Page 1

ACER

ACER_LCD_G24_SM080519V1

Service

Model ID:MB243WABNS

Service Manual

Table of Contents

Important Safety Notice------------------------------------------------------------------------------------- 01

01. Product Specification--------------------------------------------------------------------------------- 02

02. OSD Menu-----------------------------------------------------------------------------------------------08

03. Exploded Diagram

04. Assembly and Disassembly Procedures-----------------------------------------------------------12

05.

Troubleshooting----------------------------------------------------------------------------------------20

06. Firmware Upgrade Procedure------------------------------------------------------------------------31

07. Writing EDID Procedure-------------------------------------------------------------------------------33

08. Schematics and Layouts------------------------------------------------------------------------------ 35

AppendixI:UsersManual

Appendix II: Quick Setup Guide

Appendix II : Spare Parts List

Appendix IV: Software Pack

Any person attempting to service this chassis must familarize with the chassis and be aware of the

’

necessary safety precautions to be used when serving electronic equipment

------------------------------------------------------------------------------------- 10

Safety Notice

containing high voltage.

Published by LITE-ON Service Printed in Taiwan © All rights reserved Subject to modification

19th-May-2008

Page 2

Product Anouncement:

Important Safety Notice

ACER G24

Go to cover page

1

This product is certificated to meet RoHS Directive and

Lead-Free produced definition. Using approved critical

components only is recommended when the situation

to replace defective parts. Vender assumes no liability

express or implied, arising out of any unauthorized

modification of design or replacing non-RoHS parts.

Service providers assume all liability.

Qualified Repairability:

Proper service and repair is important to the safe,

reliable operation of all series products. The service

providers recommended by vender should being

aware of notices listed in this service manual in order

to minimize the risk of personal injury when perform

service procedures. Furtermore, the possibile existed

improper repairing method may damage equipment or

Using Lead-Free solder to well mounted the parts.!

! The fusion point of Lead-Free solder requested in the

degree of 220 C.°

products. It is recommended that service engineers

should have repairing knowledge, experience, as well

as appropriate product training per new model before

performing the service procedures.

NOTICE:

To avoid electrical shocks, the products should be

!

connect to an authorized power cord, and turn off the

master power switch each time before removing the

AC power cord.

To prevent the product away from water or explosed

!

in extremely high humility environment.

To ensure the continued reliability of this product,

!

use only original manufacturer s specified parts.

To ensure following safty repairing behavior, put the

!

replaced part on the components side of PWBA, not

solder side.

To ensure using a proper screwdriver, follow the

!

torque and force listed in assembly and disassembly

procedures to screw and unscrew screws.

Page 3

2

ACER G24

Go to cover page

1.1 SCOPE

This document defines the design and performance

requirements for a 24W inch diagonal , flat panel monitor

.The display element shall be a WUXGA (1920x1200)

resolution TFT-LCD (Thin Film Transistor Liquid Crystal

Display).16.7M color(RGB Hi+FRC) images are displayed

on the panel.Video input signals are analog RGB (0.7Vp-p).

When the systemis powered-on , previously stored screen

parameters for a pre-defined mode will be recalled if the

operating mode is one of stored in memory( 24 factory , 9

users timing ).This monitor operates normal by non-

interlaced mode. DDC (Display Data Channel) function is

DDC2Bi compliance Power saving function complies with

the DPMS (Display Power Management Signaling)

standard.

1.2 GENERAL REQUIREMENTS

AMLCD: LTM240CT01

LTM240CT03

1.2.1 Test Condition

Brightness level & contrast level max. Full white

pattern test mode following spec. Warm up more than

1 hr, ambient light < 10 Lux , Luminance meter

CA110 or BM7 or same equipment .

1.2.2 Test Equipment

The reference signal source is a calibrated Chroma

2135 video generator or higher.The use of other

signal generators during qualification and production

is acceptable provided the product complies with this

specification.

1.3 ELECTRICAL

This section describes the electrical requirement of the

monitor. The LCD monitor consists of an interface board , a

power board , a function key board. The interface board

wil l house the flat panel control logic , brightness

control logic, audio function control (option), key function

control, DDC and DC to DC conversion to supply the

appropriate power to the whole board and LCD flat panel ,

and transmitting LVDS signals into LCD flat panel module

to drive the LCD display circuit .The power board will

support main power DC5V to interface board, and the

power DC5.3V to audio function power of interface board,

and drive the two CCFLs (Cold Cathode Fluorescent

Tube).The interface board provides the power ON / OFF

control over the whole monitor and control for DPMS LED

indicator to function key board.

1. Product Specification

Signal Input Frequency

(Analog) V : 55Hz~76Hz

Signal Input Frequency

(Digital) V : 5 5Hz~76Hz

Connector AC Input AC100V ~ AC240V ± 10% 50/60Hz , 3 pin AC power cord

Power Consumption AC in 100V~240V active 90W, power saving < 2W

User's Control Front Empowering,Auto Adjust,Adjust(-),Adjust (+),Menu,Power

Pre-Defined Timing Factory 24

Plug and Play VESA DDC2Bi

Power Saving VESA DPMS

Input Signal Counter Tolerance

1.3.1 Interface Connectors

1.3.1.1 Power Connector and Cables

1.3.1.2 Video Signal Connectors and Cable

MONITOR SPECIFICATIONS

ITEM

Pixel clock 205MHz (Max)

Video Input Analog 0.7Vp-p

Display Pixels 640 x 480 (VGA) ~ 1920 x 1200 (WUXGA)

Sync Signal Separate SYNC for TTL (N or P)

Pixel clock 165MHz (Max)

Video Input Analog 0.7Vp-p

Display Pixels 640 x 480 (VGA) ~ 1920 x 1200 (WUXGA)

Input connector D-SUB 15 pin & DVI-D

Audio Jack

OSD

User 9

Analog :

H : 30kHz~94kHz

Digital :

H : 30kHz~94kHz

Input Impedance 75Ω

(OPTIONAL) Audio input 3.6F

Contrast , Brightness , Position ,Clock ,Phase

,Analog/Digital,RESET, Color , Language select , etc.

≦ H±1kHz, ≦ V±1Hz

SPEC

The AC input shall have an IEC/CEE-22 type male

power receptacle for connection to mains power.

The power cord shall be with length of 1.8+/-0.005

meters.

The signal cable shall be 1.8 0.005 meters long.

+/-

At the end of the cable shall be a molded-over,

shielded,triple row, 15 position, D-subminiature

connector. The CPU connection shall have captive

screw locks, which will be adequate for hand

tightening. The monitor connection may use small

screws.

