Page 1

Operator’s Guide

™

PowerScout

3037 Power Meter

Includes:

ViewPoint™ Software

January 14, 2016

Page 2

Operator’s Guide: PowerScout™ Power Meters ©2016 DENT Instruments, Inc. All rights reserved.

This manual may not be reproduced or distributed without written permission from DENT Instruments.

PowerScout™, ViewPoint™, and PhaseChek™ are trademarks of DENT Instruments, Inc. Windows®,

Windows® Vista, Windows® 7, Windows® 8, Windows® XP, and Notepad® are registered trademarks of

Microsoft Corporation.

ii

Page 3

Table of Contents

INTRODUCTION .......................................................................................................................... 6

PowerScout 3037 Serial/ PowerScout 3037 Ethernet ........................................................................................6

Unpacking the Unit .................................................................................................................................. 6

Meter Anatomy ....................................................................................................................................... 8

PowerScout™ Meter Safety Summary and Specifications ....................................................................... 9

Symbols on Equipment ............................................................................................................................ 9

PowerScout™ Résumé de Sécurité et Spécifications ............................................................................. 12

Symboles des Equipements ................................................................................................................... 12

PowerScout 3037 Technical Specifications ............................................................................................ 14

PREPPING FOR FIELD INSTALLATION .............................................................................................. 16

Installing the ViewPoint Software ......................................................................................................... 16

Connecting a Communication Cable...................................................................................................... 17

Connecting and Communicating via a USB or RS-485 Adapter ........................................................................17

Connecting and Communicating via an Ethernet (TCP/IP) Connection ...........................................................22

Communications LEDs ........................................................................................................................... 25

PS3037 Serial ....................................................................................................................................................25

PS3037 Ethernet ...............................................................................................................................................25

Version Control ...................................................................................................................................... 25

Meter Setup ........................................................................................................................................... 26

Entering Wiring Information for an Element ...................................................................................................27

Selecting a Scalar ..............................................................................................................................................29

Comms Setup ......................................................................................................................................... 31

RS-485 Settings.................................................................................................................................................32

BACnet Device Settings ....................................................................................................................................32

Ethernet Settings ..............................................................................................................................................32

Connecting the Ports ............................................................................................................................. 32

Establishing Communication Protocol ................................................................................................... 33

Switching between BACnet and Modbus Mode ..............................................................................................33

FIELD INSTALLATION .................................................................................................................. 36

Mounting a PowerScout 3037 ............................................................................................................... 36

Wiring Connections on the PowerScout 3037 ....................................................................................... 37

Completing the Field Installation ........................................................................................................... 38

Using the Pulse Output Port Function ................................................................................................... 38

Modbus Output Port Registers ........................................................................................................................39

BACnet Output Port Objects ............................................................................................................................39

iii

Page 4

Wiring CTs .............................................................................................................................................. 40

Connecting Split-Core Style Millivolt CTs to a Load .........................................................................................41

Connecting RōCoil CTs to a Load ......................................................................................................................42

CT Wire Lead Polarity .......................................................................................................................................44

Connecting Voltage ................................................................................................................................ 44

Powering the Meter .........................................................................................................................................45

PowerScout Single-Phase Connections ............................................................................................................45

PowerScout 3037 Wiring Diagrams ....................................................................................................... 47

Three-wire Delta ..............................................................................................................................................47

Four-wire Wye ..................................................................................................................................................48

Two-wire Single Phase .....................................................................................................................................49

Three-wire Single Phase ...................................................................................................................................50

Verifying Installation with PhaseChek ................................................................................................... 51

Verifying Installation with the ViewPoint Software .............................................................................. 53

Real-Time Values ..............................................................................................................................................53

Read/Write Registers—Read/Set Objects ........................................................................................................55

Firmware ..........................................................................................................................................................57

ALL THINGS MODBUS ................................................................................................................ 59

Device Registers ...............................................................................................................................................59

Configuration Registers ....................................................................................................................................59

Pulse Output/Input Registers ...........................................................................................................................61

Absolute Measurement Registers ....................................................................................................................61

Positive Power/Energy Measurement Registers ..............................................................................................65

Negative Power/Energy Measurement Registers ............................................................................................69

Net Measurement Registers ............................................................................................................................74

Protocol Commands .........................................................................................................................................76

ALL THINGS BACNET ................................................................................................................ 80

Editable Fields ..................................................................................................................................................80

Meter Specific Objects .....................................................................................................................................80

Configuration Objects ......................................................................................................................................81

Pulse Output/Input Objects .............................................................................................................................83

Absolute/Net Value Measurement Objects .....................................................................................................83

Positive Power/Energy Measurement Objects ................................................................................................86

Negative Power/Energy Measurement Objects ...............................................................................................87

iv

Page 5

v

APPENDICES ............................................................................................................................ 88

Appendix A—Additional Wiring Diagrams ............................................................................................. 88

2-CT, 3-Wire Delta ............................................................................................................................................89

3-Phase Delta with a “Wild” Leg ......................................................................................................................90

Appendix B—Connecting Multiple PowerScouts to an RS-485 Network .............................................. 91

Communication Protocol .................................................................................................................................91

Daisy Chain Layout for RS-485 Network ...........................................................................................................91

Networking Using the BACnet MS/TP/Modbus RTU Protocol .........................................................................91

Appendix C—VERIS H8035/H8036 Emulation ....................................................................................... 92

VERIS Modbus Integer Registers ......................................................................................................................93

VERIS Multipliers ..............................................................................................................................................94

VERIS Modbus Floating Point Registers ...........................................................................................................96

Appendix D—Conversion Table ............................................................................................................. 99

Decimal to Hexadecimal Conversion Table ......................................................................................................99

Appendix E—The PS3037 Optional Visual Display ............................................................................... 101

Appendix F—Troubleshooting ............................................................................................................. 102

Troubleshooting Communication Issues ....................................................................................................... 102

FREQUENTLY ASKED QUESTIONS ................................................................................................ 104

GLOSSARY ............................................................................................................................ 106

Page 6

6

INTRODUCTION

PowerScout meters monitor the voltage, current, power, energy, and many other electrical parameters

on single- and three-phase electrical systems. A PowerScout meter uses direct connections to each

phase of the voltage, and uses current transformers to monitor each phase of the current. Information

on energy use, demand, power factor, line frequency, and more are derived from the voltage and

current inputs.

The communications interface to the meters is an RS-485 serial or Ethernet connection that uses the

BACnet Master Slave Token Passing (MS/TP) protocol or Modbus protocol for sending commands and

retrieving data. A separate remote terminal unit (RTU), Data Logger, or Building Management and

Control System is usually connected to the PowerScout to provide data recording and trend logging plus

a human interface or display.

POWERSCOUT 3037 SERIAL/ POWERSCOUT 3037 ETHERNET

The PowerScout 3037 is light-weight and

compact enough to mount within an electrical

panel. It is used for long-term monitoring of

electrical systems.

Up to 127 PowerScout 3037 serial meters may be

connected to a single BACnet MS/TP network for

monitoring and recording power usage at

multiple locations within a single site. Up to 247 serial meters may be connected to a Modbus RTU

network. You may connect as many Ethernet units as equal to the amount of available IP Addresses.

There is a configurable digital pulse output port on the PowerScout 3037 that can be used to output

kWh, kVARh, or kVAh pulses to external devices, or to toggle on and off to control a remote device or

relay.

PowerScout 3037 Optional Digital Display

An optional visual display is available on the PS3037 which cycles through meter information and realtime values of Volts, Amps, KW, KVA, KVAR, etc. See Appendix.

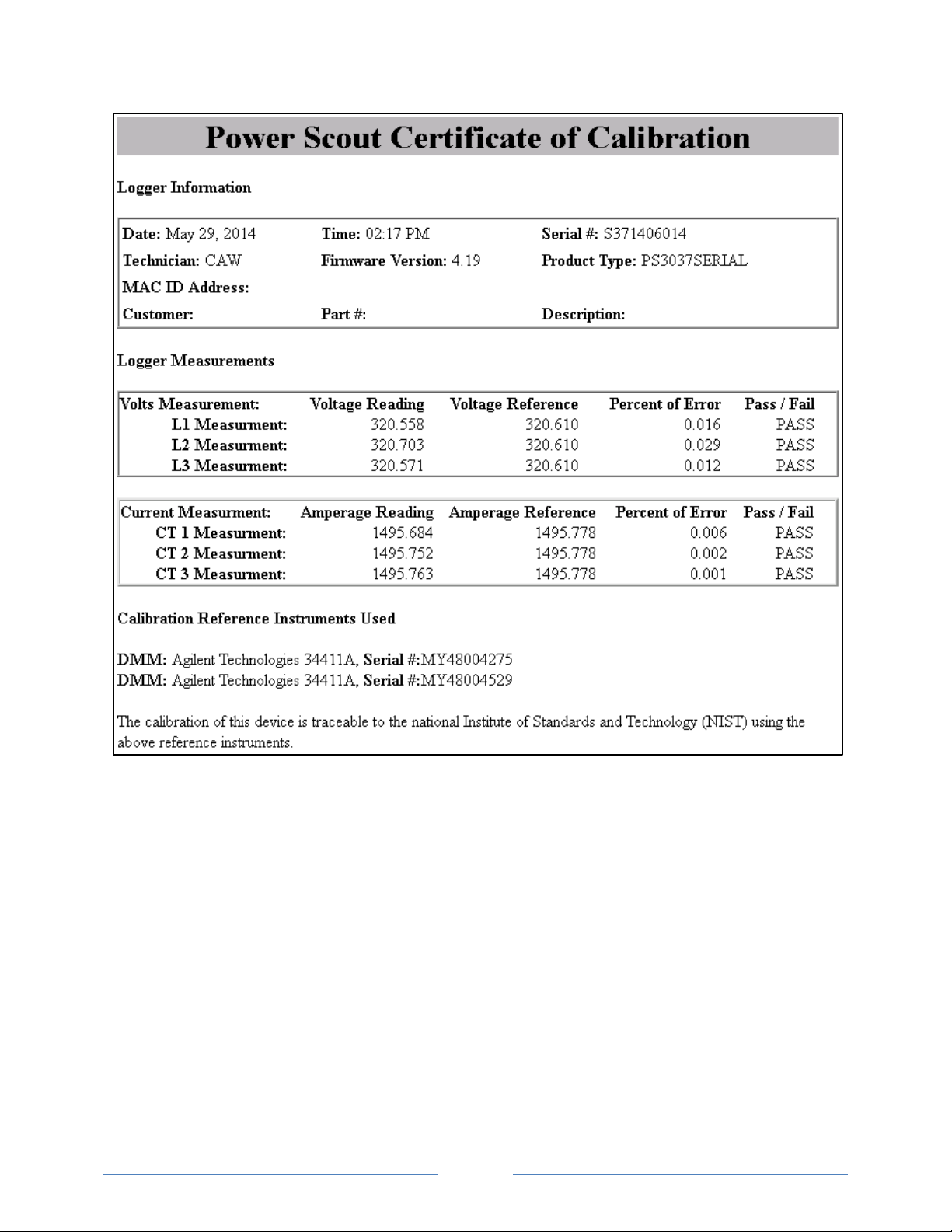

Unpacking the Unit

Your PowerScout meter comes with documents such as the Certificate of Calibration (COC) that has

information about the meter and is valuable for tech support. Be sure to set these documents aside in a

safe place when not in use.

If a Comm package was purchased as well, look for the ViewPoint software and the USB adapter. Verify

that all connectors are included (CT, voltage, comm, pulse).

Page 7

7

Example of a COC for a PowerScout 3037

Page 8

8

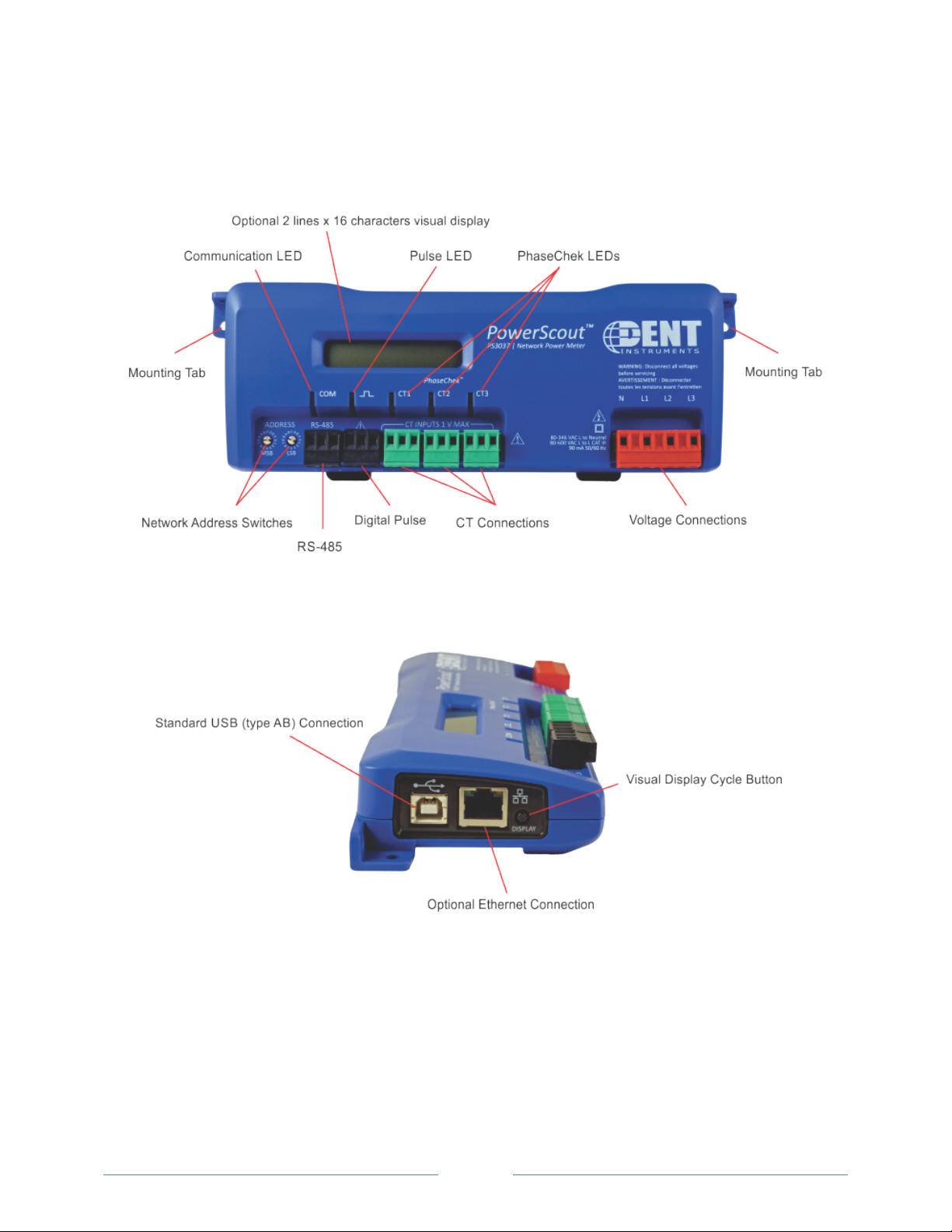

Meter Anatomy

Page 9

9

PowerScout™ Meter Safety Summary and Specifications

These items conform to the

following:

This general safety information is to

be used by both the Logger operator

and servicing personnel. DENT

Instruments, Inc. assumes no liability

for user’s failure to comply with these

safety guidelines.

The PowerScout is an Over-Voltage Category III device. Use approved rubber gloves with mechanical protection and

goggles when operating the device.

CAUTION: THIS METER MAY CONTAIN LIFE THREATENING VOLTAGES. QUALIFIED PERSONNEL MUST DISCONNECT

ALL HIGH VOLTAGE WIRING BEFORE USING OR SERVICING THE METER.

PS3037-S-N/PS3037-S-D/PS3037-E-N/

PS3037-E-D

PS3037 Series:

Conforms to UL Std 61010-1, 3rd

Edition & IEC 61010-2-030, 1

Edition

Certified to CSA Std C22.2 No.

61010-1, 3rd Edition

WARNING

Use of this device in a manner for which it is not intended may impair its means of protection.

st

Symbols on Equipment

Denotes caution. See manual for a description of the meanings.

When connecting the PowerScout to an AC load, follow these steps in sequence to prevent a shock hazard.

1. De-energize the circuit to be monitored.

2. Connect the CTs to the phases being monitored.

3. Connect the voltage leads to the different phases. Use proper safety equipment (gloves

and protective clothing) as required for the voltages monitored.

DENOTES HIGH VOLTAGE. RISK OF ELECTRICAL SHOCK. LIFE THREATENING VOLTAGES MAY BE PRESENT.

QUALIFIED PERSONNEL ONLY.

PS 3037 Hazardous voltage exist, there are no user serviceable parts inside. Do not open the enclosure.

