Page 1

Speedster22i SerDes

User Guide

UG028 (v2.1) – July 1, 2014

UG028, July 1, 2014

1

Page 2

Table of Contents

List of Figures .................................................................................................................................... 5

List of Tables ..................................................................................................................................... 6

Overview ............................................................................................................ 7

Physical Media Attachment (PMA) ..................................................................................................... 7

Clocking ............................................................................................................................................. 8

Physical Coding Sublayer (PCS)........................................................................................................ 8

Debug and Test ................................................................................................................................. 8

Major standards supported ................................................................................................................ 9

SerDes Placement ........................................................................................................................... 11

SerDes Architecture Overview ......................................................................................................... 12

Physical Media Attachment (PMA) ................................................................. 13

1. Common .................................................................................................................................. 13

2. Receiver (RX)/Transmitter (TX) ................................................................................................ 14

3. Digital PMA (DPMA) ................................................................................................................. 14

PCS Blocks in the Transmitter ( TX ) ............................................................... 16

PCS Self Test Logic ......................................................................................................................... 16

Polarity bit reversal (PBR) #0 and #1 ............................................................................................... 16

Polarity and Bit Inversion – 10/20 bit Operation ............................................................................................. 17

Polarity and Bit Inversion – 8/16 bit Operation ............................................................................................... 18

Interface Encapsulation ................................................................................................................... 20

8b/10b Encoder ............................................................................................................................... 20

Symbols and Comma Character ..................................................................................................................... 20

Running Disparity ............................................................................................................................ 20

PCS Blocks in the Receiver (RX) .................................................................... 22

Transition Density Checker (TDC) ................................................................................................... 22

Polarity Bit Reversal (PB R) .............................................................................................................. 23

Symbol Alignment ............................................................................................................................ 23

Modes of Operation ........................................................................................................................................ 24

Deskew FIFO ................................................................................................................................... 25

Functional Description .................................................................................................................................... 26

Lane-to-Lane Deskew Modes of Operation ...................................................................................... 26

2 UG028, July 1, 2014

Page 3

The deskew module can work in three modes: .............................................................................................. 26

Standards Supported by Deskew Module ...................................................................................................... 27

Elastic FIFO (Elastic Buffer) ............................................................................................................. 27

EFIFO Standards and Skip Characters .......................................................................................................... 28

EFIFO Operation ............................................................................................................................................. 29

Overflow/Underflow ......................................................................................................................................... 31

8b/10b Decoder ............................................................................................................................... 31

Bit Slider .......................................................................................................................................... 31

Interface Encapsulation ................................................................................................................... 32

PCS Self Test Checker .................................................................................................................... 32

PCS Interface ................................................................................................... 33

Gigabit Ethernet Interface ................................................................................................................ 33

XAUI ................................................................................................................................................ 34

PIPE Interface .................................................................................................................................. 34

Clocking ........................................................................................................... 36

Debug and Test ............................................................................................... 38

Loopback Modes ............................................................................................................................. 38

PMA loopback modes: .................................................................................................................................... 39

PCS loopback modes: .................................................................................................................................... 39

PMA Test Pattern Generator ............................................................................................................ 40

PMA Test Pattern Checker .............................................................................................................. 40

PCS Test Pattern Generator ............................................................................................................ 40

PRBS Generator .............................................................................................................................. 40

PCS Test Pattern Checker ............................................................................................................... 41

Latency............................................................................................................. 42

PMA Latency ................................................................................................................................... 42

PCS Latency .................................................................................................................................... 42

Configurations Support ed .............................................................................. 45

Design Flow: Creating a SerDes Design ........................................................ 49

Generating SerDes Wrapper using ACE GUI ................................................................................... 49

Single-Lane Serdes Wrapper ........................................................................................................... 50

Overview Section: ........................................................................................................................................... 53

Section on PMA Settings: ............................................................................................................................... 57

RX PMA Equalization ...................................................................................................................................... 59

RX PMA PLL ................................................................................................................................................... 60

TX PMA Driver ................................................................................................................................................ 62

TX PMA PLL ................................................................................................................................................... 62

Section on PCS Settings: ................................................................................................................................ 63

UG028, July 1, 2014

3

Page 4

RX PCS Settings ............................................................................................................................................. 64

RX PCS Symbol Alignment ............................................................................................................................. 66

TX PCS Settings ............................................................................................................................................. 68

Section on Manually Overriding PMA/PCS Register Values: ......................................................................... 69

Generation of Wrapper Files: .......................................................................................................................... 70

Files Generated by ACE-GUI ........................................................................................................... 71

Integration of SerDes Wrapper in a Design ...................................................................................... 72

Design and Wrapper Files .............................................................................................................................. 72

Dynamically Changing the SerDes Register Values....................................................................................... 75

Using sBus module to enable internal loopback ............................................................................................. 75

Placement of SerDes ....................................................................................................................... 77

Timing Constraints .......................................................................................................................................... 78

Test bench Setup for Simulation ..................................................................................................................... 79

Design Guidelines ............................................................................................................................ 80

Reset Sequence ............................................................................................................................................. 80

SerDes Placement and Clocking Limitations .................................................................................................. 80

Wide Bus ......................................................................................................................................................... 86

Design Tips ..................................................................................................................................................... 87

Variants of the Simple Design .......................................................................................................... 88

Design Bypassing PCS: .................................................................................................................................. 93

Bypassing PCS by Manually Overr iding Cor r espo ndi ng Reg ister .................................................................. 95

Dynamic Read/Write of Ser Des Re gis t e rs via SBUS .................................... 98

Overview .......................................................................................................................................... 98

Alternatives for using SBUS interface for SerDes register access: ................................................................ 98

ACX_SERDES_SBUS_IF Module ................................................................................................... 99

The Ports of ACX_SERDES_SBUS_IF Module: .......................................................................................... 100

Loopback Modes ........................................................................................................................................... 102

SerDes Registers ........................................................................................... 103

Electrical Specifications ............................................................................... 104

Operating Conditions ..................................................................................................................... 104

Transmitter .................................................................................................................................... 105

Receiver ........................................................................................................................................ 108

Eye Diagram ................................................................................................................................................. 110

Reference Clock ............................................................................................................................ 112

Jitter Specification ......................................................................................................................................... 112

Revision Histor y ............................................................................................ 113

4 UG028, July 1, 2014

Page 5

List of Figures

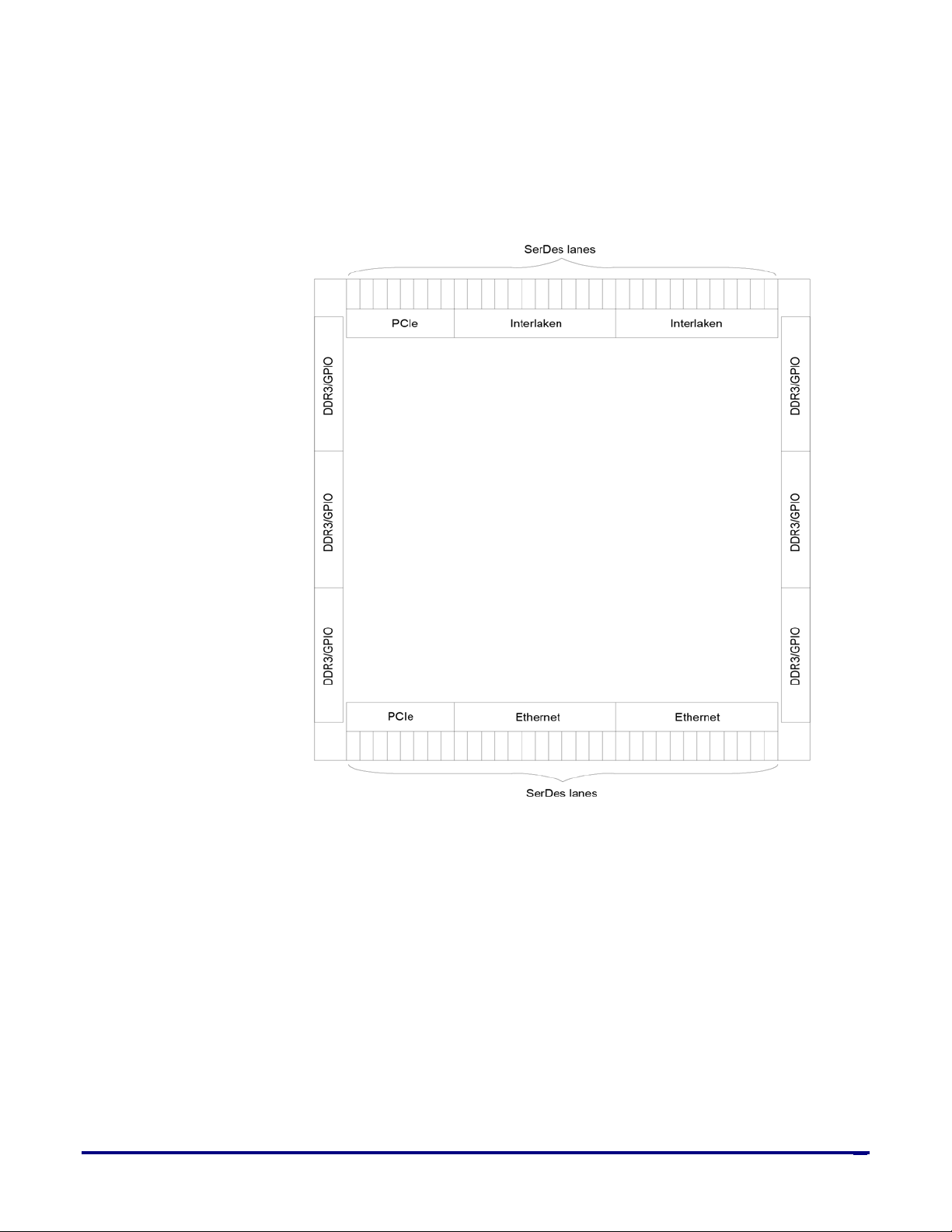

Figure 1: Location of SerDes Lanes ...................................................................................................................................... 11

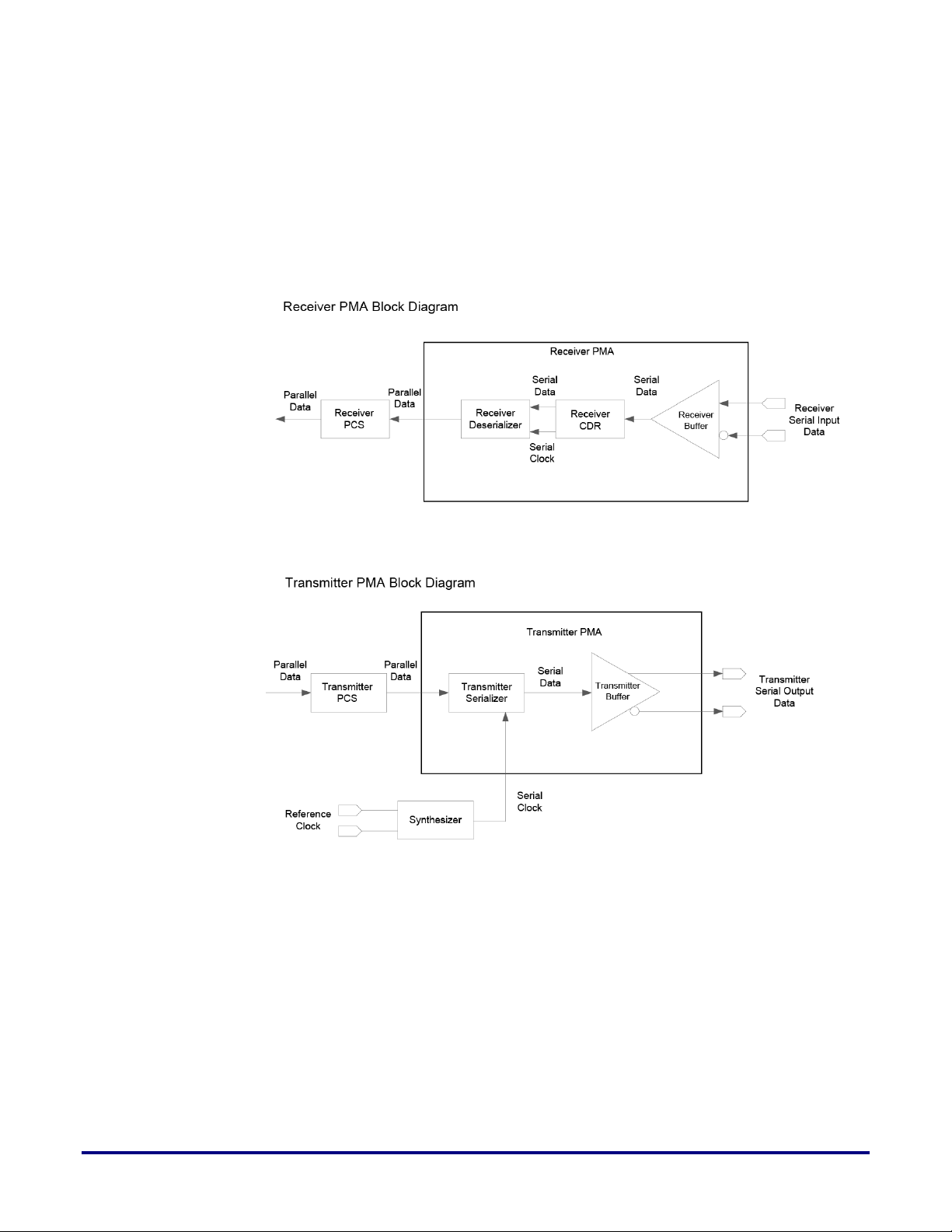

Figure 2: SerDes Architecture................................................................................................................................................ 12

