Page 1

QIRF

REFRIGERANT GAS

TRANSMITTER/SENSOR

INSTALLATION

OPERATION AND MAINTENANCE

MANUAL

Page 2

QIRF Operation And Maintenance Manual

Table Of Contents

READ BEFORE OPERATING ...................................................................................................................3

1. GENERAL INFORMATION .............................................................................................................3

1.1

P

RINCIPLE OF OPERATION

1.2

K

EY FEATURES

1.3

A

PPLICATIONS

1.4

S

PECIFICATIONS

2. INSTALLATION .................................................................................................................................7

2.1

S

ENSOR LOCATION

2.2

P

HYSICAL DIMENSIONS

2.3

G

AS SAMPLING

2.4

M

OUNTING AND SYSTEM WIRING

2.4.1 Terminals......................................................................................................................................9

2.4.2 Power Supply................................................................................................................................9

2.4.3 Wire and Cable...........................................................................................................................10

2.4.4 Digital Connection .....................................................................................................................10

2.4.5 RS-485 Terminator .....................................................................................................................10

2.4.6 RS-485 Driver Replacement .......................................................................................................11

2.4.7 4-20mA or 2-10VDC Analog Output..........................................................................................11

2.4.8 Relays Output .............................................................................................................................12

..................................................................................................................................4

....................................................................................................................................4

.................................................................................................................................5

..................................................................................................................................8

..................................................................................................................3

.............................................................................................................................7

......................................................................................................................7

......................................................................................................8

3. FUNCTION AND CONFIGURATION ...........................................................................................13

3.1

QIRF W

3.2

S

3.3

K

3.4

S

3.4.1 RS485-TX/RX:..........................................................................................................................15

3.4.2 Relay1-3 LED: ..........................................................................................................................15

3.5

L

3.6

H

3.7

QIRF M

3.8

M

3.8.1 System Settings ...........................................................................................................................18

3.9

M

3.9.1 Equipment Required ...................................................................................................................20

3.9.2 Zeroing Calibration Procedure..................................................................................................20

3.10 M

3.10.1

3.11 M

3.12 M

3.13 M

3.13.1

3.13.2

3.14 M

3.15 M

3.16 M

3.17 M

ORKING MODE

YSTEM INITIALIZATION

EYPAD

...........................................................................................................................................13

TATUS

LED....................................................................................................................................15

ATCHED RELAY RESET

USH BUZZER AND HORN

AIN MENU TREE

ENU

“1_S

YSTEM SETTING

ENU

“2_Z

EROING CALIBRATION

ENU

“3_S

PAN CALIBRATION

Span Calibration Procedure..................................................................................................22

ENU

“4_O

UTPUT TESTING

ENU

“5_S

ITE SERVICE

ENU

“6_R

ELAY DATABASE

Relay Configurations .............................................................................................................24

Relay Database Flow Chart ..................................................................................................26

ENU

ENU

ENU

ENU

“7_A-O

“8_B

“9_O

“10_S

UT DATABASE

UZZER DATABASE

UTPUT DISABLE

IMU DISABLE

....................................................................................................................13

...................................................................................................................13

...................................................................................................................15

................................................................................................................15

.................................................................................................................15

” ...........................................................................................................17

”..................................................................................................20

” .......................................................................................................22

”...........................................................................................................23

".................................................................................................................23

” .........................................................................................................24

”.........................................................................................................27

” .......................................................................................................28

”...........................................................................................................28

” .............................................................................................................28

4. MODBUS PROTOCOL SUPPORTED BY QIRF..........................................................................28

5. MAINTENANCE ...............................................................................................................................29

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

1

Page 3

5.1

5.2

DVM C

4MA

AND 20M

QIRF Operation And Maintenance Manual

ONNECTION FOR

A O

UTPUT CALIBRATION

4-20MA

MEASUREMENT

..........................................................................................29

...........................................................................29

6. TROUBLESHOOTING ....................................................................................................................30

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

2

Page 4

QIRF Operation And Maintenance Manual

READ BEFORE OPERATING

All individuals who have or will have the responsibility of using, maintaining, or

servicing this product must carefully read this manual. The product will perform as

designed only if it is used, maintained, and serviced in accordance with the

manufacturer’s instructions.

1. General Information

1.1 Principle of Operation

The QIRF Smart Sensor is a microprocessor controlled Refrigerant gas Sensor or

Transmitter using infrared sensing technology. The concentration of Refrigerant is

measured by determining the amount of absorption of light in a specific frequency band.

As most gases have their characteristic spectra in the infrared. Those spectra derive from

the molecule's composition in such a way that no two molecular gases have the same IR

spectrum. IR spectra are the fingerprints of gases, and thus allow gases to be uniquely

identified.

By transmitting a beam of IR radiation through the air, or through any particular gas

volume, and recording how much is transmitted at selected spectral lines, one may decide

which gases are present and how much of each. This is a standard and well-proven

principle, routinely used in laboratory analyses of chemical species, and is also the basis

on which our sensors are made.

An IR detector is essentially a temperature sensor and is, therefore, potentially very

sensitive to changes in the ambient temperature. However, our QIRF smart sensor

modules do it better, faster, and more precisely. The QIRF smart sensors are entirely

electronic with no moving parts, and are built around our unique QT Gas Sample Cell

with constant temperature control integrated with IR Source and IR Detector together.

This makes our IR smart sensors work from -45°C to 65°C without being susceptible to

ambient temperature fluctuations.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

3

Page 5

QIRF Operation And Maintenance Manual

Comparing with conventional gas detector, gases to be detected are often corrosive and

reactive. With most sensor types, the sensor itself is directly exposed to the gas, often

causing the sensor to drift or die prematurely. The main advantage of IR sensor or

transmitter is that the detector does not directly interact with the gas (or gases) to be

detected. In the QIRF Smart Sensor, the major functional components are protected with

optical parts. In other words, gas molecules interact only with a light beam. The IR

Source and IR Detector can be treated, making them resistant to corrosion, and are

designed such that they are easily removable for maintenance or replacement.

