RESTRICTIONS ON USE OF MATERIALS

:

Projector Service Manual

Model: S5201/S5201B/S5301WB series

Version: Rev1

First Edition (Dec. 2010)

1

Index

REVISION LIST ....................................................................................................................3

CHAPTER 1 SYSTEM SPECIFICATION .........................................................................4

Product Specification ..................................................................................................................4

Electrical Specification...........................................................................................12

Power Supply Specification ...................................................................................20

System Block Diagram ............................................................................................................. 21

Product Overview ......................................................................................................................22

CHAPTER 2 SYSTEM UTILITIES..................................................................................26

Firmware Upgrade SOP...........................................................................................................26

Method to enter factory menu .................................................................................................35

EDID Upgrade SOP ..................................................................................................................36

Serial Number Upgrade SOP ..................................................................................................39

CHAPTER 3 SYSTEM DISASSEMBLING AND REPLACEMENT ................................41

Main Unit Disassembling.......................................................................................................... 41

Module Assembly Key Point - Optical Engine ...................................................................... 46

Module Assembly Key Point – Mechanical ........................................................................... 57

CHAPTER 4 TROUBLESHOOTING ..............................................................................75

System Analysis ........................................................................................................................ 75

Optical & Optical Engine Trouble Shooting Guide ............................................................... 76

Power Supply Trouble Shooting Guide.................................................................................. 81

LED Messages Definition.........................................................................................................84

Error Count Messages Definition............................................................................................ 85

RS232 Connection ....................................................................................................................86

Adjustment / Alignment Procedure......................................................................................... 87

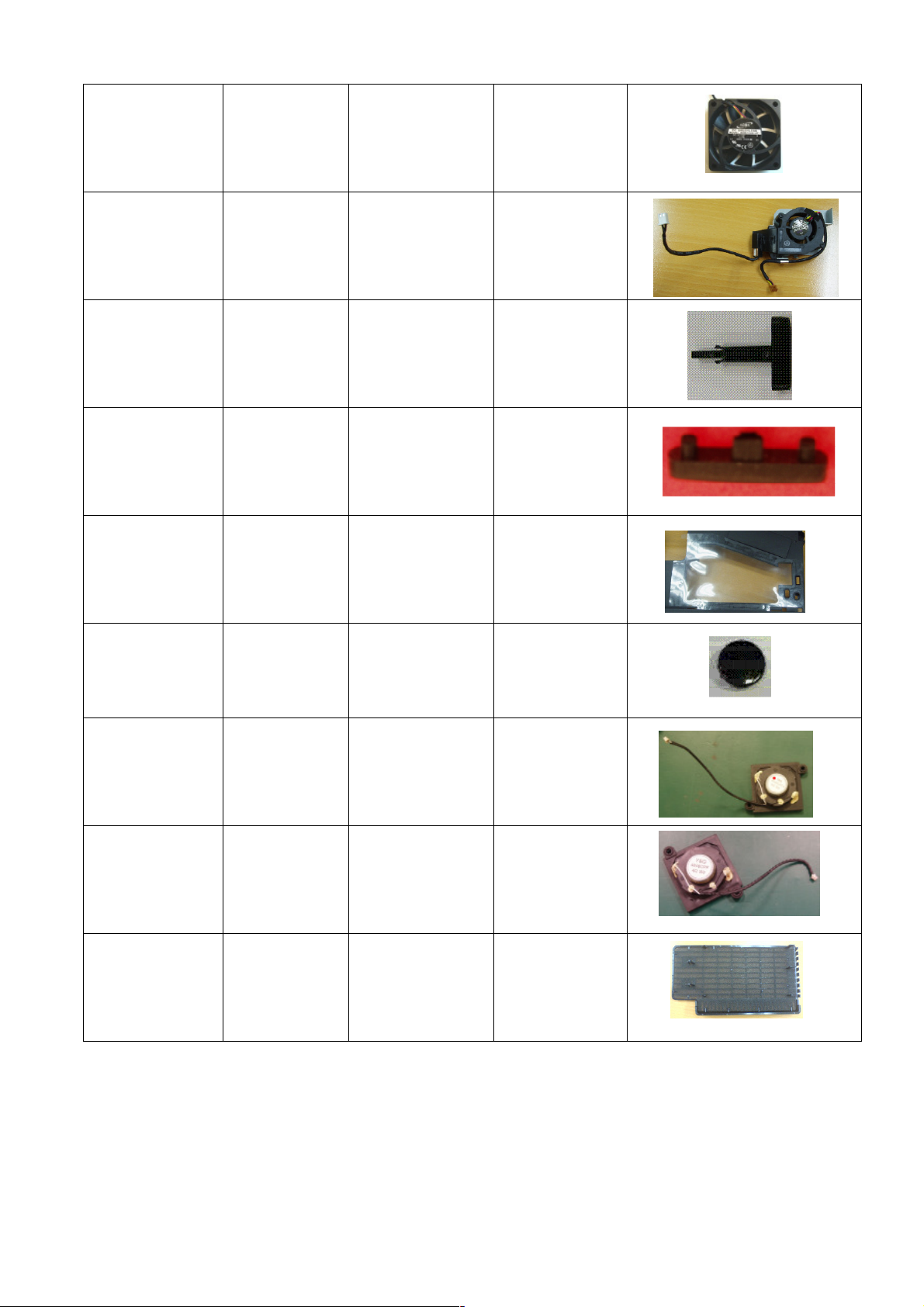

CHAPTER 5 FRU LIST ..................................................................................................90

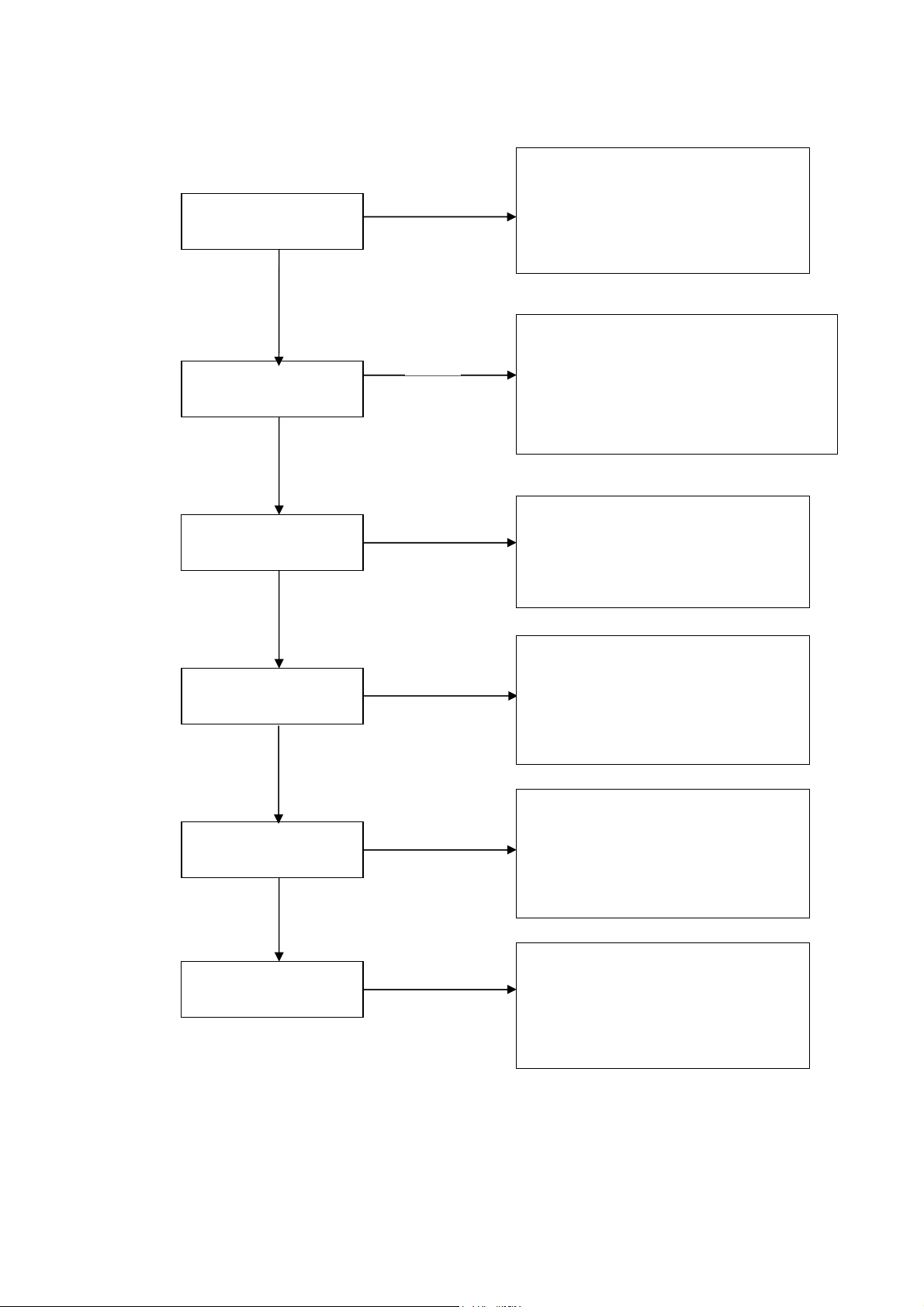

Exploded Diagram.....................................................................................................................90

Module 1 – Total Exploded View............................................................................................. 90

Module 2 – ASSY UPPER CASE ........................................................................................... 92

Module 3 – ASSY LOWER CASE .......................................................................................... 93

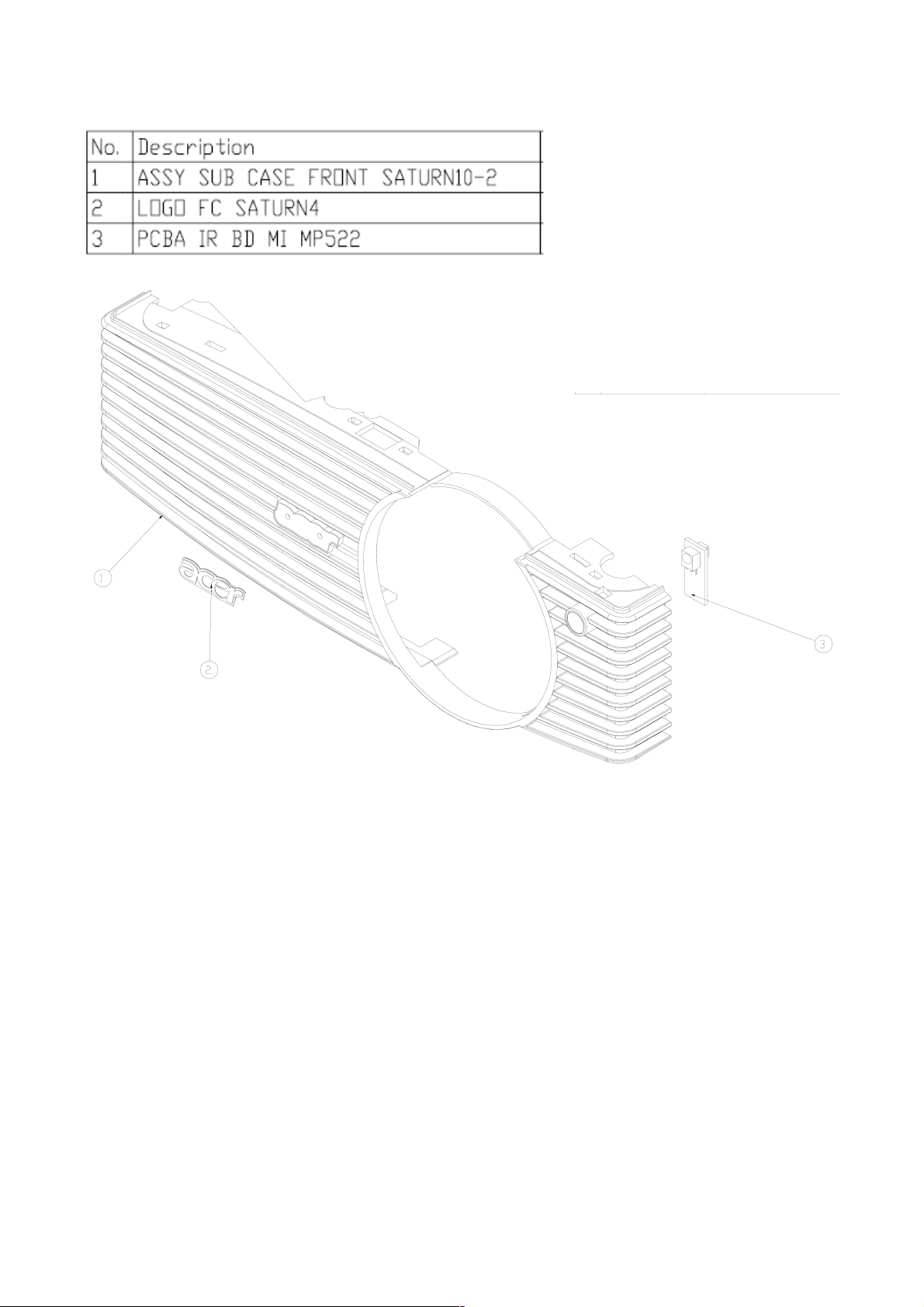

Module 4 – ASSY FRONT CASE ...........................................................................................94

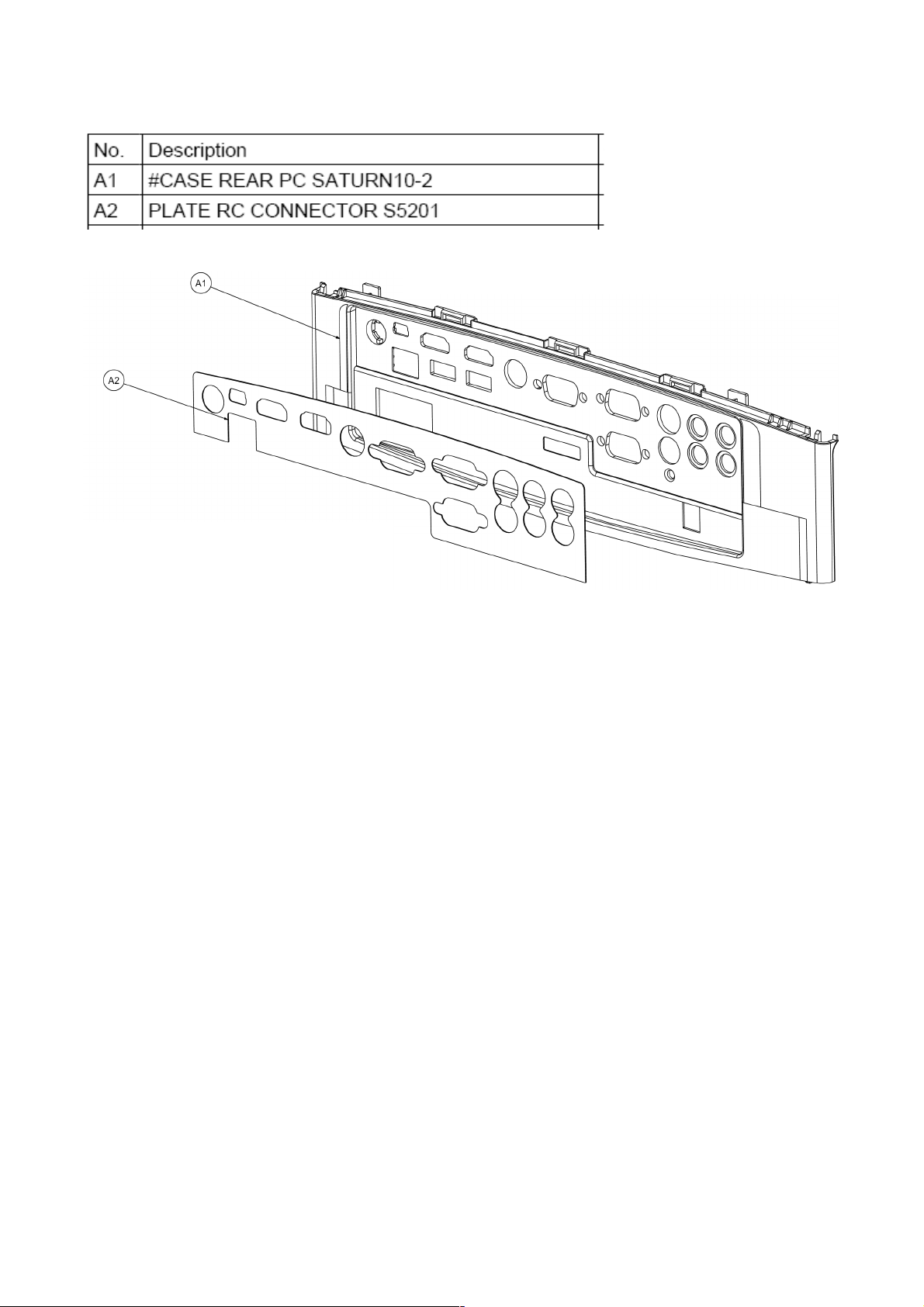

Module 5 – ASSY REAR CASE.............................................................................................. 95

FRU List ......................................................................................................................................96

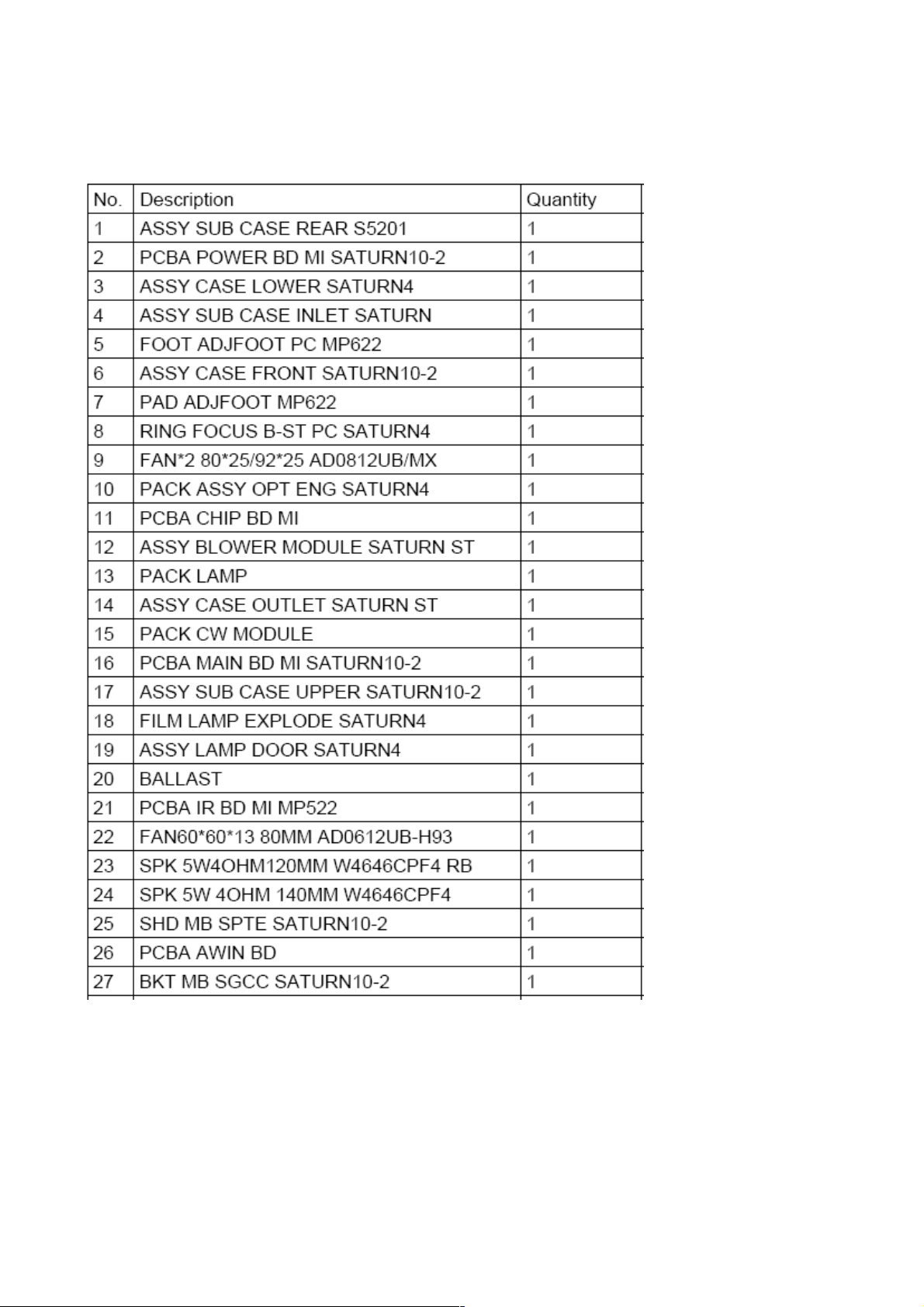

FRU List ......................................................................................................................................96

APPENDIX A - CODE LIST: IR / RS232 / DDC DATA......................................................101

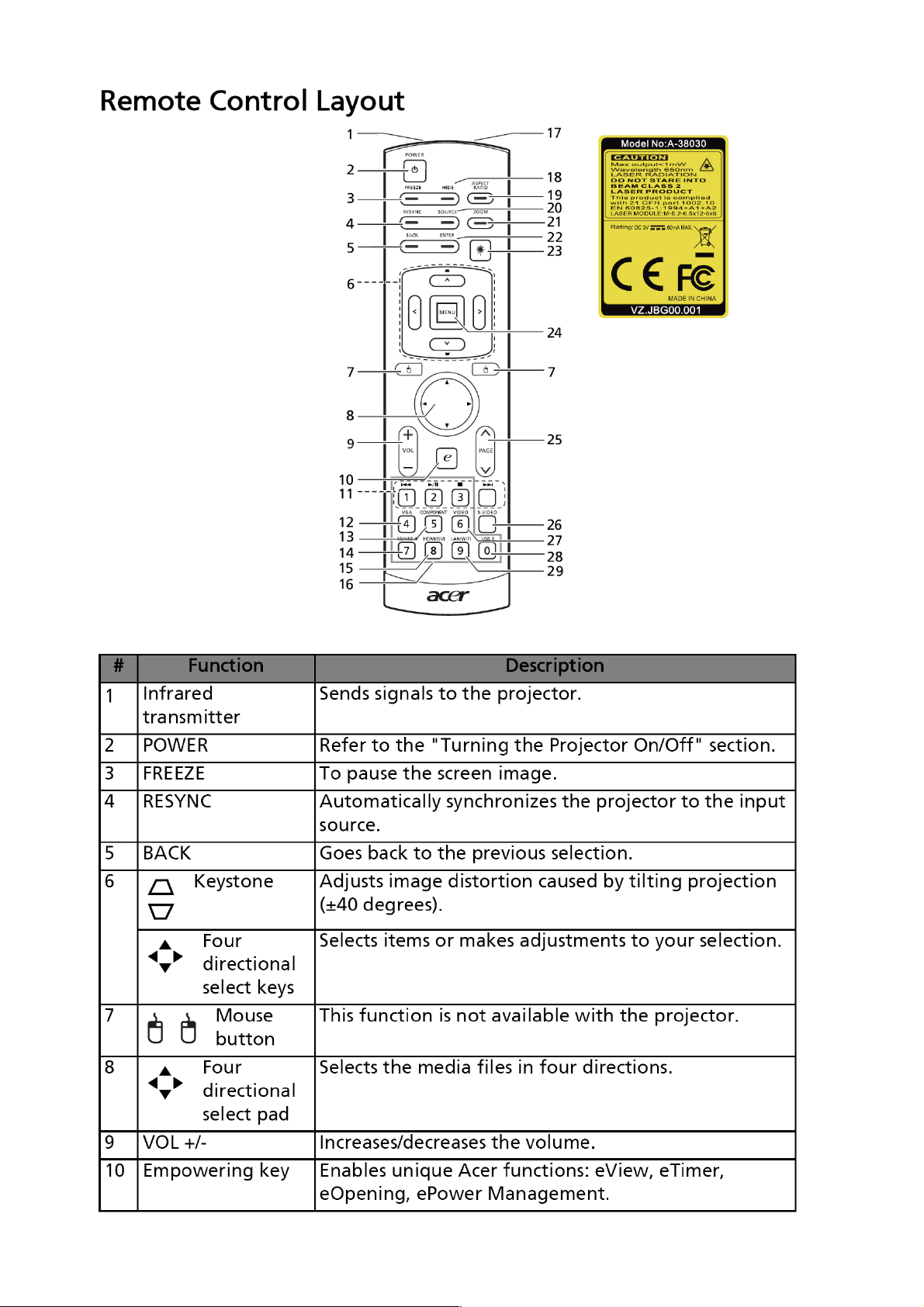

1. Remonte control code ........................................................................................................101

2. RS-232 Command Code ...................................................................................................102

3. DDC Data.............................................................................................................................104

