ACI-Automation Components A/ACS2, A/ACSX2, A/ASCS2, A/ASCS2-L, A/ASCSX2 Operating Instructions

Page 1

Installation and Operation Instructions

!

!

Part #A/ACS2, A/ACSX2

A/ASCS2, A/ASCS2-L, A/ASCSX2

WARNING:

• This product is not intended to be used for Life or Safety applications.

• This product is not intended for use in any hazardous or classified locations.

• The A/ACS2 and A/ASCS2 Series Current Switches must be used on Insulated Conductors Only!

HIGH VOLTAGE:

• Disconnect and lock out all power sources before installation as severe injury or death may result from electrical

shock due to contact with high voltage wires.

• Never rely on the LEDs to determine whether power is present at the current switch. At very low monitored input

currents the LEDs may not light.

Installation

Make sure that all installations are in compliance with all national and local electrical codes. Only qualified individuals that are

familiar with codes, standards, and proper safety procedures for high-voltage installations should attempt installation. The current

switches will not require external power, since the power for the current switch is induced from the conductor being monitored.

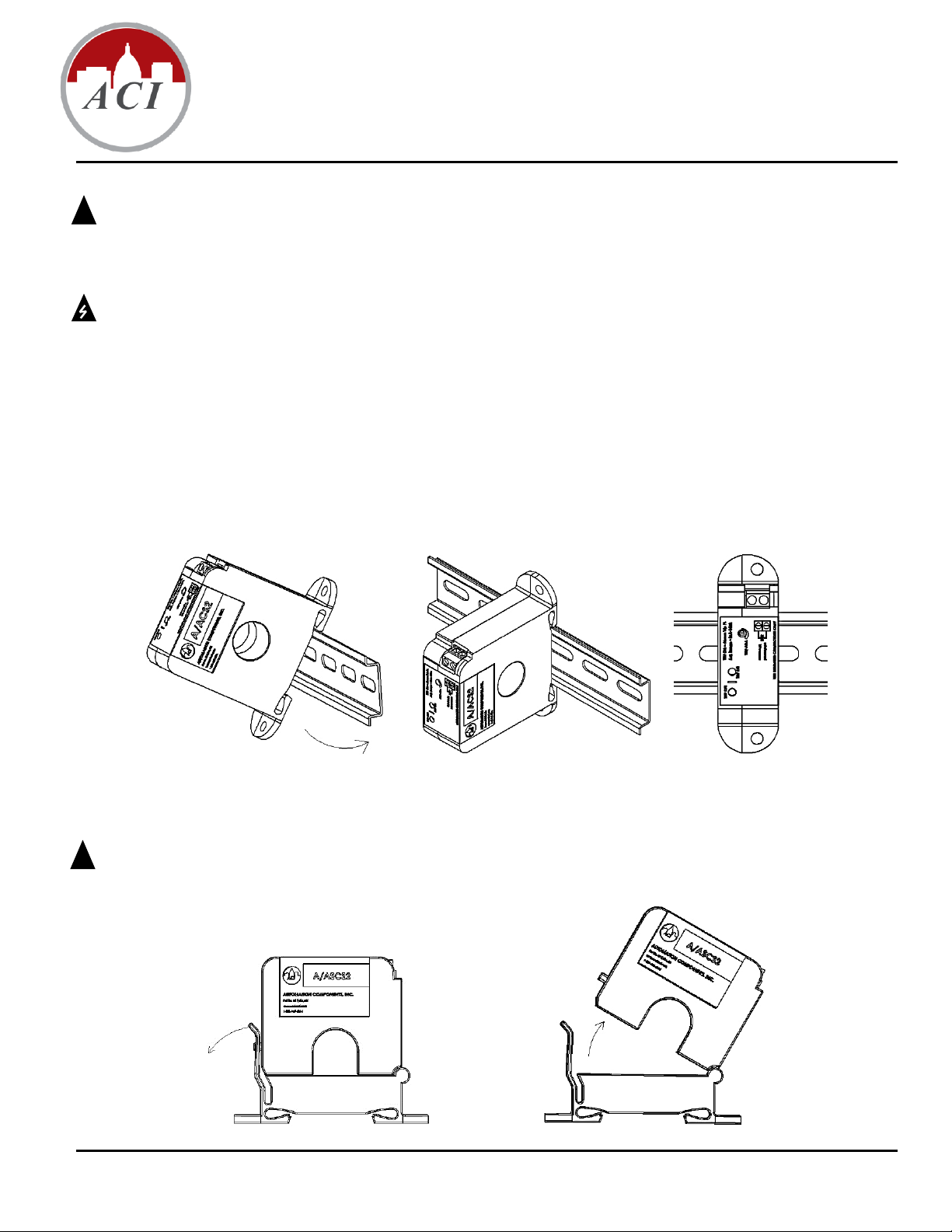

The current switch may be mounted in any position using the two #8 x 3/4” Tek screws and the mounting holes in the base, or

snapped directly on to the 35mm DIN rail (See Figure 1). Leave a minimum distance of 1” (3 cm) between the current switch and

any other magnetic devices such as contactors and transformers.