Page 4

1. Product Specification (continued)

ACER G24

Go to cover page

3

Connector P in Assignm ent

DSUB

P in Sig n a l P in Sig n a l P in Sig n a l

Red-Video

1

G reen-V ideo

2

Blue-Video

3

NC

4

DDC-GND

5

Connector Pin D escription

D-SUB Pin Description

Pin Nam e De s cription

1 R ed-Video Red video signalinput.

2 G reen-Video Green video signal input.

3 B lue -V id eo B lue v ide o s ign al in pu t.

4GND Ground

5 DDC -GND DDC ground for the VESA DDC2Bi function.

6 Red- GN D A nalog signal ground for the R e d video .

7 G reen-GN D Analog signal ground for the Green video.

8 Blue- GN D A na log signal ground for the Blue video .

9 + 5 V +5V input from host system for the V ES A DD C 2B i function.

10 Sync-GND Signalground

11 GN D Ground

12 DDC _SDA S DA signalinput for the VESA DDC B2i function.

13 H - S YN C Horizontalsignalinput from the host system.

14 V - S YN C Verticalsignal input from the host system.

15 DDC -SC L SCL signalinput for the VESA DDC 2Bi function.

6

7

8

9

10

Red-GND

Green-GND

Blue-GND

+5V

Sync-GN D

11

12

13

14

15

NC

DDC-SDA

H-SYNC

V-SYNC

DDC-SCL

DVI-I / DVI-D (If using DVI-D cable, C1, C2, C3, C4, C5 is NC)

Pin Signal Pin Signal Pin Signal

RX2-

1

RX2+

2

GND

3

NC

4

NC

5

SCL

6

SCA

7

Analog V-Sync (NC)

8

RX1-

9

RX1+

10

DVI-I / DV I-D C on nectorPin Description

Pin Name Des cr ip tion Pin Name Description

1 RX2- TM D Slink #0channel#2 differen ti alpair 16 HP Hot pl u gg i n g

2 RX2+ TM D S l i n k #0channel#2 diff eren tialpair 17 RX0- TMDSlink #0channel#0 differe nti alpair

3 GND GND for no link sha re 18 RX0+ TMDS link #0 c hannel #0 diffe rential pa ir

4 NC NC 19 GND GND for no link shar e

5NC NC 20NC NC

6 SCL Clock li nefor DDCinterface 21 NC NC

7 S DA Da ta line fo r DDC inter face 22 GN D Clo ck shie ld

Analo g

8

V-s ync for ana log inter face 23 RXC + TMDS c lock d ifferent ial pair

V- Sync

9 RX1- TMDS link #0 c hannel #1 differ ential pair 24 RXC- TMDS clock d ifferent ial pair

10 RX 1+ TMD Slink #0channel#1 differen tialpair C1

11 GND GNDfor no l in k sh are C2

12 NC NC C3

13 NC NC C4

14 5V +5V i npu t f romhost systemfor DD C2Bfunction . C5

15 GND Groun d(U si n gas Detect Cabl e)

GND

11

NC

12

NC

13

5V

14

GND

15

HP

16

RX0-

17

RX0+

18

GND

19

NC

20

Analo g

Red

Analo g

Gre en

Analo g

Blue

Analo g

H-S ync

Analo g

GND

NC

21

GND

22

RXC+

23

RXC-

24

Analog Red (NC)

C1

Analog Green (NC)

C2

Analog Blue (NC)

C3

Analog H-Sync (NC)

C4

GND

C5

Analo gRe d signal

Analo gGr een signa l

Analo gBlu e signal

H-s ync for analo gint erface

Analo gGN D

1.3.2.1 Video Signal Amplitudes

The three video inputs consist of Red ,Green , and Blue

signals, each with its own coaxial cable terminated at the

monitor. These video signals are analog levels, where 0

V corresponds to black , and 700 mV is the maximum

signal amplitude for the respective color, when each

signal is terminated by a nominal 75.0 ohms .For a given

monitor luminance levels are measured using this

defined video amplitud driving a monitor meeting the

termination requirements .The signal amplitude is not to

be readjusted to compensate for variations in termination

impedance.

1.3.2.2 Video Signal Termination Impedance

This analog video signal termination shall be 75 1%

which shall be resistive with a negligible reactive

component

.

1.3.2.3 Synchronization ( Sync ) Signals

The Horizontal Sync (HS) TTL signal is used to initiate

the display of a horizontal line. HS may be either active

high or active low, depending upon the timing .The

Vertical Sync (VS) TTL signal is used to initiate the

display of a new frame .VS may be either active high or

active low, depending on the timing

1.3.2.4 Sync Signal Levels

The monitor must accept sync signals from both 3.3 and

5 volt TTL logic families.The inputs shall sense a logic 0

when the input is 0.8 volt or less and shall sense a logic

1 when the input is 2.0 volts or greater. In addition to

these level requirements, there shall also be a minimum

of 0.3 volt hysteresis provided for noise immunity

(typically by using a Schmitt Trigger input ).That is , the

input level at which the monitor actually detects a logic 0

shall be at least 0.3 volt lower than the level at which it

actually detects a logic 1.If the monitor sync processing

circuits are designed around the 3.3 volt logic family

,then the sync inputs must be 5 volt tolerant .

1.3.2.5 Sync Signal Loading

TTL input loading shall be equivalent to one TTL input

load. When logic 0 is asserted by a sync input , the

maximum current source from any single monitor sync

input to the driver is 1.6 mA .When logic 1 is asserted ,

the maximum current source from the driver to any

single monitor sync input is 400 uA .

Ω+/-

1.3.2 Video Input Signals

No. Symbol Item M in

Fh Scanning H orizontal Frequency 30 94 kHz M inim um range

1

Fv Scanning V ertical Frequency 55 76 H z M inimum range

2

V ih H iL evel Input 2 5 Note 1)

3

V il Low L evel Input 0 0.8 V N ote 1)

4

V ideo RG B A nalog V ideo L evel 0.0 0.7 1.0 V

5

N o te 1 ) S c hm itt-T rig g er s In p u t , S upported 3.3V device H (& V) sync output from PC .

Video Input Signal

Normal

Max Unit Remark

75Ωto G round

Page 5

4

ACER G24

Go to cover page

1. Product Specification (continued)

1.3.2.6 Abnormal Signal Immunity

The monitor shall not be damaged by improper sync

timing , pulse duration , or absence of sync , or

abnormal input signal amplitude ( video and/ or sync

too large or too small) , or any other anomalous

behavior of a graphics card video generator when

changing modes , or when any combination of input

signals is removed or replaced . Additionally , under

these conditions , the monitor shall not cause

damage to the driving source

1.3.3 User Controls and Indicators

1.3.3.1Power On / Off Switch

The monitor shall have a power control switch

visible and accessible on the front of the monitor .

The switch shall be marked with icons per IEC 417 ,

# 5007 and # 5009.The switch shall interrupt the DC

supply to the monitor

1.3.3.2 Power Indicator LED

The monitor shall make use of an LED type

indicator located on the front of the monitor .