1.2 Key Features

• Infrared Sensing Technology

• Constant Temperature QT Gas Sampling Cell

• Standard RS-485 Output with OptoMux protocol and ModBus protocol

• Standard 4-20mA or 2-10VDC Analog Output

• Diffusion Sampling module or Pump-thru module

• No moving parts in diffusion or pump-thru model

• Water and corrosion resistant PVC enclosure NEMA 4, 4X

• Addressable from 0 to 31

• 4 magnetic sensors as keypad input

• 3 programmable Relays and 3 programmable Buzzers

• 2 x 8 character LCD display c/w backlight

• Operation at 18-30VDC or 15–24VAC

• 3 Relay Status LED, TX Status LED and RX Status LED

• CSA/UL approval (pending)

1.3 Applications

The QIRF is designed to monitor for the loss of refrigerant gas in a variety of

applications:

• Mechanical equipment rooms

• Propellant filling operations

• Solvent cleaning stations

• Cold storage and transport facilities

• Meat packing plants

• Supermarkets and refrigerant storage locations

• Other specialty applications using halocarbons

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

4

Page 6

1.4 Specifications

Input Power:

Fuse:

Sensor:

Gas Detected:

Range:

Accuracy:

Repeatability:

Sampling:

Panel Indicators:

Display:

Keypad:

Relays:

Buzzer:

QIRF Operation And Maintenance Manual

24VDC nominal, range 18 to 30VDC, 1.0A DC Total Max.

24VAC nominal, range 15 to 24VAC, 1.0A AC Total Max.

F1 on Display Board: Polyswitch 1.6A

F2 on Display Board: Polyswitch 50mA

Polyswitch device resets after the fault is cleared and power

to the circuit is removed

Infrared Refrigerant

User selectable: R11, R12, R22, R114, R123, R134A,

R402A, R404A, R407C, R408A, R409A, R410A, R422A,

R438A, R507A

Available on special order: R13, R14, R21, R23, R31, R32,

R41, R113, R115, R116, R125, R143a, R152, R161 …

0 to 100ppm for R123; 0 to 1000ppm for others

±3% of reading

±1% of full scale

Diffusion or Pump-through

5 Status LED’s

• RS-485 TX Status (Green)

• RS-485 RX Status (Green)

• Relay1 Status (Red)

• Relay2 Status (Red)

• Relay2 Status (Red)

2 x 8 character display c/w backlight

4 magnetic sensors with Magnet tool

3 Relays SPDT, Dry contacts

• 1.0A maximum at 30 VDC (resistive load)

• 0.3A maximum at 125VAC (resistive load)

80 db at 10 cm, 2700 Hz

Buzzer 1: Double-tap Intermittent

Buzzer 2: Intermittent 50% duty cycle

Buzzer 3: Continuous

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

5

Page 7

Output Signal:

Enclosure Rating:

Operating Temperature:

Ambient Humidity:

Storage Temperature:

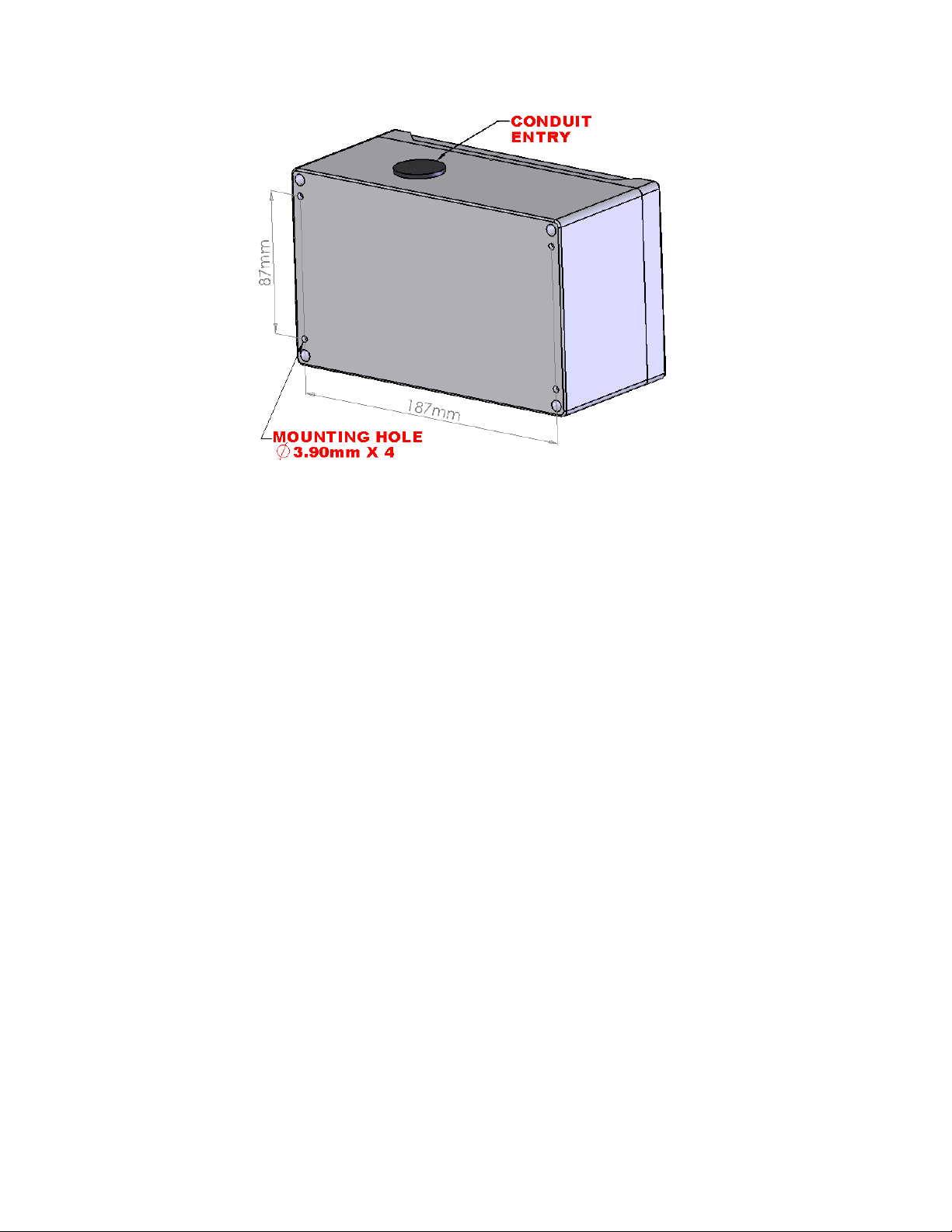

Size:

Weight:

QIRF Operation And Maintenance Manual

RS-485 with OptoMux protocol

• Available Controller: M-Controller

Q4 Controller

RS-485 with ModBus protocol

4-20mA or 2-10VDC Analog Signal

IP 66 & NEMA 4, 4X, 12 & 13

Cover Screws should be torqued to 2.5lbs-in (30cN-m)

-45°C to 65°C

5% to 95% RH (non-condensing)

-45°C to 70°C

200mm X 120mm X 90mm

Less than 1.5lbs (0.680 kg)

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

6

Page 8

QIRF Operation And Maintenance Manual

2. Installation

2.1 Sensor Location

Several factors should be considered when selecting locations to install sensors. The

following general suggestions should be considered to assure the detection of the target

gas. Select the most suitable location for each sensor.