Please Read Instructions Carefully Before Installation!

Figure 1: Sensor Placed on Rail

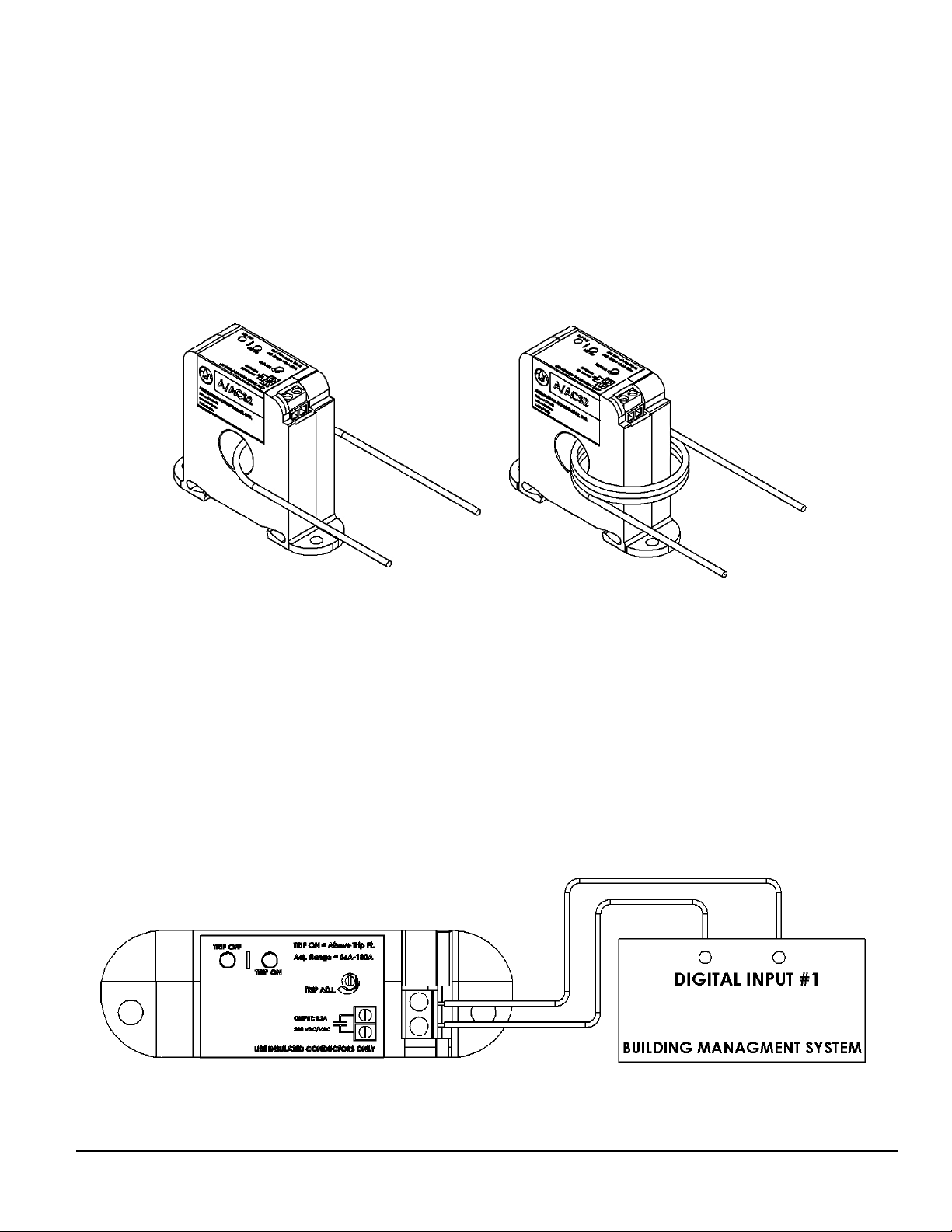

Latch Operation for A/ASCS2 Series

Press down on the side tab and swing the top of the unit up to open the split core current switch as shown in Figure 2. Press down

firmly on the cover to close the current switch. An audible “click” will be heard as the tab slides over the tongue on the base.

CAUTION: Mating surfaces of the magnetic core are exposed when the sensor is open. Electrical contact grease, present on

the cores to prevent corrosion, can capture grit and dirt if care is not exercised. Operation can be impaired if anything prevents

good contact between pole pieces. Visually check the mating parts of the core before closing the current sensor.

Figure 2: Opening A/ASCS2 Series

AUTOMATION COMPONENTS, INC Version : 5.0

Page 1 of 3 I0000788

Page 2

LEDs

The Red LED will indicate whether the current is above the adjustable trip point. The Blue LED will indicate whether the current

is below the adjustable trip point. At very low monitored input currents the LEDs may not light.

