Page 1

MTU Instructions

Page 1

ALL MTU Instructions as of 10/1/2009

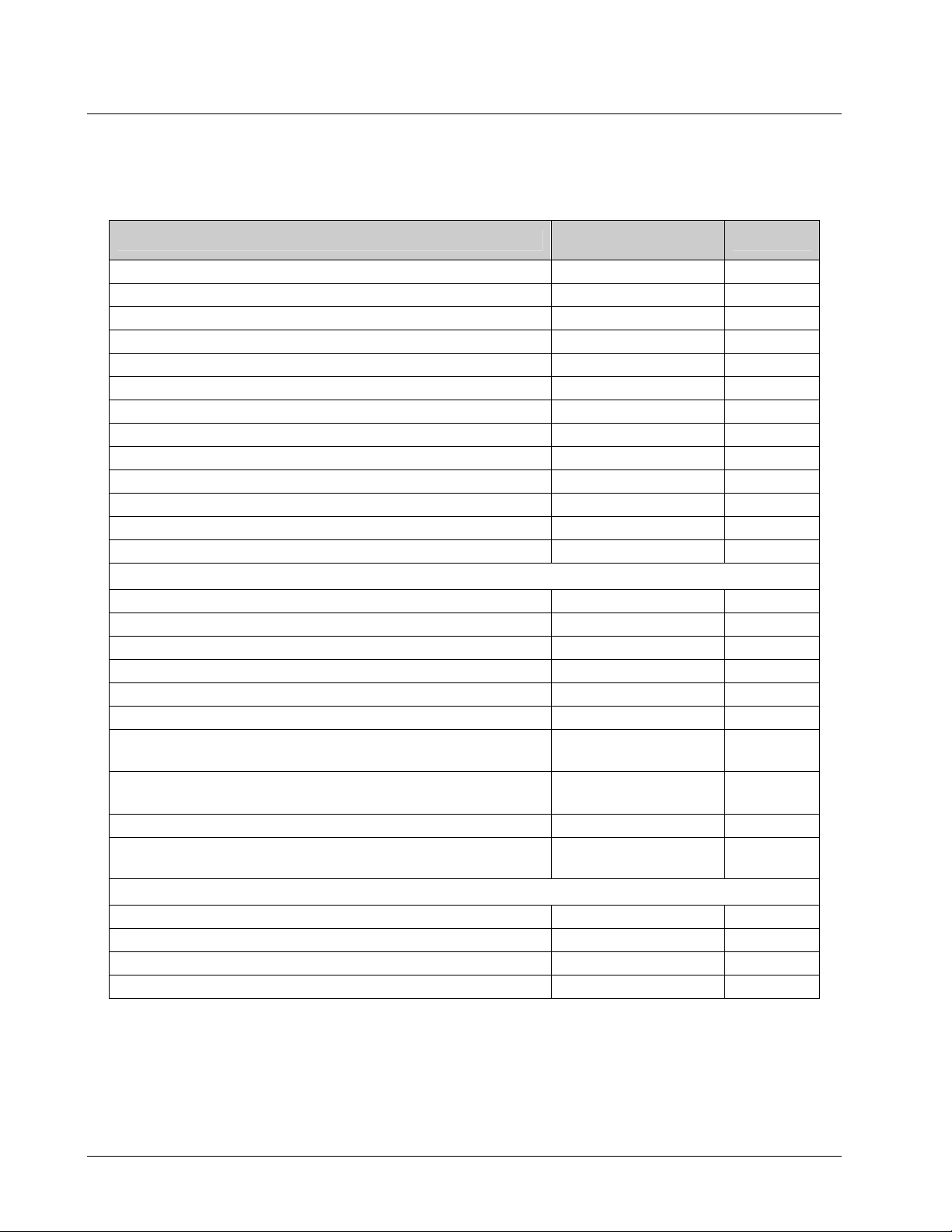

Instructions Included

Document Page

471-2000 – General Installation & Wiring Guidelines........................................................3

471-2001 – for Rockwell/Equimeter/Sensus Gas Meters (Direct Mount)..........................15

471-2002 – for Most Popular Water Meters........................................................................ 19

471-2003 – for American Meter Company Gas Meters (Direct Mount).............................25

471-2004 – for American Meter Company Gas Meters (Indirect Mount)........................... 29

471-2005 – for Carson Industries Pit Lids..........................................................................33

471-2006 – for Armor Access Pit Lids................................................................................37

471-2007 – for Invensys/Icon MTU/Electric Meter.............................................................41

471-2008 – for Hexagram Submetering Pulse Adapters ..................................................43

471-2009 – for AMCO/ABB Water Meters...........................................................................51

471-2010 – for Neptune/Schlumberger Water Meters.......................................................55

471-2011 – for Sensus/Invensys Water Meters .................................................................59

471-2012 – for Hersey Water Meters...................................................................................61

471-2013 – for Badger Water Meters..................................................................................63

471-2014 – for M-Log Sensors ............................................................................................65

471-2015 – for Rockwell/Equimeter Intermediate/Large Capacity Gas Meters..............67

471-2016 – for American Commercial/Industrial Gas Meters ..........................................73

471-2017 – for Sprague/Schlumberger 250 Gas Meters (Bracket-direct-mount)..............79

471-2018 – for Lancaster 250 Gas Meters (Bracket-direct-mount).....................................83

471-2019 – for Lancaster 175 Gas Meters (Bracket-direct-mount).....................................87

471-2020 – for Mini-Max....................................................................................................... 91

471-2021 – for Sprague 175 Gas Meters (Indirect Mount)..................................................95

471-2022 – for Metron-Farnier Water Meters....................................................................101

471-2023 – for Nicor Composite Pit Lids .......................................................................... 103

471-2026 – for American Meter Commercial & Industrial Diaphragm Gas Meters

(Hexagram Large Meter Pulser)............................................................................................107

471-2027 – for Rockwell/Equimeter Intermediate and Large Capacity Gas Meters

(Hexagram Large Meter Pulser)............................................................................................109

471-2028 – for Actaris Commercial & Industrial Diaphragm Gas Meters

(Hexagram Large Meter Pulser)............................................................................................119

471-2029 – for Dresser Roots-type Gas Meters................................................................125

471-2030 – for Romet Roots-type Gas Meters.................................................................. 131

October, 2009

Page 2

MTU Instructions

Page 2

ALL MTU Instructions as of 10/1/2009

Instructions Included (Continued)

Document Page

471-2031 – for Actaris/Schlumberger/Sprague ‘Slant-face’ Gas Meters........................137

471-2032 – for Armorcast Composite Pit Lids..................................................................141

471-2033 - for Actaris/Schlumberger/Sprague Pit/Curbside Gas Meters ......................145

471-2034 – for American Meter Company 5B-225 Gas Meters........................................149

471-2035 - for Sensus/Equimeter/Rockwell 415 Gas Meters...........................................153

471-2036 - for Sensus/Equimeter/Rockwell 175S Gas Meters........................................157

471-2037 - for Sensus/Equimeter/Rockwell 175-EMCO Gas Meters...............................161

471-2038 - for Sensus/Equimeter/Rockwell Residential Gas Meters (Indirect Mount)...163

471-2040 – for Landis & Gyr Focus Family Electric Meters............................................167

471-2041 – for Landis & Gyr S4 Family Electric Meters ..................................................169

471-2042 – for DFW Rectangular Composite Pit Lids......................................................171

471-2043 – for Carson Industries Polyplastic Pit Lids.....................................................175

471-2044 – for Sensus/Equimeter/Rockwell Gas Meters (Metric - direct mount)............179

471-2045 – for Mid-States 12" Round Pit Lids..................................................................183

471-2046 – for Alliance Rectangular Pit Lids....................................................................187

471-2047 - for Actaris/Schlumberger/Sprague ‘Flat-face’ Gas Meters...........................189

471-2051 – for Actaris Dattus fm2 and fm3 Commercial & Industrial

Diaphragm Gas Meters .......................................................................................................195

471-2052 – for Severn-Trent SmartMeter Water Meters...................................................197

471-2053 – for Endress & Hauser PROMAG Water Meters .............................................199

471-2054 – for Actaris Cyble Water Meters.......................................................................201

Page 3

MTU Instructions

Page 14

General Installation and Wiring Guidelines

Intentionally Left Blank

The FCC wants you to know…..

This equipment has been tested and complies with Part 15 and Part 90 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference. This equipment generates, uses

and can radiate radio frequency energy, and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, try to correct the interference by one or more of the following measures:

• Reorient or relocate the equipment.

• Increase the separation distance between the affected equipment and receiver.

• Consult Hexagram, Inc. for help.

Any changes or modifications to this equipment not expressly approved by the Hexagram, Inc. could void the

authorization to operate the equipment.

FCC RF Exposure Guidelines

Hexagram’s low power RF devices and their antennas must be fixed-mounted on indoor or outdoor

permanent structure(s) providing a separation distance of at least 20 cm from all persons during norm al

operation. This device is not designed (and it has no external connection) to operate in conjunction with any

other antennas or transmitters. No other operating instructions for satisfying RF exposure compliance are

needed. This unit has no user or installer serviceable parts, and requires no field adjustment or calibration.

Units are sealed at the factory, and disruption of this seal could void the authorization to operate the

equipment.

Hexagram, Inc.

23905 Mercantile Road

Cleveland, OH 44122

Page 4

MTU Instructions

Page 3

General Installation and Wiring Guidelines

Purpose & Scope

This instruction outlines general practices and procedures for the installation and wiring of

standalone, electronic interface Hexagram STAR MTUs. When installing an MTU,

always refer to these instructions in addition to

meter/MTU combination you will be installing and programming.

any specific instructions for the

Note: STAR MTUs are shipped to the customer in sealed enclosures and have passed

extensive testing and calibration procedures at the factory. No additional calibration or

adjustment is required, or can be made, without breaking thefactory seal. As calibrated,

these devices radiate a tiny fraction of the power allowable by

Exposure Limits 47 CFA CH 1.1310. There are no radio-frequency safety issues relating

to the use of this product based on this regulation.

471-2000 - 7/25/2007

FCC Radio Frequency

Page 5

MTU Instructions

Page 4

General Installation and Wiring Guidelines

Recommended Supplies

We recommend the following supplies, for which quantities will depend upon the number of

MTUs to be installed and the conditions encountered at each installation location.

