aci A/DLP-001-W-U-N-A-3, A/DLP-040-W-U-N-A-0, A/DLP-001-W-U-N-A-0, A/DLP-040-W-U-N-A-3, A/DLP-001-W-U-D-A-0 Installation & Operation Instructions

...Page 1

DLP SERIES

Installation & Operation Instructions

Phone: 1-888-967-5224

Website: workaci.com

PRECAUTIONS

• Do not switch pressure range and output

mode when power is on. Make sure to power off

the unit first, then set the DIP Switches to the

correct positions and then power on the

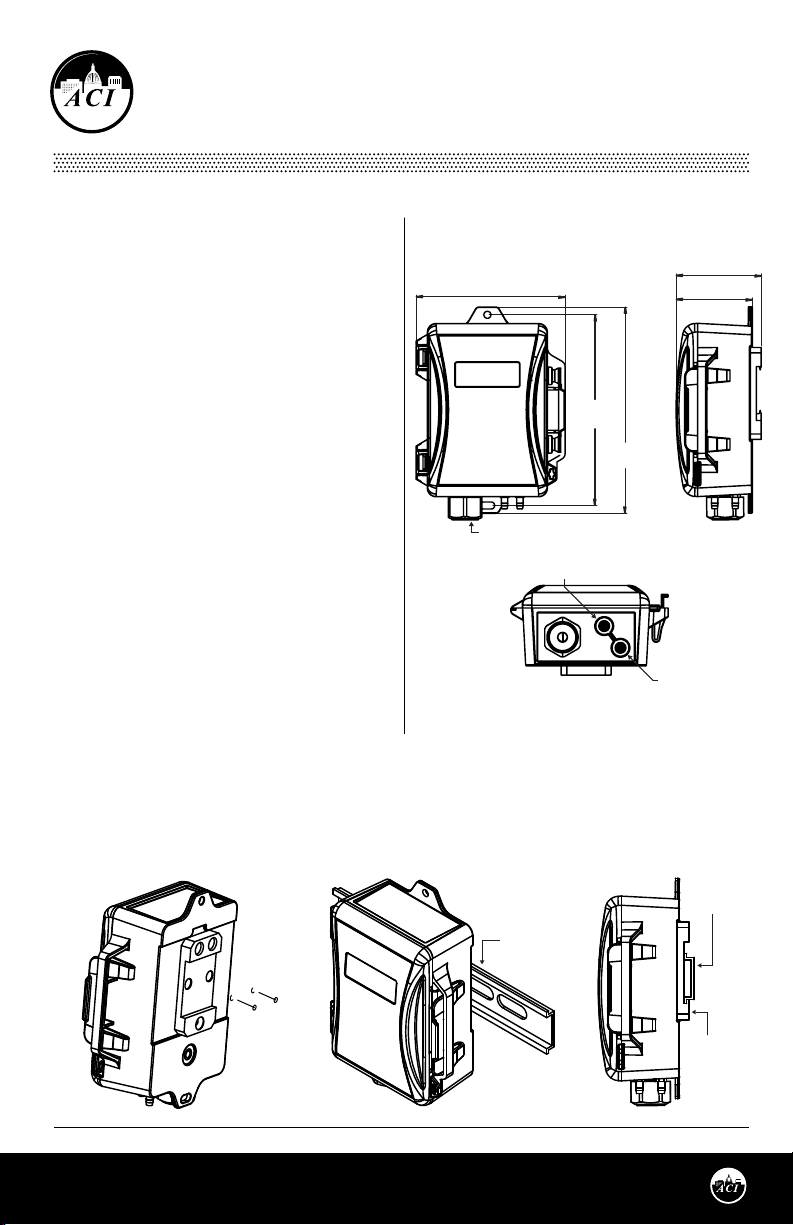

FIGURE 1: DLP DIMENSIONS

4.35"

(110.43 mm)

2.48"

(62.99 mm)

2.23"

(56.52 mm)

transmitter.

GENERAL INFORMATION

The DLP Series is based on a piezoresistive, silicon

sensing element which senses Dierential Pressure

and provides an analog output. Field selectable

analog outputs include 0-5 and 0-10 VDC, or 4-20

mA which correlate to a uni or bi-directional

pressure range from 0-0.1” up to 0-40” of water

column, depending on your model selection. Each

unit has up to 8 eld selectable, uni or bi-directional

ranges (see Figure 6 p. 3).

