable and

communicates with the DCU using FCC licensed frequencies.

Configuration

The Series 4000 MTU allows the user to change instrument configuration settings

from the NCC. The MTU checks the instrument configuration daily, and returns

the changed parameter and the new value to the NCC in a daily Change Report.

The NCC will then compare the Change Report data to the initial configuration

value transmitted to the NCC immediately after installation. In addition to these

Change Reports, the user can also configure the MTU to send a full Configuration

Report to the NCC every 30, 60, 90, or 180 days.

For added security, if there is an attempt to change the configuration settings

through the MTU USB port, the MTU will notify the NCC within 25 hours.

Read Intervals

The rate at which the MTU reads data from the instrument is configurable to

support instrument log intervals of 15 minutes or more. At the end of each interval,

the MTU will read the instrument. The data will then be transmitted back to the

NCC at an interval that is equal to the instrument log interval.

Time Synchronization

Time keeping is crucial for accurate reporting. The Series 4000 MTU and the NCC

software are designed to ensure that the internal clocks of the instrument, MTU,

and NCC all remain synchronized. In addition to synchronizing the time at initial

installation, the MTU checks the instrument clock daily. If the clock is off by more

than 10 seconds, it will automatically synchronize the instrument clock.

The MTU will send a flag to the NCC along with the amount of adjustment made

to the instrument clock for any readings that are off by more than two minutes.

When the NCC receives readings that are flagged with incorrect time, it will

automatically correct the time stamps according to the difference reported by the

MTU.

MTU Installation Requirements 3

Page 12

Security

DRAFT

Security

Hardware

The 4000 Series MTU provides options for both hardware and software security.

The Series 4000 MTU enclosure is designed to allow the user to secure the door

with a lockout device.

Software

The MTU may be configured to send the following tamper alarms to the NCC:

1. Interface tamper (configuration change via USB port)

2. Cut serial communication wire

Each tamper condition generates a corresponding alarm transmission that can be

viewed in the NCC when viewing the Premise transmissions.

The MTU can be programmed to transmit an alarm for any of these tamper

conditions. In the case of a tamper condition alarm, the unit will transmit an alarm

message every minute for a given number of times (with a default of 3). When the

tamper condition is no longer present, the alarm flag is cleared. Each time the

tamper condition is detected, the unit will trigger an alarm.

4 MTU Installation Requirements

Page 13

Alarms

DRAFT

In addition to the tamper alarms, the MTU may also be configured to send the

following alarms to the NCC:

Last Gasp

The MTU will regularly report battery voltage values to the NCC. When this value

falls below a specified value, the NCC will display a Low Battery notification.

Aclara recommends changing the battery promptly when a low battery alarm is

received. Please see Maintenance on page 35 for more information.

Pressure

The user can configure the MTU to return a pressure alarm whenever the pressure

reading from the instrument is outside a given range. If enabled, the MTU will also

begin operating in Trend Mode until the pressure returns to the desired range.

Please refer to Trend Mode on page 5 for more information.

Serial Communication Problems

Series 4000 Operation

The MTU will return an alarm to the NCC if basic communication with the

instrument is not possible. This will most likely be due to incorrect instrument

configuration.

Data Encryption

The Series 4000 MTU units support the encryption of user sensitive data. When

data encryption is enabled, all readings and data packets except for alarms will be

encrypted prior to transmission.

Trend Mode

Trend Mode is an operating mode of the MTU that, when enabled, will begin

automatically sending pressure values (and corresponding time stamps) at regular

intervals whenever a pressure or other configured alarm is received from the

instrument.

Trend Mode may also be initiated or canceled directly from the NCC. Using the

default settings for Trend Mode, the MTU will record the pressure once a minute

and transmit these readings once every six minutes to the NCC.

Read Interval

MTU Installation Requirements 5

The user may configure Trend Mode to read the pressure either once a minute or

once every five minutes.

Page 14

Trend Mode

DRAFT

Transmit Interval

The transmit interval for Trend Mode is pre-configured at six times the read

interval. That is:

• If a 1 minute read interval is selected, the transmit interval will be 6 minutes.

