ACER SDX-460V, SDX-260V User Manual

AIT Drive

2-598-755-02(1)

User’s Guide

AIT-1 Turbo TAPE DRIVE

SDX-460V Series

GB

CT

AIT-E Turbo TAPE DRIVE

SDX-260V Series

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Acer.

The information contained in this

document is subject to change without

notice.

Acer MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO

THIS DOCUMENT.

Acer shall not be liable for errors

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

Your AIT TAPE DRIVE is assigned a

Model No. ATDNA2A for regulatory

compliance certifications.

The number is indicated on the model

number label on your drive along with

the rated voltage and current.

VORSICHT

Für Kunden in Deutschland

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

• Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

2

IMPORTANT SAFEGUARDS

For your protection, please read these

safety instructions completely before

operating the appliance, and keep this

manual for future reference.

Carefully observe all warnings,

precautions and instructions on the

appliance, or the one described in the

operating instructions and adhere to

them.

USE

Power Sources – This unit should be

operated only from the type of power

source indicated on the marking label.

If you are not sure of the type of

electrical power, consult your dealer or

local power company.

For the unit with a three-wire

grounding type ac plug:

If you are unable to insert the plug into

the outlet, contact your electrician to

have a suitable plug installed. Do not

defeat the safety purpose of the

grounding plug.

AC Power cord: (for AC mains

operating unit only)

The AC power cord should have

appropriate safety approvals or

marking for the country in which the

equipment will be used. Consult your

dealer or local power company.

Cleaning – Unplug the unit from the

wall outlet before cleaning or

polishing it. Do not use liquid

cleaners or aerosol cleaners.

Use a cloth lightly dampened with

water for cleaning the exterior of the

unit.

Object and Liquid Entry – Never

push objects of any kind into the unit

through openings as they may touch

dangerous voltage points or short out

parts that could result in a fire or

electric shock. Never spill liquid of

any kind on the unit.

3

INSTALLATION

Water and Moisture – Do not use

power-line operated units near water for example, near a bathtub,

washbowl, kitchen sink, or laundry

tub, in a wet basement, or near a

swimming pool, etc.

Power-Cord Protection – Route the

power cord so that it is not likely to be

walked on or pinched by items placed

upon or against them, paying

particular attention to the plugs,

receptacles, and the point where the

cord exits from the appliance.

Accessories – Do not place the unit on

an unstable cart, stand, tripod, bracket,

or table. The unit may fall, causing

serious injury to a child or an adult,

and serious damage to the unit. Use

only a cart stand tripod, bracket, or

table recommended by the

manufacturer.

Ventilation – The slots and openings

in the cabinet are provided for

necessary ventilation. To ensure

reliable operation of the unit, and to

protect it from overheating, these slots

and openings must never be blocked or

covered.

• Never cover the slots and openings

with a cloth or other materials.

• Never block the slots and openings

by placing the unit on a bed, sofa,

rug or other similar surface.

• Never place the unit in a confined

space, such as a bookcase, or builtin cabinet, unless proper ventilation

is provided.

SERVICE

Damage Requiring Service – Unplug

the unit from the wall outlet and refer

servicing to qualified service

personnel under the following

conditions:

• When the power cord or plug is

damaged or frayed.

• If liquid has been spilled or objects

have fallen into the unit.

• If the unit has been exposed to rain

or water.

• If the unit has been subject to

excessive shock by being dropped,

or the cabinet has been damaged.

• If the unit does not operate normally

when following the operating

instructions. Adjust only those

controls that are specified in the

operating instructions. Improper

adjustment of other controls may

result in damage and will often

require extensive work by a

qualified technician to restore the

unit to normal operation.

• When the unit exhibits a distinct

change in performance - this

indicates a need for service.

Servicing – Do not attempt to service

the unit yourself as opening or

removing covers may expose you to

dangerous voltage or other hazards.

Refer to all servicing to qualified

service personnel.

4

Contents

SDX-460V/SDX-260V Tape Drive ......................................................................... 6

Introduction .............................................................................................................. 7

Product Features ............................................................................................... 7

Precautions ....................................................................................................... 8

Installation .............................................................................................................. 10

Jumper Setting ................................................................................................ 10

Option Switches (DIP Switch) ....................................................................... 11

Mounting Holes .............................................................................................. 13

Reconfiguring from 5.25" Model to 3.5" Model ............................................ 15

Orientation......................................................................................................16

Attaching and Removing the Dust Cover ............................................................... 17

Attaching the Dust Cover ............................................................................... 17

Removing the Dust Cover ..............................................................................19

Operation ................................................................................................................ 20

Location of 3 LEDs ........................................................................................20

Drive Operation .............................................................................................. 21

Interface Implementation........................................................................................ 23

Supported ATA Commands ...........................................................................23

Supported ATAPI Packet Commands ............................................................ 23

Specification ........................................................................................................... 24

Product Specifications .................................................................................... 24

Acer Contacts ......................................................................................................... 25

• Acer cannot accept liability for data written to cartridges lost as a result of

using this product.

