Page 1

Installation and Operation Instructions

3X

IND.CONT.EQ.

C

LISTED

US

3JHX

I

A/CTE-50

ACI

US

C

LISTED

3JHX

IND.CONT.EQ.

Middleton, WI

A/CTE-50

ACI

3X

!

Part # A/CTE-50, A/CTE-250,

A/CTV-50, A/CTV-250

Safety

This product is not intended to be used for Life or Safety applications.

This product is not intended for use in any hazardous or classified locations.

Disconnect and lock out all power sources before installation as severe injury or death may result from electrical

shock due to contact with high voltage wires.

Installation

Disconnect and lock out all power sources before installation as severe injury or death may result from electrical shock due to

contact with high voltage wires. Make sure that all installations are in compliance with all national and local electrical codes.

Only qualified individuals that are familiar with codes, standards, and proper safety procedures for high-voltage installations

should attempt installation. The current sensor will not require external power, since the power for the current sensor is

induced from the conductor being monitored.

The A/CTE & A/CTV Series Analog Current Sensors should be used on Insulated Conductors Only! The current sensors may

be mounted in any position using the (2) #8 x 3/4” Tek screws and the mounting holes in the base or snapped directly on to the

35mm DIN rail (See Figures 1 & 2 below). Leave a minimum distance of 1” (3 cm) between the current sensor and any other

magnetic devices such as contactors and transformers.

Please Read Instructions Carefully Before Installation!

