Page 1

Product Service Manual – V193W

Service Manual for acer: V193W

P/N:

Applicable for All Regions

Version: 001

Date:2009/6/18

Notice:

- For RO to input specific “Legal Requirement” in specific NS regarding to responsibility and liability

statements.

First Edition (June, 2009)

© Copyright Acer Corporation 2009. All Right Reserved.

- 1 -

Page 2

Content Index

1. About This Manual ............................................................................................................ 3

1.1. Trademark ........................................................................................................................ 3

2. Introduction ....................................................................................................................... 4

2.1. RoHS (2002/95/EC) Requirements .................................................................................. 4

2.2. Safety Notice .................................................................................................................... 4

2.3 .Compliance Statement ..................................................................................................... 4

2.4. General Descriptions ....................................................................................................... 4

3. Product Overview ............................................................................................................. 5

3.1. Introduction ...................................................................................................................... 5

3.2. Operational Specification ................................................................................................. 7

3.3. Operational & Functional Specification ........................................................................... 11

3.4. LCD Characteristics ....................................................................................................... 14

3.5. User Controls ................................................................................................................. 17

3.6. Mechanical Characteristics ............................................................................................ 18

3.7. Pallet & Shipment .......................................................................................................... 19

3.8. Certification .................................................................................................................... 20

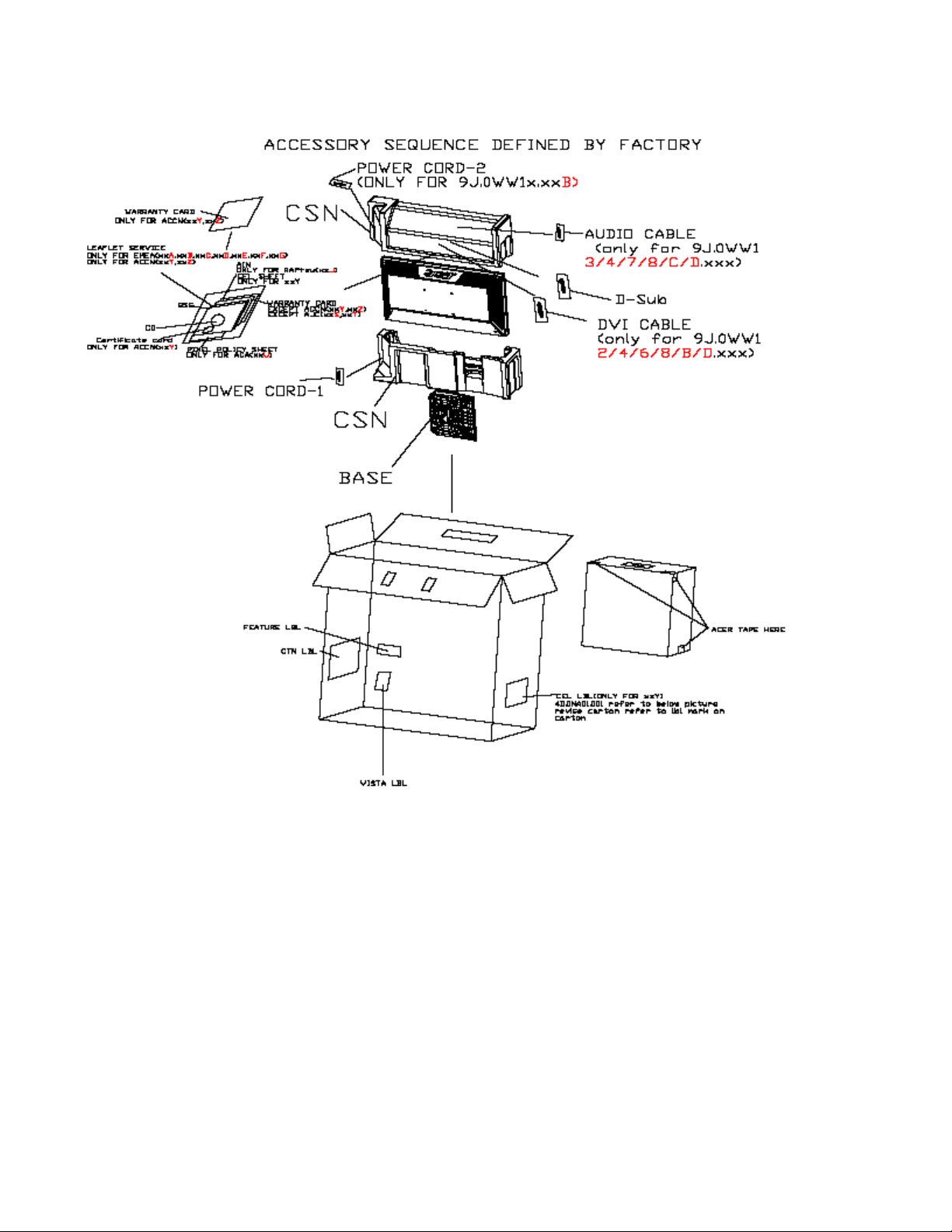

3.9 Packing ........................................................................................................................... 21

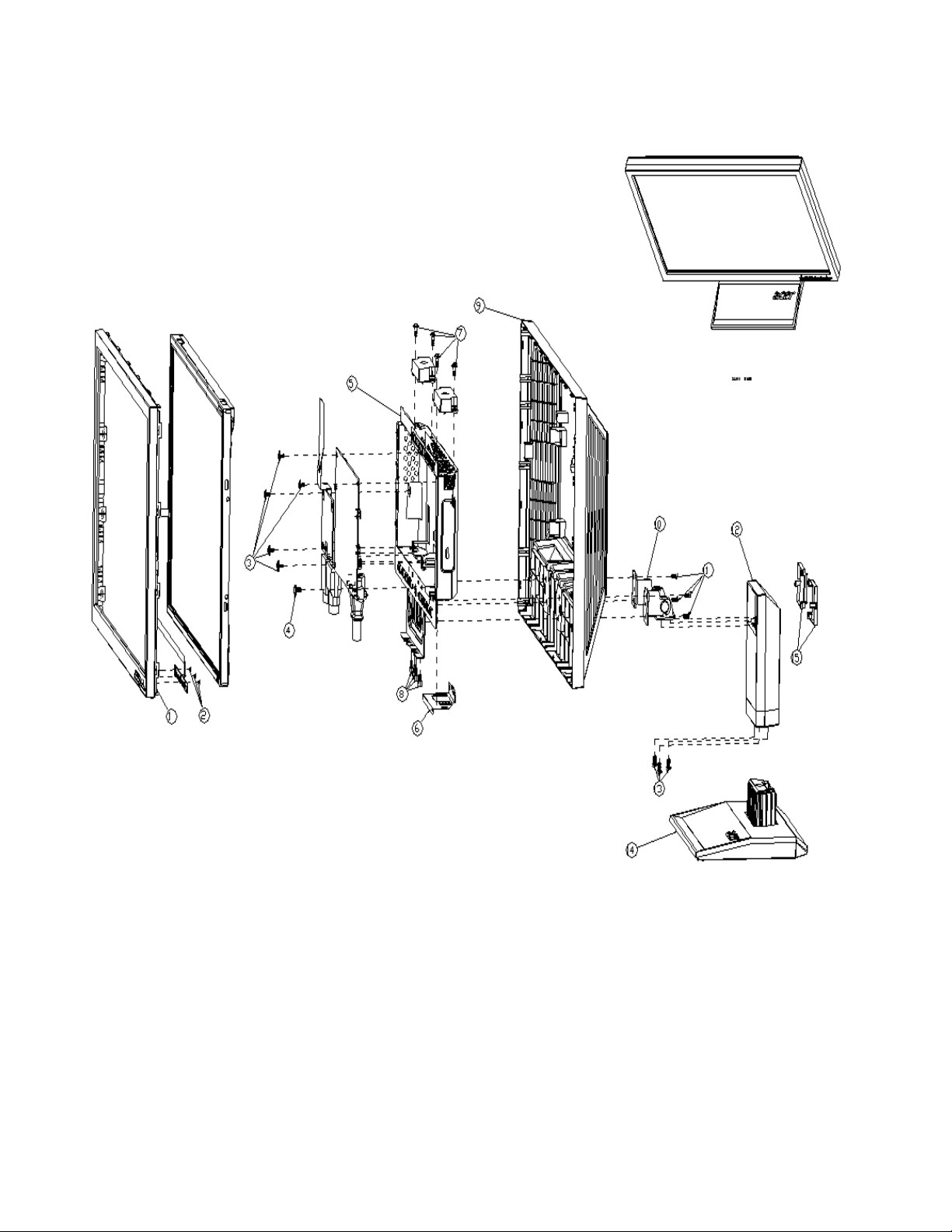

4. Disassembly /Assembly ................................................................................................. 22

4.1. Exploded View ............................................................................................................... 22

4.2. Disassembly /Assembly ................................................................................................. 24

5. Level 1 Cosmetic / Appearance / Alignment Service ................................................... 35

5.1 Alignment procedure (for function adjustment) ................................................................ 35

5.2 Software / Firmware Upgrade Process ........................................................................... 38

5.3 EDID Upgrade Procedure ............................................................................................... 43

5.4 OSD Operation Guide ..................................................................................................... 48

6. Level 2 Circuit Board and Standard Parts Replacement ............................................. 53

6.1. Trouble Shooting Guide ................................................................................................. 53

6.2 Circuit Operation Theory ................................................................................................. 59

6.3 Spare Parts List ............................................................................................................... 62

Appendix 1 – Screw List / Torque ...................................................................................... 65

Appendix 2 – Physical Dimension Front View and Side view ......................................... 68

Appendix 3 – Control Board............................................................................................... 69

- 2 -

Page 3

Abbreviations & Acronyms

1. About This Manual

This manual contains information about maintenance and service of acer products. Use this manual to

perform diagnostics tests, troubleshoot problems, and align the acer product.

1.1. Trademark

The following terms are trademarks of Acer Inc. :

Acer

Importance

Only trained service personnel who are familiar with this Acer Product shall perform service or

maintenance to it. Before performing any maintenance or service, the engineer MUST read the “Safety

Note”.

- 3 -

Page 4

2. Introduction

This section contains general service information, please read through carefully. It should be stored for

easy access place for quick reference.

2.1. RoHS (2002/95/EC) Requirements

– Applied to all countries require RoHS.

The RoHS (Restriction of Hazardous Substance in Electrical and Electronic Equipment Directive) is a legal

requirement by EU (European Union) for the global electronics industry which sold in EU and some counties

also require this requirement. Any electrical and electronics products launched in the market after June 2006

should meet this RoHS requirements. Products launched in the market before June 2006 are not required to

compliant with RoHS parts. If the original parts are not RoHS complaints, the replacement parts can be non

ROHS complaints, but if the original parts are RoHS compliant, the replacement parts MUST be RoHS

complaints.

If the product service or maintenance require replacing any parts, please confirming the RoHS requirement

before replace them.

2.2. Safety Notice

1. Make sure your working environment is dry and clean, and meets all government safety requirements.

2. Ensure that other persons are safe while you are servicing the product.

DO NOT perform any action that may cause a hazard to the customer or make the product unsafe.

3. Use proper safety devices to ensure your personal safety.

4. Always use approved tools and test equipment for servicing.

5. Never assume the product’s power is disconnected from the mains power supply. Check that it is

disconnected before opening the product’s cabinet.

6. Modules containing electrical components are sensitive to electrostatic discharge (ESD). Follow ESD safety

procedures while handling these parts.

7. Some products contain more than one battery. Do not disassemble any battery, or expose it to high

temperatures such as throwing into fire, or it may explode.

8. Refer to government requirements for battery recycling or disposal.

2.3 .Compliance Statement

Caution: This Optical Storage Product contains a Laser device. Refer to the product specifications and your

local Laser Safety Compliance Requirements.

2.4. General Descriptions

This Service Manual contains general information. There are 3 levels of service:

