Page 1

DUCT SERIES

Installation & Operation Instructions

Phone: 1-888-967-5224

Website: workaci.com

PRECAUTIONS

• DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE (24/120/230 VAC).

GENERAL INFORMATION

The Duct sensor is a single point temperature

sensor that is designed for use with electronic

controllers in commercial heating and cooling

building management systems. It is available

with multiple thermistor or RTD options.

For optimal temperature readings, follow these

tips:

• Duct probe should be placed (3) to (4) duct segments

down from any bend or obstructions and away from

90° bends.

• Mount the sensor on the top or sides of duct work;

mounting on the bottom risks damage due to

moisture.

• The sensor should be mounted in the middle of the

duct where air circulation is well mixed (no

stratication), and not blocked by obstructions.

Stratication and obstructions can cause sensing

errors. An example is downstream from a heating or

cooling coil.

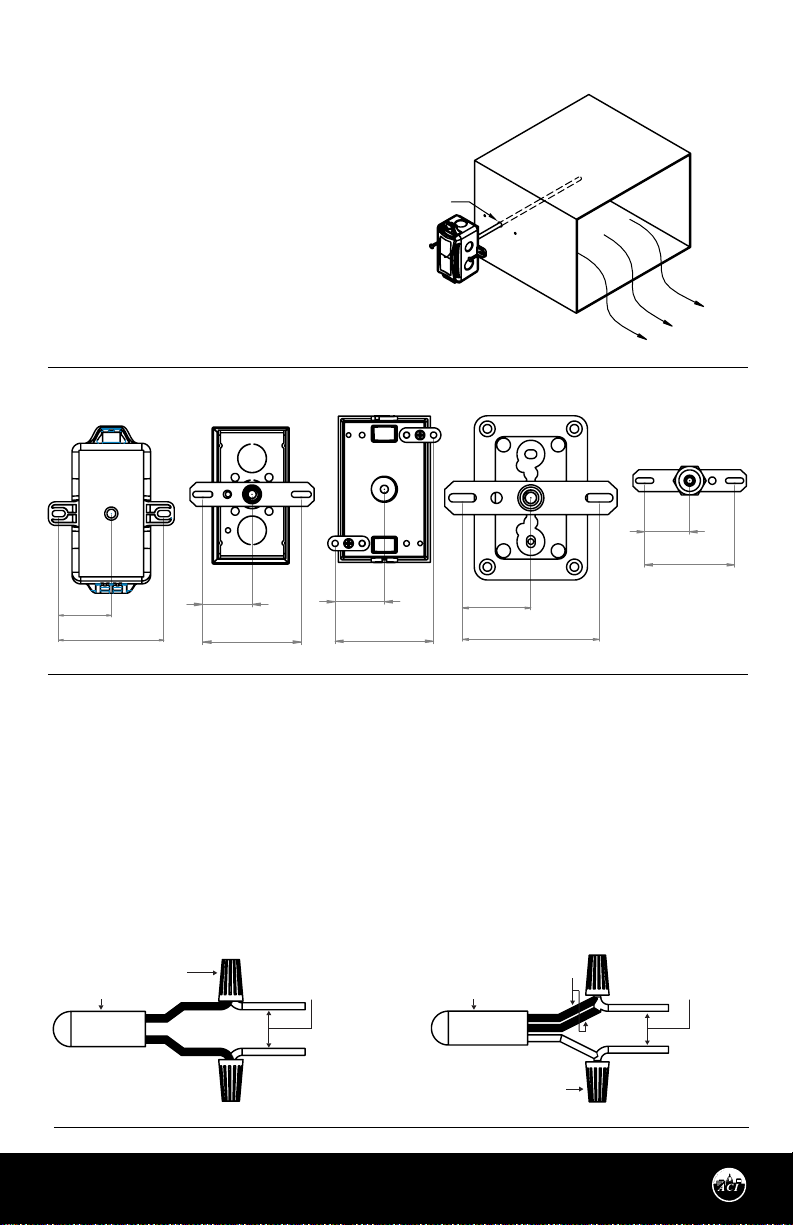

FIGURE 1: ENCLOSURE

DIMENSIONS

4.79"

(121.55 mm)

(106.68 mm)

2.35"

(59.80 mm)

