Q5/Q5 IR-Probe

GAS TRANSMITTER/SENSOR

Q5

IR-Probe

INSTALLATION

OPERATION AND MAINTENANCE

MANUAL

Q5 Operation And Maintenance Manual

1

READ BEFORE OPERATING ................................................................................................................... 2

1. SPECIFICATIONS .............................................................................................................................. 2

1.1 ELECTRICAL/MECHANICAL SPECIFICATIONS ........................................................................................... 2

1.2 SENSOR SPECIFICATIONS ......................................................................................................................... 4

2. INSTALLATION ................................................................................................................................. 6

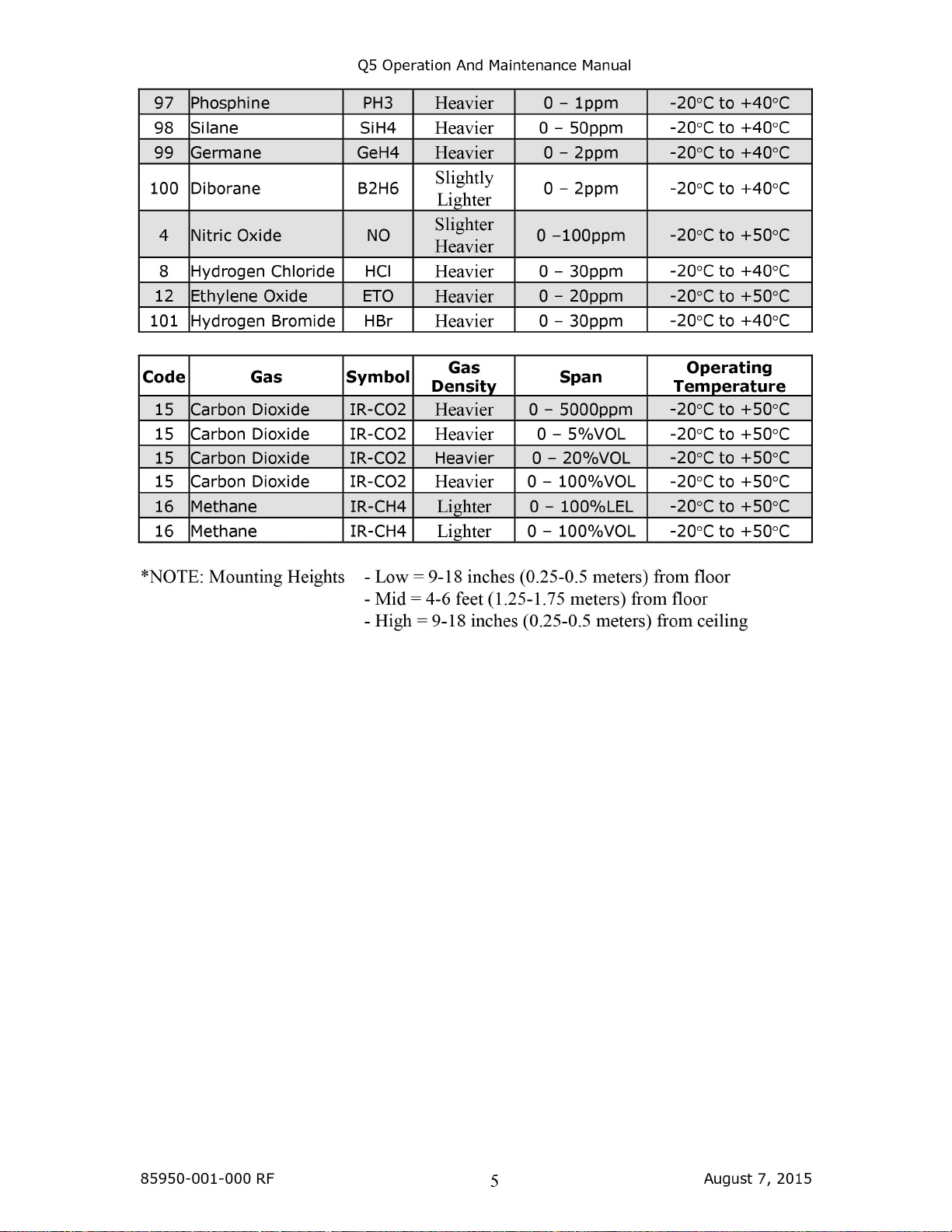

2.1 ENCLOSURES PHYSICAL DIMENSIONS ..................................................................................................... 6

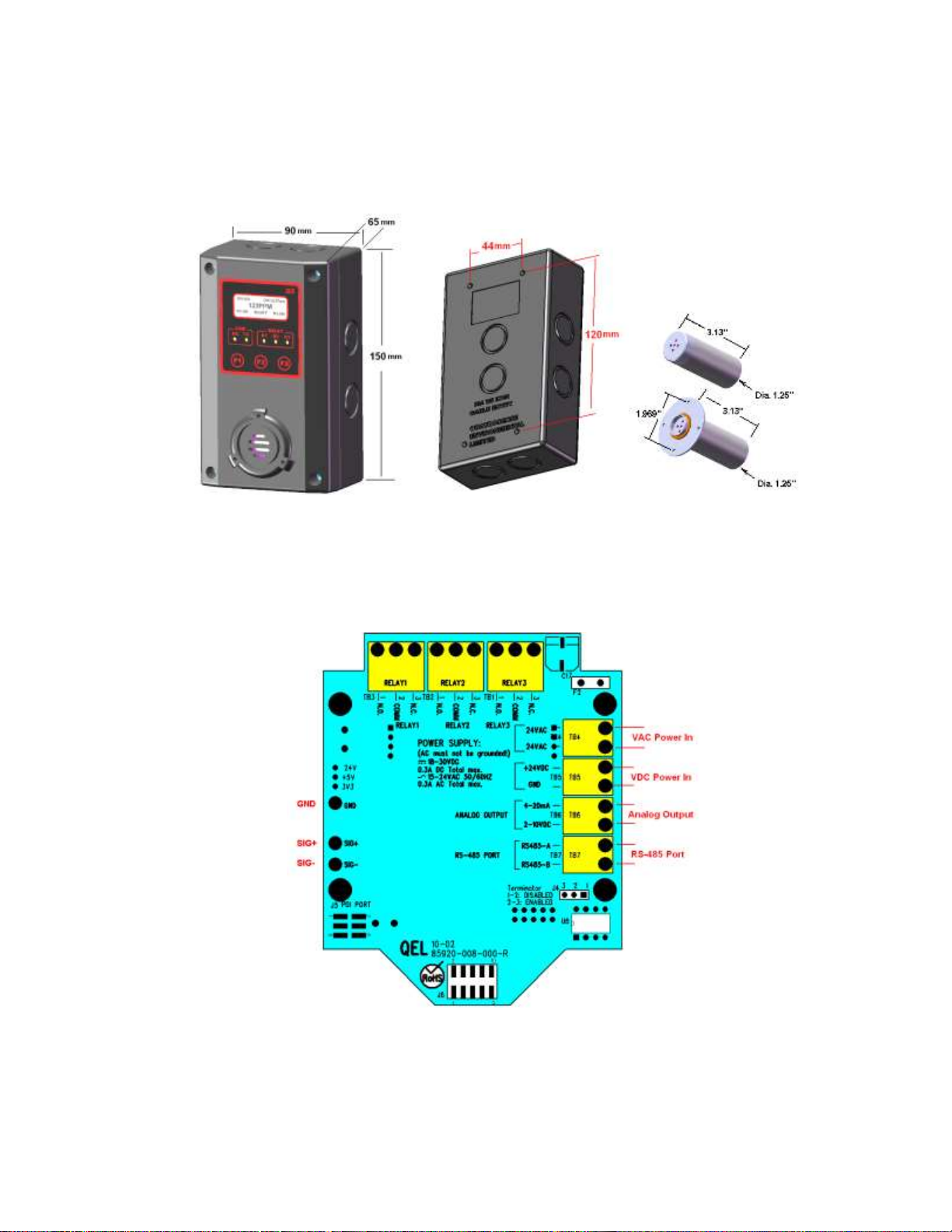

2.2 TERMINALS ............................................................................................................................................. 6

2.2.1 Wire and Cable ............................................................................................................................. 7

2.2.2 Q5 Digital Connection ................................................................................................................. 7

2.2.3 RS-485 Terminator ....................................................................................................................... 7

2.2.4 RS-485 Driver Replacement ......................................................................................................... 8

2.2.5 4-20mA and 1-5VDC / 2-10VDC Analog Output ......................................................................... 8

2.2.6 Relays Output ............................................................................................................................... 9

2.2.7 Note for Q5:.................................................................................................................................. 9

2.2.8 Certification: ................................................................................................................................ 9

3. FUNCTION AND CONFIGURATION ........................................................................................... 10