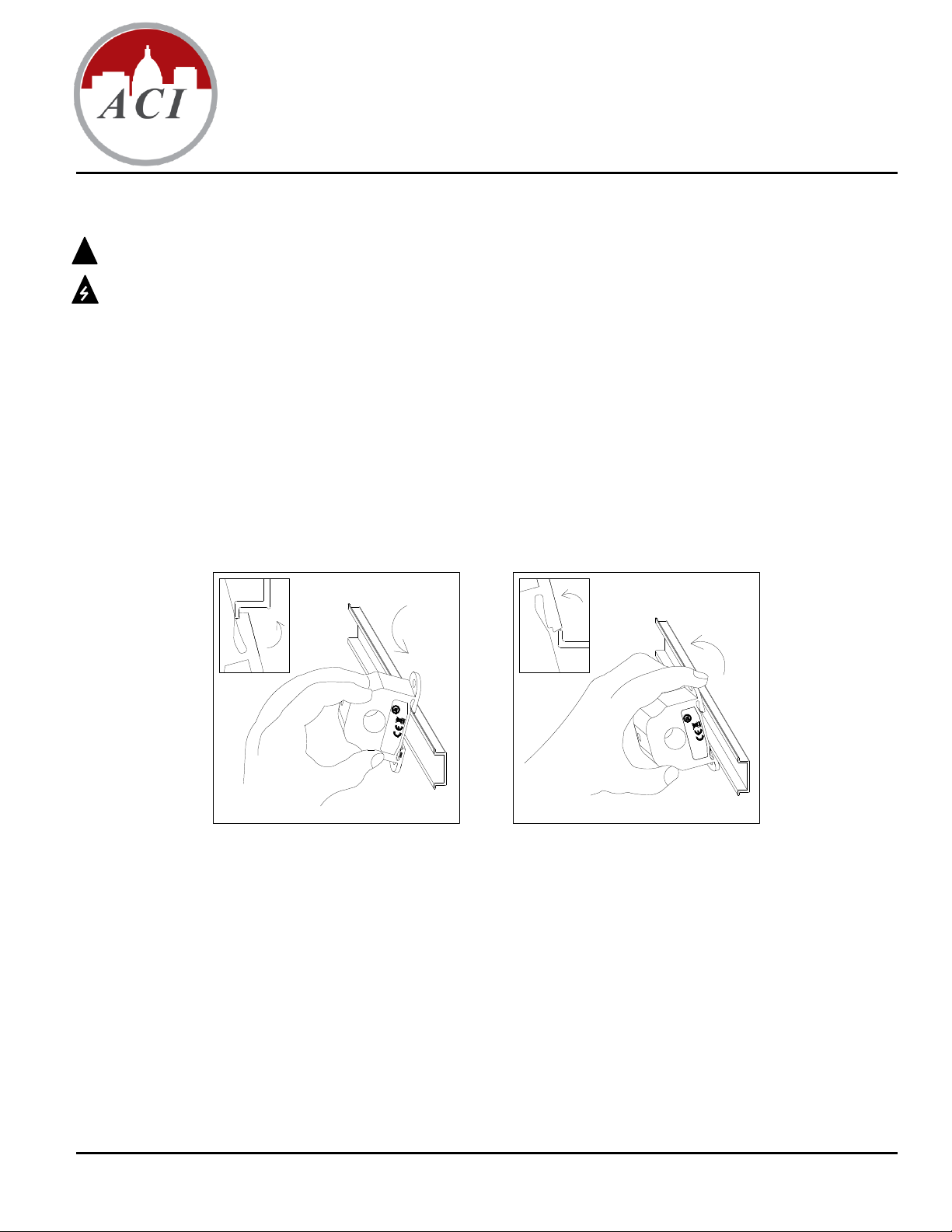

Figure 1: Sensor Placed on Rail Figure 2: Sensor Removed From Rail

Wiring

ACI recommends the use of a 2 conductor 16 to 22 AWG shielded cable, or copper wire only for all Analog current sensor

installations. A maximum wire length of less than 30 meters (98.4 feet) should be used between the A/CTE and A/CTV series

current sensors and the Building Management System or controller. Note: When using a shielded cable, be sure to connect only

(1) end of the shield to ground at the controller. Connecting both ends of the shield to ground may cause a ground loop. When

removing the shield from the sensor end, make sure to properly trim the shield so as to prevent any chance of shorting. The

current sensors terminals are polarity sensitive and represent a linear 0 to 5 or 0 to 10 VDC output signal. The recommended

torque to be used on the terminal block connections is 0.67 Nm or 5.93 in-lbs. The aperture (hole) size of the current sensor is

0.75” (1.90 cm) and will accept a maximum cable diameter of 350 MCM’s.

