Page 1

F4 Illustrator

F4 Illustrator

U. S. Patent No.

5,063,905

Other Patents

Pending

™

O

WNERSMANU AL

O

WNERSMANU AL

R

EFERENCEGUIDE

R

EFERENCEGUIDE

Serial Number:

Date Purchased:

Dealer:

&

&

Page 2

CAUTION

CONTENTS

• Read the entire manual before using the F4 Illustrator.

• The F4 is not a toy. It can cause serious injury or death.

• W ear approv ed eye and head protection,even when test firing.

• The compressed air source used with the F4 can cause serious injury or death.

• Sale or use of the F4 Illustrator is not intended for individuals under the age of 18.

• The F4 is to be used only as described in this manual.

• Fire only 0.68 caliber paintballs from the F4.

• Check the velocity of your F4 before each use. Not to exceed 300 fps.

• The F4 can fire when dropped.

• Keep the F4 unloaded and unpressurized when not in use.

• Install a barrel plug in the barrel when not in use. (One is included with the F4.)

• Replacement barrel plugs are available from your ACI dealer.

• Handle the F4 as if it is always ready to fire. It recocks during firing.

• The F4 can be dangerous up to 200 yards (180 meters).

• Don’t shoot at opponents closer than 20 feet.

• Never shoot toward individuals not wearing appro ved e ye and head protection.

• Never disassemble the F4 while it is pressurized.

• Do not touch a chilled CO2 container with bare skin; frostbite can occur.

• Using the F4 while under the influence of drugs or alcohol is disregard of public safety.

• Never shoot at the property of others.

• Learn and follow the rules of the field where you are playing.

• Always maintain control of the F4 while it is pressurized.

• Never store the F4 while it is pressurized.

• Tw o very dangerous defects require immediate attention by your dealer or qualified airsmith:

1. The air source bottle valve unscrews from the bottle.

2. The gun double fires (other than when you are running out of air).

• Do not modify your gun, especially your trigger assembly.

SPECIFICATIONS.................................................................3

OPERATION

Cocking...........................................................................4

Air Source Installation ....................................................4

Seating of Air Source......................................................4

Loading...........................................................................5

Trigger Safety.................................................................5

Firing...............................................................................5

Uncocking.......................................................................5

Air Source Removal........................................................5

TUNING YOUR GUN

Ball Retaining Spring Adjustment..................................6

V elocity Adjustment Procedures.....................................6

FIELD MAINTENANCE

Field Stripping ................................................................7

ACCIDENT CAUSES YOU CAN CONTROL.....................8

MAINTENANCE

Barrel...............................................................................9

Upper Chamber...............................................................9

Lower Chamber ..............................................................9

CLEANING SCHEDULE

Lubrication......................................................................10

SERVICE HINTS....................................................................10

TROUBLE SHOOTING HINTS...........................................11

PARTS BREAKDOWN ..........................................................13

WARRANTY INFORMATION.............................................15

Page 3

SPECIFICATIONS

CALIBER

• 0.68 Paintballs Only

BLOWBACK SEMI-AUTOMATIC POWERED BY

• Compressed CO2

• Regulated Compressed Air

• Regulated Nitrogen

WEIGHT

• 2.42 lbs. (not including loader or air source)

FULLY ENCLOSED MAIN BODY

• No Exposed Moving Parts

• Polished Anodized Aluminum With Custom Side Cuts

• Patent Pending Quick Slide Cocking

• Industry Standard Sight Rail

• Aluminum Ball Retaining Side Plate

• Laser Engraved Graphics

BALL FEED

• Powerfeed Design To Increase Feed Rate

• 7/8 inch O.D; accepts standard feed loader adapters

MUZZLE VELOCITY

• 180 fps to 330 fps

• Adjustable - External

• Self-Locking

BARREL

• Aircraft Quality Aluminum

• Microhoned and Polished

VALVE PATENT #5,063,905

• Stainless Steel

• Patented Sub Zero Antifreeze Technology

• High Performance

45 GRIP ONE-PIECE TRIGGER FRAME

• Ergonomic “Point And Shoot”Design

• Accepts Standard 45 Grip Pads

• Complies With Industry Standard 2 Hole Bottomline

• Reflex Trigger Action With 2.2 lb.Pull

• Laser Cut Tool Steel Trigger & Sear

• Trigger Shoe - Anodized Aluminum

• Push Button Positive Lock Safety

VERTICAL ADAPTER

• Accepts Standard Aftermarket Accessories

• Easily Converts To Vertical Style

OPTIONAL ACCESSORIES

• Zero-Gravity Barrel

• Sub Zero Expansion Chamber

• High Volume Cell

• Venturi Bolt With Adjustable Recock

(If Equipped)

