Page 1

BACnet DUCT SERIES

Installation & Operation Instructions

GENERAL INFORMATION

The BACnet Duct Series sensor is designed for use with

electronic controllers in commercial heating and cooling

building management systems. The ACI BACnet Duct

Series sensor can be ordered to monitor temperature, RH,

or temp/RH in commercial HVAC ductwork. It uses BACnet

MS/TP for physical connection to a BAS or controller, has

dip switches to set addresses and baud rate, and has on

board end-of-line termination. There is no analog output.

WIRING INSTRUCTIONS

The BACnet Duct Series temperature sensor has a

depluggable terminal block located on the front of the

PCB. For ease of wiring, we recommend removing the

block, wiring, and reattaching before mounting. 16 to 22

AWG two conductor shielded cable is recommended for

powering the sensors.

ACI recommends using Belden 3105 or compatible cable

for RS-485 communication wiring. This wire has 120 ohm

input impendence. The terminal blocks allow for (1) or (2)

wires to be connected in each position for daisy chaining.

Daisy chain the RS-485 wiring and do not use “Star” or “T”

wiring. Avoid running communication wires next to AC

line voltage wires. These can be sources of noise that can

aect signal quality.

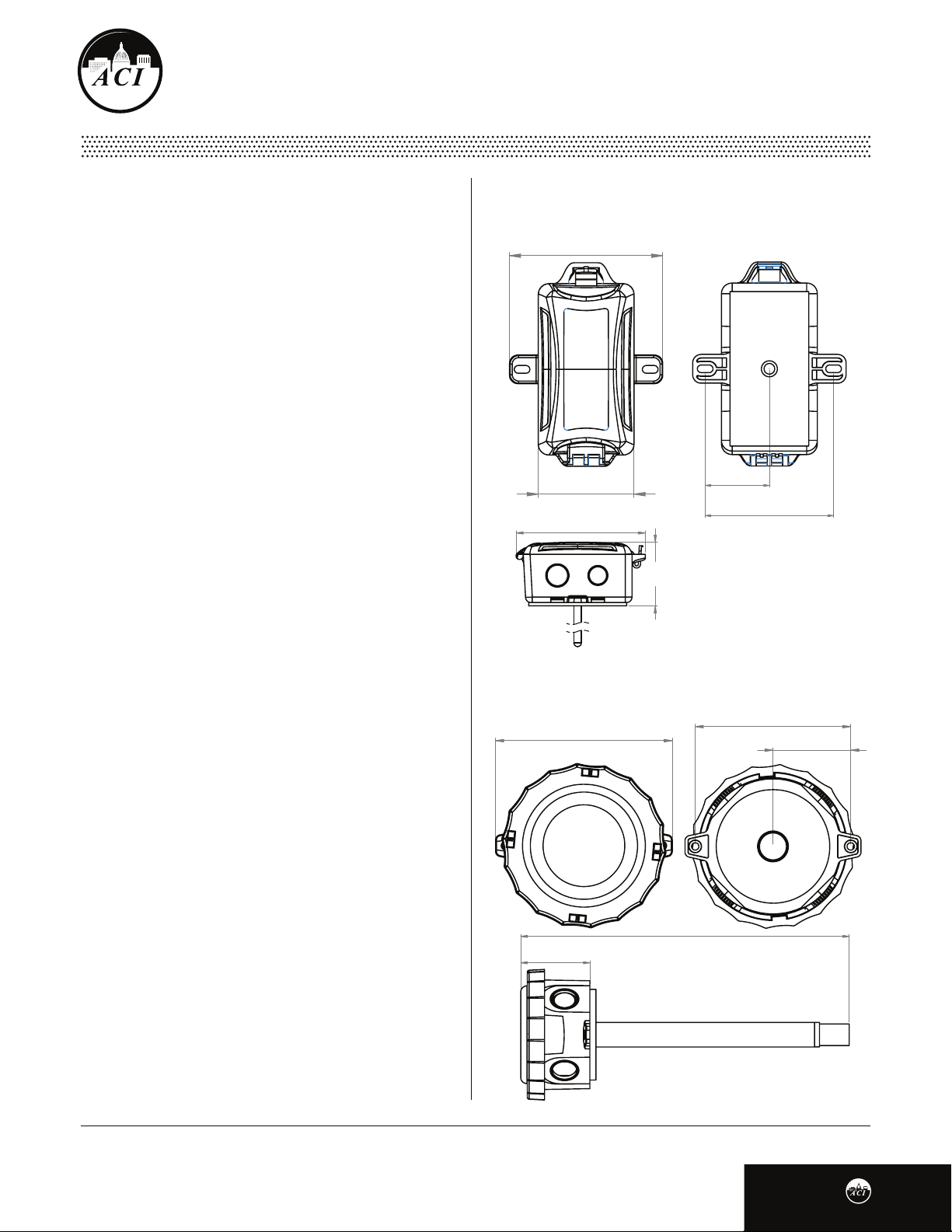

FIGURE 1: ENCLOSURE DIMENSIONS

PLASTIC BOX (-PB): TEMP. ONLY

3.60"