Page 1 of 3 I0000141

Version : 1.0

Page 2

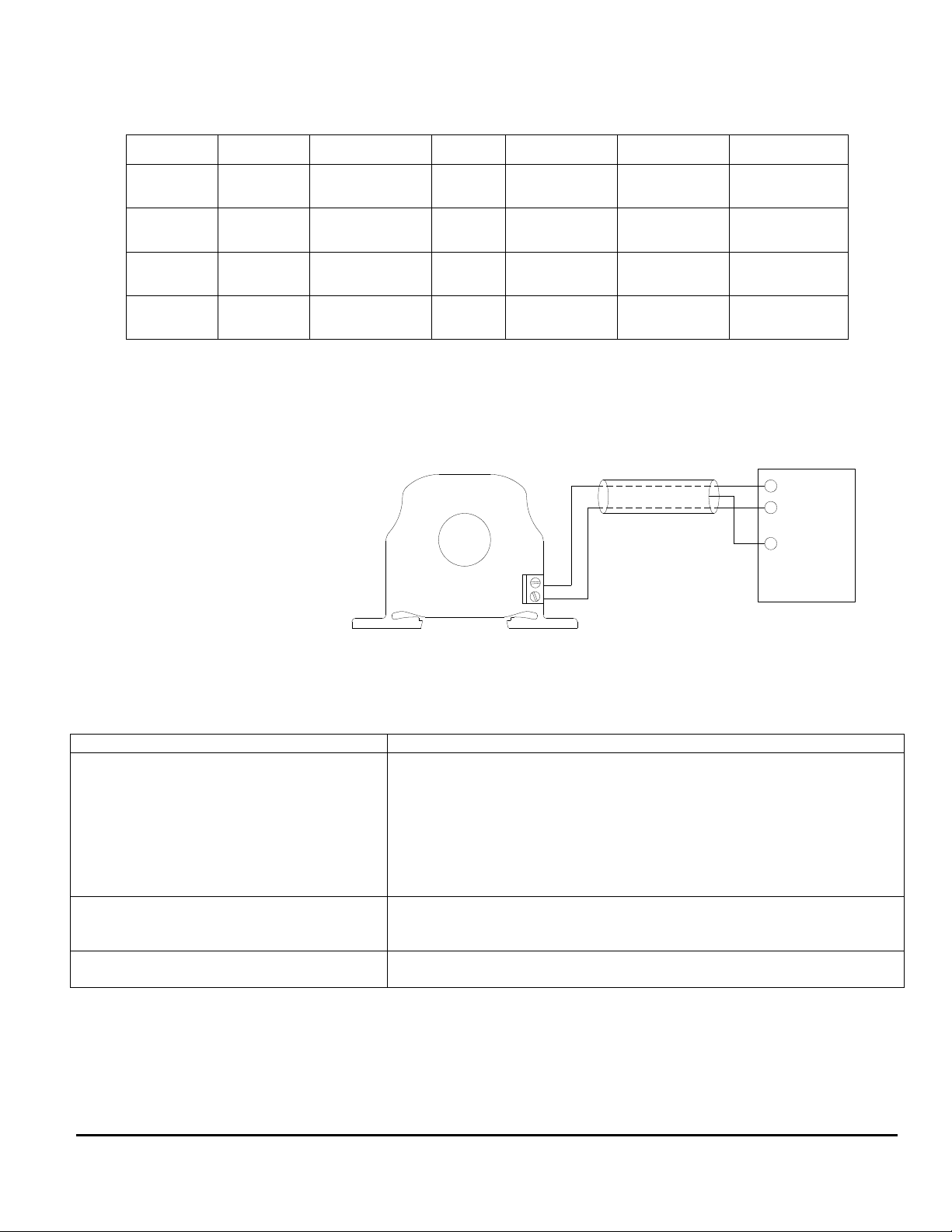

_

+

Acquisition System

PLC, DDC, or Data

+ 0-5 or 0-10 VDC

(-) Signal Common

GND (Shield)

Analog Input

Connections: Shielded, twisted pair cable is

recommended for these connections.

Note: Ground shield at control

system end only!

Power: These current sensors DO NOT

need an external power source,

since the power is self-induced

from the monitored load

or conductor.

Problem

Solution

No reading

- Verify that there is current flowing thru the conductor being monitored with a

clamp-on current probe. The power for the current sensor is induced from the

conductor being monitored.

- Check the polarity of the circuit.

- Verify that the terminals are screwed down, wires are firmly in place.

- Disconnect the wires from the current sensor output. Measure the voltage

across the current sensor output with a Voltmeter to verify that the sensor is

working properly.

Erratic readings

- Verify that the wires are terminated properly.

- In areas of high RF interference, shielded cable may be necessary to stabilize

signal.

Inaccurate readings

- If you suspect that the current sensor is not reading within the accuracy

specifications, please contact the factory for assistance.

ACI Model #

Output

Range

Jumper *

Max. Sensing

Current Voltage

Max. Continuous

Current

Max. Current for

6 seconds

A/CTE-50

0 to 5 VDC

0-10 Amps

0-20 Amps

0-50 Amps

Low

Middle

High

600 VAC

100 Amps

150 Amps

200 Amps

125 Amps

225 Amps

300 Amps

A/CTE-250

0 to 5 VDC

0-100 Amps

0-200 Amps

0-250 Amps

Low

Middle

High

600 VAC

200 Amps

360 Amps

400 Amps

250 Amps

450 Amps

500 Amps

A/CTV-50

0 to 10 VDC

0-10 Amps

0-20 Amps

0-50 Amps

Low

Middle

High

600 VAC

60 Amps

100 Amps

160 Amps

80 Amps

200 Amps

300 Amps

A/CTV-250

0 to 10 VDC

0-100 Amps

0-200 Amps

0-250 Amps

Low

Middle

High

600 VAC

160 Amps

320 Amps

400 Amps

200 Amps

400 Amps

500 Amps

Operating Specifications

*Note: All current sensors are shipped from the factory with the jumper set in the high range.

Wiring Example

Troubleshooting

Page 2 of 3 I0000141

Version : 1.0

Page 3

LISTED

C US

IND.CONT.EQ.

3JHX

Current Conversion Formulas

To convert the current sensor output signal to a current reading.

0-10 Volt output to Current reading (0 Volts = 0 Amps and 10 Volts = 250 Amps for A/CTV-250)

Example: 5 Volts current sensor output signal

Total Span = 250 Amps

Multiplier = 10V-0V/Total Span = .04

(5 Volts) / 0.04 = 125 Amps

WEEE Directive

At the end of their useful life the packaging and product should be disposed of via a suitable recycling centre. Do not dispose of

with household waste. Do not burn.

Page 3 of 3 I0000141

Version : 1.0

Loading...

Loading...