Page 4

OPERATION

Before pressurizing, check that the F4 is cocked but not loaded. If

not cocked, air may leak until the cup seal seats. Also, if not

cocked the F4 can fire as it is being pressurized.

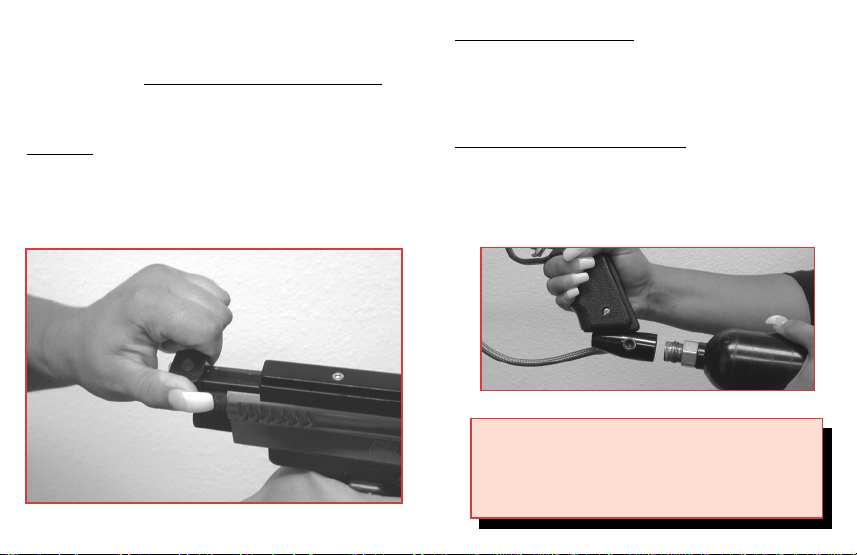

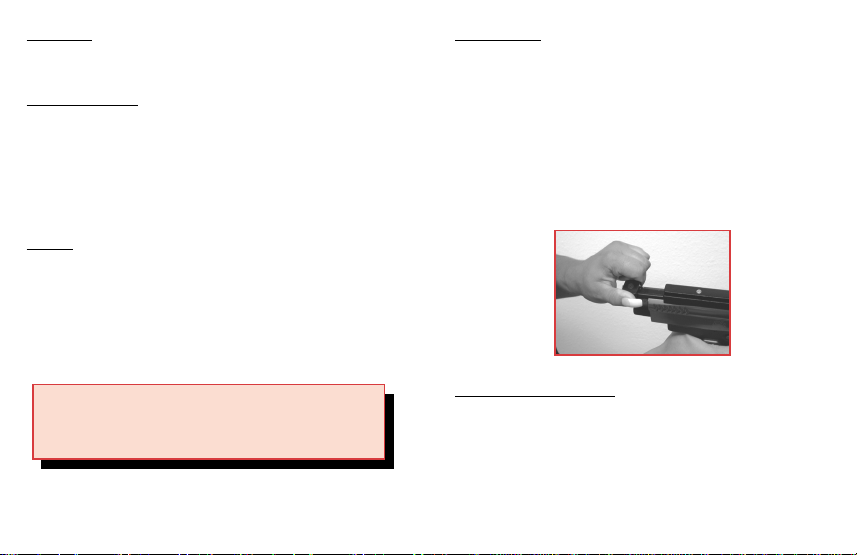

Cocking

To cock the F4, pull the cocking knob rearward until it latches. Be

careful, if you let go before it latches, the F4 can fire. DO NOT

DRY FIRE THE F4. (To pull the trigger, the safety must be dis-

engaged.)