• Acer bears no responsibility for any financial damages, lost profits, or claims

made by third parties arising from the use of this product.

5

SDX-460V/SDX-260V Tape Drive

The SDX-460V/SDX-260V drive is a high capacity data storage device

using Advanced Intelligent tape (AIT) technology. The SDX-460V/SDX260V drive achieves high data reliability through Read-After-Write, an

additional level of Error Correction Code, and other features.

The SDX-460V/SDX-260V drive stores data on tape using a standard

format called AIT (Advanced Intelligent Tape) and ALDC formats.

6

Introduction

Product Features

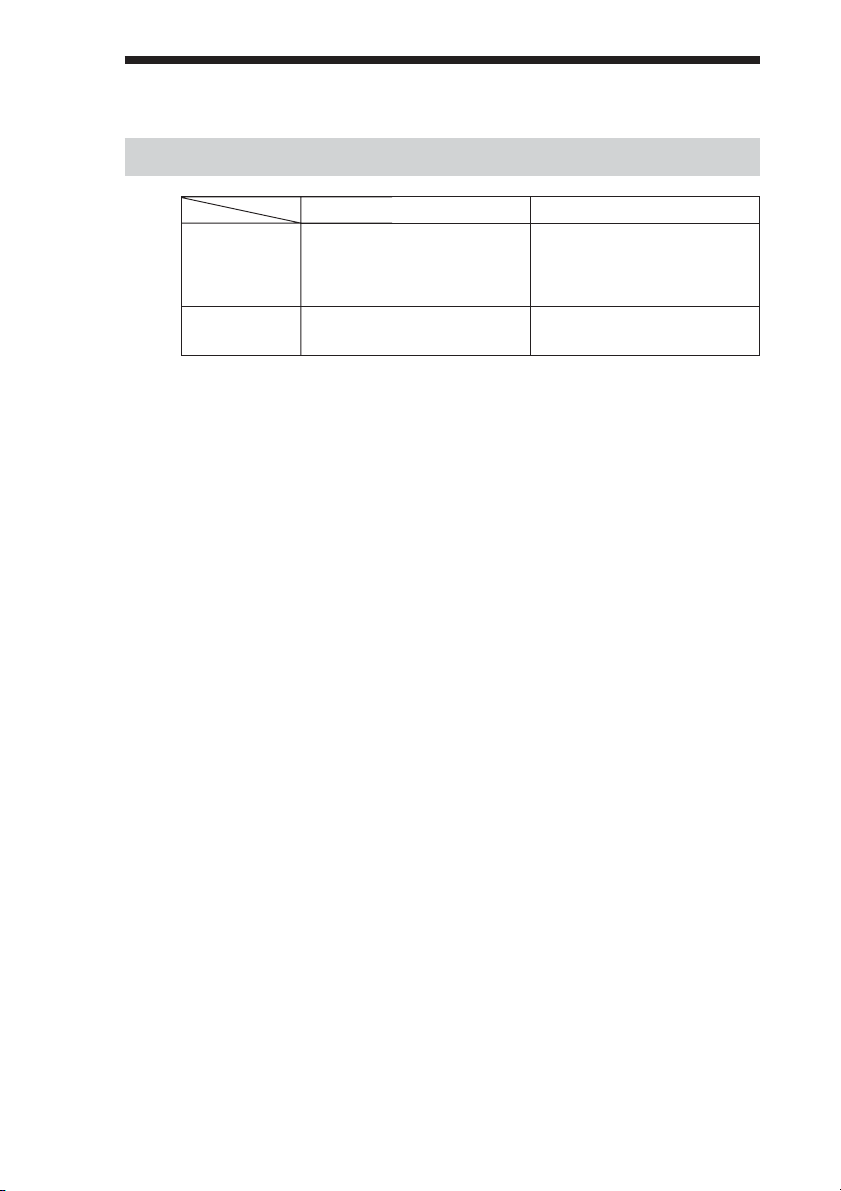

SDX-460V SDX-260V

Data Capacity

Transfer Rate

(sustained)

* Assuming a 2.6 : 1 compression ratio.