Level 1: Cosmetic / Appearance / Alignment Service

Level 2: Circuit Board or Standard Parts Replacement

Level 3: Component Repair to Circuit Boards

- 4 -

Page 5

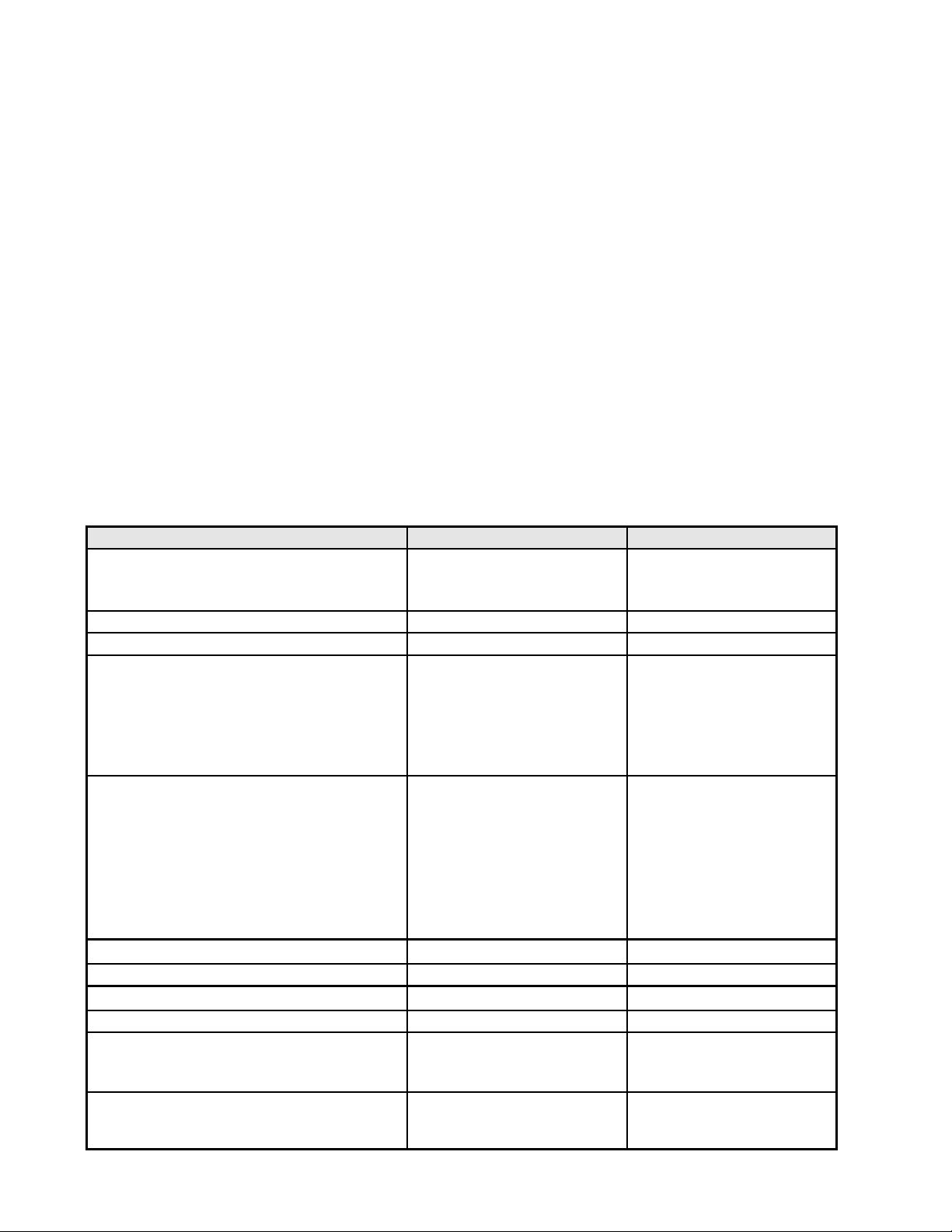

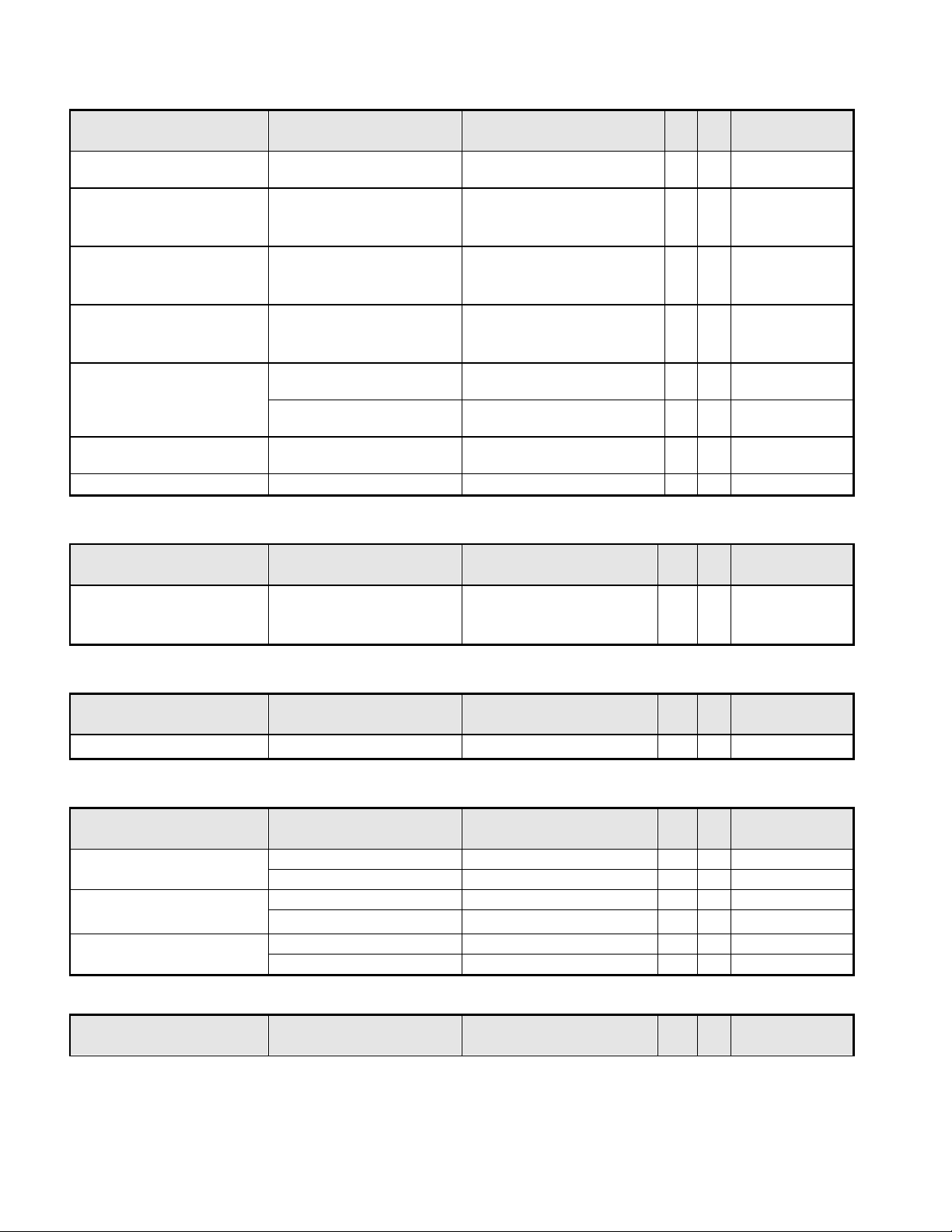

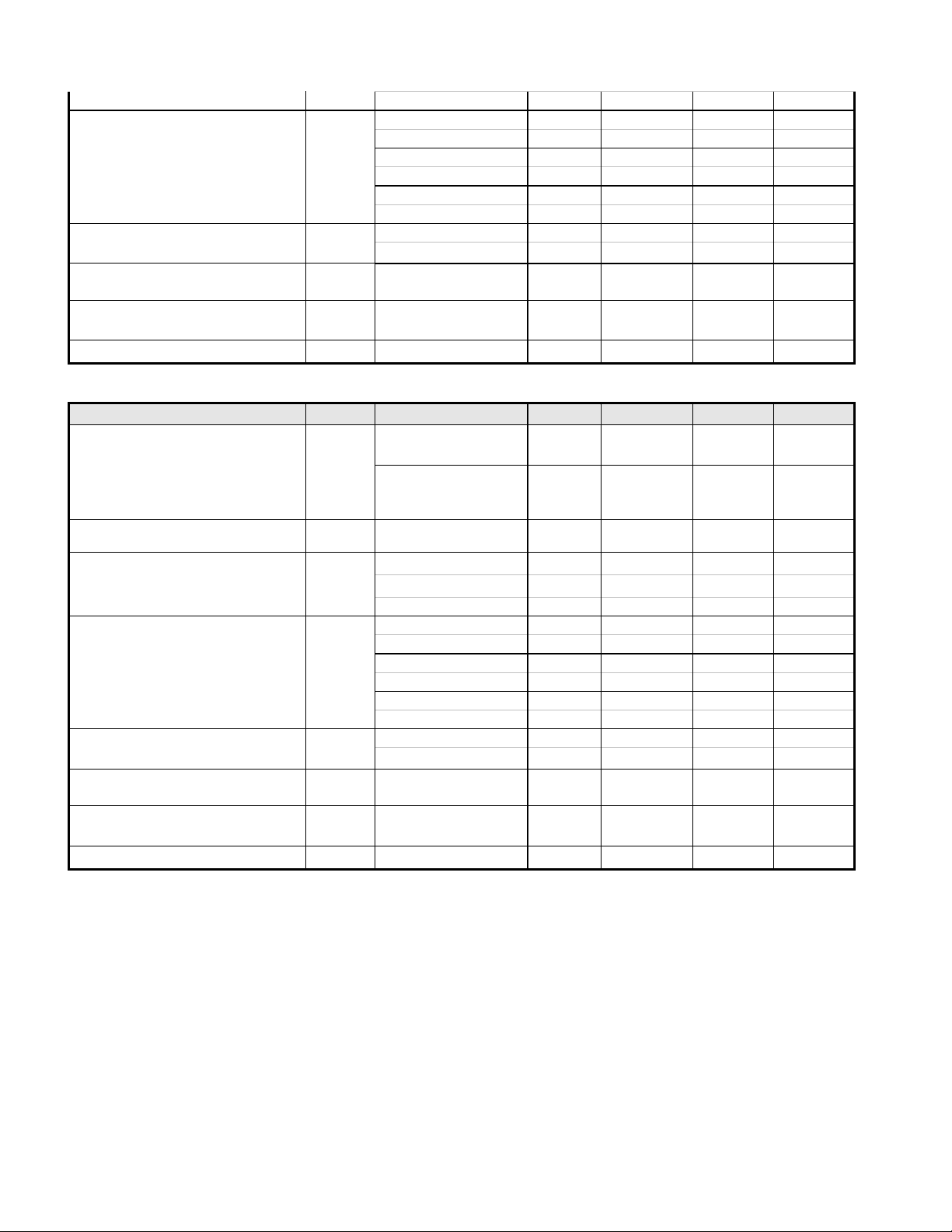

Feature items

Specifications

Remark

Panel supplier & module name

AUO M190PW01 V5

LGD LM190WX1-TLP1

SEC LTM190BT03

TN, Normally white

Screen diagonal

19”W

408.24(H) x 255.15(V)

Display Format

1440(H) x 900 (V)

Panel Display information

Pixel Pitch

AUO: 0.2835 mm x 0.2835

mm

LGD: 0.2835 mm x 0.2835

mm

SEC: 0.2835 mm x 0.2835

mm

per one triad

Viewing Angle (@ Contrast Ratio >= 10)

AUO:

R/L: 170 degrees (typ.)

U/D: 160 degrees (typ.)

LGD:

R/L: 170 degrees (typ.)

U/D: 160 degrees (typ.)

SEC:

R/L: 160 degrees (typ.)

U/D: 160 degrees (typ.)

Analog interface with Scaling supported

Yes

With 15-pin D-sub

HDMI interface with Scaling supported

NA

Max resolution mode supported

1440 (H) x 900(V)@60Hz

Number of Display Colors supported

16.7 Millions

Contrast Ratio

AUO:1000 (typ.),600(min)

LGD:1000 (typ.), 700(min)

SEC:1000 (typ.), 600(min)

Test Condition: Set Contrast

at 50, Brightness at 100,

Color at User preset

Luminance

300 cd/m2 (typ.),250 cd/m2

(min)

Test Condition: Set Contrast

at 50, Brightness at 100,

Color at User preset

3. Product Overview

3.1. Introduction

V193W is defined as our new 19”W model in ACER V series which will be the ACER project in Qisda. V193W is

defined as 19”W LCD Monitor supports 1440(H) x 900(V) resolution with DPMS (Display Power Management

System) and ACER eColor function. There are triple input types, D-sub, DVI. V193W adopts AUO panel

M190PW01 V5, LGD panel LM190WX1-TLP1, SEC panel LTM190BT03. V193W has included 1W+1W speaker.

V193W also support ACM 10000:1.

The features summary is shown as below,

*All panel spec. in Q201 definition depends on the variance of panel source.

*All spec. of monitor need to warm up at least 1hr.

* To test the “Contrast Ratio” and “Luminance” functions, the color status must be “User preset” mode.

* 1. “Contrast Ratio”: Set “brightness” at 100, and “contrast” at 50.

* 2. “Luminance”: Set “brightness” at 100, and “contrast” at 100.

- 5 -

Page 6

AC power input

Yes

90-264 Volts, 47-63 Hz.

DC power input (with AC power adapter)

No DPMS supported

Yes

<1W

LED indicator for power status showed

Yes

Blue/Amber

OSD for control & information supported

Yes

Multi-language supported for OSD

Yes

EMEA

Non-EMEA

Buttons control supported

Yes

6 buttons including 1

monitor power on/off

control button.

Flywheel control supported

No Scaling function supported

Yes

Auto adjustment function supported

Yes

“Auto-Key” function

DDC function supported (EDID ver. 1.3)

Yes

DDC2B

DDC-CI support version 1.1 or later

Yes

DDC-CI

Audio speakers supported

Yes

Audio Jack (input connector) supported

Yes

Line-in connector

Earphone Jack (Output connector)

supported

No

Microphone function supported

No Mechanical Tilt base design

Yes

From -5 to +23 degree

VESA wall mounting design

Yes

Mechanical Rotate design

No

Mechanical Lift base design

No

Kensington compatible lock design

Yes

- 6 -

Page 7

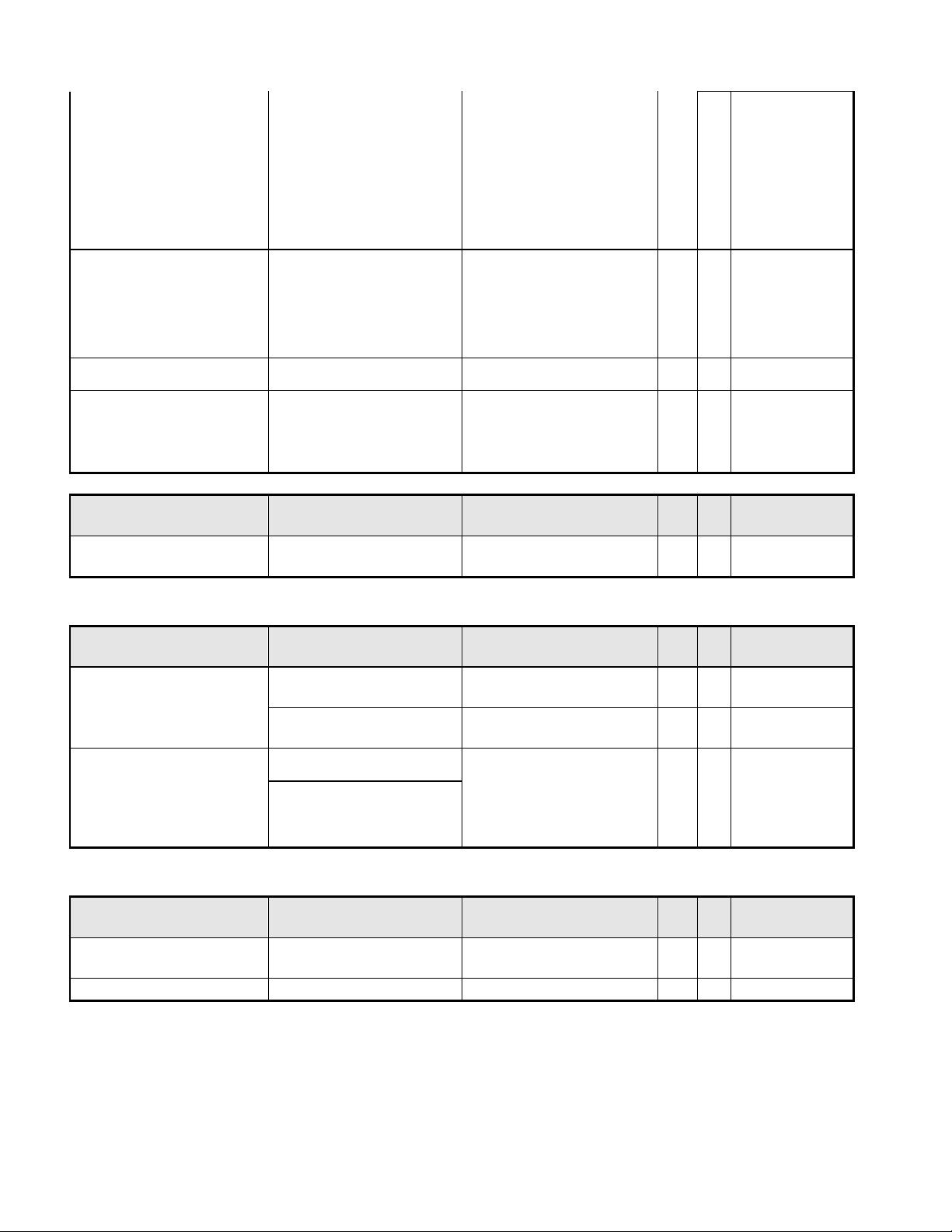

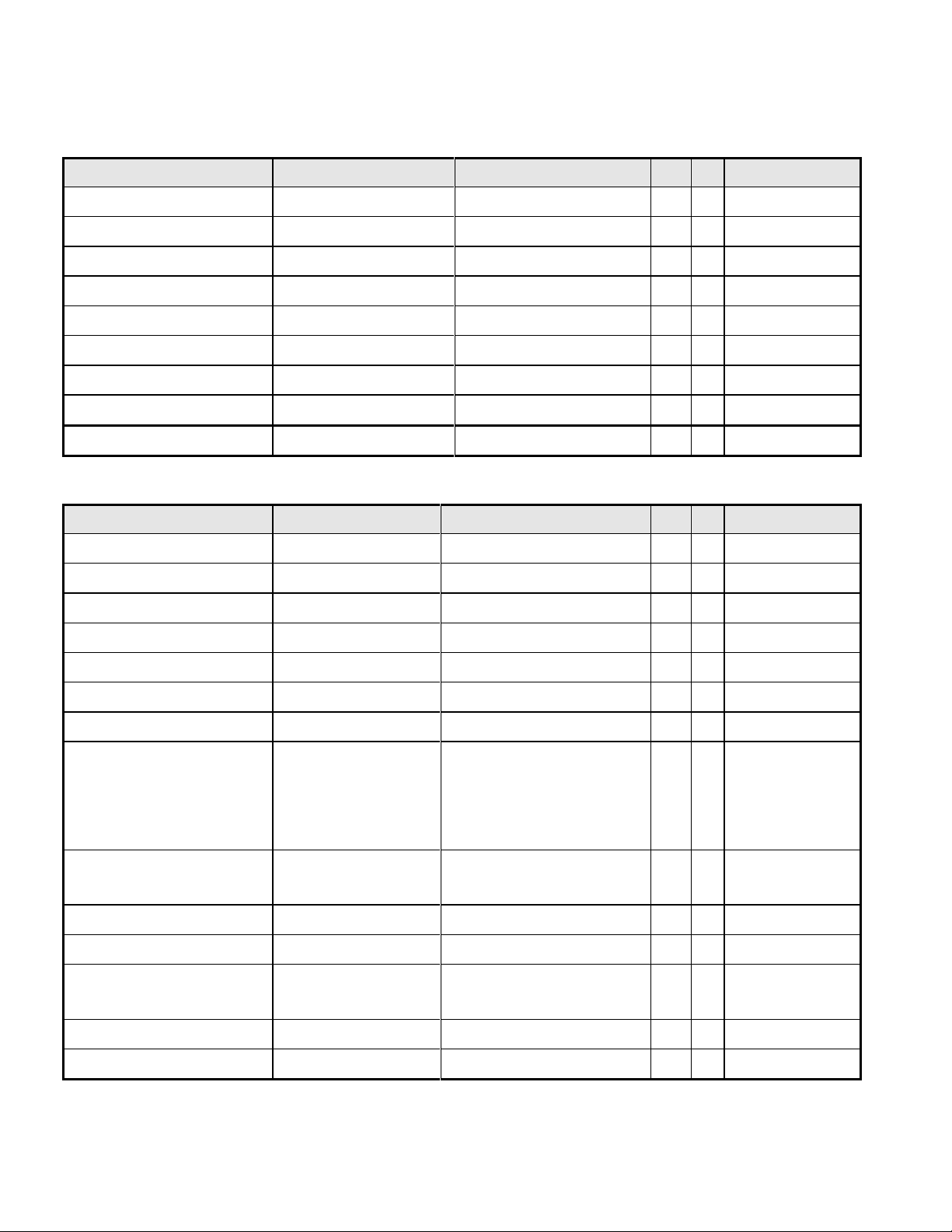

3.2. Operational Specification

Item

Condition

Spec

OK

N.A

Remark

Input Voltage range

Universal input full range

90~264VAC /47~63Hz

Input Current range

90 ~ 264VAC

< 0.7 Arms

Power Consumption

Normal “On” operation

< 31 W

LED: Blue

DPMS

DPMS “Sleep” state

< 1 W

LED: Amber

DPMS

DPMS “Off” state

< 0.5 W

LED: OFF

Inrush Current

110 VAC

220 VAC

< 30 A (peak)