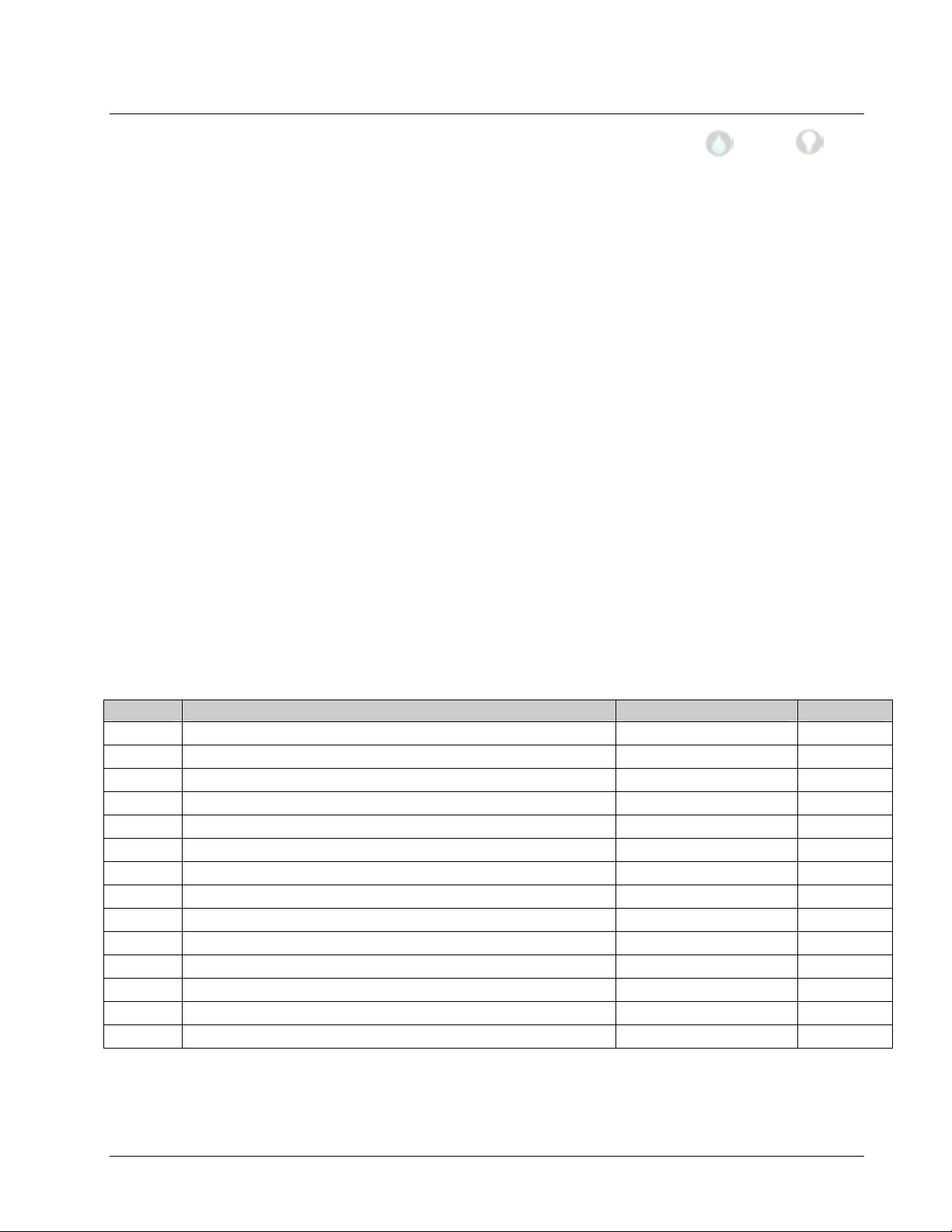

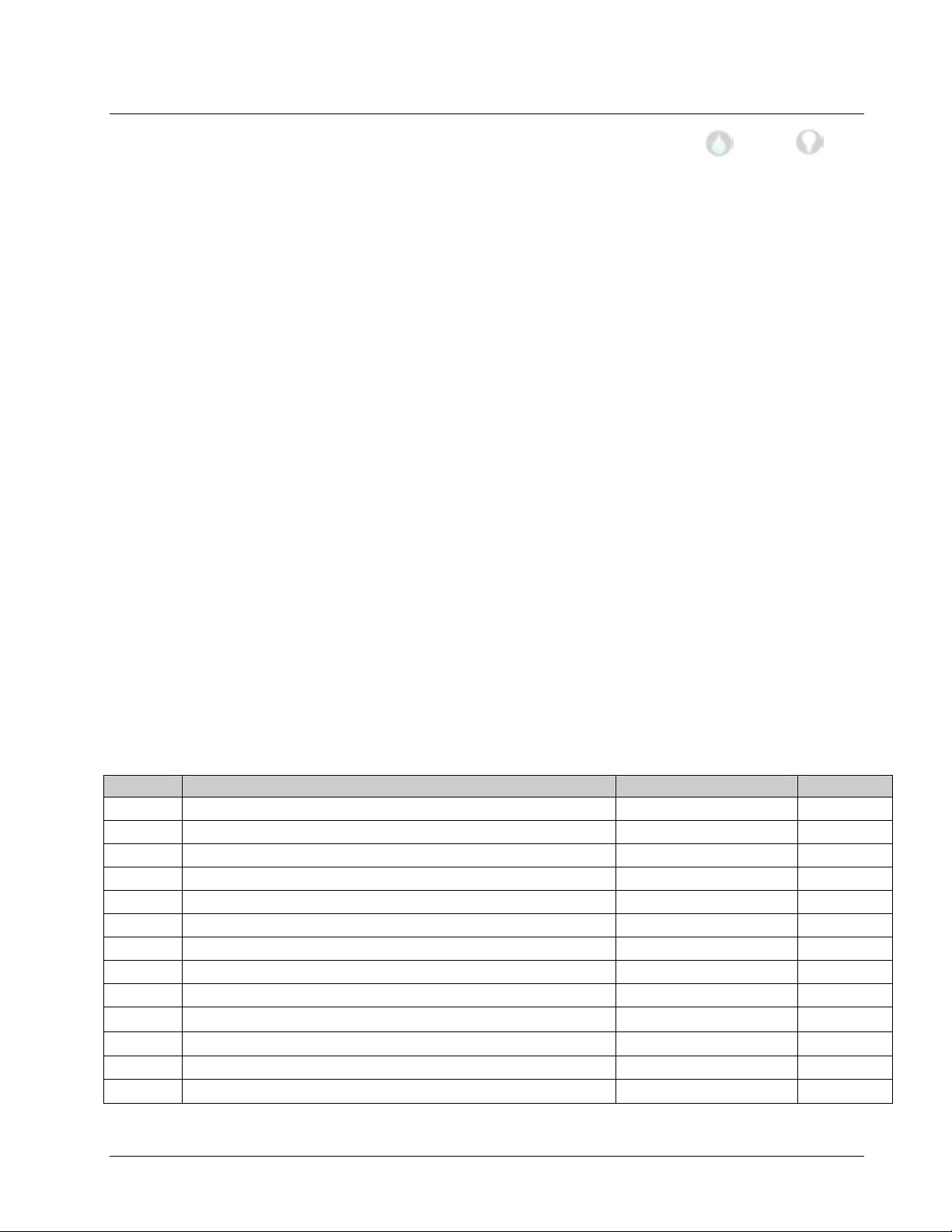

Item

Hexagram Part

Number

AMP Tel-Splice, 2-conductor 043-1910

Scotchlok, UR 2-3 wire gel-filled butt connector 043-1913

3-conductor, 22 ga, solid wire, black UV jacket 070-0506

3-conductor, 22 ga, solid wire, grey UV jacket 070-0508

AA alkaline battery, 1.5 volt (for Psion) 042-0036

Back-up battery for Psion MTU Programmer 042-0037

3M DBR-6 Direct Burial Kit (for pit unit splices) 043-1912

Sealant — White RTV 084-0082

Black electrical tape

Tie-wraps, black

Staples, telephone type, 9/16” (Arrow T-25)

Sharpie permanent marker, fine point

Plastic masonry anchors #6 x 1”, ¼” diameter

for use with Original Flatpak MTUs

Hexagram plastic spacers 056-5155H1

Phillips exterior screws 8 x 2 ½” (deck screw)

Phillips exterior screws 8 x 3” (deck screw)

Drywall screws, #6 x 1-5/8” Phillips, coarse (for indoor use)

Drywall screws, #6 x 2” Phillips, coarse (for indoor use)

MTU spacer for pipe or bar mount 056-5155K

18″ heavy-duty UV-resistant tie wrap (for bar mounting gas

067-0030

MTUs)

10-32 x 1½″ pan head machine screw (for bar mounting gas

069-103248CS

MTUs)

10-32 nut, stainless steel (for bar mounting gas MTUs) 069-3011

#10 7/16” flat washer, stainless steel (for bar mounting gas

069-3004

MTUs)

Quantity

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

As needed

for use with NEW Compact Flatpak MTUs

Long Spacers/Standoffs (for pit lid installations) 056-8150L

Short Spacers/Standoffs (for pit lid installations) 056-8150S

Phillips exterior screws 8 x 1 3/4” (deck screw)

Drywall screws, #6 x 1-5/8” Phillips, coarse (for indoor use)

As needed

As needed

As needed

As needed

Page 6

MTU Instructions

Page 5

General Installation and Wiring Guidelines

Recommended Tools

• Cordless drill (⅜”, variable speed,

1800-2000 rpm, adjustable torque

settings)

• Drill bit, ¼”, carbide tipped

• Drill bit, ¼” x 12”, carbide tipped

• #2 Phillips power screwdriver bits

• Stapler for ¼” wire and cable

(Arrow T-25M)

• Diagonal side cutters/wire cutters

• Needle nose pliers – small

• Wire stripper

• Connector crimping tool 3M 9EY

• Safety goggles

• Screwdriver, #1 Phillips

• Screwdriver, #2 Phillips

• Screwdriver, 5/16” slotted

• Screwdriver, ¼” slotted

• Screwdriver, small slotted, ⅛”

blade

• Hammer

• Clipboard

• Flashlight with batteries

• Extension cord with trouble light

• MTU Programmer with cable,

programming coil and STAR

Programming Software

MTU Wiring

General - Many MTUs connect to the

meter by means of a 3-conductor, 22gauge solid conductor wire. The wire is

housed in a PVC jacket with UV

inhibitors. A black-jacketed wire is

supplied on single-port MTUs and for port

1 of dual-port MTUs. A grey jacket is

used for the port two input to dual port

MTUs.

Wire Length – MTUs are provided with a

standard wire length of 12 feet. Additional

wire may be used if necessary. A

maximum run of up to 500 feet can be

used to position the MTU in a favorable

location. Use like-colors for cable jackets

and individual wires when extending MTU

wiring.

Some specific meters may impose other

wire length limitations. Consult the meter

manufacturer.

Wire Routing - Wires should be attached

to walls with 9/16” staples. If wire

clearance holes are needed to route wire

from the meter to the MTU, drill a ¼” hole

using an appropriate drill bit. The installer

is responsible for the selection of an

appropriate location for any hole to be

drilled.

Note: Wiring must be in accordance with

all national and local codes.

Wire Protection - A drip loop below the

MTU is not required.

Inspect wire to ensure that routing and

stapling have not caused wire damage.

Pull the wire lightly at each staple to

make sure that the staple is not set too

tightly.

Any splices made to wire must be

suitable for the environment and made in

accordance with national and local codes.

Page 7

MTU Instructions

Page 6

General Installation and Wiring Guidelines

They must be secure and made in

accordance with the connection supplier’s

instructions. Generally, gel-filled

Insulation Displacement Connectors

(IDCs) such as 3M ScotchLok or AMP

Tel-Splice connectors should be used on

all wire-to-wire connections.

Splices located outdoors or in meter pits

should be further protected through the

use of a direct burial kit. This consists of

a gel-filled plastic tube that houses the

individual wire-to-wire splices to provide

additional protection from the elements.

Since MTU transmissions are similar in

nature to cellular phone signals, a cellular

phone can be used to help to determine if

a location is suitable for MTU mounting.

If the cellular phone signal drops

dramatically or indicates no signal at the

desired location, it is possible that the

MTU signal will also be blocked at this

location. In this case, the MTU will have

to be mounted in a different location,

possibly on the outside of the structure.

Keep the MTU away from all other

electrical wires.

Note: Do not mount the MTU under

wiring such as Romex, AC power wires,

cable TV wire, or telephone wire. Do not

allow these wires to lay on top of, or in

front of the MTU.

Note: Keep the MTU six inches away

from metal items such as pipes, conduit,

electric meters, electrical boxes, and

downspouts.

Make sure screws used to mount the

MTU do not protrude and pierce or

otherwise damage any wires, cables, or

pipes.

MTU Positioning and Mounting

General - MTUs must be positioned and

mounted properly to ensure optimum RF

signal propagation. Each MTU contains

an internal antenna near the top front

surface of the sealed enclosure. As a

result, the MTU should always be

mounted vertically and the STAR logo

should face the installer.

Use of Spacer – There are two primary

styles of MTUs. The Original Flatpak

STAR MTU requires the use of a spacer

(Hexagram Part Number 056-5155H1)

when the MTU is mounted on any surface

other than wood. The NEW Flatpak

STAR MTU is a modified design that can

be directly mounted to a variety of

surfaces without the use of a spacer.

See the examples below for additional

information.