(The compression ratio varies according to the type of data.)

• Supported Format : AIT-E Turbo, AIT-1 Turbo and AIT-1 (SDX-460V)

• Burst Transfer Rate 100 MB/s Ultra DMA (mode 5)

• Large 12 MB Buffer Memory

• 3.5” Standard Height, 5.25” Half Height

• ATA/ATAPI-6 Interface

• Frame Rewrite Function

• Three levels of Error Correction Code (ECC)

• High Speed search (120 times normal Read/Write speed)

• Random Read, Append Write

40 GB uncompressed 20 GB uncompressed

(with AIT-1 Turbo 186 m tape) (with AIT-E Turbo 98 m tape)

104 GB compressed* 52 GB compressed*

(with AIT-1 Turbo 186 m tape) (with AIT-E Turbo 98 m tape)

6 MB/s uncompressed 6 MB/s uncompressed

: AIT-E Turbo (SDX-260V)

7

Precautions

Installation

Avoid placing the drive in a location subject to:

– high humidity

– high temperature

– mechanical shock and vibration

– direct sunlight

Operation

• Do not move the drive while it is operating. It may cause malfunction.

• Avoid exposing the drive to sudden changes from a low to high

temperatures. This may cause water condensation to collect inside the

drive. If the ambient temperature should suddenly rise while the drive is

turned on , wait at least one hour before turning on the drive. If you

attempt to operate the drive immediately after a sudden increase in

temperature, a malfunction may occur.

• Turning off the power to the drive while it is writing to tape may cause

the tape to become unreadable. All previously negotiated parameters will

be lost, whenever power to the drive is cycled.

Transportation

• Keep the original packing materials to facilitate transportation of the

drive.

• Always remove the data cartridge before moving the drive. After

removing the drive from the computer, repack the drive into its original

packing.

8

Useable Cartridges

The SDX-460V can be used with data cartridges marked with the AIT-E

Turbo, AIT-1 Turbo or AIT-1 logo.

The SDX-260V can be used with data cartridges marked with the AIT-E

Turbo logo.

Notes

• Be sure to use only the cartridges designed specifically for AIT.

• Do not use anything but AIT cartridges with this system, as doing so can

damage the AIT drive. Although commercially available 8 mm

videotapes resemble AIT cartridges in appearance, they have entirely

different specifications and cannot be used.