3.1 INDICATORS .......................................................................................................................................... 10

3.1.1 RS485-TX/RX ........................................................................................................................... 10

3.1.2 Relay 1-3 LED .......................................................................................................................... 10

3.2 TOOL FUNCTION ................................................................................................................................... 11

3.2.1 Enter Main Menu ........................................................................................................................ 11

3.2.2 Hush Buzzer and Relay ............................................................................................................... 11

3.2.3 Reset Latched/Hushed ................................................................................................................ 11

3.2.4 Reset MENU Password .............................................................................................................. 11

3.2.5 Exit Tool Mode ........................................................................................................................... 11

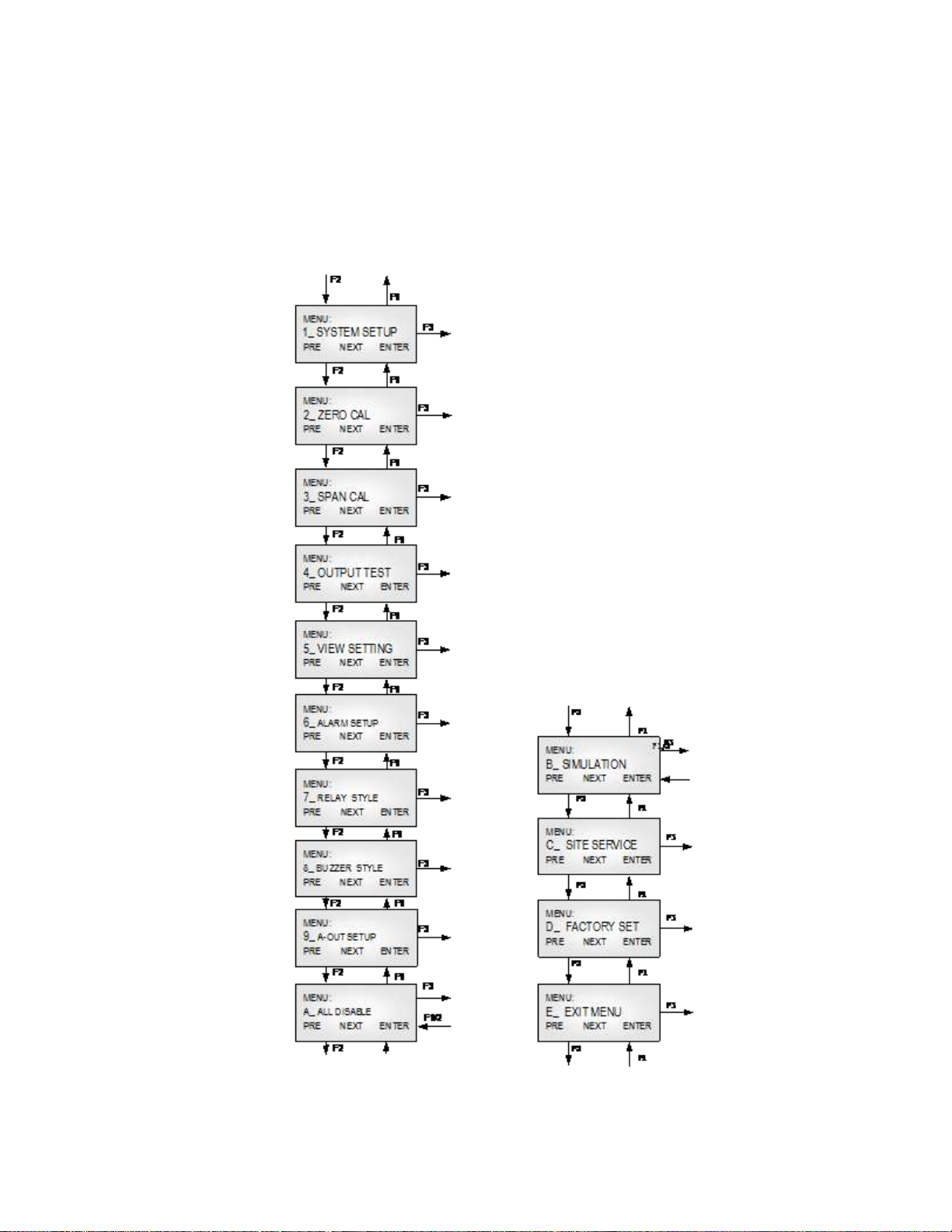

3.3 MAIN MENU TREE ................................................................................................................................ 12

3.4 MENU “1_SYSTEM SETUP” .............................................................................................................. 13

3.4.1 System Settings ........................................................................................................................... 13

3.5 MENU “2_ZERO CAL” ........................................................................................................................ 16

3.5.1 Equipment Required ................................................................................................................... 16

3.5.2 Zeroing Calibration Procedure .................................................................................................. 16

3.6 MENU “3_SPAN CAL” ........................................................................................................................ 17

3.7 MENU “4_OUT TEST” ........................................................................................................................ 18

3.8 MENU “5_VIEW SETTING” ............................................................................................................... 19

3.9 MENU “6_ALARM SETUP” ................................................................................................................ 20

3.10 MENU “7_RELAY STYLE” ............................................................................................................ 21

3.11 MENU “8_BUZZER STYLE” .......................................................................................................... 22

3.12 MENU “9_A-OUT SETUP” ............................................................................................................. 22

3.13 MENU “A_ALL DISABLE” ............................................................................................................ 23

3.14 MENU “B_SIMULATION” ............................................................................................................. 23

3.15 MENU “C_SITE SERVICE” AND “D_FACTROY SET” ................................................................. 23

4. MODBUS PROTOCOL SUPPORTED BY Q5 ............................................................................... 23

5. MAINTENANCE ............................................................................................................................... 24

5.1 DVM CONNECTION FOR 4-20MA MEASUREMENT ................................................................................. 24

5.2 4MA AND 20MA OUTPUT CALIBRATION ............................................................................................... 24

5.3 SMART SENSOR ASSEMBLY REPLACEMENT .......................................................................................... 25

5.3.1 Disassembling ............................................................................................................................ 25

5.3.2 Replacement Procedure.............................................................................................................. 25

5.3.3 Replacement Parts ...................................................................................................................... 26

5.3.4 Accessories ................................................................................................................................. 28

6. TROUBLESHOOTING .................................................................................................................... 29

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

2

Input Power:

24VDC nominal, range 18 to 30VDC, 0.3A DC Total Max.

24VAC nominal, range 15 to 24VAC, 0.3A AC Total Max.

(AC must not be grounded)

Fuse:

F2 on Main Board: Polyswitch 750mA

Polyswitch device resets after the fault is cleared and power to

the circuit is removed.

Sensor:

Combustible gases: Catalytic or NDIR

Toxic gases and Oxygen: Electrochemical

Carbon Dioxide: Non-Dispersive Infra-Red (NDIR)

Sampling:

Diffusion or Pump-through

Panel Indicators:

5 Status LED’s

RS-485 TX Status (Green)

RS-485 RX Status (Green)

Relay1 Status (Red)

Relay2 Status (Red)

Relay2 Status (Red)

Display:

LCD graphic display c/w backlight

Keypad:

3 capacitive touch sensing Keys: F1, F2, F3

READ BEFORE OPERATING

All individuals who have or will have the responsibility of using, maintaining, or servicing this

product must carefully read this manual. The product will perform as designed only if it is

used, maintained, and serviced in accordance with the manufacturer’s instructions.

The Q5 is a state-of-the-art transmitter that can operate as an independent, stand-alone system

or as part of an integrated system. The Q5 connects with analog and digital signals to virtually

any controller, PLC, or DCS. Setup procedures are simplified with user friendly push buttons

and LCD menus.

The Q5 IR-Probe is a Q5 with a remote sensing probe that uses the technique of NDIR (Non

Dispersive Infrared) to monitor the presence of hydrocarbons and carbon dioxide. The distance

between the Q5 and the IR-Probe can up to 100 meters. A 5 meter cable is included in the

package.