2

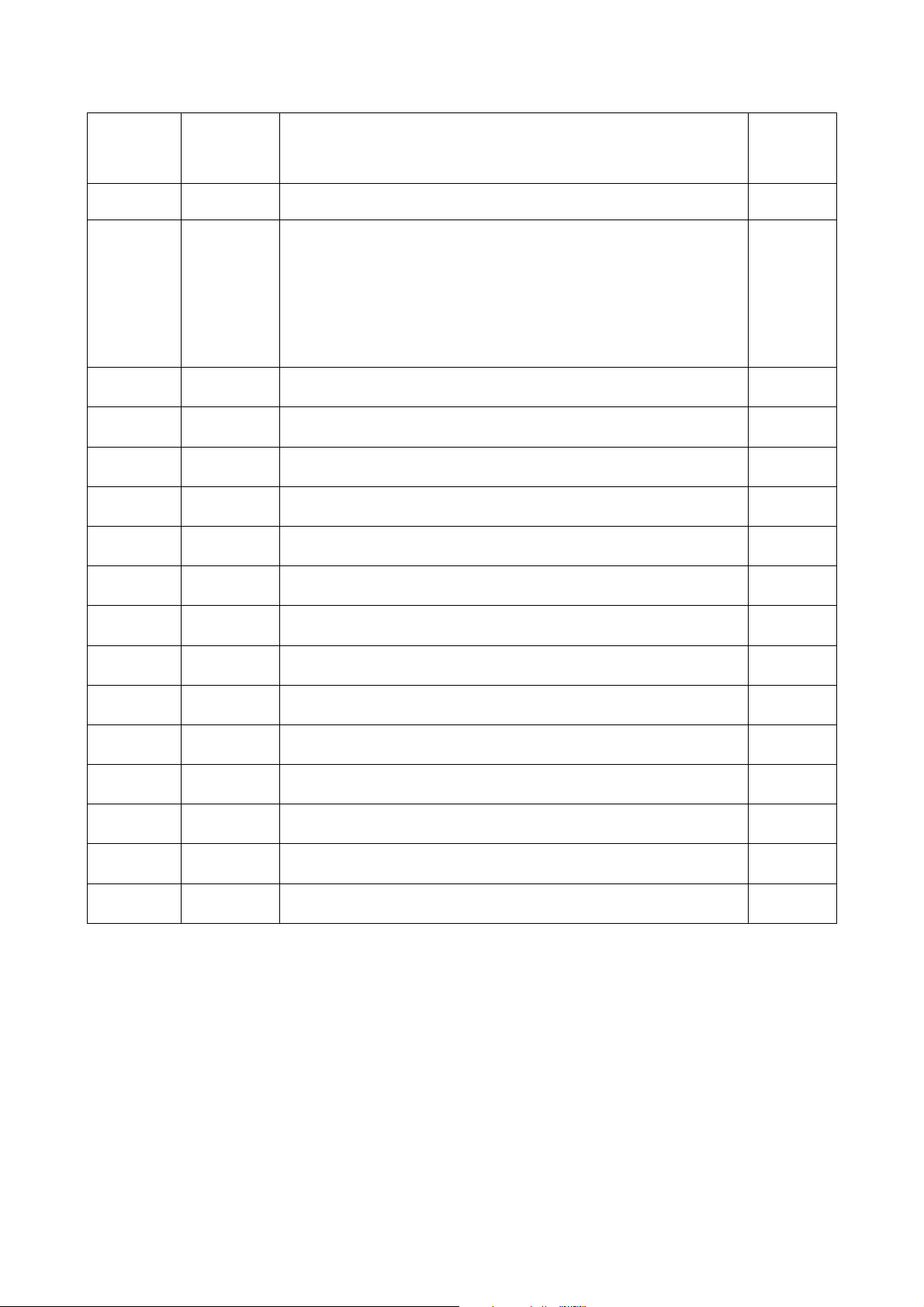

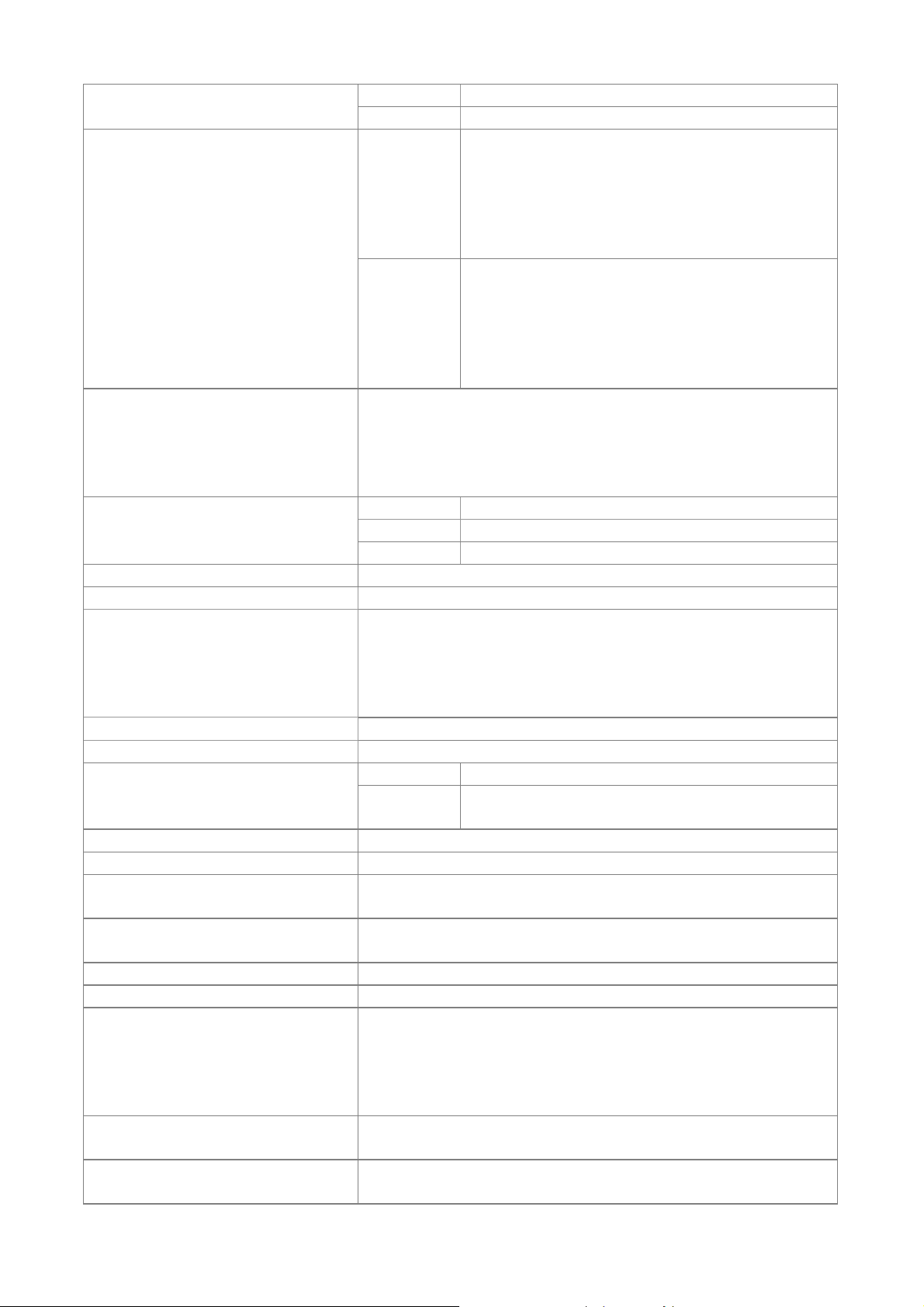

Revision List

Version

Rev0 2010.12.21 First Release

Rev1 2011.01.11

Release

Date

Revision History

Add S5201B/S5301WB

(1) Ch1-Add SPEC

(2) Ch2-Update Firmware Upgrade SOP

(3) Ch3-Disassembly process, Module Assembly Key Point

(4) Ch4-Add “DMD Image Quality “ section,

Change RS232 baud rate default to 9600.

(5) Ch5-FRU List

(6) App.-DDC data

Vendor

Model

Name

3

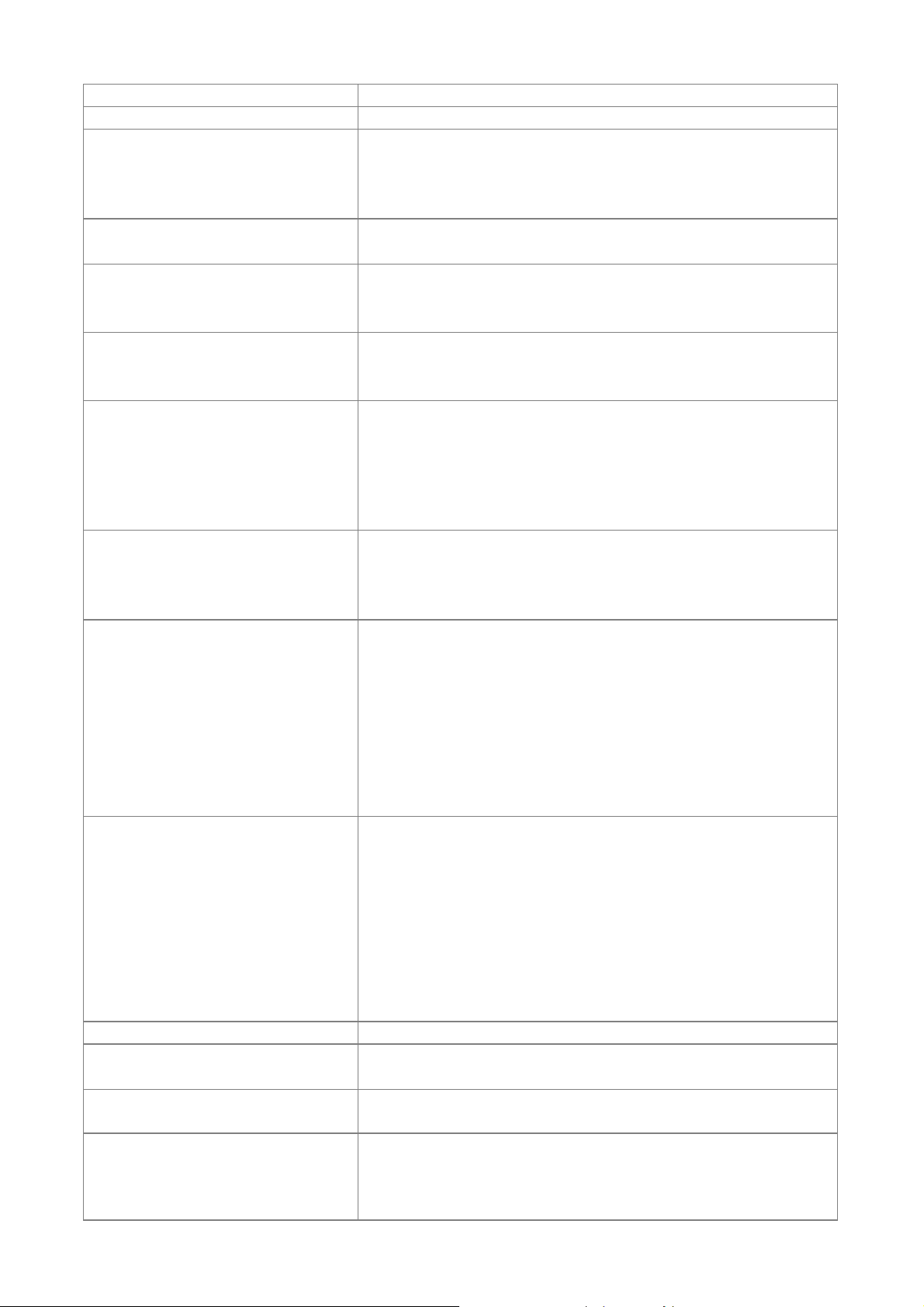

Chapter 1 System Specification

Product Specification

1.0 Optical Performance

2.0 Image Quality

3.0 Mechanical Specification

4.0 Packaging

5.0 Thermal Specification

6.0 Environmental

7.0 Regulatory

8.0 Reliability

9.0 Power Requirements

10.0 Panel Specification

11.0 Compatibility

12.0 Image Interface

13.0 Control Interface

14.0 User Interface

4

1.0 Optical Performance

Tested under 60” (diagonal) image size with Wide

projection lens position unless other specified.

1.1 ANSI Brightness Minimum 2400 Lumens

1.2 Brightness Uniformity

1.2.1 ANSI Uniformity Minimum 45%

1.2.2 JBMA Uniformity Minimum 65%

1.2.3 Upper-Down

unbalance

0.5~2

1.2.4 Left-Right unbalance 0.6~1.67

1.3 Contrast Ratio

1.3.1 ANSI Contrast Minimum 150:1

1.3.2 FOFO Contrast

without APM

1.3.3 FOFO Contrast with

APM

Minimum 1800:1

Minimum 3200:1

1.4 Light Leakage

S5201/S5201B : <0.5 lux compared to center point

within 60” (Diagonal at 0.74m) image size.

S5301WB : <0.5 lux compared to center point within 70”

1.4.1 Light Leakage in

Active Area

(Diagonal at 0.74m) image size.

Note: This light leakage in Active area is only described

as the spot light with obvious shape. It is not included

the uniformity difference of the projector for black

pattern.

1.4.2 Light Leakage out of

Active Area

<0.5 lux with 60”~80“(Diagonal at 0.74m) image size

(Except DMD Defect)

Reference meter: Vendor Lab CS1000 Spectroradio

1.5 Color

Meter (S/N: 00370975) (Spec will be confirmed at PVT

stage)

x y

1.5.1 White 0.311±0.04 0.356±0.04

1.5.2 Red 0.631±0.04 0.357±0.04

1.5.3 Green 0.339±0.04 0.570±0.04

1.5.4 Blue 0.147±0.03 0.075±0.03

1.6 Color Uniformity x y

1.6.1 White 0.040 0.040

1.6.2 Red 0.040 0.040

1.6.3 Green 0.040 0.040

1.6.4 Blue 0.040 0.040

1.7 Color Gamut Typ 60% compare NTSC

2.0 Image Quality

2.1 Throw Ratio

2.2 Zoom Ratio (tolerance

applied)

S5201/S5201B : 81”±3% Diagonal at 1m

S5301WB : 95”±3% Diagonal at 1m

1(Fixed)

2.3 Distortion

2.3.1 Keystone Distortion <1.0%

2.3.2 Vertical TV

Distortion

<1.0%

5

S5201/S5201B : |A| <= 4.5 mm, |B| <= 4.0 mm, |C| <=

2.3.3 Screen distortion

3.5 mm with 81” image size

S5301WB : |A| <= 6.0 mm, |B| <= 5.5 mm, |C| <= 4.0

mm with 95” image size

2.4 Projection Offset

S5201/S5201B : 130% ±5%

S5301WB : 110% ±5%

2.5 Focus Range

2.5.1 Visible Range 0.5~2m

2.5.2 Clearly Focus

Range

0.75~1.6 m(Spec. defined as item 2.6)

2.6 Focus

(1) If pattern can be uniformly focused (not worse than

2.6.1 区 Pattern

Limit Sample), then pass!

(2) If it’s difficult to judge, then check 2.6.2

Defocus: R<=3.0; G<=3.0; B<=3.0 pixel

2.6.2 Defocus and Flare

Flare: R<=3.5; G<=3.5; B<=3.5 pixel

Slight flare is not counted as flare.

2.6.3 Focus unbalance

2.7 Lateral Color

Adjust focus from near to far until one corner clear,

difference less than 50 cm

Center of

49”diagonal area

All other area

R-G <2/3 <1

G-B <2/3 <1

R-B <1 <1

2.8 Image Quality

2.8.1 DMD Image Quality

2.8.2 Image Imperfection

2.9 Lamp Type Philips 230W – 170W 0.9 E20.9 LL FusionStar

3.0 Mechanical Specification

3.1 Dimensions 290 x98.5x 254 mm (W x H x D)

3.2 Weight <3500g

3.3 Security Slot Kensington compatible slot 36kgf break away force

3.5 Lens Cover Detached lens cover

3.6 Feet

Fast adjustable foot in front, Adjustable foot in rear.

Front/ Rear foot Tilt:0-6 ,Right/Left: ±2.2∘ ∘

4.0 Packaging Detail refer to Packing Description

4.1 Outside Dimensions 375 x 216 x 370 mm (W x H x D)

4.2 Weight <5.5 kg (Including Accessories, Projector)

30 EA by Air;

4.3 Transportation

1500 EA @ 40’ container, or750 EA @ 20’ container by

Sea

5.0 Thermal Specification

5.1 Surface held or touched

for short periods

5.2 Surface which may be

touched

5.3 Exhaust Air

Mechanical component temperature at ambience

0~35℃

Metal < 65°C; Plastic<85°C

Metal Plastic

<65°C <85°C

<95°C

6.0 Environmental

6.1 Temperature

Operating

0~35°C, without condensation

Storage -30~65°C, without condensation

6

6.2 Humidity

Operating 10~90%RH, without condensation

Storage 10~90%RH, without condensation

Normal mode: 36dBA @ 23±2°C, CW x2

speed

Typical

Eco mode: 31dBA @ 23±2°C, CW x2 speed

Normal mode: 38dBA @ 23±2°C, CW x3

speed

6.3 Audible Noise Level

Eco mode: 33dBA @ 23±2°C, CW x3 speed

Normal mode: 38dBA @ 23±2°C, CW x2

speed

Maximum

Eco mode: 33dBA @ 23±2°C, CW x2 speed

Normal mode: 40dBA @ 23±2°C, CW x3

speed

Eco mode: 35dBA @ 23±2°C, CW x3 speed

Operating:

1. 12,000 feet @ 25°C (3.5 hours)

6.4 Altitude

2. Altitude Ramp rate: <= 3500 feet per minute (1 hour)

Non-operating:

40,000 feet @ -30 °C (1 hour)

Safety CB, cTUVus, GS, CCC

7.0 Regulatory

EMC CE, FCC, VCCI

ESD See Appendix B2.3

8.0 Reliability

8.1 MTBF 25000 hours except Lamp

Normal :

S5201 : 3500 hours, S5201B/S5301WB : 3000 hours

8.2 Lamp Lifetime

Eco: 5000 hours

(50% of Projector will have 50% initial minimum

brightness)

9.0 Power Requirements See Appendix F

9.1 Power Supply (Normal) VAC 90 – 264 (47 ~ 63Hz),

Typical 352W Max.

9.2 Power consumption

Standby

1W Max. at 100 ~ 240VAC, monitor out

function off, LAN function off, 12V outlet off

9.3 Power Connector IEC-60320C14

10.0 Panel Specification

10.1 Type

10.2 Pixels

S5201/S5201B : 0.55” XGA 2xLVDS Series 450 DMD

S5301WB : 0.65” WXGA 2xLVDS Series 450 DMD

S5201/S5201B : H: 1024 X V: 768

S5301WB : H: 1280 X V: 800

10.3 Color Depth 30 Bits (1.07 Billion Colors)

11.0 Compatibility Adhere to Electrical Specification

S5201/S5201B : PC Compatible 640X480

1024X768, compressed 1600X1200;

11.1 PC

S5301WB : PC Compatible 640X480 1024X768,

compressed 1600X1200; Composite-Sync(MAC timing

only);

11.2 Video

11.3 YpbPr

NTSC/ NTSC4.43/ PAL (Including PAL-M, PAL-N)/

SECAM/ PAL60/

NTSC (480i)/ 480p/ PAL (576i)/ 576p, HDTV (720p/

1080P)

7

11.4 DDC EDID1.3 Adhere to Appendix A

12.0 Image Interface Adhere to Electrical Specification

15 pin D-Sub (Female) x 2

12.1 Analog RGB Input

G(Y): Video amplitude 0.7/1.0 Vp-p : Impedance 75Ω

RB(CbCr): Video amplitude 0.7 Vp-p : Impedance 75Ω

HD/VD/CS: TTL Level

12.2 Video Input

RCA jack (Yellow)

Video amplitude 1.0 V

: Impedance 75Ω

p-p

4 pin Mini-Din (Female)

12.3 S-Video Input

Y: Luminance amplitude 1.0 V

C: Chroma amplitude 0.268 V

: Impedance 75Ω

p-p

: Impedance 75Ω

p-p

12.4 YPbPr Input 15 pin D-Sub (Female) x 2

Y: Luminance amplitude 1.0 V

PbPr/CbCr: Chroma amplitude 0.7 V

: Impedance 75Ω

p-p

p-p

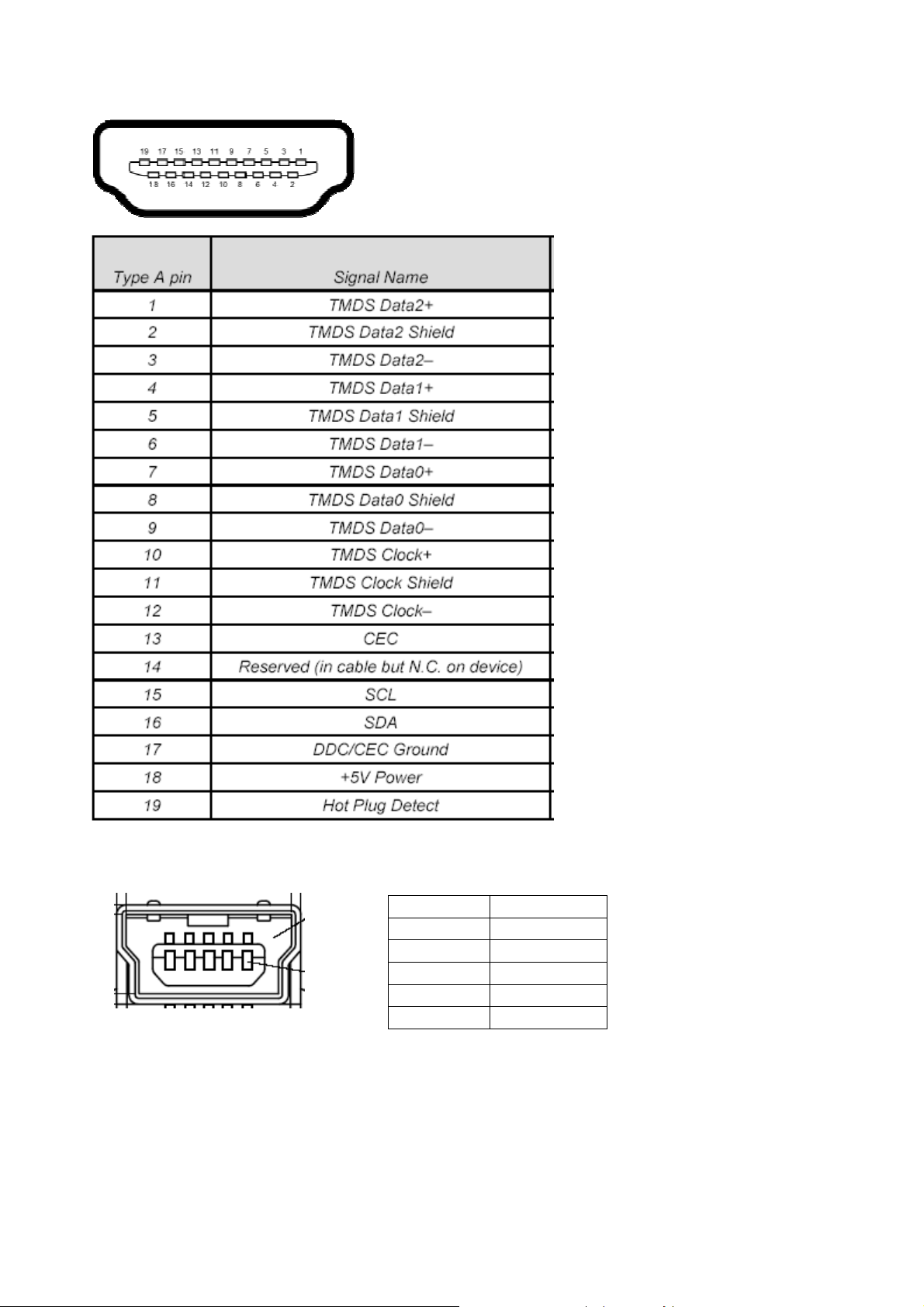

1. 19 pin HDMI connector x 2

2. HDMI V1.3/HDCP/EDID V1.3

12.5 HDMI Input

3. HDMI-Video/audio and HDMI-Graphic Signal

4. HDMI-Graphic Signal resolution is up to

1600x1200@60Hz

5. Down-mix 5.1channel to stereo channels

12.6 Analog RGB Output 15 pin D-Sub (Female) x 1 ( D-sub 1 only )

G(Y): Video amplitude 0.7/1.0 Vp-p : Impedance 75Ω

RB(CbCr): Video amplitude 0.7 Vp-p : Impedance 75Ω

HD/VD/CS: TTL Level

12.7 USB Input

(Only for S5201B /

S5301WB)

S5201 : N/A

S5201B / S5301WB :

1. Type A x2 (Photo Viewer & Multimedia)

Two port USB2.0 Host usage (PtG Function), 500mA

continuous load current each port.

2. Mini Type B x 1 (Display)

For USB2.0 Device usage (DoUSB Function)

3. Display Resolution:1024 x 768 resolution / 60Hz.

32-bit color depth

12.8 Lan Input

(Only for S5201B /

S5301WB)

S5201 : N/A

S5201B / S5301WB :

1. RJ45 LAN x 1 (Display & HD Video)

10/100Mbps Fast Ethernet connection with G/Y LED

Green LED light with cable plug-in:100M speed

Green LED dark with cable plug-in:10M speed

Yellow LED:Active flashing when cable plug-in

2. Display Resolution:1024 x 768 resolution / 60Hz.

32-bit color depth

13.0 Control Interface

13.1 IR Receiver

13.2 Serial Connector

13.3 Lan Control

IR Receiver x2 (Front, Rear)

Angle: ±0° Distance 0~10m ; ±40° Distance 0~8m

RS232 x 1(3pin mini din) , command table adhere to

Appendix A

S5201 /

S5201B / S5301WB :

RJ45 x1

Compliant to following standards,

IEEE 802.3 compliance

: Impedance 75Ω

8

IEEE 802.3u compliance

ANSI X3T12 TP-PMD 1995

S5301WB :

USB Type A for Wireless Dongle

Compliant to following standards,

IEEE 802.11b:up to 11 Mbps,2.4GHz.

IEEE 802.11g:up to 54 Mbps,2.4GHz.

IEEE 802.11n draft 6.0:up to 150Mbps,2.4GHz.