Page 8

MTU Instructions

Page 7

General Installation and Wiring Guidelines

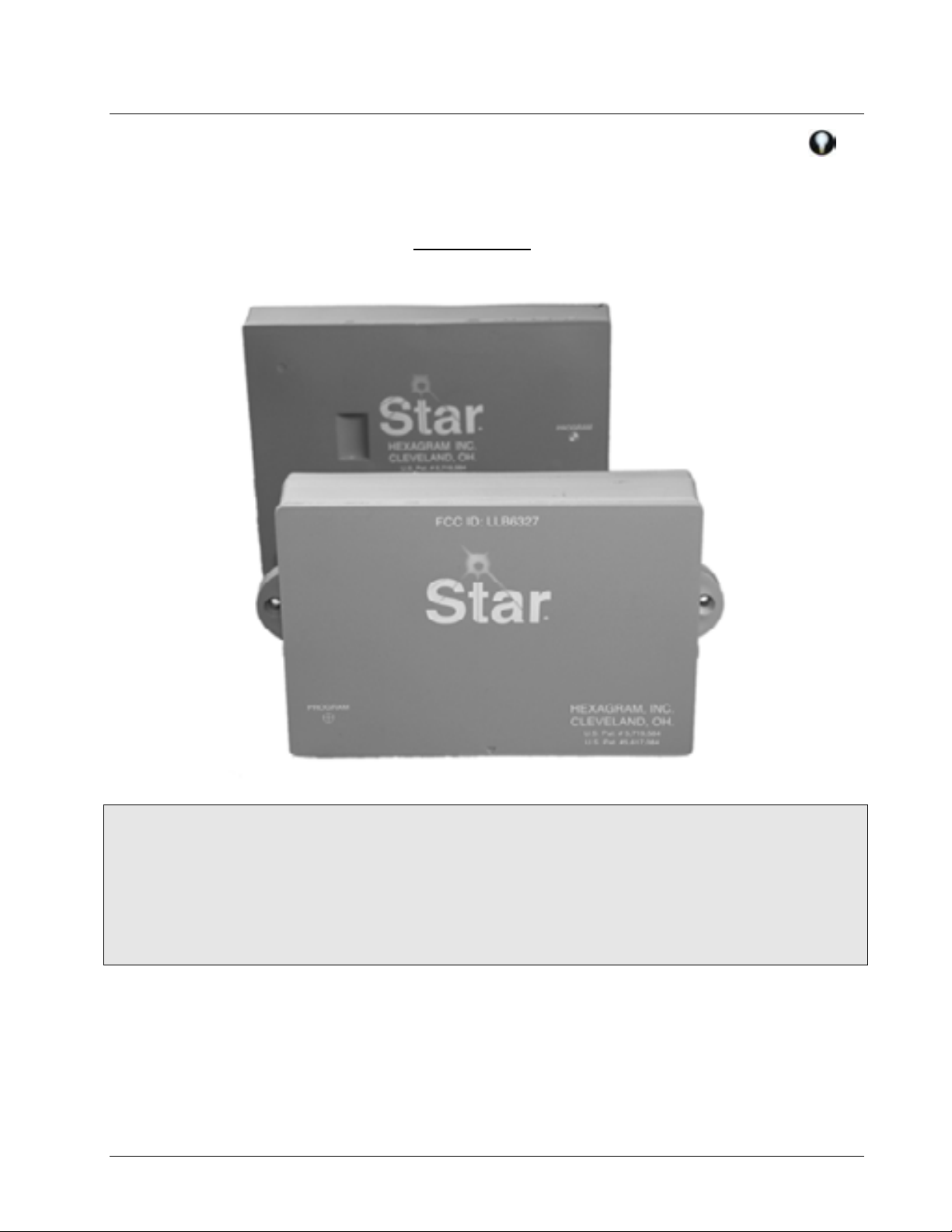

NEW Flatpak STAR MTU – An example

of the NEW Flatpak STAR MTU is shown

below. These MTUs are approximately

6.5” x 4.25” x 1.5” thick, and can be

mounted on most surfaces without the

use of a spacer.

Original Flatpak STAR MTU – An

example of an Original Flatpak STAR

MTU is shown below. These MTUs are

6.5” x 5.5” X 1” thick, and require a

spacer if mounted on any material other

than wood.

Note: Do not use a spacer when

mounting an Original Flatpak STAR MTU

on wood.

Page 9

MTU Instructions

Page 8

General Installation and Wiring Guidelines

Outdoor Mounting

MTUs mounted outdoors are typically

mounted to the side of buildings, to a

stationery post, to the piping surrounding

the meter, or to a pit lid.

Mounting to a Buiding or Post

If the unit is being mounted to the outside

of a building, the MTU will be connected

to wires that lead from the inside to the

outside of the building. If existing wire is

used, it must be of the same quality as

specified in MTU Wiring. It must also be

in good condition, without breaks,

damage, or corrosion.

Step 1 – Select a mounting location for

the MTU that will allow optimum signal

transmission.

Step 2 – Run wiring from the MTU to the

meter. If a splice is required, it may be

placed inside or outside. For special

circumstances, contact your supervisor.

If using existing wiring, remove any box

that houses the outside wires.

Step 3 – Mount the MTU on the side of

the building.

CAUTION!

Do not over tighten screws.

Excessive torque will crack

the MTU enclosure. Do not

tighten screws beyond the

point that the MTU touches

the mounting surface.

Step 4 – Make the appropriate

connections to the meter. Refer to the

specific MTU Instruction for the meter in

use.

Bar or Pipe Mounting

Particularly in outdoor gas applications, it

is sometimes convemient to mount the

MTU to the connecting piping. With the

Original Flatpak STAR MTU this is easily

done using a bar-mount spacer and two

18” long tie-wraps, (See Recommended

Supplies.)

Step 1 - Thread the tie-wraps into the bar

mount spacer as shown here.

• The MTU must be mounted

level, vertically with the STAR

logo facing the installer. Allow a

1” space between the top of the

MTU and the overhang of the

siding above it. This is critical

for proper radio signal

transmission.

• Use a Spacer (Hexagram Part

Number 056-5155H1) if

mounting an Original Flatpak

STAR MTU on a non-wood

surface.

Page 10

MTU Instructions

Page 9

General Installation and Wiring Guidelines

Step 2 - Attach the spacer to the MTU

using #10-32 stainless steel screws, nuts

and washers. Tighten the screws to 12 to

15 in-lb. On a standard drill driver with 0

to 24 torque settings, this is typically the

#10 setting.

Step 3 - Wrap the tie wraps around the

bar as needed, pulling the ties around

(through the spacer plate) as they are

tightened.

Step 4 - Adjust the MTU as needed and

pull the tie wraps tight.

Pit-Lid Mounting

For water or gas meters located in meter

pits, MTUs can be mounted to the lower

surface of the pit lid if an approved, nonmetallic pit lid is used. In these

applications, the MTU is mounted with it’s

front surface facing the bottom surface of

the lid, as shown below

Original Flatpak STAR MTU

When NEW Flatpak STAR MTUs are

mounted in this manner, spacers are

used between the MTU mounting tabs

and the lower surface of the pit lid, as

shown below.

Step 5 - Trim off the excess tie wrap,

leaving about a ½” tab.

Step 6 – Once Installation is complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

Revised Flatpak STAR MTU

Page 11

MTU Instructions

Page 10

General Installation and Wiring Guidelines

A long spacer is available, for use when

the lower surface of the pit lid is a flat,

solid surface. A short spacer is used

when the lower surface of the pit lid in

use has a ribbed construction.

Contact Hexagram for information on

approved non-metallic pit-lids.

Indoor Mounting

For an inside mount, mount the MTU

vertically on a ceiling joist. It is important

to mount the MTU as high as possible.

Note: The MTU must be mounted above

grade.

Because the outside wall of a building

can have metal siding or foil insulation,

keep the MTU a few inches away from

the outside wall. Transmissions easily

pass through wood and masonry.

Do not install an MTU inside if the

basement has a metal ceiling or foil-lined

insulation in the ceiling or if it has foil on

the sidewalls running from grade to

ceiling. This will prevent the signal from

transmitting effectively.

Do not mount the MTU if large metal

objects, such as heating ducts, block both

the front and rear of the MTU. If

absolutely necessary, a single large metal

object may be located several feet away

from the MTU.

Unfinished Basement

Step 1 – Select a mounting location for

the MTU that will allow optimum signal

transmission. In unfinished basements,

this is typically high on a ceiling joist, at

least a few inches away from outside

walls.

Step 2 – Mount the MTU.

• The MTU must be mounted

level, vertically with the STAR

logo facing the installer. Allow a

1” space between the top of the

MTU and any overhang above

it. This is critical for proper

radio signal transmission.

• Use a Spacer (Hexagram Part

Number 056-5155H1) if

mounting an Original Flatpak

STAR MTU on a non-wood

surface.

CAUTION!

Do not over tighten screws.

Excessive torque will crack

the MTU enclosure. Do not

tighten screws beyond the

point that the MTU touches

the mounting surface.

Large metal objects such as heating

ducts, steel cabinets or metal ceiling

structures can block MTU transmissions.

Select locations that are at least five to

ten feet away from objects such as these.

Page 12

MTU Instructions

Page 11

General Installation and Wiring Guidelines

Step 3 – Run wiring from the MTU to the

meter. Carefully staple the wire to the

wall every 18” and at every change in

direction using 9/16” staples. All turns

are to be at right angles. If wire must be

run on masonry, secure it with wire clips.

Run wires parallel to the joist. If a joist

must be crossed, run at a 90 degree

angle. If the MTU input cable must be

extended, use an appropriate splice.

Make sure inner conductors are not

nicked during stripping.

Step 4 – Make the appropriate

connections to the meter. Refer to the

specific MTU Instruction for the meter in

use.

Finished Basement

Step 1 – Select a mounting location for

the MTU that will allow optimum signal

transmission. In Finished basements,

this may be high on a ceiling joist in an

unfinished section of the basement or

high on an interior wall near a window or

outside wall, but at least a few inches

away from outside walls.

CAUTION!

Do not over tighten screws.

Excessive torque will crack

the MTU enclosure. Do not

tighten screws beyond the

point that the MTU touches

the mounting surface.

Step 3 - Run wiring from the MTU to the

meter. Run all wiring behind the wall if

possible. Carefully staple the wire to the

wall every 18” and at every change in

direction using 9/16” staples. All turns are

to be at right angles. If wire must be run

on masonry, secure it with wire clips. Run

wires parallel to the joist. If a joist must be

crossed, run at a 90 degree angle. If the

MTU input cable must be extended, use

an appropriate splice. Make sure inner

conductors are not nicked during

stripping.

Step 4 – Make the appropriate

connections to the meter. Refer to the

specific MTU Instruction for the meter in

use.

Note: Ceilings may contain metal.

Therefore, the MTU should be placed 2 to

3 inches down from a plaster or ‘dropped’

ceiling.

Step 2 – Mount the MTU.

• The MTU must be mounted

level, vertically with the STAR

logo facing the installer. Allow a

1” space between the top of the

MTU and any overhang above

it. This is critical for proper

radio signal transmission.

• Use a Spacer (Hexagram Part

Number 056-5155H1) if

mounting an Original Flatpak

STAR MTU on a non-wood

surface.

Page 13

MTU Instructions

Page 12

General Installation and Wiring Guidelines

Do

9 Do check your cell phone for presence

of a strong signal before entering a

building or basement. Do install the

MTU if the signal remains strong at

the installation location. (Note: This is

a guideline only. It does not guarantee

that the MTU will be received by the

DCU. However, if cell phone service is

affected by the location, it is possible

that the MTU transmission will also be

blocked.)

9 Do select the best possible location

for MTU installation that will allow

optimum signal transmission.

9 Do select a location for MTU

installation that is above grade.

9 Make sure that the MTU is located

near an outside wall, but not on an

outside wall.

9 Make sure the MTU in installed within

500 feet of the meter.

9 Do make sure that no staples have

pierced the installation wire.

9 Do mount the MTU vertically and level

with the STAR Logo facing the

installer.

9 Do keep the MTU a few inches away

from the outside wall in case of metal

siding or foil insulation.

9 Do use a spacer when mounting an

Original Flatpak STAR MTU on any

surface other than plaster or wood.

9 Do use a spacer if you need to make

a splice near the MTU and if the MTU

is mounted outside.

9 Do keep the MTU at least 6” (the

width of the MTU) from all pipes,

conduit, electric meters, electrical

boxes, downspouts, dumpsters,

garbage cans, water, electric and gas

meters, etc.

9 Do keep at least 4” between MTUs

side to side and 3” top to bottom,

when installing multiple MTUs.

9 Do mount an MTU 2” to 3” below a

plaster ceiling or the metal grid of a

drop ceiling.

9 Do use amp splices and 3M DBR Gel

kits when making splices in pits.

9 Do make sure the correct meter type

and size is selected.

9 Do make sure the MTU is

programmed on.

9 Do program the MTU as the last step.

Make sure it is mounted, wired, all

splices are completed and tucked into

place and wires are stapled in place.

9 Do follow all national and local codes

when installing MTUs.

9 Do inspect all splices, connections

and wiring for damage.

9 Do route all wires away from the MTU

case.

Page 14

MTU Instructions

Page 13

General Installation and Wiring Guidelines

Don’t

9 Don’t install the MTU if the cell phone

signal was strong outside the building

or basement and then goes into “no

service” or a very weak signal at the

MTU installation site.

9 Don’t select a location for MTU

installation that is easy to install, but

will not allow for good signal

transmission.

9 Don’t select a location for MTU

installation that is below grade.

9 Don’t place the MTU under Romex,

AC power wires, cable or TV wire,

telephone wire, etc. Don’t allow these

wires to lay on top of or in front of the

MTU.

9 Don’t mount the MTU right next to

conduit or metal pipes.

9 Don’t over tighten the screws when

mounting the MTU.

9 Don’t route the MTU wire along the

top or front of the MTU.

9 Don’t mount the MTU near 2 or more

metal objects such as heating ducts.

9 Don’t mount the MTU behind metal

objects such as washers, dryers,

furnaces, hot water tanks, metal sinks,

metal shelves, dumpsters, garbage

cans, water, electric or gas meters, or

any other large metal objects.

