Page 1

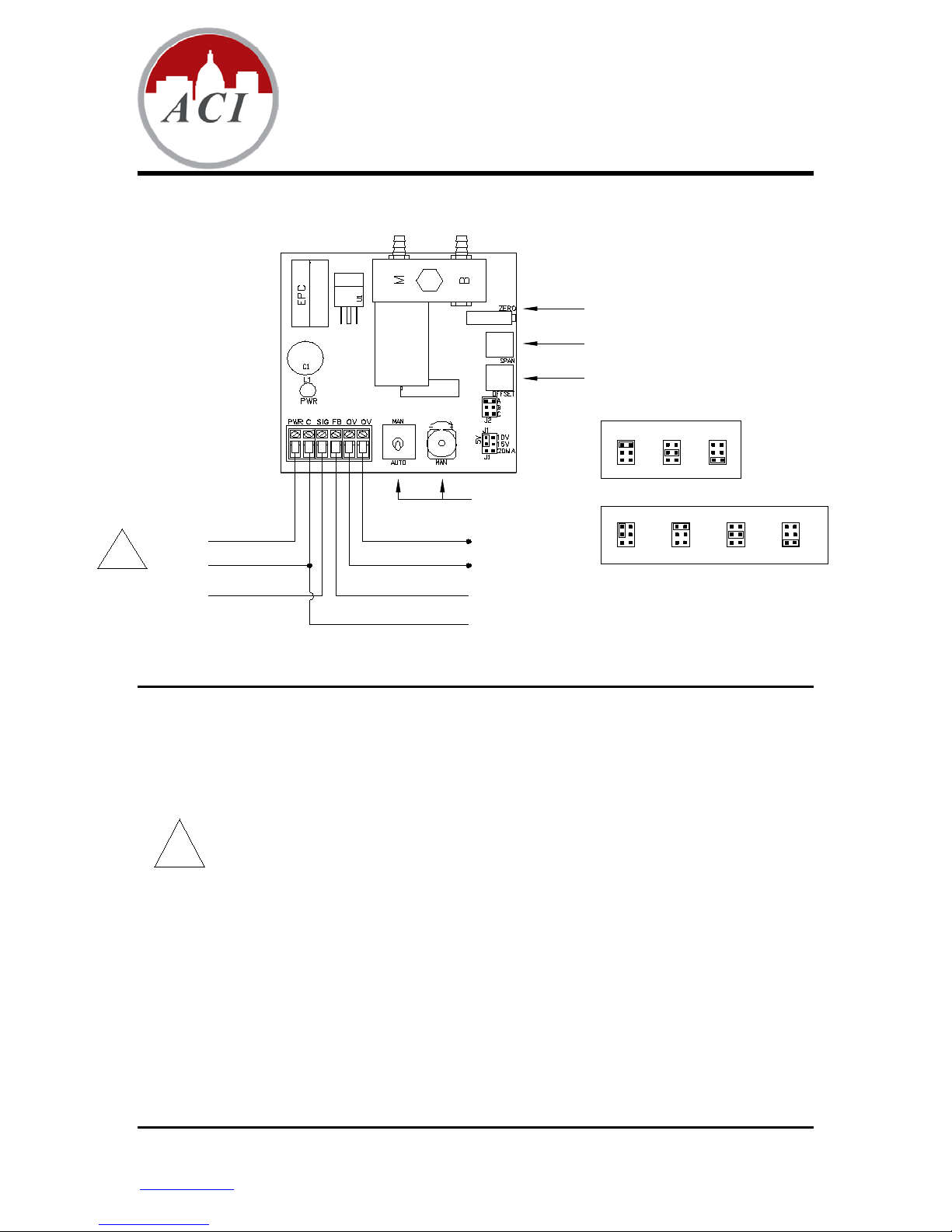

NOTE

#1

Power

(+)

(-)

Ana lo g In pu t Sign a l

(+)

(-)

Branch Pres sure

Feedback Signa l

Override Feedback

(Dr y Co nt ac t)