The LED color shall indicate the power states as

given in Table 1.

Table 1

Function LED Color

Full Power Blue color

Sleep Orange color

1.3.3.3 On-Screen Display

The Lite-ON On Screen Display system shall be

used , controlled by a Menu button. If the buttons

remain untouched for OSD turn off time while

displaying a menu , the firmware shall save the

current adjustments and exit. Also, if the video

controller changes video mode while the OSD is

active, the current settings shall be saved

immediately, the OSD turn off, and new video mode

is displayed.

Description

Key When no OSD display OSD Displayed

Menu Display

MENU

Speaker Volume/Plus

>

(with Audio)

Speaker Volume/Minus

<

(with Audio)

Auto Adjust Function

Auto

E Empowering Menu or sub.menu EXIT/Scenario mode

1. To display the OSD menu on the screen.

2. To select the OSD sub-Menu

1. Back-forward selection of the OSD menu.

2. Decrease the value after sub-menu selected.

1. Forward selection of the OSD menu.

2. Increase the value after sub-menu selected.

Menu or sub.menu auto adjust

1.3.3.4 OSD adjustment

ITEM CONTENT

BRIGHTNESS Back light Luminance of the LCD panel is adjusted.

CONTRAST A gain o f R , G and B signal is adjusted.

AUTO CONTRAST A gain of R , G and B signal auto adjust.

CLOCK The ratio of dividing frequency of the dot clock is adjusted.

PHASE The phase of the dot clock is adjusted.

H-POSITION The indication screen is horizontally moved right and left (1 Pixels pitch).

V-POSITION The indication screen is vertically moved up and down (1 Pixels pitch).

AUTO ADJUST Clock system auto adjustment, about under 8 sec.

COLOR BALANCE Select three kinds of modes. ( USER /WARM / Cold ).

OSD POSITION The OSD indication position can be adjusted.

OSD LANGUAGE

RECALL DEFAULTS All data copy from factory shipment data.

OSD DURATION Adjust OSD menu off time range from10~120 second.

POWER-SAVE

INFORMATION

NOTE : OSD MENU SEE APPENDIX A

※

Select the language used for the OSD menu among English , French ,

Italian , Deutsch and Spanish.

Back light of the LCD panel is cut when the signal is not input (AC line

power consumption 2W or less).

The frequency of the horizontal / vertical synchronizing signal under the

input is indicated.

1.3.4 Monitor Modes and Timing Capability

1.3.4.1 Format and Timing

The monitor shall synchronize with any vertical

frequency from 55 to 76 Hz , and with any

horizontal frequency from 30 to 94KHz. If the input

frequency is out of the above – specified range,

the monitor shall display a warning screen

indicating that the input frequency is out of range.

Under no circumstances shall any combination of

input signals cause any damage to the monitor .

1.3.4.2 Factory Assigned Display Modes

There are 24 factory pre-set frequency video

modes. These modes have a factory pre-set for all

characteristics affecting front-of-screen

performance. When the system is powered-

on,previously stored screen parameters for a pre-

defined mode will be recalled if the operating

mode is one of those stored in memory. If the

operating mode is not one of those stored in

memory, the monitor CPU will select the PRESET

timing for a mode that is the next lowest in

horizontal scanning frequency to the mode being

currently used. The screen parameters may be

adjusted by the use of the front bezel controls and

then may be saved as a user defined mode. The

monitor shall include all the preset video timings

shown in the following page.(Please see Note.(3) )

Page 6

1. Product Specification (continued)

e

ACER G24

Go to cover page

5

1.3.4.3 Mode Recognition Pull-in

The monitor shall recognize preset modes within a

range of +/-1KHz whichever is less for horizontal ;

and within +/-1Hz for vertical.

1.3.4.4 User Display Modes

In addition to the factory pre-set video modes,

provisions shall be made to store up to 9 user

modes. If the current mode is a user mode, the

monitor shall select its previously stored settings.

If the user alters a setting, the new setting will be

stored in the same user mode. The user modes

are not affected by the pre-set command. If the

input signal requires a new user mode, storage of

the new format is automatically performed during

user adjustment of the display (if required).(

Please see Note.(4) )

Preset timing Chart

Preset Timing C hart

Item Reso lu tion

1 720 x 400 31.472 70.4 28.325 - + VG A

2 640 x 480 31.469 59.94 25.175 - - VGA

3 640 x 480 37.5 75 31.5 - - VESA

4 648 x 500 31.234 57.735 31.234 + + M AC

5 800 x 600 37.879 60.3 40 + + VESA

6 800 x 600 46.875 75 49.5 + + VESA

7 1024 x 768 48.363 60 65 - - VESA

8 1024 x 768 60.023 75 78.75 + + VE SA

9 1280 x 1024 63.981 60 108 + + V ESA

10 1280 x 1024 79.976 75 135 + + VESA

11 1440 x 900 55.469 59.01 88.75 + - CVT -RB

12 1440 x 900 55.935 59.887 106.5 - + CVT

13 1440 x 900 70.635 74.98 136.75 - + CVT

14 1280 x 720 45 60 74.25 + + CEA -861

15 1280 x 800 49.702 60 83.5 - + CVT

16 1280 x 800 62.795 75 106.5 - + CVT

17 1600 x 1200 75 60 162 + + V ESA

18 1600 x 1200 74.006 59.924 130.25 + - CVT-RB

19 1600 x 1200 93.75 75 202.5 + +/- V ESA

20 1680 x 1050 65.29 59.954 146.25 - + CV T

21 1680 x 1050 64.674 59.883 119 + - CVT-RB

22 1680 x 1050 82.306 74.892 187 - + CVT

23 1920 x 1200 74.038 59.95 154 + - CVT-RB

24 1920 x 1200 74.556 59.885 193.25 + - CV T

NOTE : (1)76≦FV≦86 : monitor can display but doesn't guarantee.

(2) fV < 55, or fV > 86 : warning invalid mode.

(3) Factory model :

(4)Usermode:

(5) Internal F actory Reset and OSD Factory R ese t beh avior.

H-Sync V-Sync Band W idth

(KH z) (H z) (MHz ) H V

After we first burn the code into the flash, every preset-modelw e run first must do auto-adjusting.

Then it'llnot do auto-adjust again w hen we changed preset-mode back including A C on/off DC on/off.

The only way that preset-mod e do auto-adjust again is press '' Internal Factory Reset''.

The code should m emorize 9 timing mode exclusive of preset-modes as use mode and do auto-adjusting.

When user set a new m ode that is not among previously. It'll do auto-adjusting then be solved to user mod

The new m ode w ill overwrite the first m emo rized user modes.

The user modes be cleared is sam e as Factory mode. Just do '' Internal Factory R eset''.