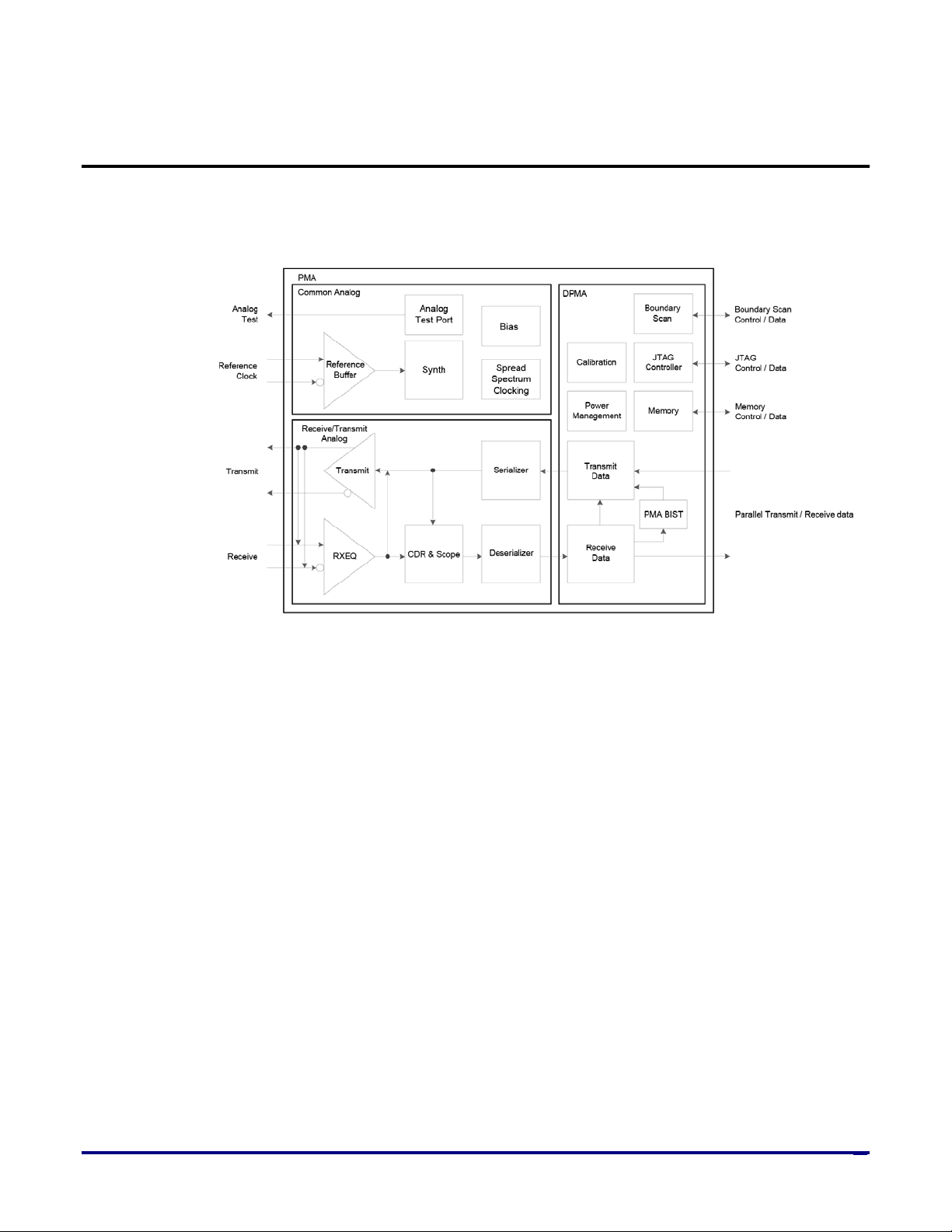

Figure 3: PMA Architecture .................................................................................................................................................. 13

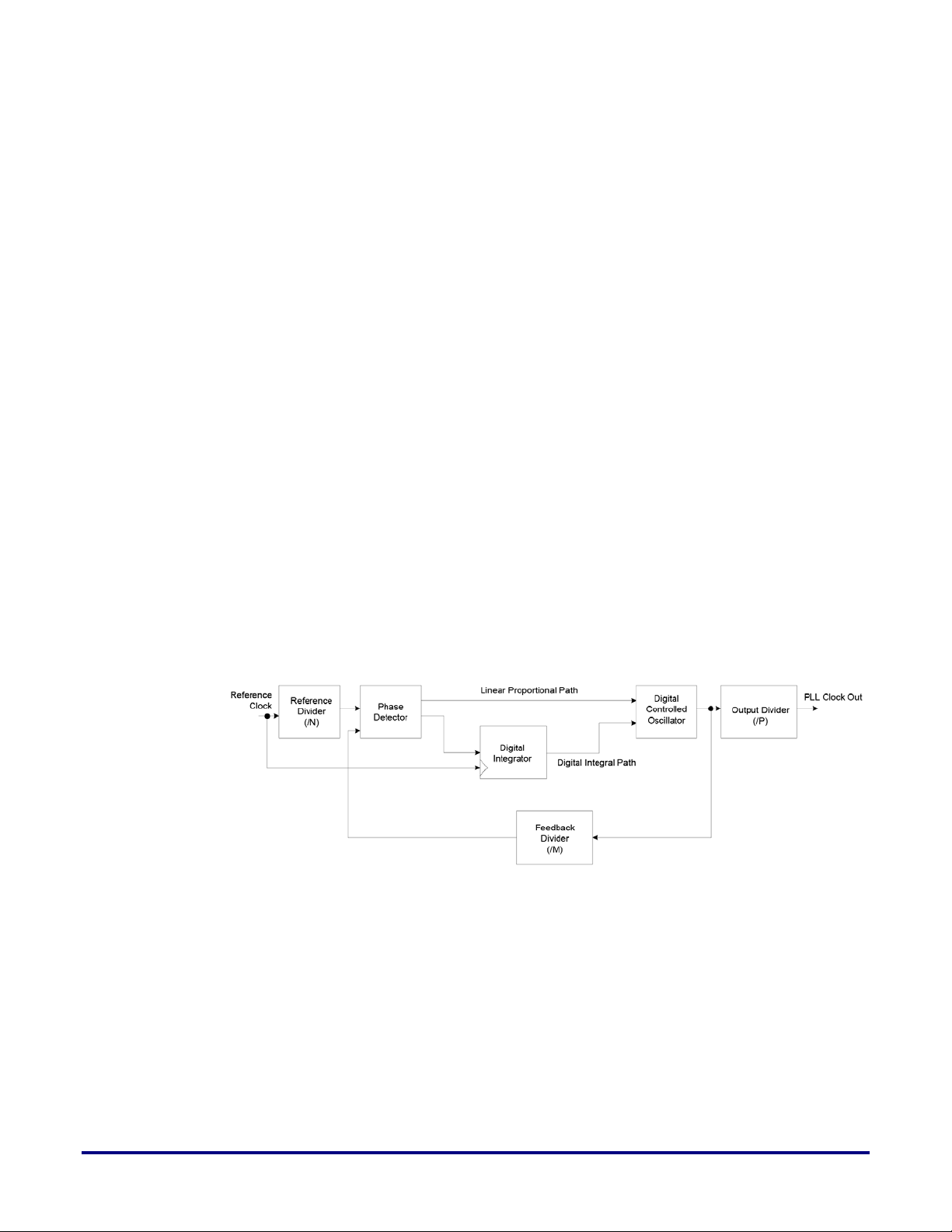

Figure 4: Synthesizer Architecture ....................................................................................................................................... 14

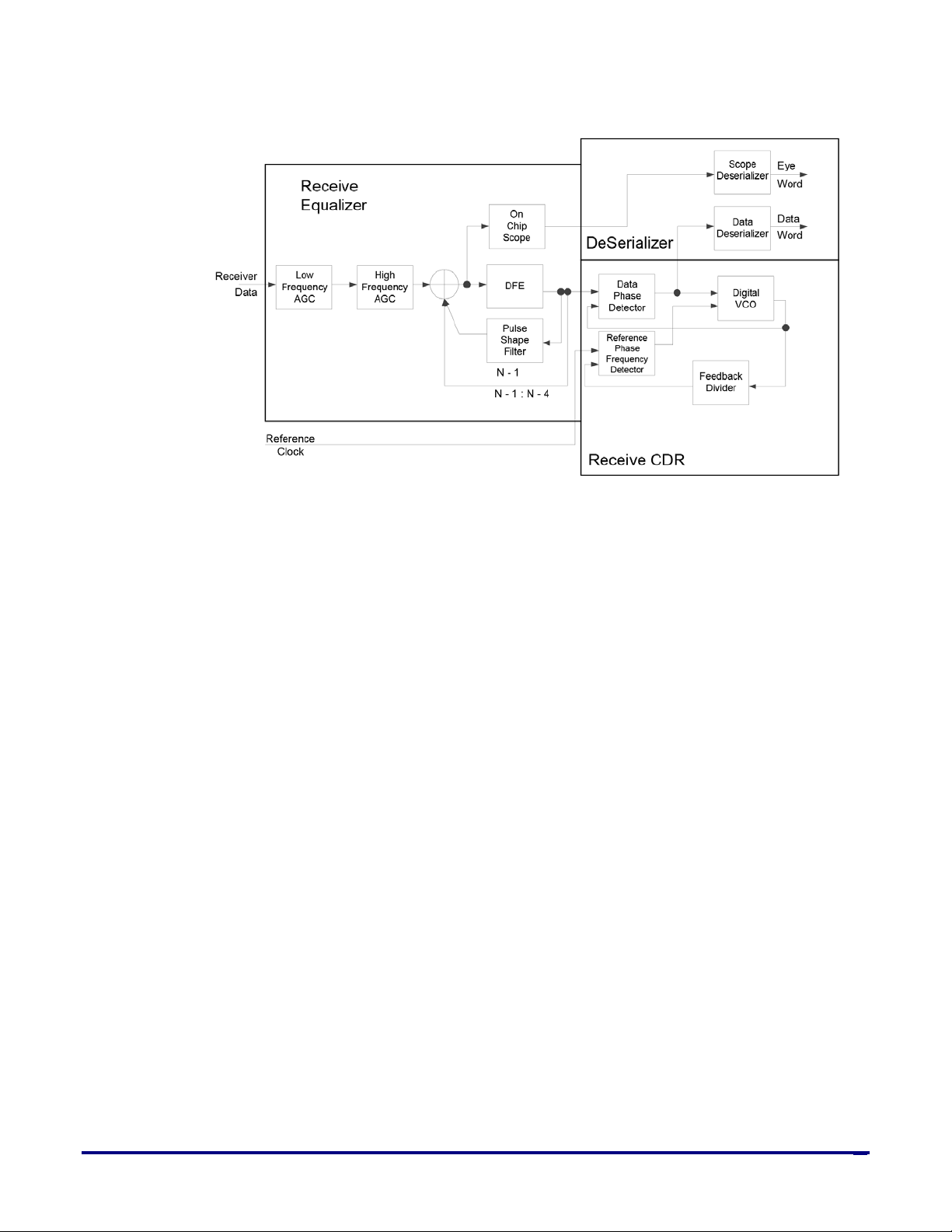

Figure 5: Receiver Architecture ............................................................................................................................................. 15

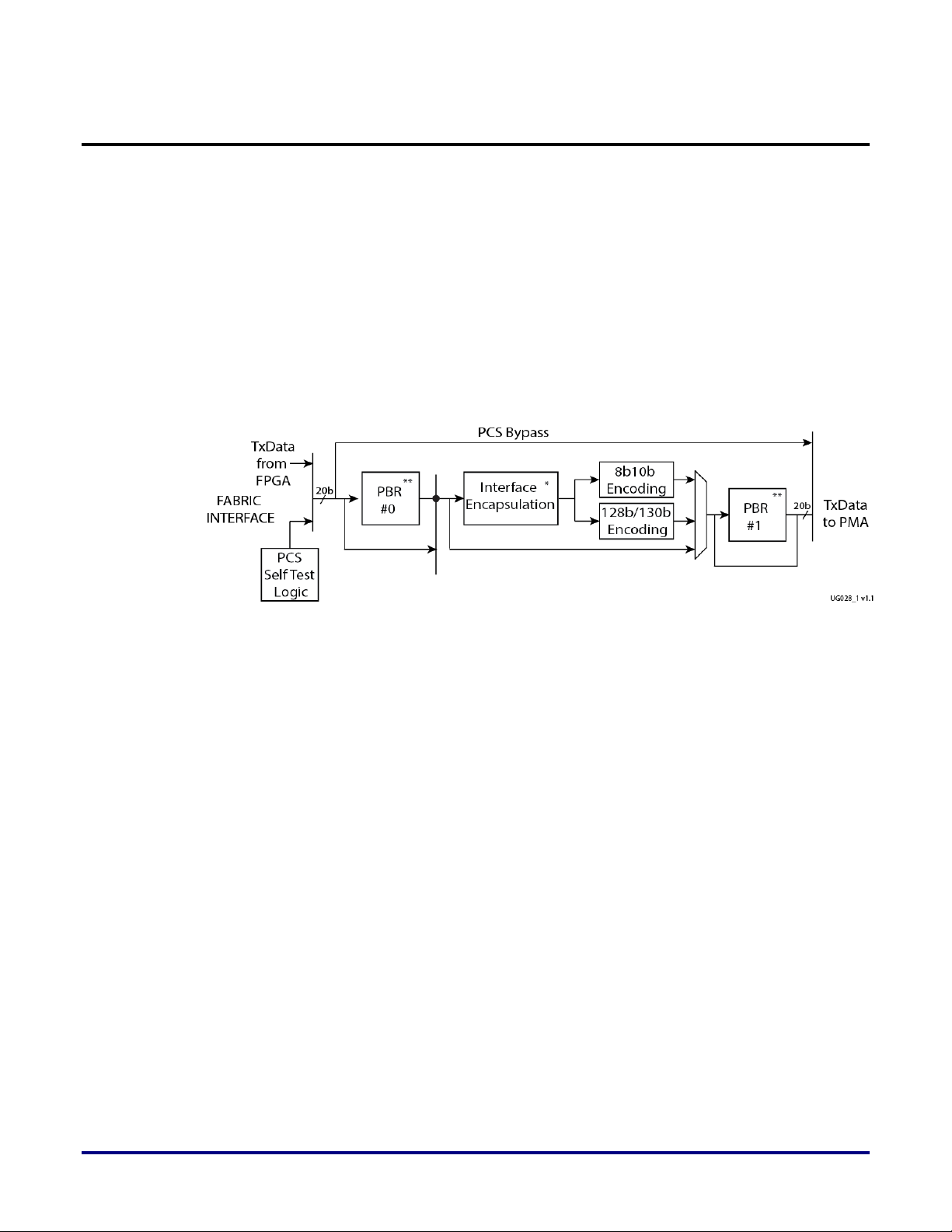

Figure 6: PCS Transmitter Block Overview ......................................................................................................................... 16