DO NOT EXCEED 600V. This meter is equipped to monitor loads up to 600V. Exceeding this voltage will cause

damage to the meter and danger to the user. Always use a Potential Transformer (PT) for loads in excess of

600V. The PowerScout is a 600 Volt Over Voltage Category III device.

Page 10

10

undesired operation.

Factor) that should be ignored.

PS3037 Pulse output: 30V max open voltage, 5mA max current.

See Pulse Output.

FCC COMPLIANCE

DC VOLTAGES

SENSOR LIMITATIONS

USE ONLY SHUNTED CURRENT TRANSFORMERS (CTs).

Do not use other CTs. Only use shunted CTs with a 333mV maximum output only. Serious shock hazard and

logger damage can occur if unshunted CTs are used. The UL listing covers the use of the following DENT

Instruments CTs that are UL Recognized and have been evaluated to IEC 61010-1:

CT-RGT12-XXXX (solid core), CT-SRS-XXX (split core), CT-HSC-020-X (20A Mini), CT-HSC-050-X (50A Mini),

CT-HMC-0100-X (100A Midi), CT-HMC-0200-X (200A Midi), CT-RXX-1310-U (RōCoil), CTRXX-A4-U (RōCoil), CTCON-1000-X, CT-CON-0150EZ-X and the CT-SRL-XXX.

The use of any other CT will invalidate the UL Listing.

PS3037-S-N/PS3037-S-D/PS3037-E-N/PS3037-E-D

This device has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at user’s own expense.

Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause

The PowerScout 3037 is designed to measure AC voltages for installations up to 600 VAC. The

PowerScout 3037 is also capable

of measuring DC voltages up to 600 VDC with the following caveats.

1) The internal fuse installed in the PowerScout 3037 is not a suitable disconnect for voltages above 80

VDC. Customers using the PowerScout 3037 for high voltage DC systems must

600 volt DC fuse with a rating of 1 amp or less. These fuses are commonly available in the solar power

market.

2) UL and ANSI testing of the PowerScout 3037 was conducted on AC systems only. DC results are

comparable but not tested.

3) DENT Instruments VIEWPOINT software does not currently have a configuration or registers that are

specific to DC systems. Values reported for voltage, current, KW, KWH will be correct however it should

be noted that the meter will also report values that pertain to AC systems (such as VARs and Power

Equipment protected throughout by double insulation (IEC 536 Class II).

install a UL listed inline

Page 11

11

MAINTENANCE

There is no required maintenance with the PowerScout. Abide by the following items:

Cleaning: No cleaning agents, including water, shall be used on the PowerScout.

Battery Life (If equipped): The lithium battery is only used to maintain the date and clock settings during power

failure and has a life expectancy of greater than 10 years. Contact DENT Instruments for service.

No accessories are approved for use with the PowerScout other than those specified in the DENT Instruments

product literature and price sheets.

If the logger appears damaged or defective, first disconnect all power and sensors. Call or email technical support

for assistance.

DENT Instruments

Bend, Oregon USA

Phone: 541.388.4774

DENTinstruments.com

Email: techhelp@DENTinstruments.com

Page 12

12

PowerScout™ Résumé de Sécurité et Spécifications

Tous les articles sont conformes à

ce qui suit:

Cette information de sécurité est

destinée à être utilisée à la fois

par l'opérateur de l'enregistreur

et le personnel de service. DENT

Instruments, Inc n'assume aucune

responsabilité pour l'utilisateur

qui ne respecte pas les directives

en matière de sécurité.

Le PowerScout est un appareil de surtension de catégorie III. Utiliser des gants en caoutchouc approuvé avec protection

mécanique et des lunettes lors de l'utilisation de l'appareil.

ATTENTION: CE METER PEUT CONTENIR DE HAUTES TENSIONS QUI PEUVENT ÊTRE DANGEREUSES. UN PERSONNEL

QUALIFIÉ DOIT DÉBRANCHER TOUS LES CÂBLES À HAUTE TENSION AVANT D’UTILISER OU DE RÉPARER

DU METER.

PS3037-S-N/PS3037-S-D/PS3037-E-N/

PS3037-E-D

PS3037 Série:

Conforme à UL Std 61010-1, 3rd

Edition & IEC 61010-2-030, 1

Certifié CSA Std C22.2 No. 61010-1,

3rd Edition

st

Edition

ATTENTION

L'utilisation de cet appareil d'une manière pour laquelle il n'est pas destiné peut annuler ses moyens de

protection.

Symboles des Equipements

Signifie prudence. Voir le manuel pour une description de la signification.

En faisant la connexion du PowerScout à une prise de courant alternatif, suivez ces étapes en ordre pour

empêcher un risque de choc.

1. Décharger le circuit à contrôler.

2. Connectez le TC aux phases à surveiller.

3. Connectez les fils de tension à des phases différentes. Utiliser des équipements de sécurité (gants et des

vêtements de protection) qui sont nécessaires pour les tensions surveillées.

INDIQUE HAUTE TENSION. RISQUE DE CHOC ÉLECTRIQUE. HAUTES TENSIONS PEUVENT ÊTRE PRÉSENTES

QUI METTENT LA VIE EN DANGER. PERSONNEL QUALIFIÉ UNIQUEMENT.

PS 3037 tension dangereuse existent, il n'y a aucune pièce réparable par l'utilisateur n'ouvrez pas le boîtier.

Page 13

13

NE PAS DEPASSER 600V. Ce compteur peut contrôler les charges jusqu'à 600V. Le dépassement de cette

tension peut causer des dommages à l'appareil et du danger pour l'utilisateur. Utiliser toujours le potentiel

transformateur (PT) pour des charges de plus de 600V. Le PowerScout est un appareil à 600 V de surtension

de catégorie III.

TENSIONS C. C.

PS3037 sortie d'impulsion: 30V max tension ouverte, 5 mA courant maxi. Voir sortie par impulsion.

LIMITATIONS DE DÉTECTEUR

UTILISEZ SEULEMENT TRANSFORMATEURS DE COURANT (TC) SHUNTÉE.

N’utilisez pas d'autres TC. Utilisez seulement des TC shuntée avec une puissance maximale 333mV. Un sérieux

risque de décharge électrique et des dommages à l'enregistreur peut se produire si des TC pas shuntée sont

utilisés. Utiliser seulement les CTs des DENT Instruments suivants qui sont énumérés jusqu'au 600V/CATIII.

CT-RGT12-XXXX (solid core), CT-SRS-XXX (split core), CT-HSC-020-X (20A Mini), CT-HSC-050-X (50A Mini),

CT-HMC-0100-X (100A Midi), CT-HMC-0200-X (200A Midi), CT-RXX-1310-U (RōCoil), CTRXX-A4-U (RōCoil), CTCON-1000-X, CT-CON-0150EZ-X et le CT-SRL-XXX.

L'utilisation de tout autre CT annulera la certification UL.

La PowerScout 3037 est conçu pour mesurer tensions c. a. pour les installations jusqu'à 600 V c. a. Le

PowerScout 3037 est également capable de mesurer les tensions c. c. jusqu'à 600 V c. c. avec les

avertissements suivants.

1) Le fusible interne installé dans le PowerScout 3037 n'est pas un dispositif de désaccouplage adéquat

pour des tensions supérieures à 80 V c. c. Les clients utilisant la PowerScout 3037 pour haute tension DC

systèmes doivent installer un UL inline 600 volts DC fusible avec une valeur nominale de 1 amp ou

moins. Ces fusibles sont couramment disponibles dans le marché des piles solaires.

2) UL ANSI et tests du PowerScout 3037 a été menée sur systèmes CA uniquement. DC résultats sont

comparables, mais pas testé.

3) Impact Instruments logiciel VIEWPOINT ne dispose actuellement pas de configuration ou de registres

qui sont spécifiques aux systèmes à courant continu. Les valeurs rapportées pour la tension, le courant,

en KW, KWH sera correct mais il convient néanmoins de noter que le compteur sera également rapport

valeurs qui se rapportent aux systèmes à courant alternatif (tels que VARs et facteur de puissance) qui

doit être ignoré.

L'équipement protégé en double isolation (IEC 536 Classe II)

Entretien

Il n'y a aucun entretien requis avec le PowerScout. Respectez les points suivants:

Nettoyage: Aucun agents de nettoyage, y compris l'eau, doit être utilisé sur le PowerScout.

Espérance de Vie de la Batterie: La pile au lithium est utilisée uniquement pour maintenir les paramètres de date

et d'heure en cas de coupure de le courant et a une espérance de vie de plus de 10 ans. Contactez DENT

Instruments pour le service.

Pas d'accessoires approuvés pour une utilisation avec le PowerScout sauf ceux spécifiés par DENT Instruments

dans ses documentations sur les produits et également sur les prix.

Si le compteur semble endommagé ou défectueux, tout d'abord déconnecter le pouvoir de l'appareil. Alors s'il

vous plaît appelez 541.388.4774 ou contacter par courriel l'assistance technique pour obtenir de l'aide.

Page 14

14

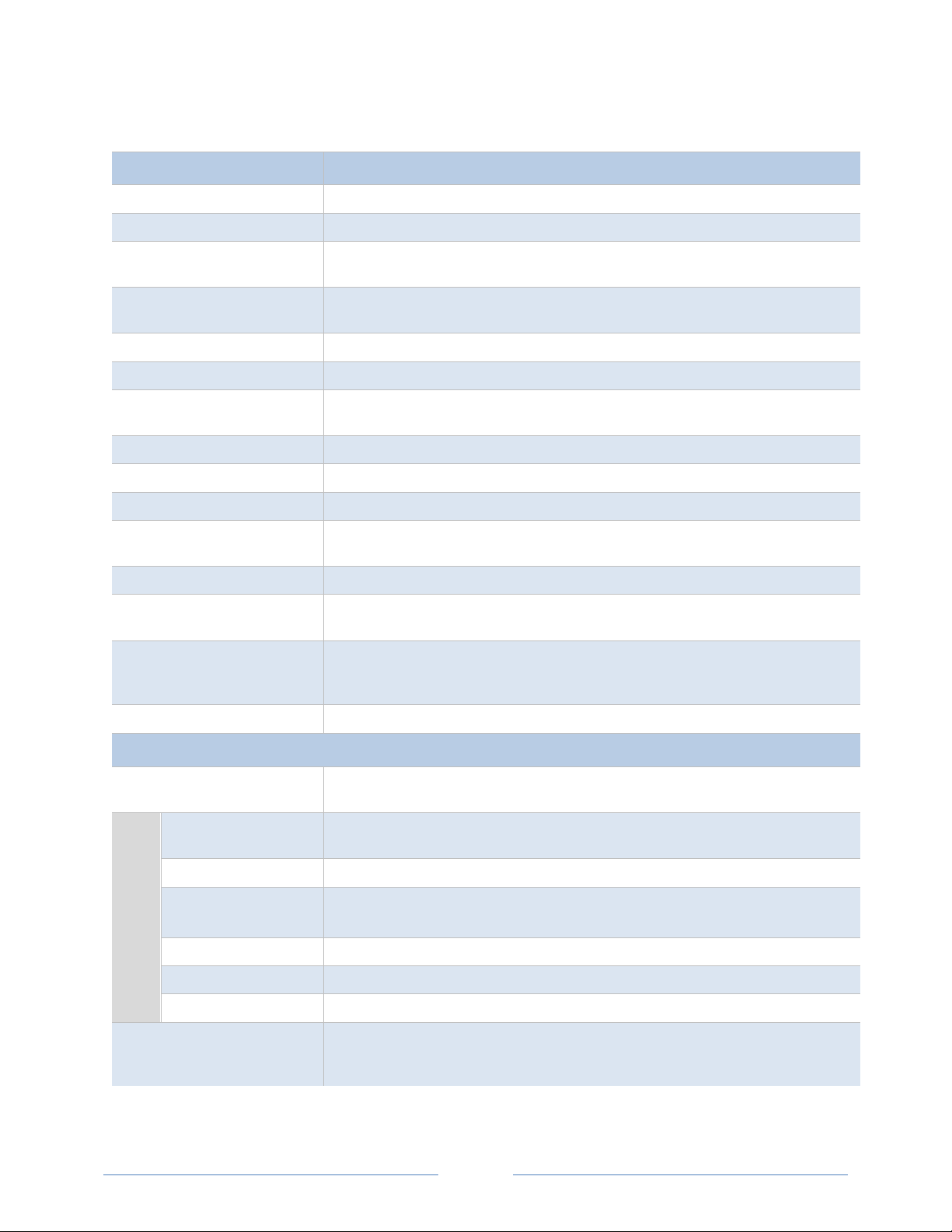

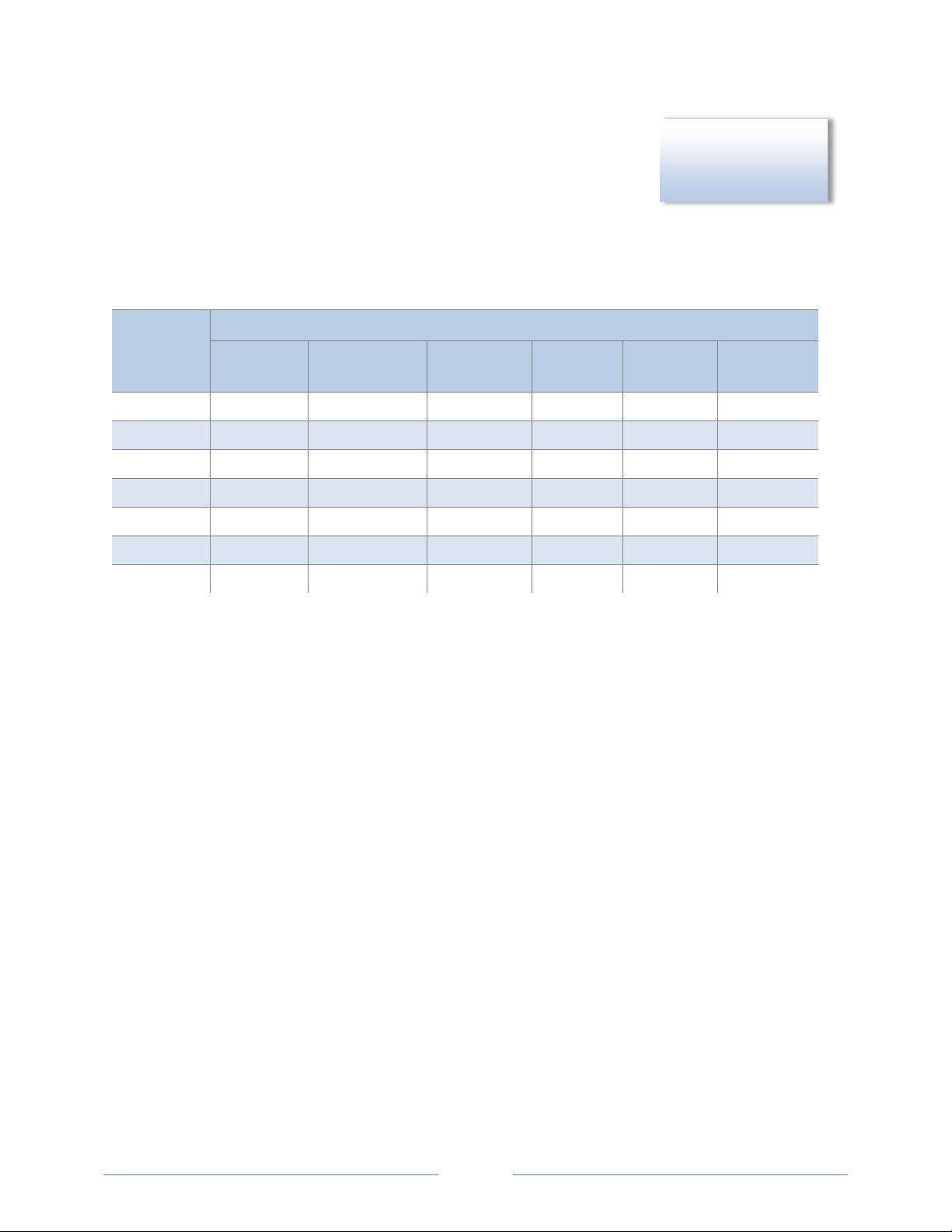

PowerScout 3037 Technical Specifications

Specification Description

Service Types Single Phase, Three Phase-Four Wire (WYE), Three Phase-Three Wire (Delta)

3 Voltage Channels 80-346 Volts AC Line-to-Neutral, 600V Line-to-Line, CAT III

Current Channels

Maximum Current Input

Measurement Type True RMS using high-speed digital signal processing (DSP)

Line Frequency 50/60Hz

Power

Power Out Unregulated 5VDC output, 140 mA max

Waveform Sampling 12 kHz

Parameter Update Rate .5 seconds

Measurements

Accuracy 0.2% (<0.1% typical) ANSI, C12.20-2010 Class 0.2

Resolution

Indicators

3 channels, 0.525 VAC max, 333 mV CTs, 0-4,000+ Amps depending on current

transducer

158% of current transducer rating (mv CTs) to maintain accuracy. Measure up to 4000

Amps RōCoil CTs

From L1 Phase to L2 Phase. 80-600VAC CAT III 50/60Hz, 90mA Max. Non-user

replaceable .5 Amp internal fuse protection

Volts, Amps, kW, kWh, kVAR, kVARh, kVA, kVAh, Apparent Power Factor (aPF),

Displacement Power Factor (dPF). All parameters for each phase and for system total.