CORDGRIP /

1/2 “ CONDUIT FITTING

MEDIA

The DLP can be used to monitor the dierential

pressure in any application that uses dry air or inert

gas.

Mounting

Find a suitable location for the enclosure. The DLP

has 2 two mounting holes located on the top and

bottom anges. Drill pilot holes for the (2) #8 x 3/4”

self-drilling screws(supplied). Use the enclosure ange as a guide, or use the dimensions listed in Figure 1.

Mount the unit vertically with the brass ttings pointing towards the ground. This ensures that any

condensation that may form in the tubing does not have an eect on the pressure sensor. If mounting the

unit horizontally, a slight zero shift may occur and care must be taken to prevent moisture from building

up in the sensor.

5.56"

(141.29 mm)

6.02"

(152.82 mm)

HIGH PRESSURE PORT

-H

-L

LOW PRESSURE PORT

FIGURE 2: DIN RAIL MOUNTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

DIN RAIL

DIN RAIL

DIN RAIL

CLIP

Version: 15.0

Version: 15.0

I0000777

I0000777

Page 2

DIN RAIL MOUNTING (Optional)

Attach the DIN Rail Mounting accessory to the

back of the enclosure using the two screws

provided. To mount the sensor on the DIN Rail,

place the bottom of the DIN Rail Clip into the

35mm DIN Rail and push the unit upward to

engage the spring clip. Now press the top of

the unit back until it locks into place - see

FIGURE 2 (p.1).

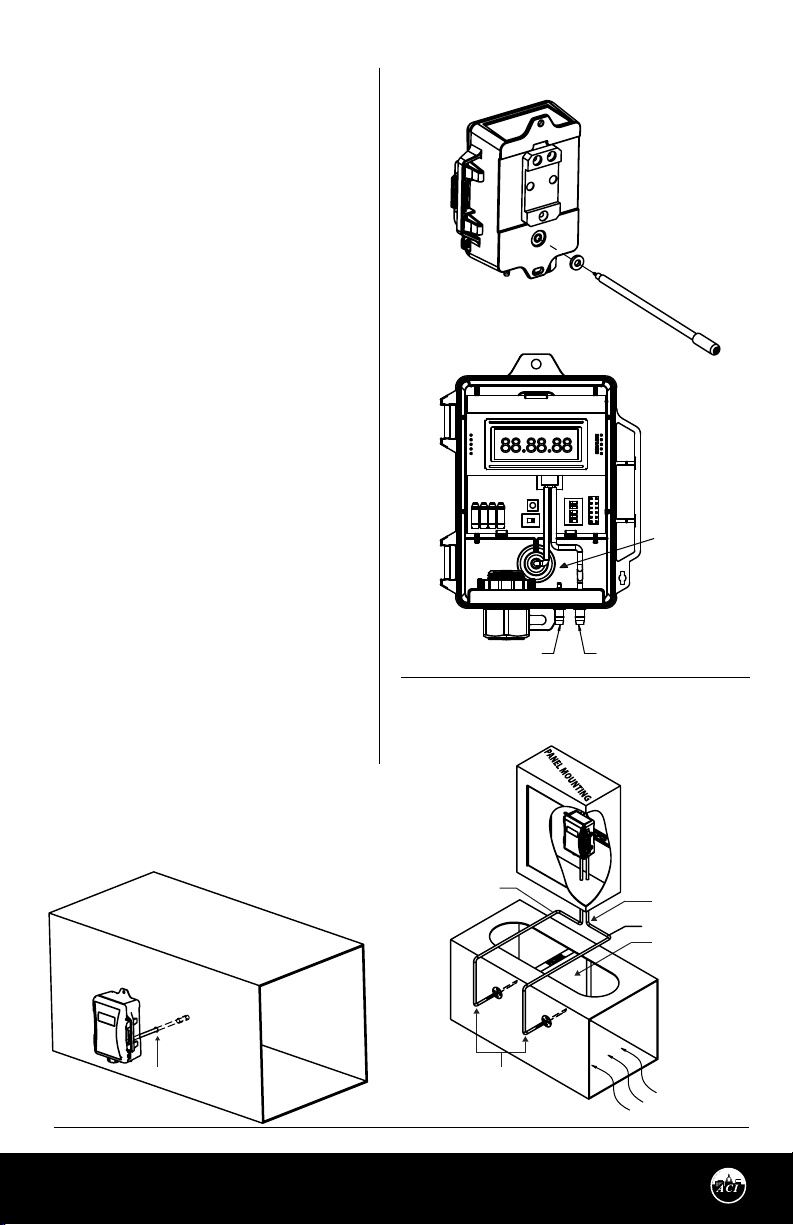

PITOT TUBE INSTALLATION

(Optional)