(91.44 mm)

2.25"

(57.15 mm)

4.79"

(121.55 mm)

2.35"

(59.80 mm)

EURO (-EH): RH and RH/TEMP.

4.30"

(109.22 mm)

1.51"

(38.25 mm)

3.01"

(76.51 mm)

3.80"

(96.56 mm)

1.90"

(48.28 mm)

PRECAUTIONS

Remove power before wiring. Never connect or

•

disconnect wiring with power applied.

It is recommended you use an isolated UL-listed

•

class 2 transformer when powering the unit with 24

VAC. Failure to wire the devices with the correct

polarity when sharing transformers may result in

damage to any device powered by the shared

transformer.

Page 1

2.12"

(53.72 mm)

10.05"

(255.32 mm)

Version 1.0

I0000804

Page 2

PRECAUTIONS (Continued)

DO NOT RUN THE WIRING IN ANY CONDUIT WITH

•

LINE VOLTAGE (24/120/230 VAC).

If the 24 VDC or 24VAC power is shared with devices

•

that have coils such as relays, solenoids, or other

inductors, each coil must have an MOV, DC/AC

Transorb, Transient Voltage Suppressor (ACI Part:

142583), or diode placed across the coil or inductor.

The cathode, or banded side of the DC Transorb or

diode, connects to the positive side of the power

supply. Without these snubbers, coils produce very

large voltage spikes when de-energizing that can

cause malfunction or destruction of electronic

circuits.

MOUNTING INSTRUCTIONS

For optimal readings, follow these tips:

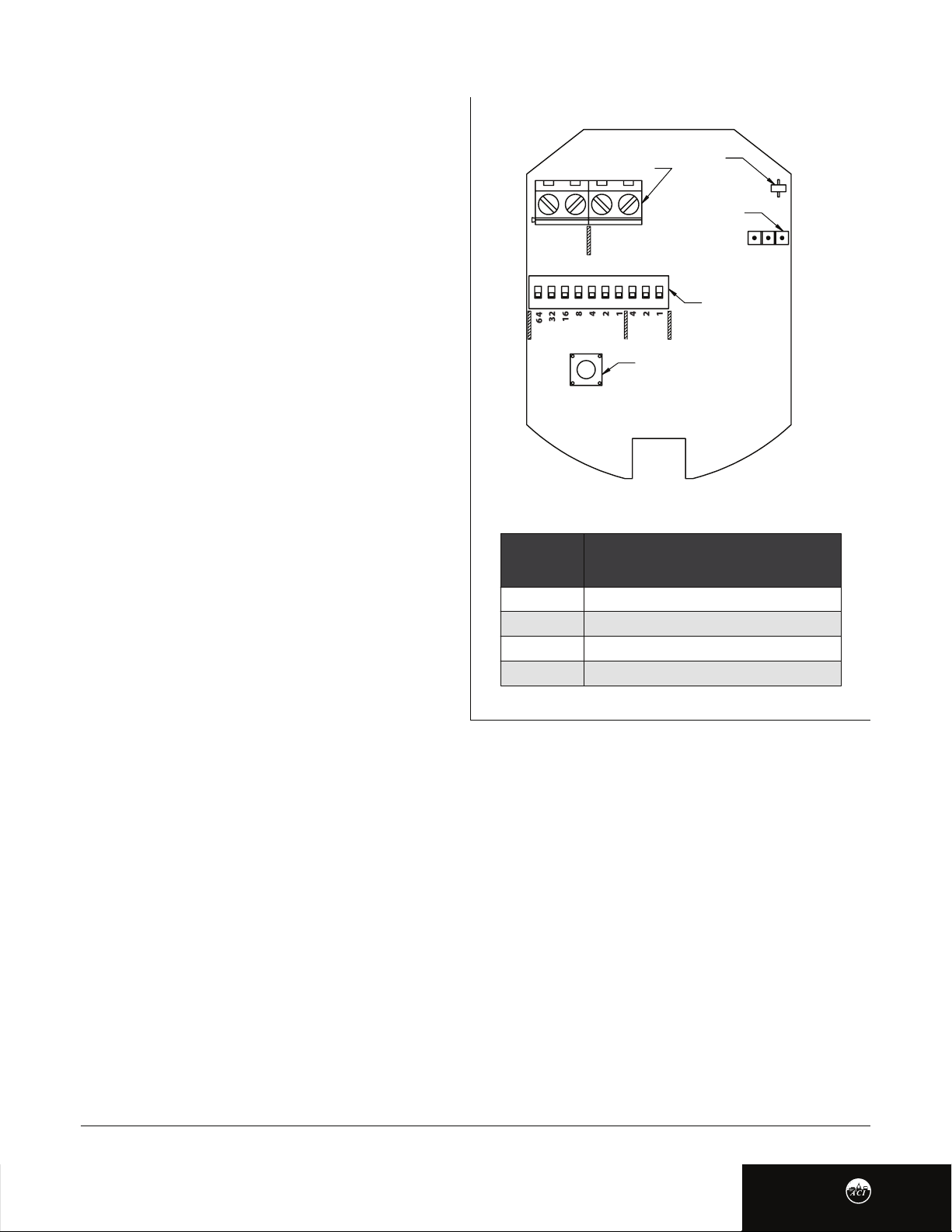

FIGURE 2: LAYOUT

TERMINAL BLOCKS

V D-GN

POWER

23618421421

4

6

ADDRESS BAUD

D+

BACNET

RESET BUTTON

LED

END OF LINE

TERMINATION

DIP SWITCH

EN DIS

The sensor should be mounted in the middle of the

•

duct where air circulation is well mixed (no

stratication), and not blocked by obstructions.

Stratication and obstructions can cause sensing

errors. An example is downstream from a heating or

cooling coil.

Duct probe should be placed (3) to (4) duct

•

TABLE 1: WIRING CONNECTIONS

TERMINAL

BLOCKS

+V

GN

D-

D+

CONNECTIONS

Power Supply Positive 12-36VDC / 24VAC

Power Supply Common or Ground

EIA-485 Data Negative

EIA-485 Data Positive

segments down from any bend or obstructions

and away from 90° bends.

Mount the sensor on the top or sides of duct work; mounting on the bottom risks damage due to moisture.

•

The BACnet Duct Temperature-only sensor uses the Plastic Box (-PB) enclosure. Alternatively, the Euro (-EH) enclosure is

used for the BACnet Relative Humidity (RH) sensor and BACnet RH/Temperature Combo sensor (see FIGURE 1). Be sure to

follow the instructions listed for your enclosure.

PLASTIC BOX (-PB) ENCLOSURE INSTALLATION

Drill a 3/8” hole in the duct and insert the probe through the hole until the foam pad is tight to the duct.

Drill pilot holes for the (2) mounting screws. Use the enclosure ange as a guide, or use the dimensions listed on page 1 to

measure out.

Now fasten and insert (2) screws #8 x ¾” TEK (provided and recommended) through the mounting holes in the ange and

tighten until the unit is held rmly to the duct.

Refer to the wiring instructions (p. 2) to make necessary connections. After wiring, shut the cover of the enclosure.

*Reference FIGURE 2

Page 2

Version 1.0

I0000804

Page 3

MOUNTING INSTRUCTIONS (Continued)

EURO (-EH) ENCLOSURE INSTALLATION

Drill a 7/8” hole in the duct and insert the probe through

the hole until the foam pad is tight to the duct. Drill pilot

holes for the (2) mounting screws. Use the enclosure

flange as a guide, or use the dimensions listed on page 1

to measure out.

FIGURE 3: DUCT MOUNTING

0.375"

(9.525 mm)

EURO (-EH)

Now fasten and insert (2) screws #8 x ¾” TEK (provided

and recommended) through the mounting holes in the

flange and tighten until the unit is held firmly to the

duct.

Refer to the wiring instructions (p. 2) to make necessary

connections. After wiring, twist the cover until the enclosure is

tightly sealed.

*Reference FIGURE 2

PLASTIC BOX

(-PB)

0.875"

(22.23 mm)

BACnet MS/TP INTERFACE

The BACnet Master-Slave/Token-Passing (MS/TP) data link protocol uses EIA-485 as a two-wire, daisy chain network. A branch is

a discrete chain of devices connected to a controller. The max number of devices per segment is (32), as per the BACnet

specications. 4000 ft (1219.2 m) is the maximum recommended length for a segment, which includes all devices from the

controller to the last device in the daisy chain. ACI’s BACnet sensors are master devices. Only master nodes are allowed to send

and receive tokens on the MSTP network.