9

Installation

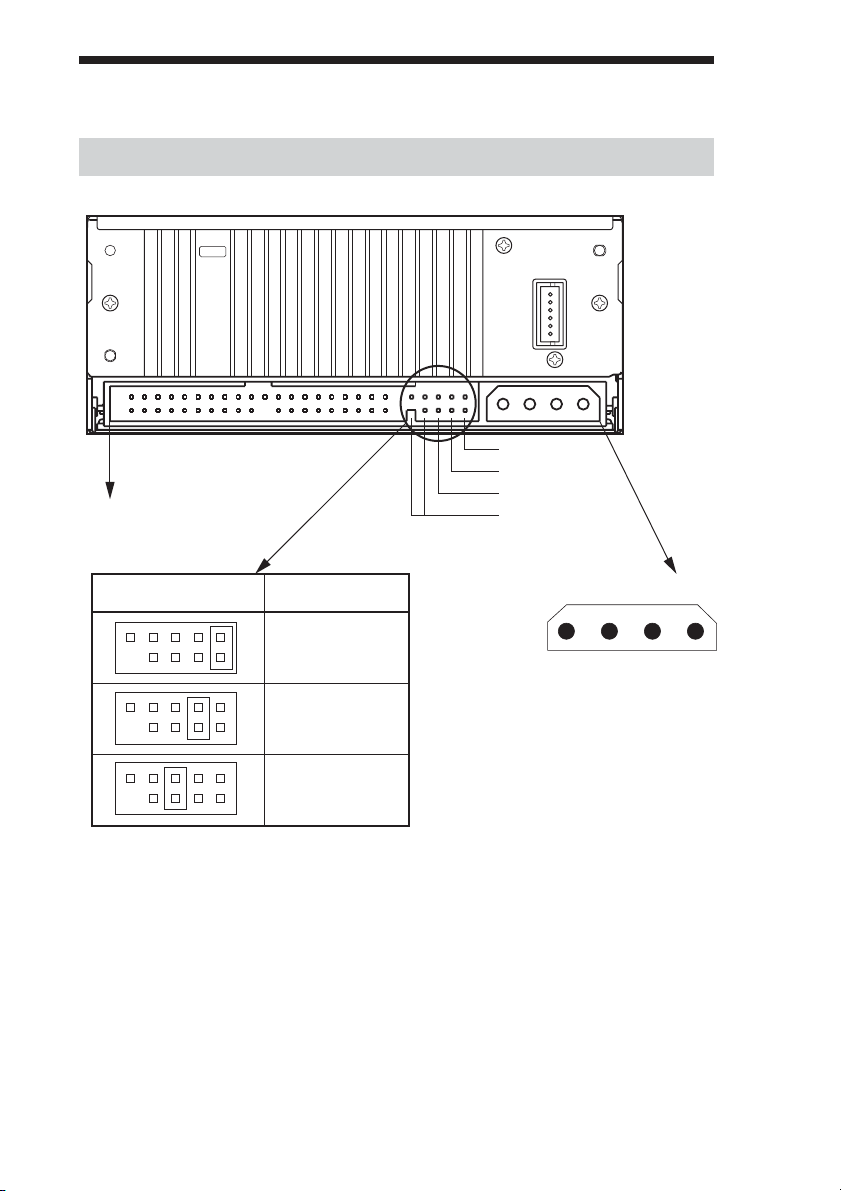

Jumper Setting

IDE Interface Connector

Master

Slave

Cable Select

No Connection

10

Jumpers Drive Setting

Master

Slave

Cable Select

Power Connector

4 3 2 1

5V GND GND 12V

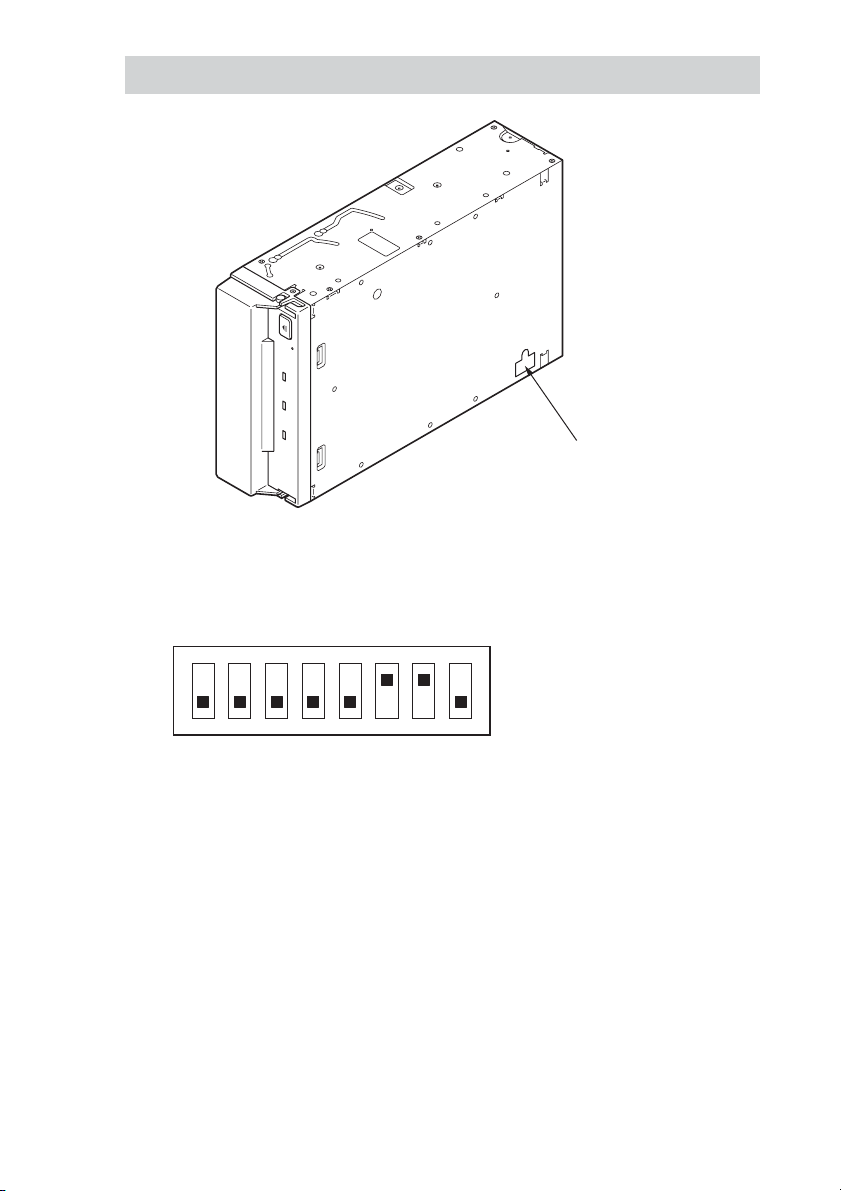

Option Switches (DIP Switch)

