Page 1

Acer Altos R520 Series

User’s Guide

Page 2

Copyright © 2006 Acer Incorporated

All Rights Reserved.

Acer Altos R520 Series

User’s Guide

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

hereof and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your server. All correspondence concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

Acer Altos R520

Model Name :

Part Number:

Purchase Date:

Place of Purchase:

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

iii

Notices

FCC notice

Class A equipment

This device has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference, in which case the user will be required to

correct the interference at personal expense.

However, there is no guarantee that interference will not occur in a particular

installation. If this device does cause harmful interference to radio or television

reception, which can be determined by turning the device off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/television technician for help

Notice: Shielded cables

All connections to other computing devices must be made using shielded cables

to maintain compliance with FCC regulations.

Notice: Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.) certified to

comply with the Class A limits may be attached to this equipment. Operation

with noncertified peripherals is likely to result in interference to radio and TV

reception.

Page 4

iv

Caution! Changes or modifications not expressly approved by the

manufacturer could void the user’s authority, which is granted by

the Federal Communications Commission, to operate this server.

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Notice Canadian users

This device does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the interference-causing equipment standard

entitled “Digital Apparatus” ICES-003 of the Canadian Deparmment of

Communications.

Laser compliance statement

The DVD-ROM drive in this server is a laser product. The optical drive’s

classification label (shown below) is located on the drive.

CLASS 1 LASER PRODUCT

CAUTION: INVISIBLE LASER RADIATION WHEN OPEN. AVOID EXPOSURE TO

BEAM.

Page 5

Important safety instructions

Read these instructions carefully. Save these instructions for future reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The product

may fall, causing serious damage to the product.

5 Slots and openings on the back or bottom side of the chassis are provided

for ventilation; to ensure reliable operation of the product and to protect

it from overheating, these openings must not be blocked or covered. The

openings should never be blocked by placing the product on a bed, sofa,

rug, or other similar surface. This product should never be placed near or

over a radiator or heat register, or in a built-in installation unless proper

ventilation is provided.

6 This product should be operated from the type of power indicated on the

marking label. If you are not sure of the type of power available, consult

your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate this

product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the total

ampere rating of the equipment plugged into the extension cord does not

exceed the extension cord ampere rating. Also, make sure that the total

rating of all products plugged into the wall outlet does not exceed the fuse

rating.

9 Never push objects of any kind into this product through the chassis slots as

they may touch dangerous voltage points or short out parts that could

result in a fire or electric shock. Never spill liquid of any kind on the

product.

10 Do not attempt to service this product yourself, as opening or removing

covers may expose you to dangerous voltage points or other risks. Refer all

servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to qualified

service personnel under the following conditions:

a When the power cord or plug is damaged or frayed

b If liquid has been spilled on the product

c If the product has been exposed to rain or water

v

Page 6

vi

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are covered

by the operating instructions since improper adjustment of other

controls may result in damage and will often require extensive work

by a qualified technician to restore the product to normal condition.

e If the product has been dropped or the chassis has been damaged

f If the product exhibits a distinct change in performance, indicating a

need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery type may present a risk of fire or

explosion. Refer battery replacement to a qualified service technician.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from children and

dispose of used batteries promptly.

14 This product is not suitable for use with visual display workplace devices

according to §2 of the German Ordinance for Work with Visual Display

Units.

Page 7

Notices iii

FCC notice iii

Laser compliance statement iv

Important safety instructions v

1 System tour 1

System features 3

Performance 3

External and internal structure 7

Front bezel 7

Front panel 8

Rear panel 9

Internal components 10

System boards 11

Mainboard 11

Backplane board 13

Mid-plane board 15

Control panel 17

System LED indicators 20

Control panel LED indicators 24

Hot-plug HDD LED indicators 25

System jumpers 27

2 System setup 29

Setting up the system 31

Pre-installation requirements 31

Connecting peripherals 32

Turning on the system 33

Power-on problems 34

Configuring the system OS 35

Turning off the system 36

Contents

3 System upgrade 37

Installation precautions 39

ESD precautions 39

Pre-installation instructions 39

Post-installation instructions 40

Opening the server 41

Removing and installing the front bezel 41

Removing and installing the top cover 43

Removing and installing the CPU air duct 45

Page 8

viii

Removing the CPU air dam 47

Removing and installing the power distribution

board cover 48

Configuring the storage devices 50

Removing and installing a hard disk drive 50

Removing and installing a slim-line optical drive 53

Removing and installing a PCI riser assembly 56

Removing and installing a PCI card 58

Upgrading the CPU 61

CPU upgrading guidelines 61

Upgrading the system memory 67

Memory module installation guidelines 68

Memory module population guidelines 68

Memory configuration overview 70

Installing and removing a power supply module 76

Removing and installing an ARMC/3 module 79

Installing and removing the SAS hardware

RAID components 82

Installing and removing the RAID activation

key and RAID cache 82

Installing and removing the RAID BBU 84

Installing and removing the SATA software RAID

activation key 87

4 BIOS setup 89

BIOS setup 91

Entering BIOS setup 92

Using the BIOS menus 94

Main 94

Advanced 96

Security 112

Server Management 114

Boot Options 118

Boot Manager 121

Error Manager 122

Exit 123

Upgrading the BIOS 125

5 Troubleshooting 127

Troubleshooting 129

Resetting the system 129

Problems following initial system installation 129

First steps checklist 130

Page 9

Hardware diagnostic testing 131

Verifying proper operation of key system lights 131

Specific problems and corrective actions 132

Error beep codes 139

BIOS POST error beep codes 139

ARMC/3 module error beep codes 141

Diagnostic POST code LEDs 142

Appendix A: Acer Altos R520

rack installation guide 149

Setting up the system rack 151

System rack installation 153

Vertical mounting hole pattern 154

Installing the system into the rack 155

Appendix B: RAID configuration 163

Configuring integrated SAS RAID 165

Configuring the integrated SAS SW RAID 167

Configuring the onboard SATA RAID 169

174

ix

Page 10

x

Page 11

1 System tour

Page 12

The Acer Altos R520 is a 1U dual-core Intel Xeonbased server equipped with numerous high

performance features designed to provide easy

server set up, remote management, highly

reliable shared storage, and handle more

demanding database or high transaction

applications.

This chapter provides a brief overview of the

system hardware, including illustrations with

component identification.

Page 13

System features

Listed below are the key features of the Acer Altos R520 server.

Performance

Processor

• Supports two dual-core or quad-core Intel® Xeon™ processors

5000 sequence with 667 MHz, 1066 MHz, or 1333 MHz front side

bus speed

• Extended Memory 64-bit Technology

• Enhanced Intel SpeedStep Technology

• Execute Disable Bit Technology

Chipset

• Intel 5000P Memory Controller Hub (north bridge)

• Intel ESB2-E (Enterprise South Bridge) I/O Controller (south bridge)

Memory

• Quad memory channels

• Eight DDR2 FBDIMM (fully buffered DIMM) slots

• Supports 512 MB, 1 GB, and 2 GB DDR2 667 MHz FBDIMM

• Support for the following RASUM (reliability, availability,

serviceability, usability, and manageability) features:

• Memory error detection and correction

• Memory scrubbing

• Retry on correctable errors

• Memory built-in self test

•Memory sparing

•Memory mirroring

3

Media storage

• Slim-line IDE optical drive

• Supports either a SAS or SATA HDD interface

Page 14

4

• For SATA models, the embedded SATA controller support

- Passive mid-plane board

- Six onboard SATA connectors

- Up to six hot-plug 2.5” SATA hard disk drives

- Intel Embedded Server RAID Technology capable of SATA

software RAID levels:

• RAID 0 • RAID 10

• RAID 1 • RAID 5 (optional)

• For SAS models, the embedded SAS controller support

- Active mid-plane board

- Up to eight hot-plug 2.5” SAS hard disk drives

- Intel Embedded Server RAID Technology capable of SAS

software RAID levels:

• RAID 0 • RAID 10

• RAID 1

- Provides optional hardware RAID support through

installation of a RAID activation key and a RAID cache on

the mid-plane board. The SAS hardware RAID levels

supported include:

• RAID 0

• RAID 6

1

• RAID 1 • RAID 10

• RAID 5 • RAID 50

1 System tour

1

Note: The active mid-plane board provides a 244-pin mini-DIMM

connector, supporting a single registered ECC non-parity DDR2400 MHz mini-DIMM to provide RAID cache. To protect from data

loss in the RAID cache in the event of power failure, you can also

install a RAID BBU.

1 Supported when available.

Page 15

Networking

• Intel ESB2 I/O controller

• Intel 82563EB Gigabit controller with dual ports

• Supports Intel I/O Acceleration Technology

PCI I/O

• Low profile riser slot

• One x8 PCI Express slot

• Full height riser slot

• One x8 PCI Express slot

• One 64-bits/133 MHz PCI-X slot (optional)

Graphic interface

•ATI® ES1000 video controller with 16MB DDR SDRAM

Server management

• BMC (Baseboard Management Controller)

• IPMI (Intelligent Platform Management Interface) 2.0

compliant

• In-band and out-band server management

• ARMC/3 (Acer Remote Management Card/3) module (optional)

• High performance KVM redirection

• Includes a dedicated NIC port

• USB mouse, keyboard, and media redirection

5

Control panel

• Mini control panel

• Standard control panel (optional)

I/O ports

• Front

•USB 2.0 port

• VGA/monitor port (optional)

Page 16

6

• Rear

• PS/2 keyboard port

• PS/2 mouse port

• Serial B port (RJ-45)

• Two Gigabit (10/100/1000 Mbps) LAN ports (RJ-45)

• Server management port (10/100 Mbps) (RJ-45)

• VGA/monitor port

• Two USB 2.0 ports

Operating system and software

• Operating system options

• Microsoft

• Microsoft Windows Server 2003

• Novell Netware 6.5

• Red Hat Enterprise Linux 4.0

• Red Hat Enterprise Linux 4.0, EM64T

•SUSE

• SUSE Linux Enterprise Server 9.0, EM64T

• ASM (Acer Server Manager)

• Easy Build

®

Windows® Server 2003, x64 edition

®

Linux Enterprise Server 9.0

3

2

1 System tour

2

Power supply

• Supports one to two 650-watts power supply modules

• Supports redundant (1+1) or non-redundant (1+0) power

configuration

System fan

• Five dual rotor system fans

2 Reserved for remote management of server. This requires installation of an

ARMC/3 module to mainboard.

3 For more information on how to install and use ASM and Easy Build utilities,

refer to the manual on the EasyBUILD DVD.