• If a 5 minute read interval is selected, the transmit interval will be 30 minutes.

If Trend Mode is canceled from the NCC or if the MTU receives a clear pressure

alarm signal from the instrument, the MTU will notify the NCC that only six more

readings will be received in Trend Mode. The MTU will read and transmit the

remaining Trend Mode reads, before it switches back to normal operating mode.

If Trend Mode is initiated manually via the NCC, it will continue for a maximum

of 30 minutes if it is not manually canceled from the NCC.

Trend Mode data is recorded and stored along with graphical representations in the

NCC for up to 13 months.

6 MTU Installation Requirements

Page 15

STAR PROGRAMMER SOFTWARE

DRAFT

The STAR Programmer application is used along with a suitable tablet or laptop and a USB cable

(Aclara part number 070-1700) to commission an MTU after installation or to turn an MTU off

prior to storage or relocation. This section provides information on the USB communication

interface and how to interact with the MTU using this application.

USB Port

The Series 4000 MTU uses a standard USB Type B port that allows for communication with a

laptop or tablet running the STAR Programmer software.

WARNING: EXPLOSION HAZARD - BATTERIES MUST ONLY BE CHANGED IN AN AREA KNOWN TO

AVERTISSEMENT:

Series 4000 Maintenance and Operations Manual 7

BE NON-HAZARDOUS

RISQUE D'EXPLOSION

L’EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX AVANT DE CHANGER LA BATTERIE.

- AFIN D’ÉVITER OUT RISQU D’EXPLOSION, S’ASURER QUE

Page 16

USB Port

DRAFT

Communication LEDs.

Two LEDs located to the right of the battery and above the COMP1 connector indicate the

direction of communication through the USB port.

• The left LED (LED 1) indicates when data is sent from the tablet or laptop through the USB

port to the Series 4000 MTU.

• The right LED (LED2) indicates when data is sent from the MTU out through the USB port

to the tablet or laptop.

8 Series 4000 Maintenance and Operations Manual

Page 17

STAR Programmer Software

DRAFT

Software

The STAR Programmer application may be used to commission an MTU after installation, read

and troubleshoot an MTU in the field, or to turn off an MTU if it will not be in use for an extended

period of time. Actions performed using the STAR Programmer software are logged and

uploaded to the Network Control Computer (NCC) for verification at the end of each shift.

Prerequisites

The STAR Programmer application requires the following to communicate with a Series 4000

MTU:

Tablet or laptop with

• Windows® 7

• > 1.5 GHz

• > 2 GB RAM

• > 80 GB HDD

• Open USB port

USB-A to USB-B cable (Aclara #070-1700)

Series 4000 Maintenance and Operations Manual 9

Page 18

Software

DRAFT

Application Installation

Use the following procedure to install the STAR Programmer software on a suitable tablet or

laptop.

1) Double-click the STARProgrammerPC.msi file.

2) Click Next to begin the STAR Programmer Setup Wizard.

10 Series 4000 Maintenance and Operations Manual

Page 19

3) Verify the installation location, and click Next.

DRAFT

STAR Programmer Software

4) Click Next to initiate the installation.

Series 4000 Maintenance and Operations Manual 11

Page 20

Software

DRAFT

5) Wait while the STAR Programmer is installed.

6) Click Close after the Installation Complete confirmation appears.

12 Series 4000 Maintenance and Operations Manual

Page 21

STAR Programmer Software

DRAFT

XML File Installation

Use the following procedure to install the XML files that accompany the STAR Programmer

application.

1) Refer to the table below when selecting the appropriate STARXML.msi file for the

installation.

N

OTE: Multiple STARXML installations cannot coexist on the same machine.

Installation Type .MSI File

PC Interactive Mode - With Encryption STARXMLPCTEST.msi

PC Interactive Mode - Without Encryption STARXMLPCTESTNONENCRYPT.msi

PC Scripted Mode STARXMLPC.msi

2) Double-click the appropriate .msi file.