1. Specifications

1.1 Electrical/Mechanical Specifications

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

3

Relays:

3 Relays SPDT, Dry contacts

1.0A maximum at 30 VDC (resistive load)

0.3A maximum at 125VAC (resistive load)

Buzzer:

80 db at 10 cm, 2700 Hz

Buzzer 1, 2, 3: Programmable tone

Tone: chirp once / chirp twice / 50% duty cycle / constant ON

Output Signal:

RS-485 with QEL Controller Protocol

Available Controller: M-Controller & Q4 Controller

RS-485 with ModBus protocol

4-20mA and 2-10VDC Analog Signal Output

Enclosure Rating:

IP 66 & NEMA 4, 4X, 12 & 13

Operating Temperature:

-40C to 70C, depends on sensor specification

Ambient Humidity:

5% to 95% RH (non-condensing)

Storage Temperature:

0C to 40C, depends on sensor specification

Size:

150mm X 90mm X 65mm

Weight:

Less than 0.5lbs

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

4

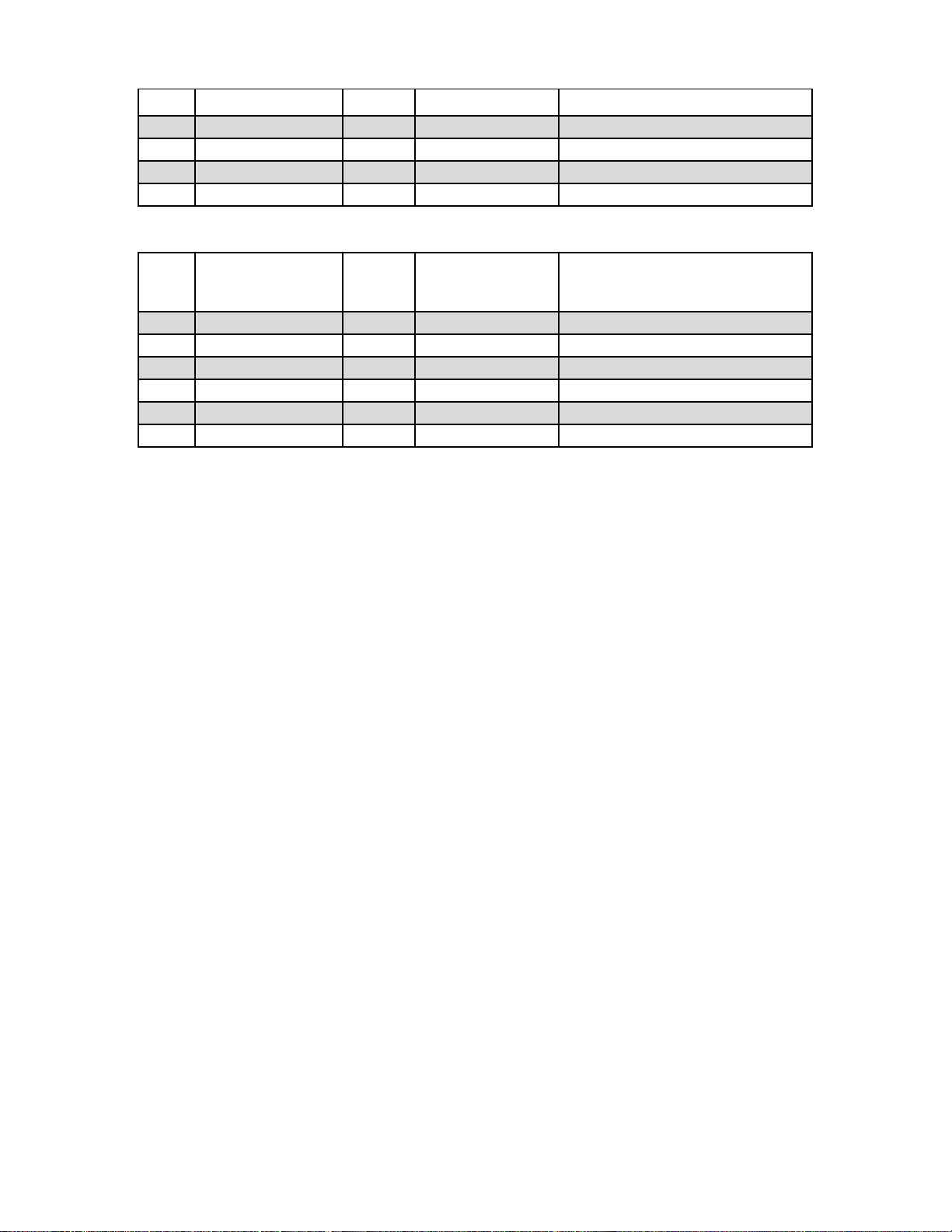

Code

Gas

Symbol

Gas

Density

Span

Operating

Temperature

16

Methane

CH4

Lighter

0 - 100%LEL

-10C to +50C

17

Propane

C3H8

Heavier

0 - 100%LEL

-10C to +50C

18

Hydrogen

H2

Lighter

0 - 100%LEL

-10C to +50C

*19

Combustible

LEL

0 - 100%LEL

-10C to +50C

*20

Ethylene

C2H4

Slightly

Lighter

0 - 100%LEL

-10C to +50C

*21

Iso-Butane

C4H10

Heavier

0 - 100%LEL

-10C to +50C

*22

Iso-Pentane

C5H12

Lighter

0 - 100%LEL

-10C to +50C

*23

Methanol

CH3OH

Lighter

0 - 100%LEL

-10C to +50C

*24

Benzene

C6H6

Lighter

0 - 100%LEL

-10C to +50C

*25

Acetone

CH3CO

Lighter

0 - 100%LEL

-10C to +50C

*26

Butanol, n-Butane

BUTAN

Heavier

0 - 100%LEL

-10C to +50C

Code

Gas

Symbol

Gas

Density

Span

Operating

Temperature

0

Oxygen

O2

0 - 25%VOL

-30C to +55C

Code

Gas

Symbol

Gas

Density

Span

Operating

Temperature

1

Carbon Monoxide

CO

Slightly

Lighter

0 – 250ppm

-20C to +50C

1

Carbon Monoxide

CO

Slightly

Lighter

0 – 1000ppm

-20C to +50C

2

Hydrogen Sulfide

H2S

Heavier

0 – 25ppm

-20C to +50C

2

Hydrogen Sulfide

H2S

Heavier

0 – 100ppm

-20C to +50C

3

Sulphur Dioxide

SO2

Heavier

0 – 6ppm

-20C to +50C

5

Nitrogen Dioxide

NO2

Heavier

0 – 10ppm

-20C to +50C

6

Hydrogen

H2

Lighter

0 – 1000ppm

-20C to +50C

6

Hydrogen

H2

Lighter

0 – 2000ppm

-20C to +50C

7

Hydrogen Cyanide

HCN

Lighter

0 – 50ppm

-20C to +50C

9

Ammonia

NH3

Lighter

0 – 100ppm

-30C to +50C

9

Ammonia

NH3

Lighter

0 – 1000ppm

-30C to +50C

11

Ozone

O3

Heavier

0 – 1ppm

-20C to +40C

13

Chlorine

Cl2

Heavier

0 – 5ppm

-20C to +50C

14

Chlorine Dioxide

ClO2

Heavier

0 – 2ppm

-20C to +40C

96

Arsine

AsH3

Heavier

0 – 1ppm

-20C to +40C

97

Phosphine

PH3

Heavier

0 – 5ppm

-20C to +40C

1.2 Sensor Specifications

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

6

2. Installation

2.1 Enclosures Physical Dimensions

The enclosure is a NEMA 4 rated enclosure and can be wall mounted with 4 screws. To

maintain the NEMA rating, it is important that the conduit opening is sealed upon installation.

2.2 Terminals

Q5 Terminals

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

7

2.2.1 Wire and Cable

Terminal blocks TB1 to TB7 accept 12 AWG to 24 AWG wire. Use 16 AWG or 18 AWG

wire for the power supply in long wiring runs, which can be up to 1km (1,000 meters) long.

We recommend using BELDEN 9841 for communications. This wire has 120 ohm input

impendence, which will eliminate RS-485 communication problems.