S5201 / S5201B : Mini Type B x 1 Terminal for page

13.4 USB Connector

up/down

S5301WB : Mini Type B x 1 Terminal for page up/down

& USB mouse

14.0 User Interface Adhere to Electrical Specification

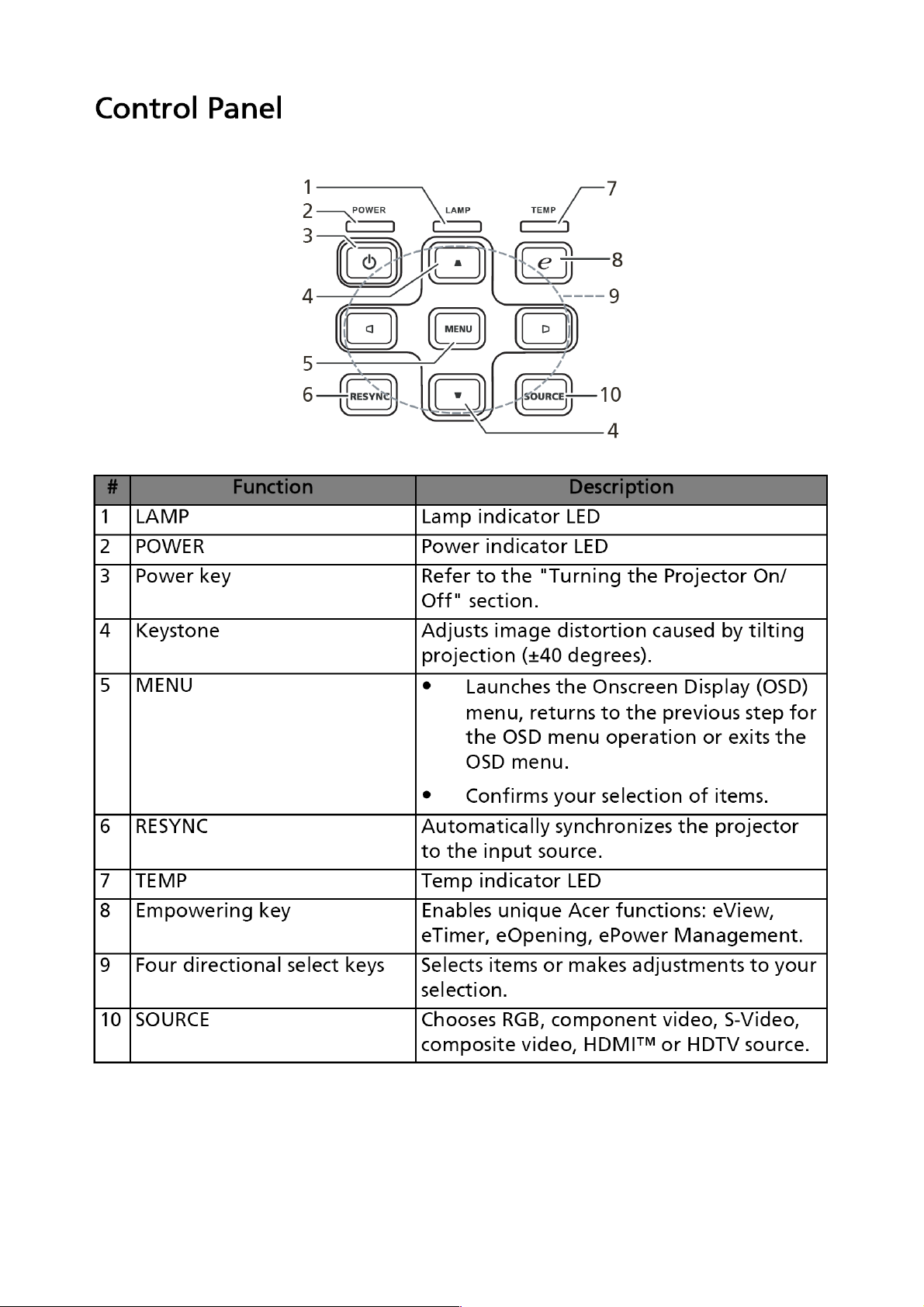

9 Keys:

14.1 Operator Keypad

Power ; Source ; Resync ; e ; Menu ; Left ; Right ;

Up(Keystone-) ; Down(Keystone+)

14.2 Indicators

14.3 Electric Keystone

3 LEDs:

Power On/Off Status; Lamp Status; Temperature Status

Manual vertical keystone and adjustable range ±40

(3D display mode XGA timing adjustable range ±17)

14.4 Digital Zoom

(Only for S5201)

S5201 :

Digital zoom 2X

Note:3D on, Digital Zoom 1.6X

S5201B : N/A

15.0 Audio

15.1 PC Audio Input

15.2 Mic Audio Input

15.3 Audio output

15.4 Speaker

Φ3.5mm stereo mini jack x 2

500mVrms 10 KΩ or more

Φ3.5mm stereo mini jack x 1

Support dynamic & audio mix function

Φ3.5mm mono mini jack x 1

Speaker 4Ω 5W X 2, Amplifier 4W X 2

VGA1 : Audio input 1

15.5 Audio input

VGA2, Composite, S-Video, Audio input 2

(for S5201B/S5301WB : LAN, USB-A source don’t

support audio function)

16.0 Lamp hour

Lamp hour = [Hour used in Normal Mode] + 3.5/5 *[Hour

used in Eco. Mode]

17.0 Closed Caption (CC)

17.1 CC version CC1/CC2/CC3/CC4

After turn off projector, there is 120 seconds called

18.0 Instant On

“Instant On stage”. At this stage, user can turn on the

projector. Aftet this stage, projector will cooling for 20

seconds, and all keypads are not allowed to operate.

Support DLP 3D PC source 100/120Hz and Video

19.0 3D Projection

source 50/60Hz

(for S5201B/S5301WB : 3D on, Digital Zoom only can

support to 1.6X)

20.0 DC output

21.0 Smart Source Detection

DC power jack (Standby mode is off)

Output 12V, 1A max

1. HW source Detection:VGA1, VGA2, HDMI1, HDMI2

9

(Only for S5201)

from DVD which need to go thru FRC

22.0 Alarm sound

(Only for S5201B/ S5301WB)

2. SW source Detection:Please see Appendix E Item 9

22.1 Power on Beep sound Frequency follows Acer SW spec 1.19. Only one volume

22.2 Timer

Frequency follows Acer SW spec 1.19. Three kinds of

volume setting

3D Projection :

This function is only for 3D contents and must wear 3D glasses.

TI DDP DDP2430 TI DDP DDP2431

• Does not support FRC (Frame Rate

Conversion)

• Can not support HQFS 60Hz 3D source

• Support FRC (Frame Rate

Conversion)

• Can support HQFS 60Hz 3D source

from DVD which need to go thru FRC

• Can only support 120Hz 3D source from

PC (VGA/DVI/HDMI)

• Can support 120Hz 3D source from

PC

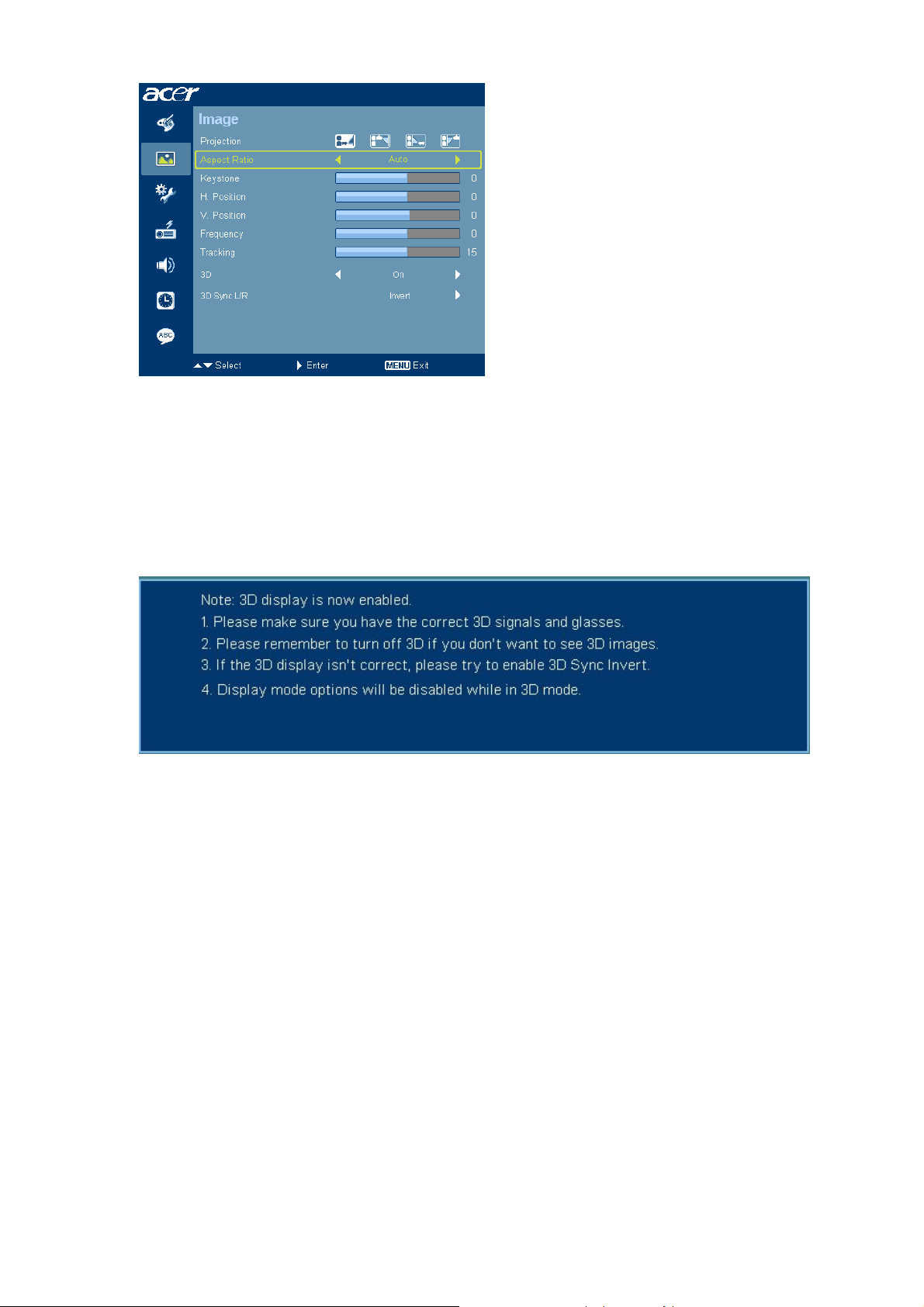

OSD :

− Add “3D”, “3D Sync L/R” in Image Page

− 3D : NVIDIA 3D, DLP 3D, off. Default is Off. All of acer 3D models are support both

NVIDIA and DLP. (V1.17 08/21 update)

− “3D Sync L/R” is adjustable when above "3D" is on. Otherwise gray out. When you

discover the inversion of the image depth (for your Left/Right eyes), do the invert

action to solve this condition. (V1.17 08/21 update)

When choose NVIDIA 3D , 3D Sync L/R is still gray out. (V1.18 09/30 update).

3D Sync L/R only enable for DLP 3D, otherwise it will be gray out (V1.18 09/30

update).

When 3D is enabled, Display Mode and Color temperature (in Color Page) is not

adjustable.

− Function disable :

When 3D is enabled, eView Management and all empowering function (eTimer,

eOpening, ePower) are gray out. eKey is disable (V1.18 09/30 update)

When meeting 60/120Hz (no matter 3D on or off, HSG only one set value), if

enduser adjust adjustable items (ex. brightness), the value will not been stored

and only for that use only.

− For DDP2430 models : 3D / 3D Sync L/R (V1.17 08/21 update) , only appear for

VGA/DVI/HDMI source. Disappear if other sources.

− For DDP2230/2431 models : no this limitation.

10

If non-3D mode (120Hz), keep normal/same brightness.

Not support timing in 3D mode requirement

• 3D function can be opened when 50/60/100/120Hz.

• Refresh rate change to not supported 3D timings under 3D mode, please

show warning message of "Input Not Supported under 3D mode", to

enforce user to change back.

Reminder screen

11

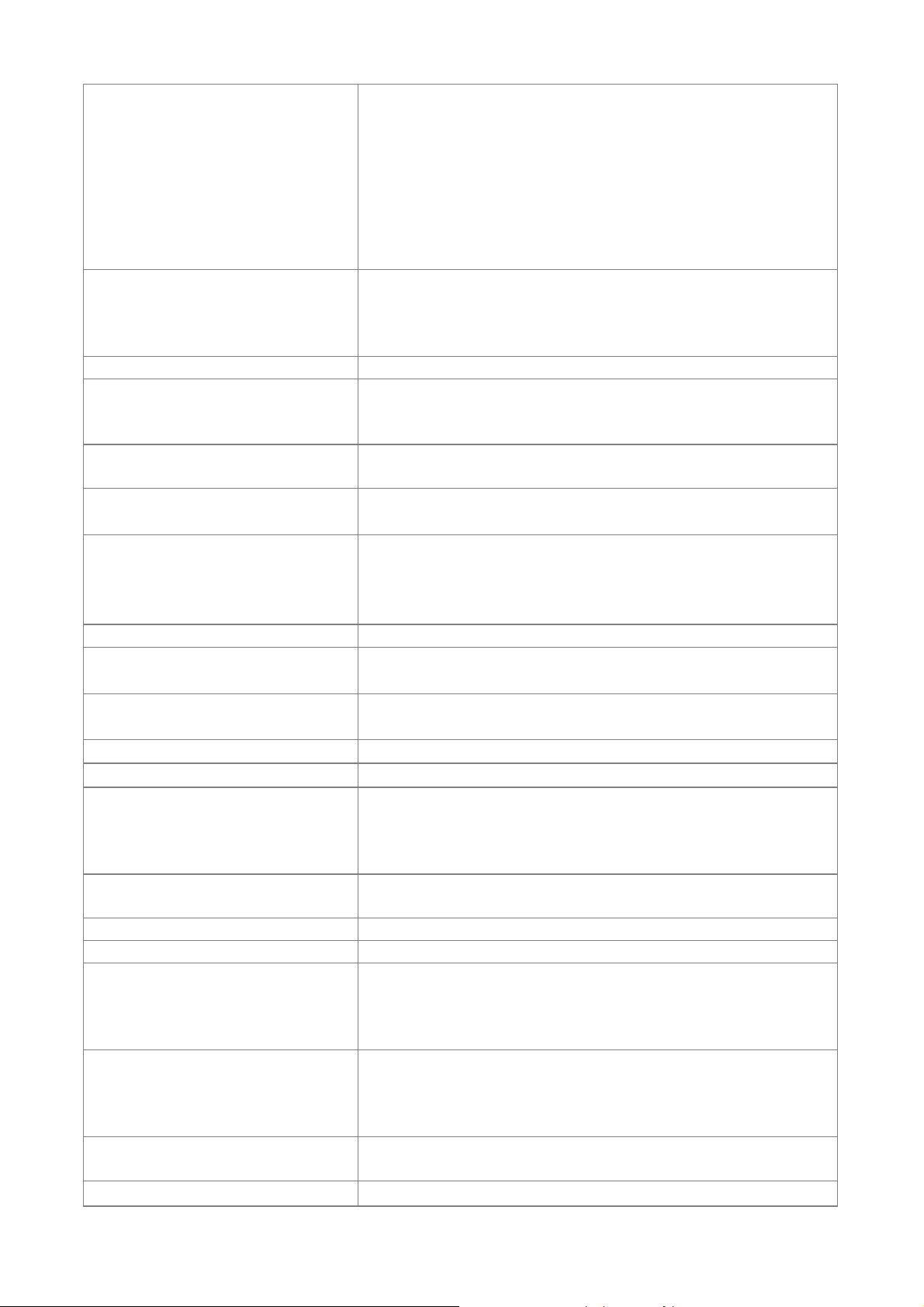

Electrical Specification

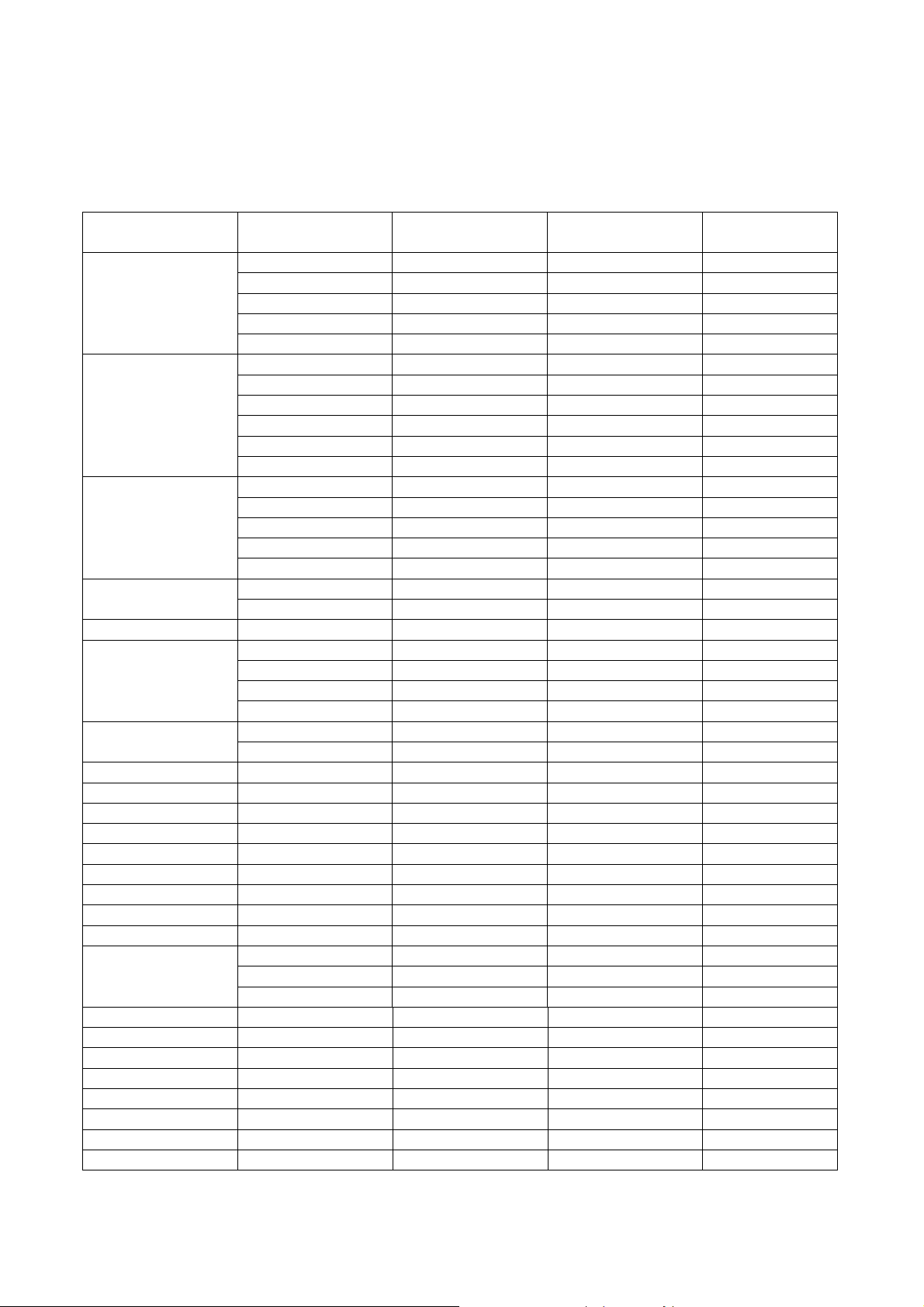

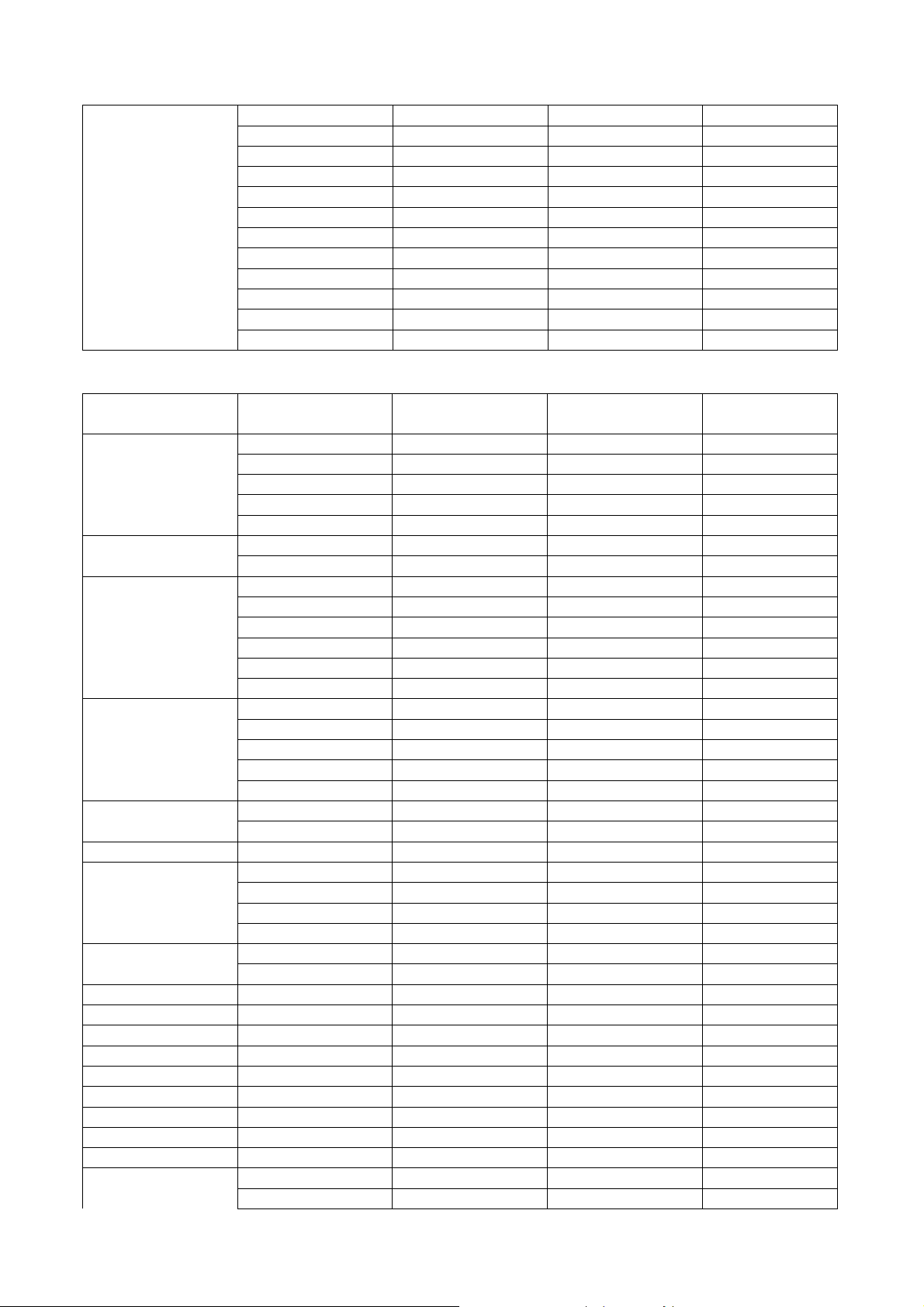

1. Timing Table

The PC timing is as following:

(For S5201):

Resolution Mode

VGA_60 59.940 31.469 25.175

VGA_72 72.809 37.861 31.500

640 x 480

800 x 600

1024 x 768

1152 x 864

1152 x 864 SXGA_85 84.990 77.094 121.500

1280 x 1024

1280 x 960

1400 x 1050 SXGA+_60 59.978 65.317 121.750

1600 x 1200 UXGA_60 60.000 75.000 162.000

640x480@60Hz PowerBook G4 59.940 31.469 25.170

640x480@67Hz PowerBook G4 66.667 35.000 30.240

800x600@60Hz PowerBook G4 60.317 37.879 40.000

1024x768@60Hz

1152x870@75Hz

1280x960@75Hz

1024x768@75Hz

1280 X 768

1280 x 720 WXGA_60 60.000 45.000 74.250

1280 x 800 WXGA_60 59.810 49.702 83.500

1440 x 900 WXGA+_60 59.887 55.935 106.500

1680 x 1050 1680x1050_60 59.954 65.290 146.250

1366 x 768 acer_16:9 59.790 47.712 85.500

1920 x1080 1920x1080_RB 60.000 66.587 138.500

1920 x1080 1920x1080_EIA 60.000 67.500 148.500

1024 x 600 acer_timing 60.000 37.500 50.400

VGA_75 75.000 37.500 31.500

VGA_85 85.008 43.269 36.000

VGA_120 119.518 61.910 52.500

SVGA_56 56.250 35.156 36.000

SVGA_60 60.317 37.879 40.000

SVGA_72 72.188 48.077 50.000

SVGA_75 75.000 46.875 49.500

SVGA_85 85.061 53.674 56.250

SVGA_120 119.854 77.425 83.000

XGA_60 60.004 48.363 65.000

XGA_70 70.069 56.476 75.000

XGA_75 75.029 60.023 78.750

XGA_85 84.997 68.677 94.500

XGA_120 119.804 98.958 137.750

SXGA_70 70.012 63.851 94.500

SXGA_75 75.000 67.500 108.000

SXGA_60 60.020 63.981 108.000

SXGA_72 72.000 76.970 134.600

SXGA_75 75.025 79.976 135.000

SXGA_85 85.024 91.146 157.500

QuadVGA_60 60.000 60.000 108.000

QuadVGA_75 75.000 75.000 126.000

PowerBook G4 60.004 48.363 65.000

PowerBook G4 75.061 68.681 100.00

PowerBook G4 75 75.20 126.00

i MAC DV (G3) 75.020 60.241 80.000

WXGA_60 59.870 47.776 79.500

WXGA_75 74.893 60.289 102.250

WXGA_85 84.837 68.633 117.500

Refresh rate

(Hz)

H-frequency

(kHz)

Clock

(MHz)