Page 17

External and internal structure

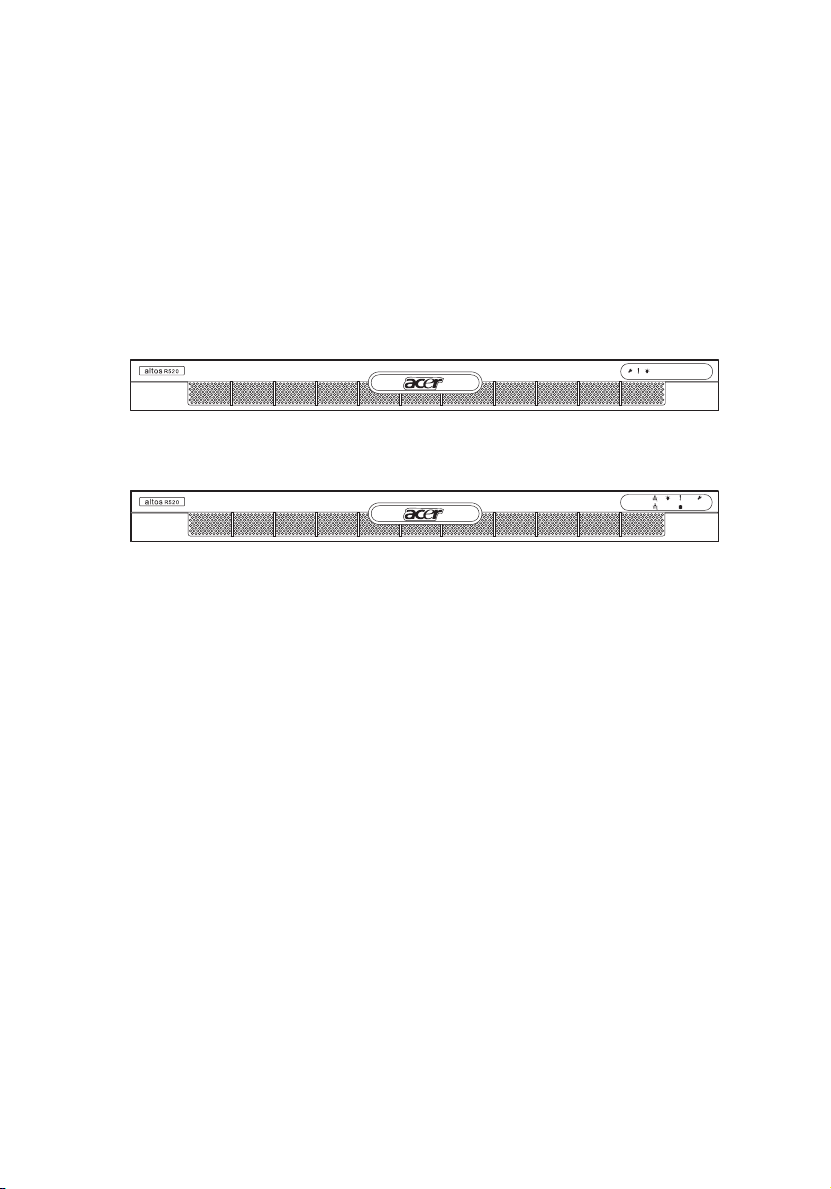

Front bezel

The front bezel provides an interface for system management via

status LED indicators. The light pipes on the backside of the front bezel

allow the system status LEDs to be monitored when the front bezel is

closed. Separate front bezels are available to support systems that use

a mini control panel or standard control panel.

Front bezel supporting mini control panel

Front bezel supporting standard control panel (optional)

The front bezel is removable to allow access to the server’s hard drives,

peripheral device, and control panel. For details on how to remove the

front bezel, see “To remove the front bezel” section on page 41.

7

Page 18

8

1 System tour

Front panel

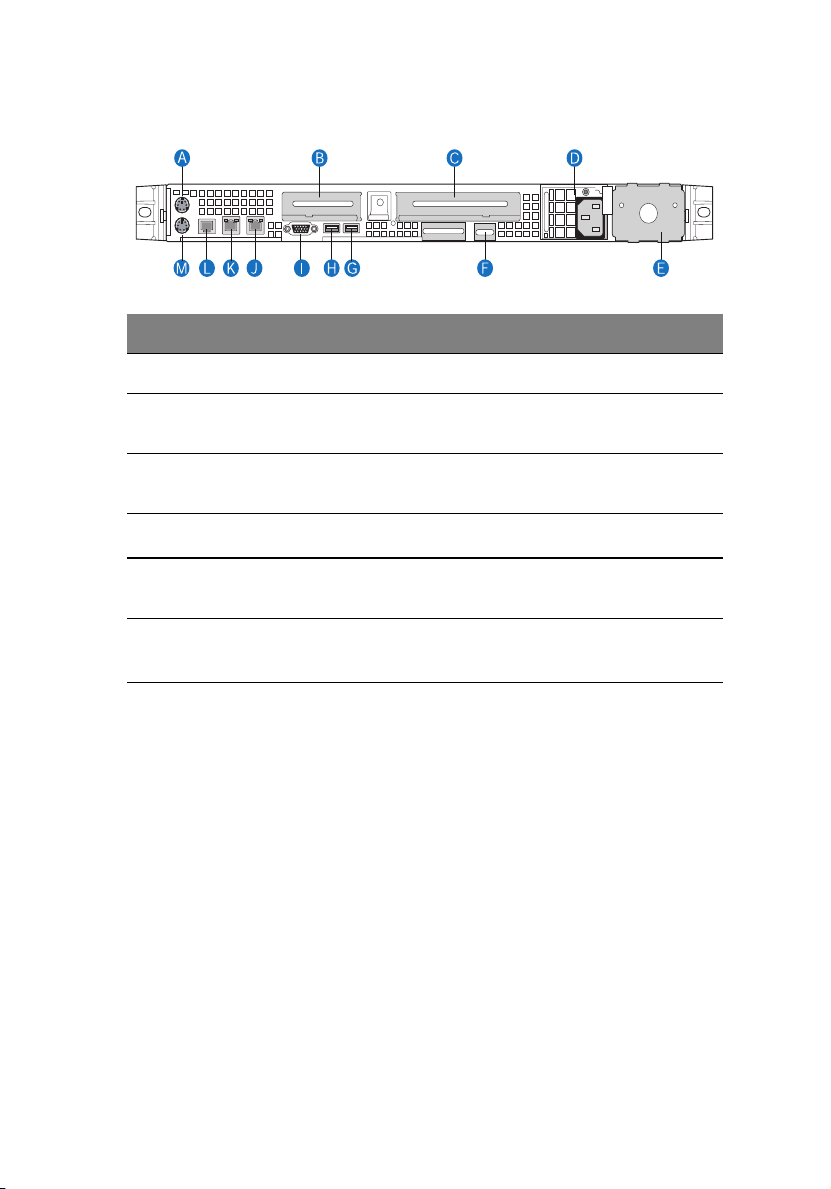

Item Component Item Component

A Rack handles D Dual-purpose bay*

B Slim-line optical drive bay E 2.5” hot-plug HDD bays

C Mini control panel bay

* The Acer Altos R520 dual-purpose bay supports either the standard control panel or two

2.5” hot-plug HDD drives.

Page 19

Rear panel

Item Component Item Component

A PS2 mouse port G, H USB 2.0 ports

9

B Low profile PCI expansion

I VGA/monitor port

slot

C Full height PCI expansion slot J, K Gigabit LAN ports (10/100/

1000 Mbps)

D

Power supply module

E Power supply module bay

1

L DB9 serial port A

M PS2 keyboard port

filler panel

F Server management port (10/

100 Mbps) (RJ-45) cover

1 The system power can be configured to support redundant (1+1) and non-redundant (1+0)

configuration.

2 Reserved for remote management of server. This requires the installation of an ARMC/3

module.

2

Page 20

10

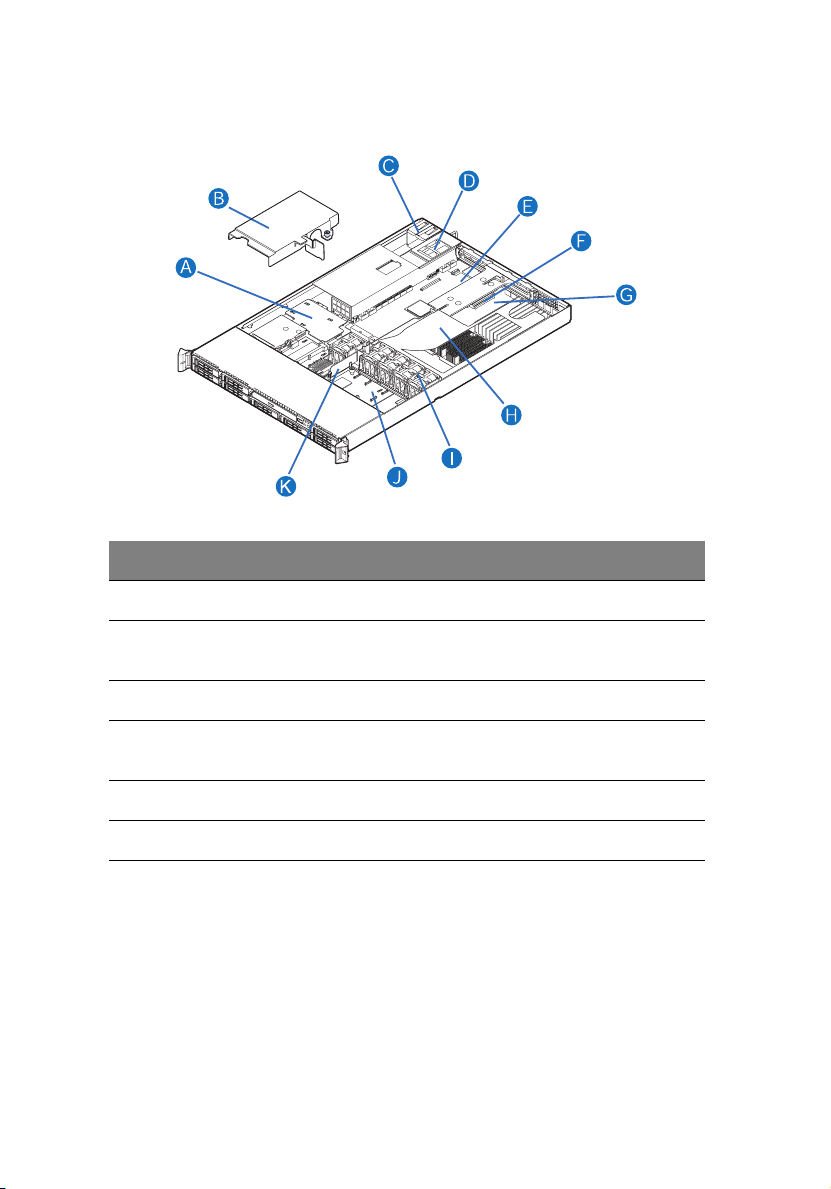

Internal components

Item Component Item Component

A Power distribution board G Memory modules

1 System tour

B Power distribution board

cover

C Power supply module 1 I System fan modules

D Power supply module bay 2

(filler panel shown)

E Riser card assembly K Bridge board

F Mainboard

H CPU air duct

J Mid-plane board (active

mid-plane shown)