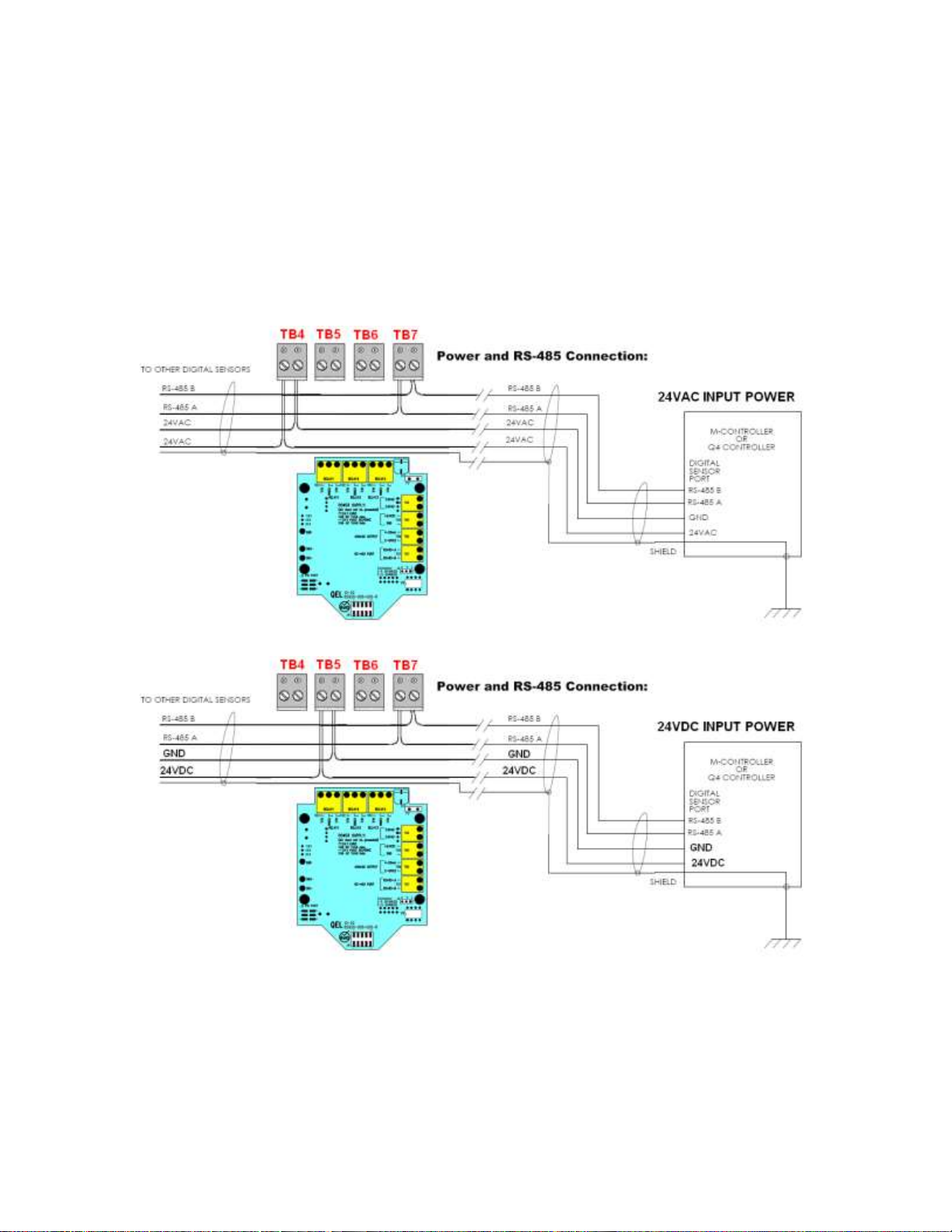

2.2.2 Q5 Digital Connection

2.2.3 RS-485 Terminator

The terminator on each end of the RS485 run is designed to match the electrical impedance

characteristic of the twisted pair wire, and will prevent signal echoes from corrupting the data

on the line. The terminator should be enabled on BOTH ends of the RS485 run. Short and

medium length ModBus/485 runs can operate without the terminating resistor. Longer runs

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

8

may require the terminating resistors. But adding terminator dramatically increases power

consumption.

Factory default setting is disabled terminator.

The Q5 supplies this resistor on the main board, and it is chosen using a jumper at J4.

J4 1-2: Terminator Disabled / OFF (default)

J4 2-3: Terminator Enabled / ON

2.2.4 RS-485 Driver Replacement

RS-485 lines in heavy industrial environments are sometimes subjected to magnetic

disturbances causing sufficient inducted power surges to damage the driver integrated circuit

(IC). This IC (U6) has a socket on the circuit card for ease of replacement in the field.

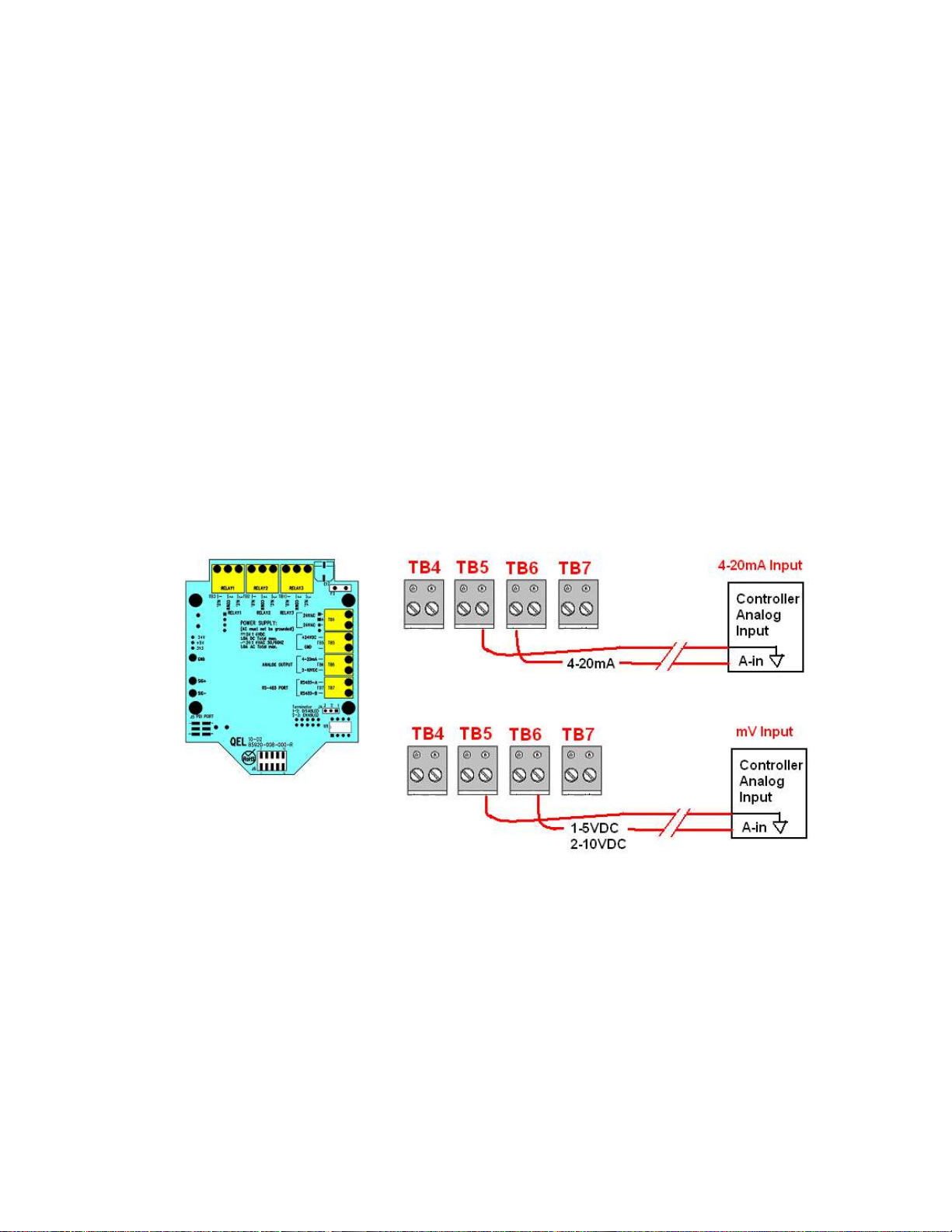

2.2.5 4-20mA and 1-5VDC / 2-10VDC Analog Output

The Q5 provides one-channel 4-20 milliamp analog outputs and programmable 1-5VDC / 210VDC analog output at the same time. The maximum output impedance is 600 ohms for the

4-20mA output. The maximum output current is 10 mA for the 1-5VDC/2-10VDC output.

Test point SIG+ and SIG- are used to measure the current inline when the Q5 is working in the

field.

The 1-5VDC/2-10VDC output can be selected through the menu. Default setting is 1-5VDC

output.

The analog output may be defined in complex ways allowing assignment of different values to

both 4 milliamps and 20 milliamps. You may even assign a gas concentration to 4 mA, which

is higher than the concentration assigned to 20 milliamps. The Q5 will draw a straight line

between them. There is no need to assign gas concentration to 1V-5VDC/2V-10VDC. When

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

9

the Q5 outputs 4mA, it also outputs 1VDC or 2VDC. When the Q5 outputs 20mA, it also

outputs 5VDC or 10VDC, which follows the 4-20mA output.

If there is any fault found in the Q5, it will output 2.5mA and 1VDC at 2-10V output or

0.5VDC at 1-5VDC output to indicate the fault.

2.2.6 Relays Output

The Q5 has three onboard programmable Single-Pole Double-Throw (SPDT) relays. These

relays can be used to control other equipment, such as fans, lights, horns, etc. eliminating the

need for a separate controller.

Three terminal blocks (TB1, TB2 and TB3) are located on the main board. Each relay can be

programmed individually.

Switching capability of each relay is:

1.0 A maximum resistive load at 30 VDC

0.3A maximum resistive load at 125VAC

2.2.7 Note for Q5:

Avoid running communication wires or sensor input wires next to AC power wires or the relay

output wires. These can be sources of noise that can affect signal quality.