9 Don’t mount the MTU in a basement

that has metal ceilings unless there is

an opening in the ceiling that is above

grade where the MTU can be

installed.

9 Don’t mount the MTU near electrical

wires.

9 Don’t stack MTUs on top of each other

(back to front).

9 Don’t install an MTU if the case is

cracked or broken.

9 Don’t mount the MTU in the center of

a basement.

9 Don’t make a connection or splice if

any of the wires are nicked or cut. Restrip the wire and start over.

9 Don’t damage insulation with staples,

or by rough handling.

9 Don’t stretch wire when installing.

9 Don’t exceed 500 feet total wire length

between the MTU and the meter.

Page 15

MTU Instruction

Page 15

for Rockwell/Equimeter/Sensus Gas Meters

Purpose & Scope

This instruction provides a procedure for installing a STAR direct-mount MTU on the

following Rockwell/Equimeter/Sensus meters: R175, R200, R250, R275, R310, R315,

RT210.

Parts Required

Ref. # Item Part Number Quantity

1 Gasket (pre-applied to MTU) 066-5155C 1

2 Blue Coupler, MTU 056-5155E 2

3 Retaining Shaft, MTU 056-5155D 1

4 MTU, Direct Mount per project 1

5 Magnet 036-0002 1

6 Gear, Blue, Standard 056-5155G4 1

7 #6 Round Spacer, Nylon 068-60812-EX 2

8 10-24 x 1 1/8” Slotted, Fillister Head Machine Screw 069-102436H 4

9 #10 Flat Washer, Acetal 069-3019 1

10 #6 x 1 1/4” Combo Panhead Sheet Metal Screw 069-060040C3 2

11 Register Cover, MTU 109-7712A 1

12 #10 x 3/4” Tri-lobular Screw 069-101424A2 2

13 Gear, Red, Extended 056-5155G3 1

14 Gear, Yellow, Odometer 056-5155G2 1

471-2001 - 7/14/2008

Page 16

for Rockwell/Equimeter/Sensus Gas Meters

Page 16

Tools Required

To mount the MTU to these meters, you

will need the following tools and

equipment:

• Cordless drill ⅜”, variable

speed, with adjustable torque

settings

• #2 Phillips bit

• Safety goggles

• Phillips screwdriver

• Slotted screwdriver

Installation Procedure

Before installing the MTU, anti-tamper,

safety, and security hardware must be

removed from the clear register cover.

Step 1 - Remove the existing clear

register cover by removing the four

screws. Discard the screws and cover.

Step 2 - Remove the register by

removing the two screws. Set the register

aside. Discard the screws.

Step 3 - Insert the four 10-24 x 1⅛”

screws through the holes on the MTU as

shown.

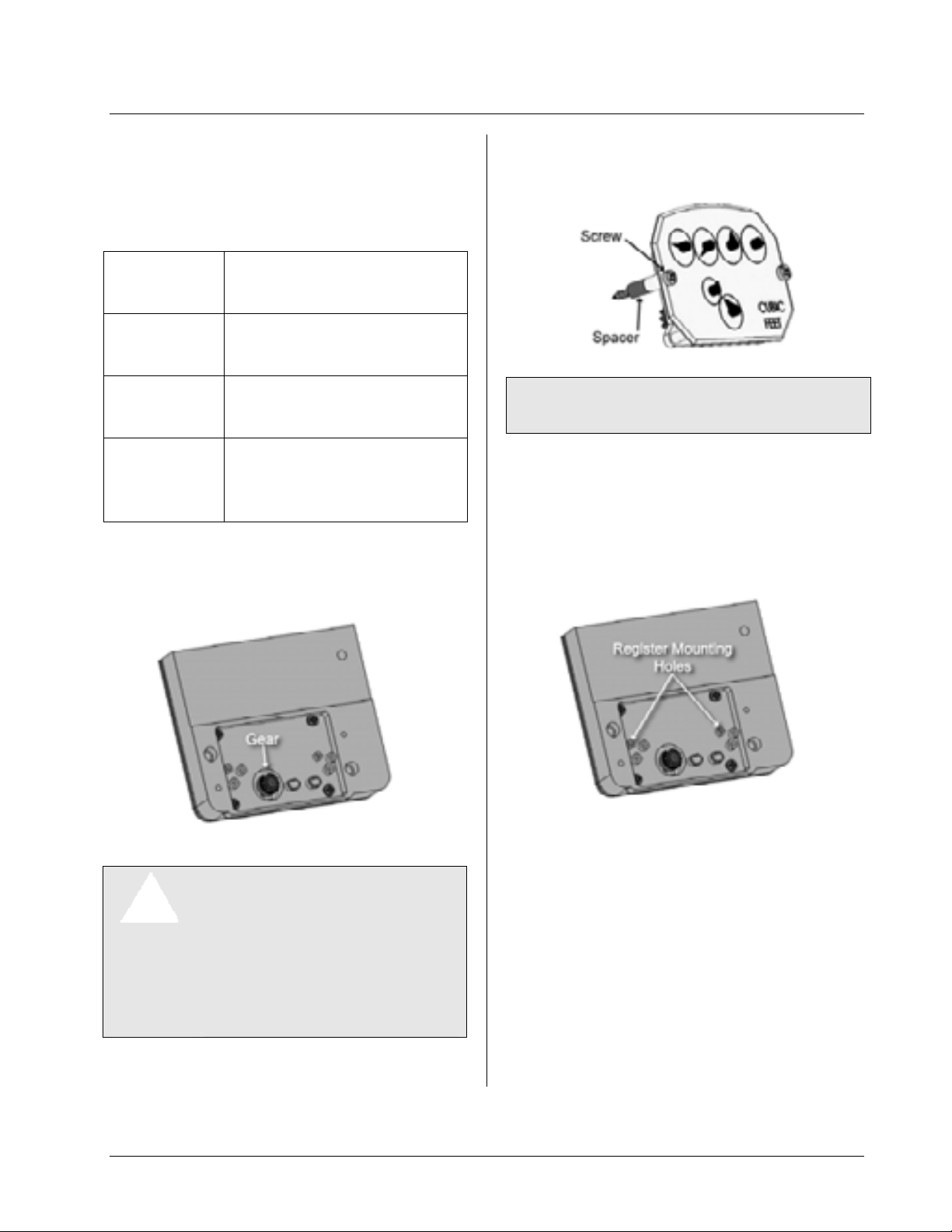

MTU Instruction

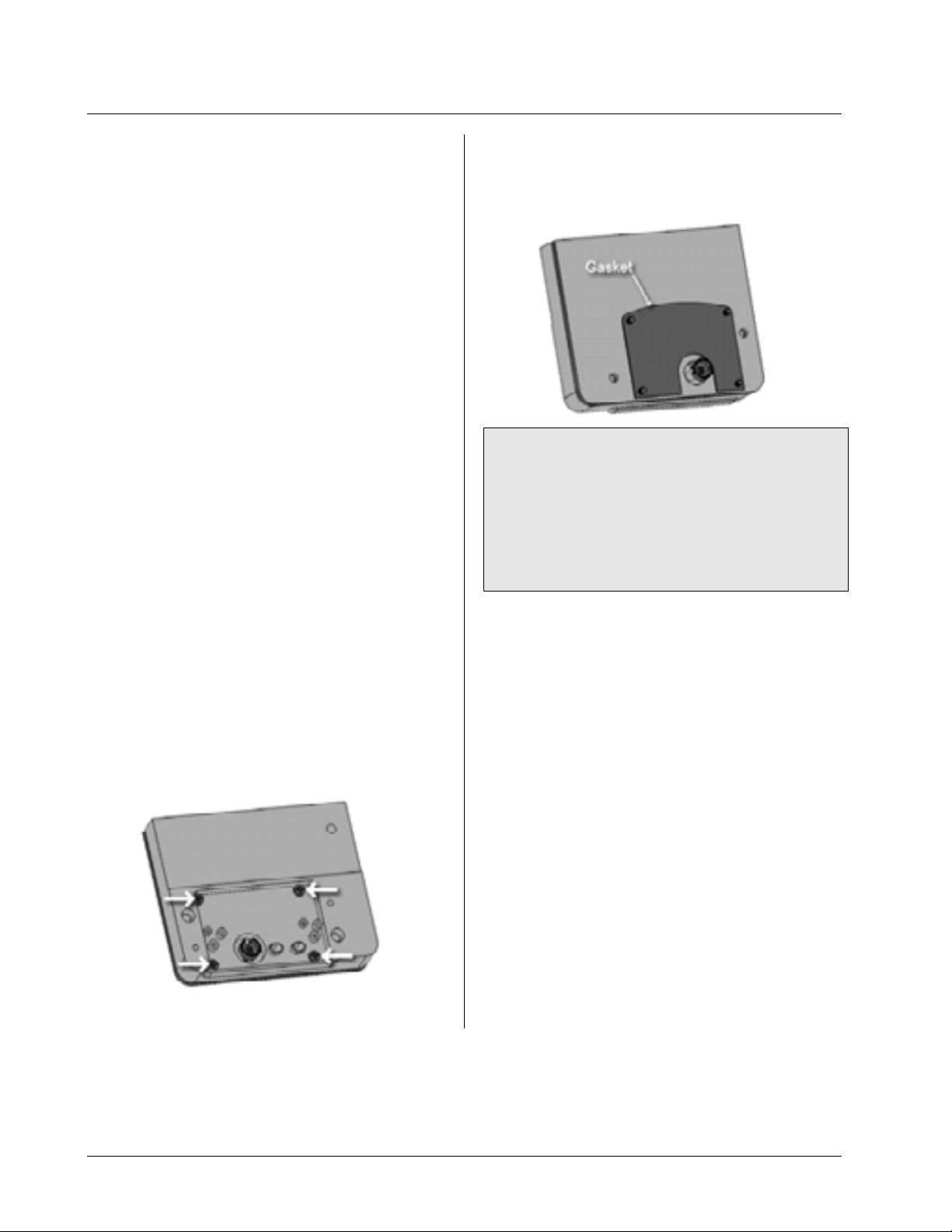

Step 4 – Turn the MTU over and insure

that there is a pre-applied gasket on the

back of the MTU as shown below.

Note: Couplers are pre-assembled to the

MTU. Insure that the couplers are firmly

attached to the shaft and that the coupler

on the front side of the MTU contains the

magnet. Also, verify that the plastic

washer is in place between the rear

coupler and the MTU.

Step 5 - Position the MTU on the meter.

Rotate the coupler so that the gear tooth

on the coupler engages with the gear

teeth on the gas meter. Orientation is not

critical, but you should be able to feel the

teeth “bite” when you turn the coupler

from the front of the MTU.

Step 6 - Tighten the four 10-24 x 1-⅛”

screws to 12 to 15 in-lb. On a standard

drill driver with 0 to 24 torque settings,

this is typically the #10 setting. Tighten

corner to corner.

Step 7 - Check the coupler. It should

have slight play — it should not bind or

turn too freely.

Page 17

MTU Instruction

Page 17

for Rockwell/Equimeter/Sensus Gas Meters

Step 8 – Select gear to fit between the

register and the MTU without binding.

Typically, the correct gear can be

selected based upon the type of index in

use, as shown in the following table.

Type of

Index

Plastic, dialtype

Brass, dialtype

Plastic,

odometertype

Place the selected gear into the coupling.

The head of the pin on the gear needs to

be facing out.

Coupler Drive Gear

Blue Gear

(Part # 056-5155G4)

Red Gear

(Part # 056-5155G3)

Yellow Gear

(Part # 056-5155G2)

Step 9 - On the register, insert the screws

and spacers.

Note: Spacers may not be required with

odometer-style registers.