Page 21

11

System boards

Mainboard

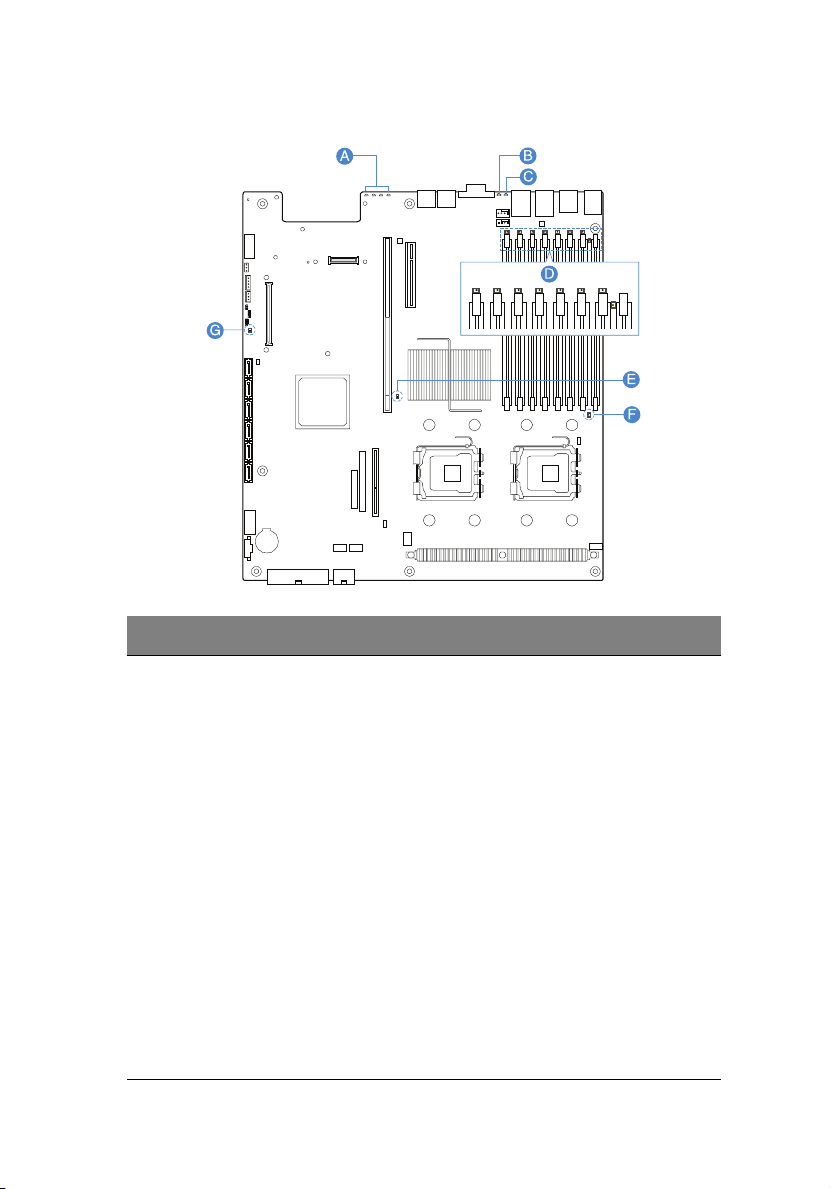

The mainboard becomes accessible once you open the system. It should

look like the figure shown below.

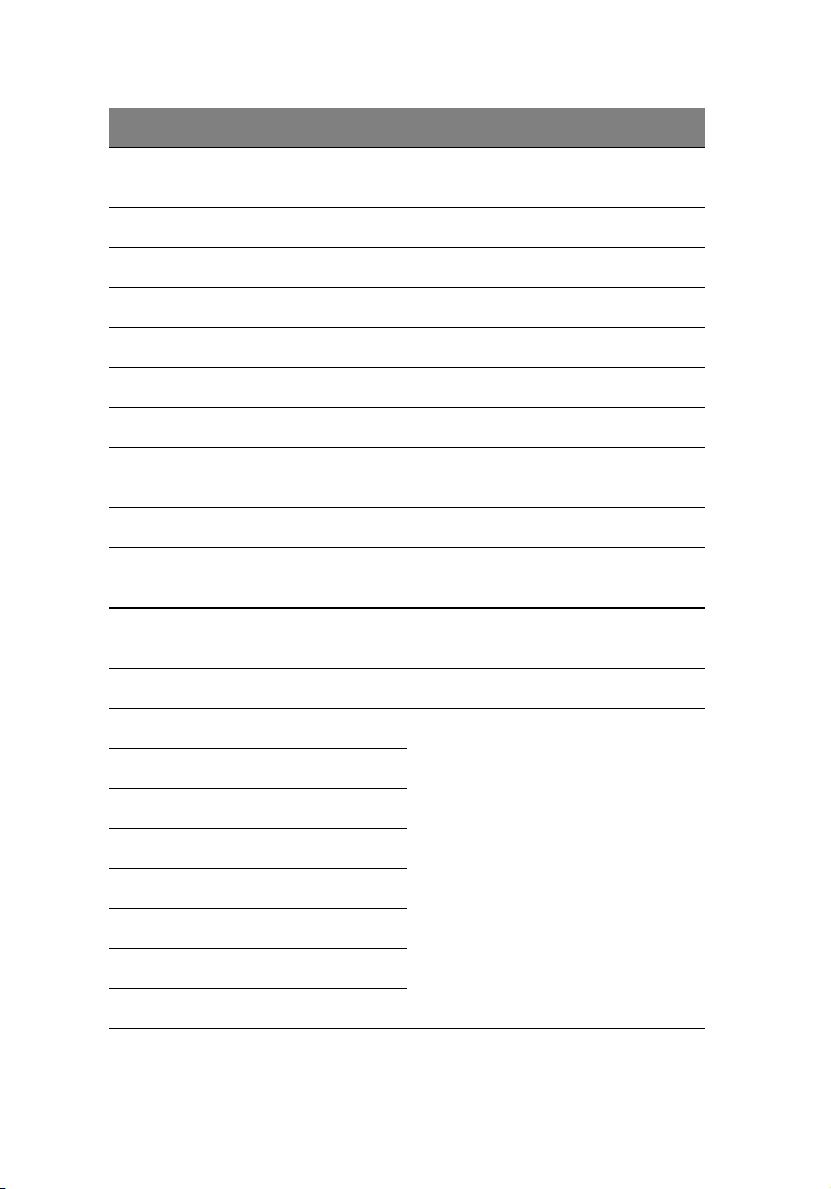

Item Description Item Description

A Rolling BIOS jumper W Battery

B Intel ESB2-E I/O controller X Power supply management

connector

Page 22

12

Item Description Item Description

1 System tour

C Diagnostic POST code

indicators

D Full height PCI riser slot Z SATA 0 connector

E Low profile PCI riser slot AA SATA 1 connector

F USB ports BB SATA 2 connector

G VGA/Monitor port CC SATA 3 connector

H System ID indicator DD SATA 4 connector

I System status indicator EE SATA 5 connector

J Gigabit LAN1 and LAN 2

ports

K Serial B port GG ARMC/3 module connector

L PS2 mouse (top) and

keyboard (bottom) port

M Serial B configuration

jumper

N FBDIMM slots JJ NIC module connector

O Intel 5000P MCH

Y Dual port USB 2.0 connector

FF SATA software RAID

activation key connector

HH System recovery settings

jumper block

II Serial A connector

P CPU socket 1

Q CPU socket 2

R CPU voltage regulator

S Bridge board connector

T IDE optical drive connector

U CPU power connector

V AC power connector

Page 23

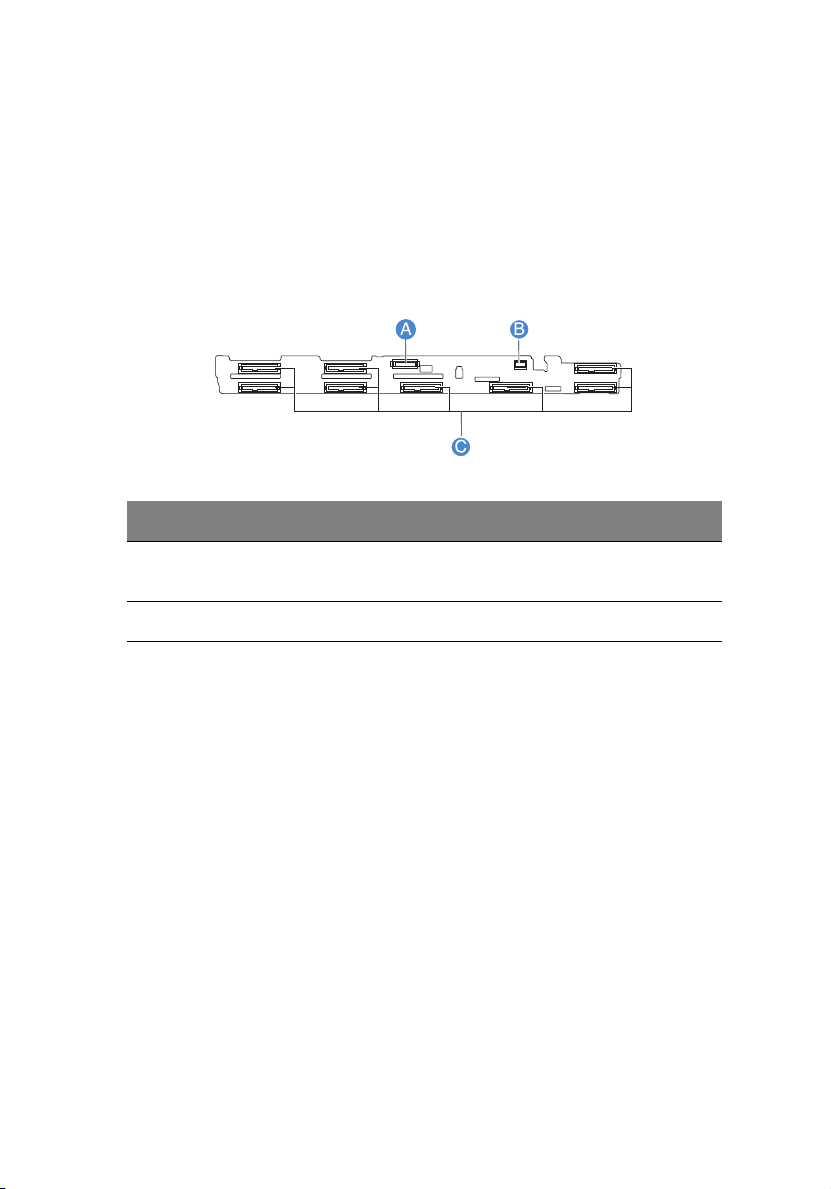

Backplane board

SAS/SATA backplane board

The backplane board installed on the rear side of the hot-plug drive

bay provides support for both SAS and SATA hard drives.

Front view

Item Description Item Description

13

A Slim-line optical drive con-

nector

B Mini control panel connector

CSAS/SATA connectors

Page 24

14

1 System tour

Rear view

Item Description Item Description

A Control panel connector D Mid-plane connectors

B USB connector E Backplane power connector

CIDE connector

Page 25

15

Mid-plane board

The mid-plane boad serves as the primary interface between the

mainboard, backplane, and control panel. It is used to determine the

desired hard drive interface for the system. There are two mid-planes

available for this system: an active mid-plane board and a passive midplane board.

Active mid-plane board (SAS model)

The active mid-plane board is used to provide SAS support. It has an

integrated LSI 1068 SAS controller that provides support for up to eight

hot-plug SAS HDDs. By default, the active mid-plane provides software

RAID levels 0, 1, and 10. With the installation of an optional RAID

activation key and RAID cache, the mid-plane can support hardware

RAID levels 0, 1, 5, 6, 10, and 50.

Note: Mid-plane will support RAID level 6 when available.