(45.18 mm)

2.34"

(59.38 mm)

1.78"

PLASTIC BOX (-PB)

3.60"

(91.44 mm)

2.25"

(57.15 mm)

GALVANIZED ENCLOSURE (-GD)

3.88"

(98.60 mm)

2.41"

(61.21 mm)

4.20"

BELL BOX (-BB)

2.95"

(75.00 mm)

MOUNTING INSTRUCTIONS

Drill a 3/8” hole in the duct and insert the probe through

the hole until the foam pad is tight to the duct. Drill pilot

holes for the (2) mounting screws. Use the enclosure

ange as a guide, or use the dimensions listed below to

measure out.

WITHOUT BOX (-DO)

0.61"

3.88"

(98.60 mm)

(24.89 mm)

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

0.98"

(15.49 mm)

NEMA -4X (-4X)

Page 1

3.88"

(98.60 mm)

2.55"

(64.77 mm)

4.72"

(119.83 mm)

3.70"

(93.980 mm)

2.19"

(55.69 mm)

Version: 2.0

I0000810

Page 2

MOUNTING (Continued)

FIGURE 2: DUCT MOUNTING

Now fasten and insert (2) screws #8 x 3/4" TEK

(provided and recommended) through the

mounting holes in the ange and tighten until

the unit is held rmly to the duct. Make sure the

foam pad is tight to the duct to eliminate any

0.375"

(9.525 mm)

possible air leaks. Refer to the Wiring Instruc-

tions (p. 2-3) to make necessary connections.

Note: All enclosures have the foam pad attached.

For the “DO” (no enclosure), the foam pad is

included, but not installed. The foam pad must be

installed prior to mounting.

FIGURE 3: MOUNTING FOR DIFFERENT CONFIGURATIONS

1.54"

1.51"

(38.25 mm)

(76.51 mm)

3.01"

(39.12 mm)

(78.23 mm)

3.08"

-PB -GD -BB -4X -DO

1.59"

(40.39 mm)

(80.77 mm)

3.18"

1.54"

(39.12 mm)

3.08"

(78.23 mm)

1.54"

(39.12 mm)

(78.23 mm)

3.08"

WIRING INSTRUCTIONS

Open the cover of the enclosure. ACI recommends 16 to 26 AWG twisted pair wires or shielded cable for all

sensors. Signal wiring must be run separate from low and high voltage wires (24/120/230VAC). All ACI thermistors and RTD temperature sensors are both non-polarity and non-position sensitive. All thermistor type units

are supplied with (2) ying lead wires, and all RTD’s are supplied with (2) or (3) ying lead wires – see FIGURE

4 (below). The number of wires needed depends on the application.

FIGURE 4: TEMPERATURE WIRING

3-WIRE RTD WIRING2-WIRE THERMISTOR or RTD WIRING

THERMISTOR OR

RTD 2WIRE

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

WIRE NUT

WIRING FROM CONTROLLER

ANALOG INPUT

Page 2

RTD 3WIRE

SAME COLOR WIRES

WIRE NUT

WIRING FROM CONTROLLER

ANALOG INPUT

Version: 2.0

I0000810

Page 3

WIRING INSTRUCTIONS (Continued)

Connect thermistor/RTD wire leads to controller analog input wires using wire nuts, terminal blocks, or

crimp style connectors. All wiring must comply with all local and National Electric Codes. After wiring,

attach the cover to the enclosure.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller. Connecting both ends of the shield to ground may cause a ground loop. When

removing the shield from the sensor end, make sure to properly trim the shield to prevent any

chance of shorting.

Note: If the controller requires a (2) wire input for a RTD, connect the (2) common wires (same

color) together. If the controller requires (3) wires, use (3) individual wires.

TROUBLESHOOTING

PROBLEM

Sensor reading is incorrect

Sensor reads infinity/very high resistance

Sensor reads low resistance

Erratic readings

SOLUTION(S)

• Verify sensor wiring to controller is not damaged and has continuity.

• Verify sensor or wires are not shorted together.

• Verify controller is setup for correct sensor curve.

• Disconnect wires from sensor terminal block, tighten terminal block

screws down, and take a resistance (ohm) reading with a multimeter.