< 60 A (peak)

Cold-start

Earth Leakage Current

264 VAC/50Hz

< 3.5 mA

Hi-Pot

1. 1500VAC, 1 sec

2. Ground test: 30A,

1sec

Without damage

< 0.1 ohm

(on-line test)

(in-lab test)

Power Line Transient

IEC1000-4-4

1KV

IEC1000-4-5 (Surge)

Common: 2KV,

Differential: 1KV

CCFL operation range

90 ~ 264VAC

AUO: 3~8mA

LGD : 3~8mA

SEC : 3~8mA

Depends on panel

source

CCFL Frequency

90 ~ 264VAC

AUO:40KHz ~ 80KHz

LGD:40KHz ~ 80KHz

SEC :40KHz ~ 60KHz

Depends on panel

source

Power cord

Color: Black

Length: 1800 +/- 50 mm

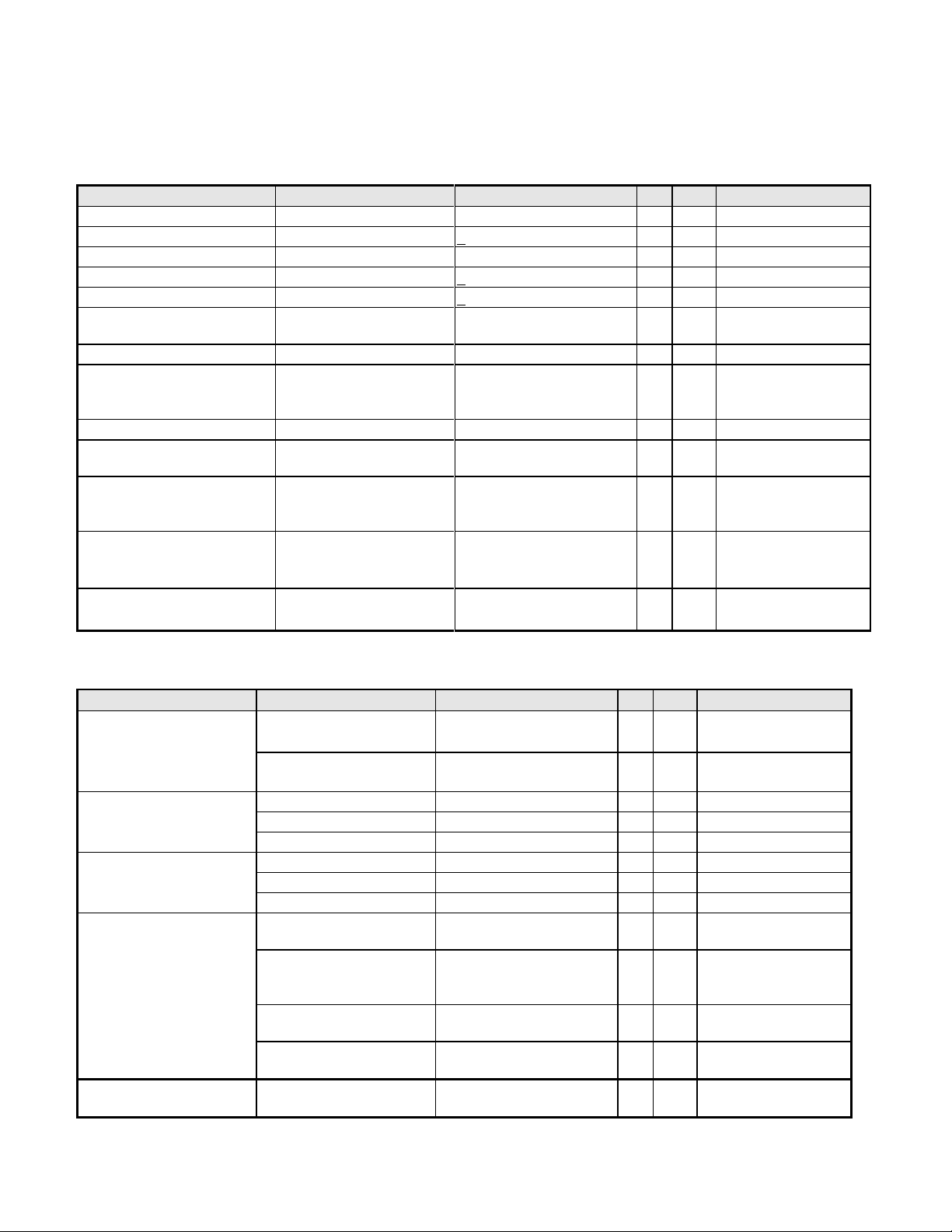

Item

Condition

Spec

OK

N.A

Remark

Signal Cable

15-pin D-Sub

Color: Black

Length: 1800 +/- 30 mm

24-pin DVI-D

Color: Black

Length: 1800 +/- 50 mm

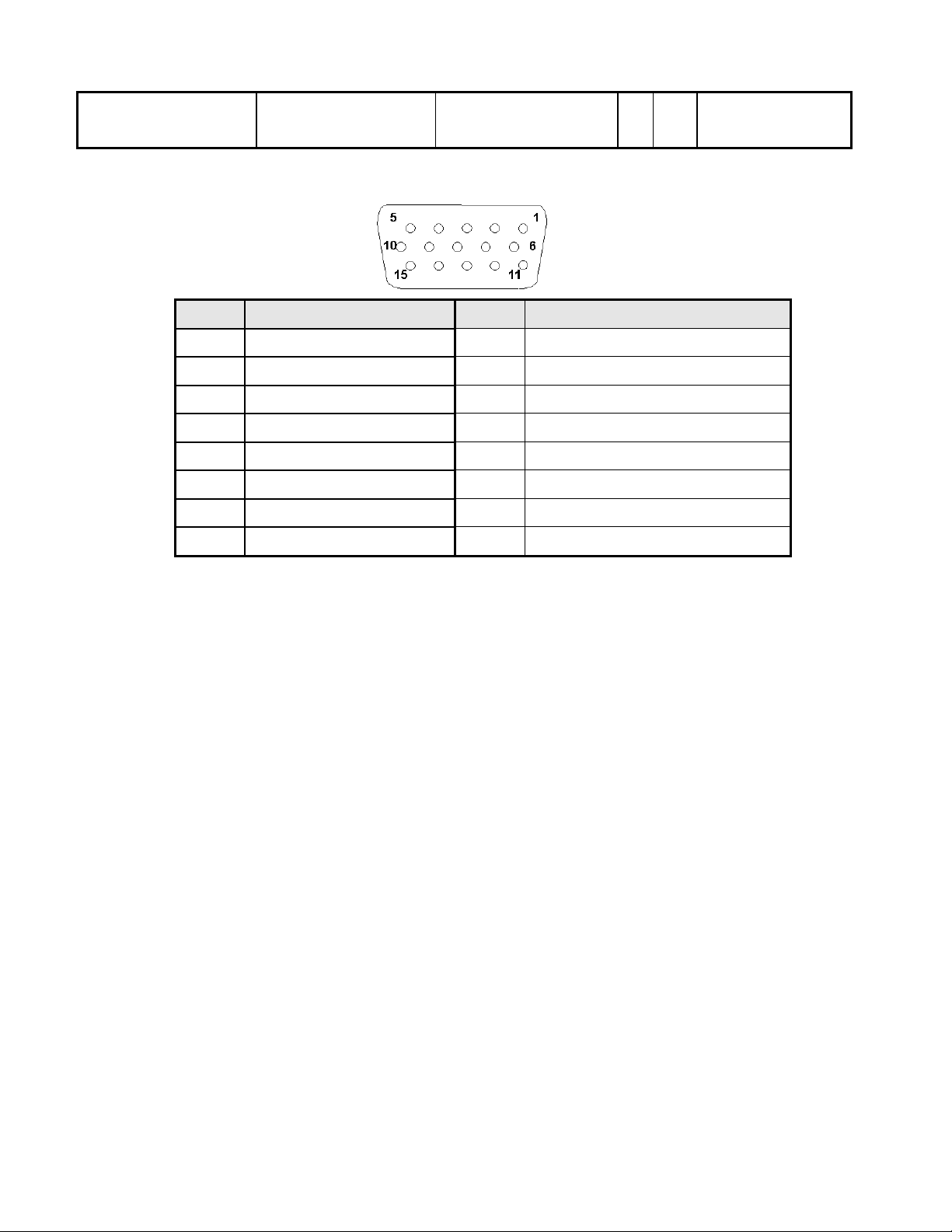

Pin assignment

15-pin D-sub connector

See Note-1

For 15-pin D-sub

24-pin DVI-D connector

See Note-2

For 24-pin DVI-D

19-pin HDMI connector

See Note-3

For 19-pin HDMI

Analog input

Signal type

Separate analog R/G/B

For 15-pin D-sub

Level

700 mV (peak to peak)

Impedance

75 Ohms +/- 1.5 Ohms

Sync input

Signal type

Separate H/V-sync

(Positive/Negative)

For 15-pin D-sub

Level

Logic High: 2.4V ~ 5.5V

Logic Low: 0V ~ 0.5V

(TTL level)

Refer to VESA VSIS

Standard V1R1

Impedance

Minimum 2.2KΩ(pull

down)

10KΩ for application

Sync Pulse Width (SPW)

0.7μs < H-SPW

1H < V-SPW

Digital input

Level

600mV for each

differential line

3.2.1 Power supply

3.2.2 Signal interface

- 7 -

Page 8

Impedance

50 Ohm TDR Scan

needed for DVI cable and

interface board

Pin

Signal Assignment

Pin

Signal Assignment

1

Red video

9

PC5V (+5 volt power)

2

Green video

10

Sync Ground

3

Blue video

11

Ground

4

Ground

12

SDA

5

Cable Detected

13

H-Sync (or H+V)

6

Red Ground

14

V-sync

7

Green Ground

15

SCL

8

Blue Ground

Note-1: The pin assignment of 15-pin D-sub connector is as below,

- 8 -

Page 9

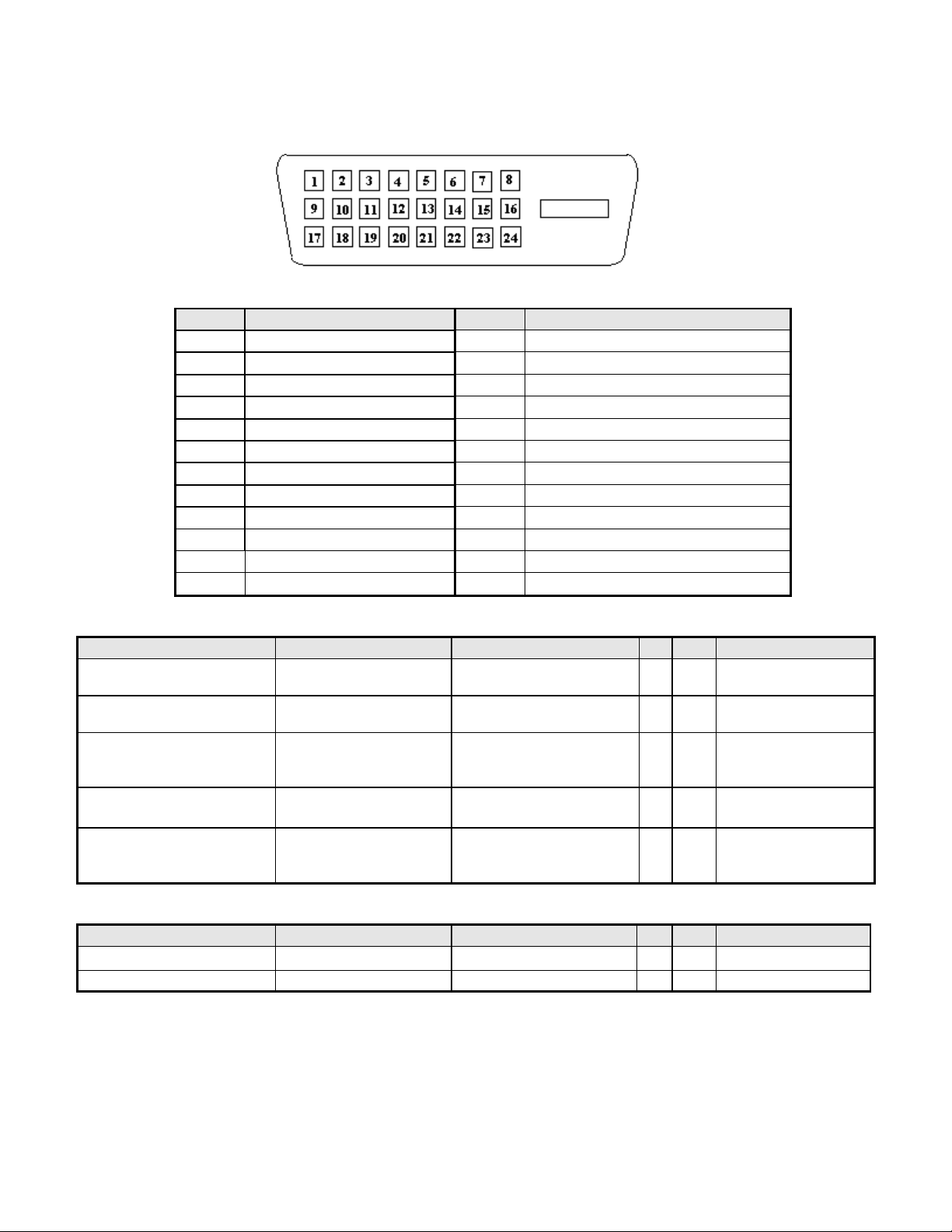

Note-2: The pin assignment of 24-pin DVI-D connector is as below,

Pin

Signal Assignment

Pin

Signal Assignment

1

TMDS RX2-

13

Floating

2

TMDS RX2+

14

+5V Power

3

TMDS Ground

15

Ground(Cable Detect)

4

Floating

16

Hot Plug Detect

5

Floating

17

TMDS RX0-

6

DDC Clock

18

TMDS RX0+

7

DDC Data

19

TMDS Ground

8

Floating

20

Floating

9

TMDS RX1-

21

Floating

10

TMDS RX1+

22

TMDS Ground

11

TMDS Ground

23

TMDS Clock+

12

Floating

24

TMDS Clock-

Item

Condition

Spec

OK

N.A

Remark

Max. support Pixel rate

136.75 MHz

Both for analog and

digital inputs

Max. Resolution

1440 x 900

Both for analog and

digital inputs

Rise time + Fall time

< 5 ms

(50% of minimum pixel

clock period)

1440x900 @ 75Hz

(max. support timing)

Settling Time after

overshoot /undershoot

< 5% final full-scale value

Refer to VESA VSIS

Standard V1R1

Overshoot/Undershoot

< 12% of step function

voltage level over the full

voltage range

Refer to VESA VSIS

Standard V1R1

Item

Condition

Spec

OK

N.A

Remark

Horizontal

31-83 KHz

Vertical

56-76 Hz

HDMI supports 50Hz

3.2.3 Video performance

3.2.4 Scan range

- 9 -

Page 10

3.2.5 Plug & Play DDC2B DDC-CI Support

Item

Condition

Spec

OK

N.A

Remark

DDC channel type

DDC2B

EDID

Version 1.3

Refer to S/W spec.

document to see the

detailed EDID data

definition.