Application Notes

The conductor being monitored may be looped through the sensor multiple times. The loops increase the current measured by the

current switch. Each time the conductor passes through the current switch window equals one loop (See Figure 3 below). To

determine the proper number of turns required, take the rated Minimum Adjustable Trip Point of the current switch (see Figure 6)

and divide it by the Operating Current of the Monitored Device, add one (1), then round up to the nearest whole number.

Example: When using the A/ACS2, a small fan operating at 0.17A should be wrapped through the sensor four times to give you a

total operating current of 0.68Amps flowing through the A/ACS2. Formula Example: (0.5A/0.17A) = 2.94 + 1 = 3.94, which

rounded up equals 4 loops.

One Loop Four Loops

Figure 3: Wires Through Sensors

Wiring

ACI recommends the use of a two conductor 16 to 22 AWG shielded cable or twisted pair copper wire only for all current switch

applications. A maximum wire length of less than 30 meters (98.4 feet) should be used between the current switch and the

Building Management System or controller. Note: When using a shielded cable, be sure to connect only (1) end of the shield to

ground at the controller. Connecting both ends of the shield to ground may cause a ground loop. When removing the shield

from the sensor end, make sure to properly trim the shield to prevent any chance of shorting. The current switch output terminals

represent a solid-state switch for controlling both AC and DC loads and are not polarity sensitive. Tighten the screws at the

terminal block connections to the recommended torque of 0.5 to 0.6 Nm (4.43 to 5.31 in-lbs.). The aperture (hole) size of the

current switch is 0.75” (1.90 cm).

Application Examples

See Figure 4 and Figure 5 for two different current switch applications using your Building Management System (DDC/PLC

Controller). Figure 4 is showing the use of the Adjustable Current Switch as a Digital Input to your DDC Controller, whereas

Figure 5 is showing you how to use the Adjustable Current Switch in conjunction with your building management system to

monitor belt loss on a motor.

Figure 4: Digital Circuit

AUTOMATION COMPONENTS, INC Version : 5.0

Page 2 of 3 I0000788

Page 3

Problem

Solution

Red LED is on but the current switch

didn’t activate

Disconnect the wires from the current switch output. Measure the resistance across the

contacts with an Ohmmeter. See Figure 6 for resistance readings for a good unit.

Red LED didn’t turn on and the

current switch didn’t activate

Verify that the conductor you are monitoring is above the adjustable trip point. If the

sensor is monitoring less than the adjustable trip point, see Figure 3.

Sensor doesn't switch at all, regardless

of current level.

Adjustment potentiometer is probably set to its maximum or minimum position. Turn

the Pot counter-clockwise all the way and verify if the LED switches from Red to Blue.

Current Switch is operating at a lowlevel current or failing to operate

within the accuracy specifications.

For A/ASCS2 Series, visually check the mating parts of the core to ensure there is no

debris between the split contacts. Remove all debris or dust manually and close the

current sensor. Continue to retest the sensor in your application. See Figure 2.

ACI Model #

Adjustable Trip Point

Resistance if switch open

Resistance if switch closed

A/ACS2

0.5 - 220 Amps

Greater than 1 Meg ohms

Less than 10 ohms

A/ACSX2

0.5 - 220 Amps

Greater than 1 Meg ohms

Less than 10 ohms

A/ASCS2

1.5 - 220 Amps

Greater than 1 Meg ohms

Less than 10 ohms

A/ASCS2-L

0.6 - 180 Amps

Greater than 1 Meg ohms

Less than 10 ohms

A/ASCSX2

1.5 - 220 Amps

Greater than 1 Meg ohms

Less than 10 ohms

Figure 5: Analog Circuit

Calibration of Adjustable Trip Point

The adjustable current switch has an operating range of 0-250 Amps, Do not exceed! The current switch has an adjustable trip

point range of 0.50 - 220 Amps, 1.50 - 220 Amps, or 0.60 - 180 Amps depending on the model. See Figure 6 to determine the

adjustable trip point range per model number. The adjustable current switch comes with its fifteen-turn adjustment potentiometer

set counter clockwise to the maximum trip point position. The adjustable current switch can monitor Underload, Normal Load,

and Overload conditions, depending on how it’s set. The procedure below is for the Normal load condition for part numbers

A/ACS2, A/ASCS2 and A/ASCS2-L.

Normal Loads:

With power on, turn the 15-turn adjustment potentiometer clockwise until the Red LED turns on and stop immediately. The

adjustable current switch is now tripped. The adjustable current switch Hysteresis (Dead Band) is 10% of the trip point typically.

Troubleshooting

Figure 6

WEEE Directive

At the end of their useful life the packaging and product should be disposed of via a suitable recycling center. Do not dispose of

with household waste. Do not burn.

AUTOMATION COMPONENTS, INC Version : 5.0

Page 3 of 3 I0000788

Loading...

Loading...