Page 1

GENERAL INFORMATION

The RH Duct and Outside transmitter is a Relative

Humidity transmitter that can be powered with either an

AC or DC supply voltage. The transmitter can also

include an optional temperature sensor for monitoring

the space temperature.

All units are shipped from the factory set up with a 4-20

mA output. The RH Duct and Outside transmitter is

field selectable with a 4-20 mA, 0-5 VDC, or 0-10 VDC

output signal that is equivalent to 0 to 100% RH.

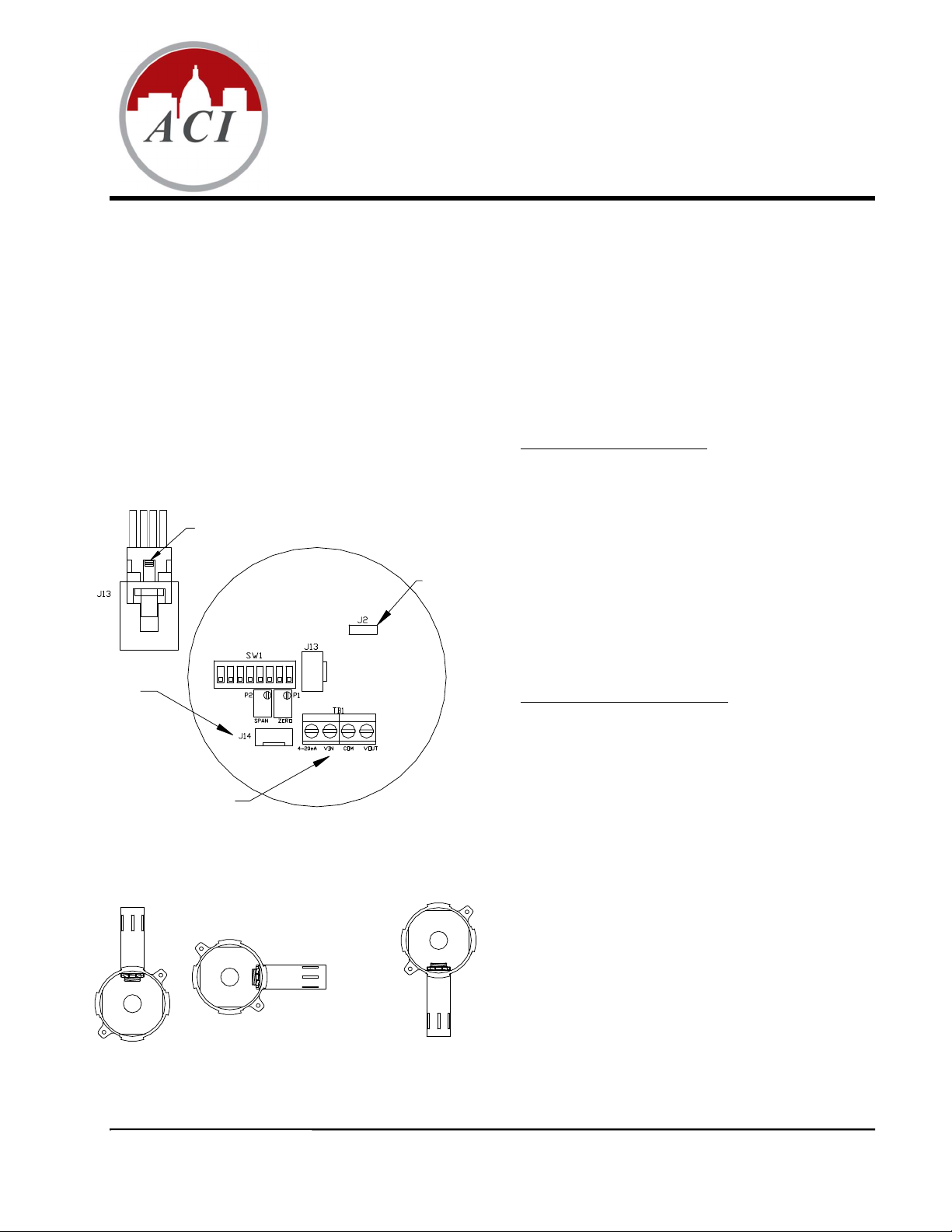

Factory Use Only

Wire Connections

Incorrect

Installation and Operation Instructions

RH Duct and Outside Series

PLEASE READ INSTRUCTIONS CAREFULLY BEFORE INSTALLATION!