DDC-CI

Version 1.1 or Later

Refer to S/W spec

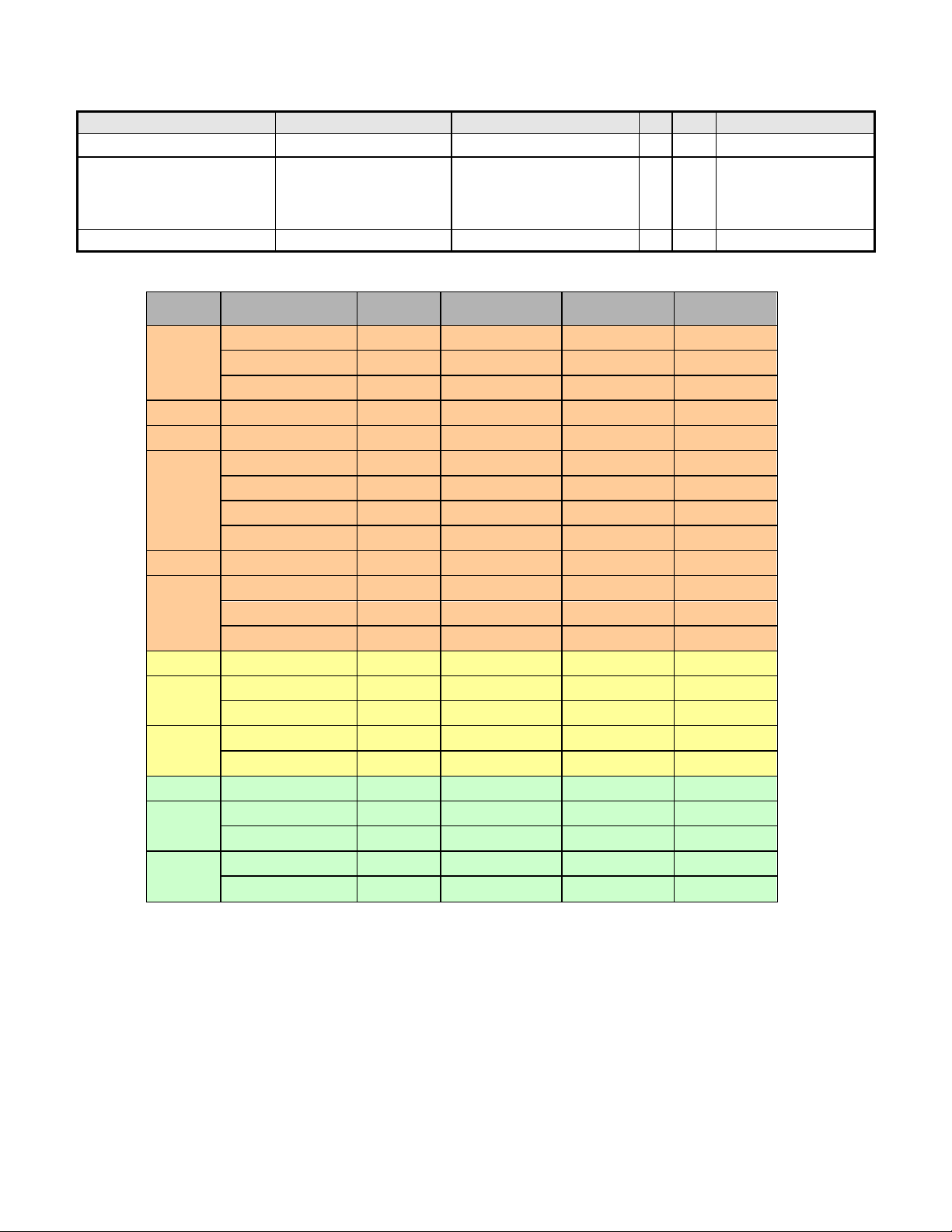

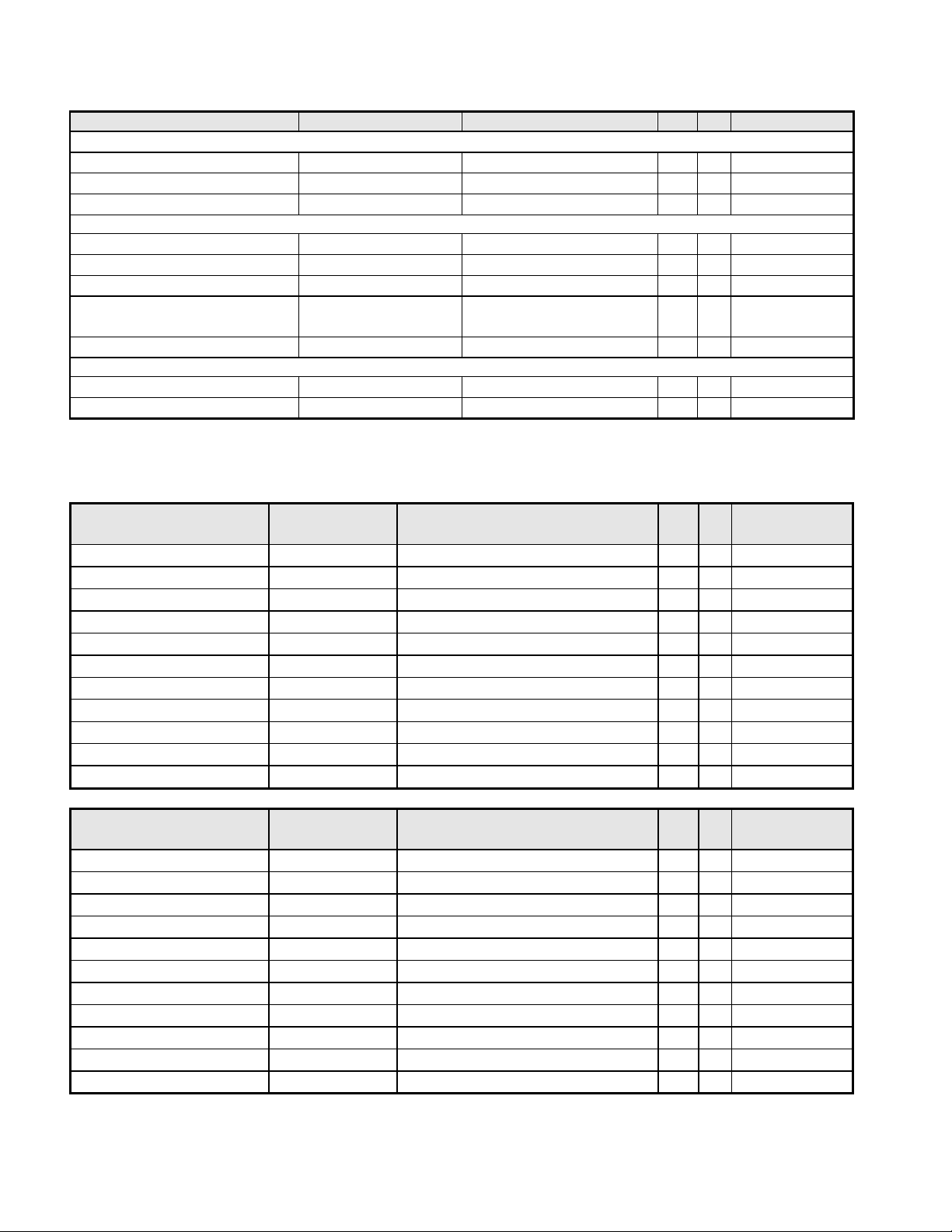

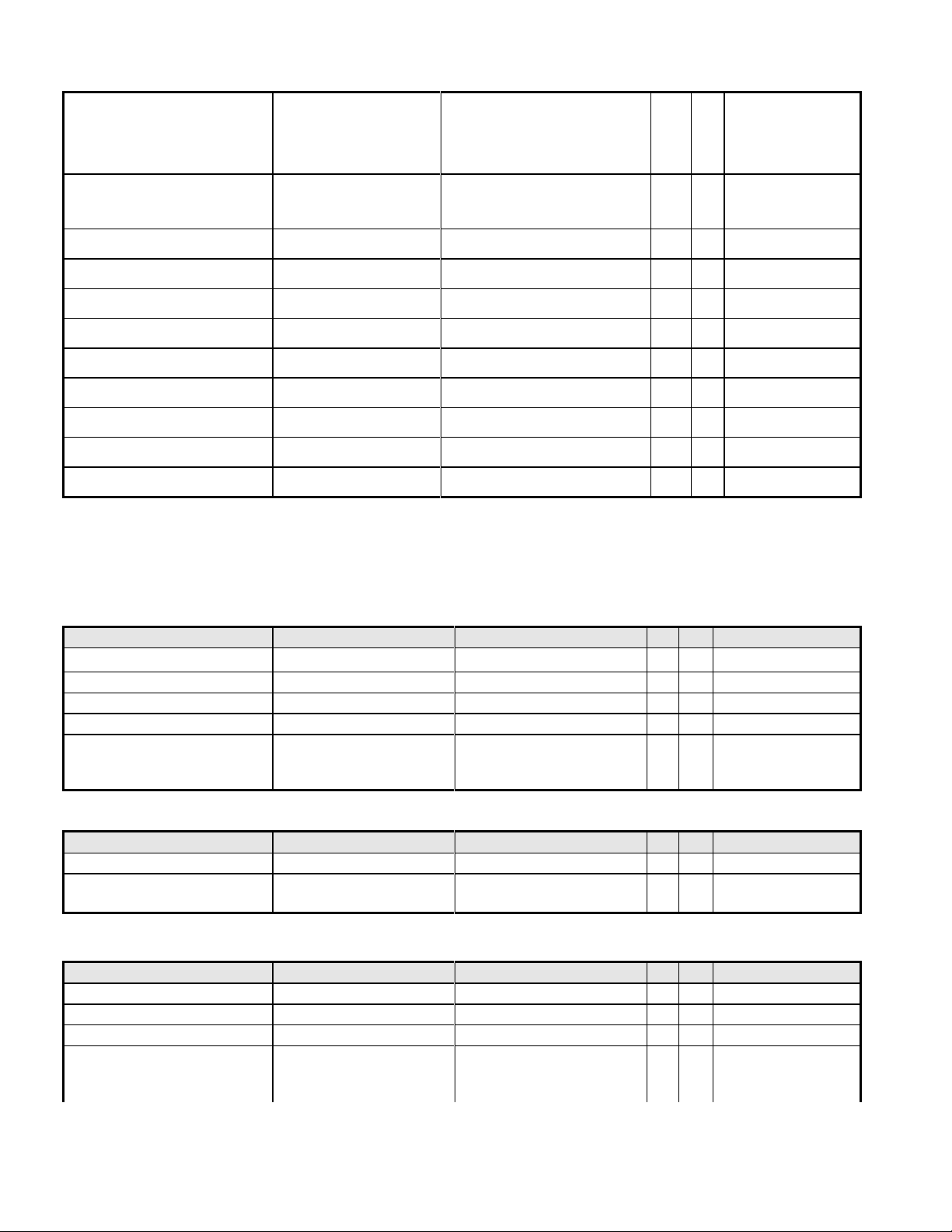

Mode

Resolution

(active dot)

Resolution

(total dot)

Horizontal

Frequency (KHz)

Vertical

Frequency (Hz)

Nominal Pixel

Clock (MHz)

640x480@60Hz

800 x 525

31.469

59.941

25.175

640x480@72Hz

832 x 520

37.861

72.809

31.500

640x480@75Hz

840 x 500

37.500

75.000

31.500

MAC

640x480@66.66Hz

864x525

35

66.66

30.24

VESA

720x400@70Hz

900x449

31.469

70.087

28.322

SVGA

800x600@56Hz

1024 x 625

35.156

56.250

36.000

800x600@60Hz

1056 x 628

37.879

60.317

40.000

800x600@72Hz

1040 x 666

48.077

72.188

50.000

800x600@75Hz

1056x625

46.875

75.000

49.500

MAC

832x624@74.55Hz

1152x667

49.722

74.55

57.28

XGA

1024x768@60Hz

1344x806

48.363

60.004

65.000

1024x768@70Hz

1328x806

56.476

70.069

75.000

1024x768@75Hz

1312x800

60.023

75.029

78.750

MAC

1152x870@75Hz

1456x915

68.681

75.062

100.000

VESA

1152x864@75Hz

1600x900

67.5

75

108

1280x960@60Hz

1800x1000

60

60

108

SXGA

1280x1024@60Hz

1688x1066

63.981

60.020

108.000

1280x1024@75Hz

1688x1066

79.976

75.025

135.000

VESA

1280x720@60Hz

1650x750

44.955

59.940

74.176

WXGA

1280x800@60Hz

1680x831

49.702

59.810

83.500

1360x768@60Hz

1792x795

47.712

60.015

85.500

WXGA+

1440x900@60Hz

1904x931

55.935

59.887

106.500

1440x900@75Hz

1936x942

70.635

75.000

136.750

3.2.6 Support Timings

Note:

1. Show “Input Not Supported” warning message.

When Vertical Frequency is over 76Hz or under 56Hz, the display is Black and showing “Input Not

Supported” warning message. (Some video timings are except for PAL, 50Hz signals.)

2. If Hf /Vf is set in the range of 31KHz~83KHz and 56Hz ~76Hz (not including some video timing), and Pixel

Clock is set in the range of 25.175MHz~173MHz(DVI and HDMI input port 165MHz for Single-Link), but is

not the above Resolution, then it will display the nearest mode.

- 10 -

Page 11

Item

Condition

Spec

OK

N.A Remark

Resolution

Any input resolution modes

which are under 1440x900

1440x900

Contrast ratio

600(min),1000(typ.)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Brightness

At R/G/B saturated

condition

300 cd/m2 (typ.),250 cd/m2

(min)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Response time

Rising + Falling time

On/off:5 ms (typ.),8ms(max)

Test Equipment:

Westar TRD 100 or

equal level

equipment ;

Viewing angle

At Contrast ratio = 10

R/L: 85/85 degrees (typ.)

75/75 degrees (min)

At Contrast ratio = 10

U/D:80/80 degrees (typ.)

70/70 degrees(min)

CIE coordinate of White

(0.313, 0.329) +/- (0.03,

0.03)

Display colors

16.7 Millions colors

6 bit+Hi-FRC

Item

Condition

Spec

OK

N.A Remark

Resolution

Any input resolution modes

which are under 1440x900

1440x900

Contrast ratio

700(min),1000(typ.)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Brightness

At R/G/B saturated

condition

300 cd/m2 (typ.),250 cd/m2

(min)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Response time

Rising + Falling time

On/off:5 ms

(typ.),10ms(max)

Test Equipment:

Westar TRD 100 or

equal level

equipment ;

Viewing angle

At Contrast ratio = 10

R/L: 85/85 degrees (typ.)

70/70 degrees (min)

At Contrast ratio = 10

U/D:75/85 degrees (typ.)

65/75 degrees(min)

CIE coordinate of White

(0.313, 0.329) +/- (0.03,

0.03)

Display colors

16.7 Millions colors

6 bit+Hi-FRC

3.3. Operational & Functional Specification

3.3.1 Video performance

*All spec. of monitor need to warm up at least 1hr.

AUO M190PW01 V5

LGD LM190WX1-TLP1

- 11 -

Page 12

SEC LTM190BT03

Item

Condition

Spec

OK

N.A Remark

Resolution

Any input resolution modes

which are under 1440x900

1440x900

Contrast ratio

600(min),1000(typ.)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Brightness

At R/G/B saturated

condition

300 cd/m2 (typ.),250 cd/m2

(min)

Test Condition: Set

Contrast at 50,

Brightness at 100,

Color at User preset.

Response time

Rising + Falling time

On/off:5 ms

(typ.),10ms(max)

Test Equipment:

Westar TRD 100 or

equal level

equipment ;

Viewing angle

At Contrast ratio = 10

R/L: 80/80 degrees (typ.)

70/70 degrees (min)

At Contrast ratio = 10

U/D80/80 degrees (typ.)