DIP Switch Positions

Default

ON

OFF

12345678

DIP Switch

1 Drive Mode (OFF)

2 Drive Mode (OFF)

3 Drive Mode (OFF)

4 Drive Mode (OFF)

5 Reserved (OFF)

6 Periodic Cleaning Req (ON)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

11

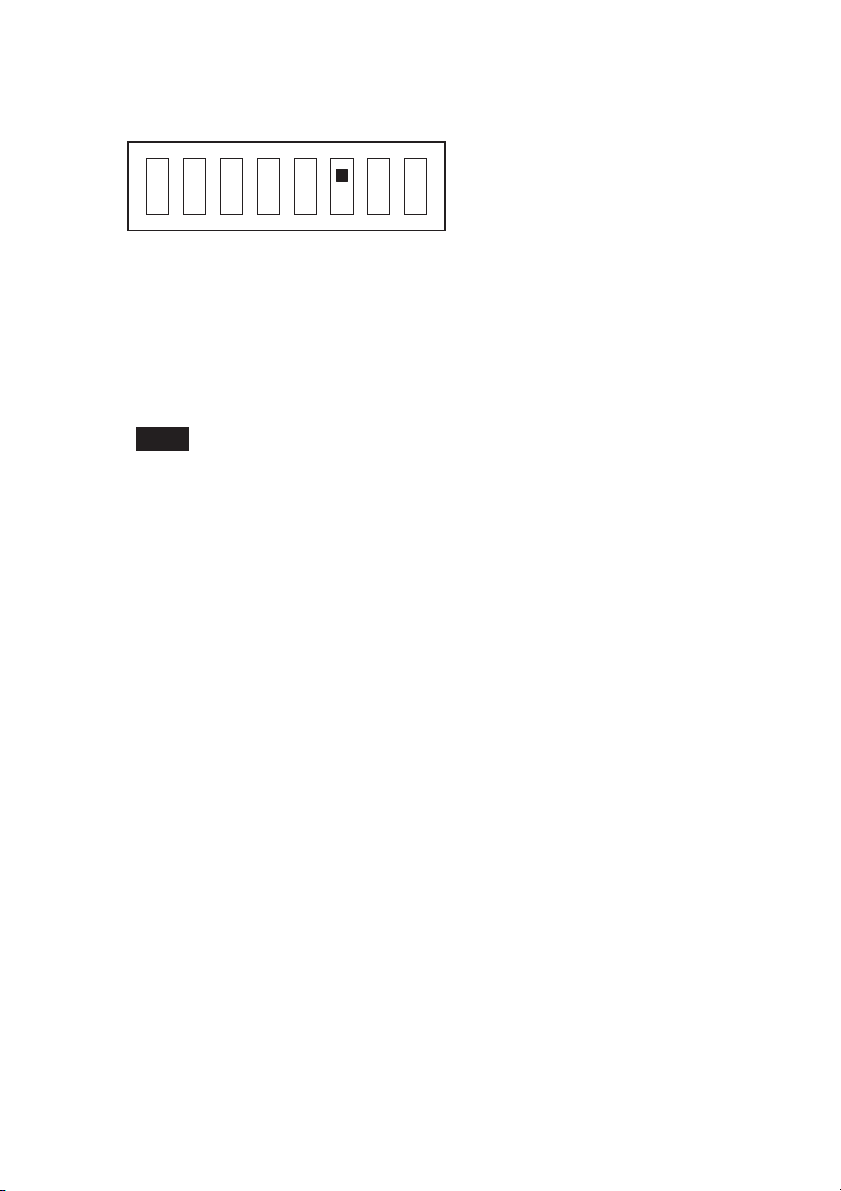

Cleaning Request Mode

Periodic cleaning requests can be enabled by a DIP switch.

1 Drive Mode

ON

OFF

12345678

2 Drive Mode

3 Drive Mode

4 Drive Mode

5 Terminator Power

6 Periodic Cleaning Req (ON)

7 DC Control (1)

8 DC Control (2)

When switch 6 is ON, cleaning requests are enabled. When enabled, the

“CLEANING REQUEST” LED on the front panel lights after every 100

hours of operation.