0.01 Amp, 0.1 Volt, 0.01 watt, 0.01 VAR, 0.01 VA, 0.01 Power Factor depending on

scalar setting

Bi-color LEDs (red and green): 1 LED to indicate communication, 3 LEDs for correct

phasing (PhaseChek™: Green when voltage and current on the same phase; Red when

incorrectly wired.) Pulse output LED.

Pulse Output Open Collector, Optically Isolated , 5mA max current, 30V max open voltage

Communication

Direct

Max Communication

Length

RS-485 Loading 1/8 unit

Communication Rate

(baud)

Data Bits 8

Serial Meters

Parity None, Even, Odd

Stop Bit 2, 1

Data Formats

User Selectable Modbus RTU or BACnet Master Slave Token Passing protocol (MS/TP)

RS-485 or Ethernet

1200 meters with Data Range of 100K bits/second or less

Modbus: 9600 (Default), 19200, 38400, 57600, 76800, 115200

BACnet: 9600, 19200, 38400, 76,800 (Default)

Modbus Protocol

-or-

BACnet Master Slave / Token Passing (MS/TP) protocol

Page 15

15

Mechanical

Mounting Rail

Compatible with a TS35/7 DIN Rail Channel

Digital Display

An optional 2 x 16 character display which auto-cycles between informational screens every

2-3 seconds, with real-time values updated every second.

Operating Temperature -7 to + 60⁰ C (-20 to 140⁰ F)

Humidity 5% to 95% non-condensing

Enclosure ABS plastic, 94-V0 flammability rating

Weight 340 g (12 ounces), exclusive of CTs

Dimensions 24.2 x 8.5 x 4.0 cm (9.5” x 3.3” x 1.6”)

Accessories

ViewPoint™ Minimum System Requirements

Operating System Windows® 7 (32 or 64 bit), Windows® 8 Pro, Vista (32 or 64 bit), XP

Communications Port One USB port or serial port

Hard Drive 50 MB minimum available

Processor Pentium Class 1 GHz or more recommended

Safety

The following are UL listed:

PS3037-S-N/PS3037-S-D/PS3037-E-N/PS3037-E-D

Serial/Ethernet Meters

The PS3037 Series:

Conforms to UL Std 61010-1, 3rd Edition & IEC 61010-2-030, 1st Edition

Certified to CSA Std C22.2 No. 61010-1, 3rd Edition

Table I-1: Technical Specifications

Page 16

PREPPING FOR FIELD INSTALLATION

There are multiple tasks that are typically completed before heading to the field, usually by your

technical support personnel. These include determining how to communicate with the meter, setting

address switches, installing ViewPoint, etc. Communication configuration must be set up in the

ViewPoint software even if you use a separate logger to record data. The more tasks completed before

installation means less time in the field.

These determinations figure into how you set up the PowerScout meter for operation:

BACnet vs. Modbus

Set the network address switches on the meter to either Modbus or BACnet

RS-485 vs. Ethernet

The type of connection is part of the configuration set up in the ViewPoint software

Laptop/PC for setup verification via USB

A convenient method for setup before going in the field, and once in the field, to easily read

real-time values

NOTE: Installation of the ViewPoint

tested with a meter prior to the field installation. A USB cable can be used when configuring the meter

in this manner.

software and a communication cable should be completed and

Installing the ViewPoint Software

The ViewPoint software is designed to let you easily configure

the PowerScout for different current transformers, check

readings, and verify correct setup. All of DENT Instruments PowerScout meters use ViewPoint software

to communicate with the meter. It needs to be installed on any computer talking to the PowerScout

3037. ViewPoint is compatible with Windows® 7 (32 or 64 bit), Windows® 8 Pro, Vista (32 or 64 bit), or

XP.

Insert the ViewPoint CD into the CD-ROM drive.

The installer starts automatically. If it does not, browse to the CD and locate the ViewPointInstaller.exe

program. Start the installer by double-clicking ViewPointInstaller.exe.

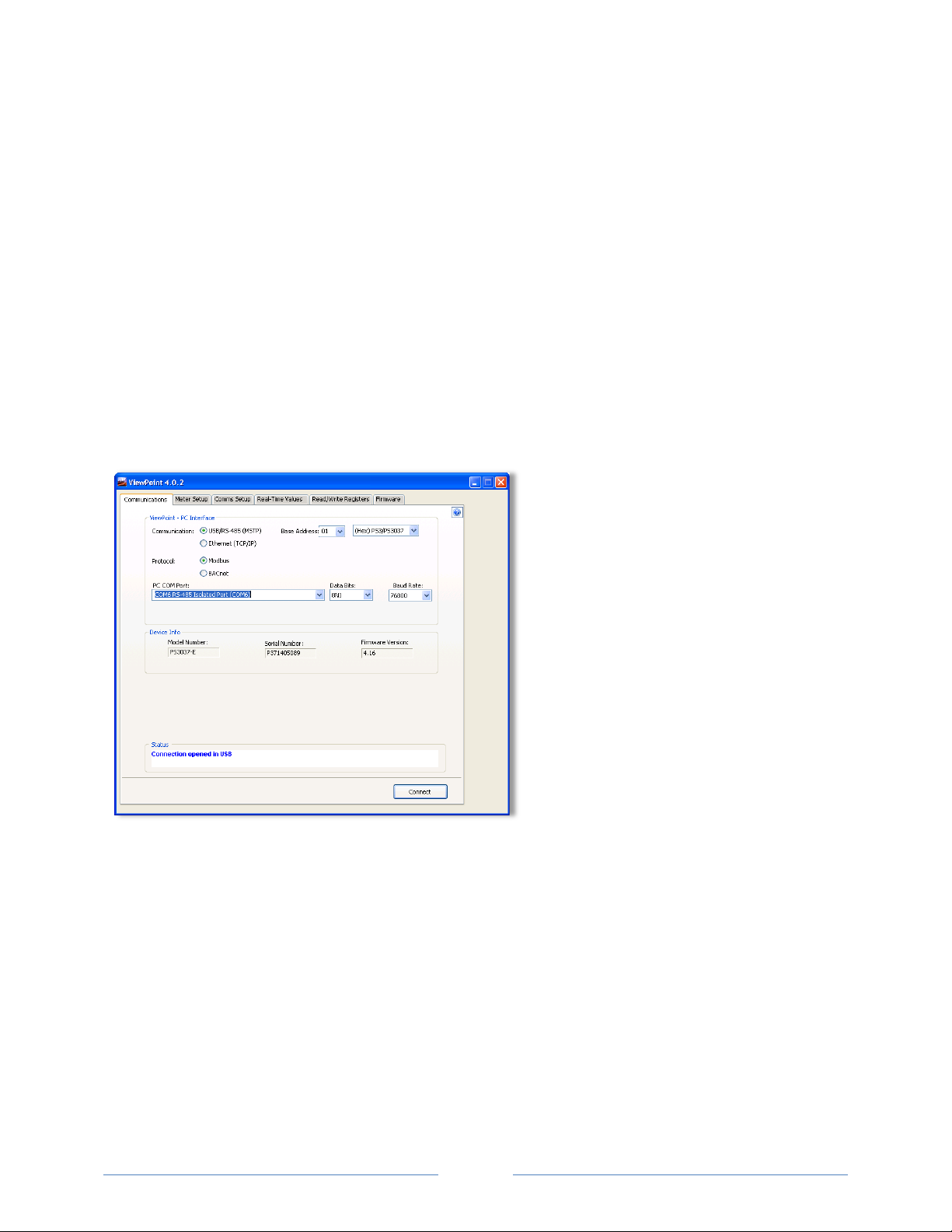

The Communication screen is displayed when ViewPoint is first started. This is where the software

networking parameters are entered to match the PowerScout networking configuration (meter type,

COM port, baud rate, base address, etc.). ViewPoint remembers your last connection and displays those

previous selections when opening the software once again.

NOTE: ViewPoint software serves several functions, such as setting up a meter, getting real-time values,

and read/write registers and objects, but for the purpose of prepping for field installation only three are

important to the process: Communications, Meter Setup, and Comms Setup. The other functions are

described later in this document.

DID YOU KNOW? ViewPoint may be

installed on multiple computers.

16

Page 17

Connecting a Communication Cable

There are various ways to communicate with a PowerScout meter and how you do so will determine

what type of cabling system you will use. To set up the meter, communication can be established with a

USB cable, an RS-485 adapter, or an Ethernet cable. Once in the field, communication between a

PowerScout meter and a logger is established with a RS-485 or an Ethernet connection. A RS-485

connection is limited in speed while an Ethernet connection is much faster.

NOTE: PowerScout meters are ordered from DENT Instruments based on the type of desired connection.

CONNECTING AND COMMUNICATING VIA A USB OR RS-485 ADAPTER

A type AB USB cable may be used between a PC and a PS3037 meter and is the preferred method for

setting up a PS3037 with Modbus protocols. The USB cable will also power the meter when connected

to a PC. When using a USB cable with a PC, each USB port on the PC generates a unique comm port in

the ViewPoint software, such as Com3 or Com4.

NOTE: A USB driver is installed when you install the ViewPoint software.

ViewPoint can read information through a USB, an RS-485 isolated COM port, or an Ethernet

connection. When the RS-485 connection is selected a base address is required (the base address is the

rotary switch settings). Address switches are ignored by both USB and Ethernet. When the Ethernet

connection is selected an IP address is required. The screen display changes based on your connection

selection.

The USB connector on the PowerScout 3037 can be used to power the unit when configuring it using

ViewPoint and Modbus protocols.

If connecting with a USB cable is not practical, the use of an RS-485 to USB adapter connected to your

PC may be used for communicating with your PowerScout. First, install the driver on the computer and

then complete the connection between the meter and the computer by plugging the RS-485 connector

into the meter.

17

Page 18

DID YOU KNOW? If an RS-485 adapter is used instead of a USB, an RS-485 driver must be installed

properly.

on your computer and power applied to the PowerScout meter before the software will function

Installing the RS-485 Adapter on a Computer

NOTE: If ViewPoint was installed first, it needs to be restarted following an RS-485 driver installation. If

an RS-486 port does not appear in the drop-down list, the RS-485 was not installed correctly.

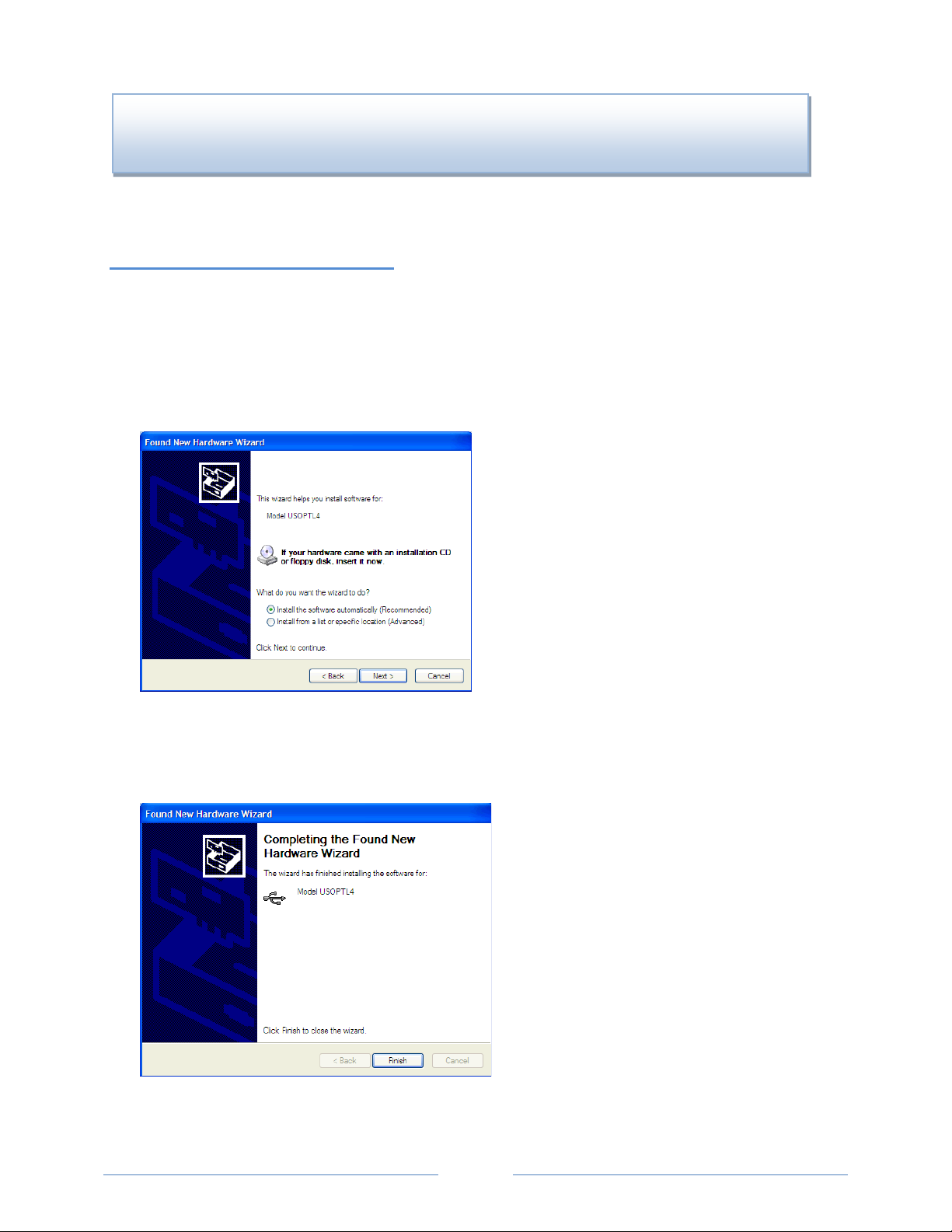

1) Insert the CD that came with the RS-485 adapter into your computer.

2) Insert one end of a USB cable into the RS-485 adapter and the other end into a USB port on the

computer.

3) The Found New Hardware Wizard window appears.

The window states “This wizard helps you install software for: Model USOPTL4,” and asks “What do

you want the wizard to do?”

4) Select Install the software automatically and click Next.

5) Click Finish when the installation is complete.

6) Remove the CD from your computer.