1. Air Currents: If there are fans, winds, or others sources of air movement, gases may

tend to rise or collect in certain areas of a facility. The local air currents should be

assessed to aid in selecting the sensor location. In outdoor situations considerations such

as prevailing winds should be accounted for. Air convection can often be more important

in determining gas concentrated areas than factors of Vapor Density.

2. Vapor Density: R11, R22, R123 and R134A are heavier than air. Detecting location

should be 9 - 18 inch (0.23m to 0.46m) above the floor.

3. Gas Emission Sources: As a rule, at least one sensor should be located in close

proximity to each point where a leak is likely to occur. This is particularly important

when a liquid having a low volatility is monitored.

4. Environmental Factors: Designed to rugged outdoor use consider the following in

selecting locations. Install sensors where they will be protected from wind, dust, snow,

water, vibration and shock.

2.2 Physical Dimensions

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

7

Page 9

QIRF Operation And Maintenance Manual

2.3 Gas Sampling

In Diffusion version QIRF, the gas sampling system is composed of a diffusion type gas

sample chamber and two vent holes on the enclosure bottom. The gas flows in and out

through the two vent plugs on the bottom of the QIRF enclosure. See above picture.

In Pump-thru version QIRF, the sampling gas is pumped through the fitting on the bottom

of the QIRF enclosure, and passed through the gas chamber, then exhausted out though

the fitting on the right side of the enclosure. Pump-thru version QIRF doesn’t have

pump inside. For gas sampling and conditioning unit, QEL provides SCS-1 (One channel

sampling and conditioning system).

2.4 Mounting and System Wiring

NOTE: The Diffusion version QIRF should be mounted 1 foot (30cm) from the

floor.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

8

Page 10

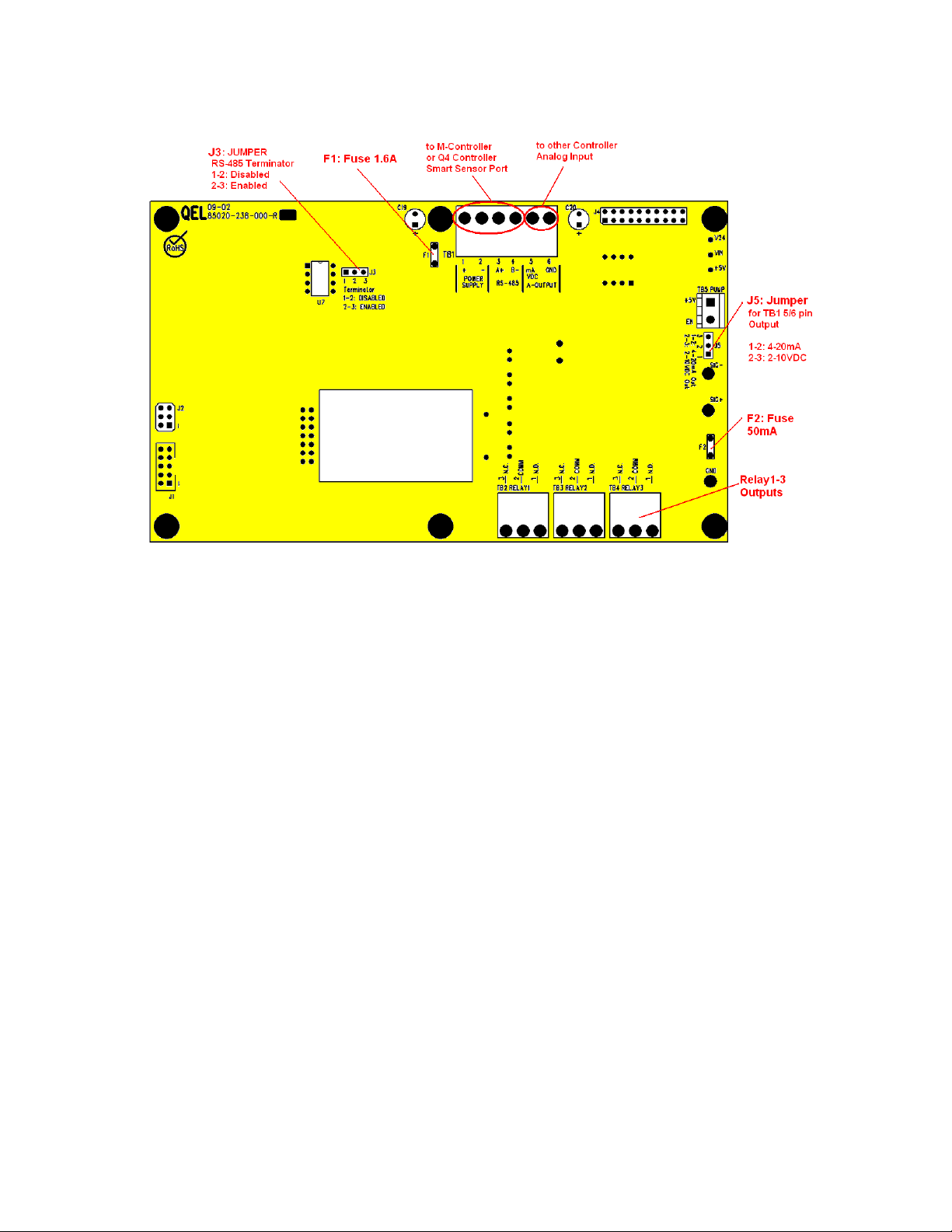

2.4.1 Terminals

QIRF Operation And Maintenance Manual

Display Board Terminals

2.4.2 Power Supply

NOTICE: Installing or using this equipment in a manner not specified by the

manufacturer could cause electric shock, bodily injury, or risk of fire.