When this LED lights, clean the drive with a head cleaning cartridge.

Note

To maintain the drive in optimum condition in environments affected by dust and other

contaminants, we recommend keeping cleaning requests enabled.

Data Compression Control DIP switch

Data compression can be selected by DIP switches. Data compression is

enabled while position 7 [DC Control (1)] is ON. Control by host can be

disabled when position 8 [DC Control (2)] is ON.

12

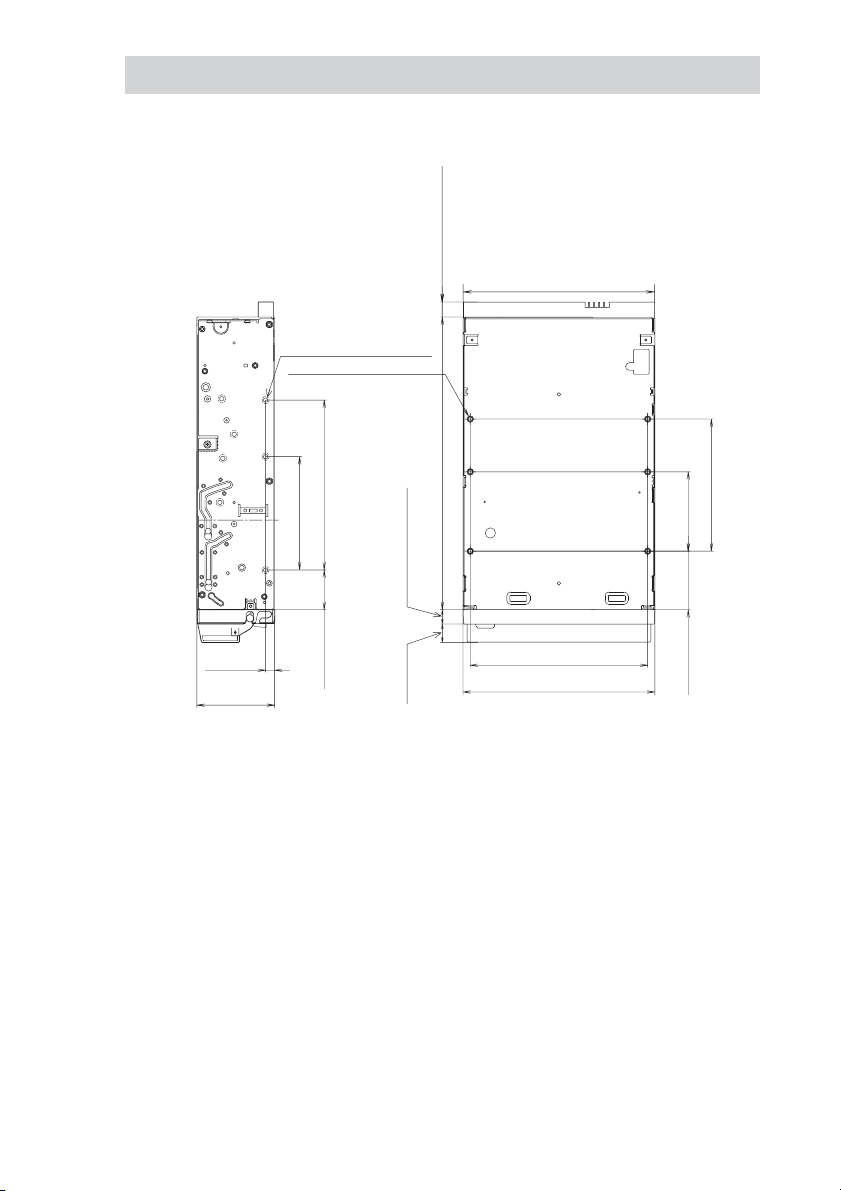

Mounting Holes

For 3.5" Standard Height

_

+

4.8 0.5mm

_

+

[0.19" 0.02"]

_

+

41.2 0.5mm

_

+

[1.62" 0.02"]

6-M3 (depth 2.5mm [0.10"] max.)

6-M3 (depth 2.5mm [0.10"] max.)