Manual Override Pot

and Manual/Auto

Switch

Offse t Pot - Set for mini mum desired

pressure with minimum input signal

Span Pot - Se t fo r maximum desired

pressure with maximum input signal

Zero Pot is Factory Set - Do not adjust

SEE

NOTE

#1

(+)

A

B

C

J2

0-10 psi

A

B

C

J2

0-15 psi

A

B

C

J2

0-20 psi

10V

15V

J1

5V

20mA

0-5 VDC

10V

15V

J1

5V

20mA

0-10 VDC

10V

15V

J1

5V

20mA

0-15 VDC

10V

15V

J1

5V

20mA

0-20mA

Pressure Output Range Selector

Signal In put Range Sele ctor

Installation and Operat ion Instructions

EPC

Analog Current or Voltage Input to Modulated Pressure Output

With Bleed Orifice

INSTALLATION

READ THESE INSTRUCTIONS BEFORE YOU BEGIN INST ALLATION.

Ground yourself before touching board. Some components are static sensitive.

Mounting:

Circuit board may be mounted in any position. If circuit board slides out of snap track, a non-conductive

“stop” may be required. Use only fingers to remove board from snap track. Slide out of snap track or push

against side of snap track and lift that side of the circuit board to remove. Do not flex board or use tools.

POWER CONNECTIONS – THIS PRODUCT ACCEPTS 24 VDC OR 24 VAC POWER.

Be sure to follow all local electrical codes. Refer to wiring diagram for connection information.

Be sure to make all connections with the power off.

1.) DC Power – Refer to wiring diagram for connection information.

If the 24 VDC power is shared with devices that have coils such as relays,

solenoids, or other inductors, each coil must have an MOV, DC Transorb, or diode

placed across the coil or inductor. The cathode, or banded side of the DC Transorb

or diode, connects to the positive side of the power supply.

2.) AC Power – Refer to wiring diagram for connection information.

Check the wiring configuration of any other loads that may be connected to this

transformer. If required by BAS or controller specification, the 24 VAC neutral can

be

earth grounded at the transformer. Analog input, digital input, and analog output

circuits should not be earth

this transformer must use the same common. If you are not sure of other field

device configuration, use separate transformers for isolation.

If the 24 VAC power is share with devices that have coils such as relays, solenoids,

or other inductors, each coil must have an MOV, AC Transorb, or other spike

snubbing device across each of the shared coils. Without these snubbers, coils

produce very large voltage spikes when de-energizing that can cause malfunction or

AUTOMATION COMPONENTS, INC Version : 2.0

2305 Pleasant View Road Page 1 of 2 I0000479

Middleton, Wisconsin 53562 (888) 967-5224

www.workaci.com

grounded at two points. Any field device connected to

Page 2

d est ruction of electr onic circuits. Refer to wiring diagram for conne ctio n infor m atio n.

3.) You should measure the actual voltage output of the secondary. If the output is not

fully loaded you may read a higher voltage than the circuit board can handle.

ADJUSTMENT OF GAUGES. If installation requires adjustment of the gauge for proper reading of the face,

turn the gauge no more than ½ turn in either direction. O-rings in the bottom of the gauge port will allow this

without leakage.

Warranty does not include malfunction due to clog ged valv e. M ain air port on EPC is filtered with the

supplied 80 – 100 micron integral-in-barb filter (Part # PN004). Periodically check the filter for contamination

and flow reduction. Replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing onto the

fittings, and use care when removing tubing to avoid damaging fittings or moving manifold

.

The bleed orifice can be unscrewed with a ¼” hex driver for cleaning or inspection. Do not lose the sealing

gasket or insert anything into the precision bleed orifice. Clean by swabbing with a degreaser and blowing

clean air through the orifice from the opposite direction.

This unit requires at least two cubic inches (minimum) of branch air line capacity (approx. 15 feet of ¼” O.D.

polyethylene tubing) to operate without oscillation. Main air must be minimum of 2 psig above highest

desired branch output pressure. Do not power without main air provided.