18

Page 19

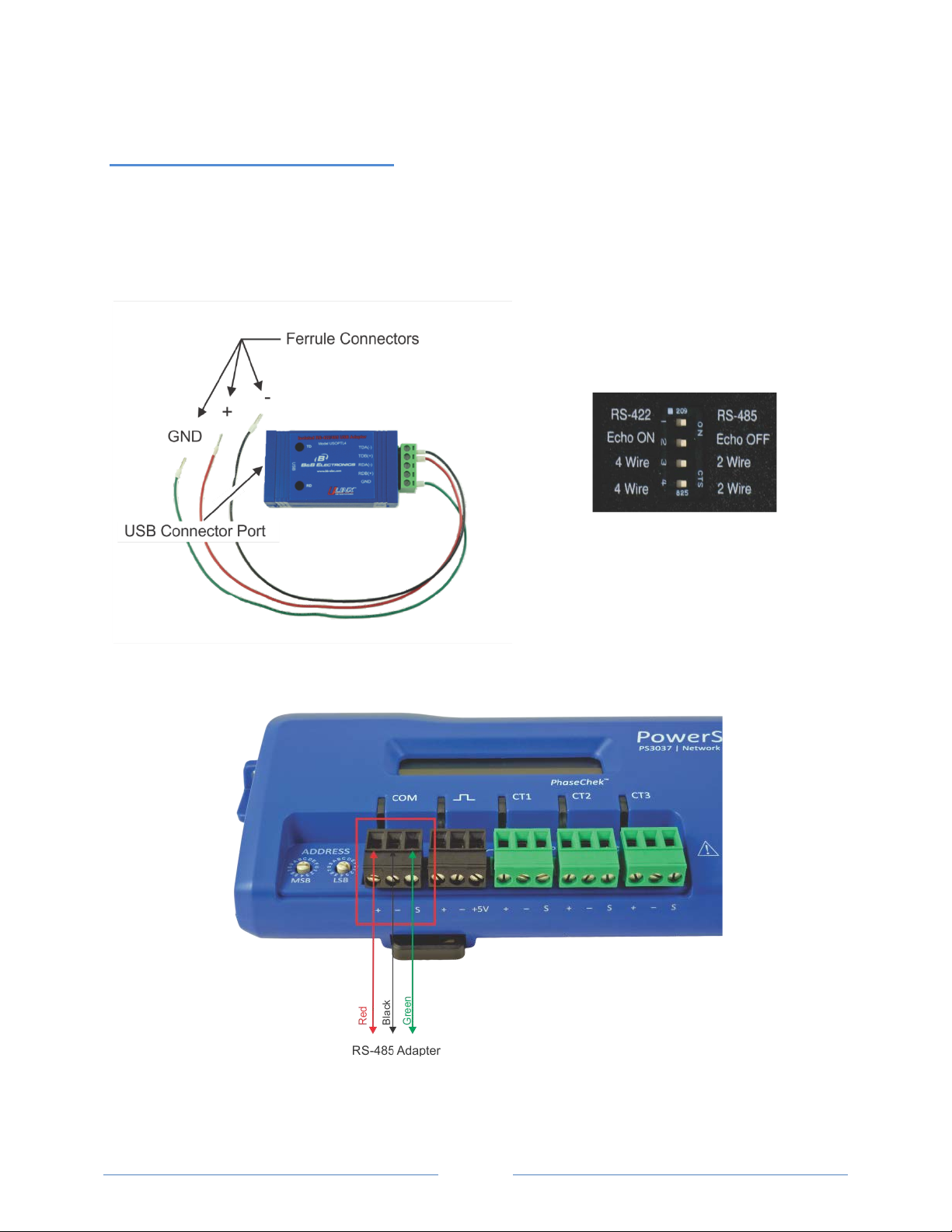

Connecting the Adapter to the

Figure II-3: RS-485 Connector on PS3037

Meter

The three wires coming from the RS-485 adapter are plugged into the COM connector. Insert each white

ferrule into the appropriate slots on the connector. The red wire inserts in the left slot (+), the black wire

in the middle slot (-), and the green wire in the right slot (Shield), Figure II-1 and Figure II-3. Verify that

the dip switches on the back of the RS-485 adapter are set to RS-485, Echo Off, 2 Wire, 2 Wire as shown

in Figure II-2 before plugging the adapter into the PowerScout 3037.

Figure II-2: Dip switches on back of RS-485

Adapter

Figure II-1: RS-485 Adapter

19

Page 20

NOTE: USB is always active on the PS3037 (and the protocol is Modbus over the USB virtual

communications port).

NOTE: If ViewPoint was installed first, it needs to be restarted following a RS-485 driver installation. If a

RS-485 port does not appear in the drop-down list, the RS-485 was not installed correctly.

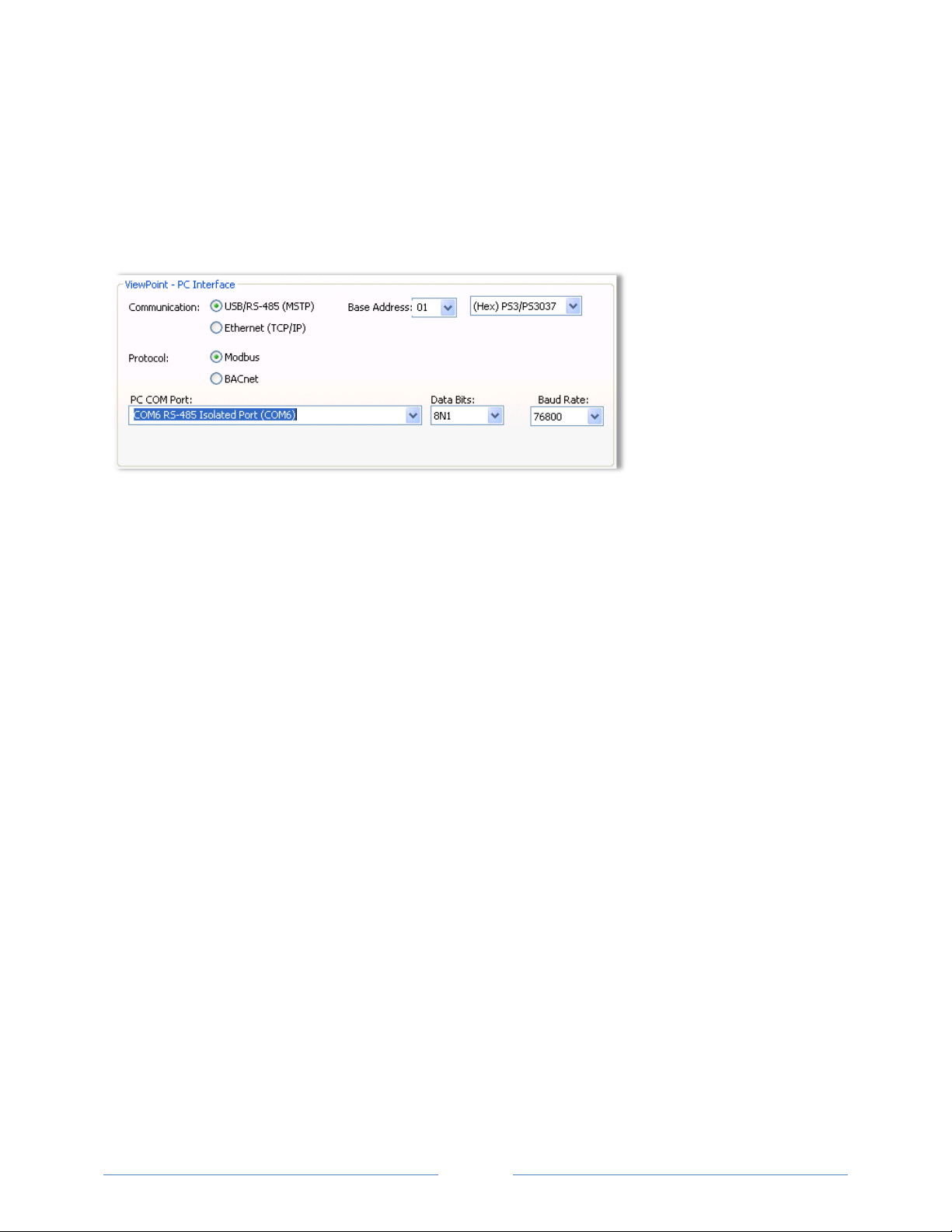

1) Select USB/RS-485 (MSTP) as your communication type.

2) Select PS/PS3037.

3) When connecting with an RS-485, enter a base address that matches the switches on the

PowerScout. A USB connection ignores address switches. See Setting the Network Address Switches

below.

4) When connecting with an RS-485, select Modbus or BACnet as your communication protocol. When

communicating over USB, whether the PS3037 is configured for Modbus or BACnet mode, the

PS3037 will communicate over the Modbus protocol.

5) Select the PC COM Port from the drop-down list. For a USB connection, select “COMxx DENT USB”

in the field, where “xx” is the port number. For an RS-485 connection using an RS-485 adapter,

select COMxx RS-485 Isolated Port (COMxx) where "xx' is the COM port number.

Default settings are used for the two remaining fields: Data Bits is 8N1 and the Baud Rate is 9600. When

BACnet is selected as your protocol an additional read-only field appears displaying the BACnet Device

ID.

20

Page 21

Setting the Network Address

Reserved for resetting the PowerScout to Modbus mode with 9600 baud,

01-7F

Available (01/001 is the factory default setting).

80-FE

Reserved for BACnet slave devices.

The rotary switches can be used to configure the communication protocol

Reserved for resetting the PowerScout to Modbus mode with 9600 baud,

01-F7

Available for Modbus slave devices.

Reserved for network wide broadcast.

The rotary switches can be used to configure the communication protocol

Switches

There are two rotary network address switches on a serial PowerScout 3037, labeled MSB and LSB.

These two switches are used to select the BACnet/Modbus address the client uses to communicate with

the PowerScout.

The rotary switches are 16-position, hexadecimal switches. The default factory setting is hex 01. The

address is a hexadecimal (hex) value, represented by the digits 0 through 9 and letters A through F. For

example, a network address of 100 in decimal is converted to 64 hexadecimal and set on the

PowerScout 3037 by:

MSB switch—select 6

LSB switch—select 4

In some cases the hex value may need to be converted to decimal when entered into the RTU or data

logger. See the Appendix for a hexadecimal conversion table.

The BACnet MS/TP MAC and Modbus address is a decimal value, represented by three digits: 000

through 009, 010-090, and 100-999.

Note: BACnet MS/TP masters only support addresses 001–127.

Hexadecimal

Address

00

FF

Hexadecimal

Address

00

BACnet Address Availability

8 bit, 1 stop bit and no parity.

to BACnet or Modbus as well as changing the baud rate if unsure of the

current settings (PS3037 only).

Table II-1: BACnet Hexadecimal Address Availability

Modbus Address Availability

8 bit, 1 stop bit and no parity.

FF

to BACnet or Modbus as well as changing the baud rate if unsure of the

current settings (PS3037 only).

Table II-2: Modbus Hexadecimal Address Availability

21

Page 22

Communication Error

If ViewPoint is unable to communicate with the PowerScout, the Status window displays the following

message in the Status field:

“Unable to establish connection with meter, please check settings and try again.”

Try the following to resolve the communication error on a serial PowerScout:

No RS-485 option available in the PC COM Port drop-down list—indicates the PowerScout is not

properly connected or the required software driver is not installed.

Modbus Base Address Switch does not match the selected hex switch settings on the

PowerScout—change the switch settings.

The selected Baud Rate does not match the PowerScout baud rate—change the baud rate.

For more information, refer to the Appendix, Troubleshooting Communication Issues.

CONNECTING AND COMMUNICATING VIA AN ETHERNET (TCP/IP) CONNECTION

Connect one end of the Ethernet cable into the PowerScout and the other end into your computer or

network. To begin communicating via an Ethernet cable you must first set it up within the ViewPoint

software that came with the meter. See Ethernet (TCP/IP) Connection in the Communicating with a

PowerScout Meter section.

The meter will require power to communicate over Ethernet. Power can be supplied by connecting the

USB or voltage lines 1 and 2.

PowerScout 3037

Figure II-4: Ethernet Connection

Keep in mind that the Ethernet connection must have an IP Address in the ViewPoint software that can

either be set manually within the software with the Use Static IP address option (for a fixed address) or

obtained automatically from the router connected to the logger using the Use DHCP option (dynamic

address). Both options have advantages. See About IP Addresses further in this document.

NOTE: When Ethernet is connected, any RS-485 connection is inactivated. The PS3037 must be power

cycled with the Ethernet cable removed in order to activate the RS-485 interface.

22

Page 23

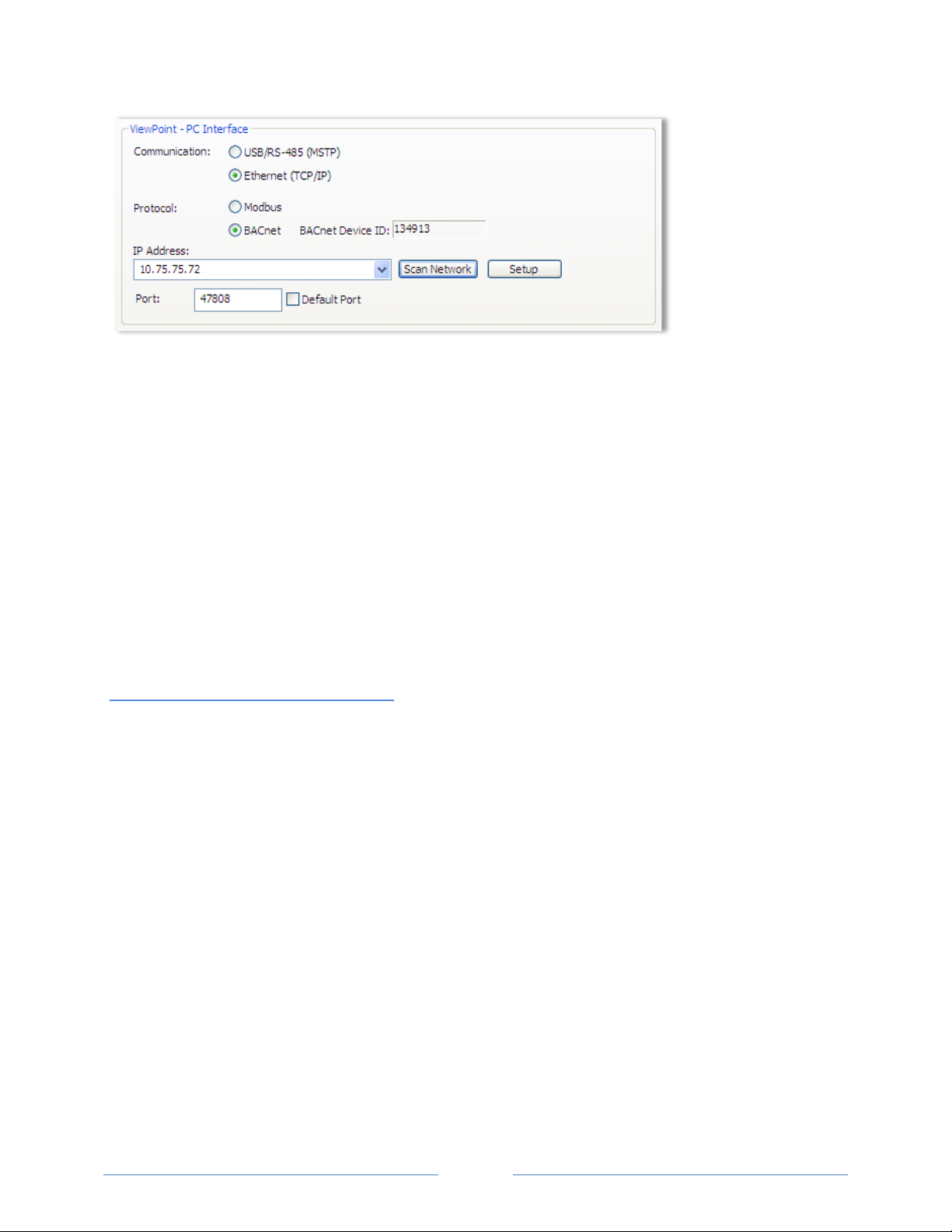

1) Select Ethernet (TCP/IP) to gather information via a network connection. When selected, the

Communications Setup screen changes and an IP Address is required as address switches are

ignored.

2) Select your mode of communication.

3) Enter the IP Address for the Ethernet connection of the meter or select one of the previously used

addresses from the drop-down list. See About IP Addresses on the following page.

-orUse the Scan Network or Setup buttons to acquire a new IP Address. See About IP Addresses on the

following page.

4) Enter the Port connected to the PowerScout. A checkbox is available to make the port the default.

Different networks may require different ports. See your network administrator.

About IP Addresses

The Ethernet connection must have an IP Address that is set manually in the IP Address: field or

obtained automatically from the router connected to the meter using the Use DHCP option (dynamic

address) found in the Logger Network Setup dialog box accessed via the Setup button. Both options

have advantages.

NOTE: A Static IP address of 192.168.1.10 is assigned in the factory to all Ethernet PowerScouts.

Static Connection: If you know an IP address that is not being used by another device on the

network, enter that address into the IP Address: field. This may require permission from a

network administrator. With a static IP address it is easy to connect to the meter as there is no

doubt about what IP address to use.

Dynamic Connection: If you want the router to assign an IP address to the meter automatically,

select Use DHCP. This may avoid the need of a network administrator as the router will assign an

IP address that does not conflict with any other devices on the network. A disadvantage of the

DHCP option is that the “lease” of the IP address may expire after a period of time and the

router could assign a different IP address. A new IP address means that ViewPoint cannot

connect to the meter until the new IP address has been entered. (See below.)

An additional option is to set the meter to DHCP and go to the router and assign a specific IP address to

the MAC address that corresponds to the meter. In this way, if the lease does expire, the router will

23

Page 24

always assign the same IP number back to the meter. This option may also require a network

administrator.