Step 10 - Mount the register to the MTU,

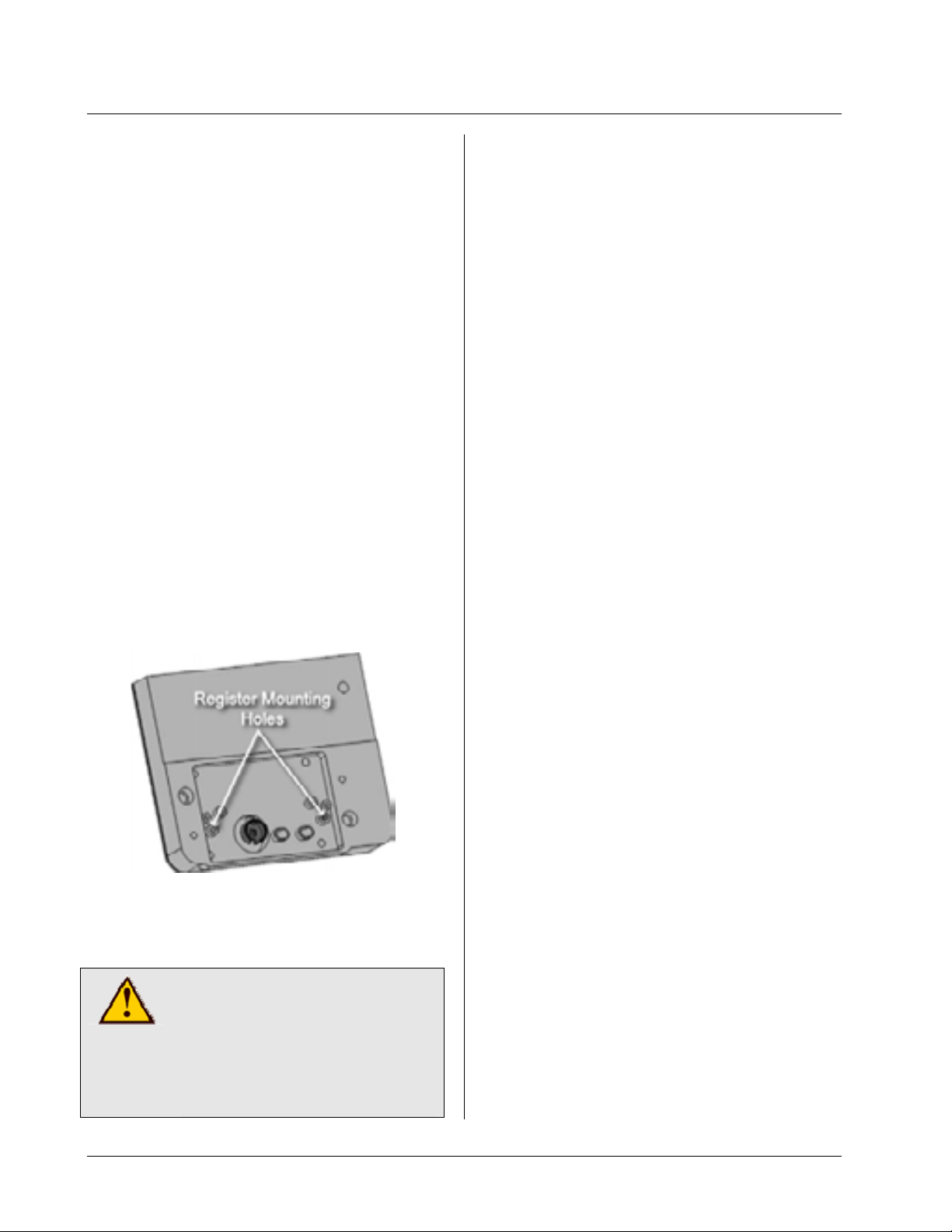

fastening it to the mounting holes shown

below. Hand tighten to a torque not to

exceed 3-5 inch-pounds. Make sure the

index register gear and the MTU coupler

gear are engaged.

CAUTION!

Do not over tighten screws.

Excessive torque may

damage the MTU enclosure.

Power tools are not

recommended for use on

steps 9-12.

Page 18

MTU Instruction

Page 18

for Rockwell/Equimeter/Sensus Gas Meters

Step 11 - After you feel engagement

between the index register gear and the

MTU coupler gear, tighten the register

screws until they are snug.

Step 12 - Place the new cover over the

register so that the top label or arrow is

on top and the vent holes are on the

bottom. Align the cover with the mounting

holes on the MTU, press it into place, and

insert the #10 x 1” screws. Hand tighten

to a torque not to exceed 3-5 inchpounds. The gasket should be

compressed slightly.

Step 13 - Replace any anti-tamper,

safety, or security hardware onto the plastic cover as required.

Step 14 – Once Installation is complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

Page 19

MTU Instruction

Page 19

for Most Popular Water Meters

Purpose & Scope

This instruction provides wiring information for connecting STAR MTUs to any of the

following popular water meters:

• AMCO and/or ABB water meters (all sizes)

equipped with Invision, Scancoder, RS Pulser,

or Type A Industrial Pulser registers and with

the AMCO/ABB V100 (PSMT) meter and the

S130/5UM hot and cold water meters.

• Neptune and/or Schlumberger water meters (all

sizes) equipped with ARB-V, Auto/ProRead or

E-Coder PLUS registers.

• Sensus and/or Invensys water meters (all sizes)

equipped with ECR or ICE registers.

• Hersey water meters equipped with Translator

or ER2 registers.

• Badger water meters (all sizes) equipped with Read-O-Matic, RTR or ADE

registers.

• Metron water meters (all sizes) equipped with OER registers.

Supplies and Tools Required

See Publication 471-2000, General

Installation and Wiring Guidelines for a

complete list of recommended tools and

supplies for MTU Installation.

Installation Procedure

Step 1 - Select a mounting location for

the MTU that will allow optimum signal

transmission, and install any needed

wiring. Be sure to follow all General

Installation and Wiring Guidelines as

outlined in Publication 471-2000.

Step 2 – Select the wiring diagram that

applies to the meter you are connecting

and make the appropriate wiring

connections.

a. Direct Wiring to Meter - MTU

wiring is supplied stripped to a

standard length that fits water

meters with screw terminals.

Simply wrap the wires around the

screw terminal and tighten the

screw hand tight. Over tightening

the screw can stress and possibly

damage the wire.

b. Water Meter with Integral Cable -

If the water meter is supplied with

an integral cable and a cable-tocable splice is necessary, use a

gel-filled wire splice designed for

outdoor (moisture applications) to

seal the individual connections.

471-2002 - 7/24/2006

Page 20

MTU Instruction

Page 20

for Most Popular Water Meters

Note: When connecting a dual port MTU

to a compound meter, connect port 1

(black jacket) to the primary, or high-flow

register and port 2 (grey jacket) to the

secondary or low-flow register.

Step 3 – Make a final visual check of the

wiring from the MTU to the meter register.

Verify that the cable routing is neat,

secure and professional.

Step 4 – Once installation and wiring are

complete, program the MTU using the

STAR Programmer Software and your

MTU Programmer.

AMCO/ABB Scancoder

MTU Cable Scancoder Register

Red G (Green)

Black B (Black)

White R (Red)

Wiring Diagrams

AMCO Invision

MTU Cable Invision Register

Red G (Green)

Black B (Black)

White R (Red)

AMCO/ABB RS Pulser

MTU Cable RS Pulser Register

Red R (Red)

Black B (Black)

White B (Black)

No Connection G (Green)

Page 21

MTU Instruction

Page 21

for Most Popular Water Meters

AMCO/ABB Type A Industrial Pulser

MTU Cable

Red

Black

White

Type A Industrial

Pulser Register

+ Positive

- Negative

- Negative

AMCO/ABB V100 (PSMT)

MTU Cable V100 (PSMT) Cable

Red Red

Black Blue

White Blue

No Connection Black

No Connection Yellow

AMCO Digital Register

MTU Cable

Red R (Red)

Black B (Black)

White B (Black)

No Connection G (Green)

AMCO Digital

Register

AMCO S130/5UM Hot Water

MTU Cable S130/5UM Cable

Red Brown

Black White

White White

Page 22

MTU Instruction

Page 22

for Most Popular Water Meters

AMCO S130/5UM Cold Water

MTU Cable S130/5UM Cable

Red Brown

Black White

White White

Neptune/Schlumberger ARB-V or

Auto/ProRead

Neptune/Schlumberger E-Coder PLUS

MTU Cable

Red B (Black)

Black G (Green)

White R (Red)

E-Coder PLUS

Register

Sensus/Invensys ECR or ICE

MTU Cable ProRead Register

Red B (Black)

Black G (Green)

White R (Red)

Note: Auto/ProRead registers must be

programmed for 3-wire mode.

MTU Cable

Red R (Red)

Black B (Black)

White G (Green)

Sensus/Invensys

Register

Note: The 8-digit Sensus ICE Register

must be programmed to deliver 6

consecutive digits of reading information

for proper operation with STAR MTUs.

Page 23

MTU Instruction

Page 23

for Most Popular Water Meters

Hersey Translator

MTU Cable Hersey Register

Red R (Red)

Black B (Black)

White G (Green)

Note: The Hersey Translator Register

must be programmed for 6-digit readings

for proper operation with STAR MTUs.

Hersey ER2

Badger RTR

MTU Cable RTR Cable

Red R (Red)

Black B (Black)

White G (Green)

Note: Some RTR registers may be

provided with only a black wire and a

white wire with a shield. For this

variation, Trim the shield off and connect

as listed below.

MTU Cable RTR Cable

Black B (Black)

MTU Cable ER2 Ca ble

Red R (Red)

Black B (Black)

White G (Green)

White B (Black)

Red W (White)

No Connection White-Shield

Page 24

MTU Instruction

Page 24

for Most Popular Water Meters

Badger ADE

MTU Cable ADE Cable

Red R (Red)

Black B (Black)

White G (Green)

Note: The Badger ADE register must be

programmed for 6-digit readings for

proper operation with a STAR MTU.

Badger Read-O-Matic

Metron OER Register

MTU Cable OER Cable

Red R (Red)

Black B (Black)

White G (Green)

Note: The 5-digit Metron OER register

must be configured for an additional

trailing zero for proper operation with

STAR MTUs.

MTU Cable

Red

Black

White

Read-O-Matic

Terminals

+ Positive

- Negative

- Negative

Page 25

MTU Instruction

Page 25

for American Meter Company Gas Meters

Purpose & Scope

This instruction provides a procedure for installing a STAR direct-mount MTU on the

following American Meter Company meters: AC-175, AL-175, AT-175, AC-250, AL-250,

AM-250, AR-250, AT-210/250, AT-350, AL-425, AC-630.

Parts Required

Ref. # Item Part Number Quantity

1 Gasket 066-5155E 1

2 Coupler, MTU 056-5155E1 2

3 Retaining Shaft, MTU 056-5155D 1

4 MTU, Direct Mount per project 1

5 Magnet 036-0002 1

6 #8 x 3/8” Combo Panhead Sheet Metal Screw 069-080012C4A 2

8 ¼-20 x 1 1/4” Slotted Fillister Head Machine Screw 069-142040GA 2

9 Register Cover 109-7712A 1

10 #10 x 1” Combo Panhead Sheet Metal Screw 069-100032C3A 2

471-2003 - 7/18/2007

Page 26

MTU Instruction

Page 26

for American Meter Company Gas Meters

Tools Required

To mount the MTU to these meters, you

will need the following tools and

equipment:

• Safety glasses

• Phillips screwdriver

• Slotted screwdriver

Installation Procedure

Before installing the MTU, all anti-tamper,

safety, and security hardware must be

removed from the clear register cover.

Step 1 - Remove the existing clear

register cover by removing the four

screws that hold it. Discard both the

screws and the cover.

Step 2 - Remove the register by

removing the two screws that hold it. Set

the register aside. Discard the screws.

Step 3 - Mount the register onto the MTU,

fastening the register to the mounting

holes shown here with the #8 x 3/8”

screws provided.

Then insert the second screw and tighten

both screws to a torque not to exceed 3-5

inch-pounds.

Note: On some odometer-style registers

like the one shown below, slight

protrusions on the back of the register

assembly can interfere with proper

alignment of the register. Should this

occur, use a diagonal cutting plier to trim

the two wire guides on the MTU to the

right of the coupler. Trim these guides as

close to flush with the MTU enclosure as

possible. (See MTU photo below.)

Start one of the two screws into the

mounting hole, and then slide the register

beneath the screw aligning the wiggler on

the register with the MTU coupler.

CAUTION!

Do not over tighten screws.

Excessive torque may

damage the MTU enclosure.

Use of Power tools is not

recommended.

Page 27

for American Meter Company Gas Meters

Page 27

Step 4 – Check that the register is

properly engaged by rotating the coupler

on the back of the MTU and observing

the register dials.