Power Supply:

Voltage: 15-24VAC 50/60Hz 1.0A AC Total max.

18-30VDC 1.0A DC Total max.

Note: AC Power Supply must be non-grounded (floating).

Note: No external over-current protection is required. Over-current protection is

provided by means of fuses F1.

Fuse F1: PolySwitch 1.6A

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

9

Page 11

QIRF Operation And Maintenance Manual

2.4.3 Wire and Cable

The terminal block plug TB1 accepts 12 AWG to 24 AWG wire, Use 16 AWG or 18

AWG wire for Power Supply in long wiring runs, which can be up to 1km (1,000 meters)

long.

We recommend using BELDEN 9841 for communications. This wire has 120 ohm input

impendence, which will eliminate RS-485 communication problems.

2.4.4 Digital Connection

2.4.5 RS-485 Terminator

The terminator on each end of the RS485 loop is designed to match the electrical

impedance characteristic of the twisted pair loop, and will prevent signal echoes from

corrupting the data on the line. The terminator should be enabled on BOTH ends of the

RS485 loop. Short and medium length modbus/485 loops can operate without the

terminating resistor. Longer runs may require the terminating resistors. But adding

terminator dramatically increases power consumption.

Factory default setting is disabled terminator.

The QIRF smart sensor supplies this resistor on the display board, and it is chosen using a

jumper at J3.

• J3 1-2: Terminator Disabled / OFF (default)

• J3 2-3: Terminator Enabled / ON

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

10

Page 12

QIRF Operation And Maintenance Manual

2.4.6 RS-485 Driver Replacement

RS-485 lines in heavy industrial environments are sometimes subjected to magnetic

disturbances causing sufficient inducted power surges to damage the driver integrated

circuit (IC). This IC U7 has a socket on the circuit card for ease of replacement in the

field.

2.4.7 4-20mA or 2-10VDC Analog Output

QIRF can provide one channel 4-20 milliamp analog outputs or 2-10VDC analog output.

The maximum output impedance is 600 ohms for 4-20mA output. The maximum output

current is 10 mA for 2-10VDC output.

Test point SIG+ and SIG- are used to measure the current online when the QIRF is

working in the field.

The module can also be used to output 2-10VDC if the Jump J5 2-3 is connected. The

default setting: J5 1-2 is connected that mean the output is 4-20mA analog output.

The analog output may be defined in complex ways allowing assignment of different

values to both 4 milliamps and 20 milliamps. You may even assign a gas concentration to

4 mA, which is higher than the concentration assigned to 20 milliamps. The QIRF will

draw a straight line between.

If there is any fault found in QIRF, it will output 2.5mA to indicate the fault.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

11

Page 13

QIRF Operation And Maintenance Manual

2.4.8 Relays Output

QIRF is equipped with three programmable Single-Pole Double-Throw (SPDT) Relays

on board, which is able to make it work alone to control other equipment, such as fans,

lights, horns, or visual alarm indicators in different applications.

Three terminal blocks TB2, TB3 and TB4 are located on the Display Board. Each relay

can be programmed individually.

Switching capability of each relay is:

• 1.0 A maximum resistive load at 30 VDC

• 0.3A maximum resistive load at 125VAC

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

12

Page 14

QIRF Operation And Maintenance Manual

3. Function and Configuration

3.1 QIRF Working Mode

QIRF has four kinds of working mode:

• Warm-up Mode: to heat up Optical Block and initialize components.

• Monitoring Mode: to measure the gas concentration and output signals.

• Zeroing Calibration Mode: QIRF is performing Zeroing Calibration.

• Span Calibration Mode: QIRF is performing Span Calibration.

3.2 System Initialization

When the QIRF smart sensor is turned on, it initializes hardware and software. As the

transmitter is warming up, the optical block is heated to a constant temperature, the LCD

will display the transmitter is in warming-up procedure.

In warming-up procedure, the reading of the transmitter will always be zero and the

analog output will always be 4mA. M-Controller and Q4 Controller will display

“Warming up” in their LCD display panel. The time for stabilizing the optical block

temperature depends on the ambient temperature and input power voltage. The lower the

ambient temperature and input voltage are, the longer it takes. Normally, at 25°C and 24V

input voltage, it takes 15 minutes. The default warming-up timer is 24 hours, the

warming-up procedure can be aborted by pressing key [ESC] for 3 seconds. The

warming-up timer can be set again in [MENU]=>[System Setting]=>[Zero/Cal Timer].

If the warming-up procedure is not aborted, when timeouts, the transmitter automatically

starts zeroing calibration, then enters into monitoring mode. If there is an error, the LCD

will display the error and the TB1 pin 5/6 will output 2.5mA if the 4-20mA analog

outputs is enabled or 1.25VDC if the 2-10VDC analog outputs is enabled. An error

message will display on the M-Controller or Q4 Controller panel.

Note: After warming-up procedure, an error [PH-DIRTY] might appear which is

caused by low ambient temperature or low input power voltage. The error will

disappear when unit is fully stabilized. If not, see section 6. Troubleshooting.

Note: No adjustments or calibration should be performed within 24 hours.

3.3 Keypad

QIRF has four keys on the front panel. To access the keypad, the magnet tool in the

product-shipping package is needed.

• Key [Up]: Scroll and Hold

• Key [Down]: View current input or output details

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

13

Page 15

QIRF Operation And Maintenance Manual

• Key [ESC]: Return to previous menu or Hush Buzzer or Reset Latched Relay

• Key [YES]: Enter Menu or Confirm answers

start

Is UP key?

NO

Is DOWN key?

NO

Is EXIT/CLEAR key?

NO

YES

YES

YES

Scroll and Hold

Display

Display Detail

about the output

Hold 3 seconds?

NO

Character "*" indicates the screen is in HOLDMode.

The screen will be held for 120 seconds

Press the DOWN key will browse the detail of the

current output which is able to be selected by UP

key.

Reset all Relays in

YES

Latched Satus

Hush all Buzzers in

Alarm Status

Is ENTER key?

NO

YES

Hold 3 seconds?

YES

PASSWORD

> NNNN

NO

Passoword is Correct?