MOUNTING INSTRUCTIONS

IMPORTANT: RH Remote Probes and some

Outside units include a Black Rubber Cap that fits

over the sensor filter. The Cap should be placed on

the sensor filter during wet/wash down processes.

The Cap must be removed for normal operation.

Duct Mounting Configuration

Drill a ¾” diameter hole in the duct where the

transmitter is to be mounted. Insert the stainless-steel

probe into the hole until the foam is in direct contact

Push tab in and pull up on the sensor

cable to remove from J13 connector

ON

1342765 8

Figure #1

Figure #2

Factory Use Only

Correct

with the duct. Attach the transmitter to the duct using

the supplied #8 X ¾” self-tapping screws.

Remove the cover and install your conduit connector or

watertight fitting. The outer knockout ring should not be

removed when using a ½” NPT conduit fitting.

After wiring the unit, place the cover back on and gently

turn until it is tight.

Outdoor Mounting Configuration

The transmitter should be mounted under an eave,

shield, or in an area out of the elements or direct

sunlight. The aluminum tube should point down when

mounting the outside transmitter. Refer to Figure #2 for

the proper mounting position.

Place the unit where it is to be mounted with the cover

facing out. Attach the unit with the supplied #8 X ¾”

self-tapping screws.

Remove the cover and install the PG11 watertight fitting

supplied with the unit. The outer knockout ring should

not be removed when using a ½” NPT conduit fitting.

After wiring the unit, place the cover back on and gently

turn until it is tight.