B

A

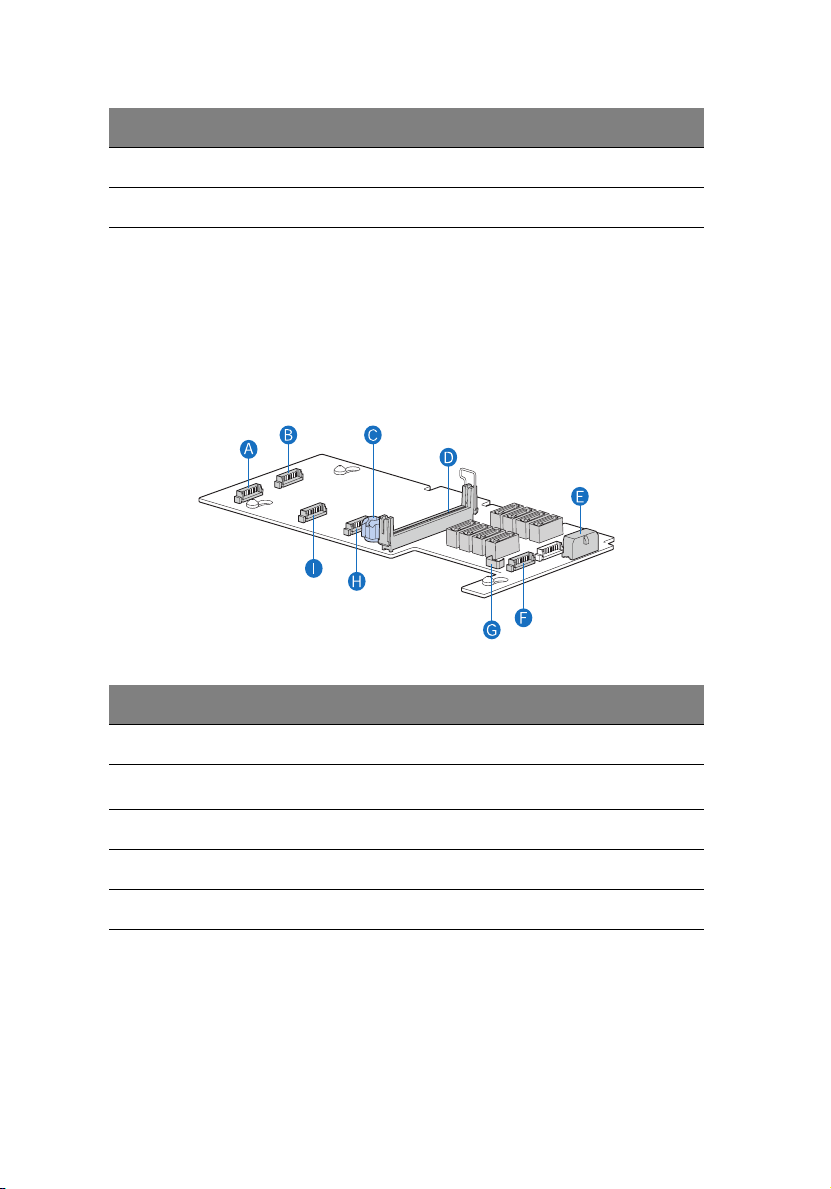

Item Description Item Description

A Fan 2 power connector G RAID BBU (battery backup

B Fan 1 power connector H Mid-plane power connector

C RAID activation key

connector

D Bridge board connector J Fan 4 power connector

C

D

E

F

K

J

I

G

H

unit) connector

I Thumbscrew

Page 26

16

Item Description Item Description

E Fan 6 power connector K Fan 3 power connector

F RAID cache slot

1 System tour

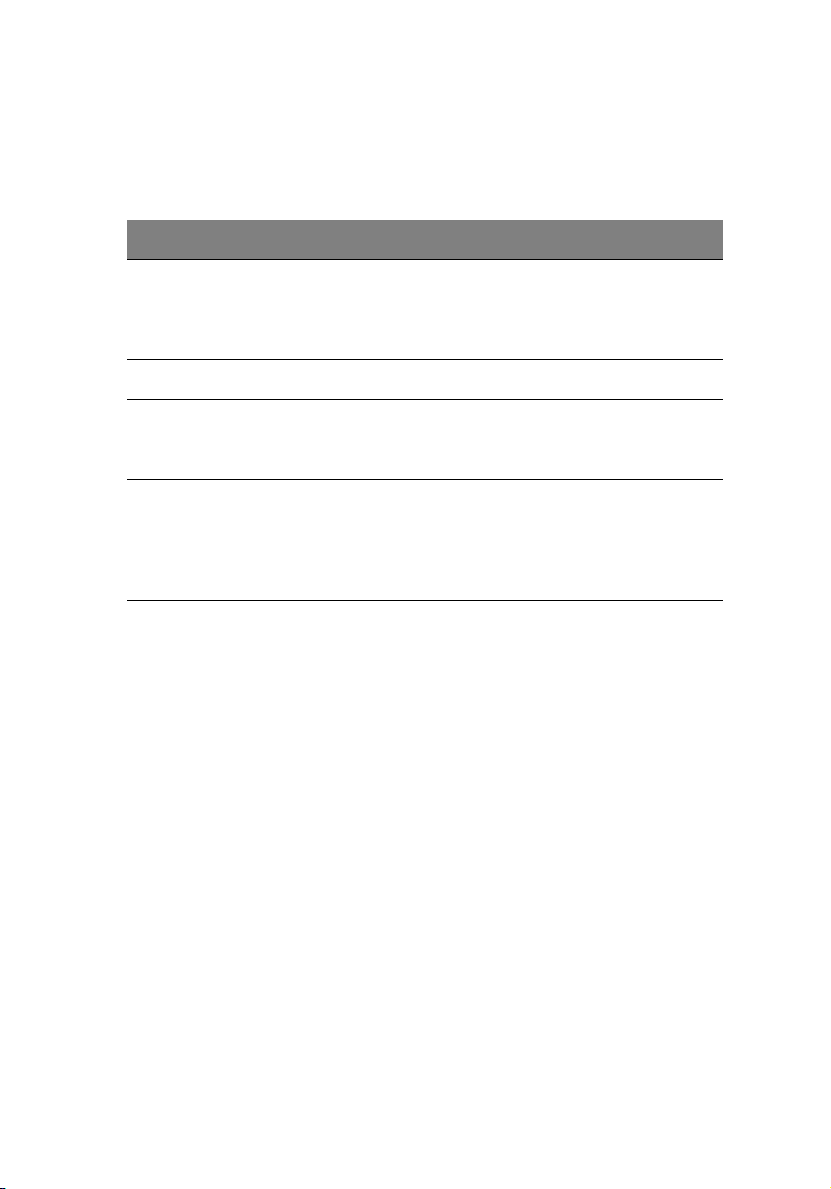

Passive mid-plane board (SATA model)

The passive mid-plane board is used to provide SATA support for the

onboard SATA controller and six SATA ports. The mid-plane also

supports up to six hot-plug SATA HDDs and software RAID levels 0, 1,

and 10. With the installation of an optional SATA software RAID

activation key can support software RAID level 5.

Item Description Item Description

A Fan 2 power connector F Fan 6 power connector

B Fan 1 power connector G

C Thumbscrew H Fan 4 power connector

D Bridge board connector I Fan 3 power connector

E Mid-plane power connector

HBA I

2

C connector

Page 27

17

Control panel

The Acer Altos R520 server supports either the mini control panel,

providing basic functionality, or the standard control panel, which adds

additional server management features. Both control panels utilize a

combination of control buttons, status LED indicators, along with I/O

ports, to centralize system control, monitoring, and accessibility.

Mini control panel

BA DC

GEF

TP02215

Item Component Item Component

A USB 2.0 port E Power/sleep button

B System identification

indicator

C System status indicator G System ID button

D Power/sleep indicator

FNMI button

Page 28

18

Standard control panel (optional)

BA F GEDC

H

I

L JK

Item Component Item Component

A LAN 2 activity indicator G System ID indicator

B LAN 1 activity indicator H System ID button

C Power/sleep button I Reset button

D Power/sleep indicator J USB 2.0 port

1 System tour

E HDD actvity indicator K NMI button

F System status indicator L VGA/monitor port

Page 29

Control panel button function overview

The following table list and describe the function of the control

buttons available on the control panel.

Control button Function

NMI button Puts the server in a halt-state for diagnostic purposes

and allows you to issue a non-maskable interrupt.

After using the interrupt, a memory download can be

performed to determine the cause of the problem.

Reset button Reboots and initializes the system.

Power/sleep button Toggles the system power on and off. This button also

functions as a sleep button if enabled by an ACPIcompliant operating system.

System ID button Toggles the front panel ID LED and the mainboard

system ID LED on and off. The mainboard system ID

LED is visible through the rear of the chassis and

allows you to locate the server you’re working on

from behind a rack of servers.

19

Page 30

20

1 System tour

System LED indicators

This section describes the different LED indicators located on

• Mainboard

• Control panel

• Hot-plug HDD carrier

• LAN port

• Hot-plug power supply module

Page 31

Mainboard diagnostic LED indicators

Item Description Color State Description

21

A Diagnostic

POST code

indicators

During the system boot process,

BIOS executes a number of

platform configuration processes,

each of which is assigned a specific

hex POST code number. As each

configuration routine is started,

BIOS will display the given POST

code to the POST Code Diagnostic

LEDs found on the rear of the

mainboard. To assist in

troubleshooting a system hang

during the POST process, the

diagnostic LEDs can be used to

identify the last POST process to

be executed.

Refer to the Diagnostic POST code

table on page 142. for a complete

description of how these LEDs are

read, and a list of all supported

POST codes.

Page 32

22

Item Description Color State Description

1 System tour

B System ID

indicator

C System

status

indicator

Blue On The system ID buton on the control

panel is activated

Off System identification is disabled

Blink Appropriate hex IPMI “Chassis

Green/

Amber

Green On System booted and ready or

Altern

ating

blink

Blink System degraded

Identify” value has been issued

Pre DC power on - 30-35 second

BMC initialization when AC power

is applied to the system

normal operation

• Unable to use all of the

installed memory

• System loses memory

redundancy when memory

mirroring takes place

• System loses memory

redundancy when memory

sparing takes place

• Redundancy loss such as power

supply or fan

• PCI-E link error

• CPU failure or disabled

• Fan alarm or failure

• Non-critical temperature and

voltage threshold crossed

Page 33

Item Description Color State Description

23

System

status

indicator

(cont.)

D DIMM error

indicators

Amber On Critical or non-recoverable

condition

• DIMM failure when there is one

DIMM present

• Run-time memory

uncorrectable error in

non-redundant mode

• IERR signal asserted

• Processor 1 missing

• Critical temperature

• Power fault

• CPU configuration error

Blink Non-critical condition

• Critical voltage threshold

crossed

• VRD hot asserted

• Fans failed or not present

• Correctable error threshold in

non-sparing and non-mirroring

mode crossed

Off AC power off

On System BIOS disables a DIMM after

it reaches a specified number of

given failures or critical DIMM

failures are detected

E, F CPU error

indicator

G5-volt

standby

present

indicator

On • CPU is disabled

• CPU configuration error is

detected

On • AC power is applied to the

system

• 5 V standby voltage is supplied

to the system by the power

supply

Page 34

24

1 System tour

Control panel LED indicators

The following table list and describe the LED indicators available on

the mini or optional standard control panel.

Indicator Color State Description

LAN1/LAN2

activity

indicator

Power/Sleep

indicator

HDD activity

indicator

System ID

indicator

System

status

indicator

Green On Link between system and network

Blink Network access

Green Off System is not powered on or ACPI S4

or S5 state

On System has power applied to it or ACPI

S0 state

Blink System is in ACPI S1 state (sleep mode)

Green Random

blink

Off No HDD activity

Blue On System identification is active

Off System identification is disabled

Green/

Amber

Green On Running or normal operation

Alternating

blink

Blink System degraded

HDD is active

Pre DC power on - 30-35 second BMC

initialization when AC power is

applied to the system

Amber On Critical or non-recoverable condition

Blink Non-critical condition

Off POST or system stop

Page 35

Hot-plug HDD LED indicators

There are two status LED indicators mounted for each hot-plug HDD

carrier. The table below list the possible drive states.