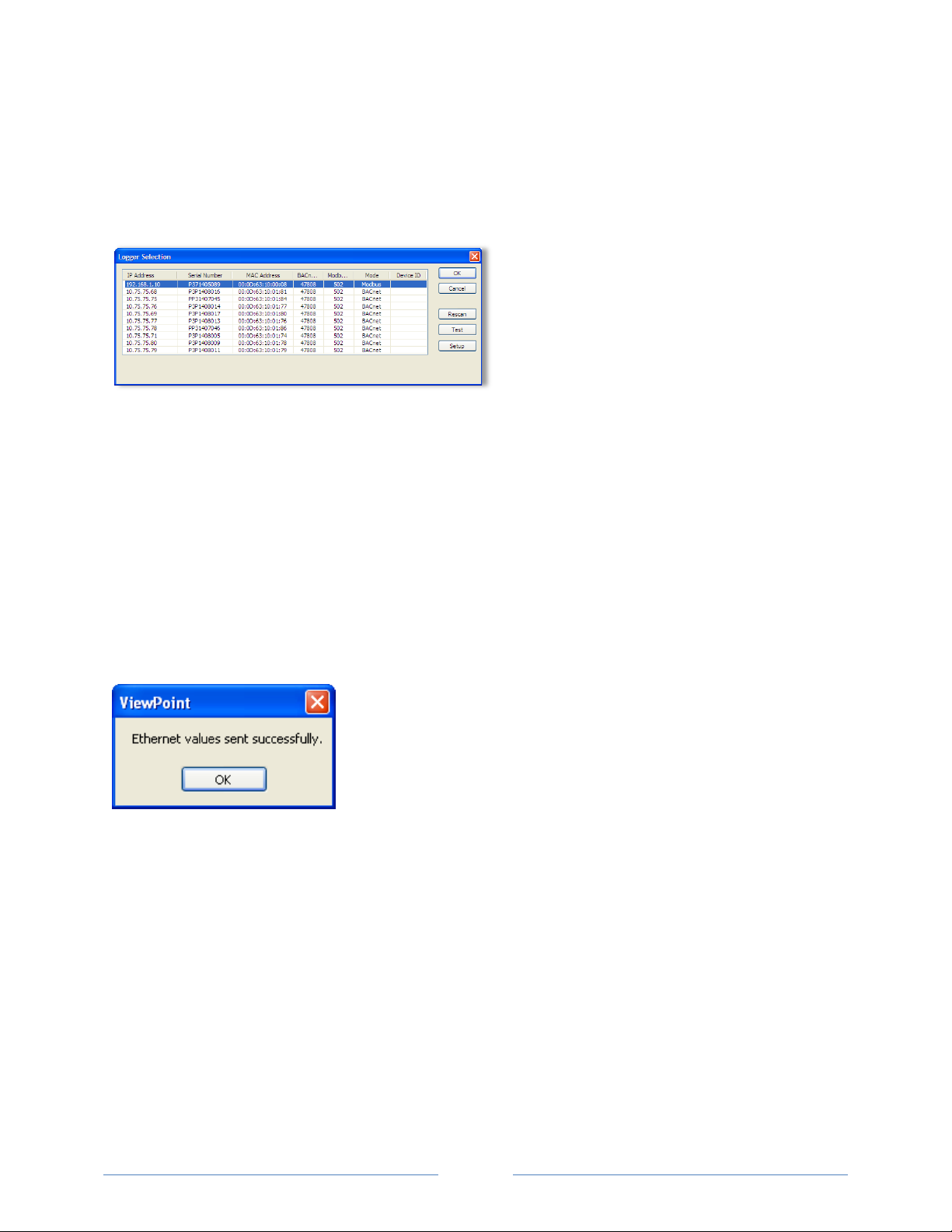

The Scan Network button scans the network for possible meters and displays them in the Logger

Selection dialog box. Look for the serial number on the meter (found on the back of the meter) to

determine which connection point is yours.

Select the correct device from the list of IP Addresses and click OK.

The Setup button displays the Logger Network Setup dialog box where network address information is

entered. See your network administrator before making changes.

When you select the Use DHCP checkbox the Dynamic Host Configuration Protocol is used to populate

the IP Address, Subnet Mask, and Gateway Address fields automatically.

NOTE: Each meter connected to the network requires its own unique network IP address. An address is

provided automatically if the network allows DHCP (Dynamic Host Configuration Protocol) and the

meter is configured to request an address.

Click Update Logger after making your selections.

ViewPoint displays the following message when the connection is successful:

24

Page 25

Communications LEDs

Steady Green

Flashing Green

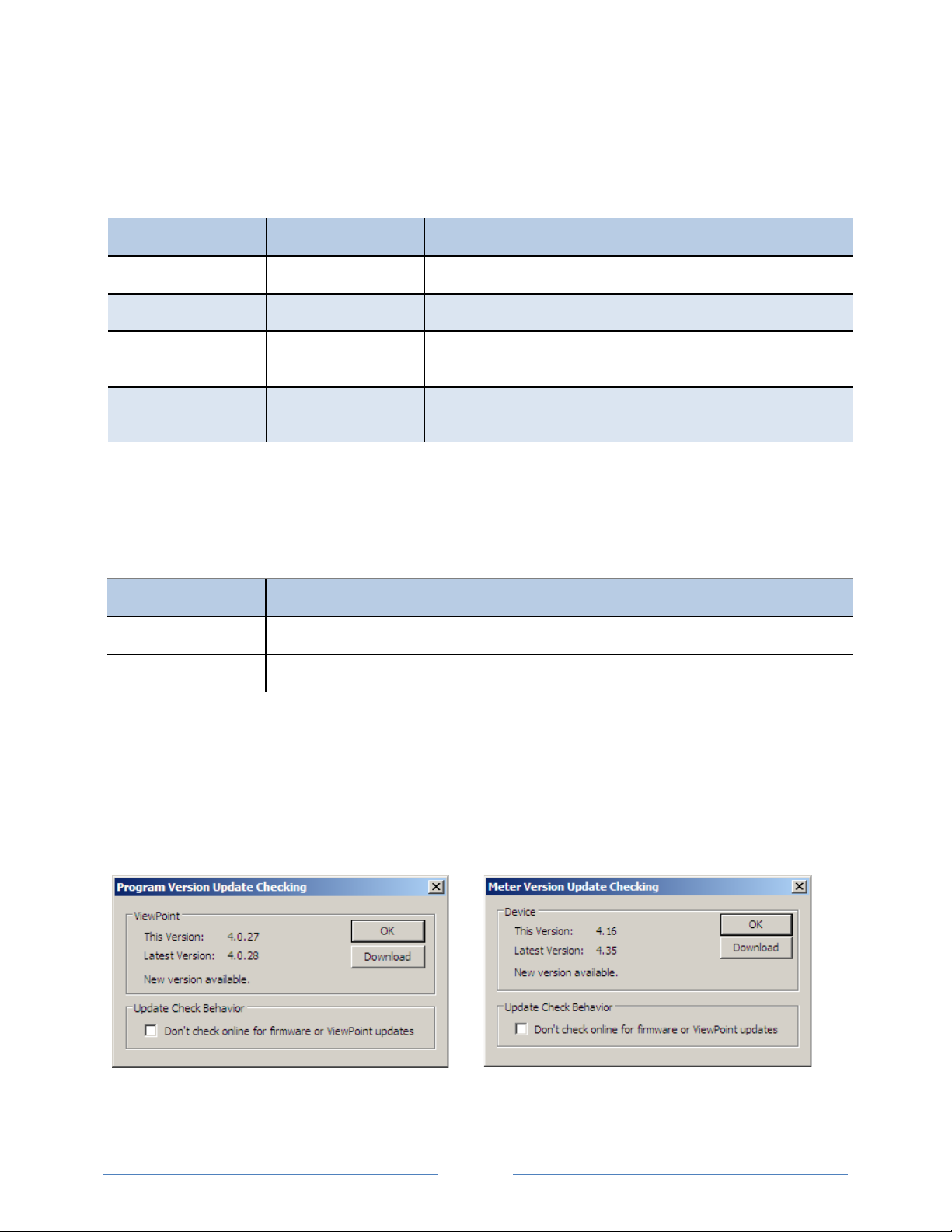

ViewPoint Update Dialog

Firmware Update Dialog

The PowerScout COM LEDs signal the following communication information.

PS3037 SERIAL

BACnet Modbus Description

Steady Green Power is applied to the meter.

Flashing Green

Steady Red Communications failure, or talking with BACnet while the meter is in

Flashing Red The meter is receiving communication on the bus for a meter at

The meter is communicating.

Modbus mode.

another address.

Table II-3: PS3037 Serial COM LED Signals

PS3037 ETHERNET

The Ethernet cable has a Link LED on its connector that glows amber when connected to the network

and flashes green during Ethernet traffic.

BACnet/Modbus Description

Steady Green Power is applied to the meter.

Flashing Green The meter is communicating.

Table II-4: PS3037 Ethernet COM LED Signals

Version Control

Installed versions of the software and firmware are checked when first connecting the meter. A pop-up

dialog box appears if either of those is out of date:

25

Page 26

Thereafter, the software is checked once every seven (7) days for the current version. Firmware is

checked each time the meter is connected. You can stop the check for updates by selecting the Don’t

check online for firmware of ViewPoint updates check box.

Click OK to close the dialog box without updating.

-or-

Click Download to begin the updating process. The DENT Instruments Tech Support Downloads website

appears with a link to the download. Once you have the file downloaded to your computer, use the

Firmware tab to download the file to the meter.

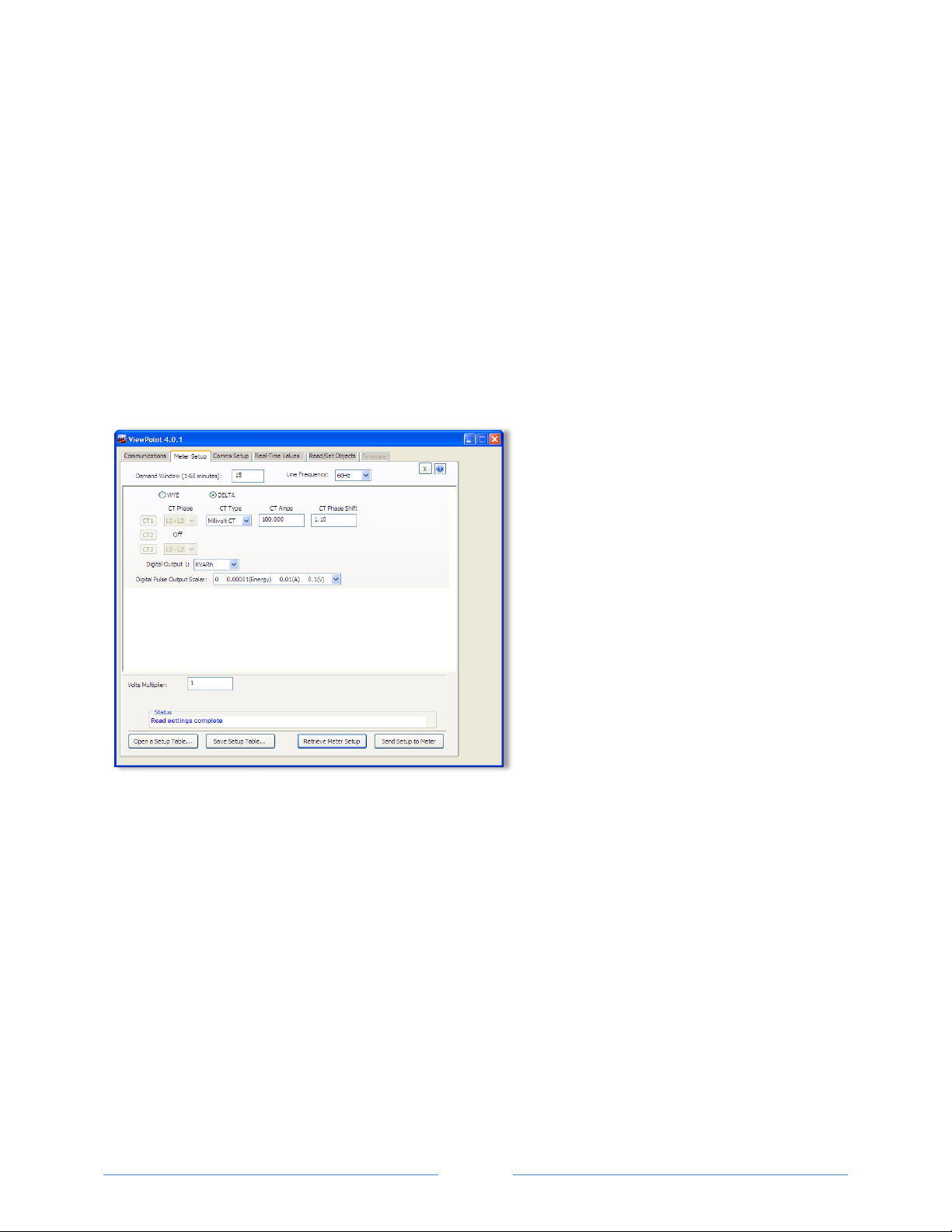

Meter Setup

Once communications is established between the PC and the PowerScout, you are now ready to

configure the meter for the field. This is accomplished in the Meter Setup tab of ViewPoint.

The Meter Setup screen allows unique changes to an element on the 3037. Within the element, CT

Phase, Type, Amps, and Phase Shift are entered, based on wiring connection, for CT1, CT2, and CT3. The

type of wiring connection and the Digital Output are also entered for the element. Overall, a Demand

Window of 1–60 minutes is available for the recording of values and a Line Frequency of 50 Hz or 60 Hz

is selectable. Also, the Volts Multiplier field can be altered when used with a step-down transformer to

allow the meter to record values as if it was connected to a higher than 600V source.

NOTE: In PowerScout meters, Peak Demand is calculated using a moving window and is averaged across

the selected demand window size. Each minute the total consumption is recalculated and compared to

the last demand window. If the new window is larger than the last recorded value it is recorded. This

value is calculated during the sampling of the waveform.

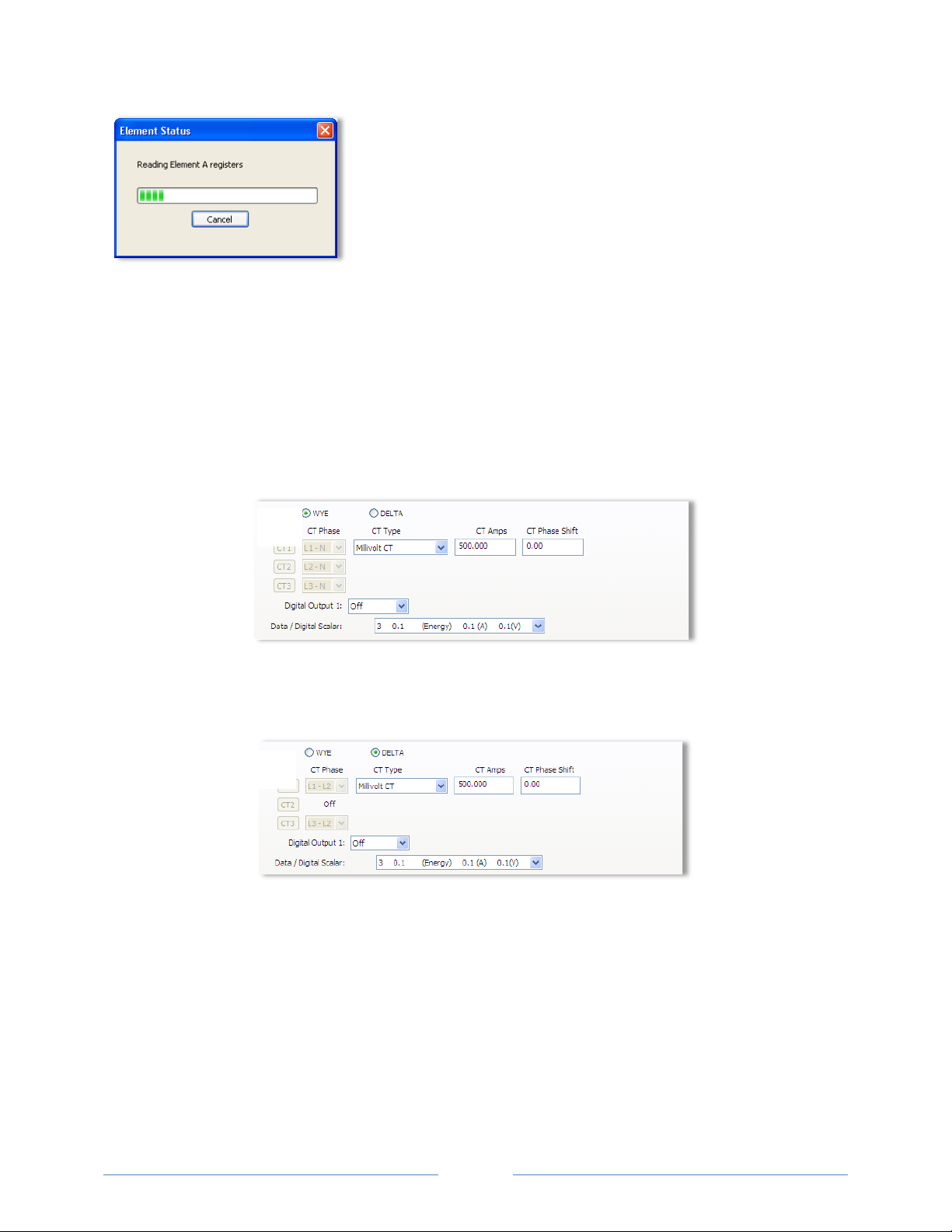

The Meter Setup screen is blank when first accessed. Click Retrieve Meter Setup to view the current

status of the element. The Element Status dialog box displays while the element is read.