Each branch must have all devices connected with (+) connected to (+) and (-) connected to (-). If a shielded cable is used, this is

not to be connected to the devices. The shield cable should only be connected on one end to earth ground, usually at the

controller. The start and end of each branch should have a termination resistor at the device level or at the controller.

Each device must be congured for the correct baud rate and have a unique address in each branch. The baud rate for the branch

is set by the controller. This product has auto-baud for ease of network conguration but setting the baud rate using the DIP

switches is recommended.

ADDRESS SELECTION

Switches 1-7 are used to set the BACnet address. Refer to TABLE 2 for switch settings. Each device in a network branch must

have a unique address. The value of each position is printed on the board. By default, the address is (0). If the device is

powered when a change is made, the device must be power cycled or reset for changes in address to be made.

TABLE 2: ADDRESS SELECTION

ADDRESS

0

1

12

SW 1 (64)

0

0

0

SW 2 (32)

0

0

0

SW 3 (16)

0

0

0

SW 4 (8)

0

0

1

SW 5 (4)

0

0

1

SW 6 (2)

0

0

0

SW 7 (1)

0

1

0

Page 3

Version 1.0

I0000804

Page 4

BAUD RATE SELECTION

Switches 8-10 are used to set the BACnet baud rate.

Refer to TABLE 3 for switch settings. Where (0) is low

and (1) is high. By default, the device is in auto-baud.

If the system’s baud rate is known, it is

recommended to set the specic baud rate to match

the system.If the device is powered when a change is

made, the device must be power cycled or reset for

changes in baud rate to be made.

TABLE 3: BAUD RATE SELECTION

BAUD RATE

Auto-Baud

9600

19200

38400

57600

76800

115200

SW 8

0

0

0

0

1

1

1

SW 9

0

0

1

1

0

0

1

SW 10

0

1

0

1

0

1

0

EOL TERMINATION

FIGURE 4: EOL TERMINATION JUMPERS

RESISTANCE SELECTION

RS-485 requires that the last device in a chain have

a termination resistor. This is controlled using a

jumper in the EN (enabled) position marked on

FIGURE 4 (right). When the jumper is set to EN

(enabled), a 120 Ω resistance is added in parallel to

the data line. When the jumper is set to DIS

(disabled), the resistance is not added. By default,

the jumper is placed in the DIS (disabled) position.

END OF LINE

TERMINATION ENABLED

EN DIS EN DIS

END OF LINE

TERMINATION DISABLED

DEVICE CONFIGURATION THROUGH BACnet

DEVICE INSTANCE

The Device Instance, by default, is 1035000 plus the Address. For example, an Address of 21 results in a default address

of 1035021. This can be changed once the device is connected to the network, but each device instance must be unique

within the network. The device instance must be unique throughout the entire BACnet network, not just this segment.

DEVICE LOCATION

The device location is optional but is intended to allow for further denition of the device’s location. The device location can

be a character string up to 64 characters in length.

DEVICE NAME

By default, the device name is based on the type of device and the address. The device name can be a character string up to

(32) characters in length. This can be changed once the device is connected to the network. For example: Temperature

Sensor - 034. The device name must be unique throughout the entire BACnet network, not just this segment.

DEVICE DESCRIPTION

By default, the device name is based on the type of device and the address. The device name can be a character string up to

(32) characters in length. This can be changed once the device is connected to the network. For example: Temperature

Sensor - 034. The device name must be unique throughout the entire BACnet network, not just this segment.

Page 4

Version 1.0

I0000804

Page 5

DEVICE CONFIGURATION THROUGH BACnet (Continued)

LED INFORMATION

One LED indicates three statuses. Solid green shows that power is good, but no data is transmitting. A solid Amber indicates that

auto-baud is set and no data has been received to set a baud rate. Green/Amber ashing indicates data is being transmitted or

received. Solid Red LED status indicates an error state, usually loss of communication on the network. If this status remains for

(10) times the APDU timeout, the device will automatically reset. If this state remains longer than that, reset the device.

TEMPERATURE CONFIGURATION

One LED indicates three statuses. Solid green shows that power is good, but no data is

transmitting. A solid Amber indicates that auto-baud is set and no data has been

received to set a baud rate. Green/Amber ashing indicates data is being transmitted

or received. Solid Red LED status indicates an error state, usually loss of communication

on the network. If this status remains for (10) times the APDU timeout, the device

will automatically reset. If this state remains longer than that, reset the device.