3) Click Next to begin the XML File Setup Wizard.

Series 4000 Maintenance and Operations Manual 13

Page 22

Software

DRAFT

4) Verify the installation location, and click Next.

5) Click Next to initiate the installation.

14 Series 4000 Maintenance and Operations Manual

Page 23

6) Wait while the XML files are installed.

DRAFT

STAR Programmer Software

7) Click Close after the Installation Complete confirmation appears.

Series 4000 Maintenance and Operations Manual 15

Page 24

Software

DRAFT

Connection

Use the following procedure to connect a tablet or laptop to a Series 4000 MTU and open the

STAR Programmer application.

1) Remove any security hardware from the

MTU door.

2) Open the door of the MTU.

4) Connect the remaining end of the USB

cable to the Series 4000 MTU.

5) Open the STAR Programmer application.

3) Connect the USB cable to the laptop or

tablet.

6) Leave the Operator and Password fields

blank and click

16 Series 4000 Maintenance and Operations Manual

Submit.

Page 25

STAR Programmer Software

DRAFT

Operation

The STAR Programmer menu functions for Series 4000 MTUs are Read MTU, Turn Off MTU,

Add MTU, Install Confirmation, and Replace Battery. Each of these functions are described in the

following sections.

Read MTU

This option allows the user to read information

from the MTU and the instrument. It will also

write configuration settings to the instrument.

Select this option to see the current MTU

settings or after changing a battery that has

completely lost power. When the user selects

the Read MTU option:

1) Select Read MTU.

2) Wait while the STAR Programmer reads

the MTU.

3) After viewing the MTU information screen,

select

the Main Menu.

OK to log the activity and return to

not

Turn Off MTU

This option allows the user to deactivate and

turn off a previously commissioned MTU.

When a Series 4000 MTU has been turned off,

the STAR Programmer software will read the

MTU Type, firmware version, and MTU ID

before turning off the MTU. The MTU will

cease all RF transmission and will only

respond to commands sent through the USB

port.

1) Select Turn Off MTU.

2) Wait while the application reads and turns

off the MTU.

3) Click OK to log the activity and return to the

Main Menu.

Series 4000 Maintenance and Operations Manual 17

Page 26

Software

DRAFT

Add MTU

Select this option to commission a new MTU

or an MTU that was turned off.

1) Select Add MTU.

3) Enter the 10-digit Account Number into the

Gas Network Node (

4) Verify the Instrument Type field has

auto-populated, and click

GNN) field.

OK.

2) Click OK to read the MTU and instrument.

5) Wait while the software commissions the

MTU. This may take several minutes.

18 Series 4000 Maintenance and Operations Manual

Page 27

STAR Programmer Software

DRAFT

6) Once commissioning is complete, the

software will return the current values

allowing you to confirm the settings.

7) Click OK to confirm the log entry and return

to the Main Menu.

8) To close the STAR Programmer application,

select File > Exit.

Series 4000 Maintenance and Operations Manual 19

Page 28

Software

DRAFT

Replace MTU

To replace an existing MTU or after installing

a new battery in an MTU that has been without

power for an extended amount of time, use the

Replace MTU option in the STAR

Programmer application.

1) Select Replace MTU.

3) Enter the 10-digit Account Number into the

Gas Network Node (

4) Verify the Instrument Type field has

auto-populated, and click

GNN) field.

OK.

2) Click OK to read the MTU and instrument.

5) Wait while the software commissions the

MTU. This may take several minutes.

20 Series 4000 Maintenance and Operations Manual

Page 29

STAR Programmer Software

DRAFT

6) Once commissioning is complete, the

software will return the current values

allowing you to confirm the settings.

7) Click OK to confirm the log entry and return

to the Main Menu.

8) To close the STAR Programmer application,

select File > Exit.

Series 4000 Maintenance and Operations Manual 21

Page 30

Software

DRAFT

Install Confirmation

This option allows the user to confirm that the

MTU can communicate with the available

DCUs and to see information about the MTU,

DCU, and the communication between the

two.