26

Page 27

ENTERING WIRING INFORMATION FOR AN ELEMENT

Begin setup by entering an amount of time (1-60 minutes) into the Demand Window and selecting a

Line Frequency from the drop-down list.

Use the following steps within an element:

1) Select WYE or DELTA as the wiring connection.

NOTE: DENT Instruments recommends using 3 CTs in a WYE connection for Delta loads.

A WYE connection automatically displays all three CTs. Any changes made to CT1 also apply to

CT2 and CT3.

Wye Wiring Connection

A DELTA connection displays only the two available CTs. Any changes made to CT1 also apply to

CT3.

Delta Wiring Connection

2) Depending on the wiring connection, make changes to CT1, CT2, and/or CT3.

CT Phase—Shows the voltage of the referenced CT

CT Type—Use the drop-down list to select the type of CT attached to the PowerScout.

CT Amps—Enter the amperage rating.

CT Phase Shift—Enter in degrees the phase shift of the CT. The default is 1.1.

27

Page 28

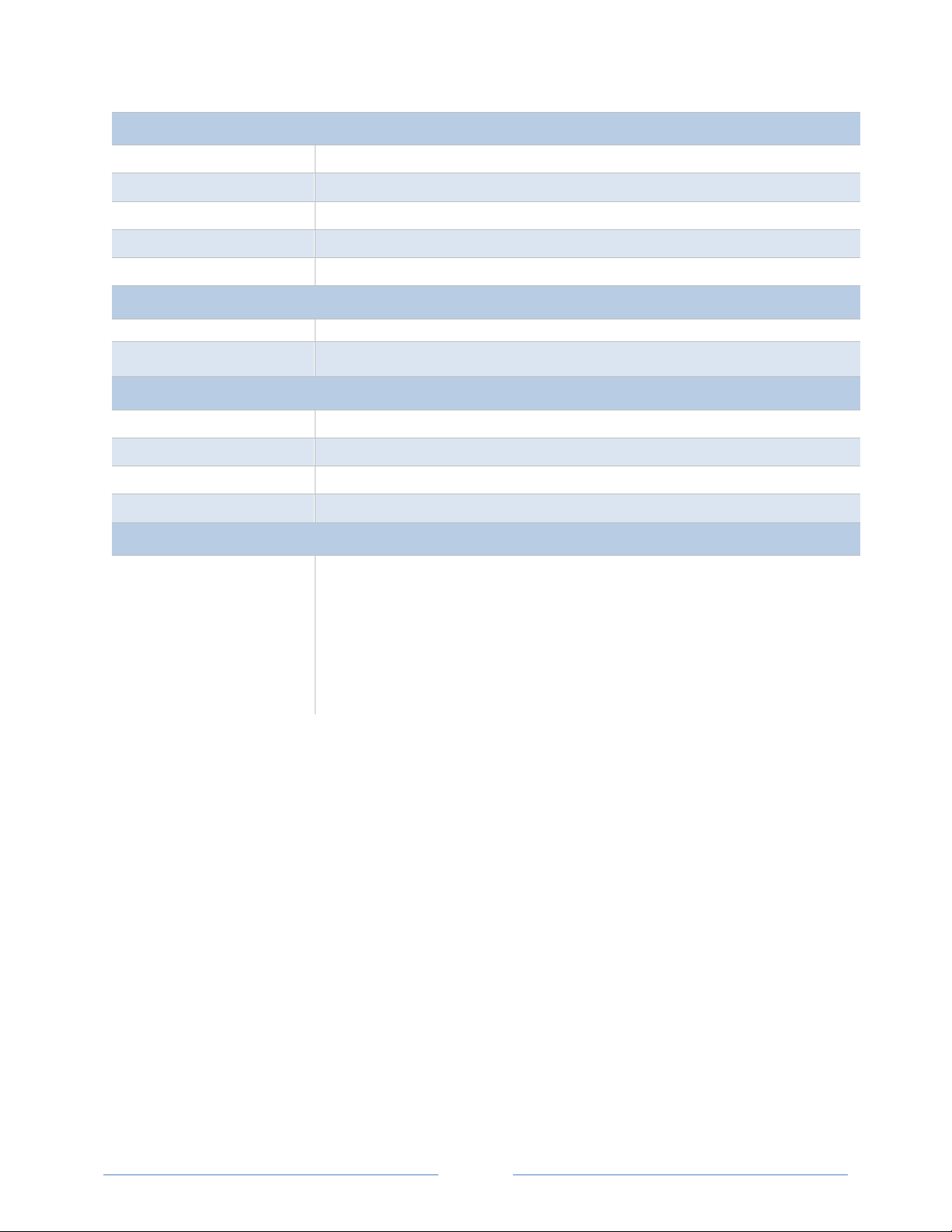

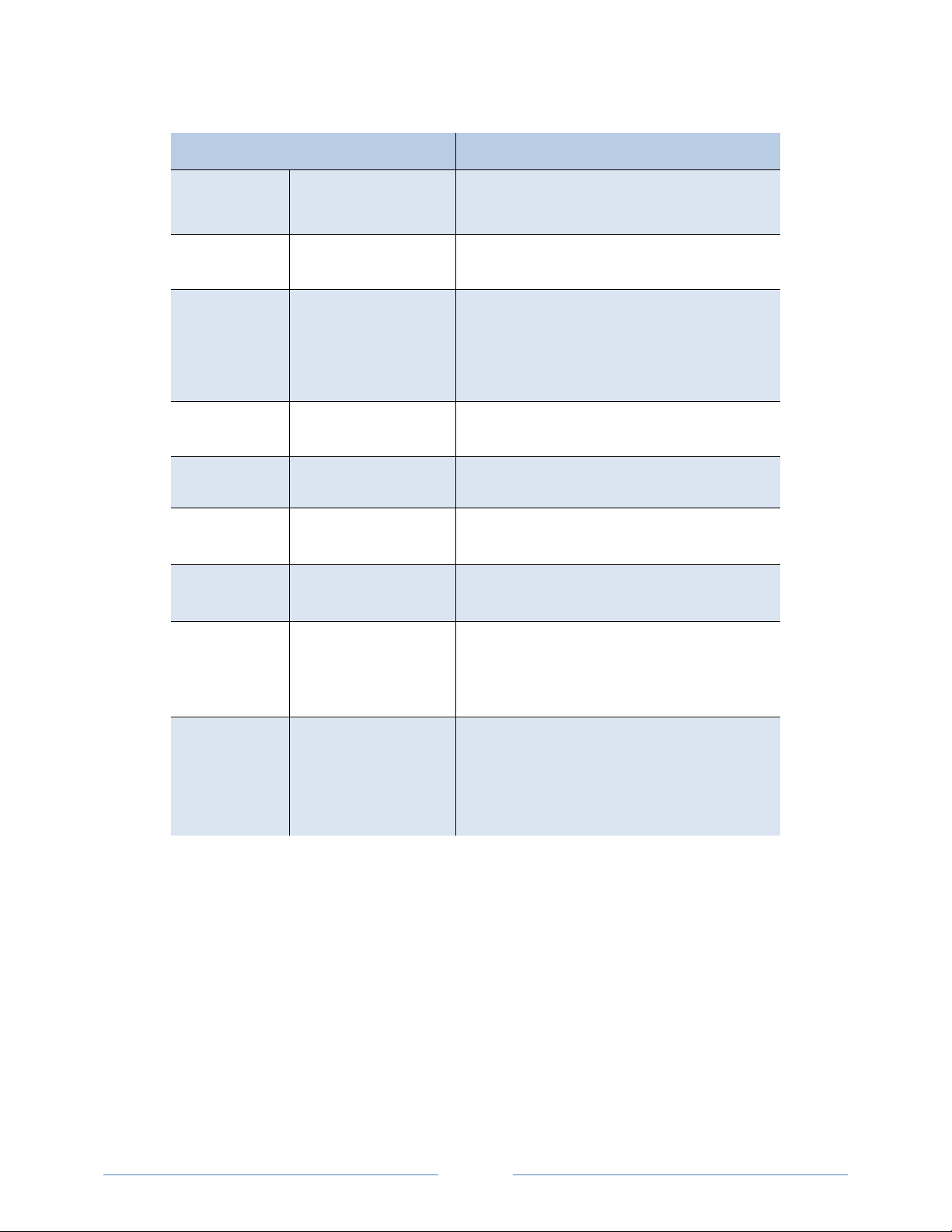

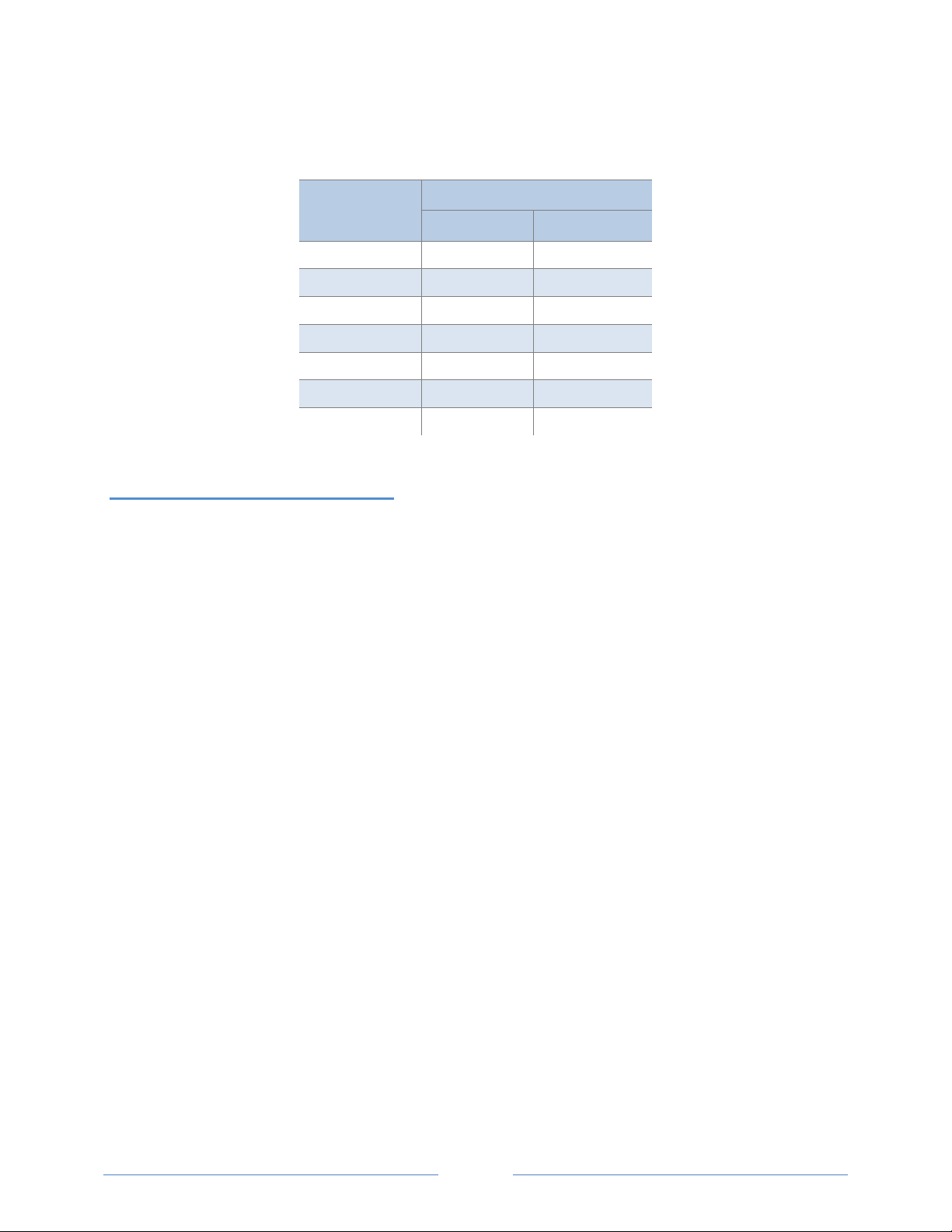

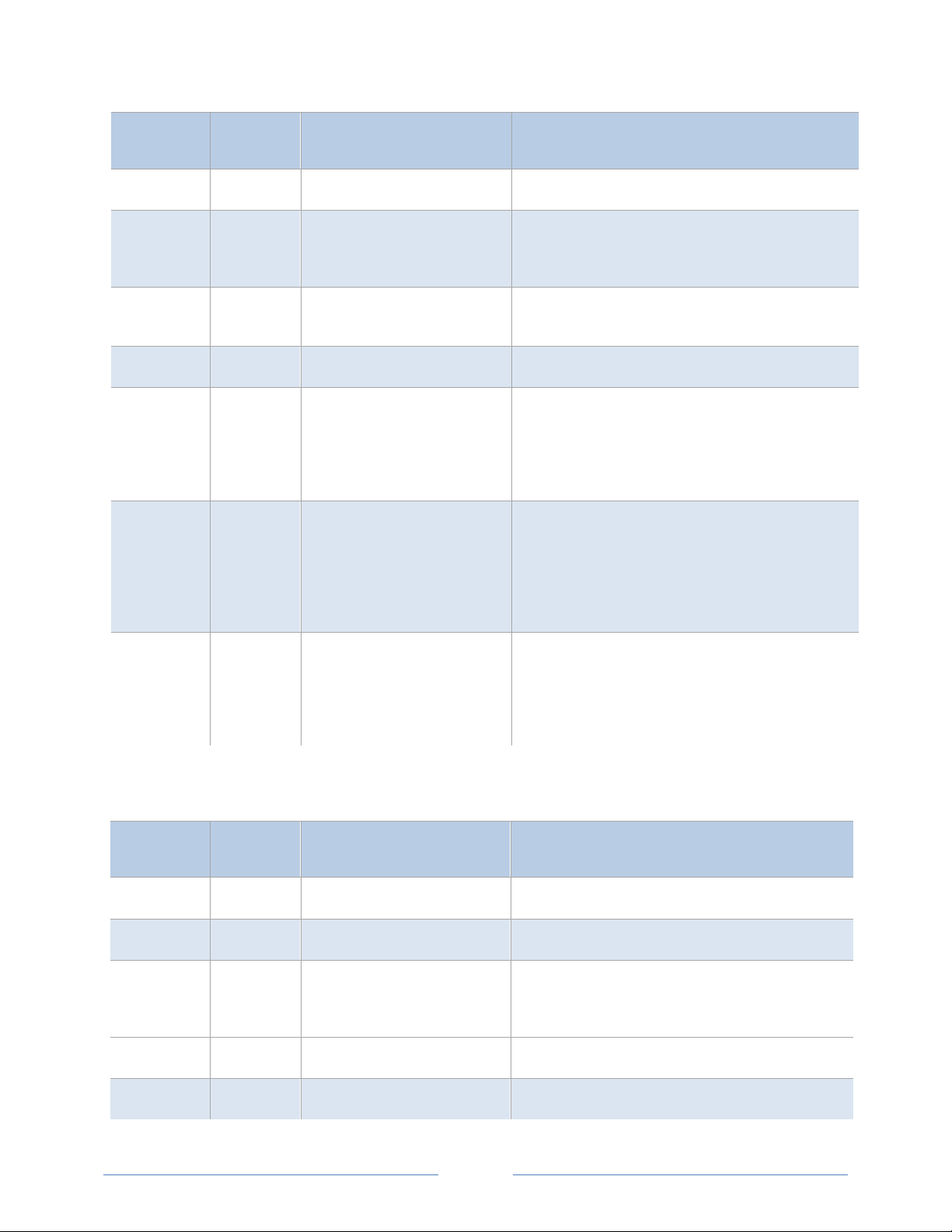

Current Transformers Recommended CT Phase Shift Values

Clamp On CT-CON-0150EZ

CT-CON-1000

Split Core Small CT-SCS-0050

CT-SCS-0100

Split Core

Medium

Split Core Large CT-SCL-0600

Split Core High

Accuracy

Hinge Mini CT-HSC-020

Hinge MIDI CT-HMC-0100

CT-SCM-0100

CT-SCM-0200

CT-SCM-0400

CT-SCM-0600

CT-SCL-1000

CT‐SHS‐0005

CT‐SHS‐0015

CT-HSAC-050

CT-HMC-0200

1.10°

0.20°

2.20°

2.20°

1.75°

1.50°

1.30°

1.30°

0.00°

0.00°

0.50°

0.50°

0.75°

0.75°

0.12°

0.30°

Revenue Grade

Toroidal Solid

Core

Revenue Grade

Split Core

CT-RGT12-0005

CT-RGT12-0020

CT-RGT12-0050

CT-RGT12-0100

CT-SRS-005

CT-SRS-050

CT-SRL-100

CT-SRL-200

CT-SRL-400

0.00°

0.00°

0.00°

0.00°

359.9°

359.77°

0.06°

0.06°

359.94°

Table II-5: Recommended CT Phase Shift Value

3) Select a Digital Output from the drop-down list if being used.