TABLE 4: UNIT SETTING

UNITS

°F

K

VALUE

64

63

TEMPERATURE AND RH OFFSET

This device allows for a temperature oset of +/-5

+/-10%. By default, these values are set to (0), meaning no oset is added.

These are set by writing to the present value of the Temperature Calibration Oset (AV0) or RH Calibration Oset (AV1).

The value written must be within the specied range or an error will be returned. To set these back to factory settings,

write any changed values to (0).

TEST MODE

For the Sensor objects (AI0 and AI1), a test mode can be set by writing the Boolean value true to the “out-of-service”

property. Then the present-value can be set to any valid test value the user requires. This allows a user to test reactions

to specic values returned by this device.

RESET

The reset button can be used to reset the device without disconnecting power. The location of this button is shown in FIGURE 3.

°C (9 °F) and an RH oset of

°C

62

TABLE 5: BACnet OBJECT TABLE

OBJECT TYPE

Device

Analog

Inputs

Analog

Values

OBJECT ID

- - - - - - - - - -

AI-0

AI-1

AV-0

AV-1

OBJECT NAME

BN11x0

Temperature Sensor

RH Sensor

Temperature

Calibration Oset

RH Calibration Oset

RANGE

0-4194302

-40.0 - 302.0

0.0 - 100

-9.0 - 9.0

-10.0 -10.0

BACnet ENGINEERING UNITS

- - - - - - - - - - - - - - - - - - - - - - - - - -

degrees-Fahrenheit (64) - default

percent-relative-humidity (29)

delta-degrees-Fahrenheit (120)

percent-relative-humidity (29)

Page 5

Version 1.0

I0000804

Page 6

PRODUCT SPECIFICATIONS

Supply Voltage:

Current Consumption:

Number Temperature Sensing Points:

Operating Temperature Range:

For Board:

For Sensor (Temp-Only):

For Sensor (RH and Temp/RH):

Temperature Measurement Accuracy:

Temperature Calibration Oset:

Number RH Sensing Points:

RH Measurement Range:

RH Measurement Accuracy:

RH Calibration Oset:

Temperature / RH Update Rate:

Communication Protocol:

Sensor Addresses:

Supported Baud Rates:

Device Instance Number:

Connections / Wire Size:

Terminal Block Torque Rating:

Storage Temperature Range:

Operating Humidity Range:

Sensing Probe & Filter Material:

Enclosure Specications:

Foam Pad Material / Flammability:

12 to 36 VDC / 24 VAC +/- 10%, 50/60 Hz (Reverse Polarity Protected)

25 mA maximum (0.67 VA)

One

-22 to 176°F (-30 to 80°C)

-40 to 302°F (-40 to 150°C)

-40 to 176°F (-40 to 80°C)

@ 77°F (25°C): +/- 1.0°F (+/- 0.5°C)

+/- 9°F (+/- 5°C) (Field Congurable)

One

0 to 100%

@ 77°F (25°C): +/- 2% from 10 to 90% RH

+/- 10% RH (Field Congurable)

4 seconds

BACnet MS/TP; EIA RS-485

0 to 127 (0 (Default); Field Selectable)

Auto Baud (Default), 9600, 19200, 38400, 57600, 76800, 115200 (Field Selectable)

1035000 + Address (example: Address 127 = 1035127; Field Congurable)

Screw Terminal Blocks / 16 AWG (1.31 mm2) to 22 AWG (0.33 mm2)

0.45 lbf-in (0.5 Nm) nominal

-40 to 185°F (-40 to 85°C)

10 to 95% RH, non-condensing

304 Stainless Steel | Diameter: 0.750” (19.05 mm)

“-PB” Enclosure: ABS Plastic, UL94-HB, Plenum Rated

“-EH” Enclosure: ABS Plastic with UV Protectant, UL94-V0

Neoprene/EPDM/SBR Polymer / UL94-HBF; FMVSS-302; MIL-R-6130C

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling centre. Do not

dispose of with household waste. Do not burn.

BACnet is a registered trademark of ASHRAE. ASHRAE does not endorse, approve or test products for compliance with ASHRAE standards. Compliance of listed products to the requirements of ASHRAE

Standard 135 is the responsibility of BACnet International (BI). BTL is a registered trademark of BACnet International.

Page 6

Version 1.0

I0000804

Loading...

Loading...