Slip the rubber washer over the threaded end

of the pitot tube, keeping the washer as close

to the threaded end as possible. Fasten the

pitot into the threaded insert on the back of

the enclosure. Press the rubber washer against

the enclosure - see FIGURE 3.

Tubing Setup When Pitot Tube is Installed

Units will be shipped with silicone tubing

attached to the high and low pressure barb

ttings. The silicone tubing will need to be

removed from the High Pressure (H) barb

tting and secured onto the pitot tube barb

tting. This will leave the high pressure barb

tting open to atmosphere, and the Low

pressure barb tting remaining at default

setup.

Pressure Connections

The recommended connection tubing is ¼”

O.D push-on tubing (1/8” to 3/16” I.D.). For best

results, all tubing lengths should be limited to

a maximum length of 75 feet (23 meters).

Longer runs will aect the response time.

FIGURE 3: PITOT TUBE INSTALLATION

Move Tubing

from High port to

Pitot tube

HIGH PRESSURE PORT

LOW PRESSURE PORT

FIGURE 5: MEASURING DIFFERENTIAL

PRESSURE ACROSS FILTER

FIGURE 4: DUCT STATIC INSTALLATION

DRILL Ø 7/16”

(11.1125 mm)

HOLE

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

LOW

A/SPT

A/VPT

POLY TUBING

HIGH

FILTER

DIRECTION

OF AIR FLOW

Version: 15.0

I0000777

Page 3

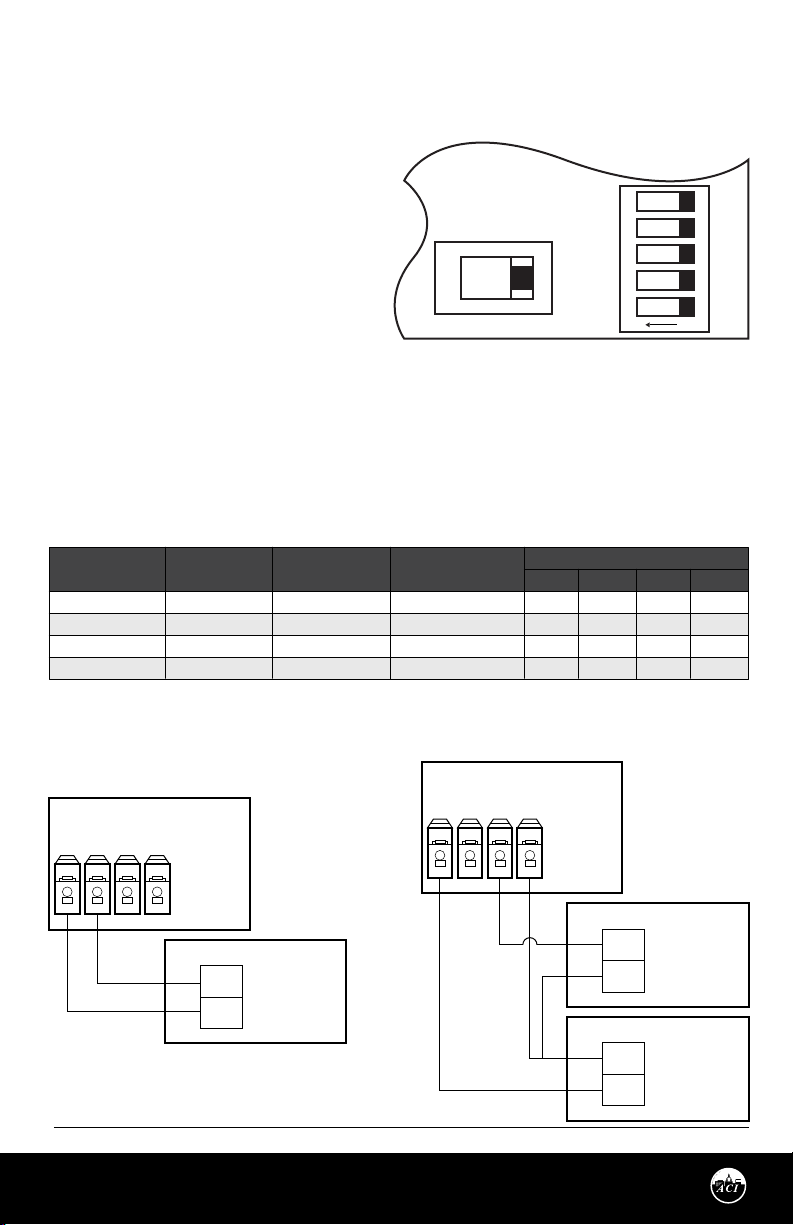

WIRING

PRECAUTIONS

FIGURE 6: SW1 and SW3 OUTPUT

SWITCHES

• Remove power before wiring. Never

connect or disconnect wiring with

power applied.

• When using a shielded cable, ground the

shield only at the controller end.

Grounding both ends can cause a ground

loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when

powering the unit with 24 VAC. Failure to

