Page 1

Automation Components, Inc.

PRESSURE | DIFFERENTIAL PRESSURE SWITCHES | AFS

AFS

Dierential Pressure Switches (Metal)

The AFS Series Dierential Pressure Switches are general purpose proving switches designed

for both HVAC and Energy Management applications. These pressure switches can be used to

sense positive, negative, or dierential air pressures when used in conjunction with an A/SPT

or A/VPT Series sampling tube. The plated housing contains a diaphragm, calibration spring

and single snap-acting contact closure with either a manual or automatic reset switch

depending on the model. The enclosure cover contains a ½” conduit knockout and guards

against accidental contact with the live switch terminal screws as well as the set point

adjusting screw.

Applications: Monitoring Filter Blockage, Proof of Flow, Prove Excessive or Insucient Flow, Alarms and Control

PRODUCT SPECIFICATIONS

Input Pressure Range:

Set Point Range:

Field Adjustable “Operate” Range:

Field Adjustable “Release” Range:

Approximate Switching Dierential:

Contact (Load) Rating:

Contact Arrangement:

Measured Media:

Maximum Pressure:

Life Expectancy:

Operating Temperature Range:

Mounting Direction:

Enclosure Material:

Sample Line Connections:

Electrical Connections:

Conduit Opening:

Agency Approvals:

Dimensions (H x W x D):

Weight:

AFS-222: 0.05 +/- 0.02” to 12” wc | AFS-262: 0.05 +/- 0.02” to 2.0” wc

AFS-460: 0.40 +/- 0.06” to 12.0“ wc

AFS-222: 0.05 +/- 0.02” to 12.0” wc | AFS-262: 0.07” to 2.0” wc | AFS-460: 0.40 +/- 0.06” to 12“ wc

AFS-222: 0.07 to 12.0” wc | AFS-262: 0.07” to 2” wc | AFS-460: 0.46” to 12“ wc

AFS-222: 0.04 to 11.2” wc | AFS-262: 0.04” to 1.9” wc

Progressive, increasing from 0.02 +/- 0.01” wc @ minimum set point to 0.8” wc @ maximum set point

AFS-222/AFS262: 300 VA pilot duty @ 115 to 277 VAC, 60 Hz; 15A non-inductive to 277 VAC, 60 Hz

AFS-460: 15A @ 125, 250, or 277 VAC / 1/2A @ 125 VDC, 1/4A @ 250 VDC /

¼ hp @ 125 VAC, ½ hp @ 250 VDC

AFS-222/AFS-262: SPDT w/ Automatic Reset | AFS-460: SPST-NC w/ Manual Reset

AFS-222/AFS-262: Air or combustion by-products that will not degrade silicone | AFS-460: Air

0.5 PSI (0.03 Bar)

AFS-222/AFS-262: 100,000 cycles minimum @ 1/2 psi (0.03 Bar) maximum pressure / cycle and

maximum load AFS-460: 6,000 cycles minimum @ 1/2 psi (0.03 Bar) maximum pressure / cycle &

maximum load

-40 to 180ºF (-40 to 82ºC)

Any vertical plane

Galvanized Steel

Accepts ¼” OD rigid or semi-rigid metallic tubing using integral compression tting, ferrule and nut /

“-112 Option”: Includes two barbed ttings that accepts ¼” exible plastic tubing

Screw type terminal with cup washers

Accepts ½” Conduit (7/8” (22.3 mm) opening)

UL, CUL, FM, CSA, CE, ISO 9001: 2008

6.25” x 4.46” x 3.18” (158.8 mm x 113.3 mm x 80.8 mm)

1.2 lbs (0.544 kg)