When the Q5 input power is AC, the 24VAC must not be grounded. A dedicated floating

24VAC may be needed if other nodes on the network are grounded, otherwise a DC power

supply is recommended.

2.2.8 Certification:

The Q5/B5 series have been certified to the following Standard:

Safety requirement for Electrical Equipment for Measurement, Control, and Laboratory UsePart 1: General Requirements CAN/CSA-22.2 No. 61010-1 Third Edition, Dated May 11, 2012; And

Safety Requirements for Electrical Equipment for measurement, Control, and Laboratory Use-Part 1:

General Requirements UL 61010-1 Third Edition, Dated May 11, 2012.

Installation must be in accordance with ANSI/NFPA 70, National Electrical Code (NEC); the

Canadian Electrical Code (CEC), Part I, CSA C22.1, and CSA C22.2 No. 0; and the

Manufacturers’ installation instructions

The Q5/B5 series have not been tested for Life Safety Applications and are not to be used in Life

Safety Applications in jurisdictions that require this certification.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

10

3. Function and Configuration

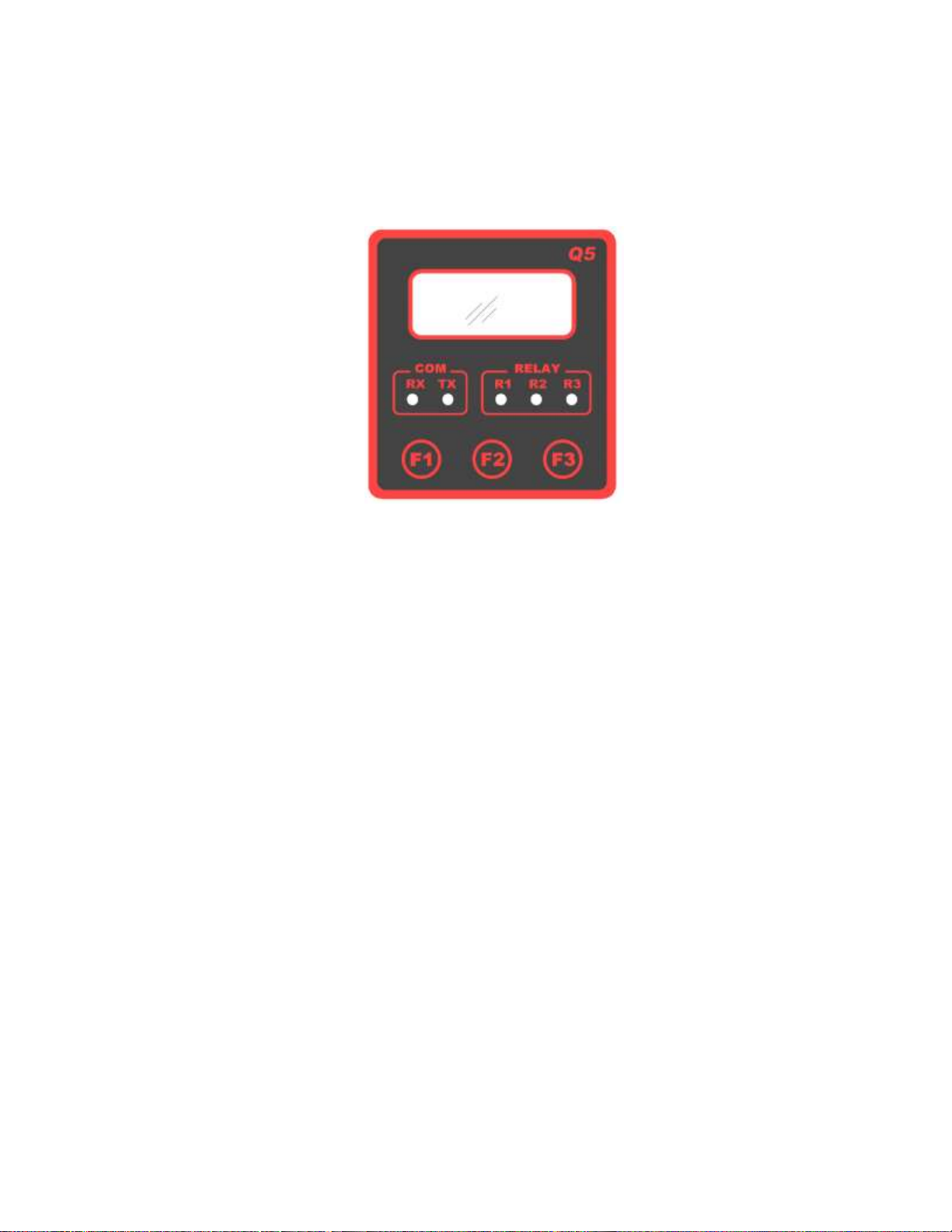

3.1 Indicators

The indicators consist of five LED’s – two to indicate RS-485 digital communication, three to

indicate the status of relays 1-3.

3.1.1 RS485-TX/RX

When the Q5 is connected to a controller system via RS-485, the traffic of the communication

can be monitored visually through the two RS-485 indicators. One is RX LED, which

indicates the data stream received in from the controller. The other is TX LED, which

indicates the data stream out of the Q5.

Note: If the TX LED or the RX LED is always ON, is indicative of a communication

problem. See Troubleshooting for RS-485.

3.1.2 Relay 1-3 LED

Indicate the status of each relay. When the relay is actuated/closed, the relay LED is ON.

When the relay is de-actuated/open, the relay LED is OFF.

Note: If you set the relay to be Normally Energized (Fail Safe), the relay LED will turn

ON at non-alarm state and turn OFF at alarm state, because the LED reflects the relay

coil status.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

11

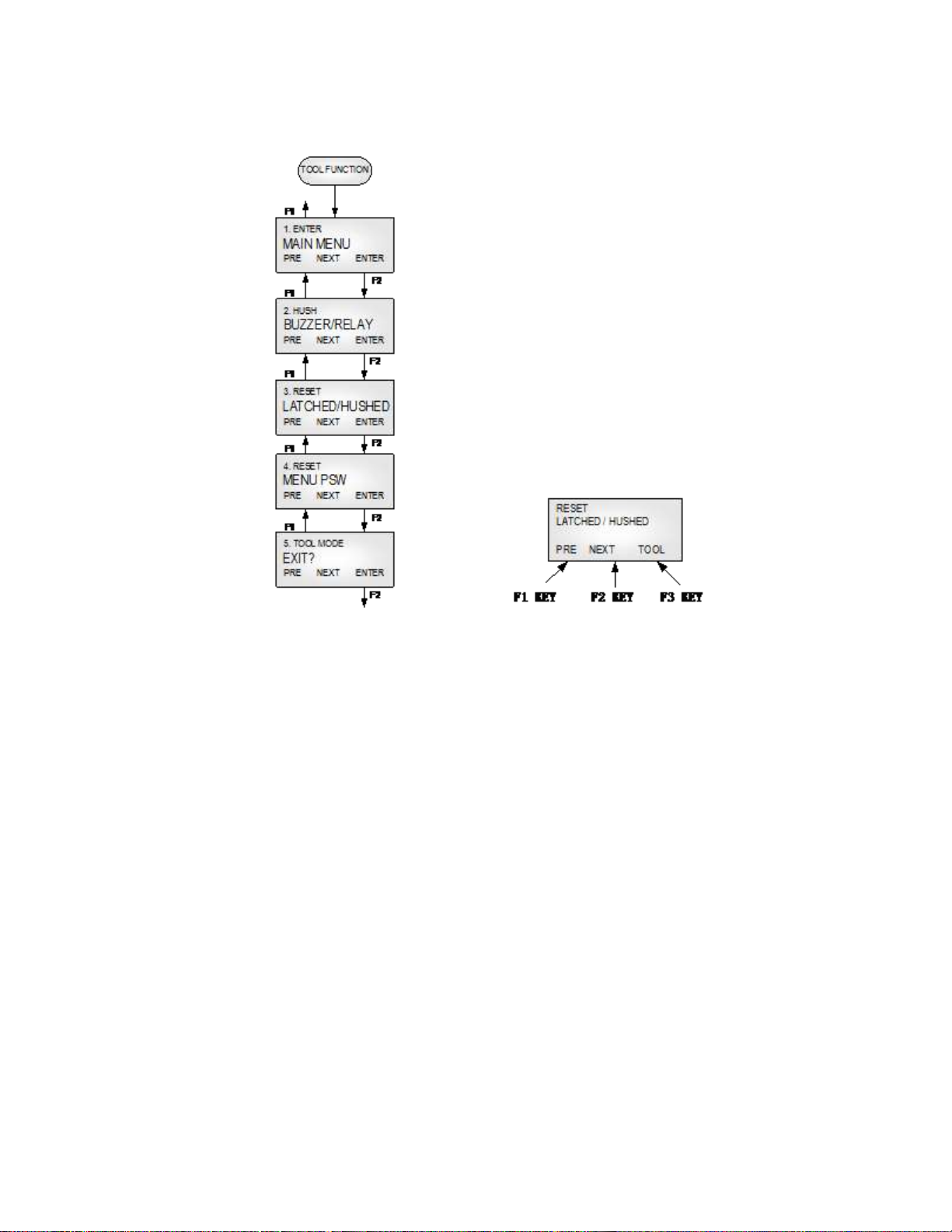

3.2 Tool Function

Press key [F3] to enter tool functions that might be used frequently in the field.