Air Source Installation

Once the F4 is properly cocked with the safety on you can pressurize it with C02, regulated compressed air or nitrogen. Only

after you understand how to handle it safely should you attempt to

pressurize your F4.

Proper Seating of Air Source

The bottle O-ring provides the seal, so just tighten the bottle until

it is snug. You should hear a brief hiss as the bottle valve opens

during the last 1/2 turn. Over tightening can damage the F4. If a

leak persists, replace the bottle O-ring.

CAUTION

Be safe! Depressurize the F4 (remove the bottle) unless

you are about to use it. Do not unscrew the bottle from

the bottle valve; you may turn the bottle into a rocket!

Page 5

Loading

Install a 7/8 elbow and loader on the ball feed tube. Following the directions of the manufacturer, fill the loader with .68 caliber paintballs.

Trigger Safety

The F4 has a trigger safety to help prevent accidental firing. With

the F4 pointing away from you, engage the safety by pushing it to

the right. When the safety is toward the left the F4 can then be

fired. The safety may not engage unless the F4 is cocked.

Remember, the only time the F4 is truly safe is when it is

unloaded and depressurized

Firing

To fire the F4, point it in a safe direction, away from yourself, and

pull the trigger. The trigger safety must be off; that is to the left.

Fire the F4 as often as you like with air, with or without paintballs

in it. This helps break it in and makes it operate smoother.

Uncocking

Before uncocking, unload. Rotate your gun to the side so paintballs in the chamber and elbow roll back into the loader. Take a

couple of shots in a safe direction to insure that the barrel is

empty. If you uncock with a ball in the chamber, it will be forced

forward into the barrel. Later when you recock, a second ball will

enter the chamber. If two balls are fired at once, they may break.

To finish uncocking, unscrew the air source, pull back the cocking

knob, pull the trigger and let the assembly move forward slowly.

DO NOT DRY FIRE THE F4. (To pull the trigger, the safety

must be disengaged.)

WARNING

Avoid dry firing (without air) — damage to the

valve body, stop pin, and cup seal can occur.

Air Source Removal

Once the F4 is properly uncocked with the safety on you can

depressurize it. To depressurize the F4, slowly unscrew the air

source paying special attention to the bottle valve. DO NOT

UNSCREW THE BOTTLE VALVE FROM THE BOTTLE.

UNSCREWING THE VALVE COULD CAUSE SERIOUS

INJURY OR DEATH.

Page 6

TUNING Y OUR GUN

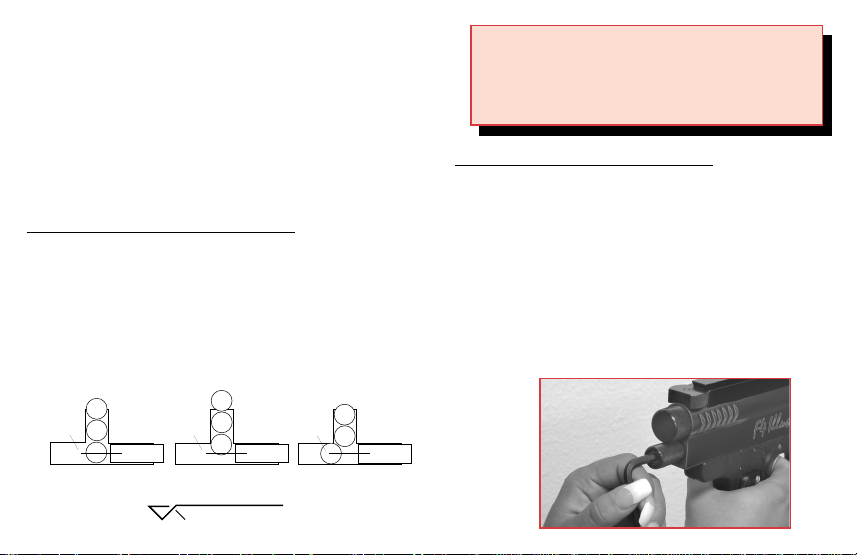

BOLT

BOLT

BOLT

Feed

Tube

Feed

Tube

Feed

Tube

Ball Retaining

Spring

Ball Retaining

Spring

Ball Retaining

Spring

A

Correct Adjustment - A single

ball will feed into the chamber

forward of the bolt

Spring Too Tight - Ball will not

feed all the way in and will be

chopped by the bolt

Spring Too Loose - A second

ball can enter the chamber and

be chopped by the bolt

Regular tuning is essential. But don’t waste time trying to tune a

gun which is:

• Dirty or poorly lubed

• Has a damaged striker O-ring

• Low on air

• Has the wrong O-rings installed

Check velocity to ensure it is not too high. It was set to 260 fps

at the factory, but it will change over time, and with temperature.

Ball Retaining Spring Adjustment

With the spring held in by the plate, and the gun cocked, the

upward bow of the spring should just make point A contact the

gun frame.

Tight: Too much bow causes drag and won’t let the ball roll

freely into the chamber - bend spring outward at point A.

Loose: Too little bow lets the ball slip forward so a second ball

can partially enter - bend spring inward at point A

CAUTION

Do not adjust velocity with the striker plug

partially unscrewed. If it is later screwed back

in, the velocity may be dangerously high.

Velocity Adjustment Procedures

Before adjusting velocity make sure the striker plug is screwed in

all the way. Your gun must be properly lubricated and free of all

dirt and debris.

Insert 3/16 hex wrench (provided) into the velocity adjustment

screw located in the striker plug as shown in the diagram below.

Turn clockwise to increase velocity. Turn counter clockwise to

decrease velocity. Check your velocity on a reliable chronograph

every quarter turn until desired velocity is reached.

Note: If the velocity screw is loose, replace the anti-drift pin (provided).

Page 7

FIELD MAINTENANCE

Before each use, your gun must be cleaned, lubed, and tuned.

❸❹

Field Stripping

To field strip your gun (refer to illustrations):

1. Depressurize gun (remove air source)

2. Unload gun

3. Uncock gun

4. Unscrew barrel

5. Unscrew bolt plug and remove bolt plug buffer.

6. Screw threaded end of bolt plug into connecting

pin access hole located in center hole of sight rail and

pull connecting pin straight out from gun.

7. Remove bolt through front of gun.

8. Swab bolt chamber back to front

Reverse order for reassembly.

❺❻

❶❷ ❼ ❽

Page 8

ACCIDENT CAUSES YOU CAN CONTROL

If the valve on your bottle is not

attached properly, the valve may

stay behind as the bottle is

unscrewed the gun and cause

serious injury or death. Proper

procedures and equipment are

required to properly attach a

valve to a bottle. Take your bottle

to a qualified airsmith if:

• The bottle valve is loose on the bottle.

• The bottle is hard to screw on to the gun.

• The bottle is hard to unscrew from the gun.

• A bottle leak is not corrected by a new O-ring.

During play with CO2 in colder areas,

rapid firing or escape of air, the surface

of your bottle can become cold enough to

freeze and seriously injure bare skin.

Keep pressure on your gun only while it

is in use. Always keep your gun under

control when it is pressurized.

WARNING

An overfilled bottle can explode.

A bottle without a safety relief on the

valve can explode.

Objects other than .68 caliber paintballs must never be placed in

or fired from your gun.

If your gun is dropped while pressurized,

it can fire! ALWAYS KEEP YOUR GUN

UNDER CONTROL!

Any attempt to

modify your

trigger can

make your gun

unsafe!

When you must keep your

gun cocked, engage the

trigger safety by moving it

to the right. Unloading and

depressurizing the gun is

always safer.

...remember, the future of paintball is in your hands.Please play responsibly and have fun.

Never put anything in front of the barrel.

Always point the F4 in a safe direction.

A paintball may still be in the barrel after you have unloaded the gun!

Your gun can still shoot with the barrel removed

DANGER: If you remove

the trigger valve screw with

pressure in the gun, and the

safety pin behind the valve

fails, the valve body will be

forced rearward and air will

escape rapidly.

NEVER REMOVE ANY PARTS OF THE F4

WHILE THE GUN IS PRESSURIZED!

NEVER FORGET, THIS GUN RECOCKS WHEN FIRED.