70/70 degrees(min)

CIE coordinate of White

(0.313, 0.329) +/- (0.03,

0.03)

Display colors

16.7 Millions colors

6 bit+Hi-FRC

Item

Condition

Spec

OK

N.A Remark

Brightness adjustable

range

At default contrast level

(saturate point) & Fullwhite color pattern

(Max. brightness value –

Min. brightness value)

≧ 100 cd/㎡

Item

Condition

Spec

OK

N.A Remark

Acoustical Noise

At 30 cm distance

≦ 22 dB/A

Refer to C326

Item

Condition

Spec

OK

N.A Remark

Temperature

Operating

0 ~ +40 ℃

Non-operating

-20 ~ +60 ℃

Humidity

Operating

10 ~ 90%

Non-condensing

Non-operating

10 ~ 90%

Non-condensing

Altitude

Operating

0~3048m (10,000ft)

Without packing

Non-operating

0~12,192m (40,000ft)

With packing

Item

Condition

Spec

OK

N.A Remark

3.3.2 Brightness Adjustable Range

3.3.3 Acoustical Noise

3.3.4 Environment

3.3.5 Transportation

- 12 -

Page 13

(1) Vibration

Package, Non-Operating

Test Specification:

1. Frequency Hertz 5 ~

250 HZ , PSD Level

0.0054 (G2/Hz)

2. Grms = 1.146

3. Sweep Time : 30

minutes per Axis

4. Axes : X,Y,Z

(2) Unpackaged Vibration

Unpackaged, Non-

Operating

Test Spectrum:

20 Hz 0.0185(g2/Hz)

200Hz 0.0185(g2/Hz)

Duration : 5 Minutes

Axis : 3 axis ( Horizontal

and Vertical axis ,Z axis)

(3) Drop

Package, Non-Operating

76 cm Height (MP stage)

(1 corner, 3 edges, 6 faces)

(4) Shock

Wooden package, Non-

Operating

1. Amplitude : Half sine-wave

50G

2. Duration : 10 ms

3. Test Times : 1

4.Test Sides : All 6 Sides

3.3.6 Electrostatic Discharge Requirements

Item

Condition

Spec

OK

N.A Remark

Electrostatic Discharge

IEC801-2 standard

Contact: 8KV

Air: 15KV

Item

Condition

Spec

OK

N.A Remark

TCO03

Electric

Band 1 < 10 V/m

Band 2 < 1 V/m

Magnetic

Band 1 < 200nT

Band 2 < 25nT

EMI

FCC part 15J class B

After Mass production

under 1dBuv for constant

measure. Besides DNSF

and VCCI class-2 are

optional.

EN55022 class B

Item

Condition

Spec

OK

N.A Remark

MTBF Prediction

Refer to MIL-217F

> 60,000 Hours

Excluding

CCFL

CCFL Life time

At 25±2℃, under 7.0mA

40,000 Hours (min)

See Note-4

3.3.7 EMC

3.3.8 Reliability

Note-4: CCFL lifetime is determined as the time at which brightness of lamp is 50%. The typical lifetime of

CCFL is on the condition at 7.0mA lamp current.

- 13 -

Page 14

3.3.9 Audio performance

Item

Condition

Spec

OK

N.A

Remark

Preamp + Power amp

(1)Output power

1 Wrms/CH @ 1KHz

(2)THD (@ 1W)

<1%

(3)S/N ratio

>40dB

Speaker Driver

(1)Nominal impedance

8 ohm

(2)Rated input power

1 W/CH

(3)Frequency response

500~20KHz SPL-10dB

(4)Output sound pressure

level

80 ± 3 dB (1W 0.5M)

(5)Dimension of box

63x25x13mm2

Audio Control

(1)Volume range

0 ~100 levels

(2)Mute On/Off

Item

Condition

Spec

OK

N.A Remark

LCD Panel Supplier

AUO

Panel type of Supplier

M190PW01 V5

Screen Diagonal

481.33 mm (19”W)

Display area

Unit=mm

408.24(H) x 255.15(V)

Physical Size

Unit=mm

428.0(H) x 278.0(V) x 16.5(D)

Weight

Unit=gram

2250 (typ.)

Technology TN type

Pixel pitch

Unit=um

283.5(H) x 283.5 (W)

Per one triad

Pixel arrangement

R/G/B vertical stripe

Display mode

Normally White

Support color

16.7Millions colors

6 bit + HiFRC

Item

Condition

Spec

OK

N.A Remark

LCD Panel Supplier

LGD

Panel type of Supplier

LM190WX1-TLK1

Screen Diagonal

481.33 mm(19”W)

Display area

Unit=mm

408.24(H) x 255.15(V)

Physical Size

Unit=mm

428.0(H) x 278.0(V) x 16.5(D)

Weight

Unit=gram

1600 (typ.)

Technology TN type

Pixel pitch

Unit=um

283.5(H) x 283.5 (W)

Per one triad

Pixel arrangement

R/G/B vertical stripe

Display mode

Normally White

Support color

16.7Millions colors

6 bit + HiFRC

3.4. LCD Characteristics

3.4.1-1 The Physical definition & Technology summary of LCD panel

AUO M190PW01 V5

LGD LM190WX1-TLP1

SEC LTM190BT03

- 14 -

Page 15

Item

Condition

Spec

OK

N.A Remark

LCD Panel Supplier

SEC

Panel type of Supplier

LTM190BT03

Screen Diagonal

481.33 mm(19”W)

Display area

Unit=mm

408.24(H) x 255.15(V)

Physical Size

Unit=mm

428.0(H) x 278.0(V) x 17.5(D)

Weight

Unit=gram

2550 (typ.)

Technology TN type

Pixel pitch

Unit=um

283.5(H) x 283.5 (W)

Per one triad

Pixel arrangement

R/G/B vertical stripe

Display mode

Normally White

Support color

16.7Millions colors

6 bit + HiFRC

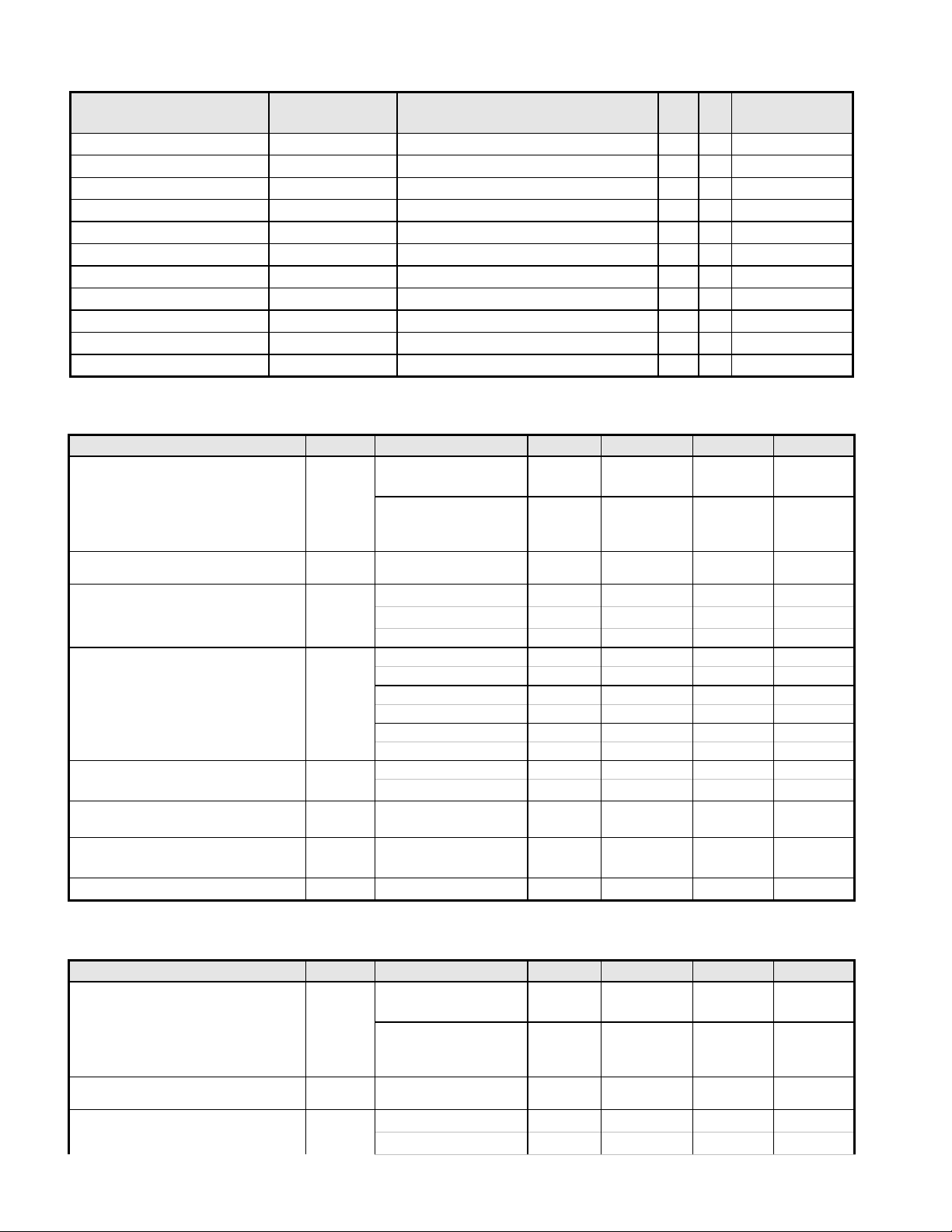

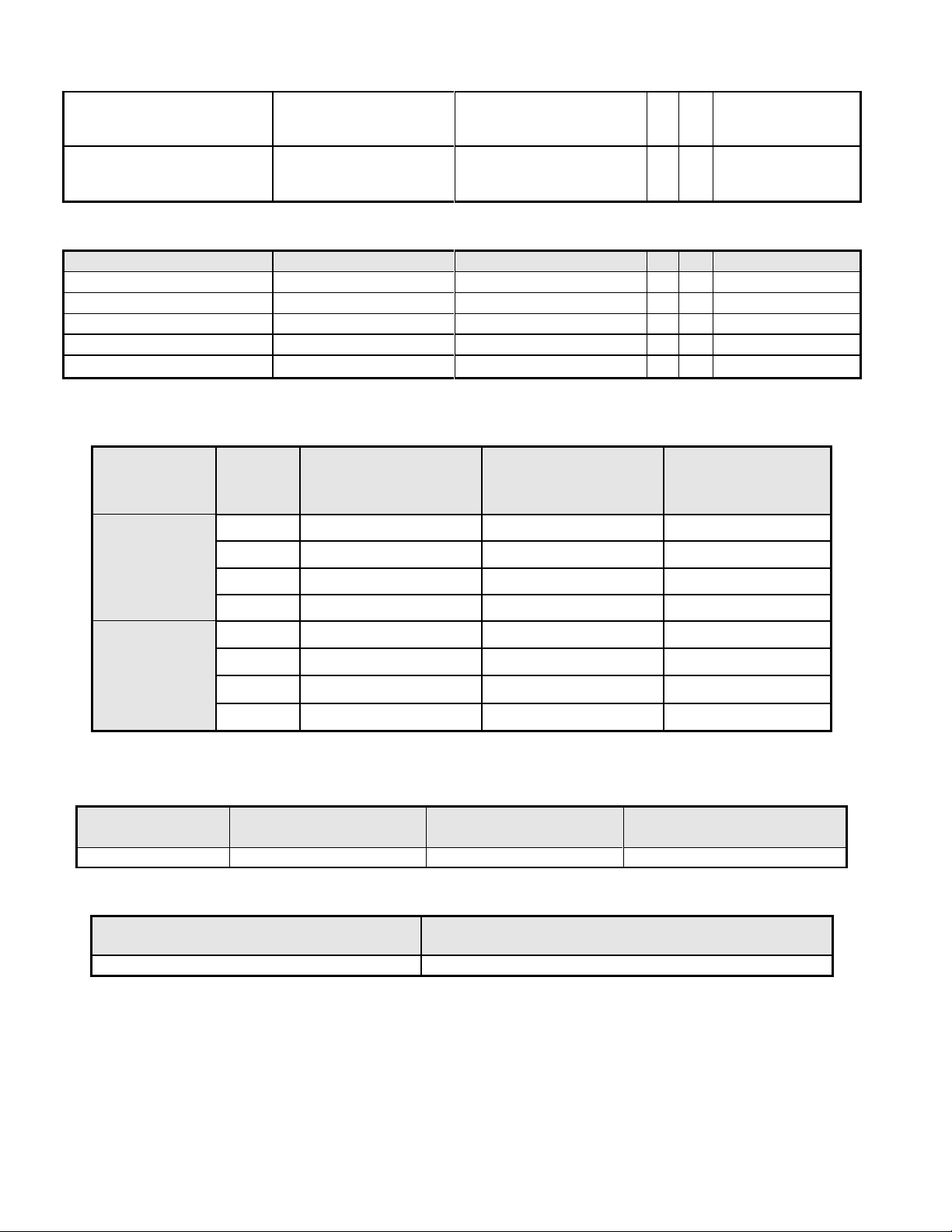

Item

Unit

Conditions

Min.

Typ.

Max.

Remark

Viewing Angle

[degree]

[degree]

Horizontal (Right)

CR = 10 (Left)

75

75

85

85

-

-

[degree]

[degree]

Vertical

(Up)

CR = 10 (Down)

70

70

80

80 - -

Contrast ratio

Normal Direction

600

1000

Response Time

[msec]

Rising Time

-

3.6

5.7

[msec]

Falling Time

-

1.4

2.3

[msec]

Rising + Falling

- 5 8

Color / Chromaticity

Coordinates (CIE)

Red x

0.617

0.647

0.677

Red y

0.308

0.338

0.368

Green x

0.260

0.290

0.320

Green y

0.564

0.594

0.624

Blue x

0.115

0.145

0.175

Blue y

0.037

0.067

0.097

Color Coordinates (CIE)

White

White x

0.283

0.313

0.343

White y

0.299

0.329

0.359

Luminance Uniformity

[%]

9 points

measurement

75

80

White Luminance @ CCFL

7.0mA (center)

[cd/m2]

250

300

-

Crosstalk (in 75Hz)

[%]

1.5

Item

Unit

Conditions

Min.

Typ.

Max.

Remark

Viewing Angle

[degree]

[degree]

Horizontal (Right)

CR = 10 (Left)

75

75

85

85

-

-

[degree]

[degree]

Vertical

(Up)

CR = 10 (Down)

60

70

75

85 - -

Contrast ratio

Normal Direction

700

1000

Response Time

[msec]

Rising Time

-

1.3

2.6

[msec]

Falling Time

-

3.7

7.4

3.4.2-1 Optical characteristics of LCD panel

AUO M190PW01 V5

* The test methods for the above items’ definition, please refer to the relative panel specification.

LGD LM190WX1-TLP1

- 15 -

Page 16

[msec]

Rising + Falling

- 5 10

Color / Chromaticity

Coordinates (CIE)

Red x

0.611

0.641

0.671

Red y

0.305

0.335

0.365

Green x

0.268

0.298

0.328

Green y

0.578

0.608

0.638

Blue x

0.117

0.147

0.177

Blue y

0.040

0.070

0.100

Color Coordinates (CIE)

White

White x

0.283

0.313

0.343

White y

0.299

0.329

0.359

Luminance Uniformity

[%]

9 points

measurement

75

White Luminance @ CCFL

7.0mA (center)

[cd/m2]

250

300

-

Crosstalk (in 75Hz)

[%]

1.5

Item

Unit

Conditions

Min.

Typ.

Max.

Remark

Viewing Angle

[degree]

[degree]

Horizontal (Right)

CR = 10 (Left)

70

70

80

80

-

-

[degree]

[degree]

Vertical

(Up)

CR = 10 (Down)

70

70

80

80 - -

Contrast ratio

Normal Direction

600

1000

Response Time

[msec]

Rising Time

-

1.3

2.6

[msec]

Falling Time

-

3.7

7.4

[msec]

Rising + Falling

- 5 10

Color / Chromaticity

Coordinates (CIE)

Red x

0.610

0.640

0.670

Red y

0.300

0.329

0.360

Green x

0.270

0.300

0.330

Green y

0.570

0.600

0.630

Blue x

0.120

0.150

0.180

Blue y

0.030

0.060

0.090

Color Coordinates (CIE)

White

White x

0.283

0.313

0.343

White y

0.299

0.329

0.359

Luminance Uniformity

[%]

9 points

measurement

75

White Luminance @ CCFL

7.0mA (center)

[cd/m2]

250

300

-

Crosstalk (in 75Hz)

[%]

1.5

SEC LTM190BT03

- 16 -

Page 17

Item

Condition

Spec

OK

N.A

Remark

Power button

Auto button(Exit button)

Right/Inc. button

Left/Dec. button

Menu button

Mode button

Input Select button

E-Key button

Mute button

Item

Condition

Spec

OK

N.A

Remark

Auto Adjust

Auto-Geometry

Brightness

Contrast

Horizontal Position

Vertical Position

Pixel Clock

Phase

Color

Cool(9300K)

Warm(6500K)

User: Separate R/G/B

adjustment

OSD Position

OSD Horizontal position

OSD Vertical position

OSD Time

From 10 sec to 120 sec

OSD Lock

Language

EMEA/Non-EMEA languages

for Asia/Europe Version

Recall

Recall All

Mode

ACER Empower Mode

3.5. User Controls

3.5.1 User’s hardware control definition

3.5.2 OSD control function definition

- 17 -

Page 18

Input Select

D-sub

DVI

HDMI

Wide Mode

Full

Aspect

Sharpness

Display Information

For input timing

Volume

Mute

Hot key for Auto

Hot key for Contrast

Hot key for Volume

Hot key for Input Select

Hot key for Mode

The detailed firmware functions’ specification, please refer to C212 S/W spec. document.