Indicator Color State Description

25

Hot-plug

HDD activity

indicator

Hot-plug

HDD failure

indicator

Amber Flash HDD is active

Amber +

Green

Green Blink Ongoing hot-plug activity

Off • No HDD is installed

Amber On HDD failure.

Green Blink Ongoing hot-plug activity

Alternate

flash

• HDD is powered on and rebuilding

RAID

• HDD is powered on and is in a fault

condition

• HDD is initiated but has no current

activity

LAN port LED indicators

Indicator Color State Description

Speed

indicator

(left)

Green/

Amber

Green On 100 Mbps connection

Amber On 1000 Mbps connection

Off 10 Mbps connection

Link/

activity

indicator

(right)

Green On Network link is detected

Off No network connection

Blink Transmit or receive activity

Page 36

26

1 System tour

Hot-plug power supply module LED indicator

The table below list and describe the bi-color LED indicator located on

the power supply module.

Indicator Color State Description

Status Off No AC power to the power supply

Green On System has power applied to it

Blink AC power cord is plugged into an

active AC power source

Amber On • No AC power

• Power supply critical event

(i.e, failure, fuse blown, fan

failed, etc.) causing shutdown

Blink Power supply displays warning

event (i.e., high temperature, high

power, high current, slow fan, etc.)

Page 37

System jumpers

Jumper name Settings Function

27

J1D2

Password clear

J1D3

Clear CMOS

J3H1

BIOS select

J1D1

BMC force update mode

J8A3

Serial B port (RJ-45)

1-2 (default)

2-3

1-2 (default)

2-3

1-2

2-3 (default)

1-2 (default)

2-3

1-2

3-4 (default)

Password enabled

Password disabled/cleared

BIOS clear CMOS

Forced CMOS clear

Force lower bank

Normal operation

BMC force update disabled

BMC force update enabled

DCD (Data Carrier Detect) to DTR

(Data Terminal Ready) signal

DSR (Data Set Ready) to DTR signal

Page 38

28

1 System tour

Page 39

2 System setup

Page 40

This chapter gives you instructions on how to set up

the system. Procedures on how to connect

peripherals are also explained.

Page 41

Setting up the system

Pre-installation requirements

Selecting a site

Before unpacking and installing the system, select a suitable site for

the system for maximum efficiency. Consider the following factors

when choosing a site for the system:

• Near a grounded power outlet

• Clean and dust-free

• Stable surface free from vibration

• Well-ventilated and away from sources of heat

• Secluded from electromagnetic fields produced by electrical

devices such as air conditioners, radio and TV transmitters, etc.

Checking the package contents

Check the following items from the package:

• Acer Altos R520 server system

•Acer EasyBUILD

• Acer Altos R520 accessory box

TM

31

If any of the above items are damaged or missing, contact your dealer

immediately.

Save the boxes and packing materials for future use.

Page 42

32

2 System setup

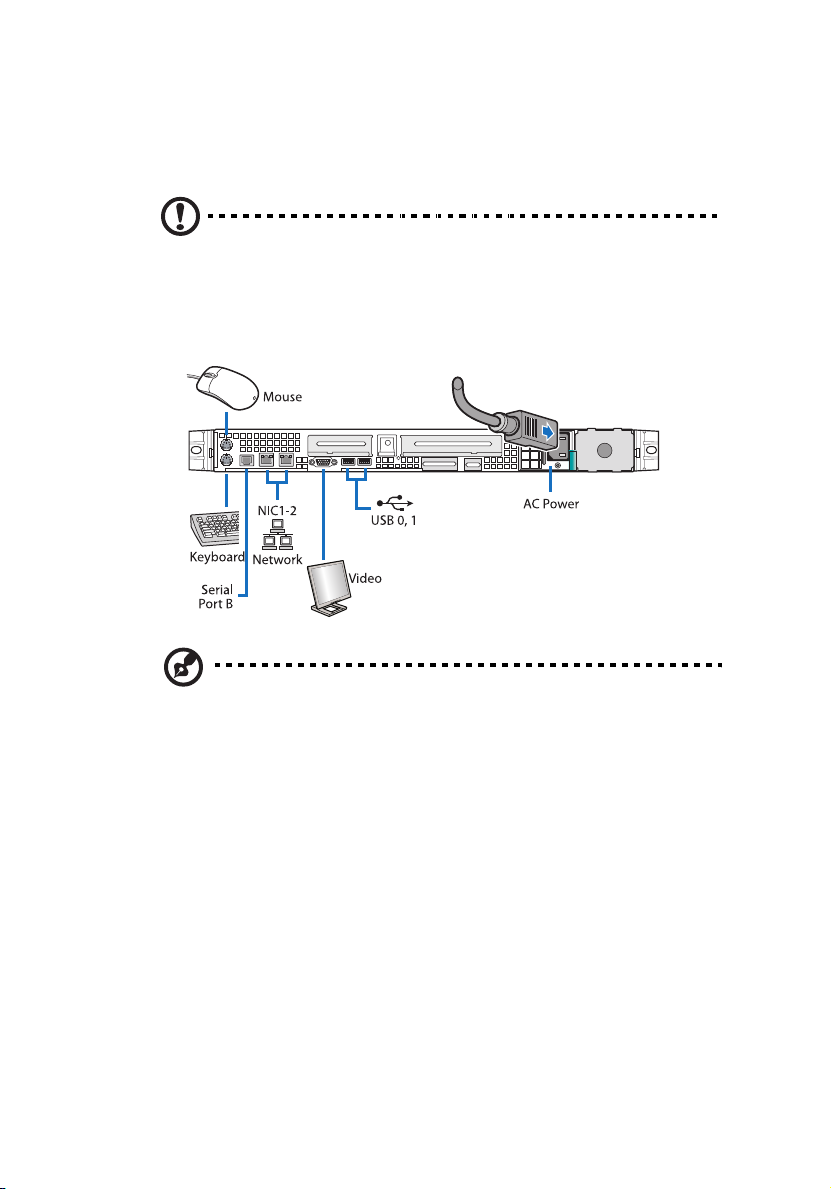

Connecting peripherals

Caution! The server operates on 100-127/200-240 VAC only. Do

not connect the system to an incorrect voltage source.

Refer to the illustration below for specific connection instructions on

the peripherals you want to connect to the system.

Note: Consult the operating system manual for information on

how to configure the network setup.

Page 43

Turning on the system

After making sure that you have properly set up the system and

connected all the required cables, you can now power on the system.

Note: After plugging in the AC power cord, allow system to warm

up for 30 seconds or until the status/fault indicator on the control

panel stops blinking before turning on the system.

Refer to “Control panel” on page 17 for the location of the status/

fault indicator. The location of the status/fault indicator will

depend on the type of control panel installed on your system.

To power on the system:

1 Remove the front bezel. See “To remove the front bezel”section

on page 41.

2 Press the power button on the control panel.

The system starts up and displays a welcome message on the monitor.

After that, a series of POST messages appears.

33

Note: If the system does not turn on or boot after pressing the

power button, go to the next section for the possible causes of the

boot failure.

If the POST finds any problems, the system will emit a beep code

followed by an error message displayed on the monitor. Aside from the

POST messages, you can determine if the system is in good condition

by checking if the following occurred:

• Power indicator on the control panel lights up (green)

• Num Lock, Caps Lock, and Scroll Lock indicators on the keyboard

light up

Page 44

34

2 System setup

Power-on problems

If the system does not boot after you have applied power, check the

following factors that might have caused the boot failure.

• The external power cord may be loosely connected.

Check the power cord connection from the power source to the

power supply module AC input connector on the rear panel. Make

sure that the power cord is properly connected to the power

source and to the AC input connector.

• No power comes from the grounded power outlet.

Have an electrician check your power outlet.

• Loose or improperly connected internal power cables.

Check the internal cable connections. If you are not confident to

perform this step, ask a qualified technician to assist you.

Warning! Make sure all power cords are disconnected from

the electrical outlet before performing this task.

Note: If you have gone through the preceding actions and the

system still fails to boot, ask your dealer or a qualified technician

for assistance.

Page 45

Configuring the system OS

35

The Acer Altos R520 server comes with Acer EasyBUILD

TM

that allows

you to conveniently install your choice of operating system. To start

using EasyBUILD, follow the steps below.

1 Locate the EasyBUILD DVD included in the system package.

2 With the system turned on, gently press the optical drive’s Stop/

Eject button.

3 When the disc tray slides open, insert the EasyBUILD DVD with the

label or title side of the disc facing upward.

Note: When handling the disc, hold it by the edges to avoid

smudges or fingerprints.

4 Gently press the disc down to make sure that it is properly

inserted.

Caution! While pressing the disc, be careful not to bend the disc

tray. Make sure that the disc is properly inserted before closing

the disc tray. Improper insertion may damage both the disc and

the CD-ROM drive.

5 Gently press the drive Stop/Eject button again to close the disc

tray.

6 The Acer EasyBUILD sequence begins. Follow all onscreen

instructions.

For more information, refer to the EasyBUILD Installation guide.

Note: EasyBUILD DVD supports Windows Server 2003, Red Hat

Linux, and SUSE operating system only.

Windows or Linux OS CD is needed when you install the OS with

the EasyBUILD DVD.

Page 46

36

2 System setup

Turning off the system

There are two ways to turn off the server. These include:

• Software power off

If you are using a Windows OS on your server, you can turn off the

server by clicking the Start button, point to Shut Down..., select

Shut down from the drop-down window then click on OK. You

can then turn off all peripherals connected to your server.

If you are using another OS, refer to the OS documentation for

instructions on how to shut down the OS.

• Hardware power off

If you cannot shut down the server using the software, press the

power button for at least four seconds. Quickly pressing the

button may put the server in a Suspend mode only.

Page 47

3 System upgrade

Page 48

This chapter discusses the precautionary measures

and installation procedures you need to know to

upgrade the system.

Page 49

Installation precautions

Before you install any server component, we recommend that you read

the following sections. These sections contain important ESD

precautions along with pre-installation and post-installation

instructions.

ESD precautions

Electrostatic discharge (ESD) can damage the processor, disk drives,

expansion boards, motherboard, memory modules and other server

components. Always observe the following precautions before you

install a server component:

1 Do not remove a component from its protective packaging until

you are ready to install it.

2 Wear a wrist grounding strap and attach it to a metal part of the

server before handling components. If a wrist strap is not

available, maintain contact with the server throughout any

procedure requiring ESD protection.

39

Pre-installation instructions

Perform the steps below before you open the server or before your

remove or replace any component:

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Place the system unit on a flat, stable surface.

4 Open the system according to the instructions on page 41.

5 Follow the ESD precautions described in this section when

handling a server component.

6 Remove any hardware structure or cable that block access to the

component you must replace or upgrade.

See the following sections for specific installation instructions on the

component you want to install.

Page 50

40

Warning! Failure to properly turn off the server before you

start installing components may cause serious damage. Do

not attempt the procedures described in the following

sections unless you are a qualified service technician.

3 System upgrade

Post-installation instructions

Perform the steps below after installing a server component.

1 See to it that all components are installed according to the

described step-by-step instructions.

2 Reinstall all components or cable that have been previously

removed.

3 Reinstall the top cover.

4 Reinstall the front bezel.

5 Connect the necessary cables.

6 Turn on the system.

Page 51

Opening the server

Caution! Before you proceed, make sure that you have turned

off the system and all peripherals connected to it. Read the “Preinstallation instructions” on page 39.

You need to open the server before you can install additional

components. The front bezel and top cover are removable to allow

access to the system’s internal components. Refer to the following

sections for instructions.