1) Select Install Confirmation.

Replace Battery

Use the following procedure after replacing the

battery in the MTU.

1) Select Replace Battery.

2) Click OK to initiate the confirmation

process.

3) Wait while the STAR Programmer reads

the MTU.

4) After viewing the MTU information screen,

select

the Main Menu.

OK to log the activity and return to

2) Click the OK button to initiate the process.

3) Wait while the STAR Programmer reads

the MTU.

4) Click OK to log the activity and return to the

Main Menu.

22 Series 4000 Maintenance and Operations Manual

Page 31

HARDWARE INSTALLATION

DRAFT

Aclara offers kits to mount the Series 4000 MTU to a wall or to a pipe with an outside diameter of

2

"- 3". Use the corresponding instructions to mount a Series 4000 MTU using one of these kits.

NOTE In addition to the mounting hardware, the installation kits also include one 10' length of

conduit, two conduit fittings, one 12' length of five conductor cable, and one 12’ length of

two conductor cable. Please refer to the Wiring section on page 29 for installation procedures

for these items.

Wall Mount

Wall Kit #109-2015-001M-020

Item Description Application Quantity

A ¼ x 2" Stainless steel wedge bolt Solid walls 4

B ¼" Stainless steel flat washer Solid and hollow walls 4

C ¼ - 20 x 2½" Stainless steel bolt Hollow walls 4

D Wall anchor Hollow walls 4

Series 4000 Maintenance and Operations Manual 23

Page 32

Wall Mount

DRAFT

Solid Wall

Follow this procedure to mount the MTU to a

solid wall.

Special Tools

In addition to standard tools and safety

equipment, you will need the following tools to

mount the MTU to a solid wall:

• Drill

• ¼" Wedge drill bit

• 0-35 ft-lb Torque-limiting wrench

Instructions

1) Determine the appropriate mounting

location for the MTU. Keep RF signal

propagation in mind when choosing a

location.

2) Position the MTU against the wall at the

desired location and mark locations for the

four bolt holes.

3) Drill holes at the four marked locations

with a ¼" Wedge Bit.

4) Insert a wedge bolt through a flat washer

and one of the mounting holes on the MTU.

5) Thread the bolt partially into the

appropriate hole drilled in step 3.

24 Series 4000 Maintenance and Operations Manual

6) Repeat steps 4 and 5 for the remaining

bolts.

7) Tighten all four wedge bolts to 27-33 ft-lb.

Page 33

Hardware Installation

DRAFT

Hollow Wall

Follow this procedure to mount the MTU to a

hollow wall.

Special Tools

In addition to standard hand tools and safety

equipment, you will need the following tools to

mount the MTU to a hollow wall:

• Drill

• ½" Drill bit

• 0-10 ft-lb Torque-limiting wrench

Instructions

1) Determine the appropriate mounting

location for the MTU. Keep RF signal

propagation in mind when choosing the

location.

2) Position the MTU against the wall at the

desired location and mark locations for the

four bolt holes.

3) Drill holes at the four marked locations

with a ½" drill bit.

4) Insert the anchor end of one wall anchor

through one of the drilled holes.

Series 4000 Maintenance and Operations Manual 25

5) Pull the anchor until it is tight against the

back side of the wall surface. Then slide the

cap forward until it is flush with the wall.

Page 34

Wall Mount

DRAFT

6) Snap off the excess strap by pressing the

top strap up and the bottom strap down.

7) Repeat Steps 4-6 for the three remaining

anchors.

8) Place a flat washer on each of the bolts, and

insert the bolts through the mounting holes

of the MTU.

9) Thread each bolt into the appropriate

anchor.

10) Tighten each bolt to 5-7 ft. lbs.