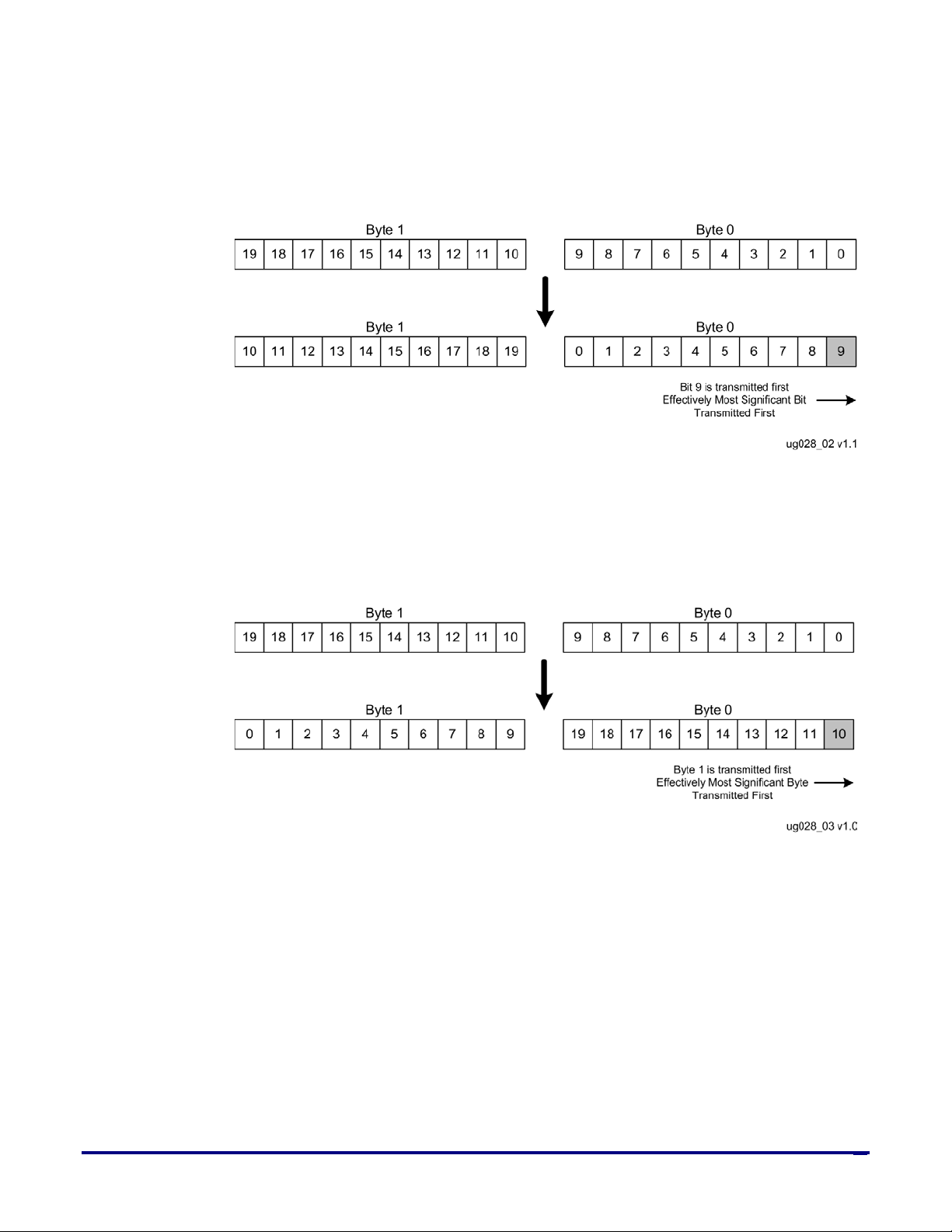

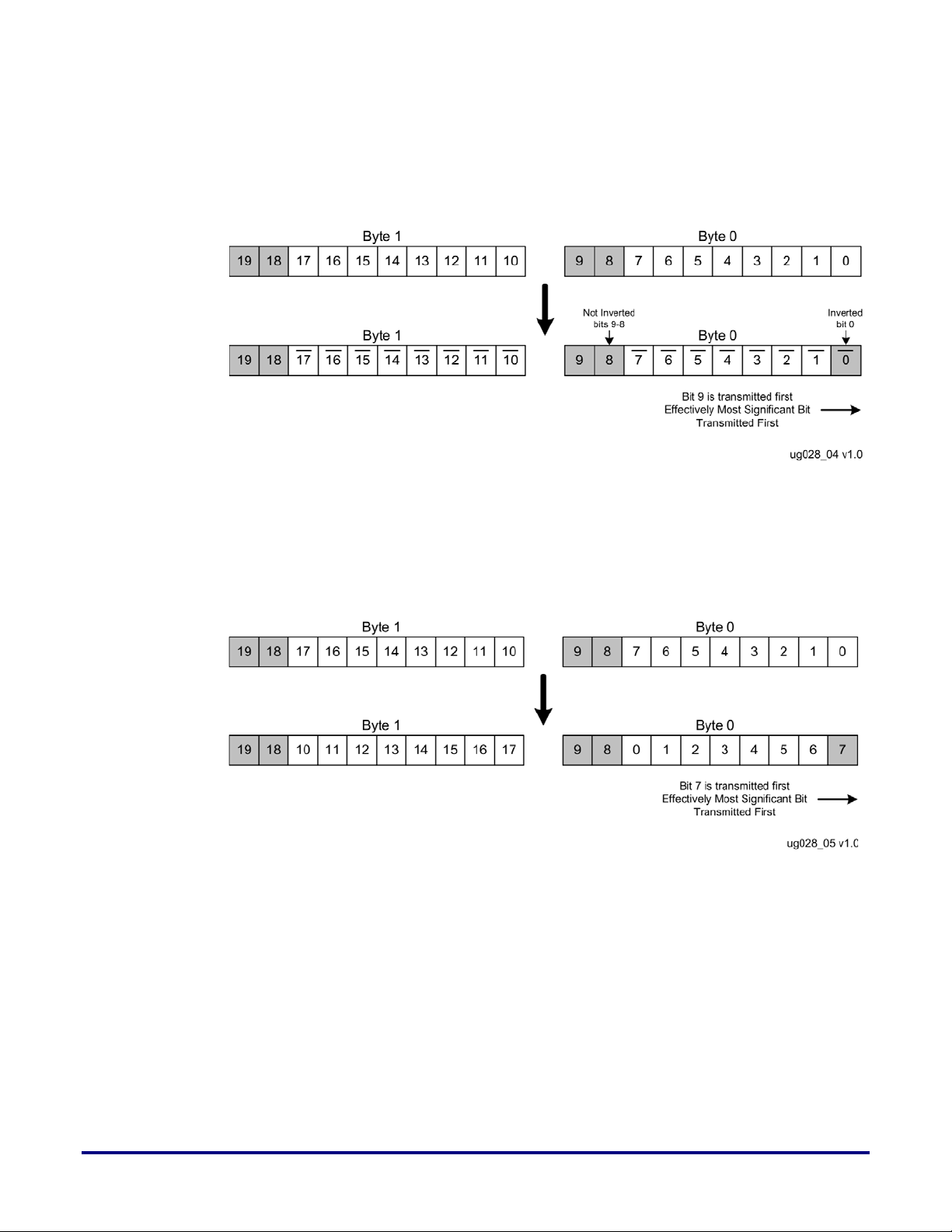

Figure 7: 20 bit Order Reversal ............................................................................................................................................. 17

Figure 8: 20-bit Byte Order Swap/Reversal ......................................................................................................................... 17

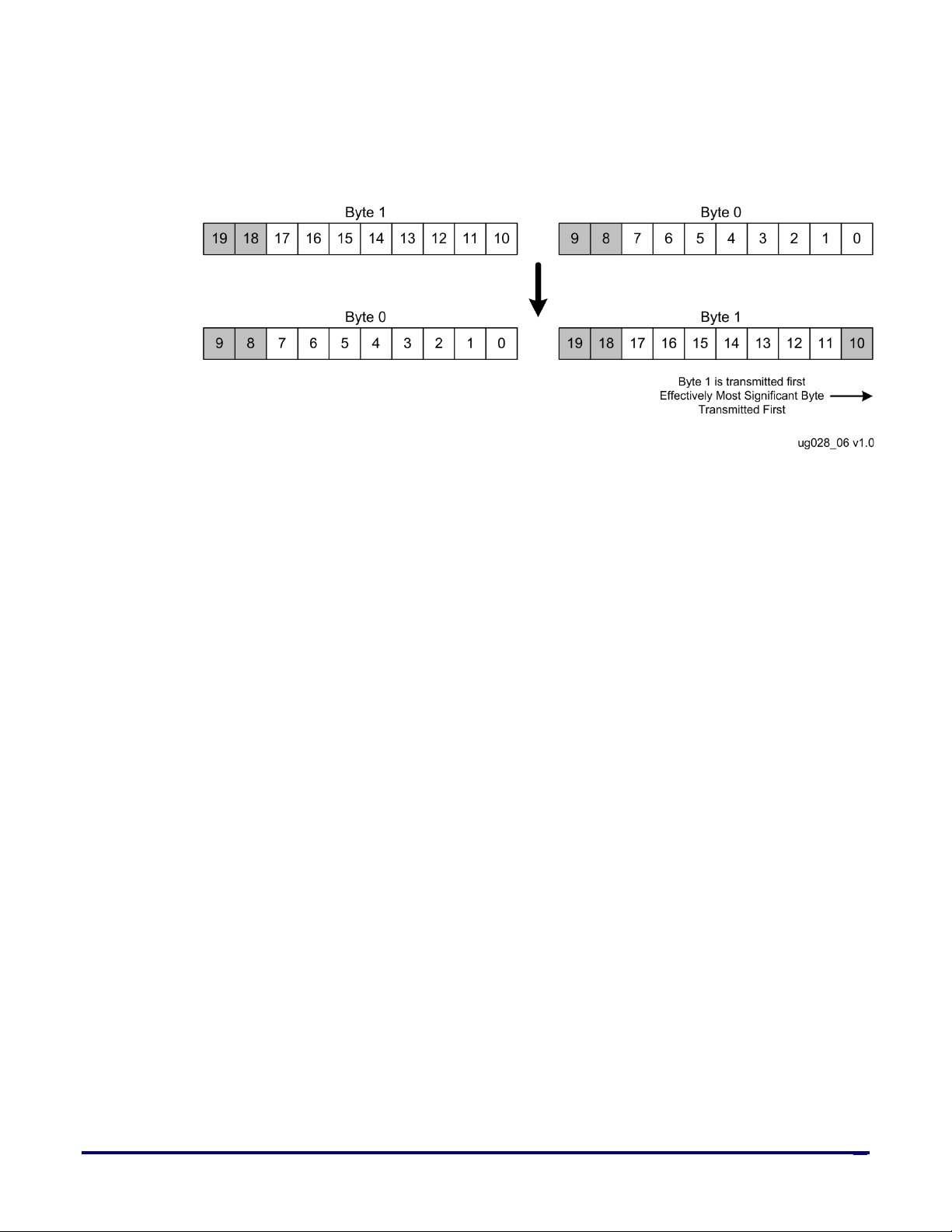

Figure 9: Polarity Inversion (16-bit Word) .......................................................................................................................... 18

Figure 10: Bit Order Inversion (16-bit Word) ...................................................................................................................... 18

Figure 11: Word Order Inversion (16-bit Word) ................................................................................................................. 19

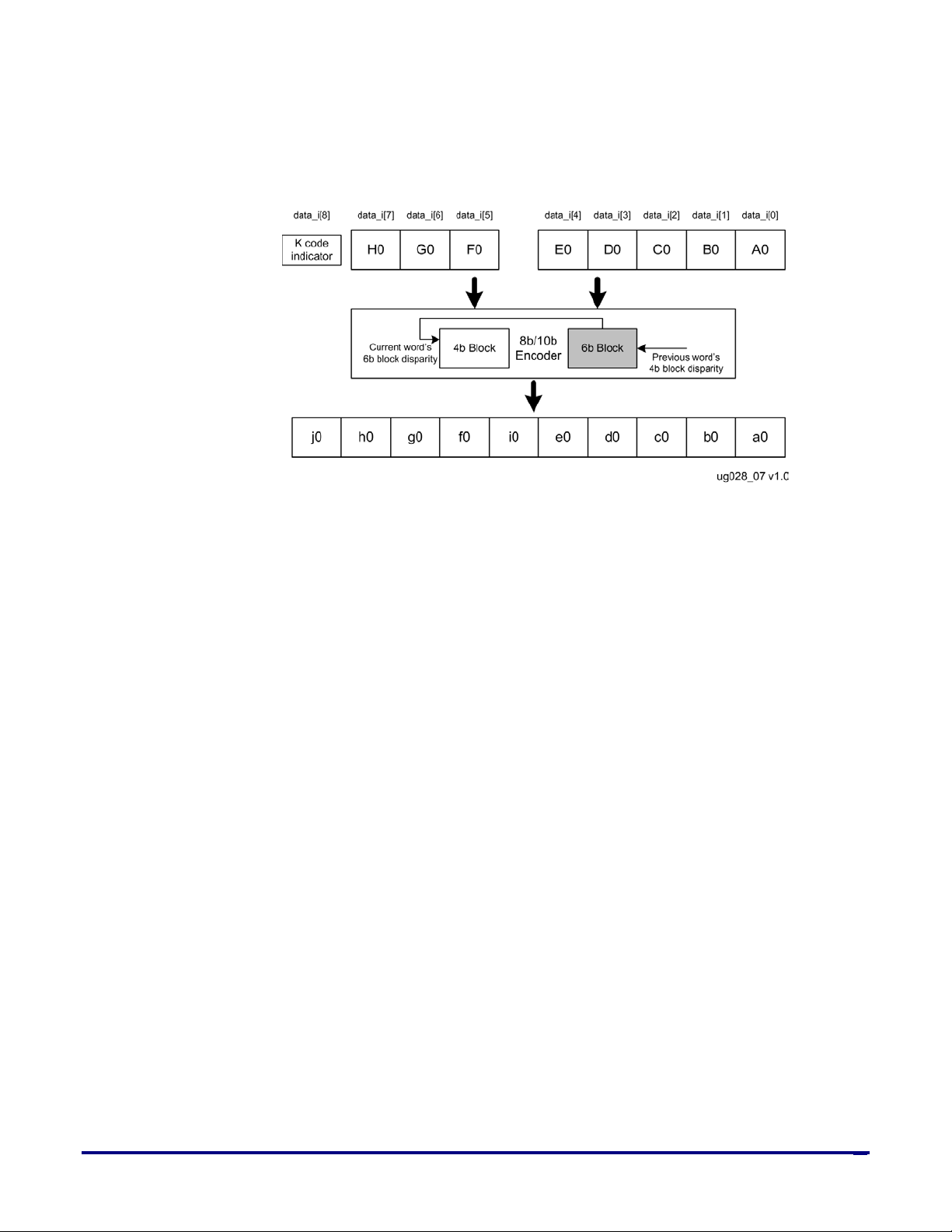

Figure 12: 8b/10b Encoding Process ..................................................................................................................................... 21