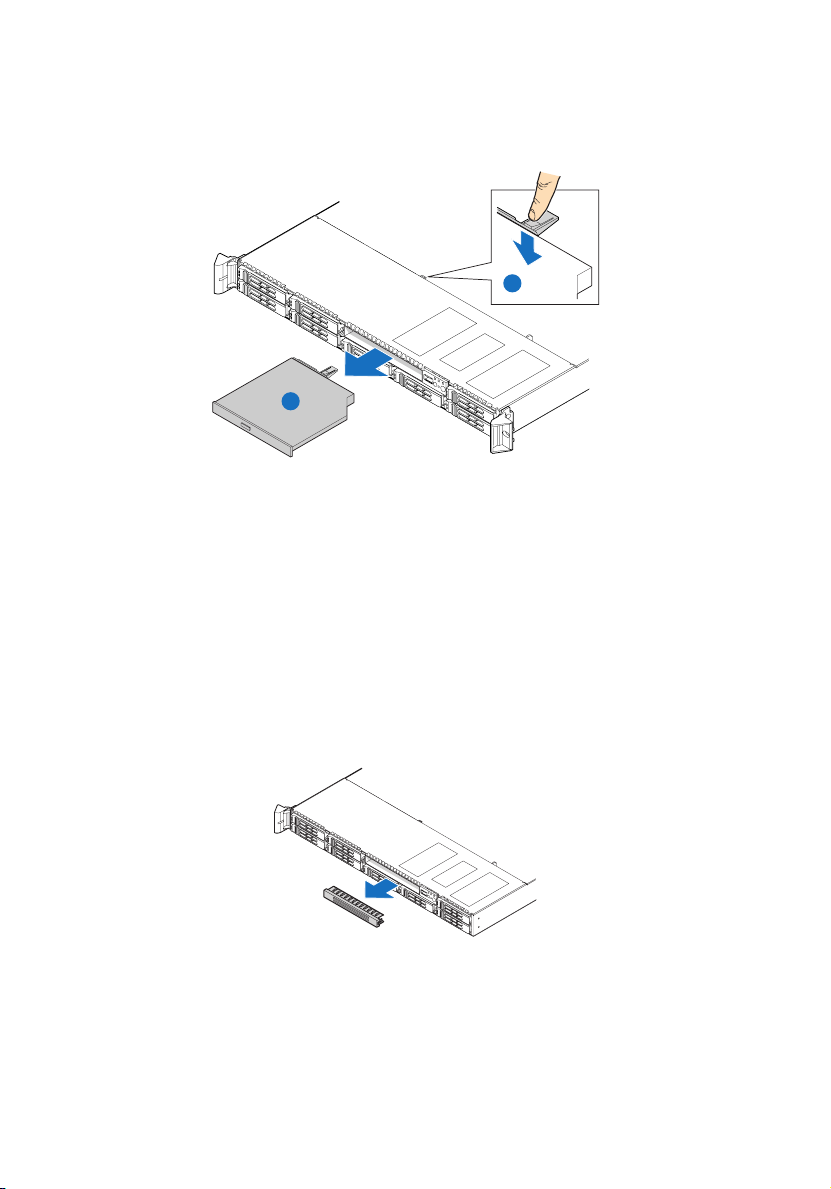

Removing and installing the front bezel

To remove the front bezel:

1 If necessary, remove any cables attached to the control panel.

2 Grasp the front bezel at the outer edge and pull it straight out.

41

Page 52

42

3 System upgrade

To install the front bezel:

1 Line up the center notch on both ends of the bezel with the center

guide on the rack handles.

2 Slide the front bezel onto the chassis until it clicks into place.

Page 53

Removing and installing the top cover

To remove the top cover:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the screw located on the top cover (A).

3 Press and hold the blue release button (B), then slide the cover

toward the back of the chassis until the cover disengage with the

slots on the chassis (C).

4 Lift the top cover away from the server and put it aside for

reinstallation later.

43

Page 54

44

3 System upgrade

To install the top cover:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Place the top cover on the chassis so that the tabs on the cover

align with the slots on the chassis .

3 Slide the top cover toward the front of the chassis until it is fully

closed (A).

4 Replace the screw on the top cover (B).

Page 55

Removing and installing the CPU air duct

Caution! Always operate your server with the CPU air duct

installed to ensure reliable and continued operation.

To remove the CPU air duct:

You will need to remove the CPU air duct to perform the following

procedures:

• Removing and installing a CPU air baffle

• Removing and installing the PCI riser assembly

• Removing and installing the PCI card

• Removing and installing a CPU

• Removing and installing a memory module

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Lift the CPU air duct from the chassis.

45

Page 56

46

3 System upgrade

To install the CPU air duct:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Place the CPU air duct over the two processor sockets. The front

edge of the air duct should touch the front fan module and the

top of the installed air duct should be flush with the top of the PCI

riser assembly.

Caution! Do not pinch or unplug cables that may be near or

under the air duct.

3 Observe the post-installation instructions described on page 40.

Page 57

Removing the CPU air dam

To remove the CPU air dam:

Important: Do not remove the CPU air dam from the CPU air duct

except when installing a second CPU to the system. The air dam

ensures proper air flow when a single CPU is installed to the

system.

Do not remove the memory air deflector.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Turn the CPU air duct over.

3 Remove the air dam by sliding slotted holes off duct pins.

47

TP02227

4 Store it in a protective packaging.

5 To install a second CPU to your system, see “Upgrading the CPU”

section on page 61 for detailed instructions.

6 Observe the post-installation instructions described on page 40.

Page 58

48

3 System upgrade

Removing and installing the power distribution board cover

To remove the power distribution board cover:

You will need to remove the power distribution board cover to

perform the following procedures:

• Removing and installing the RAID activation key and RAID cache

• Removing and installing a RAID BBU

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Loosen the thumbscrew that secures the cover to the chassis (A).

3 Pull up the cover to remove it (B).

A

B

TP02228

4 Observe the post-installation instructions described on page 40.

Page 59

To install the power distribution board cover:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Lower the power distribution board cover to the chassis (A).

3 Tighten the thumbscrew to secure the cover to the chassis (B).

B

A

TP02229

4 Observe the post-installation instructions described on page 40.

49

Page 60

50

3 System upgrade

Configuring the storage devices

The system supports 2.5-inch storage devices. It accommodates slimline optical drives and depending on system model, can support up to

six 2.5-inch hot-plug SATA hard disk drives or eight hot-plug SAS hard

disk drives.

Caution! To maintain proper system cooling, filler panels must be

installed if a device is not replaced.

Removing and installing a hard disk drive

Note: Use only Acer-qualified SAS or SATA HDDs. To purchase a

SAS or SATA HDD, contact your local Acer representative.

Caution! To ensure proper airflow and server cooling, all drive

bays must contain either a carrier with a hard drive installed in it

or a hard disk carrier cover.

Determining drive status

Each HDD carrier features two status LED indicators to display the hard

drive status. If you are replacing a failed HDD, determine which drive

has failed by checking the drive status LED. For more information on

how to determine the drive status, refer to “Hot-plug HDD LED

indicators” on page 25.

Page 61

51

To remove a HDD:

1 Observe the ESD precautions described on page 39.

2 If you are removing a failed HDD, determine which drive has failed

by checking the drive status LEDs.

3 Press the green HDD carrier latch to open the drive (A).

4 Pull out the lever and slide the carrier from the chassis (B).

B

A

5 Place the HDD carrier on a clean, static-free work surface.

6 If you are replacing a hard disk, remove the four screws that secure

the hard disk to the HDD carrier, then remove the disk from the

HDD carrier.

7 Keep the screws for later HDD installation.

Page 62

52

3 System upgrade

To install a HDD:

Note: To puchase a HDD carrier, contact your local Acer

representative.

1 Perform steps 1 to 4 listed on the “To remove a HDD” section on

page 51.

2 Remove the four screws that secure the air baffle to the HDD

carrier (A).

3 Remove the air baffle from the HDD carrier (B).

4 Save the air baffle and screws for later use.

5 Remove the HDD from its protective packaging.

6 Install a hard disk on the HDD carrier, then secure it with the four

screws (A) that came with the HDD carrier (B).

B

A

TP02231

7 With the lever still extended, slide the HDD carrier all the way into

the drive bay (A). Do not push on the lever until it begins to close

by itself.

Page 63

53

8 When the lever begins to close by itself, push on it to lock the drive

assembly into place (B).

A

B

Removing and installing a slim-line optical drive

Note: The slim-line optical drive is not hot-pluggable. Before

removing or replacing the drive, you must first power down the

server, unplug the AC power cord from the system, and turn off all

peripherals devices connected to the server.

Caution! To maintain proper system cooling, a filler panel must

be installed if a device is not installed in the bay.

To remove a slim-line optical drive:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

Page 64

54

3 System upgrade

2 Press the blue release lever to unlock the optical drive tray (A) and

slide the optical drive tray out through the front of the server (B).

A

B

TP02261

3 If no device will be installed in the drive bay, install the filler panel

in the drive bay.

If installing a new optical drive, see succeeding section.

To install a slim-line optical drive:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 If necessary, remove the old optical drive. See previous section.

3 If a filler panel is installed, remove it from the drive bay.

4 Remove the new drive from its protective packaging.

Page 65

5 Install the plastic guide on the rear of the optical device, then

secure it with the two screws that came with the optical drive kit.

TP02233

6 Slide the optical drive tray into the front opening in the server.

Make sure the back end of the plastic guide plugs into the

matching connector on the backplane board.

7 Verify that the blue release lever on the tray locks into place.

8 Observe the post-installation instructions described on page 40.

55

Page 66

56

3 System upgrade

Removing and installing a PCI riser assembly

Note: The PCI riser assembly includes an intrusion switch that

engages the system cover. The intrusion switch is provided to

allow server management software to monitor removal of the top

cover from the server.

Caution! The PCI riser assembly must be installed to maintain

proper airflow inside the server.

This section explains how to access the PCI riser assembly and remove

and install PCI cards.

To remove the PCI riser assembly:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Diconnect any cables attached to an installed PCI card.

4 Grasp both riser latches with thumb and forefinger, then pull up to

release the riser assembly.

Page 67

5 Lift the riser assembly from the chassis.

TP02236

6 Place the riser assembly on a clean, static-free work surface.

7 If you need to replace PCI cards. See “Removing and installing a

PCI card” on page 58.

8 Observe the post-installation instructions described on page 40.

57

Page 68

58

3 System upgrade

To install the PCI riser assembly:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Lower the PCI riser assembly (A), aligning the four hooks on the

back edge of the riser assembly with the matching slots on the rear

of the chassis (B).

3 Press down on the assembly until the four hooks on the rear of the

riser assembly engage the chassis rear panel slots. The riser cards

will seat into the matching sockets on the mainboard.

4 Connect the cables to the installed PCI card.

5 Observe the post-installation instructions described on page 40.

Removing and installing a PCI card

To remove a PCI card:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Remove the PCI riser assembly from the server. See “To remove the

PCI riser assembly” section on page 56.

4 Open the rear retention clip by pushing the blue slide upward and

rotating clip to the fully open position.

Page 69

5 When removing a full height PCI card, open the full length PCI

card retention clip on the front of the riser assembly by rotating it

90 degrees outward.

Note: The install sequence for low profile PCI cards on the

opposite side of the riser assembly is the same.

6 Pull up the card to remove it, then store the card in an antistatic

protective wrapper.