NEVER LOOK DOWN THE BARREL!

Unload and cock your gun before pressurizing. YOUR GUN CAN

FIRE DURING PRESSURIZING IF NOT COCKED!

A barrel plug is supplied with

your gun. It will only protect

you and the people around you

if you use it. Keep it in your

gun at all times when not in

use. Don't fire your gun with

the barrel plug in place.

Page 9

MAINTENANCE

AIR SOURCE MUST BE REMOVED BEFORE

ANY MAINTENANCE CAN BE PERFORMED

Barrel

To clean the barrel, unscrew it from the main body and swab

toward the rear. When paintball gelatin residue builds up, clean

with warm soapy water or rubbing alcohol. Residue build up hurts

accuracy.

Upper Chamber

Field strip as described on page 7 and use warm soapy water or

rubbing alcohol where needed to clean the rest of your F4.

Remove the bolt O-rings to remove paint and dirt build up from

the O-ring grooves.

Keep the bottle valve and adapter clean. Dirt entering here can

destroy the cup seal or valve body in one shot.

Lower Chamber

To clean the lower chamber see steps 1-8 on page 7, then remove

striker plug, striker spring and guide pin.

Remove bottomline from trigger housing by removing the two

screws holding it to the grip.

Remove front / rear trigger housing screws and washers and

remove trigger housing. (Notice front screw is longer with a pilot

on it to secure the valve body.)

Slide striker out the rear of the gun. If needed, insert a small

object into the bottom slot of the main body, to assist in sliding

the striker out the rear of the gun.

Clean all major components of the gun.

Inspect all O-rings and replace as needed.

Apply AIRLUBE™ upon assembly of all moving parts.

Reassemble parts in reverse order, making sure to include trigger

housing washers. Be very careful not to force parts back together,

or permanent damage may occur.

The following parts should not be removed for

routine maintenance:

Sight Rail / Quick Slide Cocking System

The sight rail should only be removed by a qualified airsmith.

Cup Seal And Valve Body

Easily damaged when removed. In clean conditions these have

lasted for more than 250,000 shots. If exposed to dirt, the cup seal

will wear rapidly. If the cup seal guide is tight on the cup seal, it

can force the seal to the side, causing the valve to leak.

Reservoir / Front Plug O-ring

Usually damaged only during removal

Page 10

CLEANING SCHEDULE

SERVICE HINTS

Every 500-1000 shots • Lubricate with AIRLUBE™

Every 1-3,000 shots • Remove bolt

• Clean upper chamber and bolt

• Check bolt O-rings

• Lubricate trigger assembly

7500-25,000 shots • Remove striker

• Clean striker and lower chamber

• Check striker O-ring for wear

Storage • Unpressurize and Unload

• Clean and Dry

• Lube

In the event of a ball break within the gun, the Field Strip procedure on page 7.

This schedule may need to be revised depending on the playing

conditions.

Lubrication

Lubrication affects recocking and velocity. AIRLUBE™ (provided) works well at all temperatures.

DO NOT USE FIREARM LUBRICANTS. THEY CAN GET

STICKY WHEN CHILLED BY CO2 OR COLD WEATHER.

Bolt Pin and Velocity Adjustment Screw

Nylon pins in these areas prevent movement when the gun is

fired. If the connecting pin or velocity adjustment screw is loose,

replace the nylon pins (supplied) by pressing them out.

king Assembly Pin

Coc

It is tool steel, and must be kept oiled or it will rust.

O-rings

The valve body O-rings will last for years if not disturbed.

Improper O-rings can interfere with recocking or cause air leakage. Keep the O-rings on the bolt and striker clean; grit and dust

abrade them rapidly.

rigger Assembly

T

Keep the assembly clean and the metal parts oiled to prevent rust.

There are no user-serviceable parts inside the trigger assembly.

Valve Body

To extend valve body life, DO NOT REMOVE IT!There is a

safety stop pin pressed into the main body to prevent the valve

body from moving backwards. If the valve body must be

removed, it should be pushed out the front of the gun with a long

nylon rod or equivalent to prevent damage to the inside of the

valve chamber. Make a note of orientation before removal of the

valve body to ensure proper assembly. Properly lube and inspect

O-rings before reinstalling valve body.