NO

YES

ENTER

MENU MODE

B

QIRF Running Mode Key Functions Flow Chart

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

14

Page 16

QIRF Operation And Maintenance Manual

3.4 Status LED

3.4.1 RS485-TX/RX:

When the QIRF is connected to a Controller System through RS-485, the traffic of the

communication can be monitored visually through the two RS-485 indicators. One is RX

LED, which indicates the data stream received in the Controller. The other is TX LED,

which indicates the data stream out of the QIRF.

Note: If the TX LED or the RX LED is always ON, that means the communication

has a problem. See Troubleshooting for RS-485.

3.4.2 Relay1-3 LED:

Indicate the status of each relay. When the relay is actuated/closed, the Relay LED is ON.

When the relay is de-actuated/open, the relay LED is OFF.

Note: If you set the relay to be Normally Energized Relay (Fail Safe), the relay LED

will turn ON at non-alarm state and turn OFF at alarm state, because the LED

reflects the relay coil status.

3.5 Latched Relay Reset

To acknowledge a latched condition, press Key [ESC] for 3 seconds. All latched relays

for which the alarm condition has been removed will reset. If the alarm condition (e.g.

high gas concentration) is still present the relay(s) will not reset.

3.6 Hush Buzzer and Horn

Press Key [ESC] to silence the buzzer and horn. Press the Key [ESC] again to remove the

hush function.

3.7 QIRF Main Menu Tree

Menu is password protected. Press and hold Key [YES] for 3 seconds, you will be

prompted to input a four-digit password. Once the password is accepted, you are allowed

into the main menu tree. Press button [Up] or [Down] to scroll through the main branch

headings, press button [YES] to enter the function, press button [ESC] to exit to up level

menu.

Factory default password is 4321.

Note: While in the Menu Tree, all normal monitoring operations stop. The alarm

status does not change.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

15

Page 17

QIRF Operation And Maintenance Manual

B

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

MENU MODE

MENU MODE

MENU MODEMENU MODE

C C1

1_ SYSTEM

SETTING

Up

2_ ZERO

CAL

Up

3_ SPAN

CAL

Up

4_ OUTPUT

TESTING

Up

5_ SITE

SERVICE

Up

6_ RELAY

DATABASE

Up

7_ A-OUT

DATABASE

Up

8_ BUZZER

DATABASE

Up

9_ OUTPUT

DISABLE

Up

10_ SIMU

DISABLE

Up

Down

Down

Down

Down

Down

Down

Down

Down

Down

Down

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

ESC

ESC

ESC

SYSTEM SETTING

ZEROING?

SUBDIVISION

YES

NN PPM

SPAN CAL?

NN PPM

ESC

ESC

ESC

ESC

ESC

ESC

ESC

OUTPUT TESTING

SUBDIVISION

SITE SERVICE

SUBDIVISION

RELAY DATABASE

SUBDIVISION

A-OUT DATABASE

SUBDIVISION

BUZZER DATABASE

SUBDIVISION

ALL OUTPUTS CAN BE

DISABLED AT CALIBRATION

SIMULATE

ENABLE

YES

YES

SEE SYSTEM SETTING Page

S3 R134a

ZERO...

S3 R134a

CAL...

SEE TESTING Page

SEE RelayDataBase Page

SEE AOUTDataBase Page

SEE BuzzerDataBase Page

READING

NNN PPM

ACCEPTED

ACCEPTED

ACCEPTED

Down

C

+

QIRF Menu Tree Flow Chart

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

16

Page 18

QIRF Operation And Maintenance Manual

3.8 Menu “1_System Setting”

System Setting Subdivision contains general settings for monitor operations,

communications and 4-20mA calibrations.

RETURN

TO UP LEVEL

S S1

PRESS KEY UP AND KEY

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ADDRESS

001

Up

BAUDRATE

4800 bps

Up

SCROLL

3 SEC

Up

BACKLIGHT

ON

Up

4mA CAL

150

Up

20mA CAL

910

Up

CHANGE

PASSWORD

Up

PROTOCOL

OPTOMUX

Up

Down

Down

Down

Down

Down

Down

Down

Down

YES

YES

YES

YES

YES

YES

YES

ESC

YES

ESC

ESC

ESC

ESC

ESC

ESC

New PSW

> NNNN

ESC

DOWN TO MODIF Y

NEW ADDR

> 0003

New Rate

> 57.6

New Rate

> 4

New Mode

> AUTO

ADJ 4mA

> 183

ADJ 20mA

> 928

YES

New Mode

MODBUS

ESC

YES

YES

YES

YES

YES

YES

YES

IN AGAIN

> NNNN

Is ModBus?

ACCEPTED

ACCEPTED

ACCEPTED

ACCEPTED

ACCEPTED

ACCEPTED

NO

YES

YES

The two func tion

are used to

calibrate An alog

Output 4-20m A.

ACCEPTED

PARITY?

ODD/EVEN/NONE

ACCEPTED

Down

GAS TYPE

ESC

R134a

Up

AUTOZERO

ESC

OFF

Up

ESC

RESTORE

DEFAULTS

Up

SPEC GAS

ESC

DISABLE

Up Down

S

QIRF Operation Manual May. 01, 2012

YES

Down

YES

Down

YES

ESC

Down

YES

S1

ESC

New Mode

> ENABLE

ESC

ESC

RESTORE

ESC

YES/NO?

New Gas?

YES

> R123

New Mode

YES

> ON

YES

YES YES

SPEC GAS

> R427A

FACTORY

DEFAULTS

ACCEPTED

ACCEPTED

SPEC UNIT

> PPM

YES

ACCEPTED

17

85050-301-000 Rev C

Page 19

3.8.1 System Settings

QIRF Operation And Maintenance Manual

Password:

Address:

Baud rate:

Scroll Rate:

Backlight:

4mA Cal

20mA Cal:

Default password is 4321.

M-Controller supports RS-485 addressing from 0 to 31 for digital sensor.

Q4 Controller supports RS-485 addressing from 0 to 3 for digital sensor.

The QIRF smart sensor RS-485 address can be defined from 0 to 255 to be

used in RS-485 OptoMux or ModBus communication. Default address is

3.

Define Baud Rate for RS-485 OptoMux or ModBus Communication.

Default baud rate is 4800 bps.

In normal operation the sensor and relay status information scrolls

automatically. Set the number of seconds for each item to be displayed.

Default value is 3 seconds.