_

+

_

+

_

+

_

+

90.0 0.3mm [3.54" 0.01"]

60.0 0.3mm

[2.36" 0.01"]

_

+

_

+

21.0 0.3mm

[0.83" 0.01"]

_

+

_

+

7.4 0.6mm [0.29" 0.02"]

_

+

_

+

9.8 0.6 mm

[0.39" 0.02"]

7.6±0.5 mm (0.30±0.02 in)

_

+

_

+

155.0 0.5mm [6.10" 0.02"]

95.5 mm (3.76 in)

_

+

94.0 0.5mm [3.70" 0.02"]

_

+

101.6 0.5mm [4.00" 0.02"]

_

+

_

+

_

+

_

+

42.0 0.3mm

[1.65" 0.01"]

70.0 0.3mm [2.76" 0.01"]

_

+

_

+

_

+

_

+

31.0 0.3mm

[1.22" 0.01"]

13

For 5.25" Half Height

6-M3

7.0mm

[0.28"]

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

47.5 0.3mm

_

+

9.9 0.5mm

_

[0.39" 0.02"]

+

_

+

21.8 0.5mm

_

+

[0.86" 0.02"]

_

+

41.2 0.5mm

_

+

[1.62" 0.02"]

7.6±0.5 mm

(0.3±0.02 in)

_

+

_

+

_

+

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

[1.87" 0.01"]

_

+

_

+

_

+

155.0 0.5mm [6.10" 0.02"]

42.0 0.3mm

[1.65" 0.01"]

70.0 0.3mm [2.76" 0.01"]

_

+

_

+

_

+

_

+

9.8 0.6 mm

[0.39" 0.02"]

_

+

7.4 0.6mm [0.29" 0.02"]

_

+

31.0 0.3mm [1.22" 0.01"]

146±0.5 mm

(5.75±0.02 in)

95.5 mm

(3.76 in)

_

+

94.0 0.5mm [3.70" 0.02"]

_

+

139.6 0.5mm [5.50" 0.02"]

_

+

146.0 0.5mm [5.75" 0.02"]

_

+

149.0 0.5mm [5.87" 0.02"]

_

+

_

+

_

+

_

+

4-M3

_

+

_

+

79.2 0.3mm [3.12" 0.01"]

_

+

_

+

47.5 0.3mm

[1.87" 0.01"]