Item

Condition

Spec

OK

N.A

Remark

Bezel opening

410.2*257.11 mm

Monitor without Stand

W x H x D mm

440.24*292.15*65 mm

Monitor with Stand

W x H x D mm

440.24*357.73*161.14mm

Carton Box (outside)

L x W x H mm

506*126*415mm

Tilt and Swivel range

Tilt: -3±1.5 ~ +15 ±1.5

degree

Swivel: None

Item

Condition

Spec

OK

N.A

Remark

Monitor (Net)

4.3Kg

Monitor with packing

(Gross)

5.3Kg

Item

Condition

Spec

OK

N.A

Remark

Flammability

>ABS<,94-HB

Heat deflection To

ABS

65 ℃

UV stability

ABS

Delta E < 8.0

Resin

1.BEZEL/BASE: ABS

:

3.6. Mechanical Characteristics

3.6.1 Dimension

3.6.2 Weight

3.6.3 Plastic

- 18 -

Page 19

Texture

Uc: AT-IM-D02;

Bezel: AT-IM-D01

Base: AT-IM-D02

Color

BEZEL : DB27A;

UC: DB27A

Base : DB27A

Item

Condition

Spec

OK

N.A

Remark

Color

Kraft

Material

B Flute

Compression strength

200KGF

Burst Strength

14 KGF/cm2

Stacked quantity

5 Layers Vertical

Stowing Type

ontainer

Quantity of products

(sets)

(Every container)

Quantity of Products

(sets)

(Every Pallet)

Quantity of pallet

(sets)

(Every Container)

With pallet

20'

900

Pallet A: 90

Pallet A: 10

Pallet B:

Pallet B:

40'

1980

Pallet A: 90

Pallet A: 22

Pallet B:

Pallet B:

Without pallet

20'

X X

X X

40'

X X

X X

Net Weight (Kg)

Gross Weight (Kg)

Dimension w/o Base

W*H*D (mm)

Dimension w/ Base

W*H*D (mm)

4.3Kg

5.3Kg

440.24*292.15*65 mm

440.24*357.73*161.14mm

Carton Interior Dimension (mm)

L*W*H

Carton External Dimension (mm)

L*W*H

498*114*400mm

506*126*415 mm

3.6.4 Carton

3.7. Pallet & Shipment

3.7.1 Container Specification

3.7.2 Carton Specification

3.7.2.1 Product:

3.7.2.2 Package:

- 19 -

Page 20

3.8. Certification

Item

Condition

Spec

OK

N.A

Remark

Environment

Green design

API Doc. 715-C49

ISO14000

Requirement

Blue Angel

German Standard

E-2000

Switzerland

EPA

USA Standard

TCO’99

TCO’03

MPR2

Green Mark

PC-Monitor

Microsoft Windows

PC98/99

DPMS

VESA

DDC 2B

Version 1.3

USB

External

Safety

UL (USA)

UL60950 3rd edition

CSA (Canada)

CAN/CSA-C22.2 No.

60950

Nordic / D.N.S.F

EN60950

FIMKO

EN60950

CE Mark

73/23/EEC

CB

IEC60950

CB

EN60950

TUV/GS

EN60950 /

EK1-ITB 2000:2003

CCC (China)

CB4943

GOST

EN60950

TUV type-approved

SASO

IEC60950

EMC

CE Mark

89/336/EEC

FCC (USA)

FCC Part 15 B

EN55022

Class B

CISPR 22

Class B

VCCI (Japan)

VCCI Class B

BSMI (Taiwan)

CNS 13438

C-Tick (Australia)

AS/ NZS CISPR22

X- Ray Requirement

DHHS (21 CFR)

USA X- Ray Standard

DNHW

PTB

German X- Ray

standard

Ergonomics

TUV / Ergo

ISO 13406-2

prEN50279

- 20 -

Page 21

3.9 Packing

- 21 -

Page 22

4. Disassembly /Assembly

4.1. Exploded View

- 22 -

Page 23

- 23 -

Page 24

ite

m

picture

Operation

Tool

Notes

1

Stick the big Al tape to

panel which can protect

the Light-wire.

The tape must cover

the connect of the

wire

2

Check and put CLM-F on

the cushion carefully,

3

Assembly the Ctrl board

to CLM-F.

4.2. Disassembly /Assembly

Assembly Procedure

Preparation before assemble

1.Clean the room for work

2.Identify the area for material

3.Prepare the implement, equipments, materials as bellow:

1.) Press-fixture

2.) working table

3.) Screw-driver

4.) knife*1

5.) glove

6.) cleaning cloth

7.) ESD protection

- 24 -

Page 25

4

Assemble the C/B with

screws*3

Screw-driver

5

Assemble the panel on

CLM-F.

Go to with Left.

6

Tear down the two tape

behind the FFC and fix

the FFC of C/B to panel

The FFC must be

affixed besides the

under edge of the

panel

7

Assemble the SPK to the

main-SHD, the correct

position reference on the

picture, then the lock 4

screws to fasten it.

Screw-driver

8

Assemble the FFC to the

I/F, the correct position

reference on the picture

Without the gap within

1

2

3

- 25 -

Page 26

9

Assemble the PCBA to

Main-SHD

10

Lock 3 screws on the

PCBA board with this

order.

Screw-driver

11

Lock 2 screws on the SPS

board with order.

Screw-driver

12 Scan for fooling

PC

Card go with panel.

13

Fasten the LVDS to panel

and fix the Main-BKT to

CLM-F

The BKT must fixed

into the clip of the BZL

1

接地螺丝

- 26 -

Page 27

14

Stick two Al foils on the

right and under between

pane land Main-BTK

Stick an Al foils on the up

between panel and MainBTK

16

Lock screws of side on

Main-Chassis with

2/4,based on DVI.

Attention the order by

one to four.

17

Assemble the L-SHD the

correct position reference

on the picture

3

4

1

2

- 27 -

Page 28

18

Insect the inverter wire

one by one and insect the

speaker wire

Keep all wires in.

19

Insert the FFC cable of

control board into the

connector of I/F board

Keep the mark in.

20

Stick two taps to fix the

speaker wire

The tap must not stick

to the part of the IF

22

Stick an acetic tape to fix

the wire one by one as the

picture for SEC panel

- 28 -

Page 29

23

Fix the big Al tape to

panel

24

Check and put CLM-F on

the Main-Chassis

carefully.

None hurt outside.

25 Assemble the Rear Cover.

26

Check and put CLM-F-abs

on working table the

carefully.

- 29 -

Page 30

27

Lock 3 screws inside the

hinge

Screw-driver

28 Lock 4 screws to RC.

(FABF-DSSDA1***)

60-80mm

#2

9±1kg.cm

29 Cover the CLM of L and R

- 30 -

Page 31

Disassembly Procedure

ite

m

picture

Operation

Tool

Notes

1

Disassemble the stand

4 screws

Screw-driver

Kick the board first.

2

disassembly the bezel

from the monitor, notice

the disassembly order :

1.Left (1) parts of bezel

2.Top (2) parts of bezel

3.Bottom (3) parts of

bezel

4. Right (4) parts of bezel

Don’t draw the BZL

When disassembly

the bezel ,notice don’t

bend the C/B .man

must wear glove

The purpose is loose

the BZL

Preparation before disassemble

1.Clean the room for disassemble

2.Identify the area for monitor

3.Check the position that the monitors be placed and the quantity of the monitor ;prepare the area for material

flow; according to the actual condition plan the disassemble layout

4.Prepare the implement, equipments, materials as bellow:

1)Press-fixture

2)working table

3)Screw-driver

4)knife*1

5)glove

6)cleaning cloth

7)ESD protection

- 31 -

Page 32

3

Turn over the

monitor ,dismantle the

Rear cover from the

monitor

4 Tear out the acetic tape

5

Unlock the wires.

6

Disassembled the SHD

shielding : 5 screw

Screw-driver

3

4 1 2

- 32 -

Page 33

7

Tear down three pieces of

Al foil

8

Tear down the Mylar and

the tap

9

Disassembled the AC-soc

shielding .

10 Unlock the LVDS wires.

- 33 -

Page 34

11

Disassembled the PCBA

shielding : 5 screws

Screw-driver

12

Disassembled the SPK

shielding : 4 screws

Screw-driver

13

Get off the panel from the

bezel

14

Get off the big tap from

the tape

15

Disassemble the control

board

Screw-driver

- 34 -

Page 35

Mode

Resolution

(active dot)

Resolution

(total dot)

Horizontal

Frequency (KHz)

Vertical

Frequency (Hz)

Nominal Pixel

Clock (MHz)

640x480@60Hz

800 x 525

31.469

59.941

25.175

640x480@72Hz

832 x 520

37.861

72.809

31.500

640x480@75Hz

840 x 500

37.500

75.000

31.500

MAC

640x480@66.66Hz

864x525

35

66.66

30.24

VESA

720x400@70Hz

900x449

31.469

70.087

28.322

SVGA

800x600@56Hz

1024 x 625

35.156

56.250

36.000

800x600@60Hz

1056 x 628

37.879

60.317

40.000

800x600@72Hz

1040 x 666

48.077

72.188

50.000

800x600@75Hz

1056x625

46.875

75.000

49.500

MAC

832x624@74.55Hz

1152x667

49.722

74.55

57.28

XGA

1024x768@60Hz

1344x806

48.363

60.004

65.000

1024x768@70Hz

1328x806

56.476

70.069

75.000

1024x768@75Hz

1312x800

60.023

75.029

78.750

5. Level 1 Cosmetic / Appearance / Alignment Service

5.1 Alignment procedure (for function adjustment)

5.1.1 Preparation:

1.) Setup input timing to any preset modes or patterns.

2.) Enter factory mode (press “Empowering” & “Power” buttons at the same time to turn on monitor).

3.) Move cursor into “Burn-in Mode” tag and select “On” to enable burn-in mode.

4.) Power off the monitor, remove the input source and then power on again.

5.) Setup unit and keep it warm up for at least 30 minutes.

6.) Setup input timing ICL-605( 1280x1024@75Hz ), 32-Grays pattern.

7.) Setup unit and keep it warm up at least 30 minutes.

5.1.2 Timing adjustment: (Analog only, it is not required for DVI-D input source)

1.) Enter factory setting area (press “Empowering” and then press “SOFTPOWER”).

2.) Check the settings to following values:

Contrast = 50

Brightness = 85

Color = Warm

Language = English

Then, turn off the monitor power.

3.) Turn on power enter user area.

Figure-1: Preset Timing modes list

- 35 -

Page 36

MAC

1152x870@75Hz

1456x915

68.681

75.062

100.000

VESA

1152x864@75Hz

1600x900

67.5

75

108

1280x960@60Hz

1800x1000

60

60

108

SXGA

1280x1024@60Hz

1688x1066

63.981

60.020

108.000

1280x1024@75Hz

1688x1066

79.976

75.025

135.000

VESA

1280x720@60Hz

1650x750

44.955

59.940

74.176

WXGA

1280x800@60Hz

1680x831

49.702

59.810

83.500

1360x768@60Hz

1792x795

47.712

60.015

85.500

WXGA+

1440x900@60Hz

1904x931

55.935

59.887

106.500

1440x900@75Hz

1936x942

70.635

75.000

136.750

Note:

1. Show “Input Not Supported” warning message.

When Vertical Frequency is over 76Hz or under 56Hz, the display is Black and showing “Input Not

Supported” warning message. (Some video timings are except for PAL, 50Hz signals.)

2. If Hf /Vf is set in the range of 31KHz~83KHz and 56Hz ~76Hz (not including some video timing), and

Pixel Clock is set in the range of 25.175MHz~173MHz(DVI and HDMI input port 165MHz for SingleLink), but is not the above Resolution, then it will display the nearest mode.

5.1.3 ADC calibration (Auto color balance adjustment)

~~Analog only, it is not required for DVI-D input source

1. Setup input timing ICL-605( 1280x1024@75Hz ), pattern 42(5-Mosaic pattern with white color block)

with Analog signals from Chroma video pattern generator. (it depends on Scaler IC supplier’s

recommendation)

2. Enter factory mode (press “Empowering” & “Power” buttons at the same time to turn on monitor).

3. Move cursor into “Burn-in Mode” tag and select “On” to enable burn-in mode.

4. Close OSD menu then press “Auto” button for auto color adjustment. (This procedure will get optimal

gain/offset(clamp) values)

5. Checking if the picture is ok, or reject this monitor and check its circuit board or wire/cable connection.

5.1.4 Color temperature adjustment

Chroma video pattern generator.

each color temperature, C0/Cool, C1/User & C2/Warm to meet following spec requirement, the 1st method is by

using external PC and IIC alignment protocol to do automatic adjustment, and the 2nd method is by manually

and must be in factory mode.

- 36 -

1. Setup input timing to any preset modes, pattern 41(full white color pattern) with Analog signals from

2. Enter factory mode (press “Empowering” & “Power” buttons at the same time to turn on monitor).

3. Move cursor into “Burn-in Mode” tag and select “On” to enable burn-in mode.

4. Make sure ADC calibration (auto color balance adjustment) had already been done.

5. Measure color temperature by Minolta CA-110 (or equivalent equipment).

6. Adjust the color temperature ~~ Two methods can be used to adjust RED, GREEN, BLUE value of

Page 37

Color temperature

(C0/cool on OSD)

X+-

0.283+(-) 0.03

Y+-

0.297+(-) 0.03

Luminance

> 180 cd/m²

Color temperature

(C2/Warm on OSD)

X+-

0.313+(-) 0.03

Y+-

0.329+(-) 0.03

Luminance

> 220 cd/m²

Color temperature

(C1/User on OSD)

X+-

Y+-

Luminance

7. Move cursor into “Burn-in Mode” tag and select “No” to disable burn-in mode.

8. Turns off the monitor power.

5.1.5. Writing EDID data into monitor

1. Setup a PC with DDC card.

2. Connect PC to monitor with a D-sub signal cable.

3. Please refer to the Q212 for the correct EDID file.

4. Runs the writing program to write the analog EDID data into EEPROM for analog input(ie. 15-pin D-

sub).

5. Repeat step 4 and write the digital EDID data into EEPROM for DVI-D input(ie. 24-pin DVI-D).

6. Read both EEPROM data and confirm it to match with the C212 definition.

(Note : The DVI-D input may not operation correctly if the digital EDID data do not exist.)

- 37 -

Page 38

Connect to target monitor

VGA signal input from 15pin D-sub

cable of PC or NB.

Connect ISP board and PC

with printer port cable

Check the Jumpers on the

ISP Circuit Board (make sure

J5, J6, J7, J8 are set at ping

1,2 )

5.2 Software / Firmware Upgrade Process

5.2.1 Hardware prepared:

Hardware Requirement:

1. ISP board x 1

2. DSUB VGA cables x 2

3. Printer cable (with one male connector and another female connector) x 1.

4. PC or Notebook with parallel (printer) port x1.

- 38 -

Page 39

5.2.2 Firmware Upgrade Procedure

Step 1:

Un-zip Port95nt and install into your computer.

Step 2:

Un-zip ISP application tool (RTDTool)

Step 3:

Press “RTD 2120 ISP” button to execute firmware program application.

- 39 -

Page 40

Step 4:

Press “64K” button to load *series*.hex file and press “64~96” button to load *extend*.hex file from your

computer.

Step 5:

Select “Erase” option and execute lightning button first, and then select “Auto” option and execute

lightning button to start upgrade firmware to the monitor.

- 40 -

Page 41

Note: you can change program speed bar to meet your equipment speed if program firmware fail.

ENTER and RIGHT to Burn In Off

5.2.3 Turn Off Burn In

IF the monitor without signal input has Burn In pattern. As the following figure

Press “MENU” and “>” key at the same time to exit Burn in mode(factory mode),and soft power key off/on

restart the monitor.

- 41 -

Page 42

5.2.4 Setup the OSD for Panels

1. Press the OSD setting

2. Choose “On” in Burn In

4. Choose “AUO” in Panel Type, and press Enter.

5. Check OSD to make sure the panel type is

match with your panel.