Polarity

Source

FACTORY PRESET VIDEO TIMINGS (DIGITAL INPUTS)

CEA-861-C

H-Active V-Active I/P H-tot. HB V-tot. VB

code

17,18 720 576 P 864 144 625 49 31.250 50.000 27.000 DVI,HDMI

19 1280 720 P 1980 700 750 30 37.500 50.000 74.250 DVI,HDMI

20 1920 1080 I 2640 720 1125 22.5 28.125 50.000 74.250 DVI,HDMI

21, 22 1440 576 I 1728 288 625 24.5 15.625 50.000 27.000 HDMI

31 1920 1080 P 2640 720 1125 45 56.250 50.000 148.500 DVI,HDMI

39 1920 1080 I 2304 384 1250 85 31.250 50.000 72.000 DVI,HDMI

2, 3 720 480 P 858 138 525 45 31.469 59.940 27.000 DVI,HDMI

4 1280 720 P 1650 370 750 30 44.955 59.940 74.176 DVI,HDMI

5 1920 1080 I 2200 280 1125 22.5 33.716 59.940 74.176 DVI,HDMI

6, 7 1440 480 I 1716 276 525 22.5 15.734 59.940 27.000 HDMI

16 1920 1080 P 2200 280 1125 45 67.433 59.940 148.352 DVI,HDMI

H-freq

(kHz)

V-freq

(Hz)

Pixel

freq

(MHz)

Inputs

■ Digital inputs (DVI, HDMI): Conflicting video- and PC

timings are to be treated as Video timings with one

exception: 640x480p/60Hz timing to be treated as PC-timing.

■

Analog input (VGA) treats all timings as PC-timings.

1.3.5 Controller Requirements

1.3.5.1 General Requirements

The monitor shall include a controller capable of

converting the analog RGB signal from a standard

WUXGA resolution video controller in the CPU to a

signal which can be displayed on the panel. The

controller will include a PLL, A/D converters, LVDS

transmitter and other circuitry necessary to perform

its function. The PLL shall be stable enough to

ensure that a static image from the CPU is placed

in the same physical location on the flat panel in

each frame.

1.3.5.2 Video Stretching

The monitor shall contain provisions to “stretch” the

video signal, so that an input signal from the

computer in any resolution smaller than 1920 x

1200 is automatically expanded to fill the entire

screen.

1.3.5.3 Panel Timing and Interface

The controller supplied with the monitor shall

control all panel timing. This controller shall

adequately insulate the monitor from the computer,

so that no possible combination of input signals

from the computer shall cause damage to the flat

panel or any other component of the monitor. The

LCD panel interface shall support the TFT

standard.

1.3.6 DC - AC Inverter Requirements

The DC-AC inverter is on the power board. The

frequencies used by the DC-AC inverter used to power the

backlight shall be chosen so as to prevent any noticeable

effects on the flat panel (such as a rolling effect).

1.3.7 Power Supply Requirements

The AC to DC converter power supply for the monitor shall

be an external AC to DC converter ”brick” This brick shall

have an IEC receptacle for main power input and a pin - in

---socket for DC power out. The brick shall provide

sufficient power for both the monitor and the backlight

assembly, and shall meet requirements specified in Table

2.

Page 7

6

ACER G24

Go to cover page

1. Product Specification (continued)

Table 2

o

C, and nominal input line

Input Voltage Range

Input Frequency Range

Power Consumption

Line Fus e

Initi al Cold Sta rt

Inrush Current

Hot Start Cycle

Under Voltage

Line Transient

AC to DC Converter Requirements

The operating range shall be from 90 to 132 and 195 to 265 AVC

sinusoidal for all models specified.

Input power frequency range sha;; be from 47.5 to 63 Hz over the

specified input voltage range.

Power consumption for the monitor shall be less than 46W over the

specified voltage and frequency ranges. In suspend or sleep mode

the power consumption will be less than 2W.

The AC input shall be fused and become electrically open as a result

on an unsafe current level. The fuse many not be user replaceable.

The power supply shall start and function properly when under full

load, with worst case conditions of input voltage, input frequenct,

operating temperature, and cold backlight lamps.

The inrush current must be limited to 30A when operated at

120VAC, and 50A when operated at 220VAC. Inrush current is

measured at an ambient temperature of 25

temperature stabilized in the power-off.

The power supply shall be damaged when switched ON for one

second and OFF for one second for seven consecutive after

operating for one hour at full load, 25

voltage.

The power supply shall contain protection circuitry such that the

application of an input voltage below the minimum specified in this

table shall not cause damage to the power supply unit nor cause

failure of the input.

The power supply shall operate within IEC 801-4 (± 1KV) and IEC

801-5 (± 2KV) for the dom estic U.S. version. The UPS power

supply shall operate and comply with CE mark.

1.3.8 Display Communications Channel

The monitor assembly shall provide a display

communications channel that conforms to VESA

DDC2Bi hardware requirements. This configuration

shall contain the 128-byte EDID file as specified by

VESA EDID standard.The monitor should not write to

the EDID file for the first two minutes of operation

following power-up UNLESS some action taken by the

user or the host CPU forces the write (for instance,

requesting the serial number via the OSD).

Furthermore, it is recommended that CMOS switches

be incorporated to isolate the DDC IC from outside

connections while the EDID Fault Management is

being updated. This is to prevent corruption of the data

by attempts to read the data while it is being changed.

1.3.9 Firmware Update Function (same ISP function)

The update firmware need through from the D-Sub

connector, use DDC I2C bus to do update firmware.

1.4 PANEL ELECTRICAL

1.4.1 General Requirements

The panel used as the display device shall be an

WUXGA resolution, 24W TFT-LCD. This panel shall be

approved for use in this monitor.

o

C, with the unit

1.4.2 Panel Timings

The controller included with the monitor shall translate all

video timings from the CPU that meet the timing

requirements listed in Panel specification into timings

appropriate for the panel. Under no circumstances may the

controller supply the panel with timings that may result in

damage. The controller shall insulate the panel from the

CPU , so that the panel shall always be driven per it's own

specification regardless of the timings being sent from the

CPU.

1.4.3 Polarizer Hardness

The outer face of the front polarizer panel shall be

covered with a coating witha#3hardness value

1.4.4 Backlight Requirements

1.4.4.1 General Requirements

The backlight assembly shall be designed to

support field replacement at the customer site or

authorized service center. The lamps shall have a

continuous operating life of at least 40,000 hours at

25. The operating life is defined as having ended

when the illumination of light has reached 50% of

the initial value. The lamps shall extend a sufficient

amount from the edge of the light guide that

sputtering over the life of the lamps shall not cause

degradation of the luminance uniformity (such as

non-illuminated bands along the edges of the

display).

1.4.4.2 Lamps Startup Time

The backlight lamps shall start about 2 sec of the

time the monitor power switch is pressed or the

monitor is restarted from a power - down mode

.The starting time shall stay about 2 sec. for the

minimum expected life of the lamps.