12

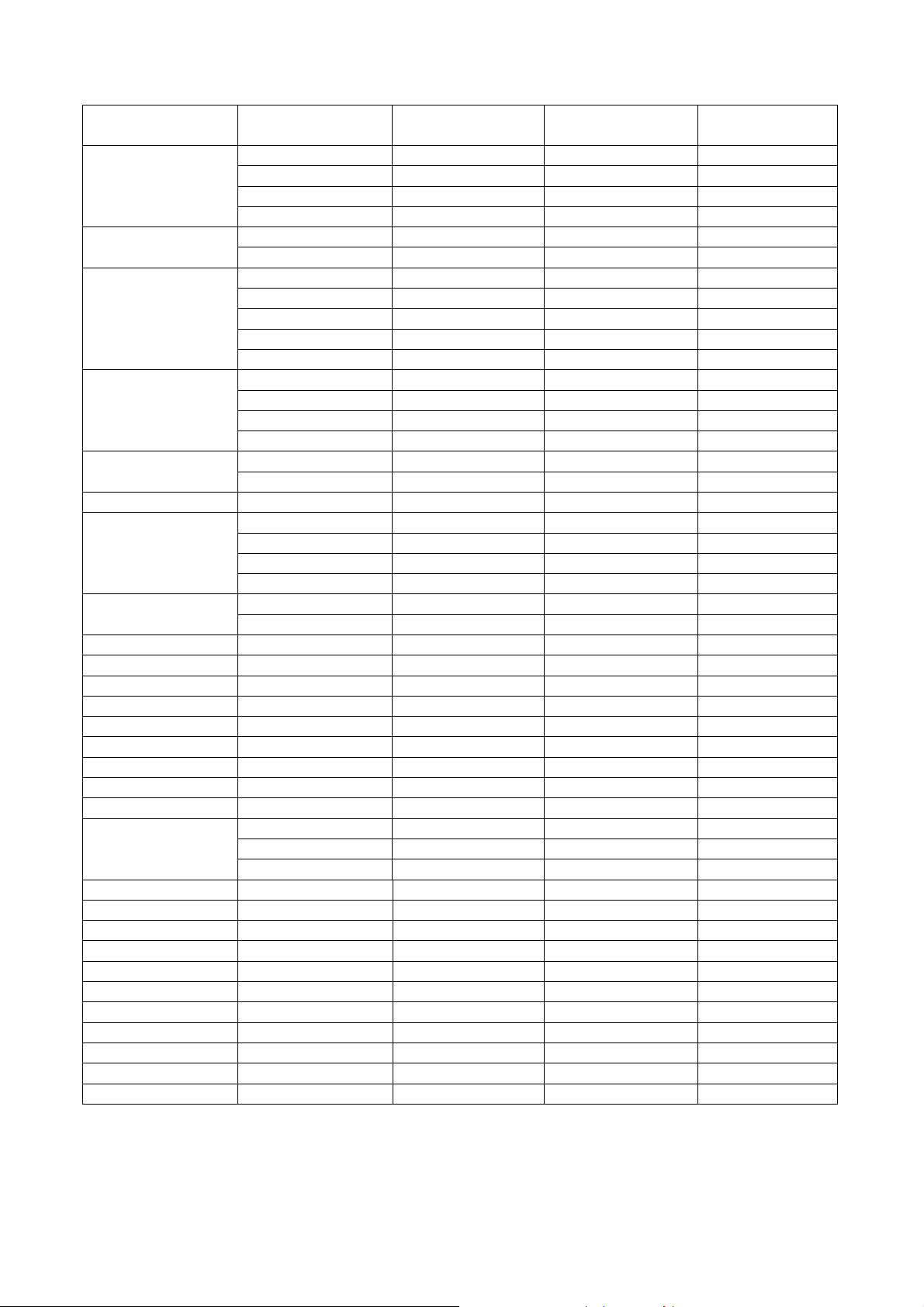

(For S5201B/S5301WB):

Resolution Mode

VGA_60 59.940 31.469 25.175

640 x 480

720 x 400

800 x 600

1024 x 768

1152 x 864

1152 x 864 SXGA_85 84.990 77.094 121.500

1280 x 1024

1280 x 960

1400 x 1050 SXGA+_60 59.978 65.317 121.750

1600 x 1200 UXGA_60 60.000 75.000 162.000

640x480@60Hz Mac G4 59.940 31.469 25.170

640x480@67Hz MAC13 66.667 35.000 30.240

800x600@60Hz Mac G4 60.317 37.879 40.000

832x624@75Hz MAC16 74.546 49.722 57.280

1024x768@60Hz

1024x768@75Hz

1152x870@75Hz

1280 X 768

1280 x 720 WXGA_60 60.000 45.000 74.250

1280 x 800 WXGA_60 59.810 49.702 83.500

1440 x 900 WXGA+_60 59.887 55.935 106.500

1680 x 1050 1680x1050_60 59.954 65.290 146.250

1920 x1080 1920x1080_RB 60.000 66.587 138.500

1920 x1080 1920x1080_EIA 60.000 67.500 148.500

1366 x 768 acer_16:9 59.790 47.712 85.500

1024 x 600 acer_timing 60.000 37.500 50.400

640 x 480 VGA_120 119.518 61.910 52.500

800 x 600 SVGA_120 119.854 77.425 83.000

1024 x 768 XGA_120 119.804 98.958 137.750

VGA_72 72.809 37.861 31.500

VGA_75 75.000 37.500 31.500

VGA_85 85.008 43.269 36.000

VGA_70 70.087 31.469 28.3221

VGA_85 85.039 37.927 35.500

SVGA_56 56.250 35.156 36.000

SVGA_60 60.317 37.879 40.000

SVGA_72 72.188 48.077 50.000

SVGA_75 75.000 46.875 49.500

SVGA_85 85.061 53.674 56.250

XGA_60 60.004 48.363 65.000

XGA_70 70.069 56.476 75.000

XGA_75 75.029 60.023 78.750

XGA_85 84.997 68.677 94.500

SXGA_70 70.012 63.851 94.500

SXGA_75 75.000 67.500 108.000

SXGA_60 60.020 63.981 108.000

SXGA_72 72.000 76.970 134.600

SXGA_75 75.025 79.976 135.000

SXGA_85 85.024 91.146 157.500

QuadVGA_60 60.000 60.000 108.000

QuadVGA_75 75.000 75.000 126.000

Mac G4 60.004 48.363 65.000

MAC19 75.020 60.241 80.000

MAC21 75.061 68.681 100.00

WXGA_60 59.870 47.776 79.500

WXGA_75 74.893 60.289 102.250

WXGA_85 84.837 68.633 117.500

Refresh rate

(Hz)

H-frequency

(kHz)

Clock

(MHz)

13

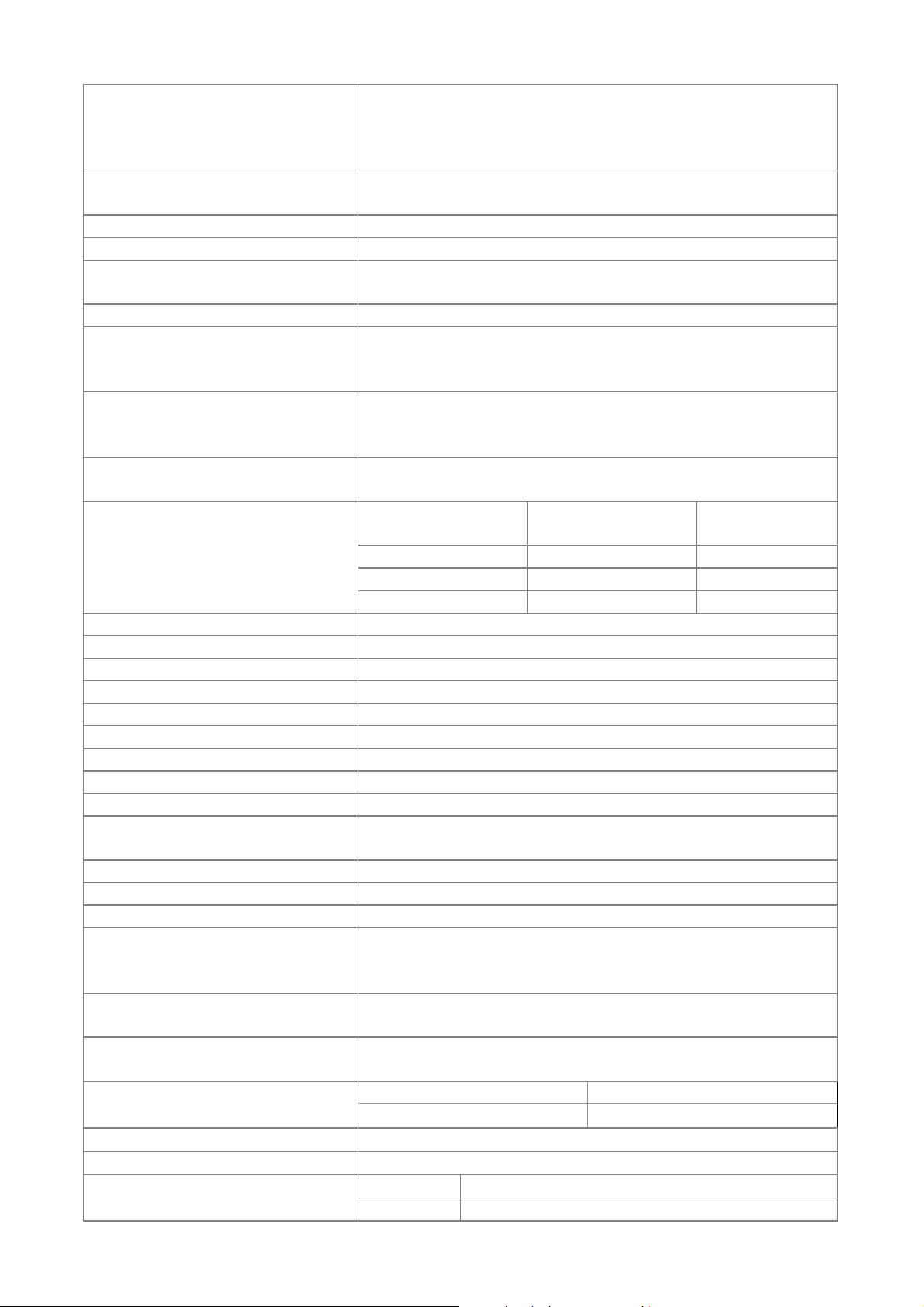

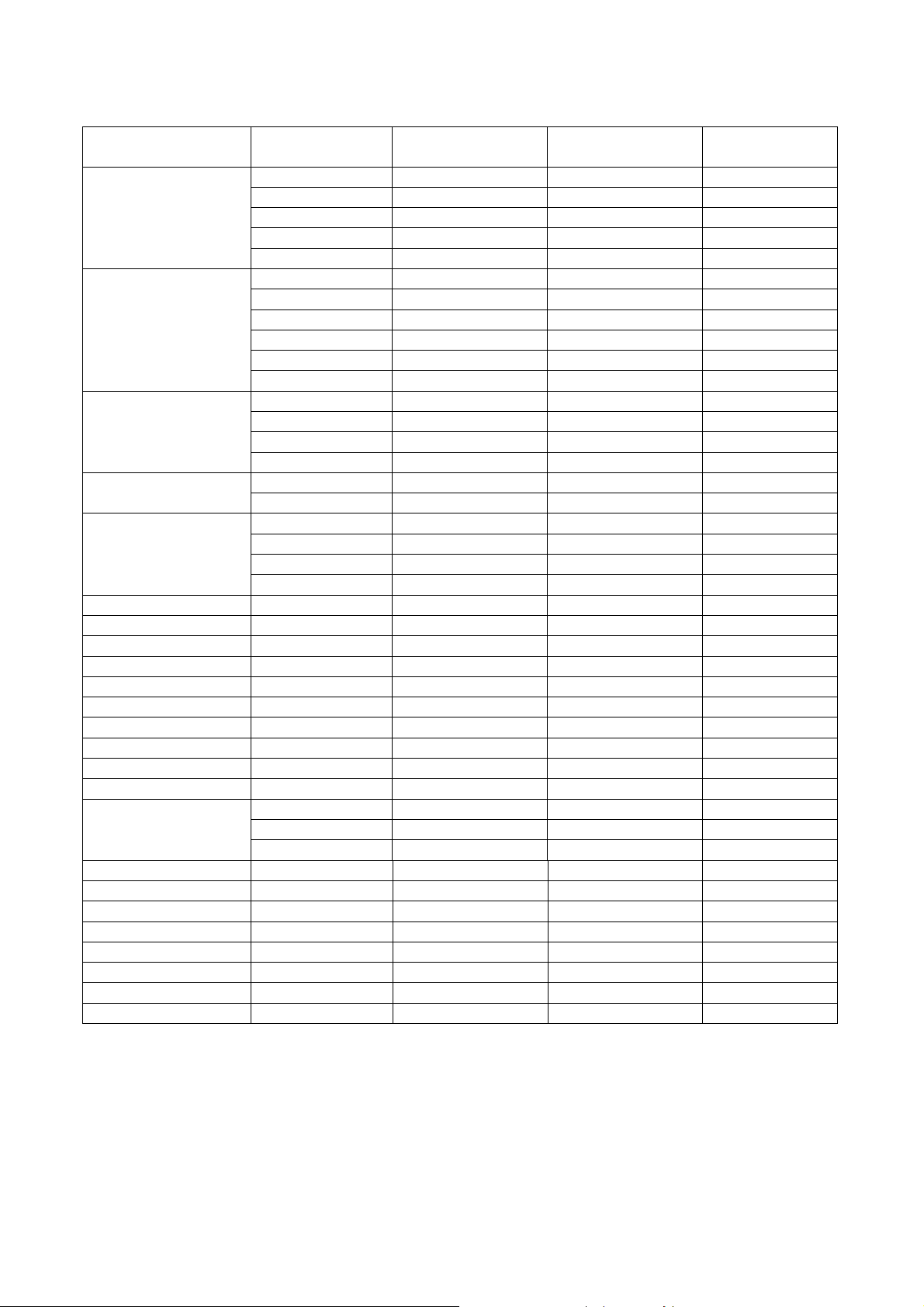

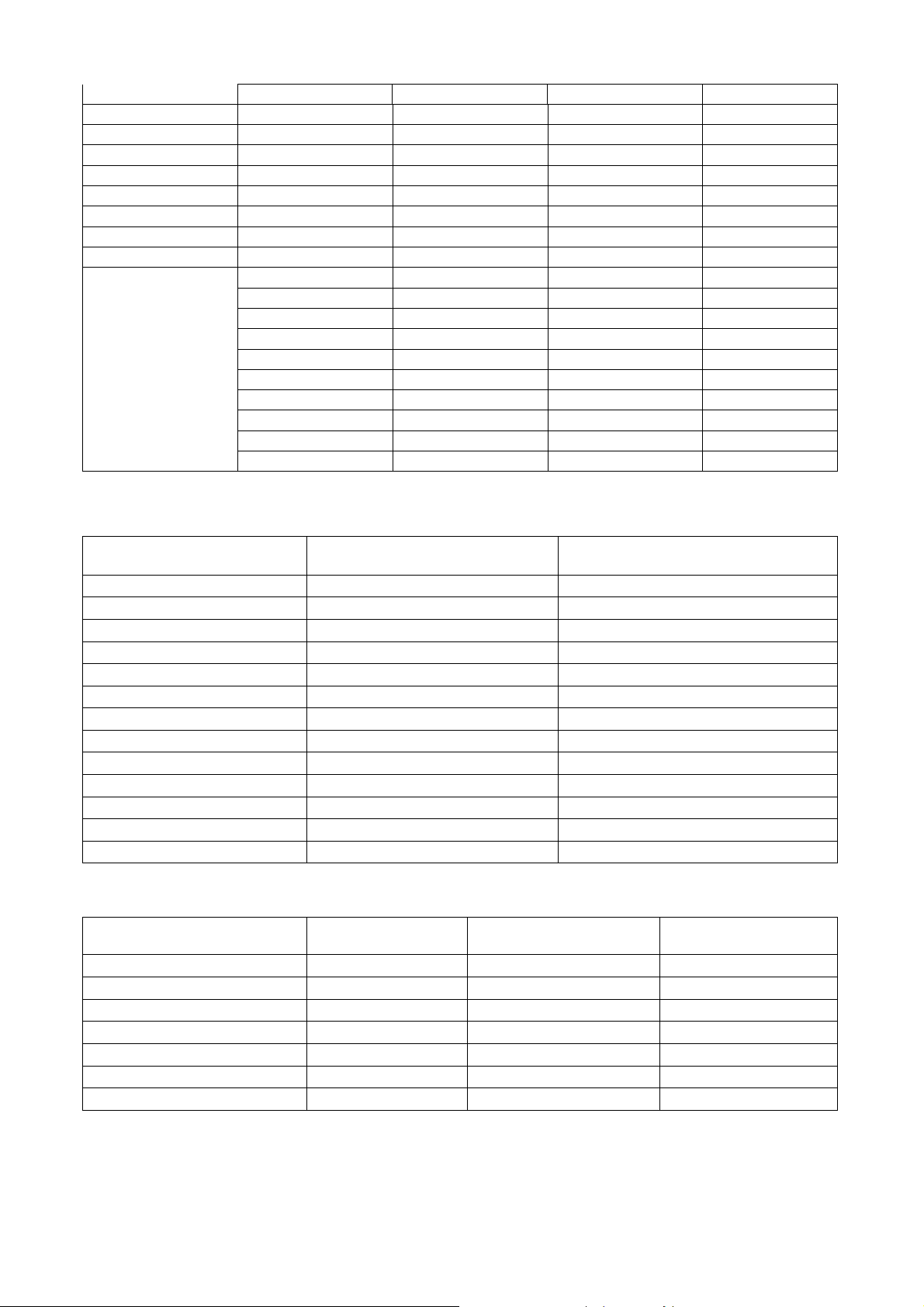

The DVI_D & HDMI (HDCP) Established timing is as following:

(For S5201):

Resolution Mode

VGA_60 59.940 31.469 25.175

VGA_72 72.809 37.861 31.500

640 x 480

800 x 600

1024 x 768

1152 x 864

1280 x 1024

1280 x 960 QuadVGA_75 75.000 75.000 126.000

1400 x 1050 SXGA+_60 59.978 65.317 121.750

1600 x 1200 UXGA_60 60.000 75.000 162.000

640x480@60Hz PowerBook G4

640x480@67Hz PowerBook G4

800x600@60Hz PowerBook G4

1024x768@60Hz PowerBook G4

1152x870@75Hz PowerBook G4

1280 x 960@75Hz PowerBook G4

1024x768@75Hz i MAC DV (G3)

1280 x 768

1280 x 720 WXGA_60 60.000 45.000 74.250

1280 x 800 WXGA_60 59.810 49.702 83.500

1440 x 900 WXGA+_60 59.887 55.935 106.500

1680 x 1050 1680x1050_60

1366 x 768 acer_16:9 59.790 47.712 85.500

1920 x1080 1920x1080_RB

1920 x1080 1920x1080_EIA

1024 x 600 acer_timing 60.000 37.500 50.400

VGA_75 75.000 37.500 31.500

VGA_85 85.008 43.269 36.000

VGA_120 119.518 61.910 52.500

SVGA_56 56.250 35.156 36.000

SVGA_60 60.317 37.879 40.000

SVGA_72 72.188 48.077 50.000

SVGA_75 75.000 46.875 49.500

SVGA_85 85.061 53.674 56.250

SVGA_120 119.854 77.425 83.000

XGA_60 60.004 48.363 65.000

XGA_70 70.069 56.476 75.000

XGA_75 75.029 60.023 78.750

XGA_120 119.804 98.958 137.750

SXGA_75 75.000 67.500 108.000

SXGA_85 84.990 77.094 121.500

SXGA_60 60.020 63.981 108.000

SXGA_72 72.000 76.970 134.600

SXGA_75 75.025 79.976 135.000

SXGA_85 85.024 91.146 157.500

WXGA_60 59.870 47.776 79.500

WXGA_75 74.893 60.289 102.250

WXGA_85 84.837 68.633 117.500

Refresh rate

(Hz)

59.940 31.469 25.170

66.667 35.000 30.240

60.317 37.879 40.000

60.004 48.363 65.000

75.061 68.681 100.00

75.000 75.200 126.000

75.020 60.241 80.000

59.954 65.290 146.250

60.000 66.587 138.500

60.000 67.500 148.500

H-frequency

(kHz)

Clock

(MHz)

14

480i 60 15.73 27.000

480p 60 31.47 27

576i 50 15.63 27.000

576p 50 31.25 27.000

720p_60 60 45.00 74.25

Video(HDMI)

720p_50 50 37.50 74.25

1080i_60 60 33.75 74.25

1080i_50 50 28.13 74.25

1080p 60 67.5 148.5

1080p 50 56.26 148.5

1080p 24 27.00 74.25

1080p 23.98 26.97 74.175

(For S5201B/S5301WB) :

Resolution Mode

VGA_60 59.940 31.469 25.175

VGA_72 72.809 37.861 31.500

640 x 480

720 x 400

800 x 600

1024 x 768

1152 x 864

1152 x 864 SXGA_85 84.990 77.094 121.500

1280 x 1024

1280 x 960

1400 x 1050 SXGA+_60 59.978 65.317 121.750

1600 x 1200 UXGA_60 60.000 75.000 162.000

640x480@60Hz Mac G4 59.940 31.469 25.170

640x480@67Hz MAC13 66.667 35.000 30.240

800x600@60Hz Mac G4 60.317 37.879 40.000

832x624@75Hz MAC16 74.546 49.722 57.280

1024x768@60Hz

1024x768@75Hz

1152x870@75Hz

VGA_75 75.000 37.500 31.500

VGA_85 85.008 43.269 36.000

VGA_120 119.518 61.910 52.500

VGA_70 70.087 31.469 28.3221

VGA_85 85.039 37.927 35.500

SVGA_56 56.250 35.156 36.000

SVGA_60 60.317 37.879 40.000

SVGA_72 72.188 48.077 50.000

SVGA_75 75.000 46.875 49.500

SVGA_85 85.061 53.674 56.250

SVGA_120 119.854 77.425 83.000

XGA_60 60.004 48.363 65.000

XGA_70 70.069 56.476 75.000

XGA_75 75.029 60.023 78.750

XGA_85 84.997 68.677 94.500

XGA_120 119.804 98.958 137.750

SXGA_70 70.012 63.851 94.500

SXGA_75 75.000 67.500 108.000

SXGA_60 60.020 63.981 108.000

SXGA_72 72.000 76.970 134.600

SXGA_75 75.025 79.976 135.000

SXGA_85 85.024 91.146 157.500

QuadVGA_60 60.000 60.000 108.000

QuadVGA_75 75.000 75.000 126.000

Mac G4 60.004 48.363 65.000

MAC19 75.020 60.241 80.000

MAC21 75.061 68.681 100.00

WXGA_60 59.870 47.776 79.500 1280 x 768

WXGA_75 74.893 60.289 102.250

Refresh rate

(Hz)

H-frequency

(kHz)

Clock

(MHz)

15

WXGA_85 84.837 68.633 117.500

1280 x 720 WXGA_60 60.000 45.000 74.250

1280 x 800 WXGA_60 59.810 49.702 83.500

1440 x 900 WXGA+_60 59.887 55.935 106.500

1680 x 1050 1680x1050_60 59.954 65.290 146.250

1920 x1080 1920x1080_RB 60.000 66.587 138.500

1920 x1080 1920x1080_EIA 60.000 67.500 148.500

1366 x 768 acer_16:9 59.790 47.712 85.500

1024 x 600 acer_timing 60.000 37.500 50.400

480p 60 31.47 27

576p 50 31.25 27.000

720p_60 60 45.00 74.25

720p_50 50 37.50 74.25

Vedio(HDMI)

1080i_60 60 33.75 74.25

1080i_50 50 28.13 74.25

1080p 60 67.5 148.5

1080p 50 56.26 148.5

1080p 24 27.00 74.25

1080p 23.98 26.97 74.175

(For all series):

YPbPr support timing is as following:

Signal format fh(kHz) fv(Hz)

480i(525i)@60Hz 15.73 59.94

480p(525p)@60Hz 31.47 59.94

576i(625i)@50Hz 15.63 50.00

576p(625p)@50Hz 31.25 50.00

720p(750p)@60Hz 45.00 60.00

720p(750p)@50Hz 37.50 50.00

1080i(1125i)@60Hz 33.75 60.00

1080i(1125i)@50Hz 28.13 50.00

1080P@60HZ 67.5 60.00

1080P@50Hz 56.26 50.00

1080P@24Hz 27.00 24.00

1080P@24Hz 27.00 24.00

1080P@23.98Hz 26.97 23.98

Video, S-Video support timing is as following:

Video mode fh(kHz) fv(Hz) fsc(MHz)

NTSC 15.73 60 3.58

PAL 15.63 50 4.43

SECAM 15.63 50 4.25 or 4.41

PAL-M 15.73 60 3.58

PAL-N 15.63 50 3.58

PAL-60 15.73 60 4.43

NTSC4.43 15.73 60 4.43

16

2. Characteristics of inputs/outputs

Signal Parameter Min Type Max

RDATA

GDATA

BDATA

Impedance 75 Ohm

Amplitude 0.7 Volts peak-to-peak

Black pedestal 0 Volts

Pixel Clock 170 M Hz

GDATA_SO

G

Impedance 75 Ohm

Amplitude 1 Volts peak-to-peak

Video amplitude 0.7 Volts peak-to-peak

Sync amplitude 0.3 Volts peak-to-peak

Black pedestal 0 Volts

Pixel Clock 170 M Hz

HDATA

Impedance 1 K ohm

Amplitude, low level 0 0.8 volt

Amplitude, high level 2.5 5 Volt

Frequency 31 99 K Hz

VDATA

Impedance 1 K ohm

Amplitude, low level 0 0.8 volt

Amplitude, high level 2.5 5 Volt

Frequency 48 120 Hz

Amplitude, low level 0 0.8 volt SDADATA

Amplitude, high level 3 5 Volt

Amplitude, low level 0 0.8 volt SCLDATA

Amplitude, high level 3 5 Volt

RXD Amplitude -25 25 Volt

TXD Amplitude -13.2

CVBS

Luminance

Amplitude, total (video+

sync)