The LCD backlight can be set to Always Off, Always On and Power

Saver. In Power Saving mode, the backlight will turn on for 10 seconds

after any Key has been pressed. Default setting is Always ON mode.

These values are established during factory calibration for 4-20mA analog

output and should not require recalibration in the field. Do not attempt to

modify these settings in the field.

Change

Password:

Protocol:

Changing these values will change the analog output signal scale.

Warning: This procedure is part of factory setup. In most

circumstances it will not be necessary to perform this procedure in the

field. These functions require the use of precision reference

instrumentation.

Change Password allows any combination of up to four digits. Default

password is 4321.

Warning: Be sure that you record the new password in a safe and

secure location!

When QIRF is connected to M-Controller or Q4-Controller, the protocol

should be set to “OptoMux”. Default protocol is OptoMux.

QIRF also supports “ModBus” protocol, responds as a ModBus Slave

using RTU protocol. When it’s set to “ModBus”, the parity bit can be

defined as “EVEN”, “ODD” and “No Parity”.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

18

Page 20

QIRF Operation And Maintenance Manual

Gas Type

AutoZero:

Default Gas Type is R134a.

Note: All units are gas calibrated using 1000ppm R134a in factory.

You can change the Gas Type to other target gas type without using

target gas to calibrate again. Zero Calibration is recommended after

the gas type is changed.

For the gas type that QIRF supports, see 1.4 Specifications

For other gas types, please consult QEL.

Note: When the unit is connected to Q4 Controller, Q4 Controller can poll

out the Gas Type automatically and display the gas type in its LCD

display. When the unit is connected to M-Controller, the M-Controller

will only use the Gas Type and Measurement Unit that are defined for the

channel in M-Controller.

QIRF is two channel detector, it’s designed to work in the situation where

the Auto Zero function is not suitable. So QIRF discards AutoZero setting,

QIRF will never do auto zero in background.

Restore

Default:

Special

Gas:

Zero/Cal

Timer:

NOTE: “AutoZero” works best in situations where the facility is

exposed to non-refrigerant-existing air at least four times in 7 days. In

facilities that are continuously occupied for 24 hours per day, or

where there could be significant sources of non-occupant related

refrigerant gas, the Auto Zero should be turned OFF.

To load defaults to all items. Perform a full factory and gas calibration to

restore the unit to correct operation. After restore default, the unit needs to

be recalibrated with Zeroing Calibration and Span Calibration

When the unit is calibrated to a special gas type that is not listed in above

Gas Type list, you can enable the Special Gas Type and input the special

Gas Type and Measurement Unit, which will override the Gas Type

defined in above Gas Type Menu for QIRF LCD display and Q4

Controller LCD display.

The timer can be set from 1 seconds to 99 hours. When the timer is

timeouts, the units will perform Zeroing Calibration automatically. If the

timer is set, the unit will work in Warming-up Mode, after Zeroing

Calibration, the unit returns to Monitoring Mode.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

19

Page 21

QIRF Operation And Maintenance Manual

3.9 Menu “2_Zeroing Calibration”

Calibration should not vary significantly over a period of years; however, it is best to

perform a verification calibration after installation, and at one-year intervals thereafter.

All units are factory calibrated.

The QIRF uses full scale as its CAL GAS concentration:

Basically, QIRF full scale for all Refrigerant gases is 1000ppm except for R123, which is

100ppm.

Gas Type Full Scale Cal Gas Concentration

R134a 1000ppm 1000ppm

R123 100ppm 100ppm

R22 1000ppm 1000ppm

R11 1000ppm 1000ppm

Others 1000ppm 1000ppm

The QIRF smart sensor is calibrated using a two-point calibration process. First, use a

“Zero Gas”, then use a “CAL Gas” containing a known concentration of a standard

reference gas, to set the second point of reference.

3.9.1 Equipment Required

• A cylinder of Zero Gas: it can be clean room air or Zero Air (20.9% Oxygen in

Nitrogen). DO NOT USE PURE NITROGEN.

• A cylinder of Cal Gas (balanced with air, DO NOT USE BALANCED

WITH NITROGEN)

• Flow Limiting Regulator(s) 0.4 to 0.6 lpm

• Tubing

3.9.2 Zeroing Calibration Procedure

2_ ZERO

CAL

YES

ESC

ZEROING?

NN PPM

YES

S3 R134a

ZERO...

ACCEPTED

Zeroing Calibration Flow Chart

Note: No adjustments or calibration should be performed within 24 hours

stabilization.

Note: Zeroing Calibration must be performed before Span Calibration.

1. Connect tubing to QIRF

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

20

Page 22

QIRF Operation And Maintenance Manual

• For Diffusion Version: Connect the zero gas supply tubing to the fitting on the

right side of enclosure

• For Pump-through Version: Connect the zero gas supply tubing to the push-in

fitting on the bottom side of enclosure

2. Turn on the gas flow and press Key [YES] to display current reading

ZEROING?

NN PPM

This screen is displaying the current reading and asking if you want to perform

Zeroing Calibration.

3. Waiting for about 3 minutes or till the reading is stable.

4. Press Key [YES] to perform Zeroing Calibration.

5. During Zeroing Calibration, the LCD will display the digital pot positions and

calibration statuses. It will take 3 to 10 minutes to perform Zeroing Calibration, then

the zero calibration data is saved and LCD displays “Accepted”.

6. If the LCD displays “Cal Error” that means something is wrong in the procedure,

repeat procedure 4 to try again. If the “Cal Error” is still displayed in the end, the unit

needs to be repaired in factory, otherwise, Zeroing Calibration has succeeded, go to

next step.

7. Turn off the gas flow and remove it.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

21

Page 23

QIRF Operation And Maintenance Manual

3.10 Menu “3_Span Calibration”

3_ SPAN

CAL

YES

ESC

SPAN CAL?

NN PPM

Span Calibration Flow Chart

3.10.1 Span Calibration Procedure

1. Connect tubing to QIRF

• For Diffusion Version: Connect the cal gas supply tubing to the fitting on the

right side of enclosure

• For Pump-through Version: Connect the cal gas supply tubing to the push-in

fitting on the bottom side of enclosure

YES

S3 R134a

CAL...

ACCEPTED

2. Turn on the gas flow and press Key [YES] to display current reading

SPAN CAL?

NN PPM

This screen is displaying the current reading and asking if you want to perform

Span Calibration.