Page 1 of 4 I0000546

Version : 5.0

Page 2

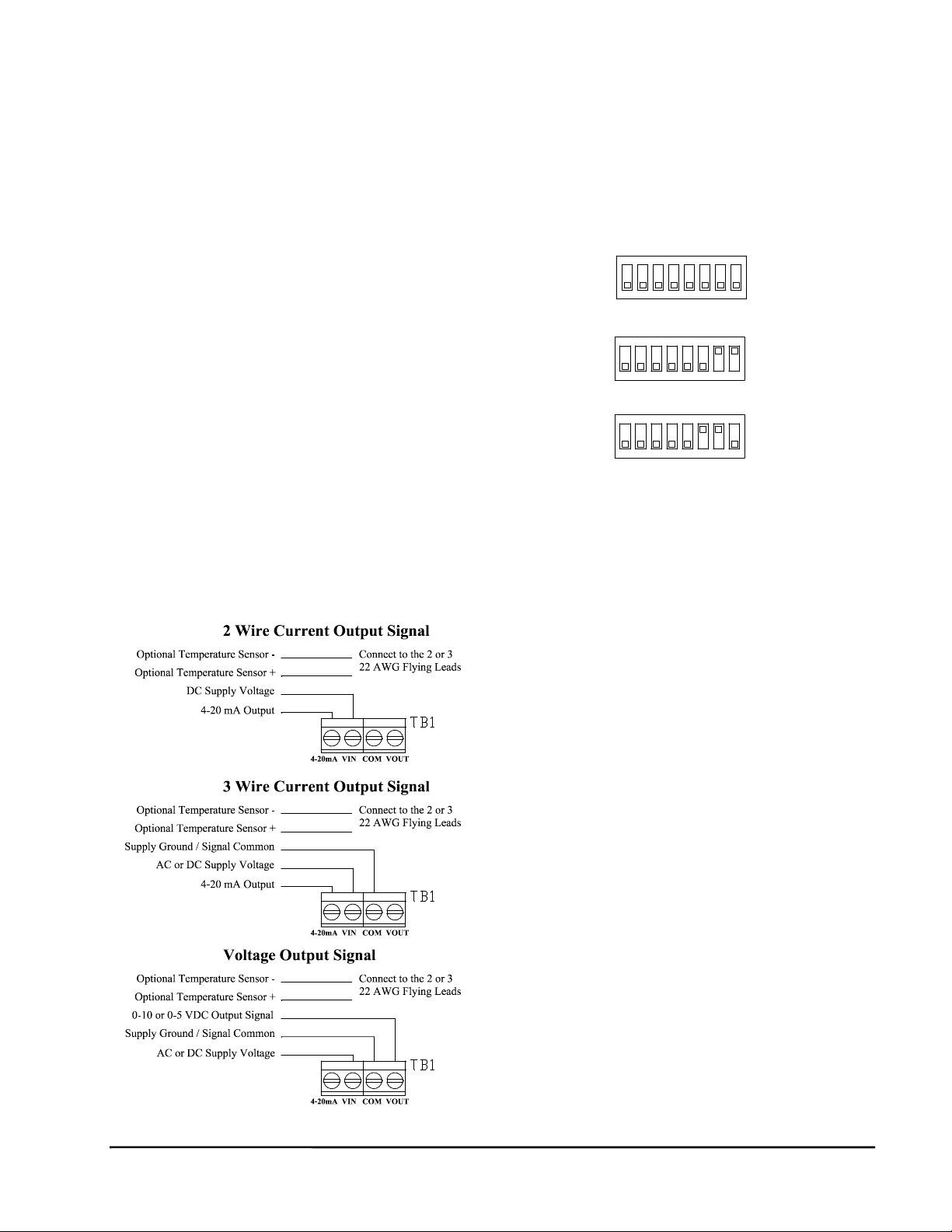

WIRING INSTRUCTIONS

16 to 22 AWG shielded cable is recommended for all

RH Transmitters. Twisted pair may be used for 2-wire

current output transmitters. If using 24 VAC power,

two separate wires must be pulled for the transmitter to

work properly; one 16 to 22 AWG shielded cable for the

supply voltage, and a second 16 to 22 AWG shielded

cable for the selected output(s). Signal wiring must be

run separate from high voltage wires (120-Volt). The

connections to the optional temperature sensor should

be made with wire nuts or crimp style connectors. Refer

to Figure #3 for wiring diagram.

Caution:

It is recommended that you use an isolated

UL-listed Class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

damage to any device powered by the

shared transformer.

Remove power before wiring. Never connect

or disconnect wiring with power applied.

When using shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

Figure #3

Version : 5.0

Page 2 of 4 I0000546

OUTPUT SELECTIONS

Switches 6, 7, and 8 are used to set the RH output

signal. Refer to Figure #4 for switch settings.

Output Selection Switches (SW1)

4-20 mA Output

ON

ON

2 3

1

OFF

ON

OFF

ON

ON

4 8

5 6 7

0-10 VDC Output

2

3

4

6 81

5ON7

0-5 VDC Output

OFF

1 4 5 6

2 3

7 8

Figure #4

REVERSE ACTING OUTPUT

The output can be changed to reverse acting mode. The

output range stays the same but the corresponding RH

value is opposite.

Example: Direct Acting (DA)

0-10V output mode,

0V = 0% RH and 10V = 100% RH

Reverse Acting (RA)

0-10V output mode,

0V = 100% and 10V = 0%

To change the transmitter to reverse acting or back to

direct acting, set switch 4 ON to put the unit in setup

mode. After switch 4 is on, switch 2 will put the unit in

direct/reverse acting mode. When switch 2 is set to ON,

the output can be used to show if the unit is in direct or

reverse acting mode. For direct acting, the output will

be 1V for 0-5V, 2V for 0-10V, and 7.2mA for 4-20mA.

For reverse acting the output will be 4V for 0-5V, 8V

for 0-10V, and 16.8mA for 4-20mA.

With switches 2 and 4 ON, each time switch 5 is set to

ON the output will change to reverse acting or direct

acting.

To reset the unit to the default setting, toggle both

switches 5 and 6 ON then OFF while both switches 2

and 4 are ON.

When all calibration is completed, remember to place

the switches back into the positions that correspond to

the output needed as shown in Figure #4.

Page 3

RH CALIBRATION INSTRUCTIONS

Note: This is only a single point calibration. All

transmitters are factory calibrated to meet/exceed

published specifications. Field adjustment should not

be necessary.

The dipswitch allows the user to calibrate the sensor

through the software. Setting switch 4 ON will put the

transmitter into setup mode allowing the increment and

decrement to work. Once in setup mode, the output will

change to 50% (2.5V for 0-5V, 5V for 0-10V, 12mA for

4-20mA). Each increment or decrement step will cause

the output to change by 0.1V for 0-5V, 0.2V for 0-10V,

and 0.32mA for 4-20mA in setup mode. This can be

used to show the user how far offset the transmitter is.

To see the starting point again set switch 1 ON. This

will show the 50% output again. When the unit is out of

setup mode the output will go back to RH output.

Increment RH Output

This will shift the RH output linearly up in 0.5% steps.