26 Series 4000 Maintenance and Operations Manual

Page 35

Pipe Mount

DRAFT

Hardware Installation

Pipe Mount Kit #109-2015-001M-21

Item Description Quantity

A

B

Series 4000 Maintenance and Operations Manual 27

Bracket assembly (

2 "- 3" Screw-drive tube clamp

5

/16

"-18 bolt, metal washer, nylon washer, & bracket)

2

2

Page 36

Pipe Mount

DRAFT

Special Tools

In addition to standard hand tools and safety

equipment, the Pipe Mounting kit also requires

the following:

• 0-20 ft-lb Torque-limiting wrench

• 0-10 in-lb Torque-limiting wrench or

screwdriver

1) Thread one of the clamps through both slots

in one of the brackets and around the pipe.

4) There are three mounting holes at the top of

the MTU and three at the bottom.

• If mounting to a Horizontal pipe, use the

top left and top right mounting holes.

• If mounting to a Vertical pipe, use the top

center and bottom center mounting holes.

2) Rotate the bracket to the desired mounting

position and tighten the clamp just enough

to maintain bracket position.

3) Thread the remaining clamp through the

remaining bracket and around the pipe.

5) Insert one of the bolts through a metal

washer, the appropriate MTU mounting

hole, and a nylon washer before threading it

into the bracket.

6) Repeat step 5 with the remaining hardware

to secure MTU to the remaining bracket.

7) Tighten both clamp screws to 7-9 in-lb.

28 Series 4000 Maintenance and Operations Manual

8) Tighten both bracket bolts to 14-16 ft-lb.

Page 37

Hardware Installation

DRAFT

Wiring

Use the following instructions to connect the MTU to a Honeywell electronic pressure monitor or

volume corrector.

Item Description Quantity

A 10' Conduit (Included in mounting kit) 1

B ½" Conduit fitting (Included in mounting kit) 2

C 12' Five conductor cable (Included in mounting kit) 1

D Five pin mating terminal (Included with MTU) 1

E Two pin mating terminal (Included with MTU) 1

F 12’ Two conductor cable (Included in mounting kit) 1

NOTE: This equipment provides non-incendive field wiring outputs for Class I, Division 2,

Group D.

Series 4000 Maintenance and Operations Manual 29

Page 38

Wiring

DRAFT

Conduit & Fittings

The cable connecting the MTU to the

instrument must be routed through the included

conduit. Use the following procedure to install

the conduit.

1) Remove the nut, sealing ring, and ferrule

from one of the conduit fittings.

2) Slide the nut and sealing ring over the end

of the conduit.

3) Insert the ferrule into the end of the conduit.

4) Thread the fitting body over the ferrule and

secure by tightening the gland nut. Tighten

the nut to 28-32 in-lb.

5) Repeat steps 1-4 to secure the remaining

fitting to the other end of the conduit.

8) Secure the fitting to the MTU with the lock

ring. Tighten the ring to 15-19 in-lb.

9) Route the conduit to the instrument.

CAUTION

10) Remove the lock ring from the remaining

Do not bend the conduit smaller than

a 3" radius.

conduit fitting and insert the fitting body

into an available opening in the pressure

monitor or volume corrector enclosure.

11) Secure the fitting to the instrument

enclosure with the lock ring. Tighten the

ring to 15-19 in-lb.

6) Remove a weather seal plug from the

bottom of the MTU enclosure.

7) Remove the lock ring from one of the

conduit fittings and insert the fitting body

into the opening in the bottom of the MTU.

30 Series 4000 Maintenance and Operations Manual

Page 39

MTU Connections

DRAFT

Use the following information when connecting the cables to the MTU.

Hardware Installation

1) Route the cable through the conduit.

2) Use the following information to connect

the cable wires to the MTU mating

connector. Secure each wire into the

connector by tightening the corresponding

set screw.

Comp1

1) Use the five conductor cable to connect the

communication terminals on the MTU with

the instrument.

MTU Connector Wire

GND (Ground) Green

ALM (Alarm) Yellow

GND (Ground) Black

TX (MTU Transmission) White

RX (MTU Reception) Red

Optional Power

1) Use the two conductor cable to connect the

MTU to an instrument supplied 10-15 VDC

power source.

MTU Connector Wire

GND (10-15 VDC ground) Black

+ (10-15 VDC positive) Red

2) Plug the MTU mating connector into the

COMP1 receptacle.