3. Waiting for about 3 minutes or till the reading is stable.

4. Press Key [YES] to perform Span Calibration.

5. During Span Calibration, the LCD will display the digital pot positions and

calibration statuses. It will take about 1 minute to perform Span Calibration, then the

span calibration data is saved and LCD displays “Accepted”.

6. If the LCD displays “Cal Error” that means something is wrong in the procedure,

repeat procedure 4 to try again. If the “Cal Error” is still displayed in the end, the unit

needs to be repaired in factory, otherwise, Span Calibration has succeeded, go to next

step.

7. Turn off the gas flow and remove it.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

22

Page 24

QIRF Operation And Maintenance Manual

3.11 Menu “4_Output Testing”

For system installation testing, it is necessary to force relay and buzzer actions. Enter this

branch as shown in the flow diagram.

The Relay Testing feature allows the user to force actuation on each relay. This function

forces an Actuate vs. De-actuate action, not an energized vs. non-energized action.

Therefore the user must be aware of those relays, which have been defined as normally

energized or not normally energized.

RETURN

TO UP LEVEL

F F1

ESC

ESC

ESC

Up

Up

Up

RELAY

TEST

BUZZER

TEST

A-OUT

TEST

Down

Down

Down

YES

YES

YES

ESC

ESC

ESC

ESC

ESC

Down

Down

YES

YES

YES

YES

YES

ESC

ESC

ESC

ESC

ESC

BUZZER

OFF

OUTPUT

20mA

RELAY 1? RELAY

Up

RELAY 2?

Up

RELAY 3?

BUZZER

ON

OUTPUT

4mA

ON

RELAY

ON

RELAY

ON

F F1

Output Testing Flow Chart

3.12 Menu “5_Site Service"

Factory Service Staff access Site Service only. Customer has no need to operate it.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

23

Page 25

QIRF Operation And Maintenance Manual

3.13 Menu “6_Relay Database”

3.13.1 Relay Configurations

Enabled:

Normally

Deenergized:

Latching:

Action On:

Action Off:

Each relay may be individually set to be enabled or disabled. If it’s

disabled, the relay is always de-actuate no matter what’s the current gas

concentration.

Default is Enabled.

Each relay may be individually set to be Normally Energized or Normally

De-energized.

Default is De-energized.

Each relay may be set to latch in Actuate status until acknowledged by a

front-panel action. Hold the button [ESC] for 3 seconds to release latched

relays.

Default is Non-Latching.

If Action On is greater than or equal to Action Off (Window=OFF):

Action On: Set the concentration at or above which the relay will actuate.

Action Off: Set the concentration at or below which the relay will deactuate.

If Action On is less than Action Off (Window=OFF):

Action On: Set the concentration below that the relay will actuate.

Action Off: Set the concentration above that the relay will de-actuate.

Defaults for 1000ppm Detection Range:

• Relay1 Action On / Off: 500 / 480 ppm

• Relay2 Action On / Off: 750 / 720 ppm

• Relay3 Action On / Off: 1000 / 950 ppm

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

24

Page 26

QIRF Operation And Maintenance Manual

Defaults for R123 100ppm:

• Relay1 Action On / Off: 50 / 45 ppm

• Relay2 Action On / Off: 75 / 70 ppm

• Relay3 Action On / Off: 100 / 95 ppm

ON Delay:

“Delay on Actuation” or “Delay on Make”. For each relay a separate time

delay may be set from 0 to 990 seconds before an alarm condition will

cause the relay to actuate.

Default is 30 seconds.

OFF Delay:

“Delay on De-Actuation” or “Delay on Break”. For each relay a separate

time delay may be set from 0 to 990 seconds before a return to a nonalarming signal condition will cause the relay to de-actuate.

Default is 30 seconds.

Fault:

Set to ON for actuating the relay if the unit reports any Faults.

Default is ON.

Window: When it’s set to ON, if the concentration is between Action ON and

Action Off, the relay will be de-actuated; if the concentration is out of the

windows (Action ON and Action Off), the relay will be actuated.

Default is OFF.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

25

Page 27

QIRF Operation And Maintenance Manual

3.13.2 Relay Database Flow Chart

CHOOSE A RELAY TO MODIFY

ESC

ESC

ESC

Up

Down

Up

Down

Up

Down

Up

Down

RETURN

TO UP LEVEL

MODIFY

RELAY1?

YES

RELAY1?

ENABLED

YES

1.NORMAL

ENERGIZE

YES

1. WITH

LATCHING

YES

MODIFY

RELAY2

RELAY1?

DISABLED

2.NORMAL

DE-ENERGIZE

2. NONE

LATCHING

YES

Up

Down

MODIFY

RELAY3

FINISHED

ACT-ON #?

> NNNN

YES

ACT-OFF #?

> NNNN

YES

ON-DLY#?

NNNN

YES

OFF-DLY#?

NNNN

YES

FAULT?

ON

YES

WINDOW?

ON

ESC

ESC

ESC

ESC

ESC

ESC

DELAY IS VALID BETWEEN 0 TO 990 SECONDS

Up

Down

Up

Down

FAULT?

OFF

WINDOW?

OFF

ANY FAULT WILL ACTUATE THE RELAY

READING OUT OF WINDOWS WILL ACTUATE THE RELAY

FINISHED!

QIRF Operation Manual May. 01, 2012

26

85050-301-000 Rev C

Page 28

QIRF Operation And Maintenance Manual

3.14 Menu “7_A-Out Database”

The Analog Database setup is almost identical to that of the relays.

QIRF will compare the concentration at 4mA and the concentration at 20mA, you may

assign a larger concentration for 4.0 milliamps than for 20 milliamps; the QIRF will still

stretch a straight line signal between the two points and then convert the current gas

reading to analog output.

Note: The Analog Output can not be disabled.

Note: When the sensor has fault, it will output 2.5mA to indicate fault status.

Conc@4mA:

Conc@20mA:

Input the gas concentration at which the 4mA is output.

Default is 0 ppm.

Input the gas concentration at which the 20mA is output.

Default is 1000 ppm.

RETURN

TO UP LEVEL

ESC

MODIFY

A-OUT?

YES

ESC

CONC @ 4mA

> NNNN

YES

ESC

CONC @ 20mA

> NNNN

YES

FINISHED!