wire the devices with the correct polarity

when sharing transformers may result in

Vout

mA

SW1

5V

SW3

BI

Pa

A

1 2 3 4 5

1

ON

OFF

UNI

10V

inWC

B

2

O

damage to any device powered by the

shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

TABLE 1: WIRING CONNECTIONS

OUTPUT SIGNAL

0-5 VDC

0-10 VDC

4-20 mA

4-20 mA

N/A = Not Applicable

N/C = No Connection

OUTPUT MODE

(SW1)

Vout

Vout

mA

mA

OUTPUT SIGNAL

(SW3 Position 4)

5 V

10 V

N/A

N/A

SUPPLY VOLTAGE

VAC/VDC

VAC/VDC

VDC

VAC

WIRE CONNECTIONS

BLACK

RED

COM

V+

COM

V+

N/C

V+

COM

V+

WHITE

VOUT

VOUT

N/C

N/C

YELLOW

N/C

N/C

IOUT

IOUT

FIGURE 7: WIRING CONNECTIONS

2-Wire, 4-20 mA

DLP

YELLOW

WHITE

VOUT

BLACK

COM

Digital Controller

AI1

V+

RED

V+ IOUT

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

3-Wire, 0-5 V / 0-10 V

DLP

YELLOW

WHITE

RED

VOUT

COM

V+ IOUT

Page 3

BLACK

Digital Controller

24 VAC/DC POWER

AI1

COM

SUPPLY

-

+

Version: 15.0

I0000777

Page 4

Open the cover of the enclosure. ACI recommends 16 to 26 AWG twisted pair wires or shielded cable for

all transmitters. Twisted pair may be used for 2-wire current output transmitters or 3-wire for voltage

output. Connect the wires to the unit’s nger push-button terminal blocks. Each DLP unit can be

congured to three output signals: 4-20 mA, 0-5 V or 0-10 V. Use the Wiring Connections and diagrams

to determine the proper wiring for your application. See TABLE 1 (p.3) for Output Mode and Output

Signal switch positions.

Note: When using 1/2” conduit, the strain relief tting must be removed from the enclosure.

Note: Make sure that any conduit or metal ttings do not come in contact with the circuit board.