(Refer to diagram on Pg 14)

Page 11

TROUBLESHOOTING

Half the guns sent in for repair are dirty, poorly lubed, or have a

damaged striker O-ring. Check these items first.

Double firing (2 or more firing cycles on a single trigger pull):

• Trigger mechanism is dirty - clean it.

• Recock force is too high - Adjust front valve spring.

• Striker is badly worn - inspect and replace if worn.

• Trigger is badly worn - remove (by airsmith); replace if needed.

• Sear is badly worn - remove (by airsmith); replace if needed.

• Sear spring has fallen off or is broken - fix or replace.

NOTE: Double firing when your gun beats down is normal; double firing

otherwise is a safety hazard and must be remedied immediately.

Gun “beats down” and fails to recock:

• Air supply is cold—give it time to warm up.

• Air supply is low—replenish it.

• Bolt and/or striker, are dirty or need lube - clean and lubricate.

• Sticky O-rings on bolt or striker (they are torn or too hard) - install new ones.

• Leaky O-rings on bolt or striker (they are torn or worn) - install new ones.

• Air bottle valve isn’t fully open - tighten bottle (don’t force it); replace bottle.

• Air bottle is too tight - loosen it (don’t force it); replace bottle.

• Cup seal is partially unscrewed from valve pin - retighten it.

• Velocity adjustment screw is too far in - unscrew and chronograph.

Velocity drops and gun “beats down” during rapid firing:

• Bottle valve isn’t fully open.

• Sliding parts need lubrication.

Velocity is very erratic (>20 fps between shots):

• O-rings on bolt or striker are nicked or torn - install new ones.

• Lube is sticky (including buildup) - clean gun and apply AIRLUBE™.

• Cup seal is loose on valve pin - retighten it.

• There is liquid C02 in the gun - is your bottle over-filled?

• Air bottle valve isn’t fully open - screw bottle further (don’t force it);

replace bottle.

• Your paintballs are not round or they vary in diameter - get better paint.

• Barrel is dirty (residue can be very hard to see) - clean with swab.

• Striker spring is bent or binding - replace it.

Accuracy is degraded:

• Paint residue or other moisture somewhere in gun - clean.

• Paintball gelatin in the barrel - clean.

• Barrel is scratched or bent - replace.

Excessive paintball breakage:

• Too much recock force.

• Paintball gelatin in barrel - clean with swab.

• Defective paintballs - get better paint.

• Defective barrel - polish or replace barrel.

• Burr on end of bolt - polish it off.

Paintball chopped in chamber by bolt:

• Bad paintballs - get better paint.

• (during an isolated shot) Ball retention spring is mis-adjusted - adjust.

• (during rapid firing) Firing rate exceeded rate at which paintballs

entered gun - check that feed path is clear OR replace paintball loader

with one which will feed paintballs into gun faster.

• Only a few paintballs left in feed system - reload.

Page 12

TROUBLESHOOTING

Bolt is Jammed:

• Paintball chip beside bolt - field strip.

Two balls fire on a single shot:

• Gun was uncocked with a ball in the chamber - unload chamber first.

• Ball retention spring is mis-adjusted - adjust.

Cocking assembly pin won’t insert:

• Bolt and striker are not lined up.

Groove on bolt near front:

• Wear from ball retention spring - this is normal and doesn’t interfere

with operation.

Excessive striker O-ring damage:

• Rough area inside gun - smooth it.

Very short bottle O-ring life:

• Bottle valve releases gas during more than last 1/2 turn of bottle instal-

lation, stressing O-ring - try a different bottle.

• O-ring and bottle threads are dry - lube them lightly.

Bottle won’t release air:

• Bottle valve is defective, or bottle is too loose or too tight.

Air is leaking:

• Air bottle is very loose - Remove it, then replace it and tighten until it

is snug.

• Cup seal is forced to the side by the cup seal guide.

• Bottle O-ring; cup seal; reservoir plug O-ring; or valve body O-ring is

defective or displaced by dirt - remove dirt or replace bad part.

• Forward lip of valve body is rough - replace.