Switch 4 must be set to ON first. After switch 4 is on,

each time switch 5 is set ON the RH output will

increase by 0.5%. The increase goes into effect each

time switch 5 is set to ON.

Decrement RH Output

This will shift the RH output linearly down in 0.5%

steps. Switch 4 must be set to ON first. After switch 4 is

on, each time switch 6 is set ON the RH output will

decrease by 0.5%. The decrease goes into effect each

time switch 6 is set to ON.

Reset RH Output

This will reset the RH output back to the original

calibration. Switch 4 must be set to ON first. After

switch 4 is on, toggle switches 5 and 6 ON then OFF.

After 5 and 6 are OFF slide switch 4 OFF.

When all calibration is completed, remember to place

the switches back into the positions that correspond to

the output needed as shown in Figure #4.

Note: Potentiometers P1 (Zero) and P2 (Span) in

Figure #1 are not used for RH sensor calibration.

They are used for factory use only

TEST INSTRUCTIONS

Test mode will make the transmitter output a fixed 0%,

50%, or 100% value. The sensor will not affect the

transmitter output. This is used for troubleshooting or

testing only.

Switches 1, 2, and 3 are used for test mode. The output

will be a fixed 0%, 50%, or 100% signal that

corresponds to the output selected with switches 6, 7,

and 8. Refer to Figure #5 for switch settings.

Test Selection Switches (SW1)

0% RH Output

ON

ON

2 3

2

3

4 8

5 6 7

6 81

4

5ON7

OFF

ON

1

50% RH Output

ON

OFF

100% RH Output

ON

2 3

OFF

1 4 5 6

7 8

Figure #5

Page 3 of 4 I0000546

Version : 5.0

Page 4

± 1% o ve r 2 0% sp an (betwe en 20 to 90 % )

RH CONVERSION FORMULAS

To convert output signal to percent RH:

4-20 mA

((mA signal) -4) / 0.16 = percent RH

Example: 12mA output signal

(12-4) / 0.16 = 50% RH

0-5 VDC

(VDC signal) / 0.05 = percent RH

Example: 1.25vdc output signal

1.25 / 0.05 = 25% RH

0-10 VDC

(VDC signal) / 0.10 = percent RH

Example: 7.50vdc output signal

7.50 / 0.10 = 75% RH

PRODUCT SPECIFICATIONS

Supp ly V olta ge

Supp ly C urrent

RH O utpu t

4-20 mA Ou tp ut: 2 5 0 Oh m L oa d 15 - 40 VD C /

18 - 28 V AC

4-20 mA Ou tp ut: 5 0 0 Oh m L oa d 18 - 40 VD C /

18 - 28 V AC (500 O h m Lo ad M ax)

0-5 V D C O ut pu t: 12 - 4 0 VDC / 18 - 28 VA C

(4K L oa d Min im um)

0-10 V DC Ou tp u t: 18 - 40 VDC / 1 8 - 28 V AC

(4K L oa d Min im um)

Vo lta ge O ut pu t: 8mA M ax

Cu rrent O utput : 2 4mA M ax

2-Wire, 4 - 20 m A

3-Wire, 0 - 5V D C, 0 - 10 V D C, or 4 -2 0m A

TROUBLESHOOTING

Problem:

No Reading

Check that you have the correct

supply voltage at the power

terminal blocks.

Check that wiring configurations

and all DIP switch settings are as in

Figures #3 and #4.

Verify that the terminal screws are

all connected tightly and that all of

the wires are firmly in place.

Erratic Readings

Verify that all of the wires are

terminated properly.

Make sure that there is no

condensation on the board.

Check that the input power is clean.

In areas of high RF interference or

noise, shielded cable may be

necessary to stabilize signal.

Inaccurate Readings

If you suspect that the transmitter is

not reading within the specified

tolerance, please contact the factory

RH M easu rem en t Ra nge

RH A ccur ac y @ 7 7oF (25oC)

Re pe atab il ity

Op eratin g H um id it y Enviro nme nt

Op eratin g Tem p. E nvir onm en t

Sto rag e Tem p. Ran ge

for further assistance.

0 t o 10 0% RH

± 2% , 3% , or 5 % from 10 to 95%

0.5 % R H

0 t o 10 0% RH

-40 t o 14 0°F (-40 to 60°C)

-40 t o 16 0°F (-40 to 71°C)

Page 4 of 4 I0000546

Version : 5.0

Loading...

Loading...