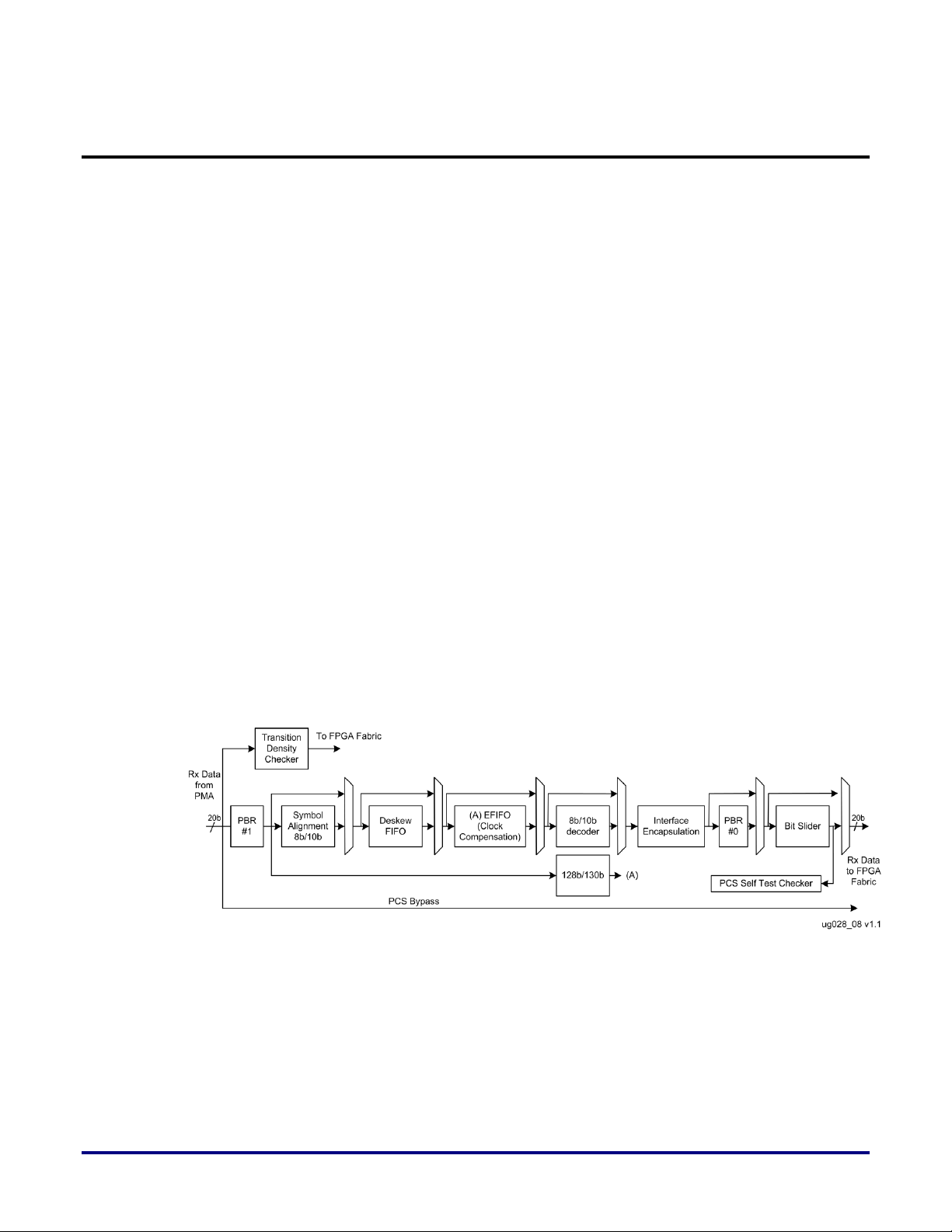

Figure 13: PCS Receive Block Overview .............................................................................................................................. 22

Figure 14: Operating principle of deskew technique ......................................................................................................... 25

Figure 15: EFIFO SKP Addition/Removal ........................................................................................................................... 29

Figure 16: EFIFO SKP Addition/Removal: PCIE, GigE (802.3) and XAUI (802.3) ......................................................... 30

Figure 17: SerDes RX and TX clocks ..................................................................................................................................... 36

Figure 18: PMA Loopback Modes ........................................................................................................................................ 39

Figure 19: Looback modes ..................................................................................................................................................... 39

Figure 20 Worst-case latency across PMA and PCS (in terms of clock-cycles) .............................................................. 44

Figure 21: Opening IP Configuration Perspective .............................................................................................................. 50

Figure 22: New IP Configuration Window ......................................................................................................................... 51

Figure 23: New IP Configuration Window- Overview Page ............................................................................................ 52

Figure 24: Outline Window ................................................................................................................................................... 52

Figure 25: IP Diagran Window ............................................................................................................................................. 52

Figure 26: New IP Configuration Window – Populating Overview Page ...................................................................... 53

Figure 27: Issues with Setting TX/RX data rate and reference clock frequency ............................................................. 56

Figure 28: Unavailable Fields ................................................................................................................................................ 57

Figure 29: PMA Settings Window – First page ................................................................................................................... 58

Figure 30: Outline Window, When Lane-Specific PMA Settings are Enabled ............................................................... 59

Figure 31: PCS Settings Window – First page ..................................................................................................................... 63

Figure 32: PCS Settings for Receiver – Default Settings .................................................................................................... 64

Figure 33: PCS Settings for Receiver – Symbol Alignment ............................................................................................... 66

Figure 34: PCS Settings for Receiver – TX PCS Settings .................................................................................................... 68

Figure 35: Generating the Wrapper Files ............................................................................................................................. 70

Figure 36: TCL console message upon successful generation of wrapper files .............................................................. 71

Figure 37: Clock Region View ............................................................................................................................................... 82

Figure 38: Physical assignment of SerDes Lanes ................................................................................................................ 84

Figure 39: SerDes Placement Guidelines ............................................................................................................................. 85

Figure 40: PCS Settings for Receiver – Configurations for Decoder and Elastic FIFO .................................................. 91

Figure 41: Disabling PCS from ACE GUI ............................................................................................................................ 95

Figure 42: Modifying Register Settings from ACE GUI .................................................................................................... 96

Figure 43: Changing Value of Register 17A to bypass PCS block .................................................................................... 97

Figure 44: Disabling PCS Decoder (default ACE Setting) ................................................................................................. 99

Figure 45: Connections for ACX_SERDES_LOOPBACK_CTRL .................................................................................... 101

Figure 46: Receiver (RX) Eye Diagram Specification ....................................................................................................... 110

UG028, July 1, 2014

5

Page 6

List of Tables

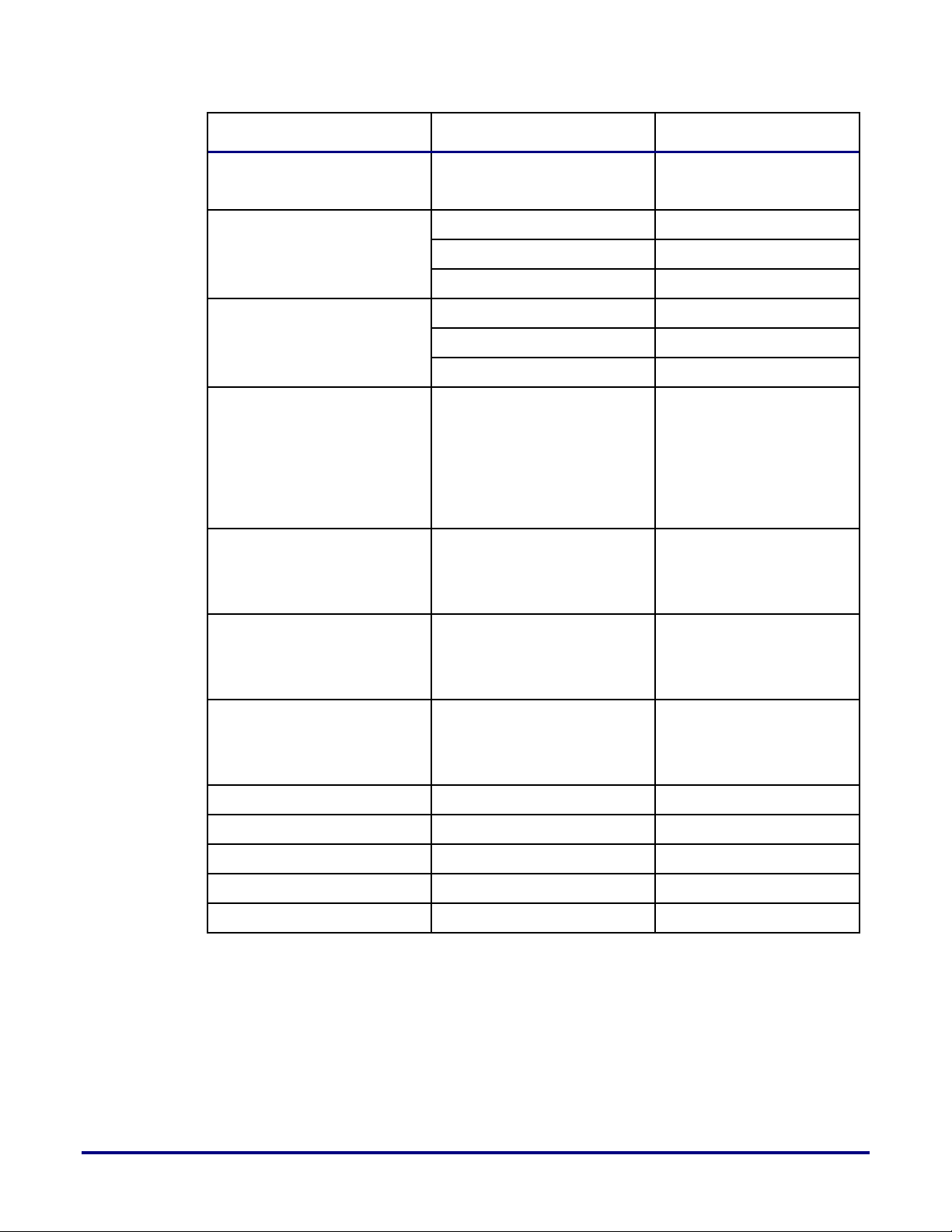

Table 1: SerDes Standards........................................................................................................................................................ 9

Table 2: Symbol Slip Paramaters........................................................................................................................................... 27

Table 3: Shift Limit .................................................................................................................................................................. 31

Table 4: List of Important Interface Signals for bit slider .................................................................................................. 32

Table 5: PIPE Interface Paramaters ....................................................................................................................................... 35

Table 6: PRBS Patterns in PMA ............................................................................................................................................. 40

Table 7: PRBS Patterns in the PCS ........................................................................................................................................ 40

Table 8: Analog latency as a function of databus width .................................................................................................... 42

Table 9: Latency across the PCS blocks ................................................................................................................................ 43

Table 10:

Table 11: Supported Receiver (RX) Features ....................................................................................................................... 47

Table 12: Entry fields for Overview page ............................................................................................................................ 53

Table 13: RX PMA Equalization ............................................................................................................................................ 59

Table 14: RX PMA PLL Settings ............................................................................................................................................ 61

Table 15: TX PMA Driver Settings ........................................................................................................................................ 62

Table 16: TX PMA PLL Settings ............................................................................................................................................ 63

Table 17: RX PCS Settings ...................................................................................................................................................... 64

Table 18: Symbol Alignment Settings (PCS) ....................................................................................................................... 66

Table 19: TX PCS Settings ...................................................................................................................................................... 69

Table 20: Signals passed between the SerDes Instance and the Top-Level module ...................................................... 73

Table 21: Modifications for simple_serdes_design_efifo (RX PCS Settings)................................................................... 89

Table 22: Operating Conditions .......................................................................................................................................... 104

Table 23: DC and AC Switching Characteristics .............................................................................................................. 105

Table 24: Jitter ........................................................................................................................................................................ 106

Table 25: Return Loss ........................................................................................................................................................... 107

Table 26: DC and AC Switching Characteristics .............................................................................................................. 108

Table 27: Receiver (RX) Eye Diagram Specification ......................................................................................................... 110

Table 28: Return Loss ........................................................................................................................................................... 111

Table 29: Reference Clock Electrical Speficiations ............................................................................................................ 112

Table 30: Reference Clock Jitter Specification ................................................................................................................... 112

Supported Transmitter (TX) Features

.................................................................................................................. 45

6 UG028, July 1, 2014

Page 7

Chapter 1 – SerDes Architecture

Overview

Achronix Speedster22i FPGAs provide very high core fabric and I/O performance which

exceeds the system bandwidth requirements of various high end applications. The

Speedster22i device family supports up to 64 full-duplex SerDes lanes, each supporting up to

11.3 Gbps data rate.

The Physical Coding Sublayer (PCS) and Physical Media Attachment (PMA) sub-blocks

together comprise a single SerDes block. The SerDes PCS has explicit support for PCIe,

10GBASE-R, 1G Ethernet and XAUI. It also has some support for various other interconnect

protocols through PCS such as Interlaken, SPI4.2, Infiniband, Fiber-Channel, SAS/SATA,

SONET, OC, OBSAI and CPRI. The SerDes can be connected either to the embedded HardIPs (PCIe, Interlaken, and 10/40/100G MAC) or to the FPGA Fabric for soft implementation of

any other protocol supported.