• Compare the resistance reading to the Temperature Vs Resistance

Curves online: http://www.workaci.com/content/thermistor-curves-0

• Verify proper mounting location to conrm no external factors are

aecting reading.

• Sensor or wires are open.

• Sensor or wires are shorted together.

• Condensation on PCB board

• Bad wire connections.

WARRANTY

The ACI Duct Series temperature sensors are covered by ACI’s Five (5) Year Limited Warranty, which is located in

the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Page 3

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 2.0

I0000810

Page 4

PRODUCT SPECIFICATIONS

SENSOR NON-SPECIFIC INFORMATION

Number Sensing Points:

Storage Temperature Range:

Operating Humidity Range:

Probe Material | Diameter:

Wire Size

Enclosure Specifications:

(Temperature, Material,

Flammability, NEMA/IP Ratings)

THERMISTOR

THERMISTOR

Sensor Output @ 25 °C (77 °F):

(Lead Wire Colors)

*Does not include CL2P

Accuracy @ 0-70 °C (32 - 158 °F):

PLATINUM

Sensor Output @ 0 °C (32 °F):

Accuracy:

BALCO

Sensor Output @ 21.1 °C (70 °F):

(Lead Wire Colors)

Accuracy:

NICKEL

Sensor Output @ 21.1 °C (70 °F):

(Lead Wire Colors)

Accuracy:

One

-40 to 80 °C (-40 to 185 °F)

10 to 95% RH, non-condensing

304 Stainless Steel | 0.250” (6.35 mm)

22 AWG (0.65 mm)

“-GD” Enclosure: Galvanized Steel, -40 to 115 °C (-40 to 239 °F), NEMA 1 (IP10)

“-PB” Enclosure: ABS Plastic, UL94-HB, -30 to 90 °C (-22 to 194 °F), Plenum Rated

“-BB” Enclosure: Aluminum, -40 to 115 °C (-40 to 239 °F), NEMA 3R (IP 14)

“-4X” Enclosure: Polystyrene Plastic, UL94-V2, -40 to 70°C (-40 to 158°F), NEMA 4X (IP 66)

“-DO” No Enclosure: Polyamide 66 (High Performance Nylon), -40 to 115 °C (-40 to

239 °F), UL94-HB

A/1.8K: 1.8 KΩ nominal (Red/Yellow)

A/3K: 3 KΩ nominal (White/Brown)

A/AN (Type III): 10 KΩ nominal (White/White)

A/AN-BC: 5.238 KΩ nominal (White/Yellow)

A/CP (Type II): 10 KΩ nominal (White/Green)

A/1.8K Series: +/- 0.5 °C @ 25 °C (77 °F)

and (+/-1.0 °C) (+/-1.8 °F)

A/100: 100 Ω nominal

+/- 0.06% Class A (Tolerance Formula: +/- °C = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value of Temperature above or below 0 °C in °C)

@ -40 °C (-40 °F): +/- 0.23ºC (+/- 0.414ºF)

@ 0 °C (32 °F): +/- 0.15 °C (+/- 0.27 °F)

1 KΩ nominal (Orange/Yellow)

@ 21.1 °C (70 °F): +/- 1%

1 KΩ nominal (Red/Red)

@ -40 °C (-40 °F): +/- 1.52 °C (+/- 2.73 °F)

@ 0 °C (32 °F): +/- 0.4 °C (+/- 0.72 °F)

@ 21.1 °C (70 °F): +/- 0.17 °C (+/- 0.34 °F)

A/CSI: 10 KΩ nominal (Green/Yellow)

A/10KS: 10 KΩ nominal (White/Blue)

A/10K-E1: 10 KΩ nominal (Gray/Orange)

A/20K: 20 KΩ nominal (Brown/Blue)

A/100KS: 100 KΩ nominal (Black/Yellow)

A/10K-E1 Series: +/- 0.3 °C (+/- 0.54 °F)

All Else: +/- 0.2 °C (+/- 0.36 °F)

A/1K: 1 KΩ nominal

@ 115 °C (239 °F): +/- 0.38 °C (+/- 0.69 °F)

@ 54.4 °C (130 °F): +/- 0.56 °C (+/- 1. 00°F)

@ 121 °C (250 °F): +/- 1.25 °C (2.25 °F)

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 2.0

I0000810

Loading...

Loading...