1 Volts peak to peak

13.2 Volt

Amplitude, video 0.7 Volts peak to peak

Amplitude, sync 0.3 Volts peak to peak

Impedance 75 ohm

Amplitude 700 m Volts peak to peak CVBS

Chroma

Audio

Impedance 75 ohm

Impedance (audio in) 10 Kohm

Amplitude (audio in) 500 mVolts rms

Bandwidth 300H

16kHz

z

S/N Ratio 40 %

Total Harmonic

10 %

Distortion

Microphone

Transducer Principle Dynamic

Impedance 300

Frequency response 600

1K ohm

16k

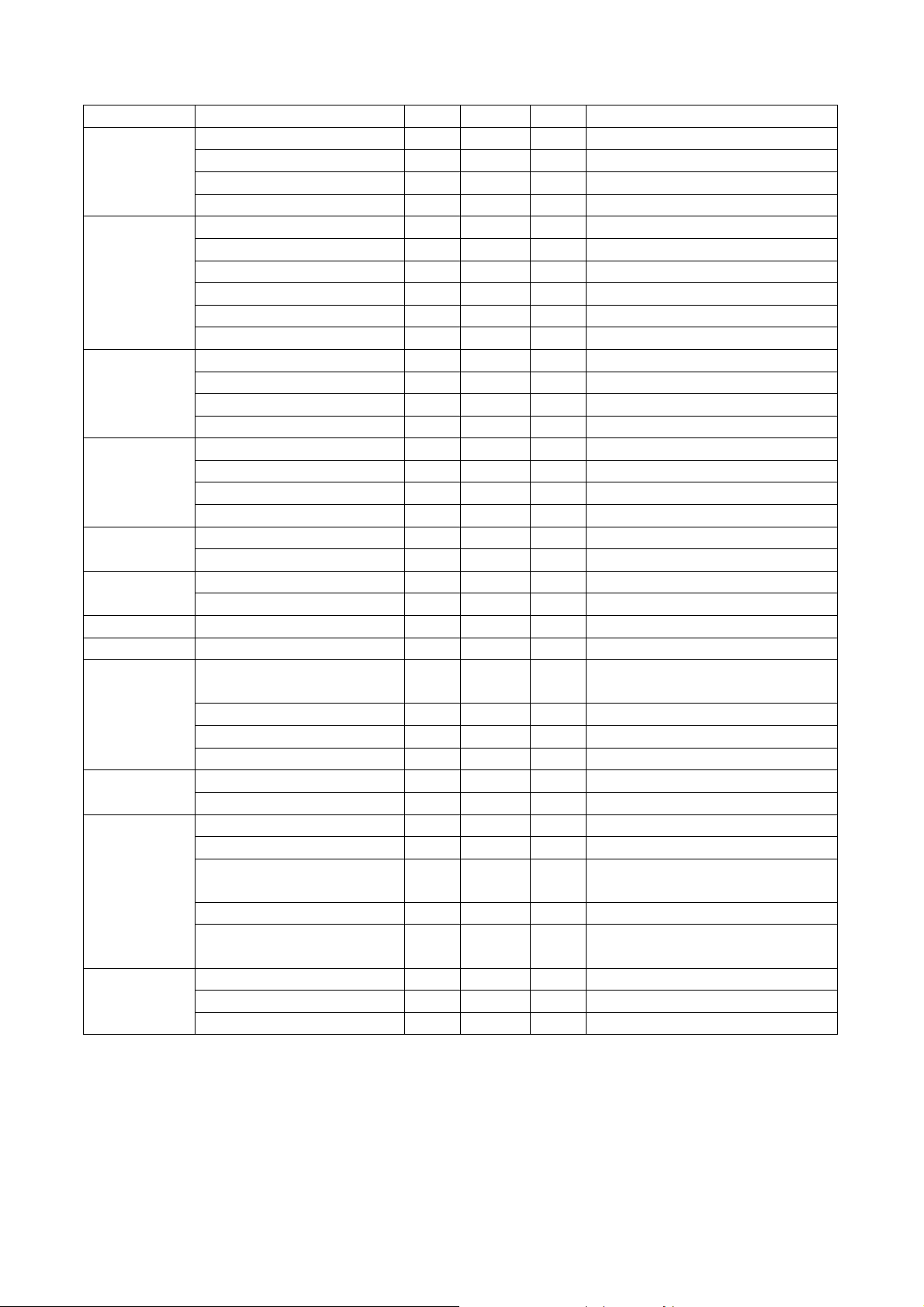

3. Electrical Interface Character

Interface Definition

Hz

15 pin definition of the mini D-sub male for DDC2B protocol

17

1

6

5

10

11

15

Pin Definition Pin Definition Pin Definition Pin

1

Red video

(Pr)

2

5 NC 6

Green Video

(Y)

Red Video

Return

3

7

Blue Video

Green Video

(Pb)

Return

9 DDCP 5V 10 GND 11 GND 12

13

Horizontal

Sync

14 Vertical Sync 15

Data clock

(SCL)

Video & Component Input

1111

Pin Definition

Composite input

Composite input

Composite inputComposite input

1

Composite video

input

S-Video input

Pin Description

3

241

1 GND

2

GND

3 Luminance

4 Chroma

Definition

4 NC

8

Blue Video

Return

Bi-directional

data (SDA)

RS232 Control Port

LAN Control Port

Pin Description

1 TX

2 RX

3 GND

Pin

1 TD+ 5

Signal Pin

Signal

Common Mode

Termination

2 TD- 6 RD-

3 RD+ 7

4

Common Mode

Termination

8

Common Mode

Termination

Common Mode

Termination

18

HDMI Input

Mini USB TYPE B (for S5201B/S5301WB)

Pin Description

1 Vbus

2 D3 D+

4 ID

5 GND

19

Power Supply Specification

1. Input Power Specification

Specification Description

Input Voltage Range

Frequency Range

The unit shall meet all the operating requirements with the range

90 ~ 264 VAC

The unit shall meet all the operating requirements with an input

frequency range 47 Hz ~ 63 Hz

Normal operation: 352W (Max)

Power Consumption

standby mode: < 1W, at 100 ~ 240VAC, monitor out function off,

LAN function off, 12V outlet off

Regulation Efficiency 80 % (typical) measuring at 115Vac and full load

2. Output Power Requirement

The power supply can provide DC output as below:

NO. Voltage

1 +12 V

2 +5V

3 +380V

Regulation Load Current Range Ripple & Noise

10 % 0 A ~ 2 A 240 mV

5 % 0.03 ~ 0.1A 100mV

370~400 0.2A 25V

3. Lamp Power specifications

Specification Description

Applicable Lamp Nor: 230W, Eco: 170W, AC operation

Starting pulse from Ignitor 2.1KV Min.

4. Power Protection

Item Criteria

Short protection No damage

OVP

5V: 6 ~6.5V, 12V: 13 ~16V, 380V: 450 ~490V <30ms

OPP DC-DC 120~160%

5. Surge test: Meet EN61000-4-5

L

N 1KV, L, N PE 2KV, Criteria B

6. Electrical Fast Transients (EFT):Meet EN61000-4-4

2 KV, Criteria B

7. Voltage Dips: Meet EN61000-4-11

0% 250 cycle; 40%, 70% reduction 5 cycle, no damage

8. Harmonic current test: Meet EN61000-3-2

20

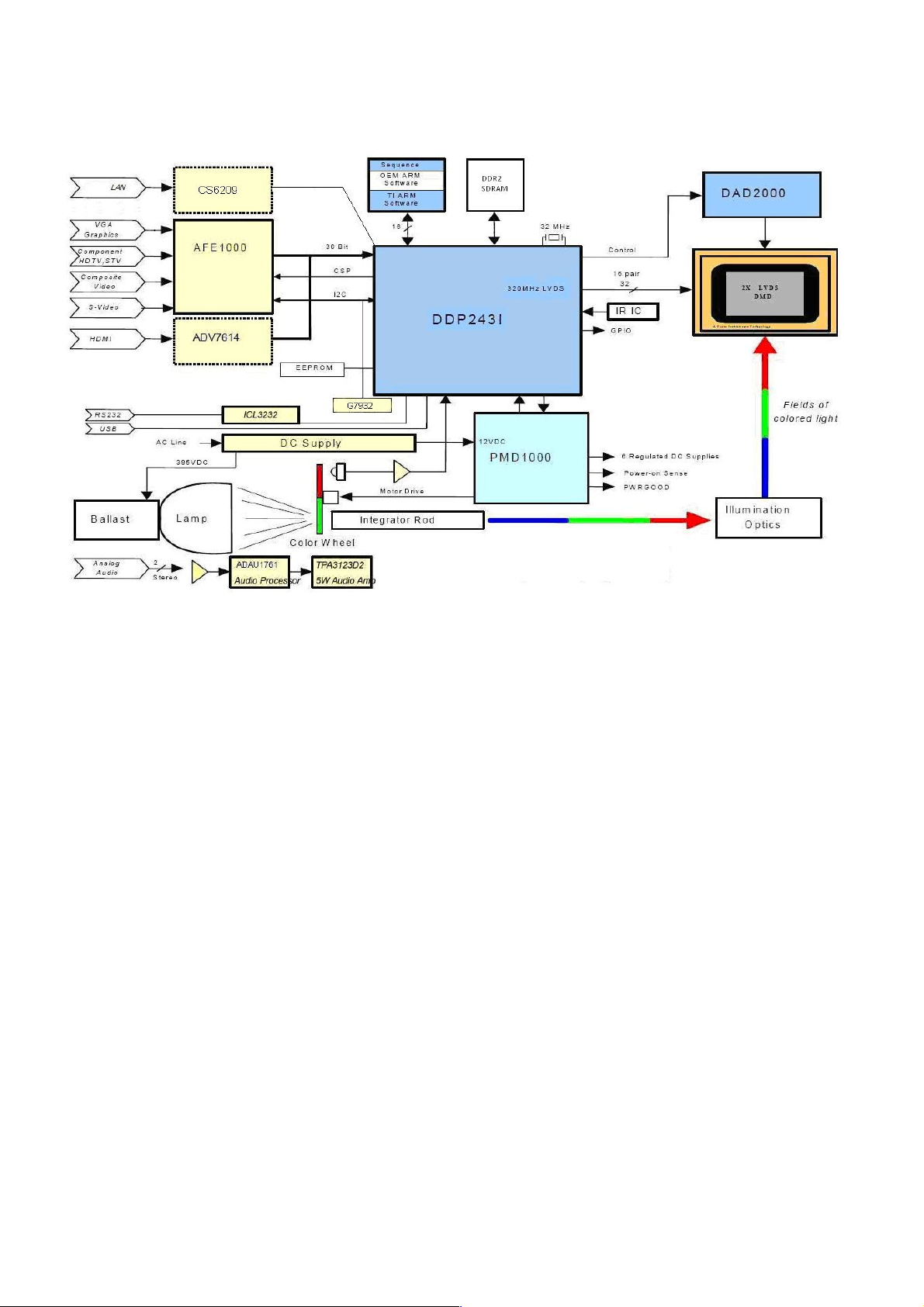

System Block Diagram

21

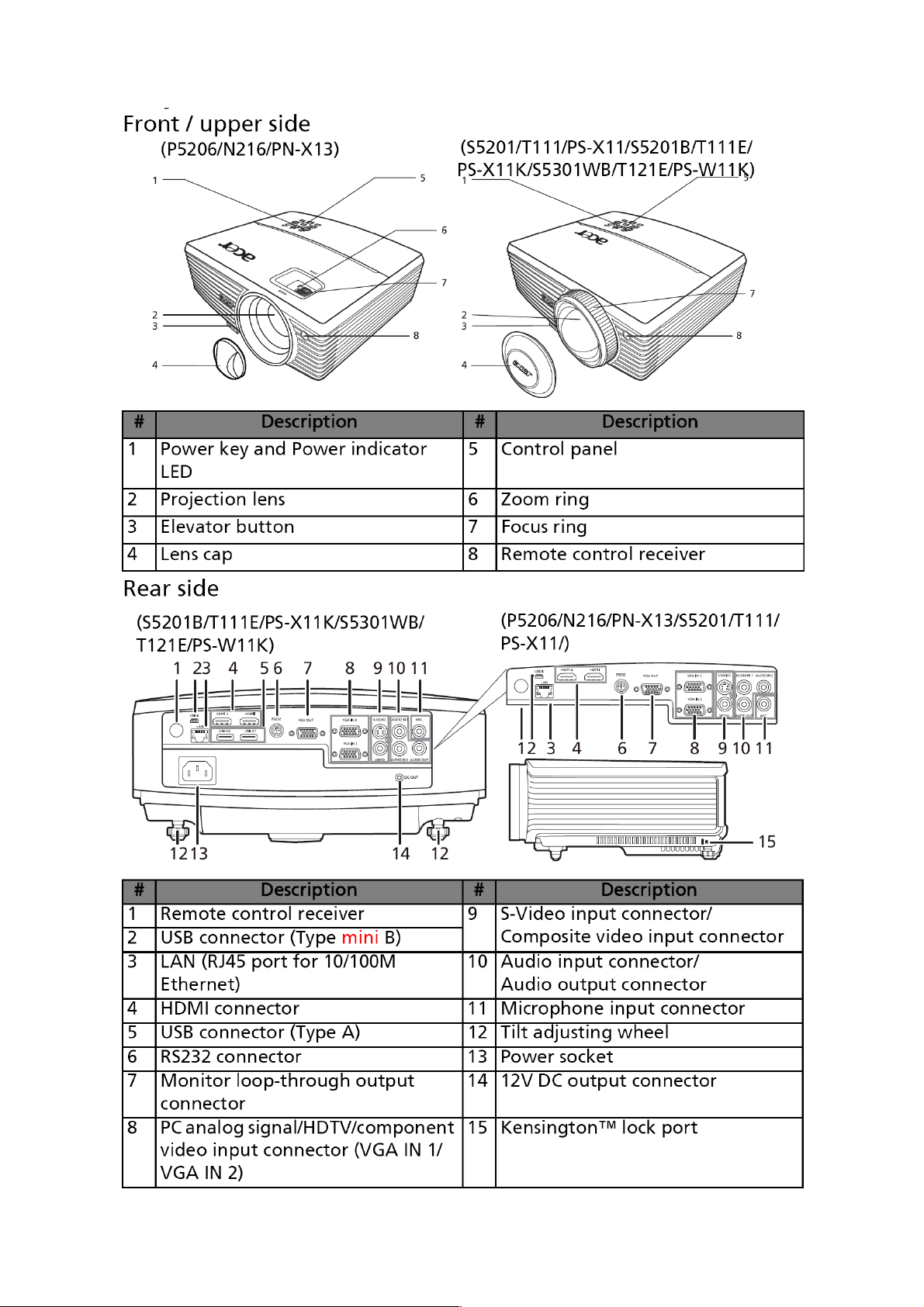

Product Overview

22

23

24

25

Chapter 2 System Utilities

Firmware Upgrade SOP

Basic Operating

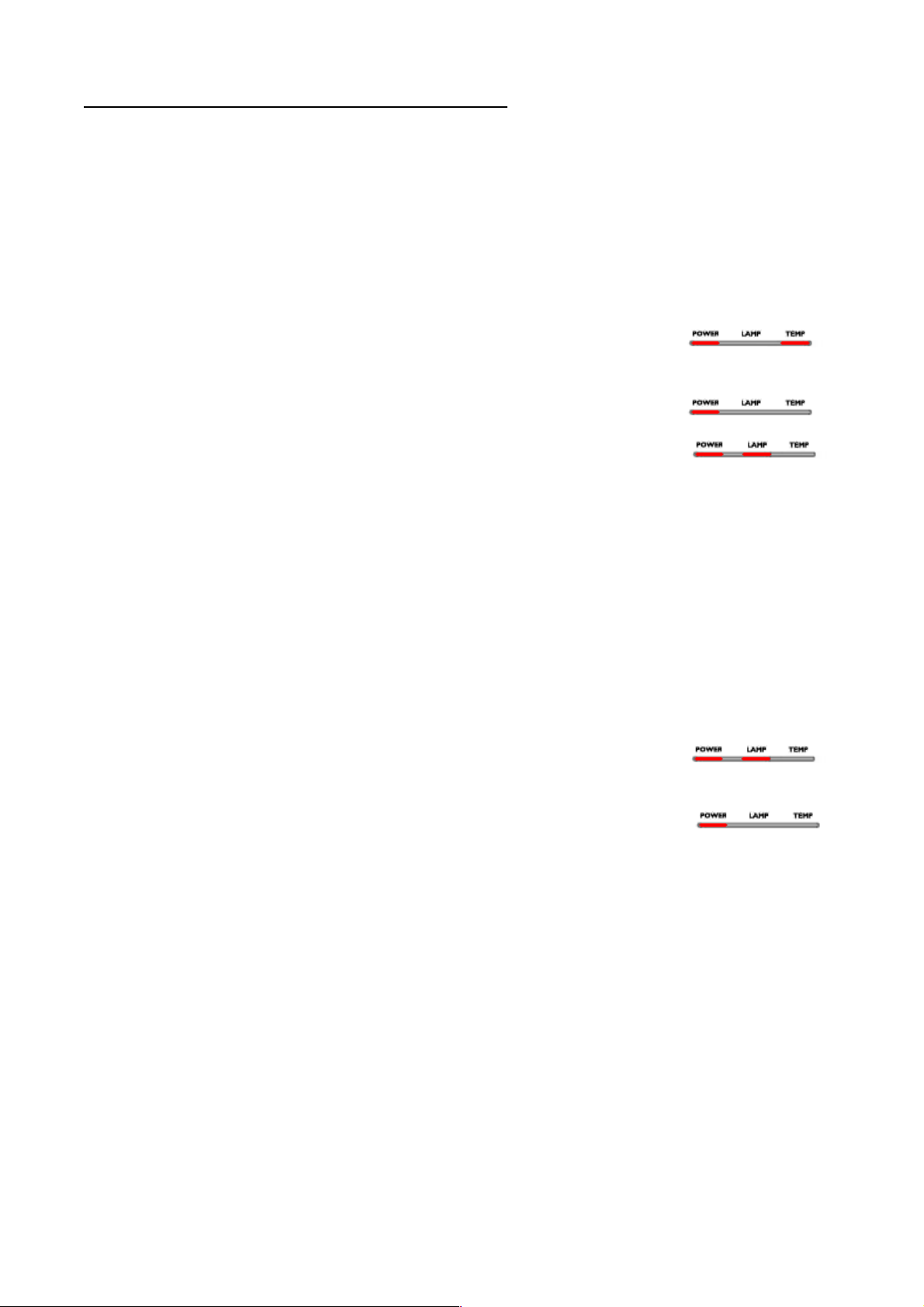

Low-Power Standby Mode::::

This mode is applied for normal situation. If you want to enter this mode, you could just

plug in power cord. Power LED will show Red for 1 sec then show Orange.

When the power LED shows Red, it means system is not ready for low-power standby.

In another word, if the power LED shows Orange, it means system is in low-power standby

mode and the whole system is not supported by power except MCU and its related circuits.

Meanwhile, the power consumption should under 1W.

Download Mode::::

This mode is applied for Download firmware or debug.

One method to enter this mode is that you should press and hold keypad Power and

Menu together, then plug in power cord. Release the two keypads until the Power LED

show Power, Lamp and Temp LED show Red continuously

The other method is to type RS-232 Command:<CR>*Stby=H#<CR>

In full-power standby mode, system will be supported by full power but not turn on

projector. You can use DLP composer and communicate with DLP ASIC. Thus, you should

download firmware in this mode.

Full-Power Standby Mode::::

This mode also can download FW, you should press and hold keypad Power and

Source together, then plug in power cord. Release the two keypads until the Power LED

show Red continuously.

26

Download MCU Code, LAN and Firmware

1. Download WT61P803/WT6702 MCU Code::::(in Low - Power Standby, for

S5201 all series)

Condition::::

Situation 1:MCU code is empty (The 1st time to plug in power cord)

Situation 2:MCU version update

System Action::::

System needs a few sec to download MCU automatically.

Downloading::::POWER and Temp LED will show red.

Download Success::::System will go back Low-Power standby mode and Power

LED will show red.

Download Fail : POWER and Lamp LED will show red.

Notice::::

Do NOT interrupt power when downloading.

2. Download CS6209 LAN Firmware::::(for S5201)

Firmware Download Procedure::::

1. Enter Factory Mode page 7

2. Under CS6209, set Lan Download On

3. Turn off projector, and the projector will download LAN firmware automatically.

System Action::::

Downloading::::POWER and LAMP LED will show RED.

Download success : system will go back low-power standby mode and Power

LED will show RED.

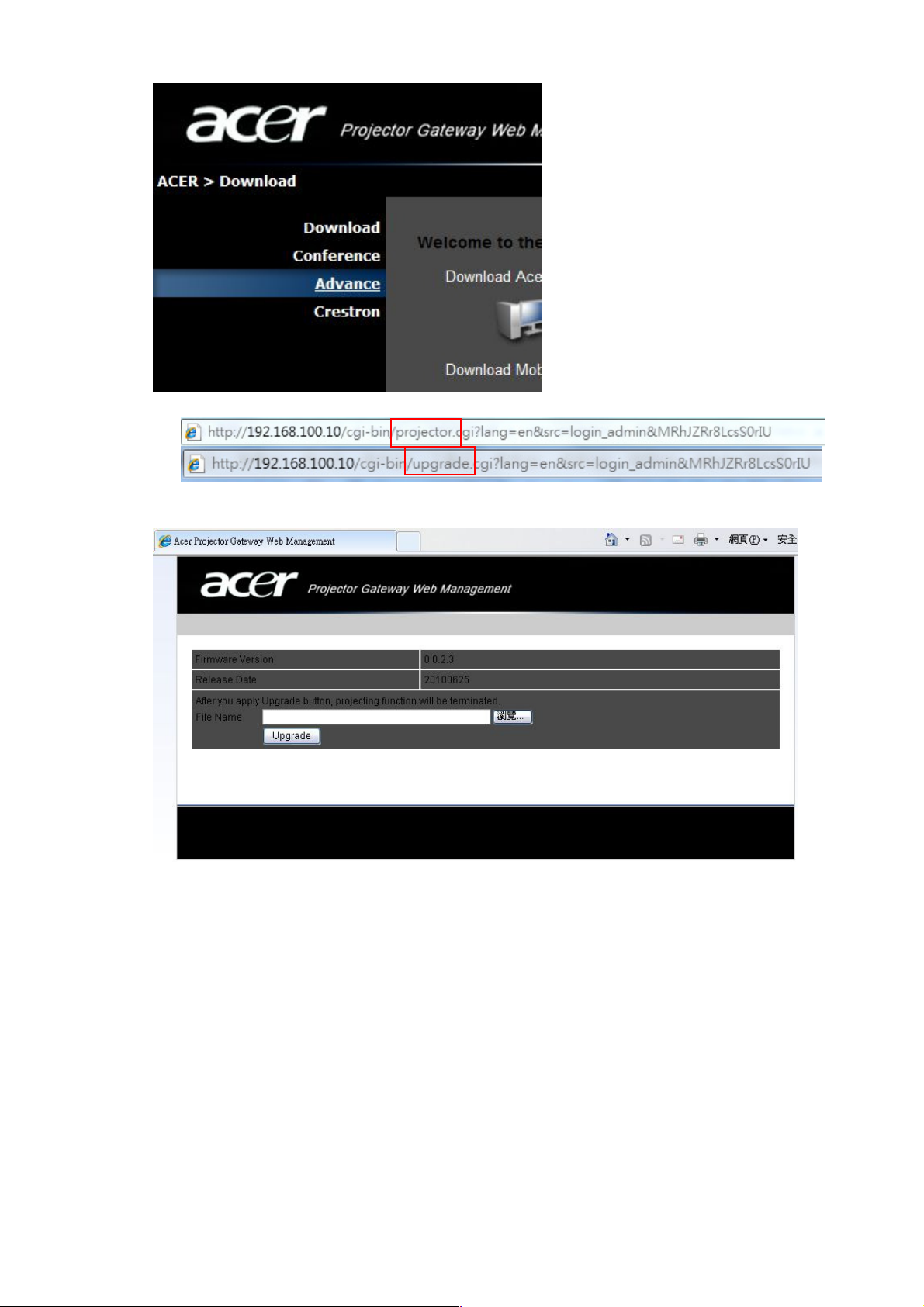

3. Download AWIND Firmware::::(for S5201B/S5301WB Extension board)

Awind firmware Upgrade procedure::::

1. Turn on projector

2. Connect PC and projector RJ45 connector with CAT 5 wire directly

3. Change projector source to LAN source(must enter OSD to turn on LAN first)

4. Wait about 10~20 sec

5. Open PC Browser and enter 192.168.100.10

6. Please connect to web and click "Advance" to log in as root. (hint:

password->123456)

27

7. after login it, modify the web address, modify “projector” to “upgrade”, as below

8. If your connection success, you will see following web:

9. Select image file (*.img) and press Upgrade.

10. Wait count down to finish upgrading.

28

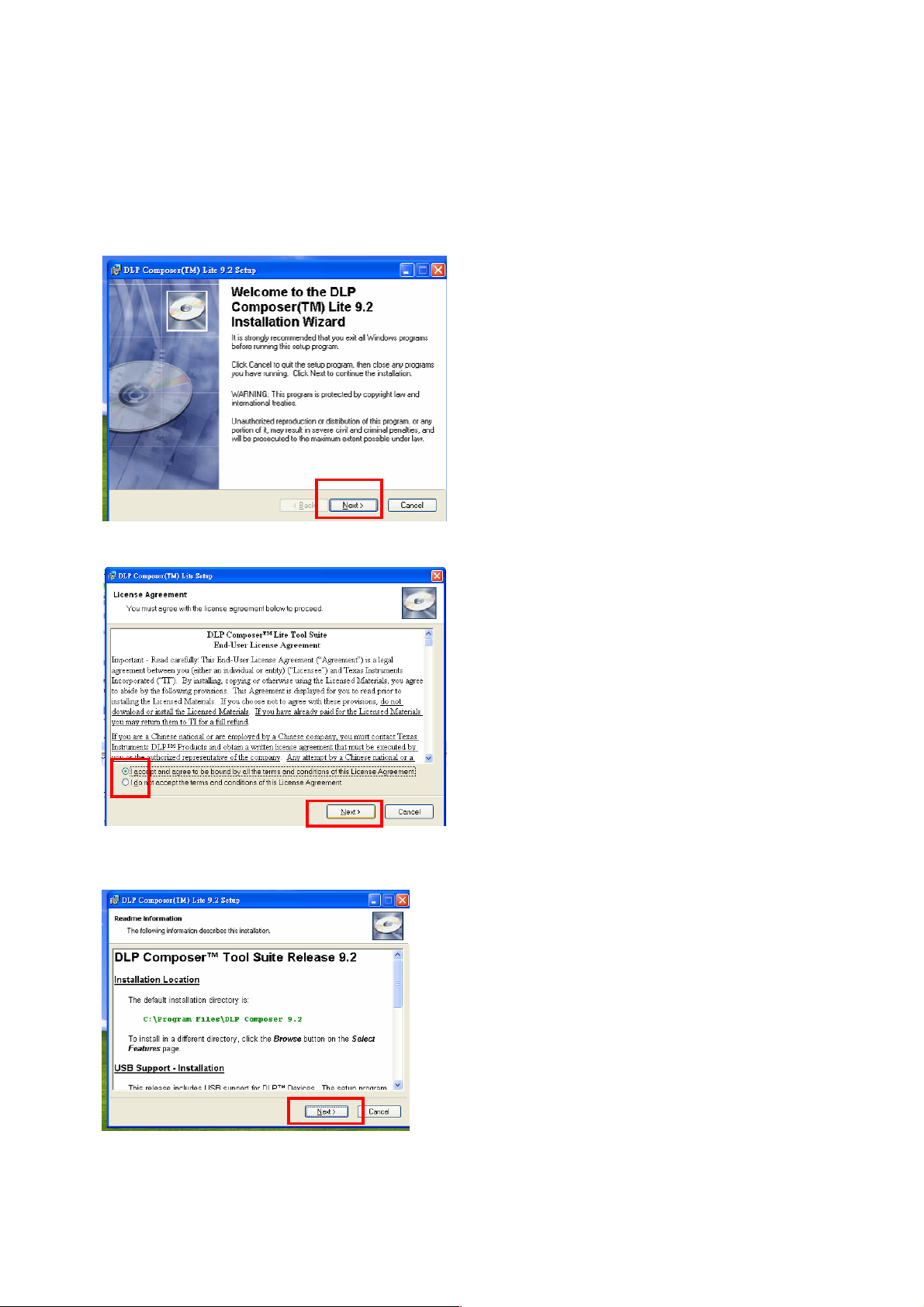

4. Download Main Firmware(For all series)::::

DLP Composer LIte Installation Process

(1) Installation

1. Double click the Setup file for DLP Composer Lite 9.0 or above version.

2. When the Installation Wizard appears, click “Next”.

3. Select to accept the License Agreement, than click “Next”

4. Click “Next” in the following steps to continue installation process.

29

Note:

The default installation directory is:

C:\Program Files\DLP Composer Lite9.2

If you want to install to a different directory (perhaps

alongside a prior release of DLP Composer™ Lite),

click the "Browse" button on the "Select Features"

page.