MTU Instruction

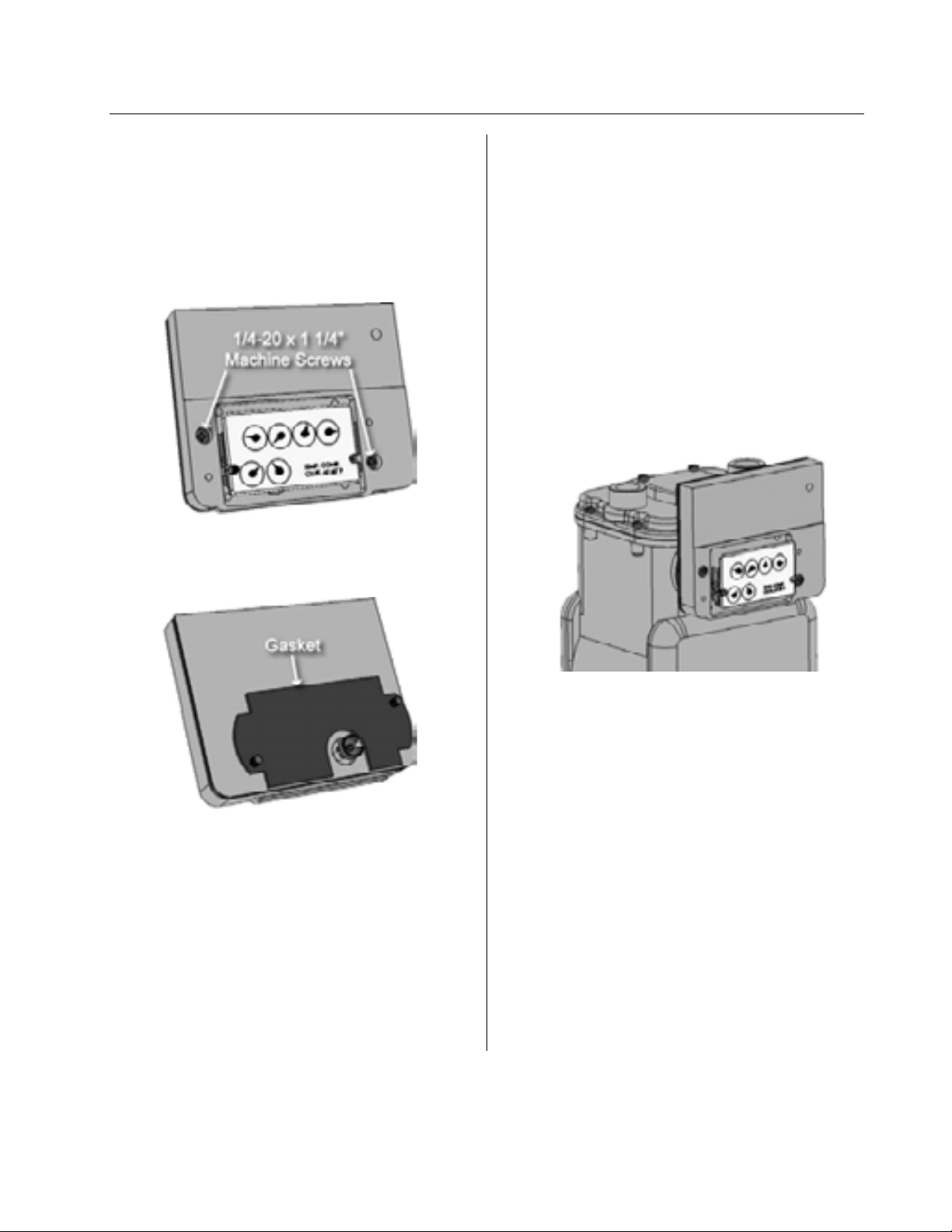

Step 5 – Next, Insert the two ¼-20 x 1

1/4” machine screws through the holes on

the MTU as shown here.

Step 6– Turn the MTU over and place the

gasket on the back of the MTU so that it

aligns over the two screws.

Half-foot Drive Quarter-foot Drive

Step 8 – Now, firmly hand tighten the two

screws to 12 to 15 in-lb. Be careful not to

over tighten the screws. Excessive torque

may damage the MTU enclosure.

Because of this, power tools are not

recommended for this procedure.

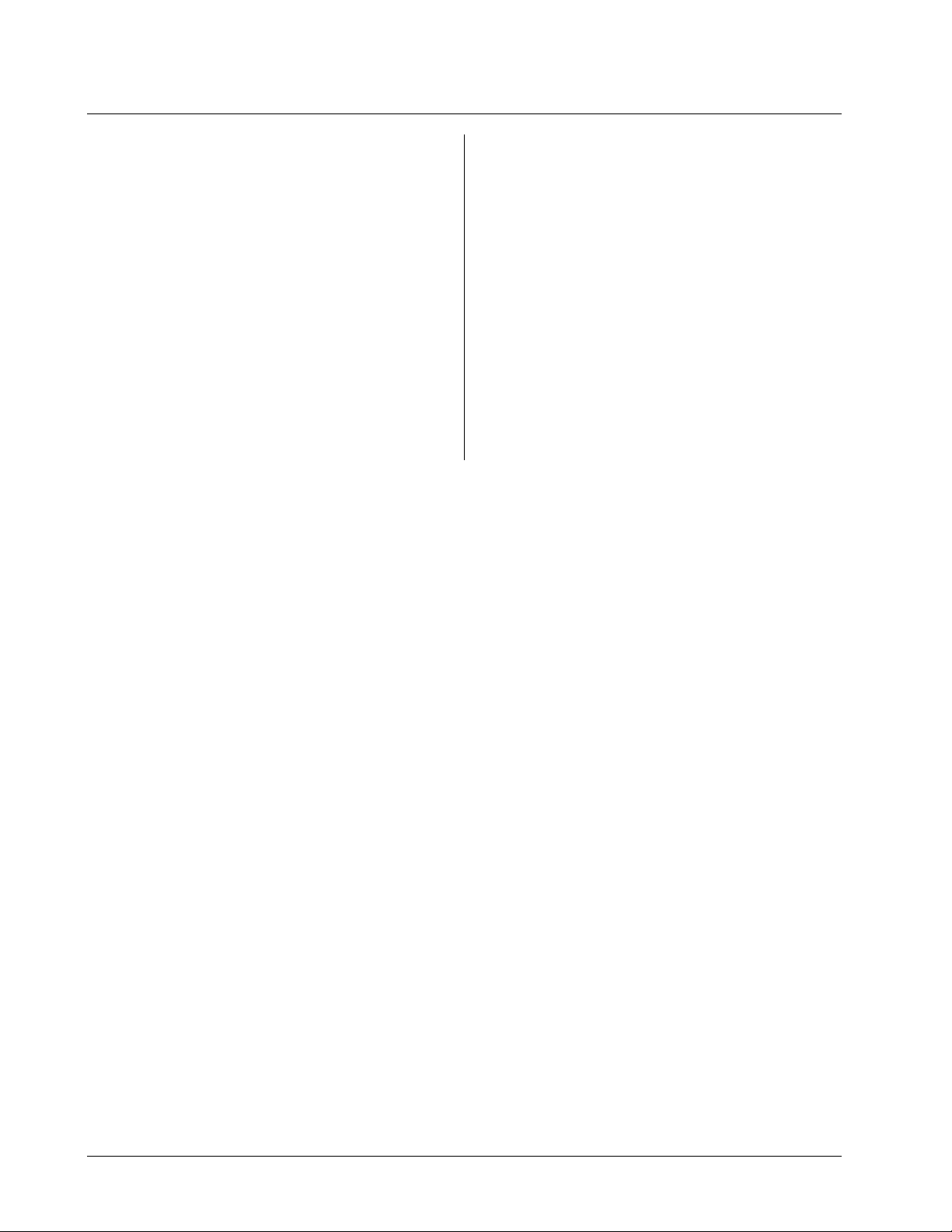

Step 7 – Next, position the MTU on the

meter. Tighten the two ¼-20 x 1 1/4”

mounting screws most of the way, and

then rotate the register dials slightly to

engage the wiggler on the gas meter. The

wiggler must engage with the rear coupler

on the MTU as shown in these

illustrations. (Coupler shown detached

from the MTU for illustration purposes

only.)

Step 9 - Check the coupling one more

time. It should have slight play — it

should not bind or turn too freely.

Step 10 - Place the new cover over the

register so that the top label or arrow is

on top and the vent holes are on the

bottom. Align the cover with the mounting

holes on the MTU, press it into place, and

insert the #10 x 1” screws. Hand tighten

to a torque not to exceed 3-5 inchpounds. The gasket should be

compressed slightly.

Page 28

MTU Instruction

Page 28

for American Meter Company Gas Meters

Step 11 – Replace any anti-tamper,

safety, or security hardware onto the

plastic cover as required.

Step 12 – Once Installation is complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

Page 29

MTU Instruction

Page 29

for American Meter Company Gas Meters

Purpose & Scope

This instruction provides a procedure for installing a STAR indirect-mount MTU on the

following American Meter Company meters: 5B-225, 225. Please also refer to

Publication 471-2000, General Installation and Wiring Guidelines for general information

covering the wiring and mounting of STAR MTUs.

Parts Required

Ref. # Item Part Number Quantity

1 Gasket Part of Item 4 1

2 Drive Foot Part of Item 4 1

3 Magnet Spyder Part of Item 4 1

4 American Meter 225 Sensor 109-7393B 1

5 Magnet 036-0002 1

6 #8 x 3/8” Combo Panhead Sheet Metal Screw 069-080012C4A 2

9 ¼-20 x 2” Slotted Fillister Head Machine Screw 069-142064HA 4

Not Shown

Not Shown

Not Shown

Not Shown

Not Shown

Not Shown

471-2004 - 7/18/2007

MTU, Indirect Mount per project 1

MTU spacer for pipe or bar mount 056-5155K 1

18″ heavy-duty UV-resistant tie wrap

10-32 x 1½″ pan head machine screw

10-32 nut, stainless steel 069-3011 2

#10 7/16” flat washer, stainless steel 069-3004 2

067-0030 2

069-103248

CS 2

Page 30

for American Meter Company Gas Meters

Page 30

Tools Required

To mount the MTU to these meters, you

will need the following tools and

equipment:

• Cordless drill ⅜”, variable

speed, adjustable torque

settings

• #2 Phillips power screwdriver

bit

• Safety goggles

• Phillips screwdriver

• Slotted screwdriver

• 7/16″ nutdriver or boxwrench

• Diagonal side cutter

Installation Procedure

MTU Instruction

Step 4 - If the meter has a stamped metal

right angle drive foot, orient the drive foot

of the index to the position of the magnet

coupler of the sensor as shown. The

index foot should be over the open or flat

area of the coupler. It should not engage

the elongated slot/hole in the magnet

coupler. When properly installed, the

magnet coupler will simply push on the

outside of the index foot to rotate it.

Installing the Sensor Assembly

Before installing the Sensor Assembly,

anti-tamper, safety, and security

hardware must be removed from the clear

register cover.

Step 1 - Remove the existing clear

register cover by removing the four

screws. Set the clear register cover aside.

Discard the screws.

Step 2 - Remove the register by

removing the two screws. Set the register

aside. Discard the screws.

Step 3 - If the meter has a stamped metal

right angle drive foot (not a round plastic

pin), verify that the nylon spacer washers

are in place, as shown here.

Page 2

Page 31

MTU Instruction

Page 31

for American Meter Company Gas Meters

Step 5 - If the meter has a round plastic

pin, align the register to the American 225

Meter Adapter. The pin on the register

must be in the hole in the coupler, as

shown. Make sure the index foot rotates

freely.

Step 6 - Place the wire into the channel

to the right.

CAUTION!

Do not over tighten screws.

Excessive torque may

damage the MTU enclosure.

Power tools are not

recommended for use on

step 7.

Step 9 - Mount register with adapter and

the original plastic cover to the meter.

Step 10 - Attach the register and adapter

assembly to the meter with the four ¼-20

x 2 fillister head screws. Tighten the

screws to 12 to 15 in-lb. On a standard

drill driver with 0 to 24 torque settings,

this is typically the #10 setting.

Step 11 - Replace any anti-tamper,

safety, or security hardware onto the

cover as required.

Step 12 - Mount the MTU, following the

wiring and mounting guidelines outlined in

Publication 471-2000, General

Installation and Wiring Guidelines. If

necessary, the MTU cable can be

extended up to 500 feet.

Note: If desired, you can mount the MTU

on the supply line using the bar-mounting

procedure below.

Step 13 – Once installation is complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

Step 7 - Fasten the register to the

adapter with the two #8 x 3/8” screws

provided. Hand tighten to a torque not

to exceed 3-5 inch-pounds.

Step 8 - Rotate the adapter arm 180

degrees from the position of the meter

indexer. An example is shown.

Bar-Mounting the MTU

Step 1 - Thread the tie-wraps into the

MTU spacer as shown here.

Page 32

MTU Instruction

Page 32

for American Meter Company Gas Meters

Step 2 - Attach the spacer to the MTU

using the provided screws and washers.

Tighten the screws to 12 to 15 in-lb. On a

standard drill driver with 0 to 24 torque

settings, this is typically the #10 setting.

Step 3 - Wrap the tie wraps around the

bar as needed, pulling the ties around

(through the spacer plate) as they are

tightened.

Step 4 - Adjust the MTU as needed and

pull the tie wraps tight.