2) Plug the MTU mating connector into the

EX PWR receptacle.

Series 4000 Maintenance and Operations Manual 31

Page 40

Wiring

DRAFT

Instrument Connections

Use the information for the appropriate meter type to connect the MTU cable(s) to the instrument.

Refer to the Electrical Connection Parameters table for electrical parameters of each connector.

Mini-Max or ERX

Use the following information to connect the

MTU cable to a Honeywell Mini-Max volume

corrector or ERX pressure monitor.

COMP1

Mini-AT

Use the following information to connect the

MTU cable to the TB2 connector on a

Honeywell Mini-AT volume corrector.

COMP1

MTU Wire Mini-Max or ERX

GND Green

ALM Yellow

GND Black

TX White

RX Red

External Power (Optional)

TB1 A- (Ground)

TB1 A+ (Alarm)

Serial I/O GND (Ground)

Serial I/O RX (Receive)

Serial I/O TX (Transmit)

MTU Wire Mini-AT

GND Green A- (Ground)

ALM Yellow A+ (Alarm)

GND Black Com (Ground)

TX White RX (Receive)

RX Red TX (Transmit)

Connect the red (positive) and black (ground) wires from the MTU to an appropriate 10-15 VDC

auxiliary power source on the instrument. Please refer to specific instrument documentation for

detailed information.

Electrical Connection Parameters

COMP1 & COMP2 (J6 & J7) Input Output External Power (J12) Input

Ui = 12 V Uo = 3.5 V Ui = 15 V

Ii = 4 mA Io = 60 mA Ii = 45 mA

Pi = 50 mW Po = 210 mW Pi = 675 mW

Ci = 250 pF Co = 0 pF

Li = 0 Lo = 0

32 Series 4000 Maintenance and Operations Manual

Page 41

Hardware Installation

DRAFT

Commissioning

After installing and connecting the MTU to the instrument, it is necessary to commission the

MTU using the Add MTU function of the STAR Programmer software. Please refer to the STAR

Programmer Software section on page 7 for more information on connecting the STAR

Programmer and adding an MTU.

Series 4000 Maintenance and Operations Manual 33

Page 42

Commissioning

DRAFT

34 Series 4000 Maintenance and Operations Manual

Page 43

Maintenance

DRAFT

MAINTENANCE

The Series 4000 MTU is designed to be largely maintenance free. Periodic replacement of the

battery, however, will be necessary over the life of the MTU. The Series 4000 MTU is powered

by a 3.6V lithium, D cell battery (Aclara part number 042-0049). The NCC reports regular battery

voltage readings, and also provides a low battery warning to provide ample time for the utility to

replace a battery without loss of data. Use the following procedure to replace the battery in a

Series 4000 MTU.

WARNING:

AVERTISSEMENT:

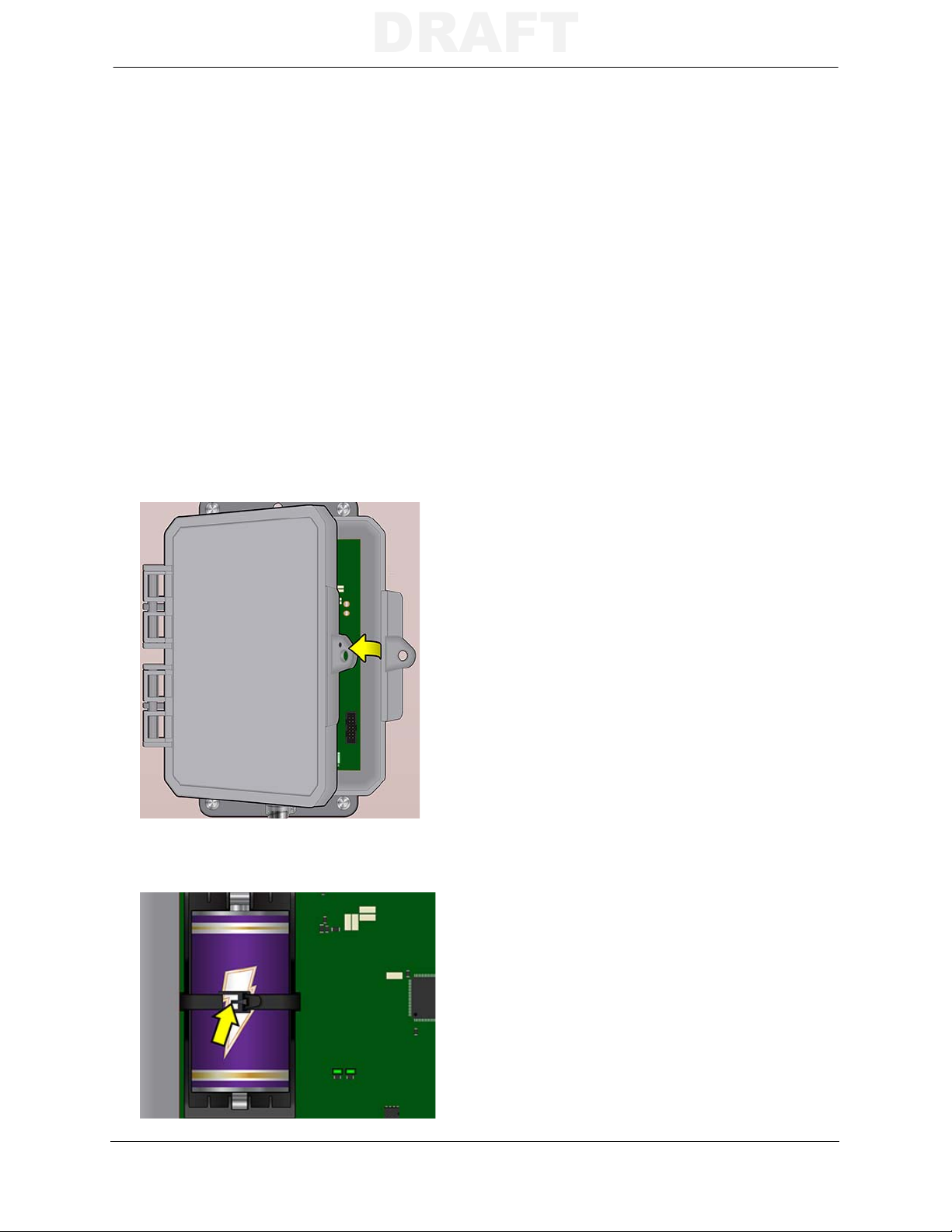

1) Remove any security hardware from the

EXPLOSION HAZARD - BATTERIES MUST ONLY BE CHANGED IN AN AREA KNOWN TO

BE NON-HAZARDOUS

RISQUE D'EXPLOSION

L’EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX AVANT DE CHANGER LA BATTERIE.

- AFIN D’ÉVITER OUT RISQU D’EXPLOSION, S’ASURER QUE

MTU door.

2) Open the door of the MTU.

5) Remove the battery from the battery holder.

6) Insert the new battery into the battery

holder. The holder is keyed so the battery

can only be installed in one direction.

N

OTE: A backup capacitor will maintain MTU

memory during battery replacement

provided power is not removed for

longer than 10 minutes. Extended

power outages may require

recommissioning the MTU.

7) Secure the new battery into the holder by

threading the tapered end of the tie through

the open end and pulling until snug against

the battery.

8) Use the STAR Programmer to log the

battery replacement.

3) Note the polarity orientation of the battery.

4) Press in on the tab to release the battery tie.

Series 4000 Maintenance and Operations Manual 35

• Connect the STAR Programmer and select

Read MTU to record the battery

replacement in the activity log. Please see

Read MTU on page 17 for more

information.

• If the MTU was without power for an

extended period of time, use the Replace

MTU option on the STAR Programmer

Main Menu. Please see Replace MTU on

page 20 for more information.

9) Close and secure the MTU door according

to utility standard practices.

Loading...

Loading...