Physical Media Attachment (PMA)

• Data rates supported

o 1.0625 – 11.3 Gbps

o 531.25 – 1062.5 Mbps using 2X over-sampling

o 265.625 – 531.25 Mbps using 4X over-sampling

• Independent lane architecture with dedicated synthesizer for each lane with no off-

chip components required

• Low power architecture (<100mW at 10Gbps)

• Support both AC and DC coupling

• Input driver with Continuous Time Linear Equalizer (CTLE) and Decision Feedback

Equalizer (DFE)

o Input voltage: 50 – 2000 mVp-p differential

o Auto-calibrating CTLE and DFE

o CTLE with up to 20dB gain tuned for key data rates

o Pulse-shaped 5-tap DFE

• Output driver with 4-tap Finite Input Response (FIR) filter with Feed Forward

Equalizer (FFE)

o Output voltage: 400 – 1500 mVp-p differential

o Slew rate: 31 – 170 ps

• Highly digital PLL architecture for the Synthesizer and CDR

o Accuracy & low jitter of an analog PLL

UG028, July 1, 2014

o Tuning range of a digital PLL

7

Page 8

o Programmable spread spectrum generation

o Support for 16-bit fractional multiplication factors

o Programmable spread spectrum clocking

o Support for fast lock mode for EPON/GPON

• On-chip scope in the receiver for measuring eye width, eye height and BER for the

incoming signal

• On-chip calibrated 100 ohm termination

• Transparent calibration engine to compensate for PVT variation

Clocking

• Support for external reference clock from 50 MHz – 300 MHz

• Support for recovered reference clock for loop timing and re-timer type applications

that eliminates the need for a cleanup PLL

Physical Coding Sublayer (PCS)

• Bypassable and Modular PCS architecture

• Support for 8b/10b and 128b/130b encoding

• Symbol alignment

• Clock and phase compensation FIFO

• Lane to lane de-skew

• Polarity inversion

• Bit reversal

• Lane bonding

• Low/Deterministic latency modes for protocols such as CPRI and OBSAI

Debug and Test

• Up to seven different near-end and far-end loopback modes in PMA and PCS

• Built-in self test (BIST)

o PRBS 7, 15, 23, 31 and 40-bit user defined pattern generators and checkers in

the PCS

o PRBS 7, 23, 31 and 40-bit user defined pattern generators and checkers in the

PMA

8 UG028, July 1, 2014

Page 9

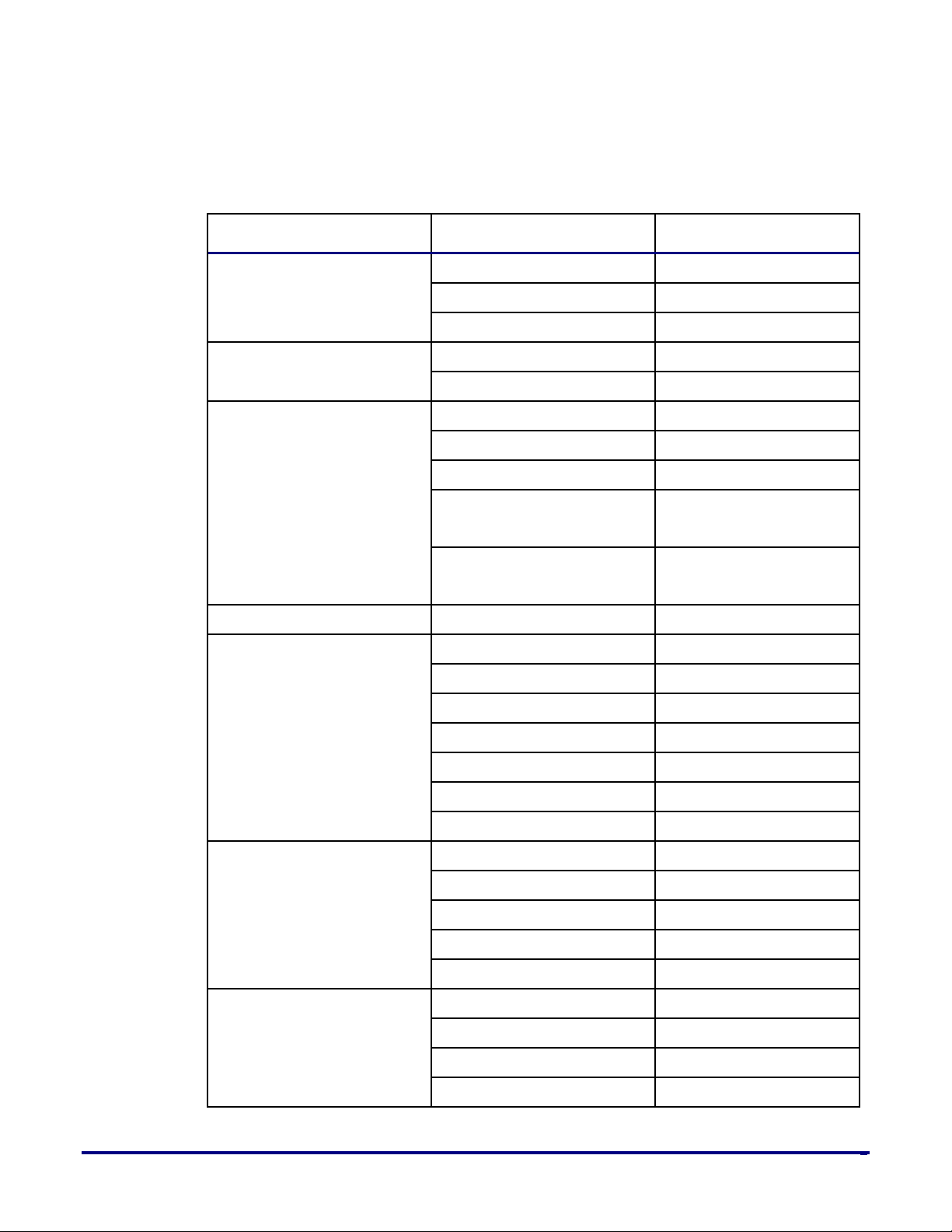

Major standards supported

Gen 2

5.0 Gbps

Gen 3

8.0 Gbps

SGMII

1.25 Gbps

XAUI (802.3ae)

3.125 Gbps

10GBASE-R (802.3ae)

10.3125 Gbps

(802.3ae)

Interlaken

--

3.125 – 10.3125 Gbps

SPI5

3.125 Gbps

SFI5.1

3.125 Gbps

SFI5.2

9.1 – 10.3125

CEI 6G

4.976 – 6.375 Gbps

CEI 11G

9.95 – 11.2 Gbps

FC-2

2.125 Gbps

FC-4

4.25 Gbps

FC-10

10.52 Gbps

OC-12

622.08 Mbps

OC-48

2488.32 Mbps

OC-192

9953.28 Mbps

Table 1: SerDes Standards

Standards Variation Data Rate(s)

Gen1 2.5 Gbps

PCI Express

Gigabit Ethernet

10 Gigabit Ethernet

OIF

1000BASE-CX 1.25 Gbps

XFI 10.3125 Gbps

10GBase-KR

10.3125 Gbps

XLAUI/CAUI

10.3125 Gbps

(802.3ae)

SFI4.2 3.125 Gbps

SFI-S 11.1 Gbps

UG028, July 1, 2014

FC-1 1.0625 Gbps

Fiber Channel

FC-8 8.5 Gbps

OC-24 1244.16 Mbps

SONET

9

Page 10

Standards Variation Data Rate(s)

6.4 Gbps

SATA-1

1.5 Gbps

SATA-2

3.0 Gbps

SATA-3

6.0 Gbps

SAS-1

3.0 Gbps

SAS-2

6.0 Gbps

SAS-3

12.0 Gbps

Gen2

6.125 Gbps

10 Gbps

10 Gbps

QDR

10.0 Gbps

JESD204B

Up to 12.5 Gbps

CPRI

--

614.4 – 9830.4 Mbps

OBSAI

--

768 – 6144 Mbps

USB

3.0

5.0 Gbps

USB

3.1

10.0 Gbps

QPI

SATA

SAS

Serial Rapid I/O

E-PON 802.3av

Gen1

Gen1

Gen1

Gen2

4.8 Gbps

1.25 Gbps

2.5 Gbps

3.125 Gbps

5.0 Gbps

1.25 Gbps

2.5 Gbps

GPON --

InfiniBand

SDR

DDR

1.25 Gbps

2.5 Gbps

2.5 Gbps

5.0 Gbps

10 UG028, July 1, 2014

Page 11

SerDes Placement

The Speedster22i device supports up to sixty-four (64), 11.3 Gbps SerDes lanes. Each side

(Top and Bottom) has thirty-two (32), 11.3 Gbps SerDes. The lanes are organized by channel

based, and are placed as illustrated in “

Figure 1: Location of SerDes Lanes

” below.

UG028, July 1, 2014

Figure 1: Location of SerDes Lanes

11

Page 12

SerDes Architecture Overview

The SerDes has an independent lane architecture. Each lane has a Physical Media Attachment

(PMA), Synthesizer (Transmit PLL), Clock and Data Recovery (CDR) and Physical Coding

Sublayer (PCS). The Receiver PMA and Transmitter PMA block diagrams are shown in

“Figure 2: SerDes Architecture” below.

Figure 2: SerDes Architecture

The SerDes primarily consists of the following blocks:

• PMA

• PCS

• PCS interface to FPGA fabric

• Clocking

• Debug and Test

12 UG028, July 1, 2014

Page 13

Physical Media Attachment (PMA)

The PMA architecture is shown in “Figure 3: PMA Architecture” below.

Figure 3: PMA Architecture

The PMA consists three major blocks:

1. Common

2. Receiver/Transmitter (RX/TX)

3. Digital PMA (DPMA)

1. Common

The common block consists of the following circuits:

• Reference clock: This circuit performs reference clock buffering and division before

feeding it to the Synthesizer.

• Synthesizer: The synthesizer (transmit PLL) generates the high speed clock for the

serializer of the Transmitter. It also has in-built circuit for spread-spectrum clocking

• Bias: The biasing circuit is responsible for controlling the offsets and biasing for the

all the analog circuits in the PMA

• Analog Test Port: This port is used by Achronix for manufacturing tests and for

debugging purposes

UG028, July 1, 2014

13

Page 14

2. Receiver (RX)/Transmitter (TX)

The RX/TX block consists of the following circuits:

• TX buffer: Converts single-ended signal to differential and performs equalization on

(or pre-emphasis) the outgoing serial signal

• RX buffer: Converts differential signal to single ended and performs equalization on

incoming signal using Continuous Time Linear Equalizer (CTLE) and Decision

Feedback Equalizer (DFE)

• Clock Data Recovery (CDR): Recovers clock and data from the incoming signal for

deserialization

• On-Chip Scope: Used for plotting an eye of the incoming signal post equalization for

debug

• Serializer/Deserializer: Converts parallel data to serial data using a high speed clock

from the synthesizer

3. Digital PMA (DPMA)

The DPMA block consists of the following circuits:

• Calibration: Performs calibration of all the analog circuits using trim settings and

offsets

• PMA BIST: Includes PRBS 7, 23, 31 and 40-bit user defined pattern generators and

checkers Power management

• Configuration registers (Memory)

• JTAG and Boundary Scan

Figure 4: Synthesizer Architecture

14 UG028, July 1, 2014

Page 15

Figure 5: Receiver Architecture

UG028, July 1, 2014

15

Page 16

PCS Blocks in the Transmitter (TX)

This section presents the transmitter (TX) data path within a PCS. The key blocks within the

SerDes transmitter are:

• Encoder: Encodes the data for transmission line. Primary goal is to ensure DC

balance by eliminating long sequence of 1’s or 0’s.

• Polarity Bit Reversal (PBR): Inverts the polarity of data and ordering of data to be

transmitted.

The building block for the SerDes IP is the 1 lane configuration. A simplified block diagram

of the TX data path is shown in Figure 6: - PCS Transmitter Block Overview . The functional

blocks shown in the diagram represent the functionality supported by a single SerDes lane. A

summary of the supported standards is covered in “Table 1 – SerDes Standards”.

Figure 6: PCS Transmitter Block Overview

* SerDes configured in Generic mode supports only 8b/10b encoding.

** Either of PBR#0 or PBR#1 can be used or both may be bypassed.

Note: The PCS block will support lane-bonding across multiple SerDes lanes (max 12)

Chapter – “Design Flow: Creating a SerDes Design” presents the ground-up steps that can be

followed to prepare a design that supports lane-bonding.

The PCS blocks on TX path are detailed below.

PCS Self Test Logic

This block generates transmit data for PCS self test, detailed in “PCS Test Pattern Generator”

and “PCS Test Pattern Checker”.

Polarity bit reversal (PBR) #0 and #1

This block can invert the polarity of the incoming data. It can also reverse the bits of the

incoming data such that effectively the most significant bit is sent first, rather than the least

significant bit (default). For 16/20bit (2 words) bit streams, the word order can also be

inverted such that effectively the most significant byte is sent first, rather than the least

significant byte (default).

There are two PBR blocks on transmission data path, as shown in “Figure 6: PCS Transmitter

Block Overview”. PBR0 is used before the protocol encapsulation block and PBR1 is used on

encoded data. Either PBR0 or PBR1 can be used. Alternatively, both of these two blocks can

be bypassed.

16 UG028, July 1, 2014

Page 17

Polarity and Bit Inversion – 10/20 bit Operation

When operating in 10bit/20bit mode, the bit order within each 10-bit word can be inverted.

This is illustrated in “Figure 7: 20 bit Order Reversal”. Effectively the most significant bit of

the least significant byte is transmitted first (i.e. bit 9 of byte 0 is transmitted first).

Figure 7: 20 bit Order Reversal

When the word order is reversed in 20-bit mode, the most significant byte (byte 1) is

swapped with the least significant byte (byte 0). This is illustrated in “Figure 8: 20-bit Word

Order Inversion”. The most significant byte will be transmitted first in such a case

Figure 8: 20-bit Byte Order Swap/Reversal

The polarity for the entire 10bit or 20bit word can be inverted as well. Polarity inversion

applies to the entire word (10 bits or 20 bits).

UG028, July 1, 2014

17

Page 18

Polarity and Bit Inversion – 8/16 bit Operation

When the polarity is inverted in 8bit/16bits mode, only bits [17:10] and [7:0] are inverted, bits

[19:18] and [9:8] are not inverted. This is illustrated in “Figure 9: Polarity Inversion (16-bit

Word)”.

Figure 9: Polarity Inversion (16-bit Word)

When the bit order is inverted in 8bit/16bit mode, bits [7:0] of byte 0 are swapped while bits

[9:8] are not swapped. Similarly bits [17:10] of byte 1 are swapped. This is illustrated in

“Figure 10: Bit Order Inversion (16-bit Word)”. In this mode, the most significant bit of the

least significant byte is transmitted first.

Figure 10: Bit Order Inversion (16-bit Word)

When the word order is inverted in 16-bit mode, byte 1 is swapped with byte 0. This is

illustrated in “Figure 11: Word Order Inversion (16-bit Word)”.

18 UG028, July 1, 2014

Page 19

Figure 11: Word Order Inversion (16-bit Word)

UG028, July 1, 2014

19

Page 20

Interface Encapsulation

This block encapsulates the protocols supported by the SerDes in Achronix FPGA. The user

may refer to Section – “PCS Interface” for details on the protocols supported. It may be noted

again that the SerDes configured in Generic mode supports only 8b/10b encoding.

8b/10b Encoder

The 8b/10b encoder generates 10-bit code groups from 8-bit data and a 1-bit control input. It

uses the code group mapping specified in IEEE 802.3 clause 36. If the fabric interface is a 16bit data path, then two 8b/10b encoders are cascaded to produce a 20-bit code group output

to the PMA for serialization.

The 8b/10b encoder essentially translates 8-bit words to 10-bit symbols. This encoding

scheme has been proven to achieve DC-balance and running disparity while providing

sufficient information for clock recovery. (See the later sections for more information on DCBalance, running disparity and clock recovery.) The 10-bit encoded output TX_dataout[9:0]

will map to bits {jhgf iedcba}per the labeling used in IEEE 802.3-2005 clause 36.

Symbols and Comma Character

While translating 8-bit words into 10-bit symbols, the 8b/10b encoder (in SerDes PCS) form

two groups of data. The lower 5-bits of data are encoded into a 6-bit group and the upper 3bits of data are encoded into a 4-bit group. Furthermore, there are 12 control symbols that are

used by 8b/10b encoding scheme for special purposes and are called K-symbols. For instance

three of these control symbols can be used for defining the boundary between data packets.

These three control symbols are called comma symbols.