Step 5 - Trim off the excess tie wrap,

leaving about a ½” tab.

Step 6 – Once Installation is complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

Page 33

MTU Instruction

Page 33

for Carson Industries 1419-3 and 1419-5 Pit Lids

Purpose & Scope

This instruction provides a procedure for mounting a STAR Flatpak MTU to a Carson

Industries Model 1419-3 or 1419-5 pit lid. This procedure does not detail the wiring of

the MTU to the meter that may be encountered inside of the pit. Please refer to

Publication 471-2000, General Installation and Wiring Guidelines in addition to any meter

specific MTU installation and programming instructions.

Parts Required

Item Part Number Quantity

MTU As required for

installed meter

¼” x 3 ½” Phillips flat-head stainless steel machine screw Source locall y 2

¼’ Stainless Keps nut Source locally 2

¼” Stainless flat washer Source locally 2

Tools Required

To mount the MTU to these Carson pit

lids, you will need the following tools and

equipment:

• Drilling fixture for Model 1419

lids.

• Safety goggles

• #3 Phillips driver bit

• 7/16” Nut driver

Note on setting the torque range: On a

drill-driver that has about 20 settings

(positions), set the adjustment to #6. Use

the lower speed range of the drill-driver.

This should amount to approximately 8 inlbs of torque. Reference the operating

instructions for your particular drill to

more accurately determine what setting to

use to achieve a torque range of

approximately 8 in-lbs.

1

• 17/64” standard drill bit

• MTU Programmer

• Cordless Drill 3/8”, variable speed,

with adjustable torque settings.

471-2005 - 2/28/2006

Page 34

MTU Instruction

Page 34

for Carson Industries 1419-3 and 1419-5 Pit Lids

Installation Procedure

Step 1 - Mount the drilling fixture onto

either model of the Carson Pit Lid. The

fixture is keyed so that it will align in only

one direction.

Step 2 - Hold the fixture secure in

position on the lid and drill two holes into

the lid using the supplied 17/64” drill bit,

through the guide holes in the fixture.

Step 5 - Insert 2 stainless screws through

the holes drilled in the top side of the lid.

Step 6 - Turn the lid over and attach the

FlatPak as shown below. Note the

FlatPak orientation. The front side (with

the STAR logo) must be placed against

the bottom of the lid. Apply a ¼” stainless

steel flat washer to each screw, then

apply the ¼-20 stainless steel keps nut to

each screw.

Step 3 - Remove the fixture from the lid.

Step 4 - Countersink the 2 holes using

the supplied ¾” 82 degree countersink,

only deep enough for the screw heads to

be flush or slightly below the surface of

the lid.

Step 7 - Tighten the hardware with the

torque driver. Use the nutdriver or

combination wrench to hold the nut if

necessary. Tighten hardware just past

snug.

CAUTION!

Use no more than 12-15 in-lbs

of torque. Do not over tighten

hardware.

Page 35

MTU Instruction

Page 35

for Carson Industries 1419-3 and 1419-5 Pit Lids

Step 8 - Turn the lid over and verify that

the heads of the screws are flush or

below the lid surface.

CAUTION!

Be sure to follow all General

Guidelines outlined in

Publication 471-2000 along

with the specific wiring

instructions for the meter

being used.

Step 9 – Wire the MTU to the meter,

folding and forming wires into valve box

as necessary so that they do not interfere

with lid locking mechanism and cannot

become pinched.

Step 10 - Installation is now complete.

You can now proceed to program the

MTU using the STAR Programmer

Software and your MTU Programmer.

Page 36

MTU Instruction

Page 36

for Carson Industries 1419-3 and 1419-5 Pit Lids

Intentionally Left Blank

Page 37

MTU Instruction

Page 37

for Armor Access Rubber Pit Lids

Purpose & Scope

This instruction provides a procedure for mounting a STAR Flatpak MTU to an Armor

Access brand rubber composite pit lid. This procedure covers the mounting of an

Original Flatpak STAR MTU or the New Flatpak STAR MTU to these pit lids. This

procedure does not detail the wiring of the MTU to the meter that may be encountered

inside of the pit. Please refer to Publication 471-2000, General Installation and Wiring

Guidelines in addition to any meter specific MTU installation and programming instructions.

Parts Required

Item Part Number Quantity

MTU As required for installed

meter

Long Spacers (for pit lid mounting of New Style Flatpak

MTUs)

#10 x 2 1/2” Phillips Pan Head Type AB Stainless Steel

Sheet Metal Screw

#10 x 2” Phillips Truss Head Type AB Stainless Steel

Sheet Metal Screw

Tools Required

To mount the MTU to these Armor

Access pit lids, you will need the following

tools and equipment:

• Safety goggles

• #3 Phillips driver bit

• Cordless Drill 3/8”, variable speed,

with adjustable torque settings.

Note on setting the torque range: On a

drill-driver that has about 20 settings

(positions), set the adjustment to #6. Use

the lower speed range of the drill-driver.

This should amount to approximately 8 inlbs of torque. Reference the operating

instructions for your particular drill to

more accurately determine what setting to

use to achieve a torque range of

approximately 8 in-lbs.

056-8150L

1

2 per New

Style MTU

installation

2 per New

Style MTU

installation

2 per Original

Style MTU

installation

471-2006 - 11/6/2006

Page 38

MTU Instruction

Page 38

for Armor Access Rubber Pit Lids

Installation Procedure

Mounting an Original Flatpak STAR

MTU to an Armor Access pit lid.

Step 1 – If there is a recess on the

bottom surface of the pit lid, place the

MTU into the recess. If no recess, center

the MTU as shown onto the inside

surface of the lid.

Pit Lid with No Recess

through the recessed mounting holes as

shown. Torque screws to approximately 8

in-lbs. MTU should be snug and flush to

the surface of the pit lid.

Pit Lid with No Recess

Pit Lid with Recess

Pit Lid with Recess

Step 2 - Attach the MTU to the pit lid with

the 2” stainless sheet metal screws

Step 3 – Wire the MTU to the meter,

making sure that the wire is routed so that

it does not become pinched when the lid

is closed.

Step 4 - Installation is now complete. You

can now proceed to program the MTU

using the STAR Programmer Software

and your MTU Programmer.

CAUTION!

Be sure to follow all General

Guidelines outlined in

Publication 471-2000 along

with the specific wiring

instructions for the meter

being used.

Page 39

Page 39

Mounting a New Flatpak STAR MTU to

an Armor Access pit lid.

Step 1 – Center the MTU as shown onto

the bottom surface of the pit lid. Place

plastic spacers under the mounting lugs

on the MTU as shown below. Be sure to

use the long spacers (Hexagram Part

Number 056-8150L).

MTU Instruction

for Armor Access Rubber Pit Lids

Step 3 – Wire the MTU to the meter,

making sure that the wire is routed so that

it does not become pinched when the lid

is closed.

Step 4 - Installation is now complete. You

can now proceed to program the MTU

using the STAR Programmer Software

and your MTU Programmer.

Step 2 - Attach the MTU to the pit lid with

the 2 ½” stainless sheet metal screws

through the 2 mounting holes and the

spacers as shown. Torque screws to

approximately 8 in-lbs. The MTU should

be snug and suspended by the spacers

above the bottom surface of the pit lid by

approximately ½”.

Page 3

Page 40

MTU Instruction

Page 40

for Armor Access Rubber Pit Lids

Intentionally Left Blank

Page 41

MTU Instruction

Page 41

for Invensys Icon MTU/Electric Meter Assembly

Purpose & Scope

This instruction provides a procedure for installing FORM 2s and FORM 12S Invensys

Icon MTU/Electric Meter Assemblies.

Supplies and Tools Required

Physical Installation of the ICON Form 2S

and Form 12S MTU/Electric Meter

Assemblies into compatible meter

sockets can be accomplished without the

use of tools.

Testing of the meter socket, however,

may require specialized equipment.

Check with the local electric utility for

required testing procedures.

WARNING!

Be sure to follow all local

safety procedures and do not

touch the exposed electrical

terminals in the meter socket.

These terminals carry the full

incoming service voltage.

Touching these terminals may

result in death or serious

injury.

Installation Procedure

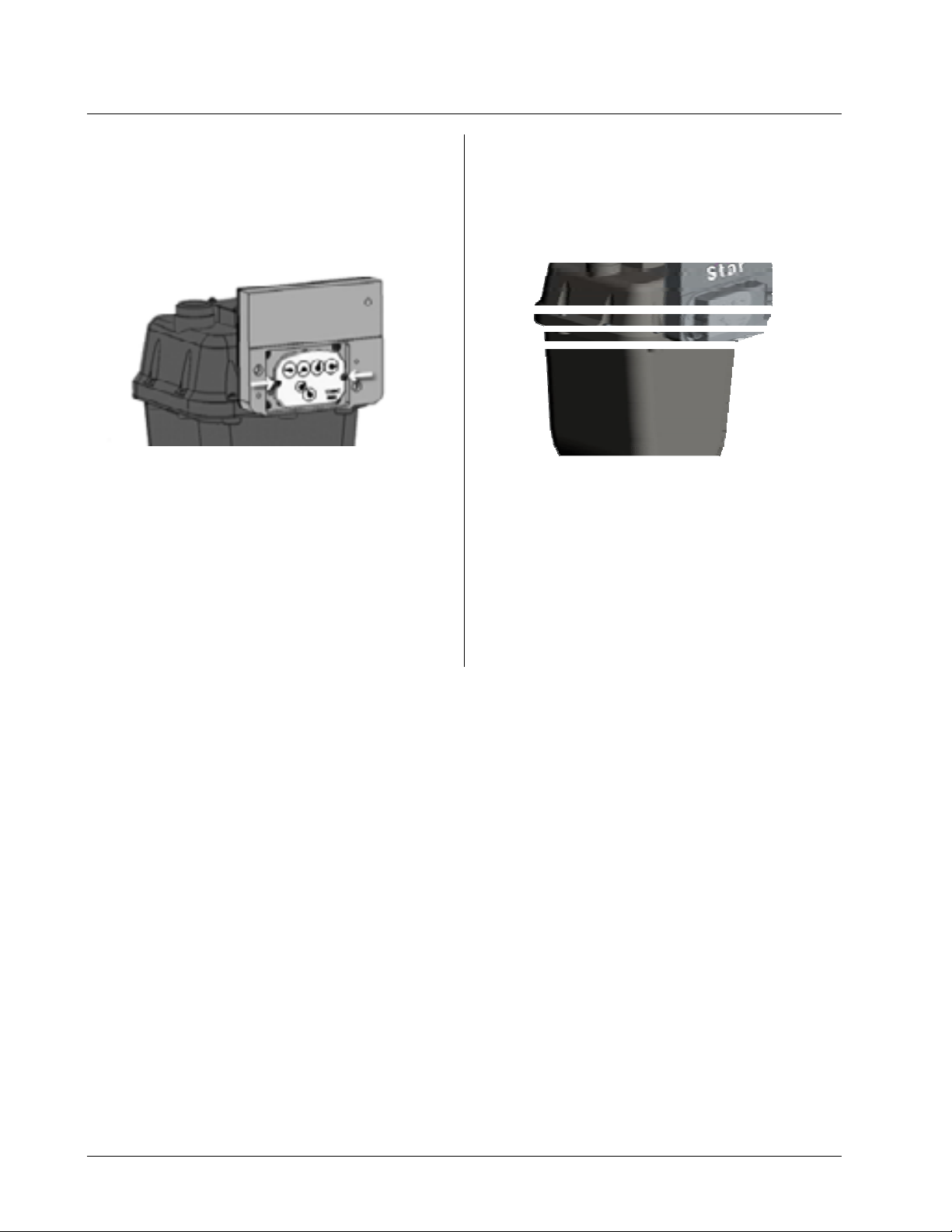

Step 1 – Complete all test procedures

required by the local electric utility and

verify that the meter socket has been

correctly installed and wired.

471-2007 - 2/28/2006

Page 42

MTU Instruction

Page 42

for Invensys Icon MTU/Electric Meter Assembly

Step 2 – (For Form 12S meters only –

Skip this step for Form 2S meters) The

neutral-blade of the Form 12S meter can

be moved. The figure below shows the

rear of the meter base with the neutralblade in the factory default, 9 o’clock

position (referenced by looking into the

meter socket.)

The neutral-blade can be moved to the 6

o’clock or 3 o’clock position to fit varying

Form 12S meter sockets using a #1

Phillips screwdriver, as follows:

e. Replace screws – Place the two

screws in the new neutral-blade

location.

Step 3 – Place the meter/MTU assembly

into the meter socket, carefully aligning

the contact blades with the corresponding

jaws in the meter base.