PRESSURE | ##

Page 2

PRESSURE | DIFFERENTIAL PRESSURE SWITCHES | AFS

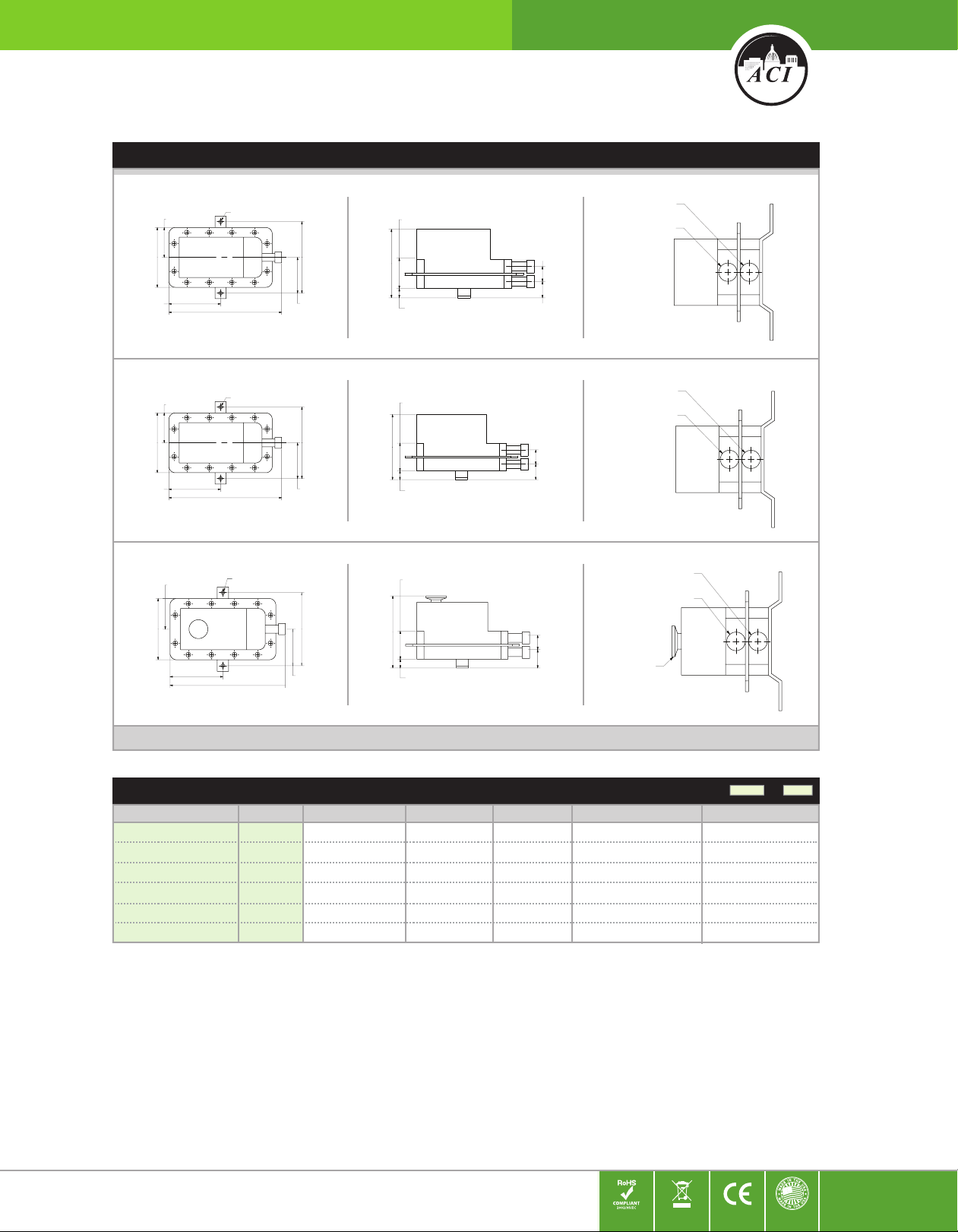

DIMENSIONAL DRAWING

AFS [222]

2x Ø.19”

(4.83mm)

3.88”

(98.55mm)

3.25”

(82.55mm)

1.38”(35.05mm)

3.25”

(82.55mm)

1.63”

(41.28mm)

Automation Components, Inc.

High Pressure Inlet

Low Pressure Inlet

0.71”(18.03mm)

2.81”

(71.37mm)

AFS [262]

3.25”

(82.55mm)

2.81”

(71.37mm)

AFS [460]

3.25”

(82.55mm)

2.81”

(71.37mm)

1.63”

(41.28mm)

1.63”

(41.28mm)

6.13” (155.70mm)

2x Ø.19” (4.83mm)

6.13” (155.70mm)

2x Ø.19” (4.83mm)

6.13” (155.70mm)

1.94”

(49.28mm)

3.88”

(98.55mm)

1.94”

(49.28mm)

3.88”

(98.55mm)

1.94”

(49.28mm)

3.25”

(82.55mm)

3.56”

(90.42mm)

.44” (11.18mm)

1.38”(35.05mm)

.44”(11.18mm)

1.38”(35.05mm)

.44” (11.18mm)

0.78”(19.69mm)

0.71”(18.03mm

)

0.78” (19.69mm)

0.71” (18.03mm)

0.91” (23.11mm)

High Pressure Inlet

Low Pressure Inlet

High Pressure Inlet

Low Pressure Inlet

Reset Button

Front View Right View Top View

STANDARD ORDERING

Model #

AFS-222

AFS-222-112

AFS-262

AFS-262-112

AFS-460

AFS-460-112

PRESSURE | ##

Item #

101788

108816

101789

118041

101791

129657

Pressure Range

0.05 to 12.0” wc

0.05 to 12.0” wc

0.05 to 2.0” wc

0.05 to 2.0” wc

0.40 to 12.0” wc

0.40 to 12.0” wc

Contact Style

SPDT

SPDT

SPDT

SPDT

SPST-N/C

SPST-N/C

Reset Style

Auto

Auto

Auto

Auto

Manual

Manual

Model # Example:

Compression Fitting

•

•

•

-OR-

101788AFS-222

Barbed Fitting

•

•

•

Revision C0000001 | Rev 1.0

Loading...

Loading...