3.2.1 Enter Main Menu

Press key [F1] to browse previous item of the current menu.

Press key [F2] to browse next item of the current menu.

Press key [F3] to enter the main menu for more configuration and settings.

3.2.2 Hush Buzzer and Relay

Press key [F3] to silence the buzzer and buzzer-style relays.

3.2.3 Reset Latched/Hushed

To acknowledge a latched condition or a hushed condition, press key [F3] to reset latched

relays and hushed buzzer for which the alarm condition has been removed. If the alarm

condition (e.g. high gas concentration) is still present the relay(s) will not reset.

3.2.4 Reset MENU Password

If you forgot the main menu password, you can reset the menu password to default password

“4321” by entering a correct active code. For the active code, contact QEL.

3.2.5 Exit Tool Mode

Press key [F3] to return to monitoring mode.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

12

3.3 Main Menu Tree

The main menu is password protected. Once the password is accepted, you are allowed into

the main menu tree.

Factory default password is 4321.

Note: While in the menu tree, all normal monitoring operations stop. The alarm status

does not change.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

13

Password:

Default password is 4321.

Address:

M-Controllers support RS-485 addressing from 0 to 31 for digital sensors.

Q4 Controllers support RS-485 addressing from 0 to 3 for digital sensors.

The Q5 RS-485 address can be defined from 0 to 255. Default is 3.

Note: In ModBus protocol, the address 0 is for broadcast.

Baud rate:

Define baud rate for RS-485 communication with QEL controller protocol,

ModBus protocol or BACnet protocol.

Q5 default baud rate is 4800 bps.

Scroll Rate:

In normal operation, the sensor and relay status information scrolls

automatically. Set the number of seconds for each item to be displayed.

Default value is 3 seconds.

Backlight:

The LCD backlight can be set to Always Off, Always On and Auto Power

Saving mode. In Auto Power Saving mode, the backlight will turn on for 10

seconds after any key has been pressed. Default setting is Always ON.

4mA Cal

20mA Cal

1V Cal

2V Cal

5V Cal

10V Cal:

These values are established during factory calibration for the 4-20mA

analog output and should not require recalibration in the field. Do not

attempt to modify these settings in the field.

Changing these values will change the analog output signal scale.

Warning: This procedure is part of the factory setup. In most

circumstances it will not be necessary to perform this procedure in the

field. These functions require the use of precision reference

instrumentation.

New

Password:

The new password can be any combination of up to four digits. Default

password is 4321.

Warning: Be sure that you record the new password in a safe and

secure location!

3.4 Menu “1_SYSTEM SETUP”

The system setup subdivision contains general settings for monitor operations,

communications and 4-20mA calibrations.

3.4.1 System Settings

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

14

Protocol:

When Q5 is connected to an M-Controller or a Q4-Controller, the protocol

should be set to OptoMux. The Q5 Default protocol is OptoMux.

The Q5 also supports ModBus protocol, responds as a ModBus Slave using

RTU protocol. When it’s set to ModBus, the parity bit can be defined as

EVEN, ODD and No Parity.

Display

Mode:

Display Instant: displays instantaneous gas concentration

Display Average:

o Displays STEL (15min average reading)

o Displays TWA (8 hour average reading)

o Displays daily peak

Display Alarm: displays alarm 1-8 status

Display Relay: displays relay 1-3 status

Display Buzzer: displays buzzer 1-3 status

Display A-Out mA: displays current 4-20mA output

Display A-Out VDC: displays current VDC output

Display Clock: displays real time clock

If there is nothing to display, the unit will display “Running…”

Auto Zero:

When AutoZero is set to ON, the unit will gather the lowest reading in 7-day

period and set the unit into Zeroing Calibration mode so that the lowest

reading goes to zero. When AutoZero is set to OFF, the unit will not adjust

its own zero and work off the last manual or factory calibration. Default

value is OFF.

NOTE: AutoZero works best in situations where the building will

purge at night (or over a weekend) to a zero concentration of target gas.

Key

Beeper:

ON: Beeping when keypad is touched

OFF: No beeping when keypad is touched

Restore

Default:

Note: Don’t do this if you don’t have calibration gas and precision

reference instrumentation to calibrate the unit

To load defaults to factory settings, to restore the unit to correct operation.

The settings below will be restored to default values:

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

15

-Password, -Baud rate, -Scroll rate, -Backlight, -Display mode, -Key beeper,

-LCD contrast, -Gas type on the Sensor Board, -Alarm settings, -

Relay/Buzzer settings, and 4-20mA/1-5VDC settings.

The unit needs to change the gas type if the sensor on the sensor board is not

the default gas type: CO, CH4 or O2. Contact QEL for instructions.

The analog output 4-20mA/1-5VDC has to be calibrated if needed.

Zero and span calibrations are needed.

ADJ Clock:

Adjust real time clock.

ADJ

Contrast:

Adjust the LCD contrast. Valid values are between 10 (light) and 50 (dark).

Default is 21.

Check

Battery

The sensor board is equipped with a coin battery. This setting will enable or

disable the Q5 to check the battery voltage and beep for a low battery level.

Default is ON.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

16

2_ ZERO CAL

CONTINUE?

XXPPM

3.5 Menu “2_ZERO CAL”

The Q5 is calibrated using a two-point calibration process. First, use a “Zero Gas”, then use a

“CAL Gas” containing a known concentration of a standard reference gas, to set the second

point of reference.

3.5.1 Equipment Required

A cylinder of Zero Gas, (clean air or nitrogen).

A cylinder of Cal Gas

Flow Limiting Regulator(s) 0.2 to 1.0 lpm

Tubing

3.5.2 Zeroing Calibration Procedure

“2_ ZERO CAL:”

Press key [F3] and the device will show the calibration notice and then ask if you want

to continue. The middle line will display the current concentration.

Apply the Zero Gas.

Wait for about 3 minutes or until the reading is stable.

Press key [F3] to confirm Zeroing Cal.

When the device is in Zeroing CAL, it will take 3 seconds to 20 seconds to complete.

When the zeroing CAL operation is over, the device will display “Accepted” and

return to “2_ZERO CAL”.

Make sure there is no Cal Error displayed. If Cal Error is reported, repeat the

procedures above. If the Cal Error is still showed up, the sensor may be expired.

Remove the gas.

Exit the menu to Monitoring Mode.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

17

3_ SPAN CAL

CAL GAS:

> XXX

CONTINUE?

XXPPM

3.6 Menu “3_SPAN CAL”

“3_ SPAN CAL”

Press key [F3] and the device will ask for the CAL GAS, input the concentration of the

calibration gas.

Press key [F3] and the device will show the calibration notice and then show the flow

rate for the span calibration. Press any key to continue, and then the device will ask you

if you want to continue. The middle line will display the current concentration.

Apply the calibration gas.

Wait for about 3 minutes or until the reading is stable.

Press key [F3] to confirm SPAN CAL.

When the device is in span cal, it will take 10 seconds to 1 minute to complete.

When the span cal operation is over, the device will display “Accepted” and return to

“3_SPAN CAL”.

Make sure there is no Cal Error displayed. If Cal Error is reported, repeat the

procedures above. If the Cal Error is still showed up, the sensor maybe expired.

Remove the gas.

Exit menu to Monitoring Mode.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

18

3.7 Menu “4_OUT TEST”

During system installation and testing, it may be necessary to force relays and buzzers on and

off.

The Relay Testing feature allows the user to force the actuation of each relay. This function

forces an Actuate vs. De-actuate action, not an energized vs. non-energized action. Therefore

the user must be aware of these relays, which have been defined as normally energized or not

normally energized.

The 4mA (1VDC/2VDC) and 20mA (5VDC/10VDC) outputs can be tested too.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

19

3.8 Menu “5_VIEW SETTING”

This function is to verify the settings for the alarms, relays, buzzers and analog outputs.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

20

Disabled or

Enabled:

Each alarm may be individually set to be enabled or disabled. If the alarm

is disabled, the alarm will not be used to calculate or trigger anything.

Default: Alarm 1 to Alarm 4 is enabled. Alarm 5 to Alarm 8 is

disabled.

Input:

One of five inputs is selected to calculate the alarm condition status to

trigger the selected outputs:

INSTANT: instantaneous gas reading.