14

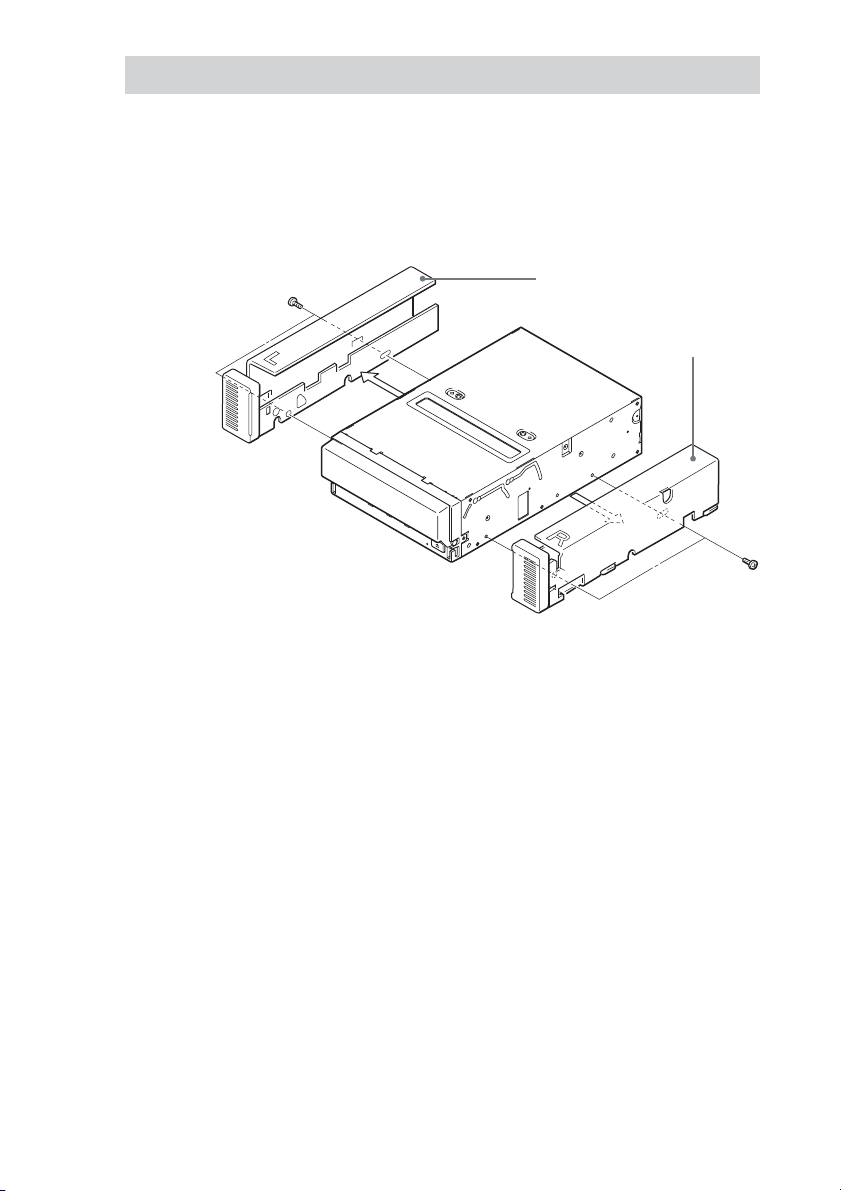

Reconfiguring from 5.25" Model to 3.5" Model

You can reconfigure the 5.25" model to the 3.5" model yourself.

1 Remove the 2 screws for each side rail.

2 Take the side rail off.

Side Rail (L)

Side Rail (R)

15

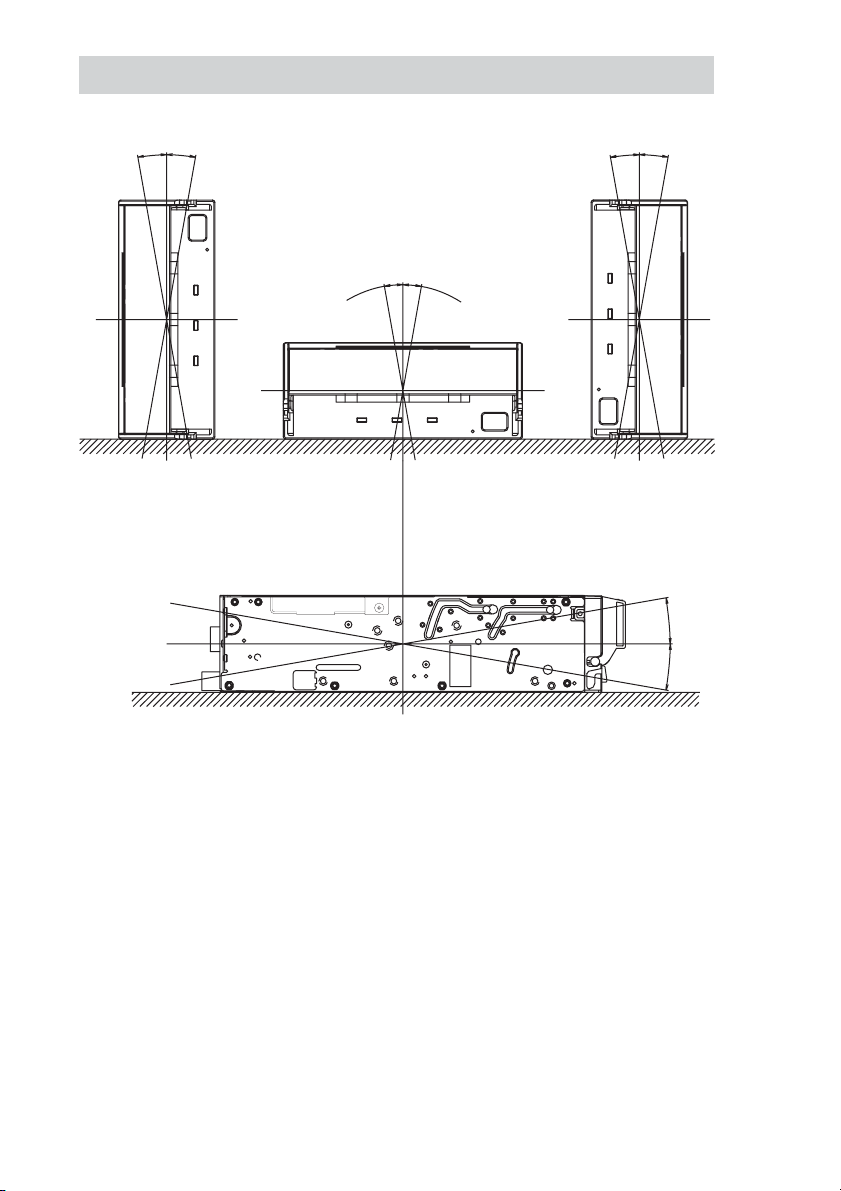

Orientation

10°10

10°10

°

10

°

10

°

°

10

°

10

°

16

Loading...

Loading...