Test conditions are as follows :

Ambient Light ---------------------- < 1.0 lux

Temperature-------------------------- 10

℃

Inactive Time ----------------------- > 24 hours

1.4.5 Defects

1.4.5.1 Visual Inspection

The LCD panel shall be inspected with all pixels

set to white,black , red , green , and blue. The color

variation, brightness variation , and overall

appearance must not be perceived as poor quality

by Lite-On . Areas and / or parameters considered

questionable shall be subjected to detailed

measurements .

.

Page 8

1.4.5.2 Display Degradation

Over the life of the product , variation of the parameters

specified in Panel specification shall be maintained

within reasonable limits.The panel must not exhibit any

significant defects while in operation ( excluding the

CCFL operation ).This does not in any way change the

warranty given by the panel manufacturer .

1.4.5.3 Light Leakage

Except for the active display area , there shall be no

light emission visible from any angle from any other part

of the display . For this test , the ambient illumination

must follow panel's specification.

1.4.5.4 Allowable Defects

No cosmetic defects are allowed except those specified

below.The conditions of visual inspections are as follows

For 24W Series.

■

Viewing distance is to be approximately 35-50cm

■

Ambient illumination is to be 300 to 700 lux.

■

Viewing angle shall be at 90 degree.

■

Defects not apparent within one minute shall be

ignored.

1. Product Specification (continued)

1.4.5.6 Smudges, Streaks and Smears

When viewing the panel oriented so as to maximize

reflected light , there shall be no visible smudging ,

streaking, smearing or other nonuniformity from

contaminants ,fingerprints,or defects in any of the

visible surfaces. This is independent of whether the

unit is operating or off .

1.4.5.7 Other Defects

Undefined defects that are considered to be

rejectable by Lite–On will be reviewed by Lite-On as

they become apparent. These panels will be referred

to the Lite - On Corporate / Manufacturer Purchasing

Agreement for disposition.

1.4.5.8 LCD Inspection

Put LCD panel on inspection table and illuminate the

panel with a daylight fluorescent lamp located above

the panel surface such that the luminance at the

LCD panel is between 1000 lux and 1500 lux .Defect

limits are given in Table 4 .

ACER G24

Go to cover page

7

1.4.5.5 Defect Terminology

Table 3 gives the descriptive terms used in classifying

defects.

Spots or lines that app ear dark in the display patterns and are

Dark / Spots /Lines

BrightS pots / L ines

PolarizerScratch

PolarizerD ent

R u bb in g L ine

New ton Ring The “rainbow” effect caused by non-uniform cell thickness.

M ottlin g

Dim Line

Cross Lines Off

Bright/DarkDot Asub–pixel(R,G,Bdot)stuckoff/on(electrical).

us ua lly the re su lt o f c o nta m ina tio n. D ef ec ts d o n o t v ary in

size o r inten s ity ( co n tras t) w he n co n tras t v o ltag e is var ied .

Contrast variation can be achieved through the u se of varying

gray shade patterns.

Spo ts o r lines that app ear light in the display patterns.

D ef ec ts d o no t v ary in size o r in ten sity (co n tras t) w h en

contrast voltage is varied. Co ntrast variation can be achieved

through the use of varying gray sh ade patterns.

W h en th e un it lig h ts, lines a pp e ar ligh t (w h ite) w ith d isp lay

pa tte rn s da rk an d d o n o t va ry in siz e. P hy sic a l d a m ag e to th e

polarizer that do es not dam age the glass

W h en th e u n it ligh ts, s po ts a p pe ar ligh t (w hite ) w ith d isp la y

pa ttern s d ark an d do n ot v ary in siz e. P h ysic al d am ag e to the

polarizer that do es not dam age the glass.

Horizontal or diagonal lines that appear gray with the display

patterns dark and m ay have resulted from an “out of control”

rub b in g pro ce ss o n the p o lyim ide o r “w a ve s” o n the B E Fs o r

prism sheets.

W h en th e un it lig h ts, var iatio n / n o n – un ifo rm ity

(sp lotc h ine ss ) a pp e ars ligh t (w h ite) w ith th e dis pla y an d

m ight vary in size.

W h en th e un it lig h ts, line( s) in the m o n ito r (v e rtica l) o r m a jor

(ho riz o nta l) a x is ap pe ar dim , bu t n o t c om p lete ly on o r off.

W h en th e un it lig h ts, lines in b oth th e m ino r an d m a jo r a x is

do not appear.

Average Diameter smaller of

(L+W)/2 or L/20+2W

< 0.1mm Non countable N / A

0.1 mm ~ 0.3 mm 10 15 mm

0.31 mm ~ 0.5 mm 10 15 mm

0.51 mm ~ 1.25 mm 5 15 mm

1.26 mm ~ 2.5 mm 3 25.4 mm

2.51 mm ~ 3.75 mm 3 25.4 mm

Greater than 3.75 mm NONE Not applicable

Note : Allowable distance between spots of two sizes is the minimum separation

number for the smaller spot. Therefore, if there are two spots, 1.30mm and 0.4mm

in diameter, they must be at least 15mm apart.

Acceptable Number Minimum Separation

1.5 Optical Characteristics

Depends on the LCD supplier's spec. Details refer to QA

Inspection Spec.

Page 9

8

ACER G24

Go to cover page

2.1 MAIN OSD MENU

Outline:

The description for control function:

2 OSD Menu

Page 10

2. OSD Manu (continued)

ACER G24

Go to cover page

9

Page 11

10

ACER G24

Go to cover page

3.1 Packing Exploded Diagram

3. Exploded Diagram

Page 12

3.2 Product Exploded Diagram

3. Exploded Diagram (continued)

ACER G24

Go to cover page

11

Page 13

12

ACER G24

Go to cover page

4. Assembly and Disassembly Procedures

4.1 Assembly procedures:

Connect the cable between power board(P802)

S1

S2

and interface board (P301)

Connect the function key cable into interface

board(P303)

Connect the cable between power board(P803)and

inverter board (Cn001)

Connect the FFC cable into interface board

P301

P303

Take a bracket chassis base on a protective

cushion and stick an insulator on the specific

position, take a power board and turn it over. Then,

put it on the specific positions of bracket chassis

base.

P802

P803

CN01

S4

S5

Use a Phillips-head screwdriver screwed the

No.1~4 screws till that interface board and bracket

chassis base firmly attached.

(No1~4 screw size=M3x6; Torque=9~10KGFxCM).

3

4

Take the key function cable out from the hole

shown as photo

Fix the function key cable with a PVC tape

2

1

S3

Use a Phillips-head screwdriver screwed the

No.1~5 screws till that power board and bracket

chassis base firmly attached.(No1~4 screw

size=M3x6; No5 screw size=M4x8;

Torque=9~10KGFxCM).