Gun won’t fire when trigger is pulled (gun cocked and safety off):

• Air source low - refill tank.

• Trigger assembly may be defective—contact airsmith or ACI for service.

Gun won’t fire a paintball, but recocks:

• Bolt in upside down

Air is leaking down the barrel:

• Gun is not cocked - cock it.

• Low air pressure - refill air supply.

• Cup seal defective - inspect and replace.

Air is leaking out the front reservoir plug:

• Reservoir plug O-ring defective - replace.

• Valve body was disturbed - call your dealer or ACI for possible service.

• Chamber wall scratched - call your dealer or ACI for possible service.

WARNING

Never attempt to perform maintenance or make repairs on

your gun until you have removed the air source.

Page 13

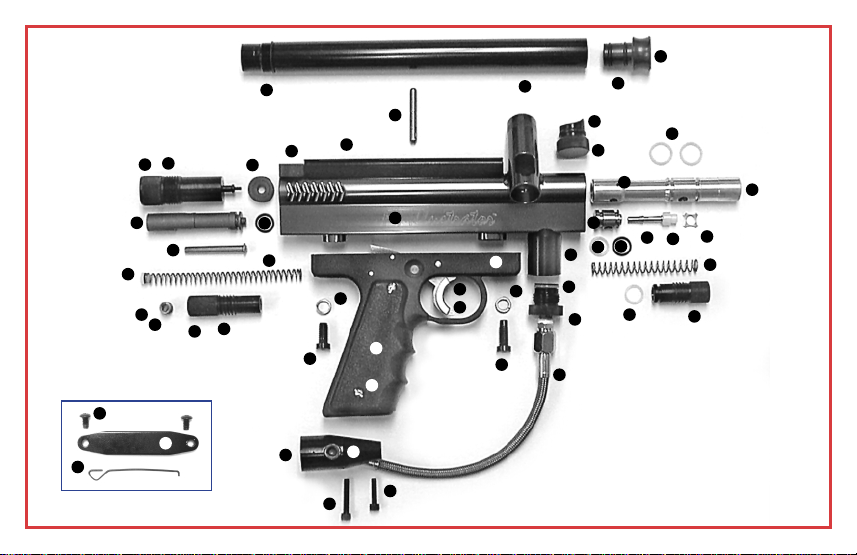

Barrel..............................................1

Barrel Plug ......................................2

Barrel Plug O-ring...........................3

Powerfeed Plug...............................4

Powerfeed O-ring ............................5

Bolt O-ring ......................................6

Bolt..................................................7

Bolt Body Lock Pin .........................8

Cup Seal Guide Star Washer.........9

Cup Seal .........................................10

Valve Stem......................................11

Valve Body......................................12

Valve Body Rear O-ring..................13

Valve Body Front O-ring .................14

Valve Spring....................................15

Front Reservoir Plug.......................16

Reservoir Plug O-ring.....................17

Vertical Adapter..............................18

Vertical Adapter O-ring...................19

High Torque Bolt .............................20

Gun To Hose Adapter O-ring..........21

Gun To Hose Adapter.....................22

9.5” Stainless Steel Hose With JIC

Fitting..............................................23

90° Nickel Plated Elbow .................24

Custom Two Hole Bottomline..........25

Bottomline Cap Screw Long ...........26

PARTS LIST

Bottomline Cap Screw Short ..........27

Bottomline NPT Plug......................28

45 Grip Bottomline Square Nut ......29

45 Grip Screw.................................30

45 Grip Screw Stand-off.................31

45 Type Wrap Around Grip.............32

Tr igger Housing ..............................33

Front Frame Screw.........................34

Frame Lock Washer........................35

Tr igger Shoe ...................................36

Tr igger Shoe Set Screw..................37

45 Trigger........................................38

Tr igger Spr ing .................................39

Tr igger Pin ......................................40

Tr igger Shim ...................................41

Safety..............................................42

Safety Ball.......................................43

Safety Spring..................................44

Safety Set Screw............................45

Sear Pin ..........................................46

45 Sear...........................................47

Sear Spring Pin ..............................48

Sear Spring.....................................49

Rear Frame Screw..........................50

Striker Plug.....................................51

Striker Plug O-ring..........................52

Velocity Adjustment Set Screw .......53

Nylon Pin ......................................54

Striker Spring Delrin Bearing ..........55

Striker Spring ..................................56

Striker Spring Guide.......................57

Striker .............................................58

Striker O-ring ..................................59

Bolt Plug Buffer...............................60

Bolt Plug .........................................61

Bolt Plug O-ring..............................62

Cocking Knob .................................63

Flathead Screw...............................64

Sight Rail ........................................65

Cocking Link...................................66

Cocking Tab Spring.........................67

Cocking Spring Set Screw..............68