The 8b/10b encoder generates 10-bit code groups from 8-bit data and a 1-bit control input. It

uses the code group mapping specified in IEEE 802.3 clause 36. If the fabric interface is a 16bit data path, then two 8b/10b encoders are cascaded to produce a 20-bit code group output

to the PMA for serialization. The 1-bit control input (datak signal) is used to identify whether

data being transmitted is a comma symbol. Asserted value for datak signal on control-line

indicates that the symbol on data-line is a comma symbol.

In Section-“Design and Wrapper Files” of the Chapter – “Design Flow: Creating a SerDes

Design”, details are provided on how to transmit 8’hBC (K.28.5) as comma symbol and 1’b1

as control signal, for a sample design. For a 20-bit data width, that design essentially uses

{2’h1, 8’hBC, 2’h1, 8’hBC}. In other words, while sending a comma symbol, TX_data[8:8] =

TX_data[18:18] = 1’b1 is sent through the control-line.

Note: On the receiver end, when the decoder finds an ‘asserted’ control-bit on control-line, it

will consider the symbol on data-line as a comma symbol. Error conditions occur if the datak

signal is asserted while there is no comma symbol on the data line (e.g. K21.5).

Running Disparity

A non-encoded data stream may have differences between the number of 1’s and the number

of 0’s. The primary goal of using running disparity in the encoding scheme is to limit the

difference between the number of 1’s and the number of 0’s that are being transmitted. This

ensures DC balance on the transmission line. A side-benefit of using running disparity is that

information from running disparity can be used in locating transmission errors. This ensures

that the output data is DC balanced. The maximum run length for 8b/10b words is 5 bits.

20 UG028, July 1, 2014

Page 21

The input disparity for the 6 bit block is based on the disparity of previous word’s 4 bit block

while the disparity for the 4 bit block is the disparity of the current word’s 6 bit block. This is

illustrated in “Figure 12: 8b/10b Encoding Process”.

Figure 12: 8b/10b Encoding Process

UG028, July 1, 2014

21

Page 22

PCS Blocks in the Receiver (RX)

This chapter describes the PCS components on the receiver data path. The functional block

diagram of the receiver is shown in “Figure 13: - PCS Receive Block Overview”. The key

blocks in the RX-PCS include:

• Transition Density Checker (TDC): Generates a trigger bit when the number of

consecutive 1’s or 0’s reaches a pre-defined value.

• Polarity Bit Reversal (PBR): Inverts data, swaps byte ordering and reverses bit-

ordering, if used on the TX data path.

• Symbol Alignment: Uses alignment characters and sequences to define the symbol

boundary on the incoming data-stream.

• Decoders: Generates 8-bit code group and 1-bit control signal from the 10-bit

encoded (received) data.

• Deskew First-In-First-Out (FIFO): Synchronizes the data received across the lanes

when lane-bonding is used.

• Clock Compensation (Elastic FIFO): Synchronizes the data received on PMA at

recovered clock domain with a system clock (typically the transmit clock).

• Bit Slider: Takes care of bit-wise skew from the fabric, when used.

• PCS Interface Encapsulation: Provides interface with the fabric. Supports Gigabit

Ethernet, XAUI, Pipe and 10G Ethernet interfaces.

• PCS Self Test Checker: Self checking module, detailed in Chapters “PCS Test Pattern

Generator” and “PCS Test Pattern Checker”

The main features for the supported standards in the PCS side can be found in Chapter

“Major standards supported”

Figure 13: PCS Receive Block Overview

Transition Density Checker (TDC)

The transition density checker monitors the parallel RX data bus from the PMA and monitors

the number of consecutive 0s or 1s, called run length. If the number reaches a pre-configured

value, the checker sets a trigger bit to indicate the transition density violation. This preconfigured value is called threshold and the minimum threshold programmed is half the

width of data path. In case scaling is used the actual threshold effective will be the one shown

in “Equation 1”

22 UG028, July 1, 2014

Page 23

Equation 1:

+

The assert signal from Transition Density Checker can be taken to fabric.

Note: Any bit transition would cause the counter to clear and the count to restart.

= (

)

Polarity Bit Reversal (PBR)

The polarity bit reversal block is used to invert data, swap byte ordering, and reverse bitordering. There are two such PCS blocks on the receive path, corresponding to the two

polarity bit reversal blocks on the transmit path.

When the polarity bit reversal on transmit path is performed before protocol encapsulation

(PBR #0 on “Figure 6: PCS Transmitter Block Overview”), the PBR block after protocol

encapsulation is used on receive path (PBR #0 on “Figure 13: - PCS Receive Block

Overview”). In contrast, if PBR operation is performed on encoded data on the transmit path

(PBR #1 on “Figure 6: PCS Transmitter Block Overview”), the PBR block before symbol

alignment/decoder block is used on the receive path (PBR #1 on “Figure 13: - PCS Receive

Block Overview”). As noted earlier, both of these blocks can be disabled, both on the transmit

and the receive paths.

Symbol Alignment

Symbol alignment uses alignment and sequence characters for identifying the correct symbol

boundary in the received data-stream. Attributes for alignment and sequence detect symbols

are specified to be 10-bit wide. But when received data-path is in 8-bit (or 16-bit) wide mode,

only the lower 8-bits of attribute will be considered.

The symbol alignment block can be configured to support a variety of standards. Some of

these standards are listed below:

• PCIe

• XAUI

• GigE

• Infiniband

• Serial Rapid IO

• SPI-5 (lock to training pattern)

• CPRI

• OBSAI

• Fiber Channel

Symbol alignment can be programmed to function in the following modes:

UG028, July 1, 2014

• Manual Mode

• Bit slip Mode

• Automatic Mode

23

Page 24

Modes of Operation

Manual Mode:

In manual alignment mode, the symbol alignment will attempt to identify a pre-configured

pattern and lock to the incoming de-serialized data-stream from the output of the PMA or

phase picking block. The alignment operation is triggered by the user logic in the FPGA on

the rising edge of RX_com_det_en. The symbol alignment block then searches for the preconfigured alignment pattern with or without trailing sequence pattern. Fabric will wait for

the lock status. Once lock to the incoming stream is achieved, the fabric can monitor error

status from the 8b/10b decoder or employ any other mechanism in fabric to identify loss of

lock. The Fabric asserts another rising edge to trigger a new alignment cycle.

Bit Slip Mode:

In bit slip mode, the user logic controls the symbol alignment using the RX_bit_slip_en

signal. Each rising edge of RX_bit_slip_en causes the symbol alignment logic to shift the

word boundary by 1-bit, and symbol alignment will attempt to match the alignment pattern

within the new word boundary. If the word boundary is not matched, the user logic can

again assert RX_bit_slip_en, possibly after waiting for a timeout causing the word boundary

to shift by another bit position. This loop continues until lock is achieved. Once lock to the

incoming stream is achieved, logic in the fabric can monitor error status from 8b/10b decoder

or employ some other mechanism in fabric to identify loss of lock. The bit slip mode supports

all attributes used for manual alignment mode. The maximum number of slips that will cause

a true change in alignment is limited to the data path width.

Automatic Mode:

In automatic alignment mode, the symbol alignment block will automatically determine the

location of the word boundary based on the pre-configured alignment characters. It will also

establish a lock acquired condition based on receiving a pre-con d count of alignment

characters (hysteresis). A loss of lock condition also can be detected by this block based on a

pre-configured count of bad code words (or alignment characters at a different word

boundary). Instead of counting every bad code word, the user can decide to count every ‘n’

bad code word for an incrementing unlock count. Also, the user can use decode/disparity

errors as per clause 36 of IEEE 802.3 to increment and decrement the unlock counter. Support

for Fiber Channel protocol involves synchronization with the 4-symbol wide transmission

word (a special code word K28.5 followed by 3 data code words). In case of Fiber Channel,

any malformed transmission word causes the symbol alignment to go out of lock based on

the un-lock count programmed.

Comma symbols are used for identifying the correct symbol boundary. Section – “Symbols

and Comma Character” introduces comma symbols and discusses on how they are used in

data output from 8b/10b encoder on the TX side of a SerDes. At the receiver end, the

incoming data is scanned for comma symbols. Once the comma symbol is found, the

deserializer resets the word boundary of the received data. The received data is continuously

scanned for the subsequent comma symbols.

24 UG028, July 1, 2014

Page 25

Deskew FIFO

The deskew block provides support for standards which require multiple lane bonding and

de-skewing of received data across multiple lanes. Lane bonding is required when the users

want to transmit data faster than is possible by using one serial link (lane). In such case, the

data is received must be aligned across the lanes. Deskew module within the SerDes takes

care of this.

UG028, July 1, 2014

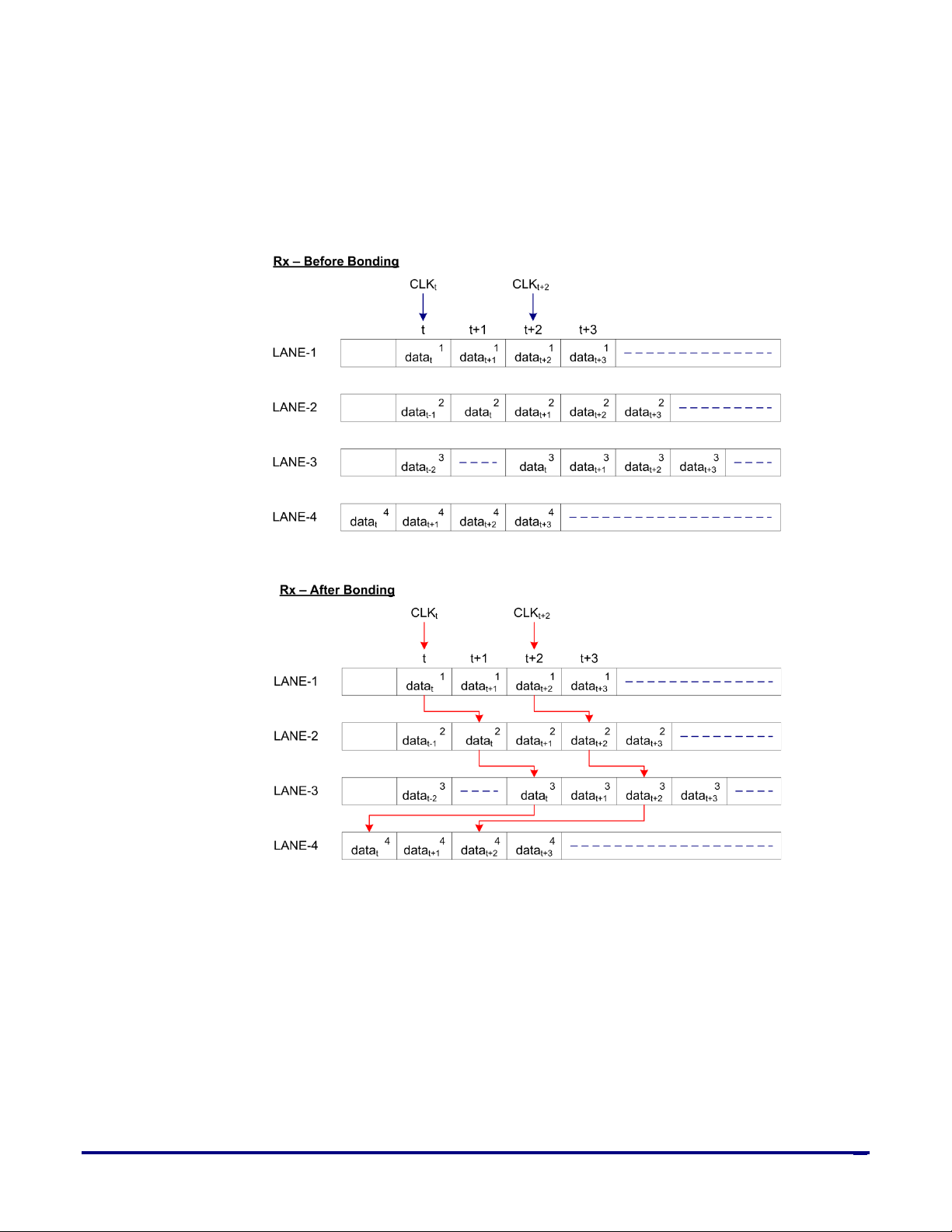

Figure 14: Operating principle of deskew technique

“Figure 14 - Operating principle of deskew technique” shows the operating principle of

deskew operation. In this figure, data is being sent using four lanes. On the receiver side,

before lane-bonding, we find that the data at time t+2on lane-1 is aligned with data at time

t+1 on lane-2 and so on. The deskew technique aims to align the data with respect to the clock

cycles. In other words, data at time t+2on lane-2 should be aligned with data at time t+2 on

the other lanes. The red lines for the clock at receiver end demonstrates this.

For lane bonding, all lanes should use the same reference clock and insert de-skew characters

at the same time on each lane. Skew between lanes is introduced by both active (CDR) and

passive (board) elements of the link. The deskew operation can result in some loss of data

when it aligns characters to the same clock cycle.

25

Page 26

Functional Description

The de-skew block uses a deskew FIFO on each lane. The writes to the deskew FIFO are

performed in the recovered clock domain for each lane. The read side of the deskew FIFO is

clocked by the clock from the initiator lane. The lanes are categorized as initiator and

followers. Any lane can be an initiator and skew is always calculated between the initiator

and each of follower lanes.

Once deskew is enabled, the skew between initiator and follower lanes are calculated

continuously by sensing deskew characters in the read side of the FIFO. The read threshold

for the FIFO needs to be programmed appropriately based on skew tolerance to avoid FIFO

under/over run. Once a deskew character is sensed, each lane starts a skew window equal to

the maximum skew allowed in the system. Based on how the lanes are skewed, the follower

lane is either lagging or leading and adjust the read clock cycles accordingly. Once the

initiator gets indication from all lanes of the bonding group that the skew calculation is over,

it declares that all lanes are aligned and asserts data valid for the down-stream logic. The

same data valid is used by the follower lanes to assert respective lane data valid. When the

initiator does not find such overlap of skew windows, it issues a reset to all FIFOs in the

bonding group and restarts the de-skew operation.

To summarize, the initiator lane generates various control signals for the follower lanes and

follower lanes send various status signals back to the initiators. Status signals are AND-ed

(e.g. for checking if the skew calculation completed in all lanes) or OR-ed (e.g. for checking if

any follower lanes window has not started), whereas control signals are used directly. These

signals go from one lane to another. The status and control signals are registered at time

intervals determined based on the number of lanes bonded

Lane-to-Lane Deskew Modes of Operation

The deskew module can work in three modes:

Manual Mode:

The rising edge of i_dskew_start will start one round of deskew operation. Lanes are

declared aligned either just after the deskew operation is completed or after an additional

check of a programmed number of aligned deskew characters in all bonded lanes at the same

time. The fabric needs to monitor received data for identifying any misalignment, and thus to

restart deskew operation. Infiniband uses manual mode of deskew operation.