15 MIN AVG (STEL): Short Term Exposure Limit, average

reading over 15 minutes.

8 HOURS AVG (TWA): 8-hour Time Weighted Average, average

reading over 8 hours.

DAILY PEAK: daily peak reading.

FAULT: If the unit reports any faults, no matter the gas

concentration, it will trigger the selected outputs.

Alarm On

and

Alarm Off

Reading:

If Alarm On is greater than or equal to Alarm Off:

Alarm On: Sets the concentration at or above which the relay will actuate.

Alarm Off: Sets the concentration at or below which the relay will deactuate.

If Action On is less than Action Off:

Action On: Sets the concentration below that the relay will actuate.

Action Off: Sets the concentration above that the relay will de-actuate.

Trigger:

Trigger Outputs: Relay 1, Relay 2, Relay 3, Buzzer 1, Buzzer 2, Buzzer 3

3.9 Menu “6_ALARM SETUP”

The Q5 supports alarm 1 to alarm 8.

Alarm is a programmable condition that can receive a selectable input and trigger relays and

buzzers.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

21

Enabled:

Each relay may be individually set to be enabled or disabled. If it’s

disabled, the relay will always de-actuate no matter what the current gas

concentration.

Default is Enabled.

Normally

Deenergized:

Each relay may be individually set to be normally energized or normally

de-energized.

Default is normally de-energized.

Latching:

Each relay may be set to latch in actuate status until acknowledged by a

front-panel action.

Default is Non-Latching.

ON Delay:

“Delay on Actuation” or “Delay on Make”. For each relay a separate time

delay may be set from 0 to 990 seconds before an alarm condition will

cause the relay to actuate.

Default is 5 seconds.

OFF Delay:

“Delay on De-Actuation” or “Delay on Break”. For each relay a separate

time delay may be set from 0 to 990 seconds before a return to a nonalarming signal condition will cause the relay to de-actuate.

Default is 5 seconds.

Style:

Normal Relay Style: Work as normal relay.

Buzzer Style Relay: When the relay is used to control a buzzer or horn.

Working as a buzzer style will make the relay have the same function as

the buzzer. It will be switched off when performing the Hush

Buzzer/Relay function in the Tool Menu.

Default is OFF.

3.10 Menu “7_RELAY STYLE”

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

22

Input:

One of four inputs is selected to calculate the analog outputs:

INSTANT: instantaneous gas reading.

15 MIN AVG (STEL): Short Term Exposure Limit, average

reading over 15 minutes.

8 HOURS AVG (TWA): 8-hour Time Weighted Averages,

average reading over 8 hours.

DAILY PEAK: daily peak reading.

Out 4mA at

Conc:

Input the gas concentration at which 4mA is output.

Out 20mA at

Conc:

Input the gas concentration at which 20mA is output.

VDC Output:

VDC Output can be selected from:

1-5VDC or 2-10VDC

3.11 Menu “8_BUZZER STYLE”

The buzzer style is almost identical to that of the relays, except the style that represents the

buzzer tone options:

Tone 1: Chirp once.

Tone 2: Chirp twice.

Tone 3: Intermittent 50% duty cycle.

Tone 4: Continuous.

The menus are identical to those for the Relay Style.

3.12 Menu “9_A-OUT SETUP”

The Q5 will compare the concentration at 4mA and the concentration at 20mA. You may

assign a larger concentration for 4mA than for 20 mA; the Q5 will still stretch a straight line

signal between the two points and then convert the selected gas reading to analog output.

Note: The analog output cannot be disabled.

Note: When the sensor has a fault, the output will be 2.5mA to indicate fault status.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

23

3.13 Menu “A_ALL DISABLE”

This function is for calibration, system testing etc. When All Disable is ON, the status of the

relay, buzzer and analog output, etc., will freeze in their current state.

Default is OFF.

3.14 Menu “B_SIMULATION”

Simulation mode is used to assist in testing the installation before commissioning. When

simulation is enabled, the unit will not detect gas concentrations; it will display the simulated

value and use it to calculate the status of relays and buzzers, as well as the 4-20mA analog

output. This feature is available for evaluating the user settings and testing the installation

(e.g.: the activation of the valve, fan speed, relay set points, etc. can be verified.)

Any concentration between 0ppm and 9999ppm can be simulated.

3.15 Menu “C_SITE SERVICE” and “D_FACTROY SET”

Factory service staff access only. The customer has no need to operate it.

4. MODBUS Protocol Supported By Q5

For ModBus protocol, please contact QEL.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

24

5. Maintenance

5.1 DVM connection for 4-20mA measurement

Interrupt the 4-20mA signal going from the Q5 to the controller (causing a fault):

o Switch the DVM to measure DC current, on the main board plug the negative

probe into GND and plug the positive probe into SIG -.

Monitor the 4-20mA signal going from the Q5 to the controller (not causing a fault):

o Switch the DVM to measure DC current, on the main board plug the negative

probe into SIG - and plug the positive probe into SIG +.

5.2 4mA and 20mA Output Calibration

These values are established during the factory 4-20mA output calibrations and should not

require recalibration in the field. Do not attempt to modify these settings in the field.

Changing these values will change the analog output signal scale.

Entry [Menu]-->[System Setting]

Choose [Out 4mA CAL]:

1. Press key [F3] to output the 4mA signal.

2. Connect the DVM to the unit as described above.

3. Press key [F1] or key [F2] to adjust the current to 4.00mA to 4.05mA.

4. Press key [F3], then the settings will be accepted and saved.

Choose [Out 20mA CAL]:

1. Press key [F3] to output the 20mA signal.

2. Connect the DVM to the unit as described above.

3. Press key [F1] or key [F2] to adjust the current to 20.00 to 20.05mA.

4. Press key [F3], then the settings will be accepted and saved

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

25

5.3 Smart Sensor Assembly Replacement

5.3.1 Disassembling

Observe all safety and electrical codes and regulations before removing enclosure lid.

Important: Calibrate the transmitter whenever a component is replaced. But if you replace a

smart sensor assembly with a sensor onboard from QEL, you don’t need to recalibrate the

transmitter, as all the calibration information has been stored in the smart sensor board in the

factory process.

5.3.2 Replacement Procedure

To replace the entire smart sensor assembly, complete the following steps:

1. Power down the transmitter.

2. Remove the four screws securing the enclosure lid assembly to the base enclosure and

remove the enclosure lid assembly.

3. Remove the two screws securing the smart sensor board and remove the smart sensor

board from the lid assembly

4. Feed the O-ring over the sensor on the new smart sensor assembly

5. Plug the new smart sensor assembly and secure with two screws. Ensure that the

connectors are correctly matched. Incorrect installation may damage the sensor

assembly and/or the display board.