4

1

2

3

5

S6

Turn over the bracket chassis base then fix the

inverter board

Use a Phillips-head screwdriver screwed the

No.1~4 screws till that inverter board and bracket

chassis base firmly attached.

(No1~4 screw size=M3x6; Torque=9~10KGFxCM).

12

3

4

Page 14

S7

4. Assembly and Disassembly Procedures (continued)

Connect cable into inverter board(CN001)

Take an inverter shielding bracket to cover the

inverter board

Use a Phillips-head screwdriver screwed the

No.1~6 screws till that inverter shielding bracket

and bracket chassis base firmly attached.

(No1~6 screw size=M3x4; Torque=9~10KGFxCM).

ACER G24

Go to cover page

13

S8

4

CNOO1

5

6

Connect the FFC cable to the connector of the LCD

panel.

1

2

3

S10

Plug in parallel direction

Angel < 5 degrees

Take lamp cables out from the holes shown as the

photo.

S9

Turn the monitor faced down and put it on the

bracket chassis module till both parts firmly

Connect FFC cable to LCD panel. There are

two locks over here when plugging in should be

noticed

S11

Plug 6 lamp cables to the connectors of inverter

board.

Page 15

14

ACER G24

Go to cover page

4. Assembly and Disassembly Procedures (continued)

S12

S13

Use a Phillips-head screwdriver screwed the

No.1~4 screws on both side and assemble the

LCD panel and bracket chassis module.

(No1~4 screw size=M3x6;

Torque=2.5 KGFxCM).

1

3

2

4

Use a Phillips-head screwdriver screwed the

No.1~2 screws. (No1~2 screw size=M4x10;

Torque=5~7KGFxCM).

1

2

S16

S17

Take a key function board to hook with front

bezeland connect to key function cable.

rc ota ua

Put a ear over n he ssembled nit nd

pmlaf

ress on force echanisms ocked nd irmly

attached

.

S14

S15

Use a Hex-head and screwdriver

Phillips-head

screwed the DVI , D-SUB and HDMI connectors

(No.1~4 Hex Nut screws

Size=M3x8;Torque=6.5 KGFxCM).

±0.5

(No.5 screw size=M3x8;

Torque= KGFxCM).

5

6.5

±0.5

4

2

3

1

Use a Phillips-head screwdriver screwed the

No.1~2 screws. (No1~2 screw size=M3x6;

Torque=5~7KGFxCM).

S18

4

3

2

1

4

3

2

1

Assemble the stand upper side to the rear cover

through the way of screwing 4 screws till both

units firmly attached.

(No1~4 Screw Size=M4x10;

KGFxCM).

1

Torque=13

1

2

2

3

1

4

Page 16

4. Assembly and Disassembly Procedures (continued)

ACER G24

Go to cover page

15

S19

S20

Assemble the hinge cover into both two sides

Stick a screen card on the front bezel with two

tapes.

S23

S24

Take two cushion foams; one is held the above

side of LCD monitor, and another is held the

below side.

Put accessories of stand, DVI cable, and

user’s manual ,power cable on specific

positions as photo below.

S21

S22

Stick Vista and TC003 label on the correct

position the same as below photo

Take a LDPE+EPE bag to cover the LCD

monitor.

S25

PUT CABLE IN THIS POSITION

PUT USER S

MANUAL IN THIS

POSITION

Move previous assembled parts into the carton then

stick Vista and feature label on the carton then

packing the carton

FEATURE LABEL

VISTA LABEL

Page 17

16

ACER G24

Go to cover page

4. Assembly and Disassembly Procedures (continued)

4.2 Disassembly procedures

Open the carton with a proper tool.

S1

Take out all accessories including D-SUB cable

S2

power cable, DVI cables, user’s manual, and

packing material from the carton.

(Note: It depends on whether users returning

the accessories.)

PUT CABLE IN THIS POSITION

FEATURE LABEL

VISTA LABEL

S4

S5

ut returned unit on a protective cushion,then

P

remove LDPE+EPE bag.

Tear off tapes to remove the screen protector

card then turn over the LCD monitor (screen

faced down),

Disassemble the stand cover.

S3

Take off two cushion foams

PUT USER S

MANUAL IN THIS

POSITION

S6

S7

Use a Phillips-head screwdriver unscrew 4 screws

to release the stand base.

(No1~4 Screw Size=M4x10;

Torque=13 KGFxCM).±1

2

3

Turn over the LCD monitor (screen faced up).

1

4

Page 18

S8

4. Assembly and Disassembly Procedures (continued)

Put the dissembled monitor closed to by myself

RIGHT SIDE

UP SIDE

LEFT SIDE

Wedge your finger between the front bezel and

the panel, then pry up on the front bezel to

disengage the locking mechanism.

DOWN SIDE

S9

ACER G24

17

Go to cover page

Hold the one upside corner of the front bezel after

separating the upside of the front bezel

Using properly force to pull up front bezel that will

let the locking mechanism of left side, right side

and down side separated

Hold one side of down side that had been

separated from front bezel

Use properly force to pull up front bezel

Insert steel rule between panel and front bezel

.Using properly force to let the locking

mechanism of front bezel and rear cover

separated

Separating all of the locking mechanism of the

front bezel in turn

S10

S11

Unhook the key function board from front bezel,

disconnect the key function cable

Page 19

18

ACER G24

Go to cover page

4. Assembly and Disassembly Procedures (continued)

S12

S13

Use a Hex-head screwdriver unscrewed 5 screws to

release the DVI ,D-SUB and HDMI connectors

(No1~4Hex Nut screws

Size=M3x8;Torque=6.5 0.5KGFxCM).

(No.5 screw size=M3x8; Torque=

2

5

4

Use a Phillips-head screwdriver unscrewed the

No.1~2 screws to lease power plug

(No1~2 screw size=M3x10; Torque=5~7KGFxCM).

6.5 0.5KGFxCM).

1

3

S15

S16

Unplug 6 lamp cables

Disconnect the FFC cable to the connector of

panel.

Use finger to push the lock according to arrow

direction then take out the FFC cable

S14

1

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws to disassemble the LCD panel

and bracket chassis module.

(No1~4 screw size=M3x6;

Torque=2.5 KGFxCM).

1

3

2

2

Take out lamp cables right through the No.1-3

S17

4

square holes and separate the bracket chassis

module and LCD panel apart.

1

2

3

Page 20

4. Assembly and Disassembly Procedures (continued)

ACER G24

Go to cover page

19

S18

S19

Examine the panel surface accoring to inspection

criteria. Put it aside.

Disconnect the cable from inverter board

Use a Phillips-head screwdriver unscrewed the

No.1~8 screws

(No1~6 screw size=M3x4; Torque=9~10KGFxCM).

(No7~8 screw size=M3x6; Torque=5~7KGFxCM).

Remove inverter shielding bracket

S21

S22

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws to release the interface board.