Auto Mode:

The deskew module is always active. Once lanes are deskewed, all lanes will continuously

look for deskew characters in data read from the FIFO. The initiator should see deskew

characters on all lanes of the bonding group at the same time. The initiator looks for aligned

deskew characters on all lanes for a certain number of times based on the value programmed

in the register, and once detected the initiator declares bonded lanes aligned. Any time the

initiator finds deskew characters not aligned on all lanes, it starts an unlock count. If the

unlock count hits the value programmed in the register, the initiator declares that the lanes

are out of lock and re-starts the de-skew operation. While unlock count is incrementing, if the

initiator finds de-skew characters are aligned on all lanes again it starts decrementing the

unlock counter. This decrement can happen once in every ‘n’ (programmed in the register)

times when lanes have de-skew characters aligned to make sure the link has overcome error

conditions. If the unlock counter reaches zero, the link remains aligned.

26 UG028, July 1, 2014

Page 27

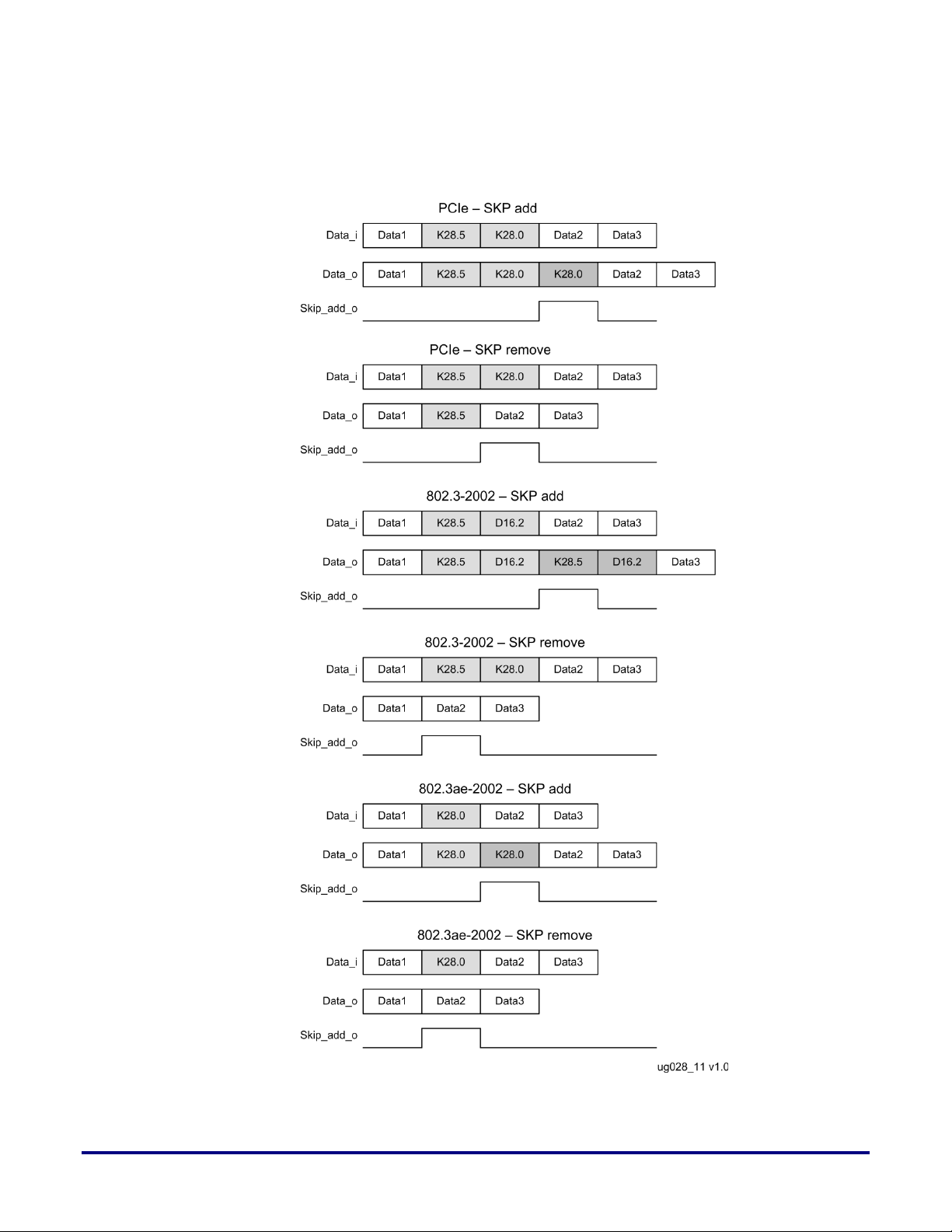

Symbol slip mode:

symbol_slip_up

symbol_slip_dn

Comments

0

0

Increment read pointer by 1

0

1

No increment 1 0

Increment read pointer by 2

1

1

Increment read pointer by 1

The deskew module does not actively remove skew across lanes. Each lane is controlled by

the fabric. Fabric continuously monitors incoming data and employ a mechanism to find out

the skew across lanes. Based on the calculation, it instructs each lane to adjust the read

pointer of FIFO. The read pointer can be incremented once by 0, 1 or 2 based on the

combination of rising edges on symbol_slip_up and symbol_slip_dn. Based on the skew

computed, the fabric may need to provide multiple transitions on symbol_slip_up and

symbol_slip_dn to get the required number of pointer adjustments.

Table 2: Symbol Slip Paramaters

Standards Supported by Deskew Module

The deskew module in Achronix SerDes has explicit support for XAUI and Infiniband. For

XAUI, align(||A||) characters are sent periodically as per section 48 in IEEE 802.3. For

Infiniband, training sequences (TS1/TS2) are used as deskew characters. Though each of

TS1/TS2 is 16 code words long, the de-skew module forms de-skew ordered set with COM

and four data symbols (D10.2). The distance (gap) between COM and data symbols should be

programmed to ‘d1 for Infiniband. In case of 10-bit data path, the max skew handled is 6bytes and for 20-bit max skew handled 2-bytes. For training in Infiniband, initially data valid

will be asserted to pass TS1/TS2/TS3 to fabric. Subsequently, data valid is removed when link

training is completed and the fabric decides to de-skew lanes bonded. Once the de-skew

operation is completed, data valid is asserted again.

UG028, July 1, 2014

Besides these two protocols, the user can use this module for deskew functions of any

protocols provided that the minimum spacing between de-skew characters are maintained.

Elastic FIFO (Elastic Buffer)

An elastic FIFO is used to synchronize the received data from the PMA recovered clock to a

system clock, typically the transmit clock. The Elastic FIFO also compensates for any

frequency offset between the recovered clock and the system clock. It compensates for the

frequency offset by adding or deleting pre-configured skip (or pad) characters from the

received data stream. The elastic FIFO in Achronix SerDes provides an indication that skip

(or pad) characters were added or deleted to the downstream logic. For PCIe, the elastic FIFO

also includes the appropriate status encoding to indicate add/delete operation.

The elastic FIFO can also be configured to be used as a simple phase compensation FIFO for

synchronizing data. When used as a phase compensation FIFO, it is left to the user to

guarantee that there is no frequency offset (jitter) between the read and write clocks.

27

Page 28

EFIFO Standards and Skip Characters

PCIe Gen3: To support PCIe Gen3, 4-bytes of skip are added at byte positions 4-7 from the

sync header associated with the skip ordered set. Skip removal happens from bytes 0-3 from

the sync header associated with the skip ordered set. Due to this particular rule of removal,

sync header and receive start block indications are delayed by 4-bytes.

PCIe Gen1/Gen2: For PCIe Gen1/Gen2, the skip ordered set is two 10-bit words – the elastic

buffer adds or deletes only the second word.

Fiber Channel: To support Fiber channel, 4-bytes of skip are added and deleted. The PCS

operates in 16-bit data-path mode at the fabric interface and 20-bit encoding internally.

XAUI: To support XAUI, the skip ordered set is one 10-bit word, which is added or deleted

by the elastic buffer.

GigE: For GigE, the skip ordered set is two 10-bit words – control followed by data. The

elastic FIFO adds or removes both of these two 10-bit words.

Other Standards: Besides these specific standards, the elastic FIFO can handle any generic

protocols in the similar line due to the programmable nature of SKIP and inverted SKIP

ordered set of length 2. The user has flexibility to include an alternate (mostly inverted) word

in the ordered set. Beyond two words skip ordered sets, only 4 words skip ordered sets can

be used, which are specific to fiber channel. The elastic FIFO generates the final data valid

from the PCS, which is used by the fabric to register data.

28 UG028, July 1, 2014

Page 29

EFIFO Operation

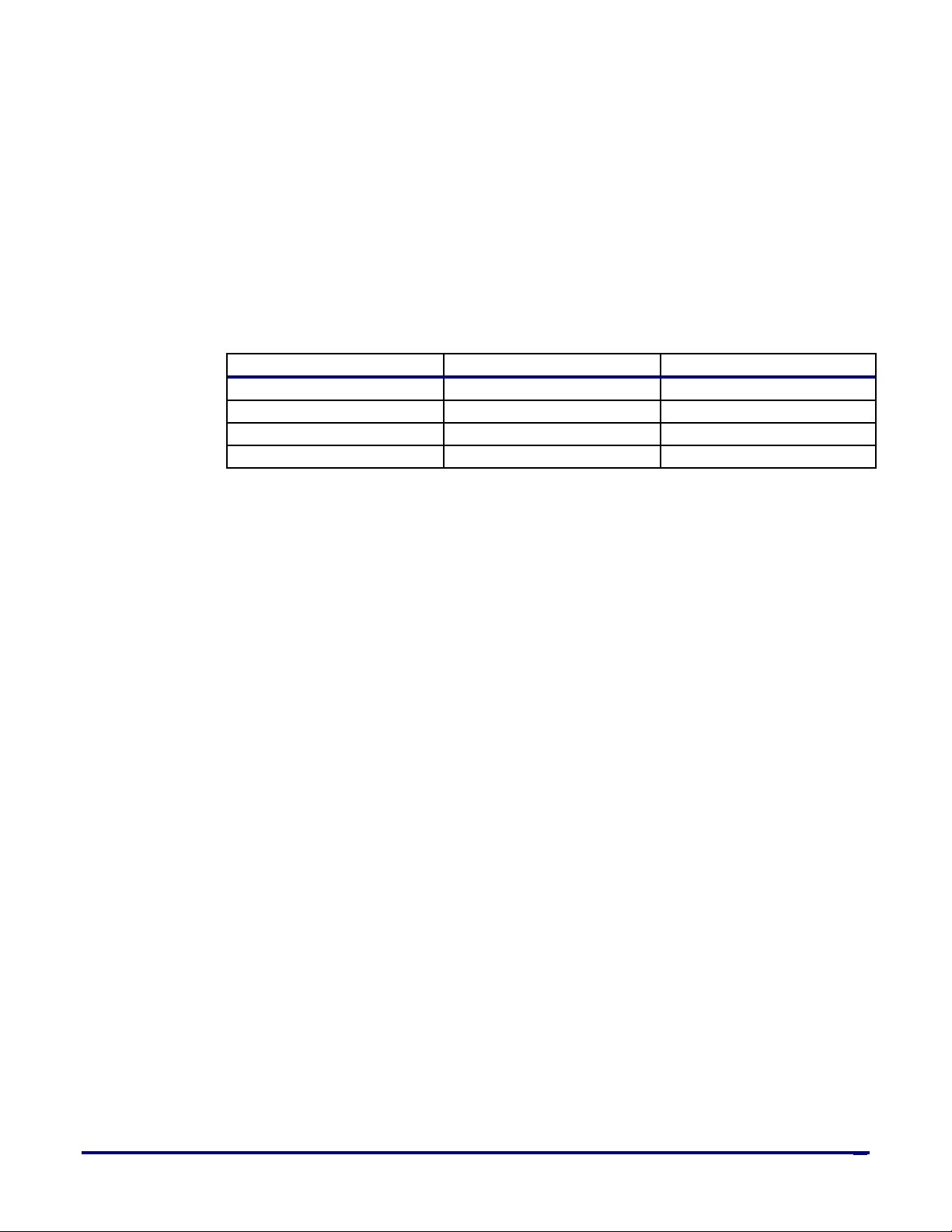

“

Figure 15: EFIFO SKP Addition/Removal

” illustrates the process of SKP addition/removal.

UG028, July 1, 2014

Figure 15: EFIFO SKP Addition/Removal

In “Figure 15: EFIFO SKP Addition/Removal” upon reset, the difference between the read

and write counters is equal to fifo_mid (half the size of the buffer; default 16).

If clk_in is operating at a lower frequency than clk_out, then the read operation is faster than

the write operation and the difference between the write and read counters will be less than

fifo_mid. In this case, to compensate for clk_in being slower, an SKP is added to the data

stream.

If clk_in is operating at a higher frequency than clk_out, then the read operation is slower

than the write operation and the difference between the write and read counters will be

greater than fifo_mid. In this case, to compensate for clk_out being slower, an SKP is

removed from the data stream.