85950-001-000 RF August 7, 2015

26

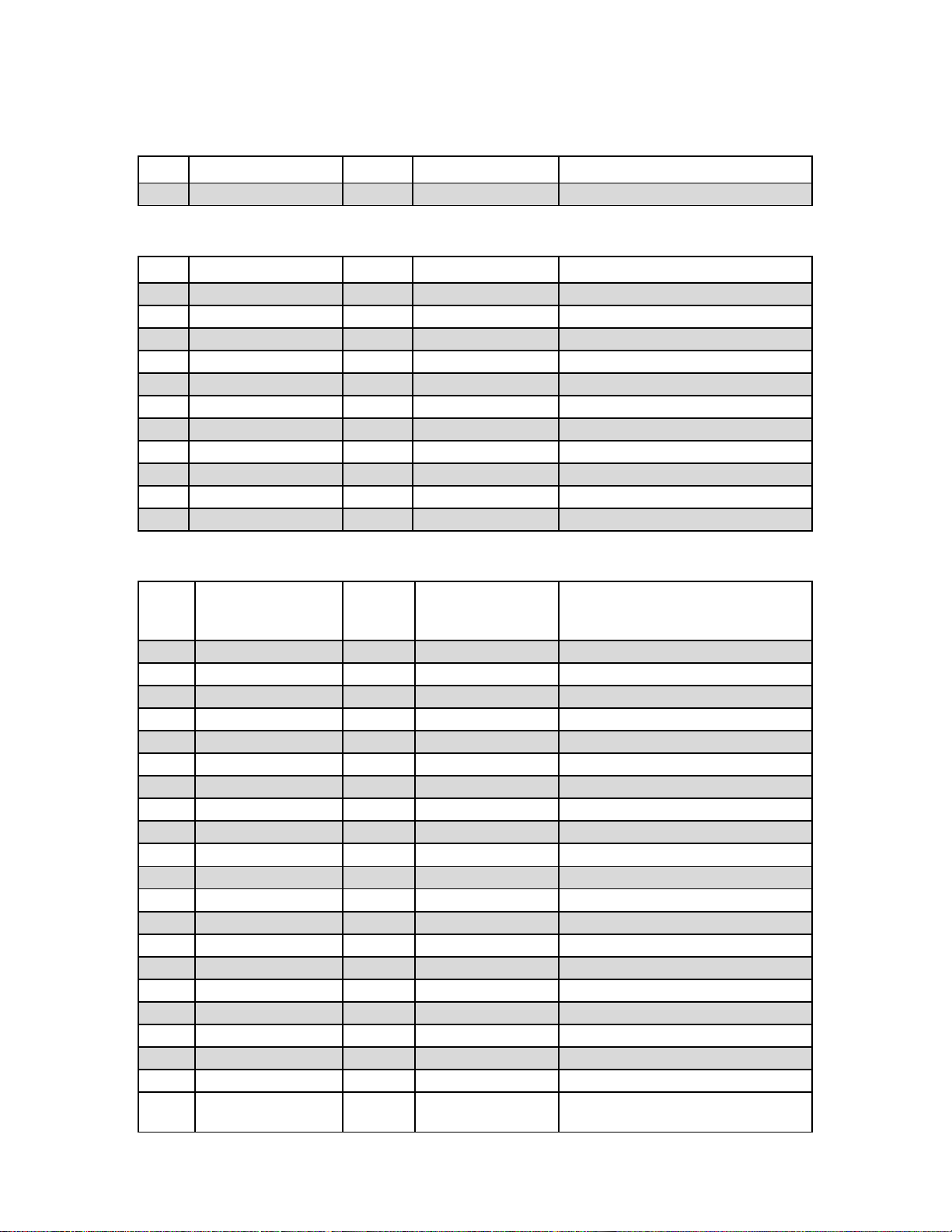

5.3.3 Replacement Parts

Code

Gas

Symbol

Span

Smart Sensor Assembly

0

Oxygen

O2

0 - 25%VOL

85930-016-000

Code

Gas

Symbol

Span

Smart Sensor Assembly

16

Methane

CH4

0 - 100%LEL

85930-017-016

17

Propane

C3H8

0 - 100%LEL

85930-017-017

18

Hydrogen

H2

0 - 100%LEL

85930-017-018

*19

Combustible

LEL

0 - 100%LEL

85930-017-019

*20

Ethylene

C2H4

0 - 100%LEL

85930-017-020

*21

Iso-Butane

C4H10

0 - 100%LEL

85930-017-021

*22

Iso-Pentane

C5H12

0 - 100%LEL

85930-017-022

*23

Methanol

CH3OH

0 - 100%LEL

85930-017-023

*24

Benzene

C6H6

0 - 100%LEL

85930-017-024

*25

Acetone

CH3CO

0 - 100%LEL

85930-017-025

*26

Butanol, n-Butane

BUTAN

0 - 100%LEL

85930-017-026

Code

Gas

Symbol Span

Smart Sensor Assembly

1

Carbon Monoxide

CO

0 – 250ppm

85930-018-001

1

Carbon Monoxide

CO

0 – 1000ppm

85930-018-201

2

Hydrogen Sulfide

H2S

0 – 25ppm

85930-018-002

2

Hydrogen Sulfide

H2S

0 – 100ppm

85930-018-202

3

Sulphur Dioxide

SO2

0 – 6ppm

85930-018-003

5

Nitrogen Dioxide

NO2

0 – 10ppm

85930-018-005

6

Hydrogen

H2

0 – 1000ppm

85930-018-006

6

Hydrogen

H2

0 – 2000ppm

85930-018-206

7

Hydrogen Cyanide

HCN

0 – 50ppm

85930-018-007

9

Ammonia

NH3

0 – 100ppm

85930-018-009

9

Ammonia

NH3

0 – 1000ppm

85930-018-209

11

Ozone

O3

0 – 1ppm

85930-018-011

13

Chlorine

Cl2

0 – 5ppm

85930-018-013

14

Chlorine Dioxide

ClO2

0 – 2ppm

85930-018-014

96

Arsine

AsH3

0 – 1ppm

85930-018-096

97

Phosphine

PH3

0 – 5ppm

85930-018-097

97

Phosphine

PH3

0 – 1ppm

85930-018-297

98

Silane

SiH4

0 – 50ppm

85930-018-098

99

Germane

GeH4

0 – 2ppm

85930-018-099

100

Diborane

B2H6

0 – 2ppm

85930-018-100

Code

Gas

Symbol

Span

Smart Sensor Assembly

Q5 Operation And Maintenance Manual

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

27

4

Nitric Oxide

NO

0 –100ppm

85930-018-004

8

Hydrogen Chloride

HCl

0 – 30ppm

85930-018-008

12

Ethylene Oxide

ETO

0 – 20ppm

85930-018-012

101

Hydrogen Bromide

HBr

0 – 30ppm

85930-018-101

Code

Gas

Symbol Span

Smart Sensor Assembly

15

Carbon Dioxide

IR-CO2

0 –5000ppm

85930-019-015

15

Carbon Dioxide

IR-CO2

0 – 5%VOL

85930-019-215

15

Carbon Dioxide

IR-CO2

0 – 20%VOL

85930-019-315

15

Carbon Dioxide

IR-CO2

0 – 100%VOL

85930-019-415

16

Methane

IR-CH4

0 – 100%LEL

85930-019-016

16

Methane

IR-CH4

0 – 100%VOL

85930-019-216

85950-001-000 RF August 7, 2015

28

5.3.4 Accessories

Pump-thru & Splash Guard Kit

Calibration Cap Kit

SKU#: 85930-006-000 SKU#: 85930-007-000

Q5 Operation And Maintenance Manual

Duct Mount Adapter Kit Free stand or Duct mount IR-Probe

SKU#: 85930-040-000

Note: For Duct Mount Installation, Q5 needs both the Pump-thru Kit and Duct Mount Kit.

Q-View & USB-RS485 Converter Kit SKU#: 85930-004-000

Q-View is Windows based software running on a PC to used configure Q5 sensors through an

RS-485 network. It supports the QEL controller protocol (OptoMux) and ModBus protocol.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

29

SYMPTOMS

PROBABLE CAUSE

SUGGESTED SOLUTION

RS-485

RX LED or

TX LED constantly ON

RS-485 bus connection has a

problem

RS-485 driver U6 is damaged

Controller side RS-485 driver

has problem

Disconnect the cable to isolate

the problem

Replace U6 IC on main board

Replace the RS-485 driver on

the controller

No response to gas

Sensor screen is dirty

Sensor has expired

Clean sensor opening

Replace smart sensor assembly,

see Replacement Parts

Apparent false alarm

Puff of gas

Not properly calibrated

Solvent fumes or interference

from high levels of interfering

gas

Radio frequency interference

Monitor is functioning

Recalibrate

Remove source of interfering gas

Check that grounding and

shielding is correct

No signal at controller

Maximum distance reached

Controller does not operate

Verify loop resistance, change

wire AWG

Troubleshoot controller

6. Troubleshooting

This troubleshooting guide is intended as an aid in identifying the cause of unexpected

behavior and determining whether the behavior is due to normal operation or an internal or

external problem.

85950-001-000 RF August 7, 2015

Q5 Operation And Maintenance Manual

30

WARRANTY STATEMENT

The information contained in this manual is based upon data considered accurate; however, no

warranty is expressed or implied regarding the accuracy of this data. All QEL equipment is warranted

against defects in material and workmanship for a period of two years from date of shipment with the

following exceptions:

Electrochemical Sensors (Toxic) Six Months

Catalytic Sensors (Combustible) One Year

During the warranty period we will repair or replace, at our discretion, any components or complete

units that prove, in our opinion, to be defective. We are not liable for consequential or incidental

damage to auxiliary interfaced equipment.

A returned material authorization number should be obtained from the factory prior to returning any

goods. All return shipments must be shipped freight prepaid and a copy of the maintenance records

should accompany the unit concerned.

Warranty should be considered F.O.B. the factory. Labour and travel time are chargeable for any field

site visits required for warranty work.

LIMITED LIABILITY

All QEL systems shall be installed by a qualified technician/electrician and maintained in strict

accordance with data provided for individual systems in the form of installation/maintenance manuals.

QEL assumes no responsibility for improper installation, maintenance, etc., and stresses the

importance of reading all manuals. QEL shall not be responsible for any liability arising from

auxiliary interfaced equipment nor any damage resulting from the installation or operation of this

equipment.

QEL’s total liability is contained as above with no other liability expressed or implied, as the

purchaser is entirely responsible for installation and maintenance of systems.

This warranty is in lieu of all other warranties, expressed or implied, and no representative or person is

authorized to represent or assume for QEL any liability in connection with the sales of our products

other than that set forth herein.

NOTE: Due to on-going product development, QEL reserves the right to change specifications

without notice and will assume no responsibility for any costs as a result of

modifications.

For further information or assistance, contact:

85950-001-000 RF August 7, 2015

Loading...

Loading...