4) Select a Data/Digital Scalar from the drop-down list.

28

Page 29

SELECTING A SCALAR

0

.00001

.00001

.00001

.01

.01

.1 1 .001

.001

.001

.01

.1

.1

2

.01

.01

.01

.01

.1

.1

3

.1

.1

.1

.01

.1

.1 4 1 1 1

.01 1 1 5 10

10

10

.01 1 1

≥6

100

100

100

.01 1 1

DID YOU KNOW: The

The use of Modbus protocols limits the data registers to a maximum of two

bytes (16 bits) or a maximum decimal value of 65535. Modbus requires that

the data be unsigned (positive) integer values. To overcome these

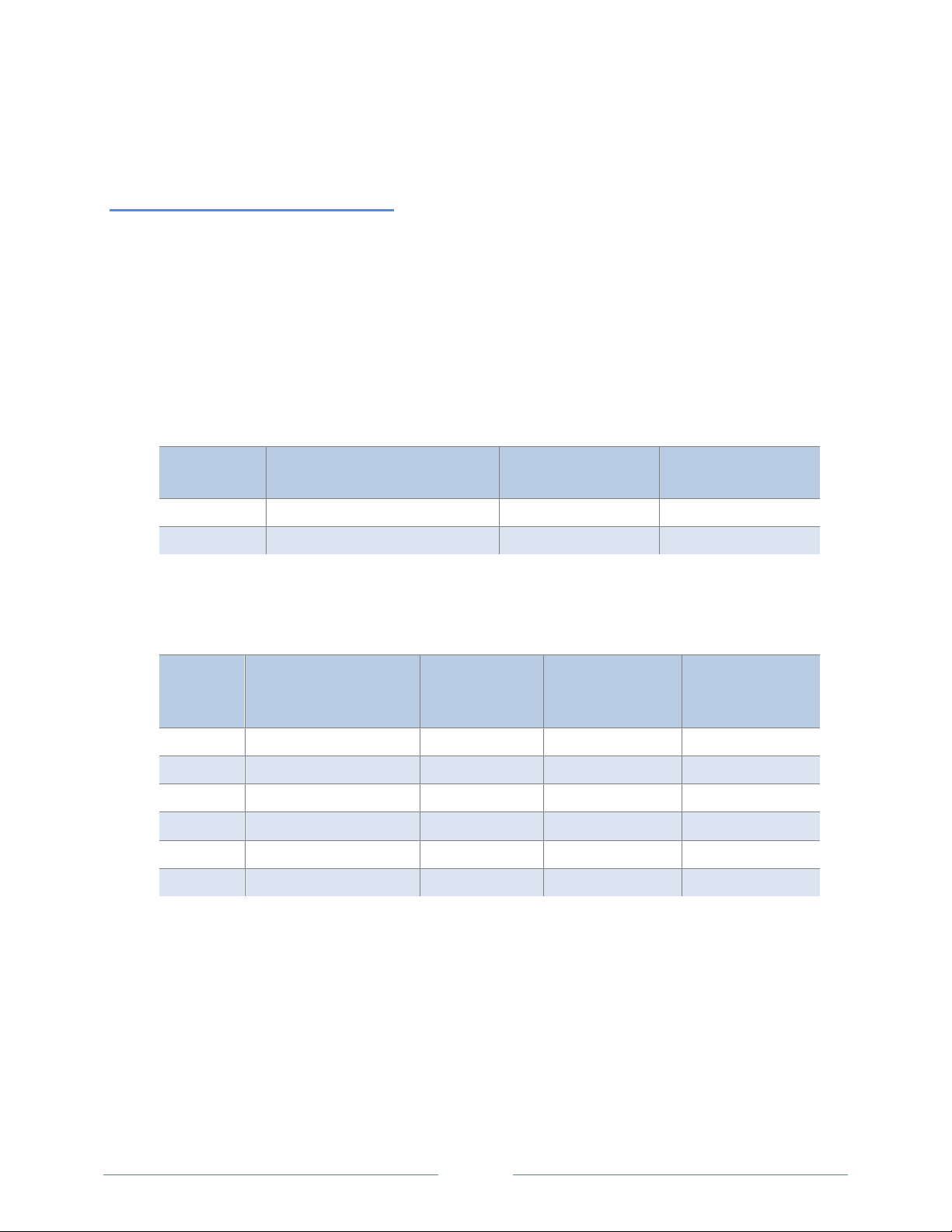

limitations some measured (and stored) values must be scaled to fit into the Modbus registers. The raw

value read from the Modbus registers is multiplied by a scalar to convert the raw data. The following

table lists the data scalars and the respective values for the PowerScout.

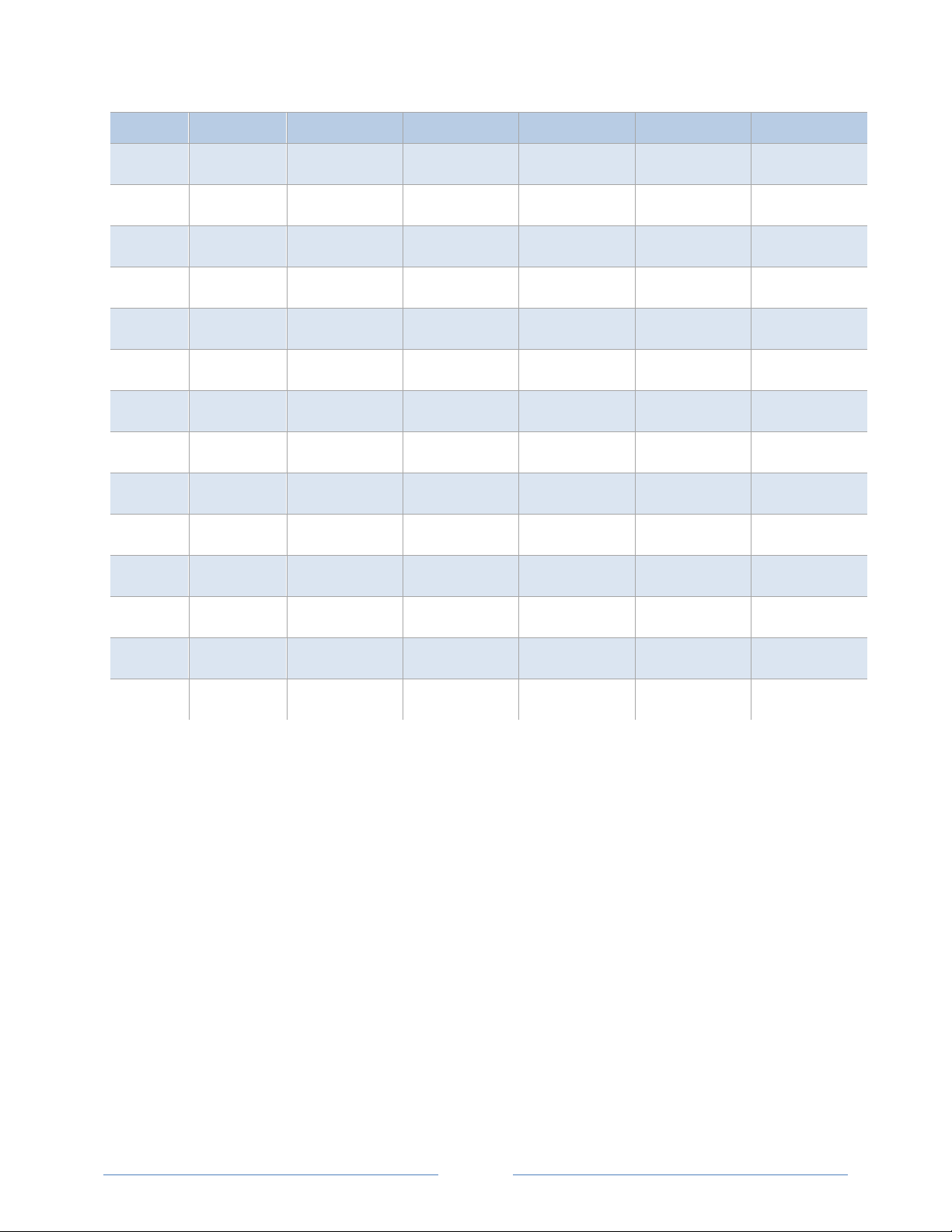

Scalar Value

Data Scalar

kW/kWh

Demand

kVAR/kVARh kVA/kVAh

Power

Factor

register value must

be less than 65,535.

Amps Volts

Table II-6: Data Scalars and Values for Registers 44001 thru 44061

The data scalar is stored in register 44602.

When selecting a data scalar, the following guidelines need to be considered:

If the data scalar selected is too low, an incorrect data result is returned from the register.

If the data scalar selected is too high, the significant digits following the decimal point are

removed.

After selecting a data scalar, the formula for calculating the actual value is:

register value X scalar value = actual value

Or, another way to state this formula is:

actual value/scalar value = register value

29

Page 30

The following table is an example when selecting a data scalar for 3-phase loads based on the CT size or

maximum current. These are the minimum recommended scalar settings.

CT Size or

Max. Current

50 Scalar 1 Scalar 2

100 Scalar 2 Scalar 2

200 Scalar 2 Scalar 2

400 Scalar 2 Scalar 2

600 Scalar 2 Scalar 3

1000 Scalar 3 Scalar 3

3000 Scalar 3 Scalar 3

3-phase Loads

230 volts 460 volts

Table II-7: Data Scalar Selection

Examples Using a Data Scalar

The following examples use kW throughout.

For example 1, the following data is used:

Volts x amps = watts 480 volts x 100 amps = 48,000 watts

Watts x 3 = system watts 48,000 watts x 3 = 144,000 watts (144kW)

Check the register’s value using the data scalar 2 value of .01:

System kW / scalar value = register value 144kW/.01 = 14,400

Since 14,400 is less than 65,535, using data scalar 2 is a good choice for this example.

For example 2, the following data is used:

480 volts x 1000 amps = 480,000 watts

480,000 watts x 3 = 1,440,000 watts (1,440kW)

Check the register’s value using the data scalar 1 value of .001:

1,440kW/.001 = 1,440,000

Since 1,440,000 is greater than 65,535, using data scalar 1 returns an incorrect result. Data scalar 1 is

not an appropriate choice.

Reviewing this example using the data scalar 3 value of .1 provides the following result:

1,440kW/.1 = 14,400

Since 14,400 is less than 65,535, using data scalar 3 is a good choice for this example.

30

Page 31

Values Requiring Two Registers

Additionally, some values (e.g., kilowatt hours) may cover a dynamic range that is larger than 65535 and

require two Modbus registers. Any parameter in the Modbus Register Assignment tables that shows

two registers (identified by the terms MSW (Most Significant Word) and LSW (Least Significant Word))

are examples of this wide-ranging parameter.

To interpret the values contained in these registers, the steps are:

1) Multiply the MSW register by 65536.

2) Add the result to the value found in the corresponding LSW register.

3) Multiply the result by the appropriate scalar value from Table II-6.

For example, assume that System Total True Energy (kWh) is desired and the

value of 5013 is read from register 44001 (LSW) and 13 is read from register

44002 (MSW) and that the register 44602 data scalar is set to 3.

To calculate the total kWh recorded:

Multiply the MSW by 65536: 13 X 65536 = 851968

Add the LSW: 851968 + 5013 = 856981

Multiply by the scalar 3 value of 0.1: 856981 X 0.1 = 85698.1 kWh

Comms Setup

DID YOU KNOW?

When reading two

register values,

ViewPoint

automatically

calculates the total

value.

Use this tab to change communication parameters for the meter, such as communication protocols and

how those communications are transferred. This screen displays the fields pertinent to your power

connection and communication protocol, so if you are connected by RS-485 then only those fields are

shown. However, if you are connected with a USB cable all fields are displayed. Changes to these fields

override any settings on the Communications tab.

31

Page 32

RS-485 SETTINGS

disable

Change the Data Bits or Baud Rate on the meter by using these fields.

NOTE: You will see the above dialog when you are connected via USB on an Ethernet PowerScout or

when connected via an RS-485 unit.

BACNET DEVICE SETTINGS

Enter a new value into any field and click Send Setup to Meter to update the Device ID (meter

identification), Max Master (# of units on network), or Max Info Frames (# of packets sent via MS/TP).

ETHERNET SETTINGS

To use BBMD: Enter an

IP Address or 0.0.0.0 to

NOTE: You will see the above dialog only when connected via an Ethernet PowerScout.

Connecting the Ports

Once your communication mode is selected, click Connect to establish a connection between the

computer and the PowerScout meter.

When the PowerScout is in the process of connecting to the computer, the Communication

Status LED flashes briefly followed by a solid green.

If the PowerScout cannot connect to the computer, the Communication Status LED flashes red

and returns to a solid green. Change the ViewPoint hardware settings and click Connect again.

ViewPoint fills the Device Info fields when the computer communicates with the PowerScout.

PowerScout meter installation can be verified using the ViewPoint software. Refer to Using ViewPoint

Software further in this document for more information.

32

Page 33

Establishing Communication Protocol

The PowerScout communicates using the BACnet MS/TP or Modbus RTU protocols via the

RS-485/Ethernet interface. To establish communication with a RS-485, the settings must meet the

following requirements:

The Modbus/BACnet address on the PowerScout and in the ViewPoint software must be set to

the same value.

The PowerScout meter default serial parameters are:

Parameter

Defaults

Baud 9600 76800

Data bits 8 8

Parity None None

Stop Bit 1 1

Table II-8: Serial Communication Settings

The supported baud rates include 9600, 19200, 38400, 57600 (Modbus only), 76800, and 115200

(Modbus only).

NOTE: The baud rate on the user interface (ViewPoint) must match the PowerScout setting. If these

settings differ, the PowerScout cannot communicate. There are no baud rate settings when connected

via Ethernet.

Modbus

Settings

BACnet

Settings

SWITCHING BETWEEN BACNET AND MODBUS MODE

Changing Communication Mode Using ViewPoint

Using the Comms Setup tab in ViewPoint is the preferred way to change communications modes

between Modbus and BACnet.

Note: The baud rate and serial settings may need to change between Modbus and BACnet. Setting

address switches to “00” will set the unit in Modbus protocol, 9600 baud rate.

If communication fails, see the section Changing Baud Rate or Communication Mode using Address

Switches (between Modbus and BACnet) on the next page.

33

Page 34

Changing the PowerScout from Modbus to BACnet mode:

1) Connect to the PowerScout using ViewPoint.

2) Go to the Read/Write Registers tab in ViewPoint.

3) Enter 44612 into the Register field or click List to select from the

Register Picker List.

4) In the Value field, enter 1833 to change to BACnet mode.

5) Click OK.

The status should say “Writing Value…”

Return to the Communications tab and connect.

Changing the PowerScout from BACnet to Modbus mode:

1) Connect to the PowerScout using ViewPoint.

2) Go to the Read/Set Objects tab in ViewPoint.

3) Enter 10190 into the Object field or click List to select from the Object Picker List.

4) In the Value field, enter 375 to change to Modbus mode.

5) Click OK.

The status should say “Writing Value…”

Return to the Communications tab and connect.

34

Page 35

Changing Baud Rate or Communication Mode Using Address Switches (between Modbus and BACnet)

This procedure is only required if Changing Communication Mode using ViewPoint (between Modbus

and BACnet) fails and the PowerScout needs to be returned to a particular communications protocol and

baud rate.

1) Power down the PowerScout (disconnect all voltage leads or the USB cable).

2) Set the rotary Address switches to “F” and “F”.

3) Power up the PowerScout (connect the black & red voltage leads to power or connect the USB

cable).

4) Set LSB to one of the following communication modes:

LSB Address

Switch

1 Modbus* Red On Off

2 BACnet Red On Red On

*Factory Default

Communication Mode RS-485 LED COM LED

Figure II-9: LSB Communication Mode

5) Next set MSB to one of the following baud rates:

MSB

Address

Baud Rate

Switch

1 9600* Off Off Green

2 19200 Off Green Off

3 38400 Off Green Green

4 57600 (Modbus only) Green Off Off

5 76800 Green Off Green

6 115200 (Modbus only) Green Green Off

PhaseChek

LED CT1

PhaseChek

LED CT2

PhaseChek

LED CT3

*Factory Default

Figure II-10: MSB Baud Rate

After powering up the PowerScout 3037, you will have 10 seconds to make changes. However, every

time a rotary switch is changed, the 10 second timer resets. After 10 seconds of no switch action, the

settings take effect and the switches revert to the Modbus Address selector if in Modbus mode or MAC

address if in BACnet mode.

FAILSAFE: If all address switches are “0,” the meter is placed in Modbus mode at 9600 baud rate.

Communication registers can be modified for baud rate and for mode.