5. When finishing installation, click “Finish”, and then restart your computer to complete the

installation process.

30

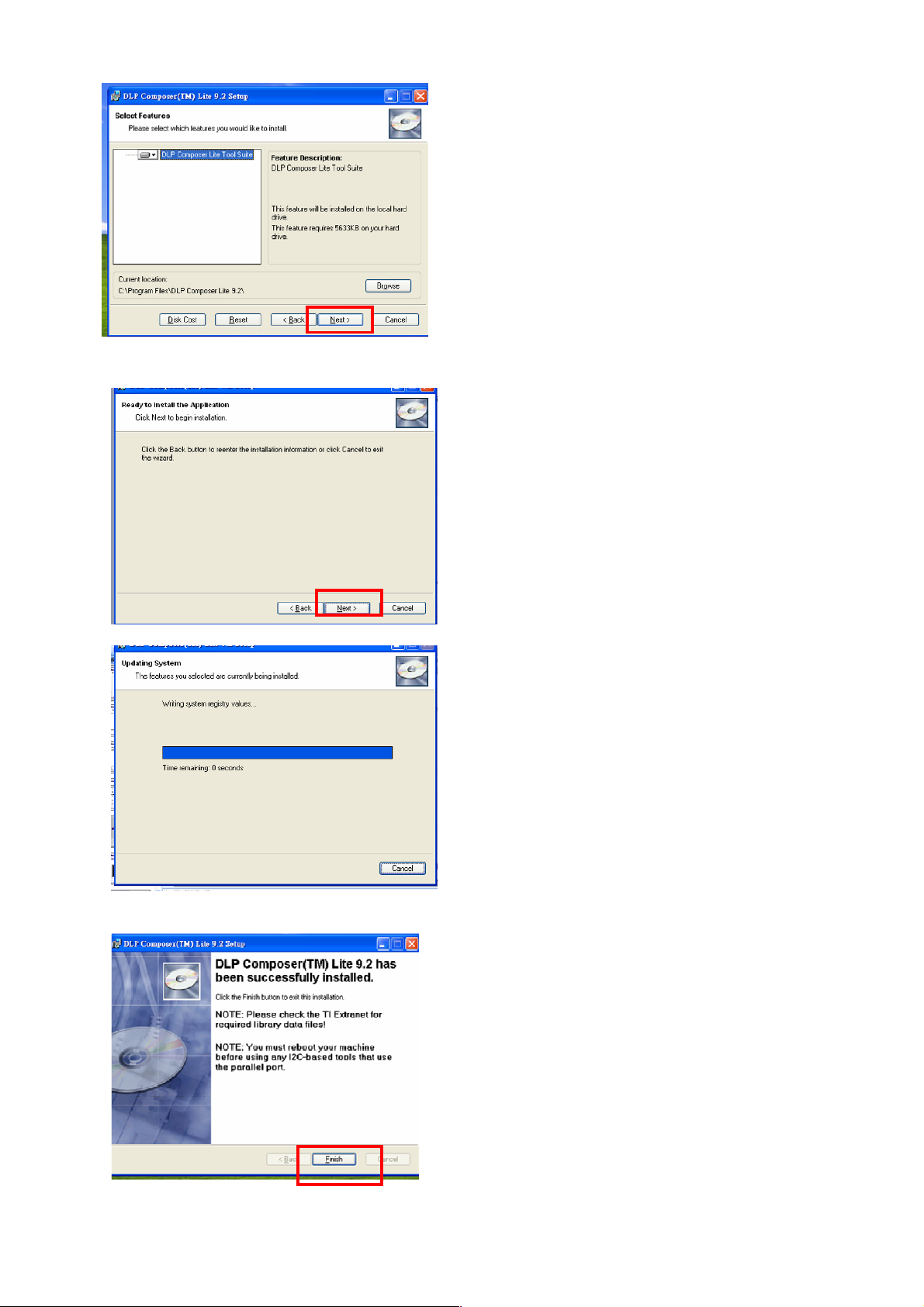

(2) Setting for your first use

Click

Click Click

Click

““““

Browse

BrowseBrowse

Browse

””””

to

to to

to

select

select select

select

Click the

Click the Click the

Click the

library

librarylibrary

library

Select Library:

1. When start to use this program to download at first time, you need to check if the library

folder is existed under the path of Library.

path for library files

path for library files

path for library filespath for library files

folder to assign

folder to assign

folder to assign folder to assign

the path.

the path.

the path.the path.

Then Click

Then Click ““““OK

Then Click Then Click

2. Check if there are library files in the assigned path. If not, unzip the library file into the

path. (You can unzip “DDP243x_Download_Tool_ Ver1.2.rar” to get the library.)

OK””””....

OKOK

31

Set communication (for download by RS232):

1. Select “Edit”->”Preference”.

2.

Select “Communications”-> “Serial Port” -> ”Config”.

3. Make sure the settings are the same as below figure-> Click ”OK”.

4. Click ”OK”.

32

(3) Download Procedure

How to download

Hardware required

1. Standard RS232 Download cable (Mini Din 3 pin male for Both terminals)

2. Personal computer or laptop computer

Software required

1. DLP Composer Lite program

2. New version FW

Download procedure

a. Connect RS-232 cable to PC and projector

b. Let projector be in Download Mode or Full-power standby mode :

-> Press and hold keypad Power and Menu together, then plug in power cord.

-> Release the two keypads.

-> Power, Lamp and Temp LED show Red continuously.

c. Execute DLP Composer Lite 9.0 or above version program

d. To select the RS-232 communications interface, choose "Preferences" from the

"Edit" menu, click the "Communications" page and choose "Serial Port".

33

e. Click on “Flash Loader” and browse the image file (new version firmware)

f. Select Complete Image Download, and make sure to check “Skip Boot loader area

(32KB)”

g. Press “Reset Bus” and check the status which should show “Bus Reset”

h. Press “Start Download” to begin update new firmware.

i. Press “Yes” to continue. (when download new firmware and power LED will show

purple.)

34

j. Wait till composer lite notice download complete.

When download complete, LED signal on projector will show standby status.

Method to enter factory menu

1. Press keypad Power and image will show Power Down OSD function

2. Press keypad Left twice then press Menu, then enter the Factory mode.

Step 1

Step 2

35

EDID Upgrade SOP

Link to Main

Link to Projector :

Link to Projector :

Equipment List

1. PC : with parallel (printer) port

2. EDID Board

3. Printer cable : 25pin male-female (connect PC to EDID board)

4. D-sub cable* : with full 15pin (connect EDID board to Projector)

5. HDMI cable*(connect EDID board to Projector)

6. DVI cable* (connect EDID board to Projector)

(*Note: Not every model’s EDID input (D-sub, DVI, HDMI) is the same. Need to check what

kind of file you need before download.)

Setup Equipment

1. Let projector be in Full-power standby mode (Press “Power” and “Source” and plug in

power cord into Projector immediately.)

2. Connect between PC, EDID board and the Projector:

DVI-D DDC download

(no need in X1130/ X1230/

X1230S/ X1235/ X1230K

series)

For

“25pin male-female

cable” (normal

printer cable)

PC with parallel

(printer) port

3. Need to set Jumper before using EDID board :

<Jumper setting :>

J6 : 1,2 short

J8 : 1,2 short

J10 : short

EDID board

For HDMI DDC

download

X1130/ X1230/ X1230S/

X1235/ X1230K series)

Please ignore this

connector

(no need in

board :

For D-sub DDC

download

36

3. How to use Download Tool :

Software Installation, Un-installation :

Unzip the “Q-EDID” program files in the same directory.

Install Q-EDID tool : Execute “Install Q-EDID.BAT” to install & register EDID Board

into the computer.

Un-install Q-EDID tool : If you want to uninstall this tool, execute “Uninstall

Q-EDID.BAT”, then it will remove EDID Board from the computer.

How to use Download Tool :

(1) Execute EDID Tools V0.16:

1. Run “Q-EDID-V016.exe”.

2. Program will appear as below picture.

(2) Write EDID:

• When write D-SUB/DVI EDID:

1. EDID Type Selection : Choose ‘‘EDID 128 Bytes’’.

2. Open Files : Click “Open File” to select file “*.DDC”

(Note : If your DDC file name is not like “*.DDC” (e.g. “*.2dc”), please rename it to “*.DDC”)

3. Write EDID : Click “Write EDID”, and it will execute writing process.

4. While complete, it will show message as ’’Write EDID OK…’’.

(Note : Check cable connection before write. It will show Write EDID OK even the connection

is not stable.)

37

Step1

Step2

Step3

Step4

(3) Read EDID:

• Read D-SUB/DVI EDID:

1. EDID Type Selection : Choose ‘‘EDID 128 Bytes’’

2. Read EDID : Click “Read EDID”.

3. While complete, it will show message’’ Read EDID OK… ‘’, and the read-out DDC will

show in the table in program.

Important Note :

Be reminded to connect Only One port every time, because the software will not be able

to identify the command signal from which port.

After connecting all equipment, always read DDC before writing DDC to ensure the

connection status is OK for writing DDC.

38

Serial Number Upgrade SOP

Hardware required

1. Standard RS232 Download cable

2. Personal computer or laptop computer

Software required

1. Acer_Service_Tool(Data)_3.1.exe

When need to use this Serial Number Upgrade program:

When it’s time to replace Main board for repair, it’s necessary to rewrite original S/N and

some adjustment values into new Main board by the following process.

Upgrade procedure

1. Prepare the download equipment: RS232 cable connect to PC and projector

2. Plug power cord into projector, and the projector will be in stand by mode.

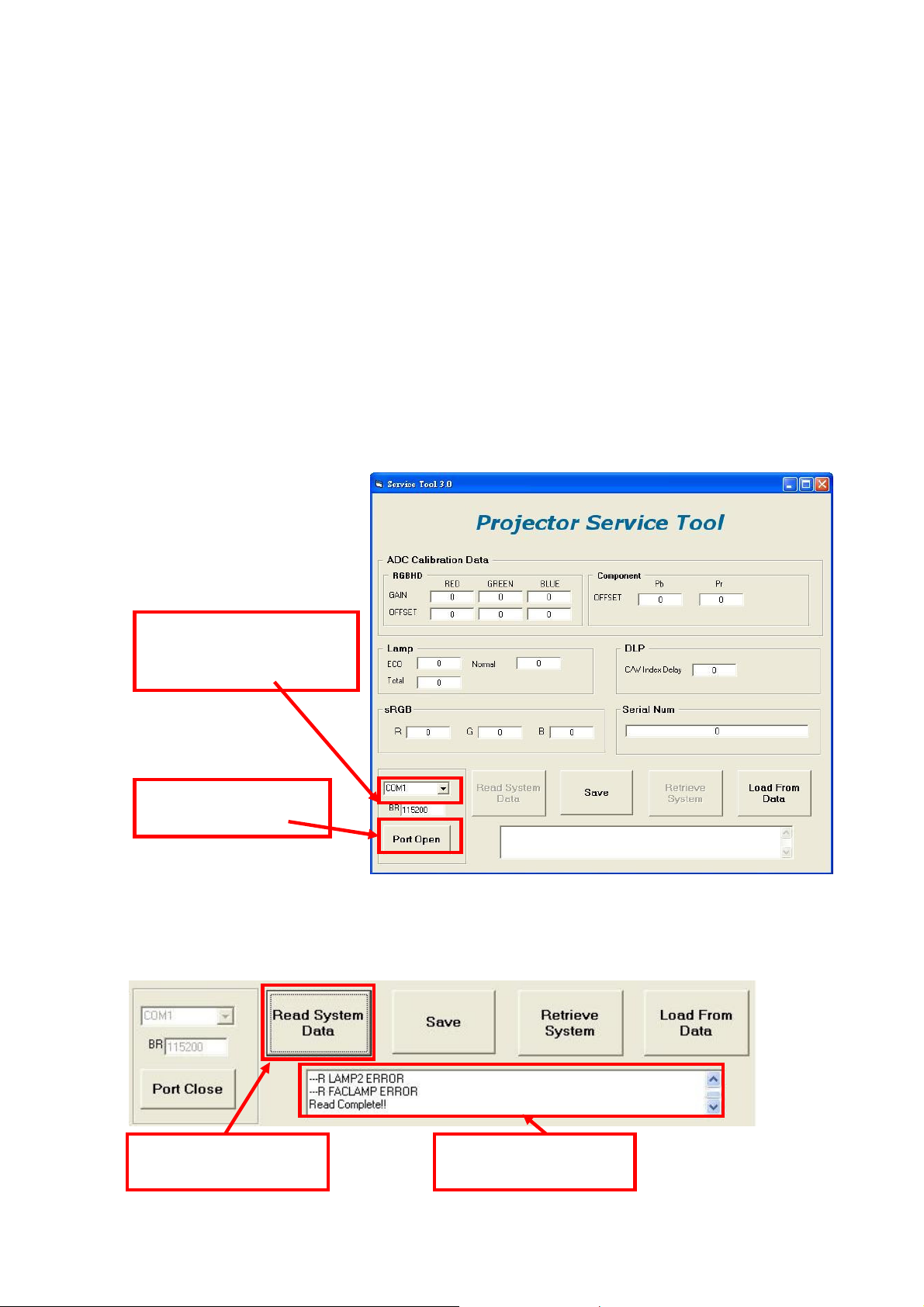

3. Execute “Acer_Service_Tool(Data)_3.1.exe”, and it will appear as below picture.

4. Change to connected COM port and Click “Port Open” icon.

4-1. Change to

connected COM Port

number

4-2. Click “Port

Open”

5. Read data from original Main board:

Click “Read system Data”, and it will read the Adjustment data (except Auto

keystone data) & Serial Number from projector and show the “Read complete”

message in information block.

5-1. Click this icon to

read all data

5-2. Show “Read

Complete!”

39

6. Click “Save” to save data into the assigned file name.

6-2. This window will

pop out, and it shows

the file saving folder.

6-3. Enter file name here.

Suggest to use Serial

Num as the file name.

6-4. Click “Save” to save

data.

6-1. Click “Save” icon.

7. Change new Main board:

(1) Unplug power cable and RS232 cable from projector, and change new Main board

into Projector.

(2) After changing Main board, reconnect power cable and RS232 cable into

Projector.

8. Write S/N & data into new Main board:

Press “Retrieve System” and write Data & SN to projector.

9. “Load from data” & “Retrieve System” :

(1) Click “Load from data” and select load file.

(2) Click “Retrieve System” to write the values into main board.

9-1. Click “Load From

Data” to load data.

9-2. Select the file

source

10. Click “Retrieve System”

to write data.

9-3. Click “Load” to

finish file load.

40

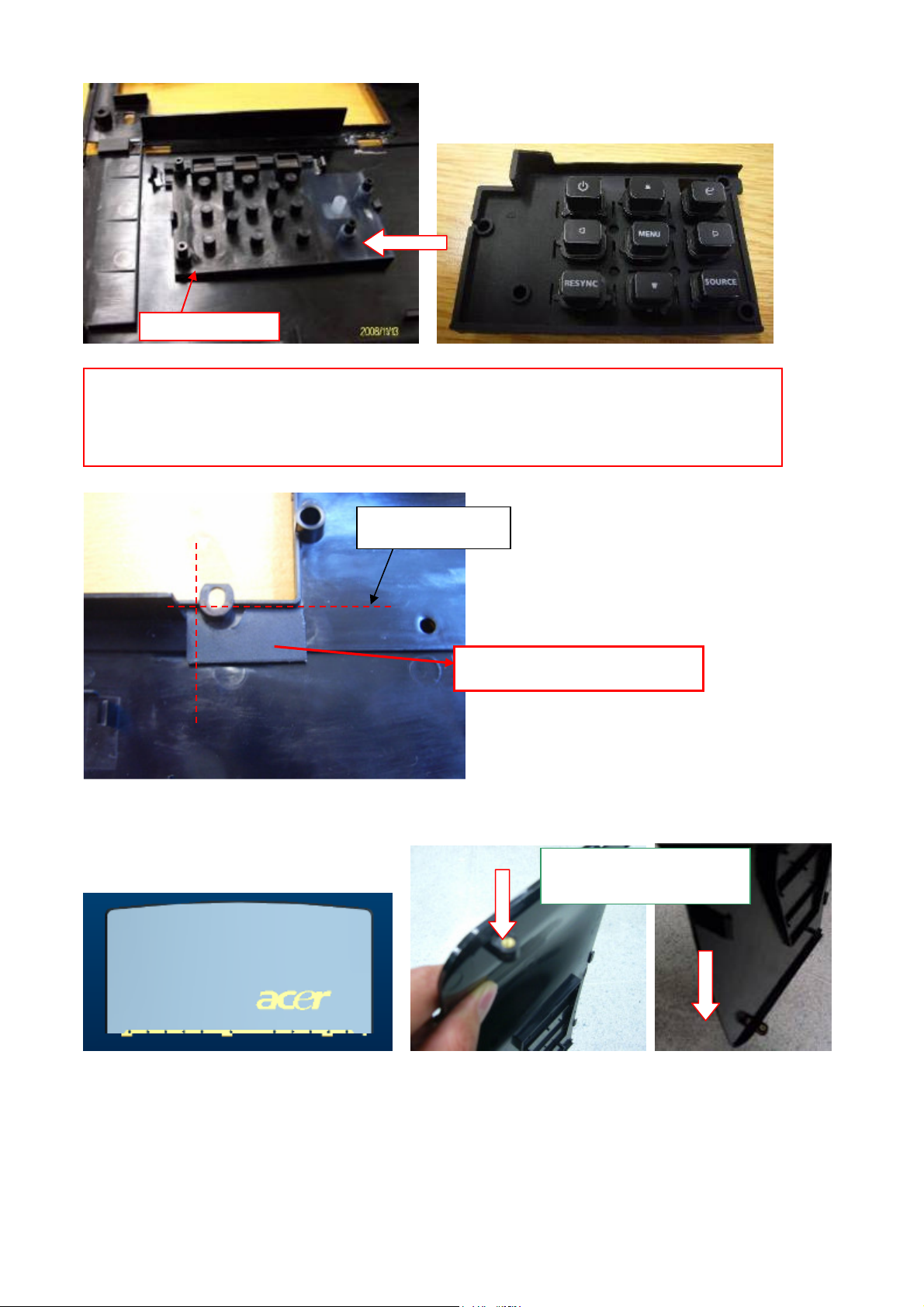

Chapter 3 System Disassembling and Replacement

2

IR 3pin Wire

Main Unit Disassembling

Tool : Screw Driver --Hex (#4-40) and Cross(Mechanical : M3,M4, Opt.Engine :M2)

Process :

Step Description Tool

(1) Disassemble the

screw*5(M3*L8) in the lowercase

and screw*2 (M2.5*L10) in the

1

inlet and outlet case.

(2) Take off the lamp-door.

(1) Disassemble the screw*3

(M3*L6) connecting the U/C with

the machine(you may need to

disclose the film on the upper

2

case).

(2) Hit the inlet-case to loose the

hook and at the same time lift the

upper case.

4

1

1

2

Hook in U/C

3

screw

driver

5

3

screw

driver

(1) Untie the tie in the engine and

loose the wire in it.(Figure1)

(2) Disassemble the screw*1

(M3*L8) connecting the F/C with

the L/C.(Figure2)

3

(3) Extract the I/R 3pin wire in the

main board and take off the front

case. (Figure 3,4)

Attention :DON'T TOUCH OR

BREAK THE LENS.

Figure1

Figure4

Hit the inlet case to

loose the hook

Figure2

at the same

time lift the

upper case

Figure3

Notice: Please release

the IR wire before take

off the Front Case.

41

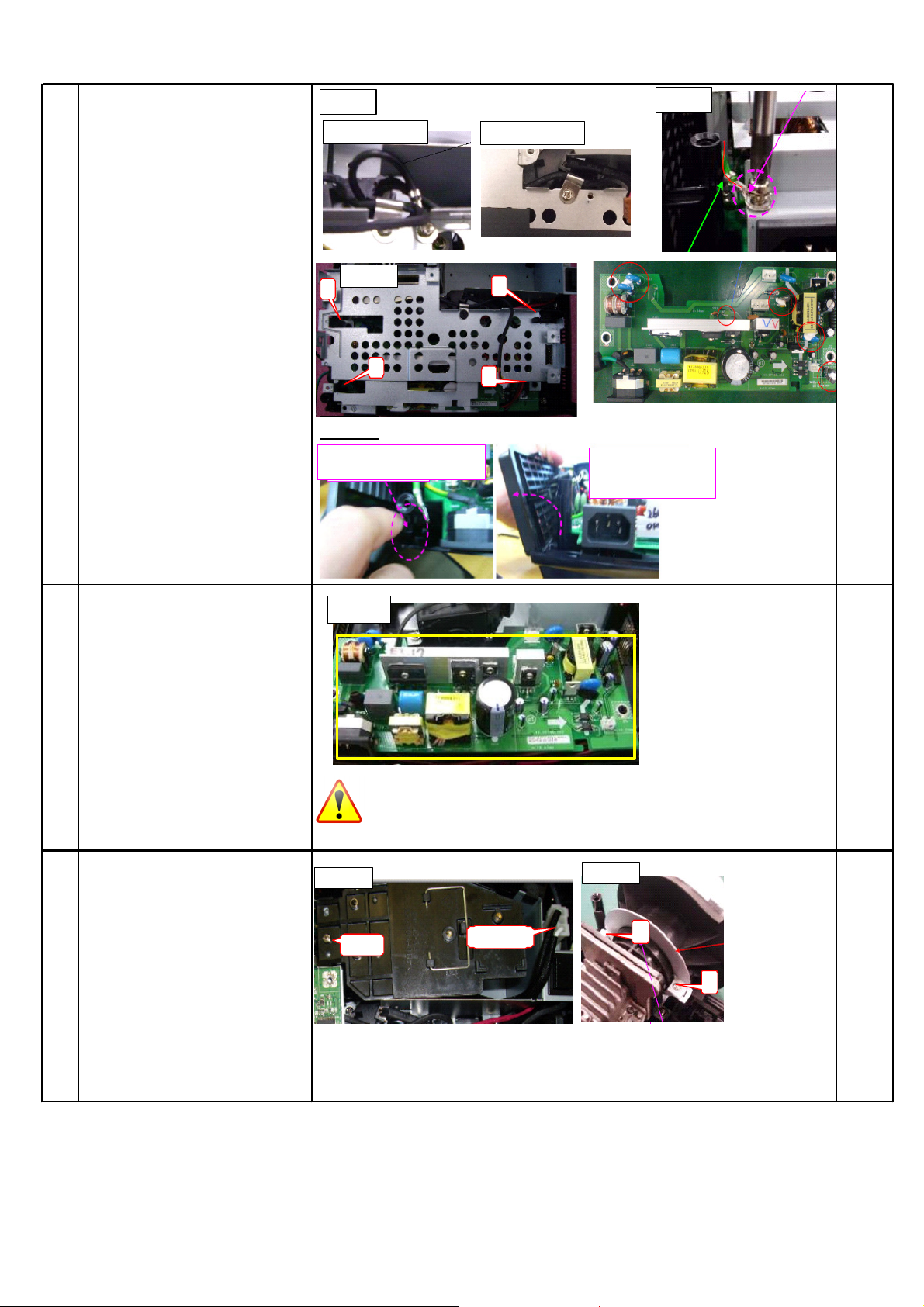

(1) Disassemble the screw*6(Hex

4

5

3pin

wire

#4-40*L6), then take off the

R/C.(Figure1).

Figure1

1 2 3 4

5 6

Figure2

loose these wires

1

2

3

(2) Disassemble the screw*5

4

(M3*L6) and loos the wires

connecting the engine and the

MB.

(3) Take off the SHD of the main

board.(Figure2)

(1) Extract all the wires in the

mainboard and loose the wire in

clips.(Figure1/2)

(2) Take off the ourlet case and

5

the Fans*2.

(3) Take off the main board.

Attention: DON'T TWIST THE

PIN UNDER THE M/B.

Figure1 Figure2

CW wire

inlet fan

IR wire

ballast

5pin wire

CW

speaker

twins fan wire

blower wire

outlet speaker wire

screw

driver

screw

driver

(1) Dismantle the screws*2

(M3*L6) to loose the EXTENSION

BD.(Figure1)

6

(2) Dismantle the STAND

OFF(M3 D6*9L) and screws*2

(M3*L6) on M/B.(Figure2,3)

Note:

Circuit boards > 10cm2 has been highlighted with the yellow

rectangle as above image shows. Please detach the Circuit boards

and follow local regulations for disposal.

Figure1

EXTENSION B D

Note:

Circuit boards > 10cm2 has been highlighted with the yellow

Figure2

Figure3

rectangle as above image shows. Please detach the Circuit boards

and follow local regulations for disposal.

screw

driver

42

(1) Dismantle the screws *2

Figure1

Figure2

inlet case)

(M3*L6) to loose the two

wires.(Figure1)

7

(2) Dismantle the Grounding

screw (M4*L6) in the shield and

loose the Grounding wire.