3. Choose “Panel Type” to press Enter.

- 42 -

Page 43

5.3 EDID Upgrade Procedure

Step 1:

Run the program “Q-EDID-V012.exe”, when the UI popped up

- 43 -

Page 44

Note: If “VGA” choose 128bytes, and “HDMI” choose 256bytes

Step 2:

Click “Open File” and select “VGA” or “HDMI” EDID file

- 44 -

Page 45

Step 3:

If load file is successful, it shows “Open EDID Table OK..”.

And then, Click “Write EDID” button to update EDID

v

Step 4:

If write EDID is successful, it shows”Write EDID OK …”

- 45 -

Page 46

And then, Click “Read EDID” button to check if successful or not.

Step 5:

If read EDID is successful, it shows”Read EDID OK …”

- 46 -

Page 47

- 47 -

Page 48

5.4 OSD Operation Guide

- 48 -

Page 49

- 49 -

Page 50

- 50 -

Page 51

- 51 -

Page 52

- 52 -

Page 53

OSD shown when key pressed?

No

Yes

Follow instructions from OSD dialog

Keypad OK?

Yes

No

Screen is Blank and

Power LED is White.

Backlight turned

ON?

Scalar output

Data ?

Yes

Proceed to

“Check Power Board”.

No

Yes

“Check LCD Module”

No

Proceed to

“Check Scalar”

Proceed to

“Check Control Board”.

6. Level 2 Circuit Board and Standard Parts Replacement

6.1. Trouble Shooting Guide

1. No Display or display is unstable (Interface Board):

- 53 -

Page 54

Checking Contorl

Board

Working ?

Yes

Yes

No

Re-plug the control

wire, then retry

Traces

OK ?

No

Replace the Control

Board, then retry

Components to

Control board OK ?

Yes

No

Replace the

components, then retry

Replace a new Control

board

Yes

2. Check Control Board

- 54 -

Page 55

3 Check Scalar

A r e a l l t h e p ow er a n d

g ro u nd p i n s a t t h e c o rre ct

v o l t a g e le v el?

A r e t h e c o rre ct R GB a n d

H s yn c si g na l fe d to

S c a l a r ?

S c a la r f a il e d

to o u tp u t d a t a

Y E S

Y E S

NO

NO

C ap ac i to rs o f C ry sta l

h a v e d a m ag e d

C h e ck t h e re m ain i n g

circ u its

M ea s u re t h e s ig n a l p a i r s

o n L VD S d a t a o u tp u t a n d

clo ck f r o m S c alar

Is t h e c o rre ct S in u s o id a l

w a ve a p p ea r e d on C ry s ta l

Y E S

A r e t h e p i x el o ut p u t

co r r e c t ?

A r e t h e s i g n als p re s e n ted

o n D Su b c o nn e c t o r?

S c a la r f a il e d

P o w er o r t h e g ro u n d p i n s

h a s b a d c o n ta cts

D S U B C on n e c to r o r

P C fa i lu re

B ad w irin g b e tw ee n

D S U B a n d S ca l a r

NO

NO

Y E S

Y E S

NO

- 55 -

Page 56

LC D m od ule fail

To d isplay

im a ge

W h ite ScreenNo P icture

NO

NO

YES

Ba d C onn ection

or con necto r,

LV D S cable

NO

LC M failed

Ba d C onn ection

or con necto r,

LV D S cable

Ba d C onn ection

or con necto r,

YES

YES

YES

NO

OK

?

YES

NO

LC D m od ule fail

To d isplay

im a ge

Con n ection betw e e n

LV DS cable a n d

LC M con n ec to r

OK ?

W h ite ScreenNo P icture

Lam p connector O K ?

NO

NO

YES

Con n ection betw e e n

LV DS cable a n d

LV DS conn e c to r

OK?

Ba d C onn ection

or con necto r,

LV D S cable

NO

Ba d C onn ection

or con necto r,

LV D S cable

Ba d C onn ection

or con necto r,

YES

YES

YES

NO

La m p w ir e

Inverter boa rd

fa iled

YES

NO

Is Q 6 5V ? Ch eck Q 6

1.1.1 Che

ck

Is U7 5V?

4 Check LCD Module

- 56 -

Page 57

5 Power Board no work troubleshooting:

No Backlight

V-inverter ok? No

Check

D703/D704

OK?

No

Yes

Replace D703/D704No

Check F601,

Q601, R615 OK?

Yes

Replace F601,

Q601, R615.

No

Reaplce IC601

Yes

+5V ok?

Yes

Check CN701 pin2

(BL-ON) is Hi?

Yes

Check CN701 pin1

(BRT-ADJ) exist?

Yes

Check I/F BD

Yes

Replace IC801 No

Yes

Replace Q808,

Q810, T801, T802.

No

Check Panel

Yes

No

No

Check

D701/D702

OK?

Replace D701/D702

No

Check Q808, Q810,

T801, T802 OK?

Check IC801

OK?

- 57 -

Page 58

6 Audio Function:

Was Audio Input

plugged?

Yes

Return Power

Function Step.

No Yes

Was Audio VDD

existed?

Audio do not work

No

Check VOL_ON

Yes

Check VOL_ADJ

Plug Audio input.

No

Check MCU send

VOL_ON control

signal or not.

No

Adjust volume

control switch to

normal.

Yes

Was CN551

plugged?

NoPlug CN551

Yes

Was Speaker

plugged?

NoPlug Speaker.

Yes

Replace IC551.

- 58 -

Page 59

6.2 Circuit Operation Theory

I. Introduction:

V193W is a 19 inch and 24bits color TFT LCD monitor, which can support the resolution up to 1280 x 1024. It

has VGA input and compliant with VESA specification to offer a smart power management. The monitor has

DDC/CI function to make the monitor communicate with PC by Acer ADM DDC/CI software, and also it has

ACM function to let the monitor contrast ratio up to 10000:1. It also offers OSD Menu for users to control the

adjustable items and get some information about this monitor.

II. Block diagram

V193W consists of a main body and a stand (base). The main body contains a AUO/ LGD TFT LCD

module with 2 CCFL lamps, a power board (includes AC/DC、 DC/DC、 inverter and panel power

source), a control board and an interface board. The block diagram is shown as below.

Fig. Block diagram for V193W LCD monitor

- 59 -

Page 60

III. Circuit Implementations:

A.) THE MAIN BODY:

A-1.) Interface board block diagram:

(a) Circuit operations:

The scaling IC has OSD and auto detecting input timing functions. OSD offers adjustable

functions to the end-users. Auto detecting timing function can detect change modes. It outputs the

digital R-G-B data, pixel clock and control signal to TCON of the LCD module. A MCU, build in

scaling IC (Realtek2525LH), is responsible for the system processing. There are two external

storing units, one is 24C16 to store the OSD function data and user preset timings.

(b) IC introduction:

1.) Realtek2525LH SCALER IC:

Realtek2525LH series products are all-in-one LCD monitor controller with analog (RGB), DVI and video

inputs, supporting UXGA/ WXSGA+WXGA+/SXGA,and integrate Realtek high performance ADC,scaling

engine,LVDS Tx,and so on.Moreover,all products are pin compatible in QFN 48-pin package to save cost and

make the design easier. The RTD also includes an ITU656 video format input port with color space converter

that makes it an attractive solution for low cost MFM and TV applications. The output section contains a 24-bit

TTL output interface and a channel LVDS transmitter for direct interfacing of commercially available LVDS LCD

panel modules. In addition, RTD2525LH embedded 16.5KSRAM dynamically stores OSD command and fonts,

- 60 -

Page 61

compatible advanced color control features.

EM I F ilter

Rectifier an d

filter

Isolatio n

pow e r

transform er

Rectifier an d

filter

In verter circu it

PW M contrller

Sw itching

elem en t

Audio circu it

Fee dback

Isolatio n

Rectifier an d

filter

LD O reg ulator

2.) EEPROM:

We use 24C16 EEPROM to store monitor user data and user preset timings. There are 16 user timing

modes are automatically saved in it. Each timing mode is allocated with 22 bytes of memory space for

information such as Sync frequencies, polarities… etc. PC can access the EEPROM data indirectly through the

SDA and SCL channels of DVI and D-sub (IIC communication). The digital and analog DDC data are stored in

two 24C02s EEPROM.

A-2.) Power board diagram:

Fig.1

- 61 -

Page 62

Picture

CATEGORY

DESCRIPTION

ACER PART NO.

LCD

LCDM19W

M190EG02-V7 P/G

AUO

LK.19005.035

Board

BOARD

PCBA IF BD A+S AU

MI V193W

55.LHV0Q.001

BOARD

PCBA SPS BD AUDIO

MI V193W

19.LHV0Q.001

BOARD

PCBA CTRL BD MI

V193W

55.LHV0Q.002

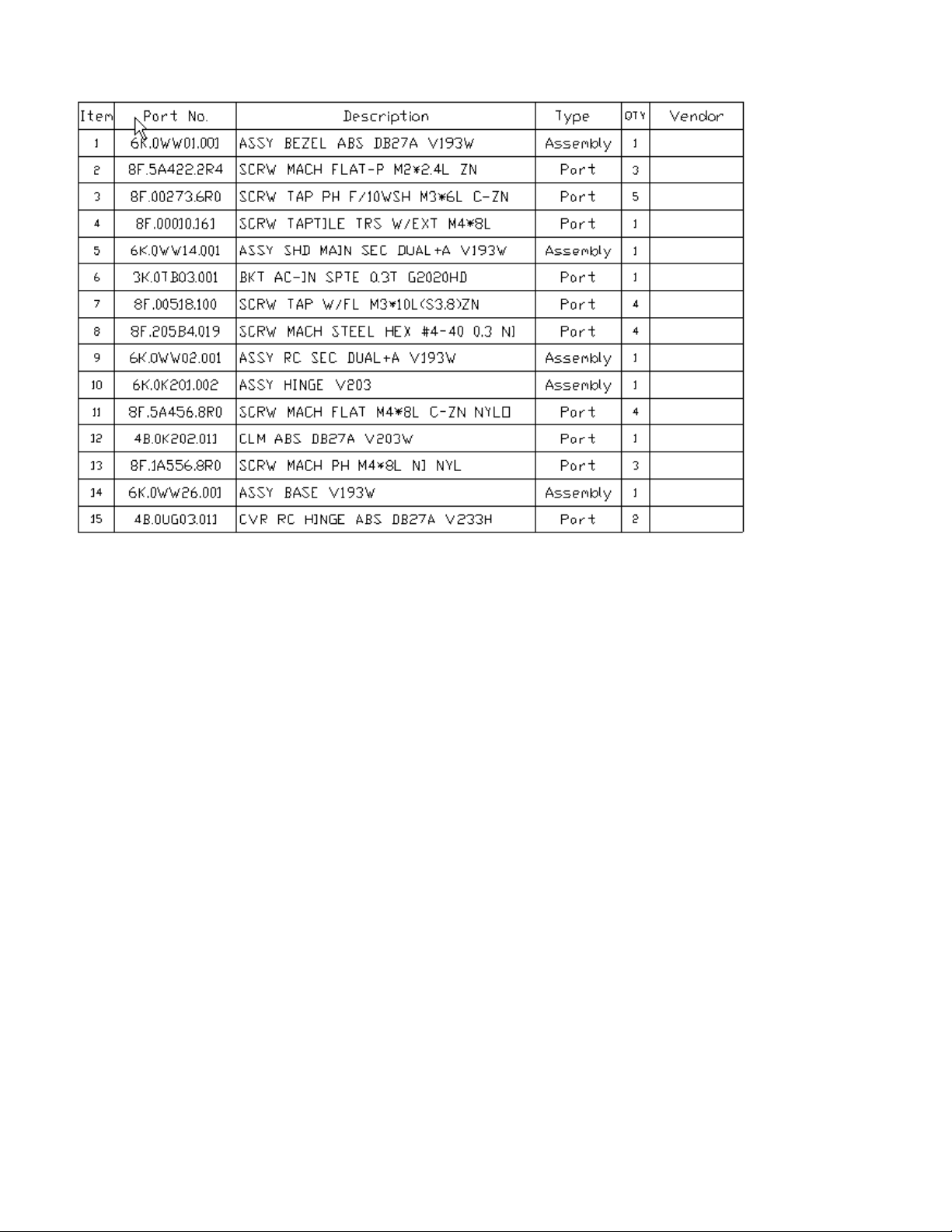

6.3 Spare Parts List

- 62 -

Page 63

Cable

CABLE

CORD SVT125V

WO/SH1.8M US DELL

27.LBJ0Q.001

CABLE

WIRE 10/11P 90MM

B173

50.LE10Q.001

CABLE

FFC LVDS 30P NO

SILVER 220SW9

50.LHV0Q.001

CABLE

FFC WIRE 7P CTRL

BD V193W

50.LHV0Q.002

CABLE

CABLE SIGNAL/C

H+V OD_5.5 1.8M

50.LBJ0Q.002

- 63 -

Page 64

Assembly

CASE/COVER/BRA

CKET ASSEMBLY

ASSY BASE W/P ANA

DB27A V203W

60.LHV0Q.004

CASE/COVER/BRA

CKET ASSEMBLY

ASSY RC ABS DB27A

DSUB+AUD AUO

60.LHV0Q.003

CASE/COVER/BRA

CKET ASSEMBLY

ASSY CLM DB27A

V193W

60.LHV0Q.001

CASE/COVER/BRA

CKET ASSEMBLY

ASSY BZL ABS

DB27A V193

60.LHV0Q.002

- 64 -

Page 65

ITEM

P/N

DESCRIPTION

MOUNTING

MATERIAL

TORQUE

(KG-CM)

HOLE SIZE

(MM)

Screw

Head

1

8F.205B4.019

SCRW MACH HEX #4-40*0.3" NI

METAL

5.0±0.6

#4-40

X

2

8F.5A224.5R0

SCRW MACH FLAT M3*5L ZN

METAL

Side mount:3±0.6

Other: 4±0.6

M3*0.5

#2

3

8F.XA356.6R0

SCRW TAP FLAT M4*6L B-ZN NYL

METAL

9.0±1.0

M4*0.7

#2

4

8F.8A356.100

SCREW MACH FPH M4*10L B-ZN

NYL

METAL

11.0±1.0

M4*0.7

#2

5

8F.5A356.8R0

SCRW MACH FH M4*8L B-ZN NYL

METAL

9.0±1.0

M4*0.7

#2

6

6K.L7204.001

ASSY SCREW M4*10L FP527

METAL

11.0±1.0

M4*0.7

#2

7

6K.L8810.001

ASSY SCREW M4*8L FP726A NLK

ISU

METAL

9.0±1.0

M4*0.7

#2

9

6K.L8811.001

ASSY SCREW M4*6 FP726A NLK

ISU

(8F.5A456.6R0+4B.L7212.001)

METAL

9.0±1.0

M4*0.7

#2

10

8F.5A422.2R4

SCRW MACH FLAT-P M2*2.4L ZN

Plastic

1.0±0.1

1.4±0.05

#1

11

8F.VA512.4R0

SCRW TAP PH M2*4L NI

Plastic

1.0±0.2

1.6±0.05

#1

12

8F.XA213.8R0

SCRW TAP FLAT/PT M2.5*8L ZN

Plastic

4.0±0.5

2.0±0.05

#1

13

8F.WA314.8R0

SCRW TAP CAP M3*1.34P*8L B-ZN

PLASTIC

5.0±1.0

2.35±0.05

#2

14

8F.XA524.6R0

SCRW TAP FLT M3*6L NI

PLASTIC

4.5±0.5

2.35±0.05

#2

15

8F.XA314.8R0

SCRW TAP FLAT M3*1.34P*8L B-ZN

PLASTIC

4.5±0.5

2.35±0.05

#2

16

8F.XA326.100

SCRW TAP FLAT M4*10L B-ZN

Plastic

7.5±0.5

3.4±0.05

#2

17

8F.MA224.5R5

SCRW TAP FLAT-P M3*5.5L ZN

Metal

None tread:8

~

10

Have tread:6~8

Aluminum:4~5

2.68±0.03

#2

18

8F.MA324.5R5

SCRW TAP FLAT-P M3*5.5L B-ZN

Metal

None tread:8

~

10

Have tread:

5.0±1.0

Aluminum:4~5

2.68±0.03

#2

19

8F.00273.6R0

SCRW TAP PH F/10WSH M3*6L CZN

Metal

None tread:8

~

10

Have tread:6~8

Aluminum:4~5

2.68±0.03

#2

20

8F.VZ526.6R0

SCRW TAP FLAT+EXTM4*6L ZN-W

Metal

10±1.0

M4*0.7

#2

21

8F.00007.144

SCREW TAP CAP #4-40*10 ZN

Aluminum

3.3±0.3

2.6±0.03

#2

Appendix 1 – Screw List / Torque

(A)

STANDARD SCREW TORQUE SPEC.