Step 4 – Install a T-bar and /or any seals

necessary to meet local requirements.

Step 5 – Make a final visual inspection to

ensure that the meter/MTU assembly is

seated and sealed properly.

Step 6 – Installation is now complete,

program the MTU using the STAR

Programmer Software and your MTU

Programmer.

When programming the integral MTU

mounted in this meter, hold the

programming coil above the top center of

the meter, as shown here.

a. Locate the configurable neutral-

blade – On the rear of the meter

base, locate the configurable

neutral-blade.

b. Remove screws – Remove the

two screws on either side of the

neutral-blade.

c. Remove neutral-blade – Remove

the neutral-blade from its molded

socket.

d. Seat neutral-blade – Seat the

neutral-blade into the desired

location.

Note: When replacing the screws, ensure

that they are snug, and that the heads are

flush with the neutral-blade.

Page 43

MTU Instruction

Page 43

for STAR Submetering MTUs with Pulse Adapters

Purpose & Scope

This instruction provides procedures for installing and programmin STAR MTUs equipped

with voltage or temperature sensing pulse adapters including the following: 501-7786P,

501-7786T, 501-7786-PP, 501-7786PR, 501-7786PT, 501-7786PT2. Please also refer to

Publication 471-2000, General Installation and Wiring Guidelines for general information

covering the wiring and mounting of STAR MTUs.

Parts Required

Item Part Number Quantity

Submetering MTU with temperature sensing pulse adapter. 501-7786T 1

(As required)

Submetering MTU with voltage sensing pulse adapter. 501-7786P 1

(As required)

Dual-port Submetering MTU with voltage sensing pulse

adapters.

Dual-port Submetering MTU with a voltage sensing pulse

adapter and a reed switch input.

Dual-port Submetering MTU with voltage and temperature

sensing pulse adapters.

Thermocouple, Type E, 20 gauge 071-0850

Wire Splice, 3M Scotchlok 314 043-1914

Cable Tie, 5.6”, Black, UV 067-0007

Pressure Sensitive Hold-downs 067-0051

Drywall screws, #6 x 2” Phillips, coarse (for indoor use) Source locally

Plastic masonry anchors #6 – 12 x 1”, ¼” diameter Source locally

501-7786PP 1

(As required)

501-7786-PR 1

(As required)

501-7786-PT 1

(As required)

1 per

temperature

sensing port.

2 per

temperature

sensing port.

3 per

temperature

sensing port.

2 per

temperature

sensing port.

2 per MTU

2 per MTU

471-2008 - 2/22/2008

Page 44

MTU Instruction

Page 44

for STAR Submetering MTUs with Pulse Adapters

Tools Required

• Crimping Pliers for Insulation

Displacement Connectors (IDCs)

• Wire cutters/stripper

• Cleaner (non-residue type) and

rag/paper towel

• Stapler for ¼” wire and cable

(Arrow T-25M)

Introduction

STAR Submetering MTUs with Pulse

Adapters provide accurate, highresolution data for point-of-use allocation

billing for a wide variety of HVAC

appliances.

Note: Only on-off devices are suitable for

application of these pulse adapter MTUs.

• Voltage Sensing Pulse

Adapters can be applied to

gas appliances that are

controlled by a standard

24VAC gas valve.

• Temperature Sensing Pulse

Adapters can be applied to

gas water heaters, fireplaces

and other HVAC appliances

that do not have 24 VAC

controls

These units produce an extremely

accurate pulse at a rate of 10 seconds

per pulse (0.1 Hz or 6 pulses per minute)

when the specified input conditions

(voltage or temperature) are met. These

pulses are counted by the MTU which

periodically transmits the accumulated

count to nearby Data Collector Units.

Note: The submetering MTUs discussed

in this instruction are for indoor use (dry

locations) only.

Connecting Voltage Sensing (Type P) Inputs

Voltage Sensing (Type P) inputs are

provided with a 2-wire connection that

can be wired across (in parallel with) the

24 VAC gas valve solenoid of the furnace

or other HVAC appliance.

Simply connect the RED and BLACK

wires across the gas valve solenoid.

Once connected in this way, a voltage of

between 18 and 30 VAC applied across

the valve solenoid will cause the MTU to

begin pulsing and recording usage.

CAUTION

Do not connect the white wire

of the MTU when connecting

voltage sensing inputs. Cut

the white wire back to the

cable jacket. Connecting the

white wire may damage the

MTU.

Typical Furnace Application

This procedure covers a typical

installation of a voltage/current sensing

pulse adapter on a gas furnace.

Step 1 - Turn the furnace setting to "Pilot"

so that it will not operate during the

installation process.

Step 2 - Mount the MTU on a wall, joist or

other convenient location near the

furnace to be monitored. Run the cable

from the MTU to the gas valve solenoid of

the device. Trim or extend the MTU

cable, as needed. Care must be taken to

protect the cable from damage by hot

surfaces or sharp sheet metal. Use

insulated staples or cable ties as needed.

Note: Be sure to follow all General

Mounting & Wiring Guidelines outlined in

Publication 471-2000.

Page 45

MTU Instruction

Page 45

for STAR Submetering MTUs with Pulse Adapters

Step 3 – Connect the RED and BLACK

leads from the MTU across (in parallel

with) the 24 VAC control input to the gas

valve. On most gas valves, these

connections can be made at the terminals

on the gas valve solenoid.

Step 4 – Program the MTU using the

MTU Programmer as outlined in the

Programming section of this document.

Step 5 - Return the furnace setting to

"Run".

Connecting Temperature Sensing (Type T) Inputs

Temperature Sensing (Type T) inputs are

provided with a two wire connection

designed to be directly connected to a

Type E thermocouple that is supplied with

the temperature sensing MTU. When the

thermocouple reaches a temperature of

◦

110

- 130◦ C (230◦ - 265◦ F), the MTU will

begin pulsing and recording usage.

By convention, Type E thermocouples are

supplied with two color-coded leads.

● The VIOLET lead is the positive

side and must be connected to the

RED wire of the MTU Input Cable.

● The RED lead of the thermocouple

is the negative side and must be

connected to the BLACK wire of

the MTU input cable.

Typical Hot Water Heater Application

This procedure covers a typical

installation of a temperature sensing

pulse adapter on a gas hot water heater.

Step 1 - Turn the hot water heater setting

to "Pilot" so that the heater will not

operate during the installation process.

Step 2 - Insert the copper thermocouple

sleeve into the space under the draftinducer cone at the top of the water

heater. Position the tip of the

thermocouple INTO the center of the flue

as shown below. ( ½ to ¾ of an inch)

Page 46

MTU Instruction

Page 46

for STAR Submetering MTUs with Pulse Adapters

Gently shape the copper sleeve on the

thermocouple so that it does not contact

the metal surface of the draft hood or the

top of the hot water tank as shown in the

side view illustration.

Step 3 - Clean the surface area of the hot

water heater under the thermocouple.

Dry thoroughly. Locate and mount the

two pressure sensitive hold-downs in the

cleaned area. Locate one hold-down at

the approximate center of the copper

sleeve and the other at the very end so

that they firmly anchor the thermocouple.

Thread a cable tie through the slot in the

hold-downs to fasten the thermocouple.

If necessary, gently form the copper

sleeve to facilitate mounting while

insuring that the tip of the thermocouple is

in the center of the flue and the copper

sleeve is not in contact with metal

surfaces.

Step 4 - After the thermocouple sleeve is

secure, route the thermocouple wire near

the inlet or outlet water pipe. Use the

third cable tie to secure the thermocouple

wire to the pipe as a strain relief.

Step 5 - Mount the MTU on a wall, joist or

other convenient mounting location using

two screws. Run the cable from the MTU

to the end of the thermocouple wire. Trim

excess MTU cable, as needed. Care

must be taken to protect the cable from

damage by hot surfaces or sharp sheet

metal. Use insulated staples or cable ties

as needed.

Note: Be sure to follow all General

Mounting & Wiring Guidelines outlined in

Publication 471-2000.

● Connect the VIOLET

thermocouple wire to the RED

MTU wire.

● Connect the RED thermocouple

wire to the BLACK MTU wire.

Do not remove the insulation from either

the MTU wires or the thermocouple wires;

the IDC is designed to pierce the

insulation.

Step 7 – Program the MTU using the

MTU Programmer as outlined in the

Programming section of this document.

Step 8 - Return the hot water heater

setting to "Run".

Typical Burner/Fireplace Application

This procedure covers a typical

installation of a temperature sensing

pulse adapter on a burner or fireplace.

Step 1 - Set burner or fireplace control so

that the appliance does not come on

during installation.

Step 2 - Fasten thermocouple so that the

tip is near, but not in, the flame when the

gas is burning. Use metal clamps or wire

fasteners to secure the thermocouple.

(NOTE: Clamps or wire fasteners are not

provided by Hexagram. Individual

installation conditions will determine the

type of fastener to be used.) A location

must be selected that allows the

thermocouple tip to reach at least 130° C

(400° F). However, the tip temperature

must not exceed 350° C (660° F). If a

pilot light is present, keep the

thermocouple at least 6" away from the

pilot flame.

Step 6 - Splice the MTU wire to the

thermocouple wire using the two IDCs

provided.

Step 3 - Route thermocouple wire away

from the appliance.

Page 47

MTU Instruction

Page 47

for STAR Submetering MTUs with Pulse Adapters

Step 4 - Mount the MTU on a wall, joist or

other convenient mounting location well

away from the heat source using two

screws.

CAUTION

The MTU must be located

away from the appliance and

ONLY in a location that

remains at room temperature.

Run the cable from the MTU to the end of

the thermocouple wire. Trim excess MTU

cable, as needed. Care must be taken to

protect the cable from damage by hot

surfaces or sharp sheet metal. Use

insulated staples or cable ties as needed.

Note: Be sure to follow all General

Mounting & Wiring Guidelines outlined in

Publication 471-2000.

Step 5 - Splice the MTU wire to the

thermocouple wire using the IDCs

provided. Use a cable tie(s) to provide

strain relief for the wiring.

Step 8 - Reset the burner or fireplace

control so that the appliance can run.

Programming

Note: The 501-7786PT2 MTU requires

Star Programmer Software version 6.0.0

and meter table version 3.85 or higher.

Step 1 - Turn on the Psion MTU

Programmer by pushing On/Esc.

Note: A “Communication Error”

message may occur:

● If an attempt is made to read

and/or program the MTU and the

MTU is receiving input from the

gas appliance to which it is

wired.

OR

● If an attempt is made to read

and/or program the MTU and

there is a wiring error in the

wiring between the MTU and the

thermocouple.

● Connect the VIOLET

thermocouple wire to the RED

MTU wire.

● Connect the RED thermocouple

wire to the BLACK MTU wire.

Do not remove the insulation from either

the MTU wires or the thermocouple wires;

the IDC is designed to pierce the

insulation.

Step 6 - Secure the MTU wire. Verify

that the MTU cable does not run near the

burner and does not enter any region

where the temperature will exceed 70° C

(160° F).

Step 7 – Program the MTU using the

MTU Programmer as outlined in the

Programming section of this document.

Verify that the gas appliance is off and

that the thermocouple is correctly

connected.

Step 2 - Highlight the STAR icon (in the

Psion desktop screen) using the left/right

arrow keys. Press

At this point, the STAR software loads

along with the Meter table, Database

table, and Appointment table. If these are

loading for the first time, it may take

several minutes. When complete, the

serial number verification screen will

appear.

Enter.

Page 48

MTU Instruction

Page 48

for STAR Submetering MTUs with Pulse Adapters

Step 3 - A screen asking if the operator

wishes to change the Psion’s serial

number is displayed.

This number should match the last four

digits of the serial number etched on the

back of the Psion. Typically, select

N to

accept the serial number as is. Pressing

will take the operator to a screen where

the serial number can be changed, if

necessary.

Step 4 – You are now at the logon

screen.

Y

NOTE: - At midnight, the software

automatically resets to require re-entry of

the log-on information. This is a security

measure in case the Psion is lost or

stolen.

Step 5 - The “Set Time & Date” screen is

displayed.

Make any corrections to the time and

date as required. Press Enter when

finished. It is not necessary to reset the

time if it is less than 5 minutes off.

Step 6 - The main menu of the STAR

software is now displayed.

Log on by entering the following

information:

a - Operator: The Psion operator file

will accommodate up to 99 separate

operator user codes. This user code is

“Install” followed by an assigned

operator code. Enter your assigned

code number immediately after “Install”

without any spaces. Press Enter when

finished. Example: Install6

b - Enter the password. This password

will typically be assigned by a project

manager. Press

Example:

Acme

Enter when finished.

Note: Use the DEL key to backspace and

make corrections.

At the top of the screen the installer