(Figure2)

S5201/5201B

Figure2

S5301WB

(1) Dismantle the screws*4

(M3*L8) connecting the PB shield

and the L/C, then take off the

shield. (Figure1)

8

(2) Take off the inlet case

following the way indicated

below.(Figure2), then extract all

the wires in the power board.

9 (3) Take off the power board.

Figure1

4

2

At first, push here. (Take apart

Figure3

1

3

screw

driver

Along arrow, pull inlet

case and can take

apart inlet case.

(1) Extract the white lamp wire in

the lamp box, and disassemble

the screw*1(M3*L6) connecting

the lamp module in the machine,

then take off the lamp module.

10

(Figure1)

(2) Dismantle the screw*2(M3*L6)

of the BKT in the neck of the

engine and take off the

BKT.(Figure2)

Figure 1

screw

Circuit boards > 10cm2 has been highlighted with the yellow

Note:

rectangle as above image shows. Please detach the Circuit boards

and follow local regulations for disposal.

Figure 2

lamp wire

2

1

screw

driver

43

(1) Disassemble the screw*3

1

1

Tool

1

2

(M2.5*L10), then take off the

engine. (Figure1)

11

(2) Disassemble the screw*2

(M3*L8) and take off BKT under

the engine. (Figure2)

Figure1

Figure2

3

2

1

2

1

screw

driver

(1) Take off the ballast mylar

(Figure1)

(2) Extract all the wire in the

ballast and the Dismantle the

screw*2(M3*L6), then take off the

ballast.(Figure2)

12

(3) Dismantle screw*2 (M3*L6)

connecting the blower with the

machine and take off the the

blower.(Figure3)

(4) Dismantle screw*3 (M3*L8)

connecting the lamp box with the

machine and take off the

lampbox.(Figure4)

Step Discription

(1) Disassemble the ring

focus.(pull it out with force.)

(2) Disassemble the screws*3

(M3*L6) connecting the len and

take off the len carefully.

ATTENTION:

1

THE LEN'S SURFACE OR

DON'T TOUCH

BREAK THE LEN.

Figure1

Figure2

Circuit boards > 10cm2 has been highlighted with the yellow

Note:

Figure3

Figure4

rectangle as above image shows. Please detach the Circuit boards

and follow local regulations for disposal.

Optical Engine Dismantle SOP

2

screw

driver

2

3

1

3

2

screw

driver

(3) Disassemble the screws*3

PULL

(M3*L4) connecting the frame

and take off the frame.

(1) Disassemble the spring

screws*4(M3*L7.5) connecting

the Hsink and take it off.

(2) Take off the chip under the

2

Heatsink and the baffle under

the chip.

(3) Rotate the switch to loose

the chip and take it off.

3

1

Note:

rectangle as above image shows. Please detach the Circuit boards

2

4

Circuit boards > 10cm2 has been highlighted with the yellow

and follow local regulations for disposal.

3

screw

driver

44

(1) Disassemble screws*2

1

3R0

M2*L3

(M3*L5) connecting the BKT

and take it off.

3

(2) Disassemble

screw*1(M3*L4) and take off

the C/W module.

(1) Dismantle

screws*2(M2.5*L5) connecting

4

the ILL module and take it off.

(2) Take off the detail parts in

the ILL module if necessary.

(1)Take off the Sphere len in

the HSG

(2) Dismantle screws*2 (M2*L3)

5

to loose the clip covering the

L/P module.

(3) Take off the L/P module.

BKT

Sphere len

2

1

M3*L4

2

L/P clip

C/W module

L/P clip

screw

driver

screw

driver

screw

driver

L/P

45

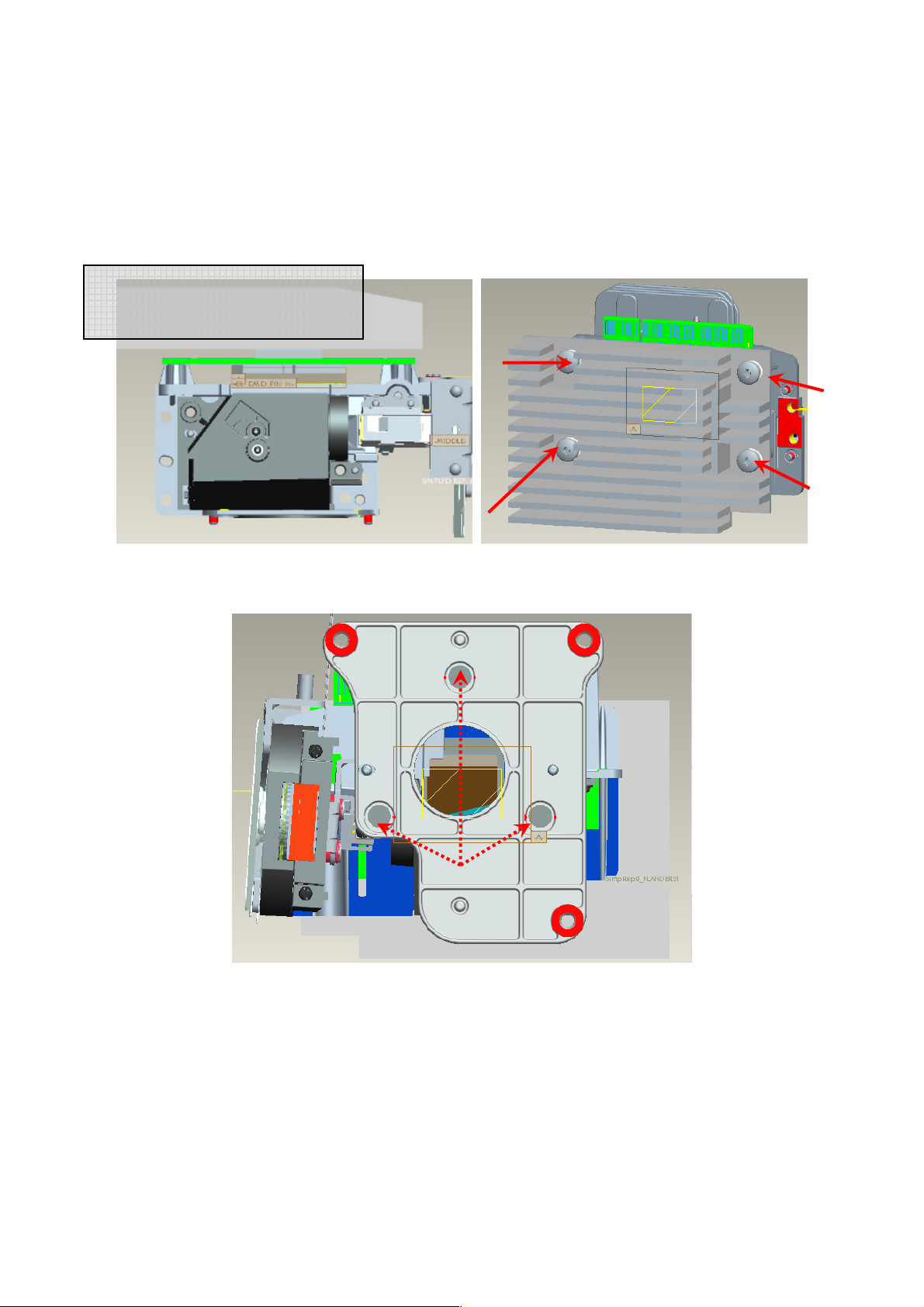

Module Assembly Key Point - Optical Engine

1. Light Pipe Module assembly and overfill alignment

1.1 Assembly LP Module to HSG DMD

i. Assembly two Overfill adjustment screws to HSG DMD (Fig. 1-1).

** Adjustment criteria refer to below item (Fig. 1-2).

ii. Assembly “Clip LP” and lock with screw well (Fig. 1-3).

iii. Press CLIP of RE_BKT_LP first, and then push it into the hole (Fig. 1-4).

iv. Placed LP Module on LP datum of “DMD HSG” and adjustment screw well, shown

v. (Fig. 1-5).

vi. Assembly “Baffle LP” first (Fig. 1-6) & push “Baffle LP” to hook DMD HSG

(Fig. 1-7).

vii. When Lock the screw of Baffle LP, the hand must push the left corner of Baffle LP

before (Fig. 1-8).

viii. Lock the screw of Baffle LP well then release the hand (Fig. 1-9).

1.2 Overfill Adjustment @ LP Module

Overfill Adjustment Criteria:

i. Pre-assembly 2 adjusting screws. Criteria shown as (Fig.1-2)

ii. Alignment Sequence:

a. To adjust “Horizontal Adjustment Screw” firstly, and then “Vertical Adjustment

Screw”.

b. Refer to Fig. (1-2)

1.3 For Overfill Re-adjustment:

a. Those 2 Adjustment Screws must be released closely to the “Pre-assembly”

positions first (Fig. 1-24-9).

b. ollow adjustment steps shown in Item 1-24.5-ii.

Overfill Vertical

Adjustment Screw

Overfill Horizontal

Adjustment Screw

Fig. 1-1

46

Pre assemble this screw

not over the side

Pre assemble this screw not

over the bottom surface.

Fig. 1-2

Clip LP

1. Press down

the Clip

2. Insert the

LP Module

Screw

Fig. 1-3

Fig. 1-4

47

LP Datum

of DMD

HSG

Fig. 1-5

1. Place Clips on BKT surface

Overfill adjustment screws

1. Place Clips on

BKT surface

Fig. 1-6 Fig. 1-7

Push on the left corner until

lock the screw well

2. Push Baffle LP

to hook DMD HSG

Lock the screw well

Fig. 1-8 Fig. 1-9

48

2. Assembly FM Module:

Place FM on “HLD FM” surface(Fig. 2-1) and use “Clip FM” to fix FM(Fig. 2-2).

Clip FM hook

the punch

points

Fig. 2-1 Fig. 2-2

Touch the

side surface

3. Assembly HSG ILL Module:

3.1 CM Assembly

I. Insert “Clip CM Side” first, and then place “Clip Front CM” to fixed-shaft of ILL SUB

before locking screw (Fig. 3-1, Fig. 3-2).

II. Assemble Mylar SUB HSG to HSG ILL well (Fig. 3-3).

III. Assemble CM to HSG ILL and to make CM contact three datum on the HSG ILL

Well (Fig. 3-3).

IV. Assemble” MYLAR CM ” to the CMD firstly, “CLIP TOP CM”(with forceps) to the

“HSG ILL” (Fig. 3-4,).

V. To check and make sure “CLIP of CM” hooks the HSG ILL very Well (Fig. 3-5).

VI. Paste “Sponge tube AL” on cannelure of” HSG ILL” (Fig. 3-6).

3.2 FM Module Assembly

i. FM Module must be placed to fixed shaft and on the datum surface of “ILL SUB” and

then lock with screw well (Fig. 3-7).

Fixed shafts

Clip CM Side

of ILL SUB

Fig. 3-1 Fig. 3-2

Screw

49

Datum1 Datum3

MYLAR SUB HSG

Clip UP CM MYLAR CM

Datum2

Fig. 3-3

Fig. 3-4 Fig. 3-5

Sponge

Screw

Fig. 3-6 Fig. 3-7

50

4. AL, HSG ILL and HSG DMD Assembly:

4.1 Placed “AL” on the “HSG DMD”. The “raised surface” of “AL” shall toward “DMD

direction” (Fig. 4-1).

4.2 To assemble ”HSG ILL SUB Module” with “HSG DMD” and cover over on “AL” and the

then lock with screws(Fig. 4-2).

Fixed shafts& holes

AL

Screw

DMD Direction

Fig. 4-1 Fig. 4-2

5. DMD and Chip B/D Module:

5.1. Judge Chip B/D and DMD alignment keying first (Fig. 5-1, 5-2).

5.2. Alight keying and Assemble DMD to Chip B/D (Fig. 5-3).

5.3. Push DMD slightly and use screwdriver rotate clockwise button to lock (close notation)

DMD on Chip B/D (Fig. 5-4).

Alignment keying

Fig. 5-1 Fig. 5-2

51

Open notation

Fig. 5-3 Fig. 5-4

5.4 Place Damper on the surface of Chip-BD Fig. 5-5.

Button

Close notation

Chip-BD Damper

.

Fig. 5-5.

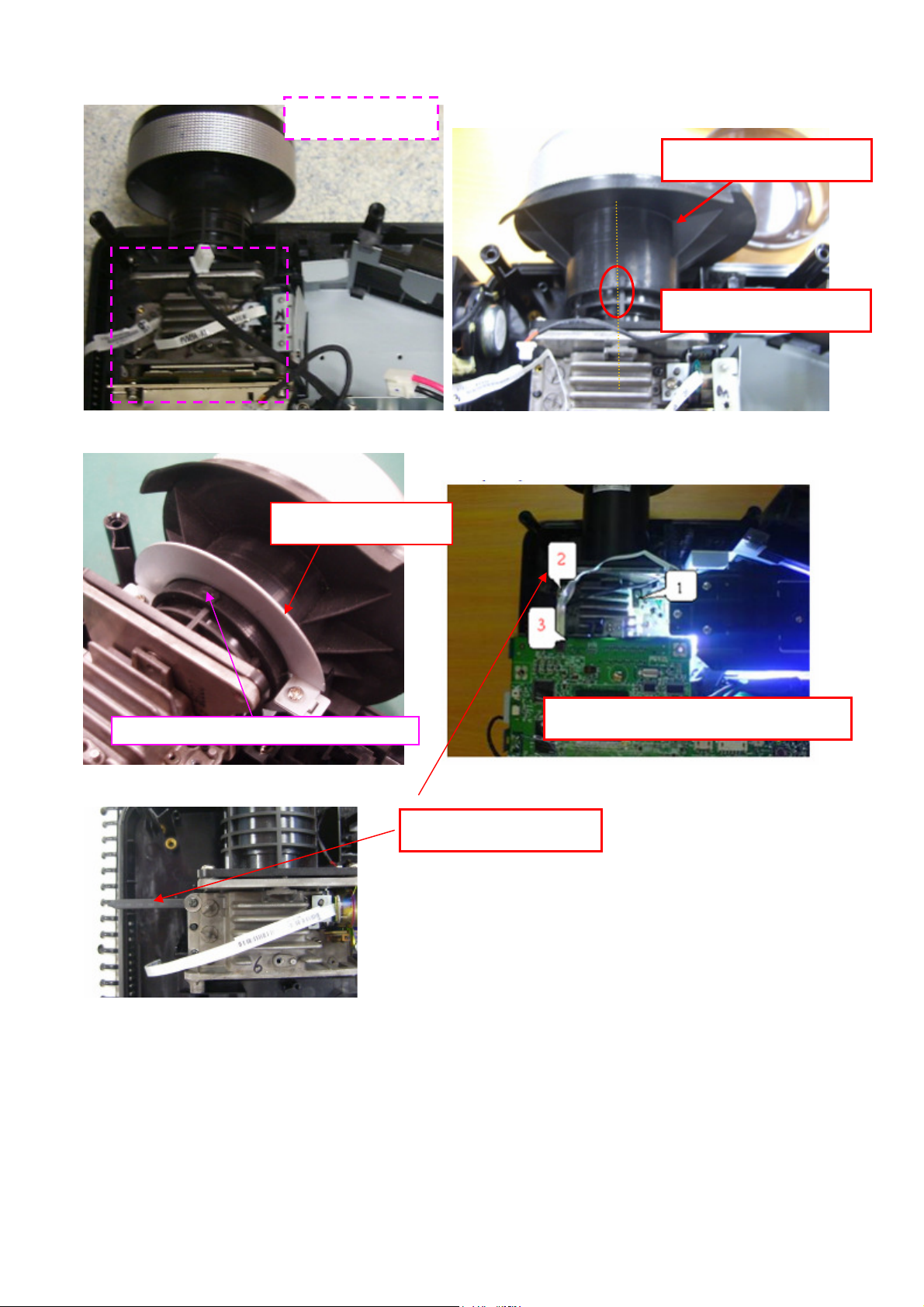

6. Assembly Optical Engine:

6.1 Assemble “CW Module” to “DMD HSG” and lock with screws well (Fig.6-1).

Screw

Fig.6-1

52

6.2 (Only for S5201B) : Paste the spong on Mylar CW, for touching lower case (Fig. 6-1-1)

Align 2

lines

Paste

sponge

Sponge

Fig. 6-1-1

6.3 Assemble “BKT LINK Lamp” to “DMD HSG” and lock with screws well(Fig. 6-2).

Screw*2

Fig. 6-2

7. Assembly OP ENG

7.1 Assemble “Baffle DMD” to “HSG DMD” (Fig.7-1).

7.2 Assemble “Sponge DMD” to “HSG DMD” (Fig.7-1).

7.3 Assemble Chip B/D Module to “HSG DMD” (Fig. 7-2, 7-3).

53

Alignment keying

Sponge DMD

Baffle DMD

Fig.7-1

Sponge DMD

Fixed shafts of

DMD HSG

Fig.7-2

Fig.7-3

54

7.4 Assemble Thermal Pad & Gasket Hest-sink then place contact DMD (Fig. 7-4, 7-5).

○

4

i. Press center of Heatsink before assemble spring screws, and then keeps press until

spring screw assembly finish.

i. Pre-fastening Sequence: [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ].

ii. Fastening Sequence: [ 2 ] - [ 1 ] - [ 4 ] - [ 3 ].

iii. Screw Torque must be confirmed to be 6 kg-cm.

Press center of Heatsink when

assemble spring screw

○

1

Fig. 7-4 Fig.7-5

○

3

○

2

7.5 Assemble “Lens Frame” and lock with screws well (Fig. 7-6).

Screw*3

Fig. 7-6

55

7.6 Pre-assemble Lens and Pre-Lock with screws. Sequence [1]-[2]-[3]

○

1

7.7 Assemble “Ring Focus”

Ring Focus

○

2

○

3

56

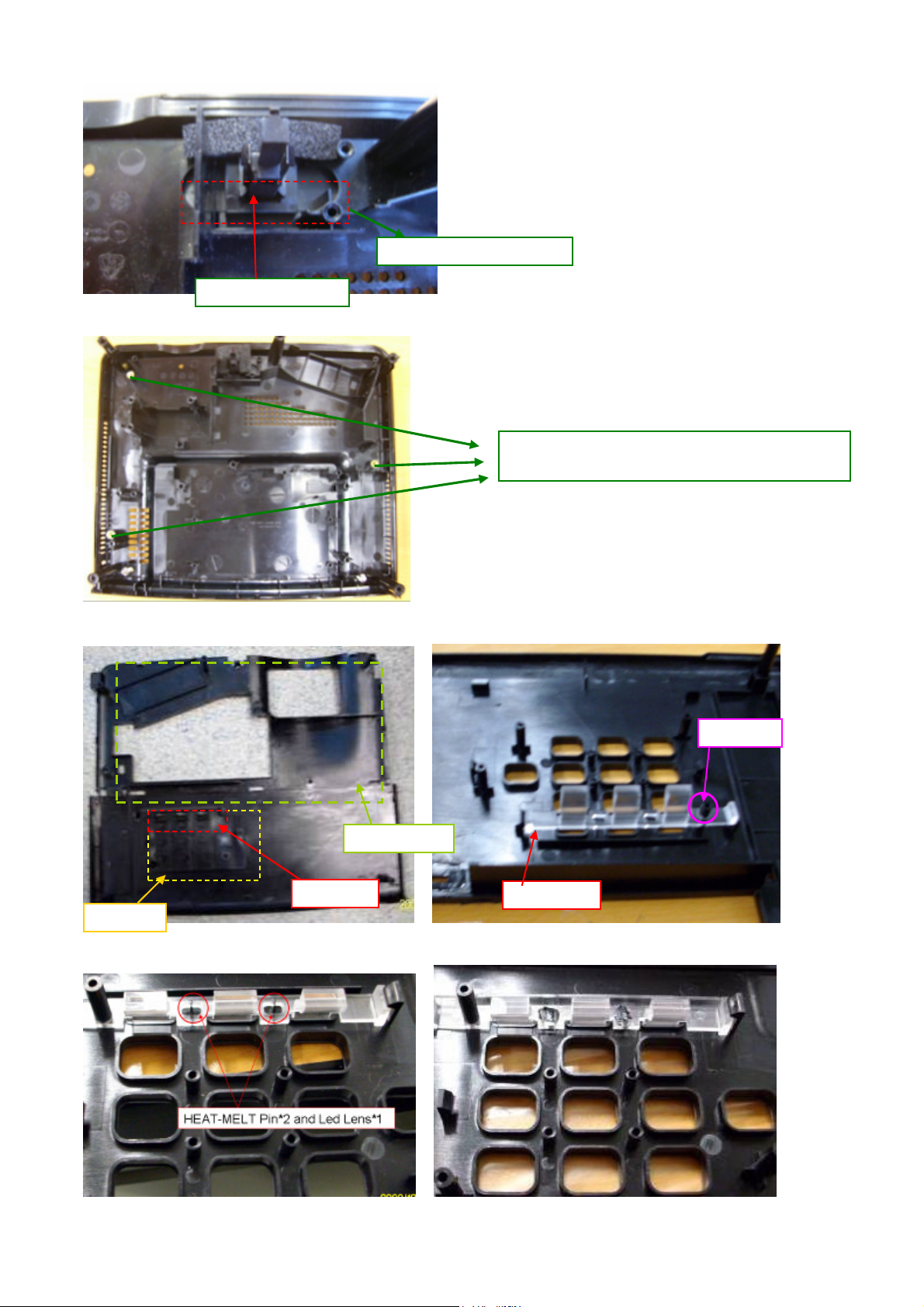

Module Assembly Key Point – Mechanical

1. Appearance Case assembly concern

1.1 Lower Case module

Adjust Foot x1

(Free drop)

Sub_Assy M2.5 Heat melt

nut*3

Sub_Assy M3 Heat melt

Label

Adjust Foot x2

(thread)

Mold in nut*3

Sub_Assy M4 Heat

melt nut*2

nut*2

SATURN Adjust Foot(rear):

SATURN Adjust Foot(raer):

Spring

Add glue on thread

Stand off*2

Push button

foot

57

Sponge Align the boss

Sponge adjust

1.2 Upper Case module

M3 Screw

SCRW MACH PH W/FL M3*5L NI

Align Pin

KEYPAD

LED LENS

DOOR LAMP

LED LENS

58

Rubber keypad

Please make sure:

1. Press all rubber close to upper case.

2. After assembled please check rubber surface even.

Align these ribs

1.3 Lamp door module

Mylar for U/C light leakage

M2.5 heat melt nut

direction

59

1.4 Front Case and Rear Case module

Front Case

ASSY_SUB:

Heat Melt IR

LENS

Please make

sure IR lens

fixed close to

front case.

ASSY_SUB: IR_board &wire

Please make sure IR board fixed

hook

use M3 screw to fix it

on FC

IR LENS Rear

Please make sure

IR lens fixed close

to rear case.

60

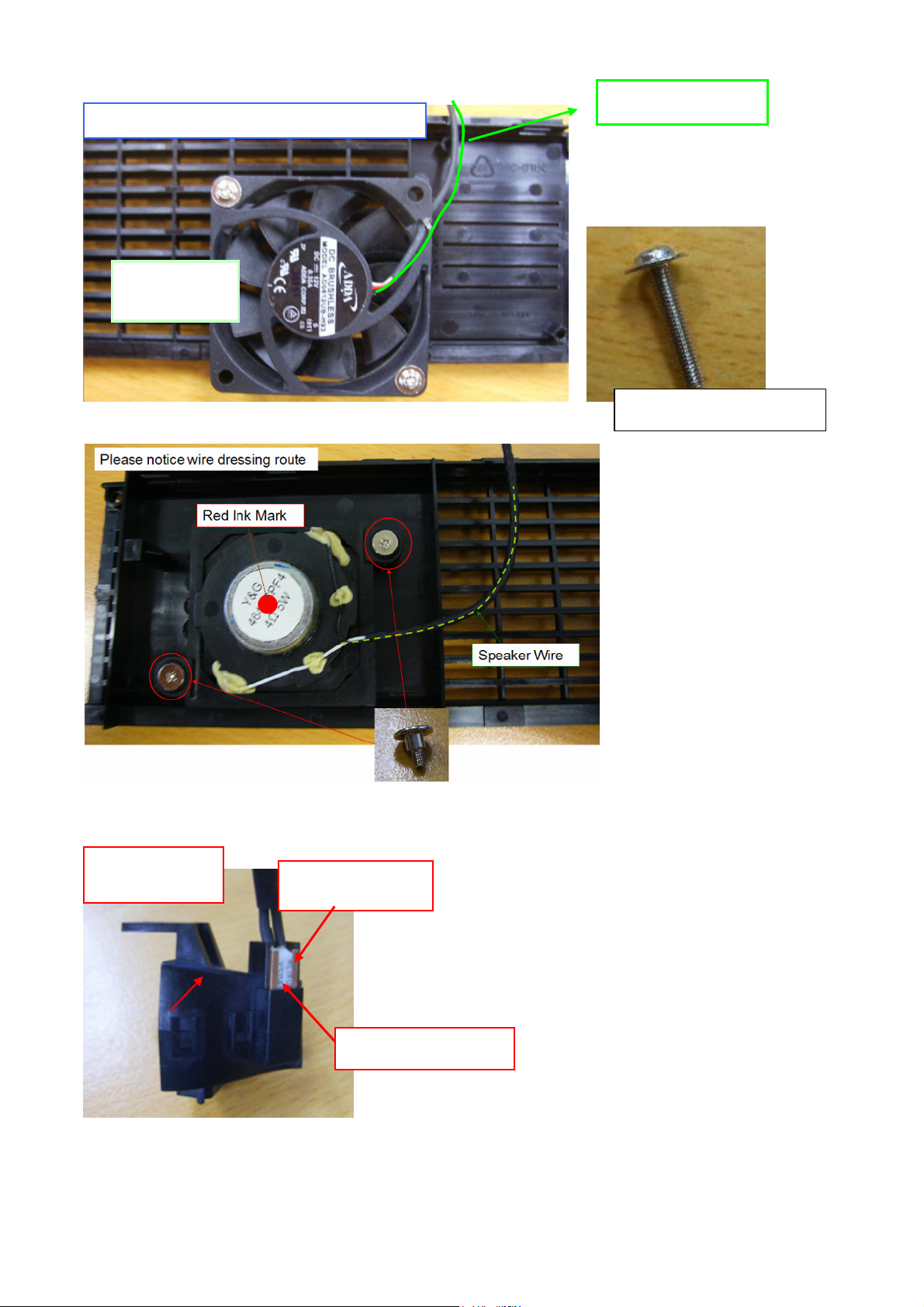

1.5 Inlet Case and Outlet Case module

route

Inlet Case Module

Please notice wire dressing

Align pin on

inlet-case

Notice: The align pin must insert to

fan 6013 completely

61

NI

fan wire direction

Inlet Case Module & Fan

FAN60*60*

13

2. Lamp Box & Blower, Power Board assembly concern

Assy_Nozzle

Cu plate: Opening face

outside.