Sight Rail Cap Screws....................69

Ball Retaining Plate........................70

Ball Retaining Spring......................71

Side Plate Screw............................72

Valve Stop Pin................................73

Receiver Main Body .......................74

Connecting Pin ...............................75

Barrel O-ring...................................76

Page 14

61

58

55

54

53

Ball Retaining Side Plate

72

71

2

76

75

65

62

57

51

52

70

63

60

59

56

50

25

26

74

35

32

30

28

27

37

36

1

33

35

34

23

3

4

5

12

13

18

21

22

6

8

11

10

14

17

7

9

15

16

Page 15

WARRANTY INFORMATION

Limited Warranty Statement

Air Concepts Industries, Inc., warrants that your F4 Illustrator is free

from defects in materials and workmanship for a period of one year from

the original date of purchase by the initial owner. (For guns used for

rental, the warranty is limited to three months.) During this period, any

defective parts will be repaired or replaced with new, or at the option of

Air Concepts Industries, Inc., refurbished parts. All parts replaced under

this warranty become the property of Air Concepts Industries, Inc.

User installable parts will be replaced upon receipt by us of the defective

part and proof of purchase identifying initial gun purchase date and serial

number. Otherwise, your gun must be shipped prepaid to us, with proof

of date of purchase. You are responsible for shipping your gun, or gun

parts to us, and for insuring against loss during shipping. For detailed

instructions on obtaining warranty service, phone us at 909-350-9176.

Call before shipping your gun.

Exclusion and Limitations

This warranty does not extend to the cup seal or O-rings, nor to any

parts, such as air bottles or adapters, which are not manufactured by Air

Concepts Industries, Inc., nor to any parts made defective by accident,

misuse, abuse, or modification.

Except as expressly stated herein, Air Concepts Industries, Inc., makes no

warranties, express or implied, including but not limited to any implied

warranties of merchantability or fitness for any purpose beyond that for

which the F4 was designed. This warranty gives you specific legal rights.

You may have other rights which vary from state to state.

Air Concepts Industries, Inc., shall not be liable for any incidental or

consequential damages arising from the use of the F4 Illustrator or from

the breach of the warranty set forth herein.

THE SPORT OF PAINTBALL

The sport of paintball involves games in which opposing players attempt

to shoot each other with dye-filled projectiles called “paintballs”.

Paintball is a serious sport which makes rigorous demands on players’

physical and mental abilities. When played in a safe manner, it can provide a rewarding experience not available in any other sport.

There are hazards in any active sport such as paintball. Serious injuries

are rare, but do occur.

A 0.68 caliber paintball moving at high velocity adds a special dimension

of hazard to paintball sports. At a minimum, it can cause pain and a

bruise. It can break the skin and cause bleeding. If it strikes an unprotected eye, ear, or mouth it can cause blindness, deafness, or even death. If it

strikes a young child in a sensitive body area, it can cause crippling or

death. This is why proper safety gear for players, isolation of spectators

from the play area, and proper handling of paintball guns are absolutely

essential.

The importance of always following safety rules, and the risk of serious

injury, require an adult level of maturity when using paintball guns. This

is why sale of the F4 Illustrator is limited to individuals 18 years of age

and older.

If after reading this you do not want to assume the risk of playing paintball, please return your F4 Illustrator to the dealer. If you have difficulty

returning it, please contact us at 909-350-9716.

The information in this manual is subject to change without notice. It

is not a commitment on the part of Air Concepts Industries, Inc.We

reserve the right to improve and change products with no obligation

to modify products previously sold.

Loading...

Loading...