(No1~4 screw size=M3x6; Torque=9~10KGFxCM).

3

4

Use a Phillips-head screwdriver unscrewed the

No.1~5 screws to disassemble the power board.

(No 1~4 screw size=M3x6; No 5 screw

size=M4x8; Torque=9~10KGFxCM).

2

1

S20

8

7

3

6

2

5

1

4

Use a Phillips-head screwdriver unscrewed the

No.1~4 screws

(No1~4 screw size=M3x6; Torque=9~10KGFxCM).

Remove the inverter board

12

S23

1

2

3

Disconnect all of the cable

P301

4

5

3

4

P303

P802

CN01

P803

Page 21

20

ACER G24

5. Troubleshooting

Go to cover page

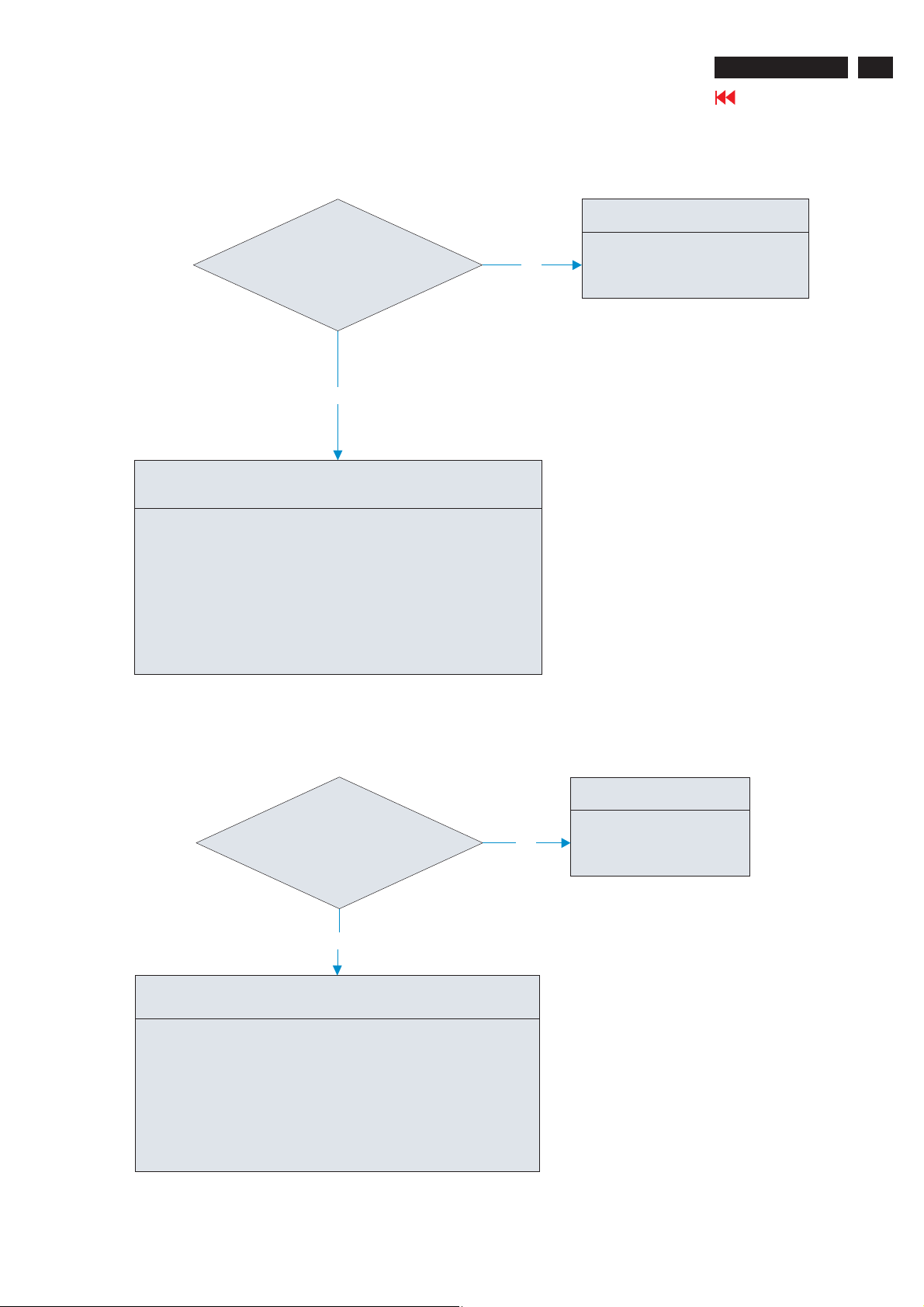

5.1 No display on the screen (Screen is black and colour of LED is amber.)

Does OSM display upon pressing

the “MENU” button?

OK

Check if the sync signal output

from connected computer and the

video cable is connected properly

OK

Proceed to “5.4 Abnormal Screen” section.

NG

NG

Proceed to “5.5 Abnormal OSM display” section.

Input the sync signal of computer, or change to a

standard shipped cable for cross test.

Page 22

5. Troubleshooting (continued)

5.2 Nothing displays on the screen (Screen is black and colour of LED is blue.)

Check if the backlight is

slightly lightened from upper

corners (right/left) of LCD

panel

OK

Proceed to “5.3 Checking the backlight unit” section

NG

ACER G24

Go to cover page

21

Does RGB video

signals output

from connected PC host?

OK

Check if OSM menu

is displayed upon pressing the

“MENU” key

OK

Proceed to “5.4 Abnormal Screen” section.

Check if 3.3V is

supplied from I301 pin2; 2.5V is

supplied from I303, pin2, and

the 1.8V power is supplied from

I302 pin2.

NG

NG

OK

1. Change pattern of video signal outputs from

the PC host to optimum resolution.

2. Reconnect the video cable.

3. Cross-test the other workable video cable.

Check if video signal cable

is connected properly between

LCD monitor and PC host

OK

Check if the

NG

Voltage on I301, I303,

I320 pin3 is high DC

level at 5V.

OK

Failure Point

The cable is disconnected.NG

Failure Point

NG

1.Printedwireisbrokenbetween

P301 pin1, pin2, pin3, pin4 and

I301, I303, I320.

2. Check power board

Check all LVDS signal pins;

output from I314

OK

Failure Point

1. The cable is broke between

P306 and LCD panel.

2. LCD panel is defected.

NG

Failure Point

I301, I302, I303, or I320 is

damaged.

Failure Point

Printed wire is broke or short

between P306, I314

Page 23

22

ACER G24

Go to cover page

5.3 Check the backlight unit

5. Troubleshooting (continued)

Check the BKLT_EN signal of

rectangle input P301 pin11 at TTL

high level.

OK

Check the PWM signal

supplied from I314

pin251 is a PWM,

pulse-width modulation.

OK

Failure Point

Inverter of LCD module is defected.