- 65 -

Page 66

ITEM

P/N

DESCRIPTION

MOUNTING

MATERIAL

TORQUE

(KG-CM)

HOLE SIZE

(MM)

Screw

Head

1

8F.00274.8R0

SCREW FPH TAP M3*8L NI

Plastic

5.0±1.0

2.35±0.05

#2

2

8F.00003.143

SCRW TAP PAN #4-40*3/8

Aluminum

3.3±0.3

2.6±0.03

#2

3

8F.VG434.4R0

SCRW TAP PAN F/WSH M3*4L C-ZN

METAL

No thread:8~10

Have thread:6~8

Aluminum:4~5

2.68±0.03

#2

4

8F.1A356.100

SCRW MACH PAN M4*10L B-ZN NYLO

Metal

11.0±1.0

M4*0.7

#2

5

6K.L1G06.001

ASSY SCRW M4*12L L1740

METAL

11.0±1.0

M4*0.7

#2

6

8F.5A356.120

SCRW MACH FHM4*12L B-ZN NYL

METAL

11.0±1.0

M4*0.7

#2

7

8F.PA526.8R0

SCREW TAP PAN M4*8L NI

PLASTIC

7.5±0.5

3.4±0.05

#2

8

8F.5A554.5R0

SCRW MACH FLAT M3*0.5P*5L NI N

METAL

Side mount:3±0.6

Other: 4±0.6

M3*0.5

#2

9

8F.GA224.8R0

SCRW TAP CAP M3*8L Zn

Metal

4±0.6

M3*0.5

#2

10

8F.00518.100

SCRW TAP W/FL M3*8L (S3.8) ZN

Metal

4±0.6

2.65±0.05

#2

1

1

8F.00524.8R0

SCRW M FH M4*8L(D7.5)B-ZN NYL

P

L

A

S

T

I

C

1

1

±

0

.

6

M

4

*

0

.

7

#

2

1

2

8F.5A224.6R0

SCRW MACH FLAT M3*0.5P*6L ZN

M

e

t

a

l

4±0.6

M3*0.5

#

2

13

8F.MA524.4R0

SCRW TAP FPH M3*4L(6/0.8) NI

Metal

5±0.5

2.65±0.05

#2

14

8F.VZ524.6R0

SCRW TAP FLAT+EXT M3*6L C-ZN

Metal

7±1.0

M3

#2

15

8F.5A456.8R0

SCRW MACH FH M4*8L B-ZN NYL

METAL

9.0±1.0

M4*0.7

#2

16

8F.1A556.8R0

SCRW MACH PH M4*8L NI NYL

METAL

9.0±1.0

M4*0.7

#2

17

8F.00010.161

SCRW TAPTILE TRS W/EXT M4*8L

Metal

9±1.0

M4*0.7

#2

*SCREW Q’TYPE AND POSITION

REFERRED TO C328.

*NOTES:

1. (A)STANDARD SCREW TORQUE SPEC.

2. (B)SPECIAL SCREW TORQUE SPEC.

3. T: TAPPING SCREW.

4. M: MACHING SCREW.

D-SUB Connector

SCREW TORQUE SPEC.

DVI Connector

SCREW TORQUE SPEC.

(B)

SPECIAL SCREW TORQUE SPEC.

- 66 -

Page 67

SCREW TORQUE: 3± 0.5 (KGCM)

SCREW TORQUE : 3± 0.5(KGCM)

SCREW D-SUB

SCREW DVI

- 67 -

Page 68

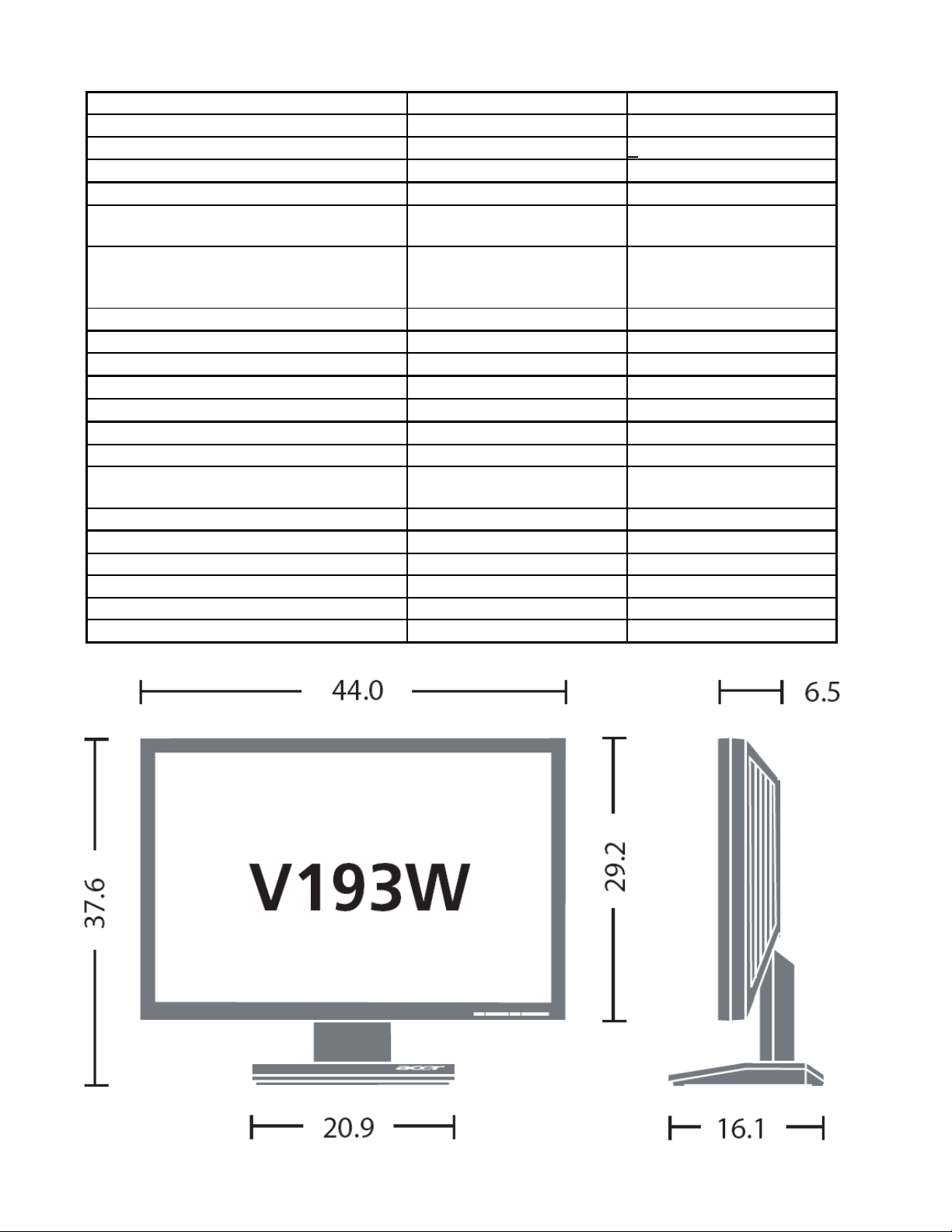

Appendix 2 – Physical Dimension Front View and Side view

Fig. 1 Physical Dimension Front View and Side view

- 68 -

Page 69

Appendix 3 – Control Board

- 69 -

Page 70

5

4

3

2

1

ED ID_VC C

D D

C8

0. 1U Z

C C

SDA_A

SCL_A

B B

+3.3V PC5V

DN 4

BAV70

A1

A2

J

U1

1

2

3

4

A0

VCC

A1

WP

A2

SCL

GND

SDA

AT2 4C02 N-10SU-1.8

NC 10K J

8

7

6

5

R30 5

2N3904S

Q9

R5

12K J

C16

47P J

ED ID_VC C

R67

10K

E C

D1

BZV 55C6V2

A K

R6

12K J

R12

150 J

R11

150 J

D2

C17

47P J

PZU6 .2B2

R68

10K

R69

B

A_D etect

20K J

PZU6 .2B2

A K

D3

A K

D4

PZU6 .2B2

PZU6 .2B2

R100 0 J

A K

TP41

TP42

TP43

D5

A K

TP44

R19

10K J

R20

10K J

T65

J1

G1G2

6

1

11

7

2

12

8

3

13

14

15

R17

100 J

R18

100 J

D-s ub 15

TP58

9

4

10

5

C21

22P J

C20

12P J

TP40

TP62

TP63

TP64

A_D etect

TP59

TP38

TP60

TP39

TP61

A_D etect

HS1

R1

75 J

L1

R1+

+3.3V

K

DN1

C1

J

BAV99

0. 1U Z

A

R2

75 J

VS1

G1+

+3.3V

K

DN2

C2

J

BAV99

0. 1U Z

A

R3

75 J

B1+

+3.3V

K

DN3

C3

J

BAV99

0. 1U Z

A

Z60

L2

Z60

L3

Z60

C5

4.7 P C

C6

4.7 P C

C7

4.7 P C

R4

100 J

R9

56 J

R10

100 J

R13

56 J

R14

100 J

R15

56 J

C9 0. 047U 16V

C11 0.0 47U 16V

C12 0.0 47U 16V

C13 0.0 47U 16V

C14 0.0 47U 16V

C15 0.0 47U 16V

RED 1-

RED 1+

GREE N1-

GREE N1+

BLUE1-

BLUE1+

A A

5

4

3

2

Qisda Corporation

Pro j ect Code

D-S UB I NPUT

Title

Size D ocument Number Rev.

PCB P/N

4H. 0K 40 1.S01

<Si z e >

M o n d a y , De c e m b e r 15 , 2 0 0 8

D ate: Sheet

Lo uis Yang

M o del Name

PCB Rev.

S0 1

Rev iew e d By A p p ro ved ByPre p ared By

Bli ght Hsu A llen PC Lee

1

O E M /O D M M o del Name

OEM

<D o c >

of

1 6

0

Page 71

5

4

+5V

3

2

U9 s pe c.

Vd s= -3 0V , Vg s= +/ -12V

Id =- 3. 5A w he n am bi en t te mp .= 70 deg re

1

D D

C C

B B

Reset circuit for CMO L03 over

rush current

C102

0. 1U K

PA NEL_ ON

G6 97 L293T1UF

5

/RESET

CD

4

NC

U9

VCC

GND

R59

R307

1K J

1

2

3

R308

20K

12

+

10K J

C68

22 U 25V

B

R60

10K J

R58

100K J

Q6

2N3 904S

E C

+5V

G

C69

0. 1U K

D

S

U7

AO3401L

12

+

C66

22 U 25V

LC D_ 5V_PO WER

C67

R30

150 J

0. 1U K

R31

150 J

LC D_ 5V_PO WER

G(1)

S(2)

R61 0 J

R62 0 J

R63 0 J

RXE IN3+

RXE IN3RXE CKIN+

RXECLK-

RXE IN2+

RXE IN2-

RXE IN1+

RXE IN1-

RXE IN0+

RXE IN0-

RXO IN3+

RXO IN3-

RXO CKIN+

RXO CKIN-

RXO IN2+

RXO IN2-

RXO IN1+

RXO IN1-

RXO IN0+

RXO IN0-

TP5

TP6

TP9

TP10

TP11

TP12

TP13

TP14

TP15

TP16

TP17

TP18

TP19

TP20

TP21

TP22

TP23

TP24

TP1

TP2

TP3

TP4

D(3)

G1

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

G2

J7

G1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

G2

2KK20 85030

Screw Holes

1

5

4

3

2

H1

A A

HOL E-V8

5

9

8

7

6

G ND G ND G ND

5

4

3

2

H2

HOL E-V8

1

9

8

7

6

4

5

4

3

2

H3

HOL E-V8

1

9

8

7

6

Optical Points

OP1

3

OP2

OP3

Qisda Corporation

Pro j ect Code

Tit le

Panel output

S ize Document Number Rev.

PCB P/N

<S i z e >

4H.0K601.S01

M o n d a y , De c e m b e r 15 , 2 0 0 8

Da te: S h eet

Pre p ar ed By

Lo uis Yang

2

Model Name

PCB Rev.

S 0 1

Re view ed By Ap p rove d By

OEM /OD M Model Name

< D o c >

1 5

Blight Hsu A llen PC Lee

1

OE M

0

of

Page 72

5

D D

C C

J2

RX2-

1

1

9

9

17

17

2

2

10

10

18

18

3

3

11

11

19

19

4

4

12

12

20

20

5

5

13

13

21

21

6

6

14

14

22

22

7

7

15

15

23

23

8

8

16

16

24

24

G1

G1

G2

G2

2K2 200902 4

TP66

TP67

TP68

TP69

TP57

TP54

TP56

TP55

PZU 6.2 B2

D8

A K

RX1RX0RX2+RX2+

RX1+RX1+

RX0+RX0+

D VI-I_ SCL

PZU6 .2B 2

BZV5 5C 6V2

A K

TP45

TP46

TP47

TP48

TP49

TP50

TP51

TP52

DV I- I_SD A

TP53

R XC+

R23

4.7K J

RXC-

D6

HD CP_ CTR L

A K

D7

Lou is HDCP (0116)

4

A_D ete ct

A_D ete ct

R21

130 J

R22

130 J

D_D et ect

Hot -Plug

SCL _D

SD A_D

DV IPC5 V

C33

0. 1U Z

Cab le _De tect_ D

R304

D9

BZV5 5C 6V2

A K

R16

D_D et ect

47 J

1K J

WP _ DVI

3

PZU 6.2 B2

PZU 6.2 B2

2

RX0-

RX0+

RX1-

RX1+

RX2-

RX2+

RXC-

R XC+

+3.3V

C22

DN 6

0. 1U Z

BAV 99

K

J

C23

K

A

DN 7

0. 1U Z

J

BAV 99

C24

K

A

DN 8

0. 1U Z

J

BAV 99

C25

K

A

DN 9

0. 1U Z

J

BAV 99

C26

K

A

DN 10

0. 1U Z

J

BAV 99

C27

K

A

DN 11

0. 1U Z

J

BAV 99

C29

K

A

DN 12

0. 1U Z

J

BAV 99

A

D10

C31

0. 1U Z

A K

D11

C32

A K

0. 1U Z

C30

DN 13

0. 1U Z

BAV 99

1

R110

10

RX0M

R111 10

RX0P

R112 10

RX1M

R113 10

RX1P

R114 10

RX2M

R115 10

RX2P

R116 10

R117 10

RXC M

RX CP

K

J

A

Chu ng Ha o ESD ( 0131)

D N5

A1

R8

R7

12K J

12K J

C19

C18

47 P J

47 P J

5

SCL _D

SD A_D

WP _ DVIWP _ DVIWP _ DVIWP _ DVI

WP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVIWP _ DVI

DV IPC5 V

B B

A A

J

BAV 70

R306

10K J

A2

8

7

6

5

+3. 3V

U2

A0

VCC

A1

WP

A2

SCL

GND

SDA

AT2 4C 02N- 10 SU-1.8

C10

0. 1U Z

1

2

3

4

Qisda Corporation

Pro j ec t Code

DVI I NPUT

Tit le

Size D oc u ment Number Rev.

PCB P/N

<S i z e >

M o n d a y , D e c e m b e r 1 5 , 20 0 8

D at e: Sh eet

Pre p ared By

4

3

2

Lou is Yang

M ode l Name

4H .0K401. S01

O E M /O D M M od el Name

OEM

PCB Rev.

S0 1

Rev iew ed By A p p rove d By

Bli gh t Hsu Allen PC Lee

1

<D o c >

2 6

of

0

Page 73

5

4

3

2

1

+3.3V TMD S_VD D

D D

12

+

R 1.8 DVC C

C45

47 U 25 V

C35

0 .1 U Z

C36

0 .1 U Z

+3.3V

C88

1 U K

U1 2

1

IN

RM2101B0DA

3

OUT

GND

TAB

2

4

gi ac hi n 25 25 L (07 19)

Op tion

LH --> R2 5 1k ohm

C C

B B

U13

NC /RM2 101 D0 DA

1

VIN

GND

2

RX ECK IN+

RX OCK IN+

RXE CLK-

RX OCK IN-

VOUT

R 1.8 DVC C+3.3V

3

LR --> R 25 6.2k ohm

C37

0 .1U Z

Z220

L5

12

+

C46

47 U 25 V

TM DS_ VDD

R25

1K J

U 8

G1

RX1 P

RX1 M

RX0 P

RX0 M

RXC P

RXC M

BL UE1-