35

Page 36

FIELD INSTALLATION

Mounting tabs,

PowerScout 3037 mounted

Handle with care

Once your PowerScout meter is set up for the desired communication method and protocol, it’s ready to

install out in the field.

Mounting a PowerScout 3037

WARNING! Remove the meter from all sources of voltage before mounting.

PowerScout meters must be installed in an approved electrical panel or enclosure using proper

installation practices according to the local electrical codes.

To mount the PowerScout 3037, use the two tabs provided at both ends of the case. Securely

mount the PowerScout near a dedicated circuit disconnect breaker.

within electrical panel

36

located on each end

of meter case

Page 37

The PowerScout 3037 can also be mounted on a 35 mm width DIN rail.

Top hat rail EN 50022

Wiring Connections on the PowerScout 3037

High voltage MAY BE PRESENT. Risk of electric shock. Life threatening voltages may be present.

Qualified personnel only.

Haute tension peut être présente. Risque de choc électrique. Tensions dangereuses peuvent

être présentes. Personnel qualifié uniquement.

PowerScout 3037 meters have the following connections:

USB port for powering the meter and communicating during setup, a three-wire connector for

the RS-485 BACnet/Modbus link, and an Ethernet port (optional).

Digital output port. The port can be used to output kWh, kVARh, or kVAh pulses to external

devices, or to toggle on and off to control a remote device or relay.

Three CT inputs.

Four voltage connections. Voltage leads are customer supplied. PowerScout meters are self-

powered from L1 and L2.

37

Page 38

Completing the Field Installation

0

.00001

.00001

.00001

1

.001

.001

.001

2

.01

.01

.01

3

.1

.1

.1 4 1 1 1 5 10

10

10

≥6

100

100

100

Follow these steps to complete the field installation of your PowerScout meter:

Connect whatever communications cable you are using to the building network.

Connect your pulse output, if used. The port can be used to output kWh, kVARh, or kVAh pulses

to external devices, or to toggle on and off to control a remote device or relay. See Using the

Pulse Output Port Function.

Connect the CTs. See Wiring CTs.

Connect the voltage and power the meter. See Connecting Voltage.

Using the Pulse Output Port Function

Pulse output is used to generate pulses for external devices such as data loggers that can accept pulses

but do not have BACnet or Modbus capability. The PowerScout 3037 can generate pulses based on

accumulated value(s) such as system kWh, system kVARh, and system kVAh. When a pulse is generated

by the meter, the pulse LED will briefly flash, otherwise it will remain dark.

When in Modbus, the pulse output is scaled by the Modbus data scalar register 44602. When in BACnet,

the pulse output is scaled by the CT Pulse Scalar object 12030. The pulse scalar table is the same as the

Modbus data scalar table. For example, when the data scalar is set to 3, each pulse will represent

.1kWh, .1kVAh and .1kVARh.

Pulse Scalar Value

Data Scalar

kWh kVAh kVARh

Table III-1: Pulse Scalar Values

38

Page 39

For system pulse output:

kWh pulse output—write 44001 into the pulse output configuration object.

kVAh pulse output—write 44011 into the pulse output configuration object.

kVARh pulse output—write 44008 into the pulse output configuration object.

MODBUS OUTPUT PORT REGISTERS

Modbus

Register

Offset Register Name Detailed Description

0 = output LOW (closed)

1 = output HIGH (open) [default]

Register 45110 must = 0 to use

0 = No pulses, Port may be used as an

on/off—

open/closed switch

44001 = System kWh pulses

44008 = System kVARh pulses

44011 = System kVAh pulses

0 = normally open (HIGH)

1 = normally closed (LOW)

44402 4401/5301

45110 5109/5309

45111 5110/5310

Port 1 output control

when used as an on/off—

open/closed switch

Digital Port 1

Configuration

Turns pulses on/off

Port 1 pulse output relay

type

Table III-2: Modbus Digital Port Pulse Output

BACNET OUTPUT PORT OBJECTS

Refer to the following two tables to configure the PowerScout output port when using the BACnet

protocol.

Object

Identifier

13020

Port 1 output control when used as an

on/off—open/closed switch

Object Name Detailed Description

0 = output LOW (closed) 1 = output HIGH

(open) [default]

Object 13100 present value must = 0 to use

0 = No pulses, Port may be used as an

on/off—

13100

13110 Port 1 pulse output relay type

Digital Port 1 Configuration

Turns pulses on/off

open/closed switch

44001 = System kWh pulses

44008 = System kVARh pulses

44011 = System kVAh pulses

0 = normally open (HIGH)

1 = normally closed (LOW)

Table III-3: BACnet Digital Port 1 Pulse Output

39

Page 40

Wiring CTs

1) Insert the CT wires into the connector/s. See the following CT Type Wiring

Connections table for the correct wiring configuration.

CT Type Wiring Connections

Split-Core *2 wire (+, –)

PowerScout 3037

1) Attach the CTs onto the PowerScout connections labeled CT 1, CT 2 and CT 3.

2) Place the CTs on the phase wires of the load to be monitored and corresponding to the phase of the

voltage leads. The CT labeled CT 1 must be placed on L1 phase voltage wire, CT 2 must be on the L2

voltage and CT 3 on the L3 voltage. Refer to PhaseChek

the CT LEDs and verifying the CT installation.

™

later in this section for information about

RōCoil *3-wire (+, –, shield)

40

Page 41

CONNECTING SPLIT-CORE STYLE MILLIVOLT CTS TO A LOAD

1) Open the CT by holding on to the removable leg and pulling it apart.

2) Connect CT around the load conductor to be measured. Make sure the maximum current of the

conductor does not exceed the maximum CT rating listed on the CT data sheet.

3) Carefully re-connect the removable leg while ensuring the CT core alignment matches. The

conductor should be in the inside of the CT window.

4) Repeat Steps 1-3 if you are using more than one CT.

41

Page 42

5) Connect the white wire on the CT to the positive

D

? Correct orientation of a CT is

terminal on the measuring device.

6) Connect the black wire on the CT to the negative

terminal on the measuring device.

ID YOU KNOW

required to ensure proper measurement. If an

arrow is shown on the CT label, it should be

pointed toward the load. Otherwise, use the

instructions printed on the CT.

CONNECTING RŌCOIL CTS TO A LOAD

To install the RōCoil CT to the conductor(s):

1) Open the CT by squeezing the connector latch and

pulling it apart.

2) Connect the CT around the load conductor to be

measured. Orient the CT so that the arrow on the CT

case points towards the load. Make sure the maximum

current of the conductor does not exceed 5,000 amps.

3) Push the connector back together with the conductor

within the loop of the CT.

Repeat the above three steps if you are using more than

one RōCoil CT.

To connect the CTs wires to the terminals on the PowerScout:

1) Connect the CTs brown wire to the negative terminal on the

connector. See photo.

2) Connect the CTs white wire to the positive terminal on the

connector.

3) Connect the bare shield wire from the RōCoil to the “S”

shield terminal that is part of the connector. This reduces

interference and improves accuracy of the CT.

42

Page 43

Negative

Positive

Shield

PowerScout 3037 w/RōCoil CTs

Connecting RōCoil CTs

attached to load

43

Page 44

CT WIRE LEAD POLARITY

D

? The PowerScout is rated

CT Type CT Lead + CT Lead -

Rogowski (RōCoil)* White Brown

Split Core mV White Black

Clamp On mV Red Black

Table III-4: CT Polarity

NOTE: The directionality for Rogowski CTs is the arrow points toward the load (e.g. motor).

* RōCoils have a shield wire which must be connected to the meter. This reduces interference and

improves accuracy of the CT.

Connecting Voltage

1) Connect the voltage leads (L1, L2, L3, and N, as necessary) to the meter. A voltage lead of 14 AWG

THHN Minimum 600VAC rating (or equivalent in order to maintain 600VAC safety rating of the

device) is required.

2) Connect the leads to the circuit breaker.

a) Refer to the wiring diagrams in for wiring

connection specifics. Follow local electrical codes

during this installation.

b) IMPORTANT: Verify the breaker is marked as the

disconnect breaker for the meter.

NOTE: Refer to the Safety Summary in the Introduction

section for information on DC voltage connections.

ID YOU KNOW

for 600V Over-Voltage Category III.

Cat III is for measurements performed in

the building. Examples are

measurements on distribution boards,

circuit-breakers, wiring including cables,

bus bars, junction boxes, switches, and

socket outlets in a fixed installation, and

equipment for industrial use. Other

equipment could include stationary

motors with a permanent connection to

the fixed installation.

44

Page 45

OWERING THE METER

P

Connect the PowerScout meter 14 AWG THHN

Minimum 600VAC rating (or equivalent in order to

maintain 600VAC safety rating of the device) voltage

leads as close as possible to a building-installed,

dedicated circuit disconnect breaker. Mark the breaker

as the “disconnect” for the PowerScout. Refer to the

wiring diagrams for specifics of the wiring connections.

Follow local electrical codes during this installation.

PowerScout meters are self-powered from the L1 and L2

lines. When 80–600VAC or DC is placed across the L1 and

L2 wires, the three phasing LEDs begin to flash in

sequence.

POWERSCOUT SINGLE-PHASE CONNECTIONS

The PowerScout meter can be used to monitor single-phase loads. There are several guidelines to keep

in mind about this type of connection:

1) The PowerScout is powered from a potential between L1 and L2. This can be phase-to-phase (230V)

or phase-to-neutral (115V). With a single-phase 230V panel, the L1 and L2 voltage leads are

connected between the L1 and L2 voltage sources. With a 115V circuit, the L1 voltage lead is

connected to the L1 “hot lead,” and the L2 voltage lead is connected to neutral.

2) Each CT must be paired with the correct voltage source. The current and voltage need to be in-

phase for accurate measurements. For instance, CT 1 would monitor branch circuit supplied by

voltage source L1, and so on.

3) The neutral must be connected because the PowerScout uses line-to-neutral measurements for all

calculations.

A Typical 230V Single-Phase Panel Setup (US Wire Colors)

Connect the Black L1 voltage lead to Voltage L1, Red L2 voltage lead to L2 voltage, White Neutral voltage

lead to neutral. CT1 would monitor L1 loads and CT2 would monitor L2 loads. Based on the above

guidelines, CT3 can be used if the Blue L3 voltage lead is connected to either L1 or L2. As long as voltage

lead L3 and CT3 are in-phase, the PowerScout meter will provide correct kW readings. If the Blue L3

voltage lead was connected to L2 voltage source, then CT3 could monitor any L2 branch circuit. Or, if the

Blue L3 voltage lead was connected to L1 voltage source, then CT3 could monitor any L1 branch circuit.

45

Page 46

A Typical 115V Single-Phase Panel Setup

Connect the Black L1 voltage lead to Voltage L1 (hot), Red L2 voltage lead to Neutral, and White N

voltage lead to neutral. CT1 would monitor the L1 load. CT3 can be used if the Blue L3 voltage lead is

connected to L1. CT3 could then monitor any L1 branch circuit.

System Values

System values are the sum of L1 + L2 + L3 measurements. System values may not be meaningful since

two different devices or loads can be monitored by a single PowerScout element.

When paired with the right voltage phase, each CT provides individual kW/kWh readings for that CT

channel.

46

Page 47

PowerScout 3037 Wiring Diagrams

THREE-WIRE DELTA

Use a Service Type 0 (zero) value for BACnet Object 12080 or a 0 (zero) value for Modbus Register 44607

on this wire configuration. DENT Instruments recommends using the 3 CT Method (WYE) for delta loads.

47

Page 48

FOUR-WIRE WYE

Use a Service Type 0 (zero) value for BACnet Object 12080 or a 0 (zero) value for Modbus Register 44607

on this wire configuration.

48

Page 49

TWO-WIRE SINGLE PHASE

Use a Service Type 0 (zero) value for BACnet Object 12080 or a 0 (zero) value for Modbus Register 44607

on this wire configuration.

49

Page 50

THREE-WIRE SINGLE PHASE

Use a Service Type 0 (zero) value for BACnet Object 12080 or a 0 (zero) value for Modbus Register 44607

on this wire configuration.

50

Page 51

Verifying Installation with PhaseChek

PhaseChek1 is a unique feature of the PowerScout series instruments that simplifies installation by

ensuring proper CT orientation and avoiding faulty data collection.

Verifying the PowerScout Meter Setup Using the LEDs

The PowerScout 3037 uses three bi-color PhaseChek LEDs. These LEDs provide the following

information:

All LEDs are green—the system power factor is greater than 0.55 and the CTs are properly

placed on the corresponding voltage phases.

Any one LED is red—there is a phasing connection error.

Two LEDs are red and one is green—two CTs are reversed.

All three LEDs are red—all CTs are incorrectly connected.

DID YOU KNOW? If the total system

power factor is less than 0.55, the

LEDs will be red even if

connected properly. This

situation is rare but could occur

if, for example, the load to be

monitored is a lightly loaded

electric motor where it is

common for the power factor to

be less than 0.55 and the

corresponding LEDs will be red.

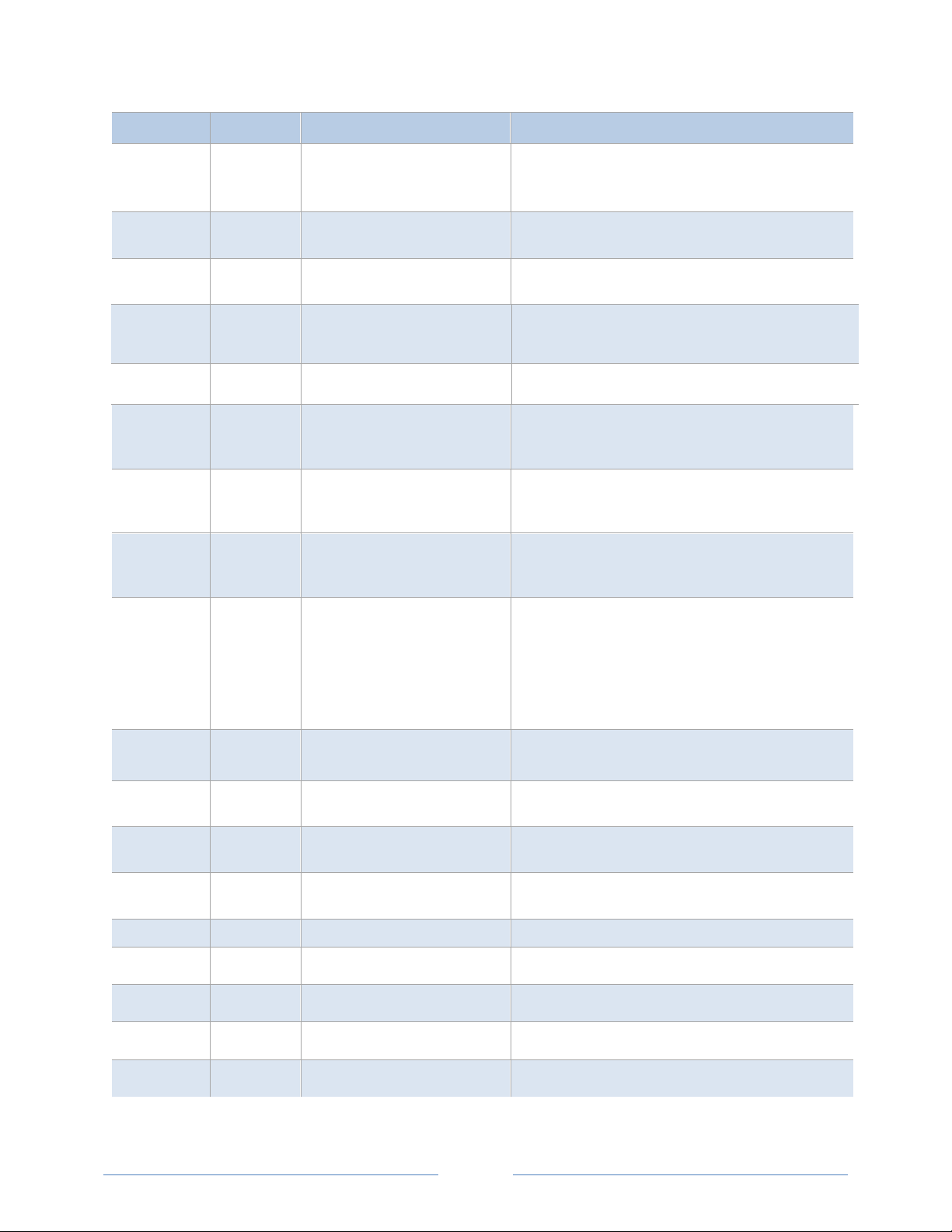

The following table describes the PhaseChek error conditions and the appropriate correction.

PhaseChek Error Table

CT1 CT2 CT3 Error Description Correction

Setup is correct and the system power factor

is greater than 0.55.

-orAll CTs are disconnected.

All CTs are incorrectly connected,

-or-

The system power factor is less than 0.55.

1