TABLE 2: STANDARD MODEL NUMBERS

OUTPUT SIGNAL

A/DLP-001-W-U-N-A-0

A/DLP-010-W-U-N-A-0

A/DLP-040-W-U-N-A-0

A/DLP-001-W-U-N-A-3

A/DLP-010-W-U-N-A-3

A/DLP-040-W-U-N-A-3

A/DLP-001-W-U-D-A-0

A/DLP-010-W-U-D-A-0

A/DLP-040-W-U-D-A-0

A/DLP-001-W-U-D-A-3

A/DLP-010-W-U-D-A-3

A/DLP-040-W-U-D-A-3

ITEM #

140769

140774

140777

141072

141074

141076

140773

140776

140778

141073

141075

141077

DESCRIPTION

0-0.1", 0.2", 0.5", 1", Without Display

0-1", 2", 5", 10", Without Display

0-10", 20", 30", 40", Without Display

0-0.1", 0.2", 0.5", 1", Without Display, With Pitot Tube and DIN Rail Clip

0-1", 2", 5", 10", Without Display, With Pitot Tube and DIN Rail Clip

0-10", 20", 30", 40", Without Display, With Pitot Tube and DIN Rail Clip

0-0.1", 0.2", 0.5", 1", With Display

0-1", 2", 5", 10", With Display

0-10", 20", 30", 40", With Display

0-0.1", 0.2", 0.5", 1", With Display, Pitot Tube, and DIN Rail Clip

0-1", 2", 5", 10", With Display, Pitot Tube, and DIN Rail Clip

0-10", 20", 30", 40", With Display, Pitot Tube, and DIN Rail Clip

ZERO FUNCTION

FIGURE 8: AUTO ZERO BUTON - SW2

The DLP unit should be “ZEROED” before

pressure is applied to the unit. The zero button

is used to cancel out any osets caused by

installation and sensor drift. The Zero

adjustment must be performed with NO

pressure applied to either side of the sensor.

AUTO

ZERO

SW2

Remove the tubing connected to the H(High)

and/or L(Low) pressure ttings. Push “ZERO”

button for more than three seconds before installation or whenever necessary.

For units with LCD display, “AUTOZERO” icon will be on when the unit enters zero mode. If zeroing

process is successful, the “AUTOZERO” icon will ash twice.

PRESSURE RANGE SELECTION

If a custom calibrated pressure range is ordered, DO NOT change the Pressure Range Selection DIP switch

settings. Table 2 lists ACI’s 12 standard model #’s.

Page 4

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 15.0

I0000777

Page 5

UNIDIRECTIONAL AND BIDIRECTIONAL

MODE

The DLP can operate in either unidirectional mode (0 – X

inWC) or bidirectional mode (± X inWC). Each unit could have

up to eight eld selectable, uni or bidirectional ranges.

TABLE 3: MAXIMUM PRESSURE

ACI Part #

Maximum Pressure

(inWC)

DLP-001-W

DLP-010-W

DLP-040-W

1

10

40

CAUTION

• See TABLE 3 for your DLP model’s maximum pressure.

• DO NOT switch pressure range or output mode when POWER is ON. Make sure POWER to the

unit is OFF. Failure to do so WILL NOT ALLOW any new switch settings to take place.

• Choose differential pressure range based on the expected differential pressure in your

application. Move switches to the correct positions and THEN POWER ON the transmitter.

FIGURE 9: SWITCH SETTINGS

[UNIDIRECTIONAL] DLP-001-W

0 to 1 inWC

BI

5V

Po

A

1

[UNIDIRECTIONAL] DLP-010-W

0 to 10 inWC

BI

5V

Po

A

1

[UNIDIRECTIONAL] DLP-040-W

0 to 40 inWC

BI

5V

Po

A

1

[BIDIRECTIONAL] DLP-001-W

-1 to 1 inWC

BI

5V

Po

A

1

[BIDIRECTIONAL] DLP-010-W

-10 to 10 inWC

BI

5V

Po

A

1

[BIDIRECTIONAL] DLP-040-W

-40 to 40 inWC

BI

5V

Po

A

1

UNI

10V

inWC

B

1 2 3 4 5

2

ON

UNI

10V

inWC

B

1 2 3 4 5

2

ON

UNI

10V

inWC

B

1 2 3 4 5

2

ON

UNI

10V

inWC

B

1 2 3 4 5

2

ON

UNI

10V

inWC

B

1 2 3 4 5

2

ON

UNI

10V

inWC

B

1 2 3 4 5

2

ON

0 to 0.5 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 5 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 30 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-0.5 to 0.5 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-5 to 5 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-30 to 30 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

0 to 0.2 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 2 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 20 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-0.2 to 0.2 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-2 to 2 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-20 to 20 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

0 to 0.1 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 1 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

0 to 10 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-0.1 to 0.1 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-1 to 1 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

-10 to 10 inWC

BI

5V

Po

A

1 2 3 4 5

1

ON

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

UNI

10V

inWC

B

2

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 15.0

I0000777

Page 6

Unidirectional Mode

• DIP switch SW3 position ve set at UNI side.