A

B

TP02241

7 Observe the post-installation instructions described on page 40.

To install a PCI card:

59

Note: When installing PCI-X cards into the full height riser board,

the cards must be installed starting with the top slot first,

followed by the middle and then the bottom. Any card populated

in the bottom PCI slot will cause the bus to operate at 66 MHz.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Remove the PCI riser assembly from the server. See “To remove the

PCI riser assembly” section on page 56.

4 Open the rear retention clip by pushing the blue slide upward (A)

and rotating clip to the fully open position.

Page 70

60

3 System upgrade

5 When installing a full height PCI card, open the full length PCI card

retention clip on the front of the riser assembly by rotating it 90

degrees outward (B).

6 Remove the filler panel, if installed.

7 Insert the PCI card into the selected slot (C). Make sure the card is

properly seated.

B

A

C

TP02240

8 Close both retention clips.

9 Observe the post-installation instructions described on page 40.

Page 71

61

Upgrading the CPU

The server supports two dual-core or quad-core Intel Xeon processors

5000 sequence with system bus speeds of 667 MHz, 1066 MHz or 1333

MHz, and core frequencies starting at 1.6 GHz.

CPU upgrading guidelines

When installing CPUs the following rules must be observed:

• Use only Acer-qualified CPUs.

• Each CPU socket include a CPU and heat sink.

• When two CPUs are installed, both should have identical revision,

core voltage, and bus/core speed values.

• When only one CPU is installed, it must be installed in CPU 1

socket.

• System is designed to provide up to 130 W of current per

processor. Processors with higher current requirements are not

supported.

To install a CPU:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

Warning! The heat sink becomes very hot when the system

is on. NEVER touch the assembly with any metal or with

your hands.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 If installing a second CPU, remove the CPU air dam first. See

“Removing the CPU air dam” section on page 47.

4 Locate the processor socket.

Page 72

62

3 System upgrade

5 Push the socket retainer lever handle down and away from the

socket to release it (A), then pull the lever to a fully open, upright

position (B).

6 Push the rear tab with your finger tip to bring the front end of the

load plate up slightly (A).

7 Lift the load plate (B).

8 Remove the CPU from its protective packaging.

9 Position the CPU over the socket (A), making sure the CPU cutouts

match the socket notches, then insert the CPU into the socket (B).

Caution! The underside of the CPU has components that may

damage the socket pins if installed improperly. CPU must align

correctly with socket opening before installation. DO NOT drop

processor into the socket.

Page 73

10 Remove the protective socket cover by grasping the socket cover

tab (A) and pulling it away from the load plate (B).

63

11 Store the protective socket cover for future use.

12 Close the load plate (A), then press the retainer lever down to lock

the load plate in place (B, C).

Page 74

64

3 System upgrade

13 If the heat sink does not have thermal grease on the bottom, apply

thermal grease to the heat sink base.

14 Install the heatsink and fan

Caution! The heat sink has a thermal interface material (TIM) on

the underside. Use caution so that you do not damage the TIM.

(1) If a protective film is installed on the TIM, remove it.

(2) Set the heat sink over the processor, aligning the four captive

screws with the four screw posts surrounding the processor.

(3) Loosely screw in the captive screws on the heat sink corners in

a diagonal manner.

Note: Do not fully tighten one screw before tightening another.

(4) Gradually and equally tighten each captive screw until each is

firmly tightened.

3

2

1

4

TP02328

15 Observe the post-installation instructions described on page 40.

Page 75

65

To remove a CPU:

If you are replacing a CPU on the system, the heat sink must first be

removed.

Important: Before removing a CPU from the mainboard, make

sure to create a backup file of all important data.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

Warning! The heat sink becomes very hot when the system

is on. NEVER touch the assembly with any metal or with

your hands.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Locate the CPU you want to remove.

4 Remove the heat sink.

(1) Loosen the four captive screws on the heat sink.

(2) Twist the heat sink lightly to break the seal between the

heatsink and the processor.

Page 76

66

3 System upgrade

(3) Lift the heat sink from the processor.

Caution! If it does not pull up easily, twist the heat sink again. Do

not force the heat sink from the processor. Doing so could damage

the processor.

(4) Place the heat sink upside down on a flat surface.

Note: Wipe off the thermal grease from both the heat sink and

processor using an alcohol pad.

5 Pull the CPU socket retainer lever handle down and away from the

socket to release it.

6 Lift the load plate.

7 Pull out the CPU from the socket, then store it in an anti-static bag.

8 If installing a replacement processor, see “To install a CPU”.

9 Observe the post-installation instructions described on page 40.

Page 77

67

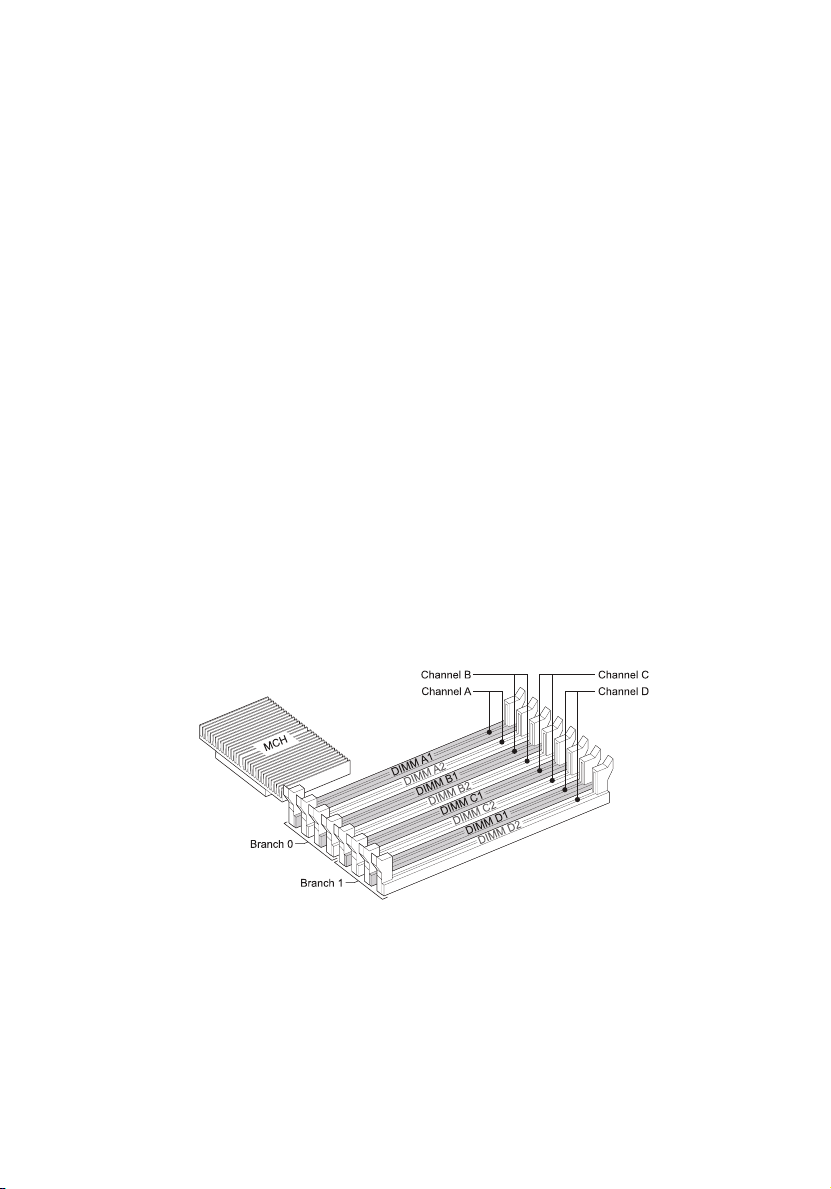

Upgrading the system memory

Acer Altos R520 server supports eight DDR2 fully buffered DIMM slots

with four FBDIMM memory channels. Each channel can support up to 2

dual ranked DDR2 FBDIMMs. The memory channels are organized in to

two branches for support of mirrored memory configuration. Up to 8

FBDIMMs or a maximum memory size of 32 GB physical memory in

standard non-mirrored mode and 16 GB physical memory in a mirrored

configuration are supported by the server.

On the server, a pair of channels becomes a branch where each branch

consists of:

•Branch 0

• Channel A - DIMMA1 and DIMMA2

• Channel B - DIMMB1 and DIMMB2

•Branch 1

• Channel C - DIMMC1 and DIMMC2

• Channel D - DIMMD1 and DIMMD2

Page 78

68

3 System upgrade

Memory module installation guidelines

The following rules apply when installing fully-buffered memory

modules to the server:

• The system must have a minimum of one 512 MB FBDIMMs

installed. When installing additional memory, refer to the tables

on “Memory module population order” on page 69 for proper

population order.

• Use only DDR2 FBDIMMs. Other DIMMs will not fit into the socket.

Attempts to force a non-DDR2 FBDIMM into a socket will damage

or the slot or the FBDIMM.

• Hold FBDIMMs only by the edges. Do not touch the components or

gold edge connectors.

• Install FBDIMMs with gold-plated edge connectors only.

Memory module population guidelines

The following configuration rules must be observed when populating

memory modules:

• In a minimum memory configuration, the FBDIMM should be

installed in DIMM A1 slot.

• Install FBDIMM pairs in the following order:

• Channel A: DIMM slots A1 and A2

• Channel B: DIMM slots B1 and B2

• Channel C: DIMM slots C1 and C2

• Channel D: DIMM slots D1 and D2

• FBDIMMs within a given channel must be identical with respect to

size, speed, and organization.

Page 79

69

Memory module population order

The tables below list the suggested DDR2 FBDIMM module population

for standard, mirrored or sparing configuration.

Standard configuration

Branch 0 Branch 1

Channel A Channel B Channel C Channel D

DIMM A1 DIMM A2 DIMM B1 DIMM B2 DIMM C1 DIMM C2 DIMM D1 DIMM D2

512 MB

512 MB 512 MB

512 MB 512 MB 512 MB 512 MB

512 MB 512 MB 512 MB 512 MB 512 MB 512 MB

512 MB 512 MB 512 MB 512 MB 512 MB 512 MB 512 MB 512 MB

1 GB

1 GB 1 GB

1 GB 1 GB 1 GB 1 GB

1 GB 1 GB 1 GB 1 GB 1 GB 1 GB

1 GB 1 GB 1 GB 1 GB 1 GB 1 GB 1 GB 1 GB

2 GB

2 GB 2 GB

2 GB 2 GB 2 GB 2 GB

2 GB 2 GB 2 GB 2 GB 2 GB 2 GB

2 GB 2 GB 2 GB 2 GB 2 GB 2 GB 2 GB 2 GB

Mirrored configuration

Branch 0 Branch 1

Channel A Channel B Channel C Channel D

DIMM A1DIMM A2DIMM B1DIMM B2DIMM C1DIMM C2DIMM D1DIMM

512 MB 512 MB 512 MB

512 MB 512 MB 512 MB 512 MB 512 MB

1 GB 1 GB 1 GB

1 GB 1 GB 1 GB 1 GB 1 GB

2 GB 2 GB 2 GB

2 GB 2 GB 2 GB 2 GB 2 GB

(Mirror)

(Mirror)

(Mirror)

(Mirror)

(Mirror)

(Mirror)

512 MB

(Mirror)

1 GB

(Mirror)

2 GB

(Mirror)

512 MB

(Mirror)

512 MB

(Mirror)

1 GB

(Mirror)

1 GB

(Mirror)

2 GB

(Mirror)

2 GB

(Mirror)

D2

512 MB

(Mirror)

1 GB

(Mirror)

2 GB

(Mirror)

Total Memory

Physical

Memory

Detected

by OS

2 GB 1 GB

4 GB 2 GB

4 GB 2 GB

8 GB 4 GB

8 GB 4 GB

16 GB 8 GB

Page 80

70

Sparing configuration

3 System upgrade

Branch 0 Branch 1

Channel A Channel B Channel C Channel D

DIMM A1DIMM A2DIMM B1DIMM B2DIMM C1DIMM C2DIMM D1DIMM

512 MB

512 MB 1 GB 512 MB

(Sparing)

512 MB

512 MB 512 MB

(Sparing)

512 MB

512 MB 512 MB

(Sparing)

1 GB

1 GB 2 GB 1 GB

(Sparing)

1 GB

1 GB 1 GB

(Sparing)

1 GB

1 GB 1 GB

(Sparing)

2 GB

2 GB 4 GB 2 GB

(Sparing)

2 GB

2 GB 2 GB

(Sparing)

2 GB

2 GB 2 GB

(Sparing)

512 MB 2 GB 1 GB

(Sparing)

512 MB 512 MB

(Sparing)

1 GB 4 GB 2 GB

(Sparing)

1 GB 1 GB

(Sparing)

2 GB 8 GB 4 GB

(Sparing)

2 GB 2 GB

(Sparing)

(Sparing)

(Sparing)

(Sparing)

512 MB 512 MB

1 GB 1 GB

2 GB 2 GB

D2

512 MB 4 GB 2 GB

(Sparing)

1 GB 8 GB 4 GB

(Sparing)

2 GB 16 GB 8 GB

(Sparing)

Total Memory

Physical

Memory

Detected

by OS

Memory configuration overview

The system supports the following memory configuration that allow

flexibility in performance, redundancy, and ability to upgrade.