29

Page 30

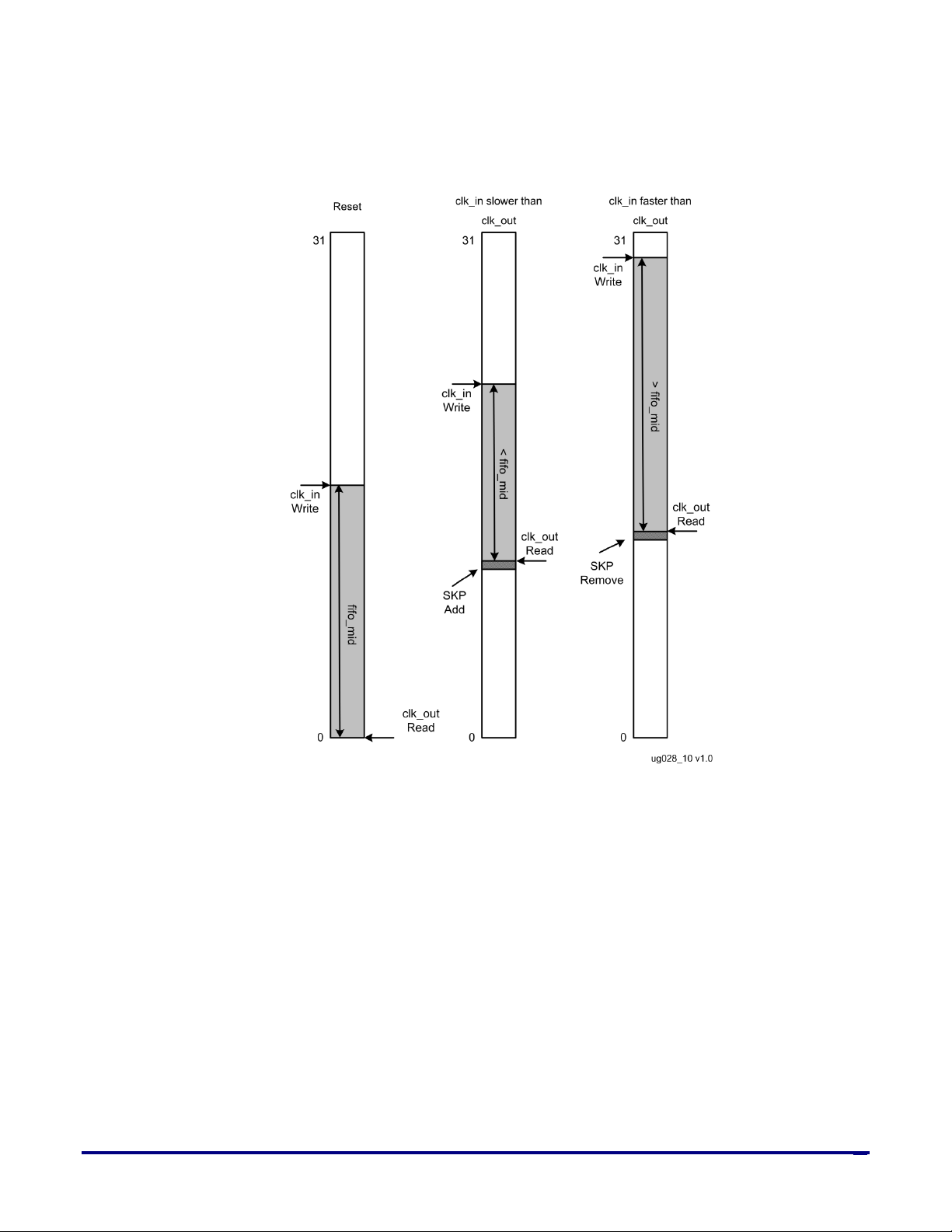

“Figure 16: EFIFO SKP Addition/Removal: PCIE, GigE (802.3) and XAUI (802.3)” illustrates

SKP additions and removals for PCIe, GigE (802.3), and XAUI (802.3ae). Note that in the

figure, data_i and data_o are not actually aligned, they are merely depicted so for clarity.

Figure 16: EFIFO SKP Addition/Removal: PCIE, GigE (802.3) and XAUI (802.3)

30 UG028, July 1, 2014

Page 31

Overflow/Underflow

Data Path width

Shift limit

20

83

16

79

10

73 8 71

If the difference between the write and read counters is greater than fifo_full, then the

overflow signal is asserted. If the difference between the write and read counters is less than

fifo_empty, then the underflow signal is asserted.

8b/10b Decoder

The 8b/10b decoder generates 8-bit code groups and 1-bit control from 10-bit encoded

(received) data. It uses the code group mapping specified in IEEE 802.3 clause 36. If the fabric

interface is a 16-bit data path, then two 8b/10b decoders are cascaded to produce 16-bit data

to the fabric. The decoder handles various error conditions. All error conditions are reported

per each byte lane.

The 8b/10b code allows 12 special (K) characters, but most standards generally support fewer

K characters and need the reserved K characters to be declared as code errors. So register

programming is possible to pre-configure 11 characters that can be declared as invalid for

deciding code error if seen in the receive data stream, and assuming that at least one special

character will be needed.

Any 10-bit code word that is not present in Tables 36-1, 36-2 of the IEEE 802.3-2005

specification shall be considered as invalid code word. In addition, 11 code words

corresponding to the K characters can be included (programmable) to be flagged as invalid

code words. If the 10-bit code word is present in Tables 36-1 or 36-2, but corresponds to the

wrong column (per current running disparity calculation), the wrong column indication is

asserted. Disparity and code errors are not mutually exclusive; however code error and

wrong column are mutually exclusive.

For XAUI and Gigabit Ethernet, a code error or disparity error will cause the error indication

to be propagated downstream. For PCIe, if a code error and disparity error are detected on

the same byte, the pipe_RXstatus is encoded to indicate a code error.

Bit Slider

The bit slider is a barrel shifter that can be used to control bit-wise skew from the fabric. This

feature can be used to implement any user specific algorithm for lane alignment and deskew. It can also be used in conjunction with the symbol slip mode of the de-skew FIFO to

attain a wide range of de-skew. The symbol slip mode can be used for coarse alignment (with

1 or 2 symbols shifting per request) and the bit slider can be used for finer alignment within a

symbol. The barrel shifter width is limits are shown in “Table 3: Shift Limit” below.

Table 3: Shift Limit

UG028, July 1, 2014

The MSBs is shifted to the location of the LSBs and the LSBs are discarded. There is a 6-bit

select control from the fabric to pick the active data to be driven to the fabric. For example, in

31

Page 32

the 20-bit mode of operation, the most significant 20-bits of data are placed on bits 19:0 of the

Port

Description

Primary input from SerDes. Used to select data window for

removing bit skew

bit_slider_enable

Register bit[1] @’h092 to enable bit-slider

word_mode

Register bit[3] @’h000 to select data path width – 1 word or 2 word

8bit_mode

Register bit[2] @’h000 to select type of encoding - 8(16) or 10(20)

barrel shifter and the least significant 20-bits are discarded. The 6-bit select control can select

a range of active bits, from [19:0] (for a select value of 0x00) to [82:63] (for a select value of

0x3F).

“Table 4: List of Important Interface Signals for bit slider”, provides a list of important

interface signals used for bit slider.

Table 4: List of Important Interface Signals for bit slider

bit_range_sel[5:0]

Interface Encapsulation

This block encapsulates the protocols before passing data to the fabric. Details on the

standards supported by Achronix FPGA can be found in Section –“PCS Interface”.

PCS Self Test Checker

When PCS self-testing feature is used, this block checks for the correctness of the receive data.

Details on this block are available in “PCS Test Pattern Generator” and “PCS Test Pattern

Checker”.

32 UG028, July 1, 2014

Page 33

PCS Interface

The PCS interface provides the general interface between the PCS and the core fabric. The

PCS supports the following interfaces:

Gigabit Ethernet Interface

The PCS in Achronix SerDes supports 10G Ethernet, compliant with section 36, 37 of IEEE

802.3. Functionalities implemented are PCS transmit, carrier sense, synchronization, receive,

and auto-negotiation.

The PCS transmit process is facilitated at both the GMII and PMA interfaces to the PCS. At

the GMII interface (fabric side), the PCS uses 8-bit synchronous data-path with packet delimiting, done by separate transmit control (TX_en, TX_err) and receive control signals

(RX_dv, RX_err). At the PMA interface, the PCS uses 10-bit data path, which uses 10-bit code

groups. Besides generating 10-bit code groups continuously based on GMII signals (TXd[7:0],

TX_dv, TX_err), transmit process also generates GMII signal col if reception is concurrent

with transmit. The transmit process also monitors auto-negotiation to determine whether it

needs to send data or reconfigure the link. As part of transmit process, the state machines

shown in Figures 36-15 and 36-16 of IEEE 802.3 are implemented. To enable carrier sense the

PCS generates an internal flag.

• Gigabit Ethernet Interface

• XAUI

• PIPE Interface

• 10G Ethernet Interface

The PCS Synchronization process determines whether the PMA is functioning reliably. The

PCS Synchronization process continuously accepts code-groups and conveys received codegroups to the PCS Receive process. For synchronization, a symbol alignment module is used.

For synchronization, the state machines shown in Figures 36-9 of IEEE 802.3 are

implemented.

The PCS Receive process continuously accepts code-groups. The PCS Receive process

monitors these code-groups and generates RXD <7:0>, RX_DV, and RX_ER on the GMII, and

the internal flag used by the Carrier Sense and Transmit processes. For synchronization, the

state machines shown in Figures 36-7 of IEEE 802.3 are implemented.

The PCS Auto-Negotiation process sets the xmit flag to inform the PCS Transmit process to

either transmit idles interspersed with packets as requested by the GMII or to reconfigure the

link. The PCS auto-negotiation process is specified in the state machine shown in Figure 37-6

of IEEE 802.3. As part of auto-negotiation, the PCS will advertise only as a 1G link full-duplex

partner. The following management registers are currently implemented:

a. Control register (Register 0)

b. Status register (Register 1)

c. AN advertisement register (Register 4)

d. AN link partner ability base page register (Register 5)

These management registers are accessible through SBUS i/f (P1). A MDIO-to-SBUS bridge

can be implemented in the fabric. The reset duration of these controllers is programmable

via register, and the max duration is defined as 0.5sec as per IEEE 802.3.

UG028, July 1, 2014

33

Page 34

XAUI

The PCS supports XAUI compliant with section 48 of IEEE 802.3. The Protocol block

implements the Transmit and Receive state machines as per Figures 48-6 and 48-9 of IEEE

802.3. For synchronization, de-skew and clock compensation operations, symbol alignment,

de-skew and elastic buffers in PCS are used. 8b/10b encoders and decoders are used for

handling 10-bit code groups.

When communicating with the XGMII (fabric side), the PCS uses in each direction 32 data

signals and 4 control signals. When communicating with the PMA, the PCS uses a 40-bit

code-group in the transmit direction and in the receive direction. Each set of 40-bit data

signals conveys four lanes of 10-bit code-groups. The 40-bit code-group signals are organized

into four lanes: the first PCS code-group is aligned to lane 0, the second to lane 1, the third to

lane 2, and the fourth to lane 3. Code-group alignment, lane-to-lane de-skew, and provision

for clock rate compensation are made possible by embedding special non-data code-groups

in the idle stream.

The PCS Transmit process continuously generates code-groups based upon the TXd [31:0]

and TXc [3:0] signals on the XGMII, sending them to the PMA service interface.

The PCS Synchronization process indicates whether the PMA is functioning dependably,

which can be determined without exhaustive error-rate analysis. The PCS Synchronization

process continuously accepts unaligned and unsynchronized code-groups from the PMA,

obtains 10-bit code-group synchronization, and conveys synchronized 10-bit code-groups to

the PCS de-skew process as per Figure 48-7 in IEEE 802.3.

The PCS de-skew process continuously accepts synchronized code-groups, aligns the codegroups to remove skew between the lanes introduced by the link, and conveys aligned and

synchronized code-groups to the PCS Receive process. At the end of the de-skew process, the

PCS will have successfully de-skewed and aligned code-groups on all PCS lanes. The deskew process always looks for non-aligned code-groups across 4-lanes and initiates de-skew

operations as per Figure 48-6 in IEEE 802.3.

Clock rate compensation is required when the received clock from the PMA and the clock on

which data is sent to fabric are different in terms of jitter. The PCS compensates by inserting

or deleting SKIP (||R||) characters in the encoded idle stream. Insertion and deletion is only

done after SKIP (||R||) is detected – not arbitrarily on any positions.

The Receive process operates in two modes as per Figure 48-9 in IEEE 802.3: date and idle

mode. In data mode, valid code-groups received are mapped to corresponding XGMII data

or control characters regardless of whether the control characters are valid XGMII control

characters. Invalid or error code-groups are mapped directly to XGMII Error control

characters. In idle mode, an idle code-group is translated to XGMII Idle control characters.

All code-groups are mapped on a lane by lane basis.

PIPE Interface

The PCS supports the PIPE interface compliant to the Intel PIPE 3.0 specification. It supports

a 10/20-bit data path for gen1/gen2 and 16-bit for gen3. Similarly, it supports 2.5G, 5.0G and

8.0G throughput on the PMA. For gen1/gen2, 8b/10b endec and gen3 128b/130b endec are

used. This interface allows the embedded PCIe MAC to configure the PMA and decide upon

the next course of action based on the status sent out by the PMA. Besides the functions

described in the PIPE interface specifications, it facilitates the MAC in setting up the receive

equalizer in the PMA. When the PCS is supporting PCIe/PIPE, lane de-skew is done by the

MAC and clock compensation is done by the elastic buffer in the PCS.

The PCS also supports a 128b/130b encoder, specifically targeted for PCIe gen3 (based on

draft 0.5 of the PCIe 3.0 specification). The interface is compliant to the PIPE 3.0 specification.

34 UG028, July 1, 2014

Page 35

The 128b/130b encoder is disabled on power up, and enabled when the rate bits coming from

PCIe Mode

PCLK

PMA Data Width

2.5 Gbps Gen1

250 Mhz

10 bits

2.5 Gbps Gen1

125 Mhz

20 bits

5.0 Gbps Gen2

500 Mhz

10 bits

5.0 Gbps Gen2

250 Mhz

20 bits

8.0 Gbps Gen3

500 Mhz

16 bits

the MAC are configured to 2’b10. The PCS layer support for PCIe gen3 also includes glue

logic to switch the PMA data width to 16-bit mode and programming final rate bits for PCIe

gen3 operation. “Table 5: PIPE Interface Paramaters” shows various supported combinations

of clocking speeds and data-widths.

Table 5: PIPE Interface Paramaters

UG028, July 1, 2014

35

Page 36

Clocking

“Figure 17: SerDes RX and TX clocks” gives an overview of the clocks inside the SerDes. The

PMA of a SerDes lane generates two clocks, a TX word clock synthesized from the reference

clock, and an RX word clock recovered from the incoming serial data stream. The frequency

of these clocks is the data rate divided by the word width. For instance, a 10Gbps data rate

with 20 bit data width results in a 500MHz clock. Since the TX and RX clocks are generated

separately, they must be designated as unrelated in the timing constraints. In the most basic

mode, these TX and RX clocks are used to clock the data in their respective directions, and

are brought into the FPGA fabric for use by the user design.

Because each SerDes lane has its own PMA to generate a TX clock and an RX clock, the clocks

of different lanes are unrelated to each other, and consequently there is no synchronization

between the data of different lanes. Some protocols distribute data over a group of SerDes

lanes to increase bandwidth; typically, the lanes in such a group must then be synchronized

to give the appearance of a single high-bandwidth data stream. To synchronize multiple

SerDes lanes, Lane Bonding is used. As the Figure illustrates, when Lane Bonding is enabled,

a single lane is designated as master, and its TX and RX clocks are used to clock all the lanes

in the group. The deskew FIFO is used to convert data from the recovered clock domain to

the master RX domain; see Section “Deskew FIFO” for more details.

Figure 17: SerDes RX and TX clocks

36 UG028, July 1, 2014

Page 37

Although each lane has its own clock output pins to the fabric, with lane bonding these are

all just route-throughs of the master clock: regardless of which clock output pins are used,

only one clock net is routed inside the fabric. This is an important feature of Lane Bonding,

because the FPGA fabric can only accommodate a limited number of distinct clocks. Lane

Bonding divides the number of distinct clocks inside the core by the size of the group. Note

that Lane Bonding is only possible when all lanes share the same reference clock, both at the

near end and at the far end.