SCRW MACH PH W/FL M3*16L

Thermal breaker-

Text face outside

62

SEAT

Screw M3*6L Match

CLIP MOUNT and

MOUNT SEAT

BKT

Nozzle

Blower

CLIP MOUNT and MOUNT

Lamp Box module

Door Switch

Lamp

connector

Louver Lamp Box

Please press to

bottom and check

hook position.

Door Switch

63

Align the BKT

Align the BKT

Mylar on

BKT lamp

box

The two pin with heat

shrinkage tube away from

the lamp box

attach tape on lampbox

align the edge first

then align the edge

secend

64

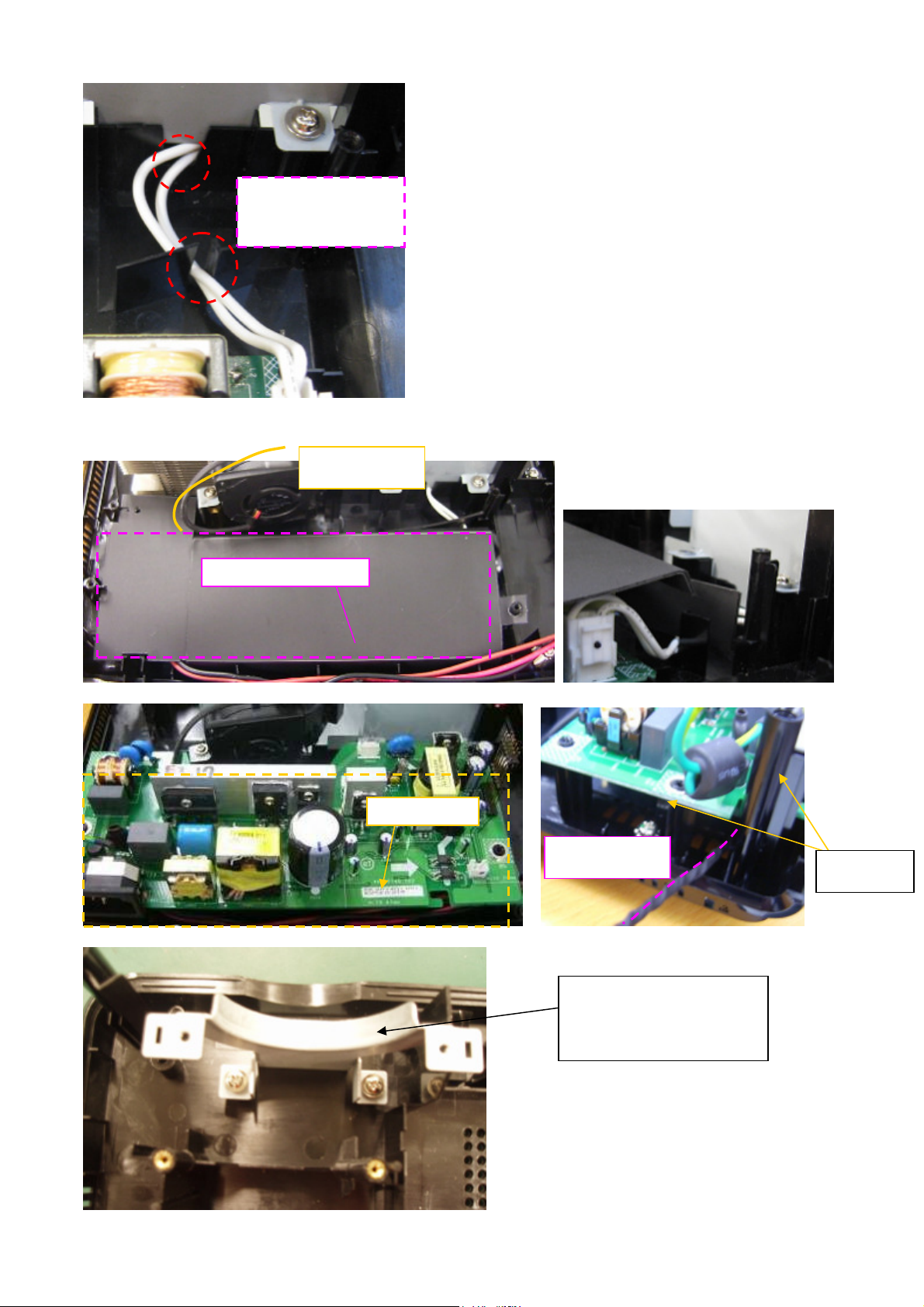

3. Ballast wire alignment concern

Ballast

Ballast Mylar EMI

Wire ballast dressing

Notice wire cross dressing

blower

Lamp

box

Wire under the lamp box

65

Ballast to lamp

wire addressing

4. Power Board and Main Board wire alignment

Wire Blower

Mylar ballast align pin

Power Board

Wire Ballast

BOSS*2

BKT ST Lens Bottom

66

lens

OPTICAL ENG.

Rubber for light leakage on ST

The arrow align the line on ST

lens

BKT ST Lens Top

Notice: The Engine screw Priority

Clip on Eng screw-2

67

5. BKT MB & Mylar

Mylar1

Mylar2 Mylar3

Align the edge

cover this surface

cover this surface

Assy the inlet-case before PW-BKT

Notice wire slot

68

Wire clip

Wire clip

Here is slot

Notice: The Bkt. Not pressed

the part on power board

Fan 8025

Fan 8025 wire

Grounding

Clip

Fix --Wire Fan8025 & 9225

Fix—Wire speaker

Yellow Green wire goes through here.

69

6. MB and Awin BD

STAND OFF M3 D6*9L CU

Fix this screw at first

M3 screw mach

Slot insert

Awin BD

CW wire

Wire dressing

regular and avoid

breaking wire.

Wire saddle

use clip to bind

speaker wire,IR wire, & CW wire

wire Fan6013

70

with U/C

Ballast

SHD Main

-

Board At first assemble back side then front side.

Put upper case vertically

directly

wire insert to main-board

This screw fixed

Wire ballast

Rear Case

Upper Case

Push rear cover vertically.

Please check gap.

71

attach mylar on UC

Second

align this edge

First

Screw

72

Before fixed screw, please check all

hooks.

Notice wire dressing

and don’t interfere

with lamp holder

Film lamp exploded

73

7. Overall wire review

Notice: lamp wire dressing.

74

Chapter 4 Troubleshooting

4.

Check Main Board

System Analysis

Keypad LED OK

No

Step:

1. Check Lamp Door

2. Check Power Board and Interlock

3. Check Connection between PWR

BD and Main BD

Yes

1. Check Lampen wire , Lamp wire and

No

If Power On, Lamp

On?

Ballast wire

2. Check C/W and wire connection

3. Check Main board

4. Check Lamp

5. Check Ballast

Yes

Yes

No Signal?

1. Check Input Cable

2. Check OSD Source set up

3. Check Main board

No

Power Auto Turn Off

No

IR Remote Control

NG?

No

Pixel Fail?

Yes

Yes

Yes

1. Check OSD Lamp Hours

2. Check Lamp Door

3. Check Lamp still light or not?

4. Check Fan still spin or not?

5. Check Thermal status

1. Check Remote module battery

2. Check Remote module

3. Check IR Reciver on Main board

4. Check IR Reciver on IR board

1. Check the connection between

Main BD and Chip BD

2. Check the connection between OP

engine and DMD Chip

3. Check Chip board

4. Check Main board

75

Optical & Optical Engine Trouble Shooting Guide

No. Item Trouble Shooting Guide

1 Brightness

2 Uniformity

1. Change lamp

1. Change lamp

1. Check ADC calibration

2. Check user’s menu brightness & contrast are default

3 FOFO Contrast

3. Clean DMD

4. Clean PL

5. Check ILL stop assy

1. Clean PL

4 ANSI Contrast

2. Clean DMD

3. Change PL

5 Color

6 Color Uniformity

7 Blue Edge

8 Blue/Purple Border

9 Focus

10 Dust

11

Horizontal/Vertical

Strips

1. Check color wheel delay

2. Check CW 50% point. Replace CW if necessary

1. Change lamp

1. Refer to Item#2-1 (attached below)

2. Change CM

3. Change SUB HSG

1. Refer to Item#2-1(attached below)

2. Change CM

3. Change SUB HSG

1. Change Projection Lens

2. Check parallel between PL datum and DMD

Clean DMD

1. Check connector between chipBD and MainBD

2. Re-install DMD with chipBD

3. Check if any pin of C-Spring is missing, damaged or dirty

4. Change new ChipBD/C-Spring

5. Change new DMD

12 Pixel Fail Change new DMD

2-1. “Blue Edge” Trouble Shooting:

I. Re-adjust “Overfill” first.

For Overfill Re-adjustment:

i. Those 2 Adjustment Screws must be released for around 2 mm first.

ii. Alignment Sequence:

a. To adjust “Horizontal Adjustment Screw” firstly, then “Vertical Adjustment

Screw”.

b. Refer to Figure 2-1..

76

(2) Overfill Vertical

Adjustment Screw

(1) Overfill Horizontal

Adjustment Screw

Fig. 2-1

II. Re-assemble LP module—include LP, LP Baffle, LP clip.

DMD Image Quality

1. Scope

This document specifies the image quality requirements applicable to the DLP®.55XGA

Type X, Series 450 Value, and DLP

TM

.65WXGA-800 Value Component Set. The

Component Set provides the DLP®. 55XGA Type X and Series 450 Value Projector with

digital imaging functionality based on Digital Micromirror Device (DMD) technology.

2. Definitions: (Defects and Test Screens)

Blemish

A blemish is an obstruction, reflection, or refraction of light that is visible, but out of focus

in the projected image under specified conditions of inspection (see Table 1). It is caused

by a particle, scratch, or other artifact located in the image illumination path.

Dark pixel

A single pixel or mirror that is stuck in the OFF position and visibly darker than the

surrounding pixels.

Bright pixel

A single pixel or mirror that is stuck in the ON position and visibly brighter than the

surrounding pixels.

Unstable pixel

A single pixel or mirror that does not operate in sequence with parameters loaded into

memory. The unstable pixel appears to be flickering asynchronously with the image.

Adjacent pixel

Two or more stuck pixels sharing a common border or common point, also referred to as

a cluster.

Row or Column Defect

The reset boundary artifact is a single row of pixels on the reset group boundaries that

are visibly darker or lighter than the neighboring rows of pixels.

Pond of Mirrors (POM)

POM is a rectangular array of off-state mirrors surrounding the active area.

Eyecatcher

Eyecatcher's are blemishes appearing in the area outside of the Active Area. These are

due to particles and various DMD window or window aperture “defects”

including: digs, voids, and scratches.

77

Border Artifacts

Border artifacts are a general category of image artifacts that may show up on screen in

the area outside of the active array. Border artifacts include: Exposed Bond Wires,

Exposed Metal 2, and Reflective Edge.

Bond Wires

Bond Wires are the electrical connections between the die and the DMD ceramic

package. If visible, they will appear as short light parallel lines outside of the

Pond of Mirrors (POM).

Exposed Metal 2

Exposed Metal 2 is due to a shift in positioning of either the die or the window

aperture, which may allow light to be reflected off of the layer of metal 2 that is below the

super structure (mirrors). This defect is located outside of the POM.

Reflective Edge

Reflective Edge is light that may reflect from the edge of the DMD window aperture onto

the projection screen. It will appear as a thin diffuse line outside of the POM.

Blue 60 Screen

The Blue 60 screen is used to test for major dark blemishes. All areas of the screen are

colored a Microsoft Paintbrush blue 60 (green and red set at 0, blue set at 60). NOTE: If

linear degamma is not used then the Microsoft Paintbrush values must be adjusted to

match the degamma table being used in order to generate an equivalent blue level on the

test screen image.

Gray 10 Screen

The Gray 10 screen is used to test for major light blemishes. All areas of the screen are

colored a Microsoft Paintbrush gray 10 (green, red, and blue set at 10).

NOTE: If linear degamma is not used then the Microsoft Paintbrush values must be

adjusted to match the degamma table being used in order to generate an equivalent gray

level on the test screen image.

Gray 30 Screen

The Gray 30 screen is used to test for the reset boundary artifact. All areas of the screen

are colored a Microsoft Paintbrush gray 30 (green, red, and blue set at 30).

NOTE: If linear degamma is not used then the Microsoft Paintbrush values must be

adjusted to match the degamma table being used in order to generate an equivalent gray

level on the test screen image.

3. ACCEPTANCE REQUIREMENTS

3.1 Conditions of Acceptance

All DMD image quality returns will be evaluated using the following projected image test

conditions:

Test Set degamma shall be linear.

Test Set brightness and contrast settings shall be set to nominal.

The diagonal size of the projected image shall be a minimum of 60 inches.

The projection screen shall be 1X gain.

The projected image shall be inspected from an 8 feet minimum viewing distance.

The image shall be in focus during all Table 1 tests.

3.2 Test Sequence

Tests shall be run in the sequence listed in Table 1.

78

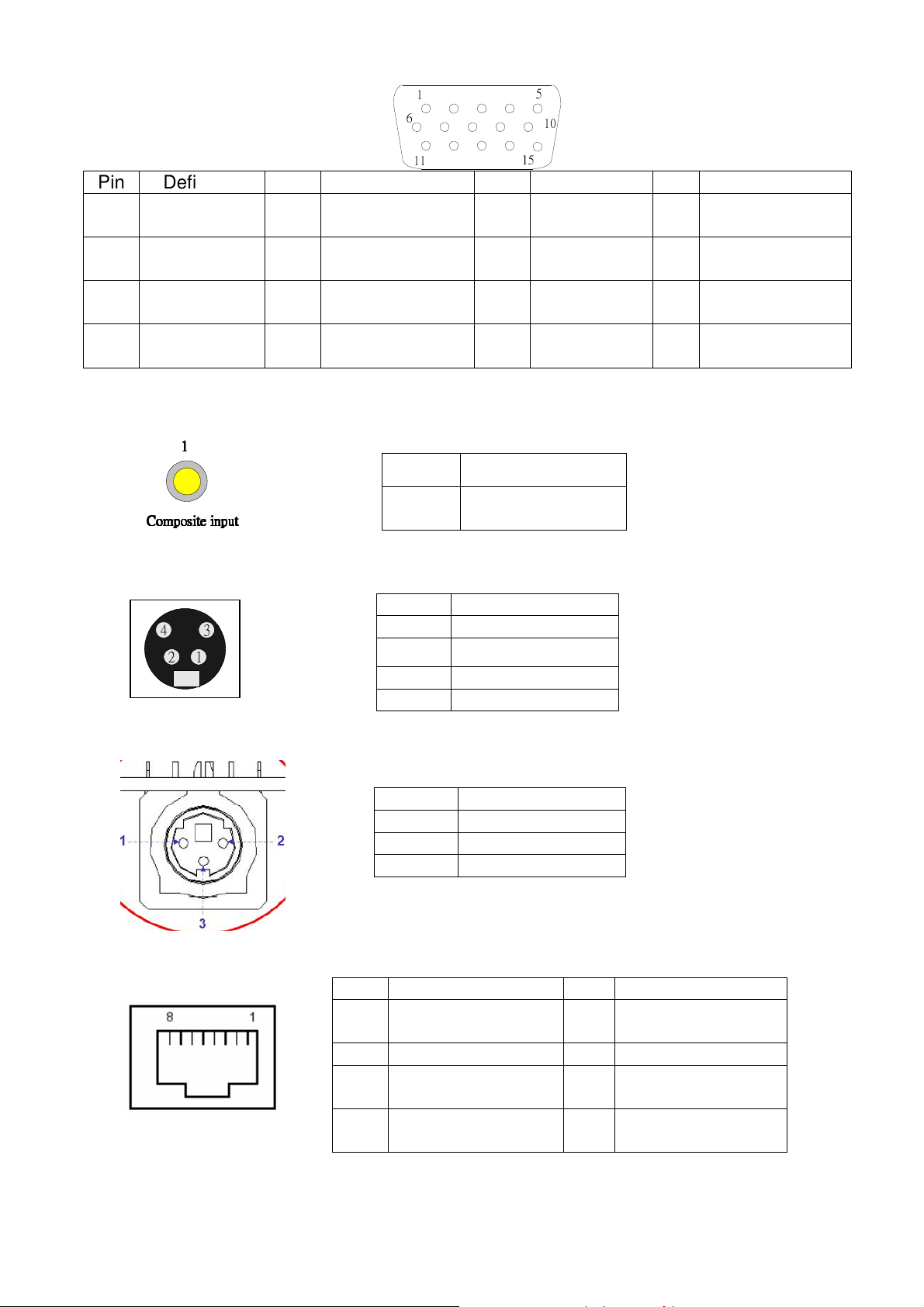

Table 1 Image Quality Specification (for S5201/S5201B)

SEQ#

1

Test SCREEN ACCEPTANCE CRITERIA

Major Dark

Blemish

Blue 60

1. 4 visible dark blemishes are allowed in the ≦

active area

2. No blemish will be >1.5” long/diameter

1. 4 visible dark blemishes are allowed in the ≦

active area

2. No blemish will be >1.5” long/diameter

2

Major Light

Blemish

Gray 10

Reset

3

Boundary

Gray 30 No reset boundary artifacts allowed

Artifact

4

5

Eyecatchers /

Border Artifacts

Projected

Images

Any screen Eyecatcher and border artifacts are allowed

1. Any screen

2. Gray 10

3. Any screen

4. Gray 10

5. Whit

6. Any screen

7. Any screen

1. No adjacent pixels

2. No bright pixels in Active Area

3. No unstable Pixels in Active Area

4. 1 right pixel in the POM≦

5. 4 dark pixels in the Active Area≦

6. No DMD window aperture shadowing on the

Active Area

7. Minor blemishes are allowed

Table 2 Image Quality Specification (for S5301WB)

SEQ#

Test SCREEN ACCEPTANCE CRITERIA

1. ≦4 visible dark blemishes are allowed in the

1

Major Dark

Blemish

Blue 60

active area

2. No blemish will be > 1” long/diameter

1. ≦4 visible dark blemishes are allowed in the

2

Major Light

Blemish

Gray 10

active area

2. No blemish will be > 1” long/diameter

Reset

3

Boundary

Gray 30 No reset boundary artifacts allowed

Artifact

4

Eyecatchers /

Border Artifacts

Any screen Eyecatcher and border artifacts are allowed

1. No adjacent pixels

5

Projected

Images

8. Any screen

9. Gray 10

10. Any screen

11. Gray 10

12. Whit

13. Any screen

14. Any screen

2. No bright pixels in Active Area

3. No unstable Pixels in Active Area

4. ≦ 1 right pixel in the POM

5. ≦ 4 dark pixels in the Active Area

6. No DMD window aperture shadowing on the

Active Area

7. Minor blemishes are allowed

Notes:

1. Projected blemish numbers include the count for the shadow of the window artifact in

addition to the artifact itself.

2. During all Table 1 tests, projected images shall be inspected in accordance with the

79

conditions of inspection specified in Section 3.

3. The rejection basis for all cosmetic DMD defects (scratches, nicks, particles) will be the

projected image tests referenced in Table 1.

4. Devices that meet this image quality specification but are deemed undesirable by the

customer may not be returned to TI without prior approval by TI.

5. Screens < Gray 10 shall not be used as a basis for rejecting a DMD for image quality.

80

Power Supply Trouble Shooting Guide

1. Introduction

This document is prepared to be a guide to repair trouble sets, some problems

happen more frequently are taken as example in it.

2. Problems

(a) no power

No power

Check power

Is CN701 pin11 =5v?

No

Is door SW press down?

No

Check lamp door

Yes

Yes

Change main BD

Change power BD

81

(b)lamp can not turned on

Yes

Yes

Yes

Lamp can not turned on

has lamp wire connect

correct? (Ballast bd

between lamp)

has power wire connect

correct? (power bd

between ballast bd)

No

Wire connect certainty

No

Wire connect certainty

has enable wire connect

correct? (main bd to

ballast bd)

A

No

Wire connect certainty

82

A

Has TH breaker wire connect

correct? (main bd to ballast bd)

Yes

Has color wheel operation normally?

Yes

If change ballast bd, lamp can be

Turned on or not?

No

Wire connect certainty

No

Change color wheel

No

Change lamp

Yes

Change ballast bd

83

LED Messages Definition

Power_LED Power_LED Lamp_LED Temp_LED

Blue Red Red Red

Power Plug

Standby -- ON -- --

Power button ON ON -- -- --

Lamp retry

Cooling state --

Power button OFF:

Cooling completed;

Standby Mode

Firmware Download ON ON -- -Thermal sensor

error (T2≧85℃)

(Lamp Over

Temperature) OSD

shows “Projector

Overheated”

Thermal sensor

error (T1

OSD shows

“Projector

Overheated”

Fan lock error OSD

shows red “Fan

Fail, Will

automatically turn

off soon”

Lamp error (Lamp,

ballast)

Color Wheel fail ON --

≧40℃

-

-

0.5 second H(On),

0.5 second L(Off)

flashing

-- ON -- --

ON -- -- ON

)

ON -- -- ON

ON -- --

ON -- ON --

Flash ON to OFF Flash ON to OFF Flash ON to OFF

-- -- --

0.5 second H(ON),

0.5 second L(OFF)

flashing

-- --

0.5 second H(ON),

0.5 second L(OFF)

flashing

0.5 second H(On),

0.5 second L(Off)

flashing

--

84

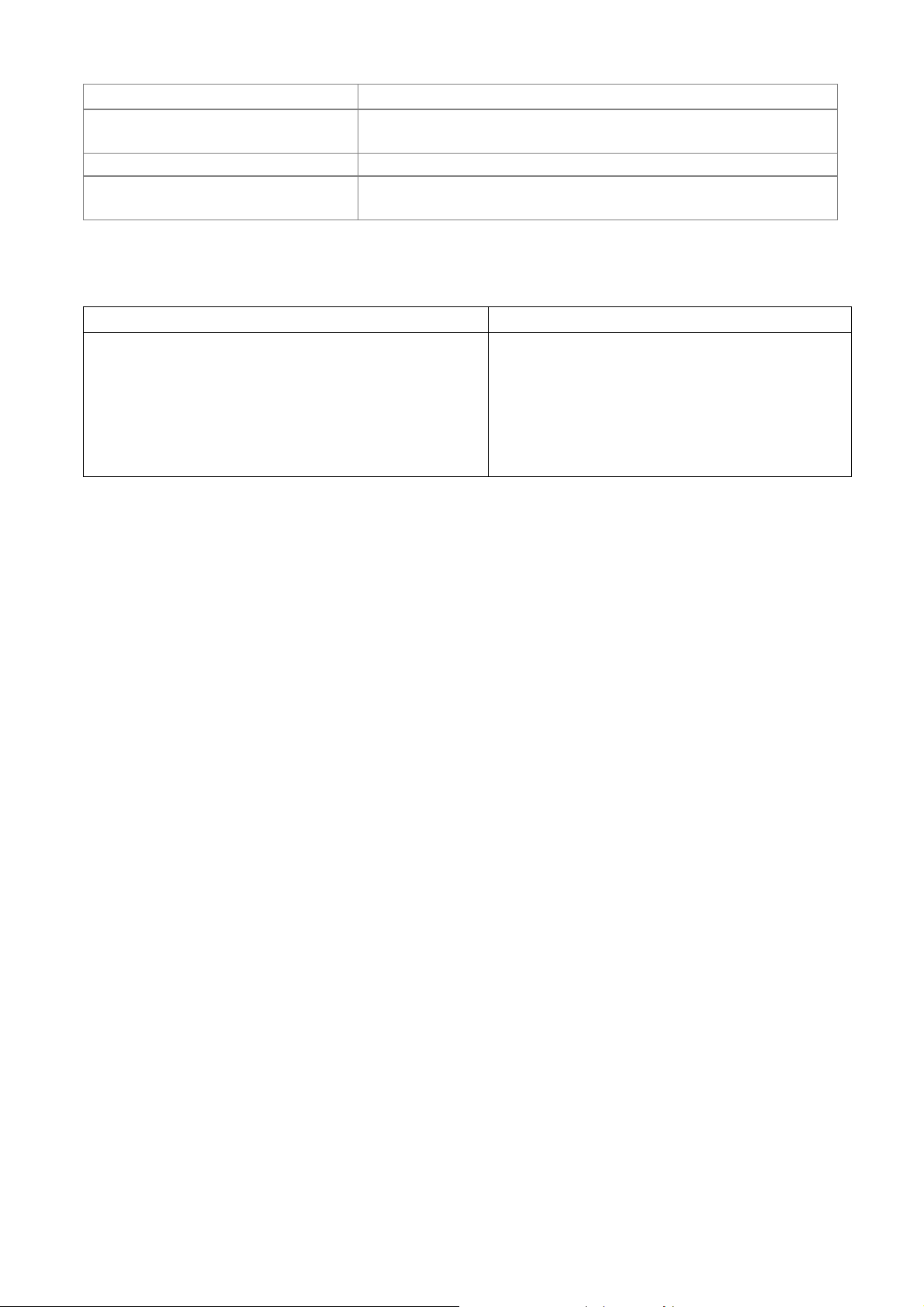

Error Count Messages Definition

Error Count Definition Specification

LAMP Fail error

FAN 1 Speed Error

FAN 2 Speed Error

FAN 3 Speed Error

FAN 4 Speed Error

Sensor 1 Open Error

Sensor 1 Short Error

Temperature 1 Error

FANIC 1 I2C ERROR

LAMP OFF DETECT LAMPLIT

LAMP FAN SPEED ERROR SPEED OVER ± 20%