CHECKOUT

With power off, select one of the four input signal combinations by moving the jumper shunt J1 identified as

“Input Signal Range Selector”. Select a preset pressure output range by moving jumper shunt J2 identified

as “Pressure Output Range Selector”, or set custom range as described below.

SETTING CUSTOM OUTPUT PRESSURE RANGE. Verify the MAN/AUTO switch is in the AUTO position.

In AUTO, the manual override pot is inactive, the override contacts are open, and the analog input signal is

supplying the set-point. The offset pot may be adjusted to any desired offset between 0 and 14 psig. When

in the MANUAL position, the override contacts are closed, the offset pot is inactive and the manual override

pot is supplying the set point (the analog input signal is locked out). Supply power and the LED power

indicator will light, but only measurement will verify proper voltage.

1. Setting the minimum pressure. Make sure the signal connections are made and input is at

minimum. Place the manual override switch to the AUTO position. Adjust the OFFSET pot to the

desired pressure output, or until the actuator just starts to move. The adjustment range of the

OFFSET pot is 0 to 9 psig (62.05 kPa), 0 to 14 psig (96.53 kPa), or 0 to 19 psig (131 kPa)

depending on the range selected. Zero pot is factory set – DO NOT ADJUST.

2. Setting the maximum pressure. Now place the manual override switch to the MANUAL position.

Turn the MANUAL pot to produce the maximum branch line pressure available. Turn the SPAN pot

for the maximum desired output pressure, or until the actuator just stops. Be sure the MAIN air

pressure is at least 2 psig greater than the desired maximum branch output pressure.

3. Repeat. Because the OFFSET and SPAN pots are slightly interactive, steps 1 and 2 must be

repeated until the desired minimum and maximum pressures are repeatable. Since the MANUAL

pot is set for maximum pressure, it is only required that you switch the manual override switch back

and forth from MANUAL to AUTO when repeating steps 1 and 2. Calibration is usually

accomplished in less than 3 iterations. Apply minimum and maximum input signals and measure

response. Response between the minimum and maximum values will be linear, therefore soft w ar e

algorithms are easy to derive.

The feedback signal range on all selections is 0 to 5 VDC and is proportional to the output pr es sure rang e

selected. The output and feedback signal will continue to vary proportionally if the input signal is increased

beyond its upper limit (if there is enough main air available).

The EPC is a constant bleed interface and utilizes a precision bleed orifice to maintain a measured flow of

air across the valve. The branch exhaust response time is determined by the combined ex haus t air flow as

well as pressure differentials. If power to the EPC is lost, it will continue to bleed through the orifice until

branch pressure is 0 psig. To use the manual override, place the AUTO/MAN switch in the Man position.

The potentiometer is now operable, and by turning the knob you may increase or decrease the pneumatic

output. EU Commission Directive 2002/95/EC (RoHS) Compliant

Power Supply Voltage: Air Supply:

24 VDC (+10%/-5%) Maximum 25 psig (172.38 kPa), minimum 18 psig (124.11 kPA)

24 VAC (± 1 0%) 50/60 Hz at terminals Main air supply, 0–10 psig (68.95 kPa), 0-15 psig (103.43 kPa), and

Supply Current: 0-20 psig (137.9 kPa) jumper selectable output pressure ranges.

180 mA max. Air Flow, @ 20 psig (137.9 kPa) main/15 psig (103.43kPa)

Feedback Signal Output: Exhaust Rate: 41 scim

Factory Calibrated 0-5 VDC = range selected Accuracy: 1% full scale at room temperature,

Input Signal Ranges: 0-5 VDC @ Infinite Ohms 2% full scale at 32 to 120°F (0 to 48.8°C)

0-10 VDC @ Infinite Ohms Override Contact Rating: 24 VAC or 24 VDC, 1A maximum

0-15 VDC @ Infinite Ohms

0-20mA @ 250 Ohms

AUTOMATION COMPONENTS, INC Version : 2.0

2305 Pleasant View Road Page 2 of 2 I0000479

Middleton, Wisconsin 53562 (888) 967-5224

www.workaci.com

Loading...

Loading...