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

27

Page 29

QIRF Operation And Maintenance Manual

3.15 Menu “8_Buzzer Database”

The buzzer setup is almost identical to that of the relays, except that there are three butter

options.

• Buzzer 1: Double-tap Intermittent

• Buzzer 2: Intermittent 50% duty cycle

• Buzzer 3: Continuous

Buzzer 3 has highest priority and Buzzer 1 has lowest priority.

The menus are identical to those for the Relay Database. For Relay Database detail and

flow chart, please refer 3.13 Menu “6_Relay Database” on page 24.

3.16 Menu “9_Output Disable”

This function is for calibration, system testing etc. When Output is disabled, the relay,

buzzer and analog output, etc., statuses will freeze in whatever state they are already in.

Default is “Output Enabled” when the unit is powered up.

3.17 Menu “10_Simu Disable”

Simulation Mode is to assist in testing the installation before commissioning. When the

simulation is enabled, the unit will not detect gas concentration, it will display the

simulating value and use it to calculate the statuses of relays and buzzer, as well as 420mA analog output. This feature is available for evaluating the user settings and testing

the installation (e.g.: the travel of the valve, fan speed, relay set points, etc. can be

verified.)

Any concentration between 0ppm and 9999ppm can be simulated.

Default is “Simu Disabled” when the unit is powered up.

4. MODBUS Protocol Supported By QIRF

For ModBus protocol, please contact QEL.

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

28

Page 30

QIRF Operation And Maintenance Manual

5. Maintenance

5.1 DVM Connection for 4-20mA measurement

• QIRF is Offline of the 4-20mA loop:

o Switch DVM to measure DC current, plug the probe “-“ into GND and

plug the probe “+” into SIG- on the Display Board.

• QIRF is Online of the 4-20mA loop:

o Switch DVM to measure DC current, plug the probe “-“ into SIG - and

plug the probe “+” into SIG + on the Display Board.

5.2 4mA and 20mA Output Calibration

These values are established during factory 4-20mA output calibrations and should not

require recalibration in the field. Do not attempt to modify these settings in the field.

Changing these values will change the analog output signal scale.

• Entry [Menu]-->[System Setting]

• Choose [4mA CAL]:

1. Press Key [YES] to output 4mA signal

2. Connect DVM to the unit as described above

3. Press Key [Up] and Key [Down] to adjust the current to 4.00mA to 4.05mA

4. Press Key [YES] again, then the settings will be accepted and saved

• Choose [20mA CAL]:

1. Press Key [YES] to output 20mA signal

2. Connect DVM to the unit as described above

3. Press Key [Up] and Key [Down] to adjust the current to 20.00 to 20.05mA

4. Press Key [YES] again, then the settings will be accepted and saved

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

29

Page 31

QIRF Operation And Maintenance Manual

6. Troubleshooting

This troubleshooting guide is intended as an aid in identifying the cause of unexpected

behavior and determining whether the behavior is due to normal operation or an internal

or external problem.

SYMPTOMS PROBABLE CAUSE SUGGESTED SOLUTION

RS-485

RX LED or

TX LED constantly ON

In Warm Up Mode too long

Error Report

[PH-DIRTY]

[LP-SHORT] /[LP-OPEN]

[CAL-ERR]

• RS-485 bus connection has

problem

• RS-485 Driver U7 is damaged

• Controller side RS-485 Driver

has problem

• In Warming up process

• Temperature sensor broken

• Heater is broken

• IR Source or Lamp Dirty

• Gas Sample Cell Dirty

• Signal Fault

• Drift too much

• Lamp Short/Open

• Calibrating Error

• Disconnect the Cable to isolate

the problem

• Replace U7 IC on display board

• Replace RS-485 Driver in

Controller

• Wait for the block to warm up

• Check IR Block Assembly

• Check IR Block Assembly

• Return to Factory

• Return to Factory

• Return to Factory

• Re-zeroing calibration

• Check IR Block Assembly

• Recalibration or Adjust POTs or

IR Source LED is constant

ON or OFF, not blinking

Reading abnormally high or

low or jumping around

randomly

• Other Error

• Main Board has problem

•

Heater is short/Open

• Dirty Sensor Block

• Excessive moisture

• Weak IR Source

• Temperature Sensor Loose

Check Gas Flow or Use different

calibration gas or Replace weak

IR Source Assembly or Replace

Broken IR Detector Assembly

• Return to Factory

• Check Firmware and Driver

• Check IR Block Assembly

• Return to Factory

• Add filter to gas inlet

• Replace IR Source Assembly

• Check IR Block Assembly

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

30

Page 32

QIRF Operation And Maintenance Manual

WARRANTY STATEMENT

The information contained in this manual is based upon data considered accurate; however, no

warranty is expressed or implied regarding the accuracy of this data. All QEL equipment is

warranted against defects in material and workmanship for a period of two years from date of

shipment with the following exceptions:

Electrochemical Sensors (Toxic) Six Months

Catalytic Sensors (Combustible) One Year

During the warranty period we will repair or replace, at our discretion, any components or

complete units that prove, in our opinion, to be defective. We are not liable for consequential or

incidental damage to auxiliary interfaced equipment.

A returned material authorization number should be obtained from the factory prior to returning

any goods. All return shipments must be shipped freight prepaid and a copy of the maintenance

records should accompany the unit concerned.

Warranty should be considered F.O.B. the factory. Labour and travel time are chargeable for any

field site visits required for warranty work.

LIMITED LIABILITY

All QEL systems shall be installed by a qualified technician/electrician and maintained in strict

accordance with data provided for individual systems in the form of installation/maintenance

manuals. QEL assumes no responsibility for improper installation, maintenance, etc., and

stresses the importance of reading all manuals. QEL shall not be responsible for any liability

arising from auxiliary interfaced equipment nor any damage resulting from the installation or

operation of this equipment.

QEL’s total liability is contained as above with no other liability expressed or implied, as the

purchaser is entirely responsible for installation and maintenance of systems.

This warranty is in lieu of all other warranties, expressed or implied, and no representative or

person is authorized to represent or assume for QEL any liability in connection with the sales of

our products other than that set forth herein.

NOTE: Due to on-going product development, QEL reserves the right to change

specifications without notice and will assume no responsibility for any costs as a

result of modifications.

For further information or assistance, contact:

QIRF Operation Manual May. 01, 2012

85050-301-000 Rev C

31

Loading...

Loading...