• Standard configuration

• Memory mirroring

• Memory sparing

Memory mirroring and memory sparing features are mutually

exclusive, only one of these memory modes can be enabled at one time

and not both at the same time.

Page 81

71

Standard memory configuration

The system is capable of supporting a minimum of only one FBDIMM

installed on the DIMM A1 slot. However, for system performance

reasons, we recommend that at least two memory modules must be

installed per branch. The modules must cover the same slot position on

both channels and FBDIMM pairs must be identical with respect to size,

speed, and organization. FBDIMMs that cover adjacent slot positions

do not need to be identical.

When adding four FBDIMMs to a standard non-mirrored

configuration, the memory modules must be populated in DIMM slots

A1 and B1 first then DIMM slots C1 and D1. It allows both memory

branches to operate in parallel and simultaneously to achieve

equivalent performance.

Mirrored memory configuration

Memory mirroring is implemented in the MCH and the system BIOS.

You can configure the system to maintain mirrored copy of the data in

memory. When operating in mirrored mode, both branches operate in

lock step. In mirrored mode, branch 1 contains a replicate copy of the

data in branch 0. The minimum FBDIMM configuration to support

memory mirroring is four FBDIMMs, populated as shown in the figure

below:

All four memory modules must be identical with respect to size, speed,

and organization.

Page 82

72

3 System upgrade

To upgrade to a four FBDIMM mirrored memory configuration, four

additional FBDIMMs must be added to the system. All four memory

modules in the second set must be identical to the first with the

exception of speed. The memory controller hub (MCH) will adjust to

the low-speed FBDIMM memory.

Note: After upgrading system memory to this feature, the

memory RAS setting in the BIOS setup must be set to Mirroring

configuration. Refer to the BIOS setup’s Configure Memory RAS

and Performance screen on page 101 for more information.

Memory sparing configuration

The system provides FBDIMM sparing capabilities. Sparing is a RAS

feature that involves configuring a FBDIMM to be placed in reserve so

it can be use to replace a failed FBDIMM.

Note: FBDIMM sparing occurs within a given bank of memory and

is not supported across branches.

The system supports two types of memory sparing configurations:

• Single branch mode sparing

In single branch mode sparing the following population rules must

be observed:

• DIMM slots A1 and B1 or DIMM slots A2 and B2 must be

identical in organization, speed, and speed

• DIMM slots A1 and A2 or DIMM slots B1 and B2 need not be

identical in organization, size and speed

• Sparing should be enabled in the BIOS setup utility

• System BIOS will configure rank sparing mode.

• The largest memory size among the DIMM pairs (DIMM_A1,

DIMM_B1) and (DIMM_A2, DIMM_B2) will be selected as the

spare pair unit.

• Dual branch mode sparing

Dual branch mode sparing requires that all eight FBDIMM slots be

populated and must comply with the following population rules:

Page 83

73

• The following FBDIMM slots must be identical in organization,

size and speed.

• DIMM slots A1 and B1 • DIMM slots C1 and D1

• DIMM slots A2 and B2 • DIMM slots C2 and D2

• The following DIMM slots need not be identical in

organization, size and speed.

• DIMM slots A1 and A2 • DIMM slots C1 and C2

• DIMM slots B1 and B2 • DIMM slots D1 and D2

• Sparing should be enabled in the BIOS setup utility

• BIOS will configure rank sparing mode.

• The largest memory size among the DIMM pairs (DIMM_A1,

DIMM_B1) and (DIMM_A2, DIMM_B2) and (DIMM_C1,

DIMM_D1) and (DIMM_C2, DIMM_D2), will be selected as the

spare pair units.

Note: After upgrading system memory to this feature, the

memory RAS setting in the BIOS setup must be set to Sparing

configuration. Refer to the BIOS setup’s Configure Memory RAS

and Performance screen on page 101 for more information.

To install FBDIMMs:

Caution! Use extreme care when installing a FBDIMM. Applying

too much pressure can damage the connector. FBDIMMs are keyed

and can be inserted in only one way.

Note: The number labels next to the FBDIMM slots correspond to

proper installation sequence.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Locate the DIMM slots on the mainboard.

Page 84

74

3 System upgrade

4 Open the clips on the DIMM slot(s) (A).

5 Align (B) then insert the FBDIMM into the socket (C).

6 Press the holding clips inward to lock the FBDIMM in place (D).

Note: The DIMM slot is slotted to ensure proper installation. If

you insert a FBDIMM but it does not fit easily into the socket, you

may have inserted it incorrectly. Reverse the orientation of the

FBDIMM and insert it again.

7 Observe the post-installation instructions described on page 40.

To remove FBDIMMs:

Before you can install a new DIMM in a socket, first remove any

previously installed DIMM from that socket.

Important: Before removing any DIMM from the mainboard,

make sure to create a backup file of all important data.

Page 85

75

Caution! Use extreme care when removing DIMMs. Too much

pressure can damage the connector. Apply only enough pressure

on the plastic levers to release the DIMM.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Press the holding clips on both sides of the DIMM slot outward to

release the DIMM (A).

3 Gently pull the DIMM upward to remove it from the DIMM slot

(B).

4 Observe the post-installation instructions described on page 40.

To reconfigure the system memory:

The system automatically detects the amount of memory installed. Run

the BIOS setup to view the new value for total system memory and

make a note of it.

Page 86

76

3 System upgrade

Installing and removing a power supply module

The server has two power supply module bays on the rear panel that

accept hot-plug power supply modules. The system ships out with only

a single power supply module installed. You have the option to

purchase an extra power supply module to provide the system with a

redundant power source. A redundant power configuration enables a

fully-configured system to continue running even if one power supply

module fails.

WARNING! To reduce the risk of personal injury or damage to

the equipment, the installation of power supply modules

should be referred to individuals who are qualified to service

server systems and are trained to deal with equipment capable

of generating hazardous energy levels.

WARNING! To reduce the risk of personal injury from hot

surfaces, observe the thermal labels on each power supply

module. You can also consider wearing protective gloves.

WARNING! To reduce the risk of personal injury from electric

shock hazards, do not open the power supply modules. There

are no serviceable parts inside the module.

Caution! Electrostatic discharge can damage electronic

components. Make sure that you are properly grounded before

handling a power supply module.

Caution! Due to chassis airflow disruption, a power supply bay

should never be vacant for more than two minutes when the

server is powered on. Exceeding five minutes might cause the

system to exceed the maximum acceptable temperature and

possibly damage the system components.

Caution! The power supply is only hot-pluggable if you have a

redundant system with two power supplies installed. If you

only have one power supply installed, before removing or

replacing the power supply, you must first take the server out

of service, turn off all peripheral devices connected to the

system, turn off the system by pressing the power button, and

unplug the AC power cord from the system or wall outlet.

Page 87

77

To install a second power supply module:

1 Remove the top cover. Perform the instructions described in “To

remove the top cover” section on page 43.

2 If a filler panel is installed, use the finger hole to remove the filler

panel out of the bay (A).

TP02242

3 Insert the power supply module into the right bay, labeled power

supply bay 2, until it locks into place.

TP02243

4 Verify that the LED on the power supply are functioning. Refer to

the “Hot-plug power supply module LED indicator” on page 26

for more information.

Page 88

78

3 System upgrade

To remove a power supply module:

Caution! Power supply hot-plug operations should be performed

only if a failure occurs in the power supply.

1 If there are more than one power supply modules installed,

determine which power supply module has failed. Refer to the

“Hot-plug power supply module LED indicator” on page 26 for

more information.

2 Remove the AC power cord from the power supply being replaced.

3 Press the power supply latch to release the power supply module

from the chassis (A).

4 Use the handle to pull the power supply module out of the server

(B).

B

A

TP02244

5 Install a new power supply module or install a filler panel to the

empty bay.

Page 89

79

Removing and installing an ARMC/3 module

The optional ARMC/3 module provides server management firmware

and functionality to the system.

To remove an ARMC/3 module:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Remove the NIC module.

a Pull up the module to remove it from the connector.

b Remove the three standoffs from the mainboard, then keep

the standoffs for later NIC module installation.

4 Hold the module both by the finger grip loop and by the opposite

corner (A).

Caution! Do not bend or twist the module.

Page 90

80

3 System upgrade

5 Pull up the module to remove it from the connector (B).

6 Observe the post-installation instructions described on page 40.

To install an ARMC/3 module:

Note: Prior to installing the ARMC/3 module module, you must

remove the server management port cover module cover on the

rear of the server.

1 Observe the ESD precautions and pre-installation instructions

described on page 39.

2 Remove the CPU air duct. Perform the instructions described in “To

remove the CPU air duct” section on page 45.

3 Insert the standoff into the hole in the ARMC/3 module. The

standoff installs on the bottom side of the module (A).

Page 91

4 Attach the module to the ARMC/3 module connector on the

mainboard and snap the standoff into the matching hole on the

mainboard (B).

5 Install the NIC module.

a Install the three standoffs to the mainboard.

b Attach the module to the NIC module connector on the

mainboard and matching standoff holes.

81

6 Observe the post-installation instructions described on page 40.

Page 92

82

3 System upgrade

Installing and removing the SAS hardware RAID components

The system supports SAS hardware RAID through the active mid-plane

and backplane board. The server platform supports SAS hardware RAID

0, 1, 5, 6 (when available), 10, and 50 levels. Functionality for SAS

hardware RAID is enabled by using the following components:

• RAID activation key and RAID cache

The RAID activation key works in conjunction with the RAID cache

to provide hardware RAID.

• RAID BBU

If power to the storage I/O processor drops below specifications,

the RAID BBU maintains the contents of the DIMM by keeping the

DIMM in self-refresh mode until power is restored. After power is

restored, data can be safely written to drives, maintaining the

integrity of the disk array.

Installing and removing the RAID activation key and RAID cache

To install the RAID activation key and RAID cache:

1 Observe the ESD precautions and pre-installation instructions

described on page 39.