Page 1

Automation Components, Inc.

QTS-1710GAS

QTS-1710

Combustible Sensor Series

The QTS-1710 Series utilizes catalytic pellistor bead technology for the measurement of combustible

gases. The standard sensor is resistant to poisoning substances such as silicones, sulfur compounds,

and chlorinated compounds. It is mounted in an explosion-proof housing, which is rated Class 1,

Division 1, Groups A, B, C, and D. The transmitter provides a 4-20 mA output linear to the LEL (Lower

Explosive Limit) of the calibrated combustible gas. The analog transmitter operates on a power supply

of 12-30 VDC in a three wire configuration, and is also mounted in an explosion-proof housing, rated

Class 1, Division 1, Groups B, C and D. Test jacks are provided to monitor the transmitter signal

without interrupting the output. All transmitters are calibrated using a correlation method with

Methane calibration gas and detection constants as shown. Calibration with actual target gas is

available upon special request; use “S” for special calibration in the options section of the ordering grid.

Automation Components, Inc.

101

Page 2

GAS QTS-1710

SPECIFICATIONS

Automation Components, Inc.

Supply Voltage

Outputs

Accuracy/Repeatability

Zero Drift

Response Time

Temperature Range

Operating Humidity

Operating Pressure

Sensor Life Span

Sensor Type

Mounting Height

Enclosure Rating

Enclosure Material

Product Dimensions

+12-30 VDC 125 mA maximum

4-20 mA, into 700Ω at 24 VDC (Three wire)

+/- 1% LEL Methane

< 2% of range/month @ 68

Less than 10 seconds for a 50% FS step change | Less than 30 seconds for a 90% FS step change

o

-40

to 122oF (-40o to 50oC)

0 to 99% RH non-condensing

Atmospheric +/-10%

3 to 5 years typical (under normal conditions)

Dual element poison resistant catalytic pellistor bead

4 to 6’ above floor (1.5 to 2.0 meters)

NEMA type 4X; type 7 & 9 | Explosion Proof Class 1 Div 1 Groups B,C,D; 316 series stainless steel sensor

Cast Aluminum, Epoxy Coated

(L) 10.25” (W) 4.50” (H) 3.50”

o

F (20oC)

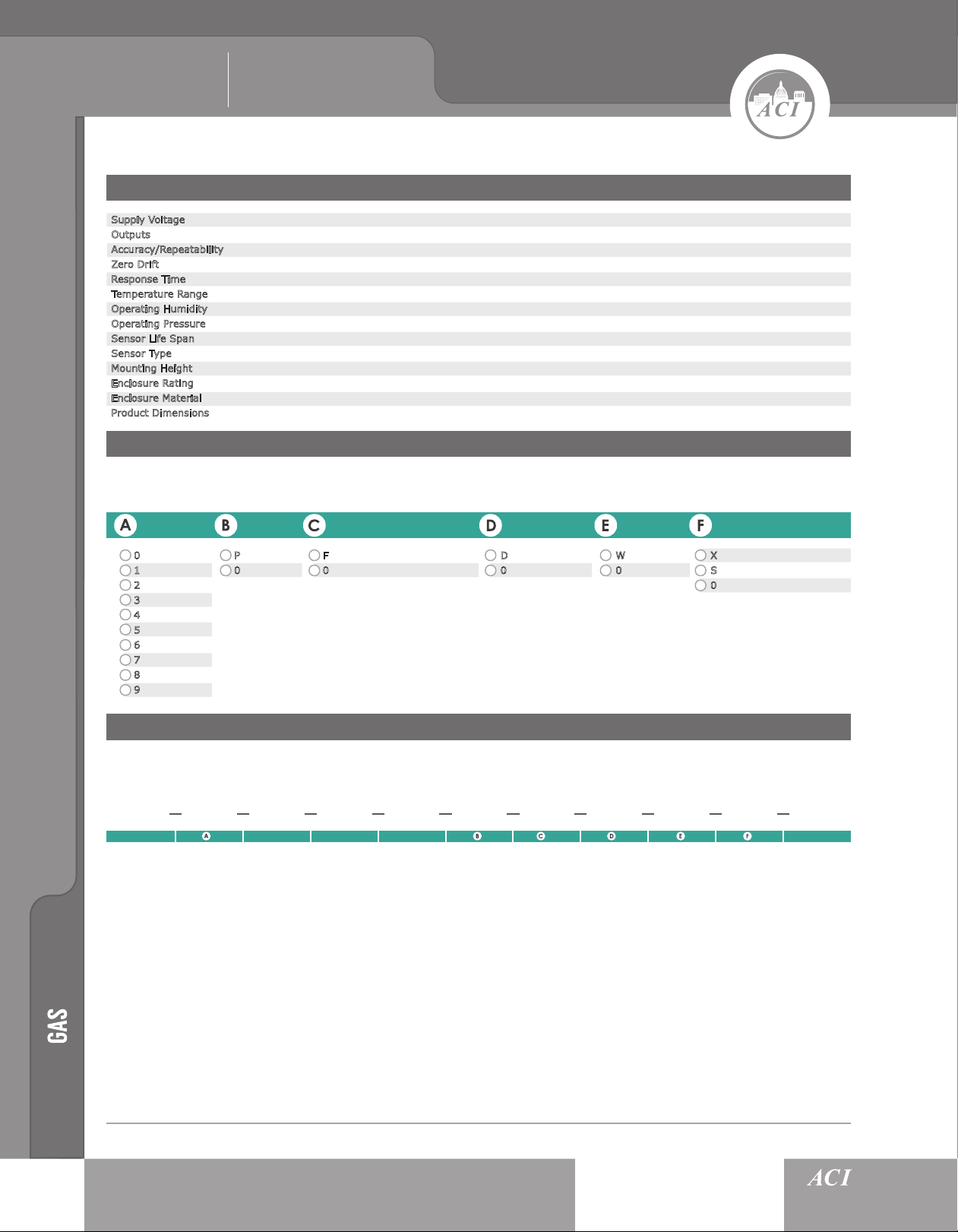

ORDERING

Select one Gas Type (A), one Guard (B), one Adapter (C), one Duct Mount (D), one Coating Option (E) & Options (F).

Gas Type Guard

0 (Methane)

(Acetylene)

1

(Ethane)

2

(Propane)

3

(n-Butane)

4

(n-Pentane)

5

(n-Octane)

6

(Hydrogen)

7

(Gasoline)

8

(Other)

9

P (Guard)

(No Guard)

0

Adapter

F (Remote Calibration Adapter)

(No Adapter)

0

Duct Mount

D (Duct Mount)

(No Mount)

0

Coating

W (Coating)

(No Coating)

0

Options

X (Non-Standard Calibration)

(Special)

S

(None)

0

BUILD PART NUMBER

After completing (A), (B), (C), (D), (E) & (F) from the above table, fill in the Part Number Table below. “Output, Enclosure Type and Revision

(X)”are factory defaults. An example part number is offered.

QTS-171 X S 0

SENSOR SERIES OUTPUT FACTOR PROVIDED ENCLOSURE FACTORY PROVIDED

EXAMPLE: QTS-1710 - 0 - 1 - X - S - P - 0 - 0 - 0 - 0 - 0

102

Loading...

Loading...