• DIP switch SW3 positions one and two are for Pressure Range Selection

Bidrectional Mode

• DIP switch SW3 position ve set at BI side.

• DIP switch SW3 positions one and two are for Pressure Range Selection.

Note: In Bidirectional mode, a value of 0 inWC will have an output equal to 50% of the output signal range

(12mA, 2.5V, 5V).

ADDITIONAL LCD FEATURES

LCD Engineering Units Adjustment

This option is ONLY for units with LCD display. Switch DIP switch SW3 position three to select Pa or inWC.

If switched with power on, unit change will not take place until power is cycled.

“Out Of Range”

“OUT OF RANGE” icon will be on when dierential pressure is over or under the minimum or maximum

pressure range selected. If a DLP unit is outputting “OUT OF RANGE”, please turn o the unit immediately,

and check the pressure input with a gauge or other test instrument. Once the pressure has been veried,

set the Pressure Range Selection DIP switch to the proper positions based upon your maximum expected

dierential pressure.

CALIBRATION

DLP utilizes a digital pot for Span calibration and is factory set. There is no Span potentiometer for

adjustment. In the event you require Span calibration, the unit must be sent back to ACI.

The Oset can be adjusted using the Auto Zero function discussed on pg 4. Drift is a function of stress

relaxation over time and this results in the oset shifting, and not the span . Periodically re-zeroing the

device will eliminate the eect of drift.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 15.0

I0000777

Page 7

PRODUCT SPECIFICATIONS

SPECIFICATIONS

Supply Voltage:

Supply Current:

Output Signals:

Response Time (0-100% FSO):

Output Update Rate:

Accuracy¹:

Zero Function:

Thermal Effects²:

Proof Pressure / Burst Pressure³:

Operating Temperature Range:

Compensated Temperature Range:

Storage Temperature Range:

Operating Humidity Range:

Media Types:

Enclosure Material / Flammability Rating:

Wiring Connections:

Conduit Knockouts:

Pressure Fitting Material:

Tubing Size Accepted:

Note: Accuracy includes linearity, hysteresis & repeatability @ 71°F (21.5°C)

Note: Shift is relative to 71°F (21.5°C)

4-20 mA Output: 16-36 VDC (250 Ω Load max.) / 22-36 VDC (500 Ω Load max.)

0-5 VDC / 0-10 VDC Output: 16-36 VDC / 24 VAC (+/- 10%)

4-20 mA Output: 24 mA minimum | 0-5 VDC / 0-10 VDC Output: 6 mA maximum

Current Output: 4-20 mA, 2-Wire (Standard); (Current limited to 21.4 mA max)

Voltage Signals: 0-5 VDC / 0-10 VDC, 3-Wire; Output limited @ 5.25 & 10.5 VDC)

8 seconds

1 second

+/- 0.5% FSO; +/- 0.25% (Only for Specied Range)

Pushbutton Zero Function

+/- 0.067% FSO / °F (0.12% FSO / °C)

A/DLP-001: Proof: 270 inWC (67.2 kPa) | Burst: 415 inWC (103.3 kPa) for 1 inWC (249.8 Pa)

A/DLP-010: Proof: 350 inWC (87.12 kPa) | Burst: 550 inWC (136.9 kPa) for 10 inWC (2490.8 Pa)

A/DLP-040: Proof: 562 inWC (140 kPa) | Burst: 1004.7 inWC (250 kPa) for 40 inWC (9963.6 Pa)

-4 to 185 °F (-20 to 85 °C)

32 to 122 °F (0 to 50 °C)

-22 to 185 °F (-30 to 85 °C)

10 to 95% RH, non-condensing

Dry air or inert non-conductive gases

Flame Retardant Polycarbonate; UL94-5VA

Finger Pushbutton (Spring) Terminal Blocks; accepts 16-24 AWG wires

Watertight Cordgrip Installed (1/2" NPT Conduit ttings accepted when Cordgrip removed)

Nickel Plated Brass or Stainless Steel

1/4" O.D. x 0.170" I.D. Poly Tubing

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

WARRANTY

The ACI DLP is covered by ACI’s Five (5) Year Limited Warranty, which is located in the front of ACI’S

SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

Page 7

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Version: 15.0

I0000777

Loading...

Loading...