NG

Does the I306 pin16

output a TTLvoltage level

at “H” status? <or> Is BKLT_EN

signal of the rectangle being

OK

Failure Point

1. Printed wire is broke

between I314 pin251 and P301.

NG

2. I314 is defected.

output?

Printed wire is broken

between I306 pin16 and

NG

P301.

Failure Point

Page 24

5.4 Abnormal Screen:

5. Troubleshooting (continued)

Check R.G.B video signals

output from PC host

to D-Sub R.G.B connector

OK

Check the R.G.B signals

on I314 pin40, pin42, and pin45 which

should have voltage level at 0.7Vpp

max.

Failure Point

1. Check connected PC host if there’s no R.G.B

NG

NG

signals output.

2. Video signal cable disconnected.

Failure Point

Green, Blue, Red signals are flow in the same

path. In the case, the Red signal is example.

1. Printed wire is broken between D-Sub [R] and

I314 pin45.

2. R391 is short.

3. C356 is open.

4. R390 is open.

ACER G24

Go to cover page

23

OK

Check all LVDS signal pins

of I314 whether if

output correct signals.

OK

Proceed to “5.8 Checking the resolution change

IC movement” section.

NG

Failure Point

1. The I314 is defected.

2. Printed wire is broken between I314 and P306.

Page 25

24

ACER G24

5. Troubleshooting (continued)

Go to cover page

5.5 Abnormal OSM display - OSD Adjusment Problem

Check the input TTL level

whether if it was altered upon

pressing the function keys.

OK

Proceed to “5.4 Abnormal Section”

Failure Point

1. Printed wire is broken between P303 pin 2 and I306 pin 87.

NG

2. Printed wire is broken between P303 pin 3 and I306 pin 88.

3. Printed wire is broken between P303 pin 4 and I306 pin 89.

4. Printed wire is broken between P303 pin 5 and I306 pin 90.

5. Printed wire is broken between P303 pin 6 and I306 pin 22.

6. Printed wire is broken between P303 pin 7 and I306 pin 1.

7. C325, C326, C327, C328, C329,C330 is short.

8. R339, R340, R341, R342, R343, R346, R347, R348,

R349, R350 ,R351, R352 is short or open.

9. I306 is defected.

(Note: more than one components defected is possible.)

Page 26

5.6 Abnormal Plug and Play Operation

5.6.1 Abnormal DDC2 (D-SUB)

Confirm the output of serial

data on I312 pin6 synchronize SCLK at

5. Troubleshooting (continued)

TTL level

OK

Failure Point

ACER G24

25

Go to cover page

Failure Point

I312 is defectedNG

1. The host machine isn’t communicating in DDC2 mode.

2. The video cable may have defected or may not be established

connection for DDC.

3. The I312 pin6 and P304 pin15 may have no signal or incorrect.

4. The R374, R377 is open.

5. I312 pin6 is short.

6. The input source cable is defected.

7. Check I312 pin5 signal whether if correct.

5.6.2 Abnormal DDC2 (DVI)

data on I313 pin6 synchronize SCLK at

Failure Point

Confirm the output of serial

I313 is defectedNG

TTL level

OK

Failure Point

1. The host machine isn’t communicating in DDC2 mode.

2. The video cable may have defected or may not be established

connection for DDC.

3. The I313 pin6 and P305 pin6 may have no signal or incorrect.

4. The R393 or R397 is open.

5. I313 pin6 is short.

6. The input source cable is defected.

7. Check I313 pin5 signal whether if correct.

Page 27

26

ACER G24

Go to cover page

5.7 Checking the interface circuit of sync signal

5.7.1 Checking the control circuit of horizontal sync pulse

Check the horizontal

sync signal on I314 pin46

TTL level

OK

Proceedto“5.8Checkingthe

resolution change IC movement”

section

5. Troubleshooting (continued)

1. Video cable is defected.

2. Printed wire is broken between P304 pin13 and I314 pin46.

3. FB305, R364, R363 is open.

NG

4. R371, C336, D305 is short.

5. I311 is defected.

Failure Point

5.7.2 Checking the control circuit of vertical sync pulse

Check the vertical sync

signal on I314 pin47 TTL level

OK

Proceed to “5.8 Checking the resolution

change IC movement” section

NG

Failure Point

1. Video cable is defected.

2. Printed wire is broken between P314 pin14 and I314 pin47.

3. FB306, R368, R369 is open or more than one component.

4. R370, C335, D303 is short.

5. I311 is defected.

Page 28

5. Troubleshooting (continued)

5.8 Checking the resolution change IC movement

Is there +3.3V

SuppliedonI314pin107,

pin48, pin61, pin250, pin12, pin70,

pin170, pin184, pin203, pin216,

pin236, pin252, pin20, pin28,

pin38, pin19, pin37,

pin131?

OK

Is there +1.8V

supplied on I314 pin16, pin22,

pin50, pin2, pin78, pin96, pin143,

pin160, pin181,

pin225

NG

NG

Proceed to “5.9 Checking the DC/DC converter

circuit” section

Proceed to “5.9 Checking the DC/DC converter

circuit” section

ACER G24

Go to cover page

27

OK

Is 14.318MHz

clock input to I314 pin35

and pin36 at TTL level

during power on?

OK

Is +3.3V supplied to

I314 pin9 at low level

(Reset again)?

OK

Failure Point

I314 is defected.

Is 14.318MHz clock output

NG

NG

Print wire is broken between I306

pin12 and I314 pin9.

from X302 pin1 at TTL level

during power on?

Failure Point

Print wire is broken between X302

pin1 and I314, pin36

Check the output

of 3.3V “H” pulse from

I306 pin12

OK

Failure Point

NG

Failure Point

X302 is defected.

Failure Point

I306 is defected.

Page 29

28

ACER G24

Go to cover page

5.9 Checking the DC/DC converter circuit

5. Troubleshooting (continued)

Failure Point

Check if the 5V is output

from P301 pin1, pin2, pin3, pin4

to I301, I303, I320 pin3.

OK

Check if the 3.3V, 2.5V

and 1.8V line voltage is output

from I301, I302, I303 pin2

OK

Failure Point

Printed wire is broken

between I301, I302, I303

pin2, and I314 power supply

pin.

Printedwireisbrokenbetween

NG

P301 pin1, pin2, pin3, pin4 and

I301, I303, I320 pin3.

Is the output

NG

FB301 being supplied to

I301, I303, I320 pin3?

OK

Failure Point

I301, I303, I320 is defected.

NG

Failure Point

Printedwireisbroken

between I301, I303, I320

pin3 and output of FB301

Page 30

5.10 Checking the inverter board circuit

Does 22V output pin

have voltage around 20V?

Does On/Off pin have voltage over 3V?

Does brightness pin have voltage in

the range of 0V~3.2V?

OK

5. Troubleshooting (continued)

NG

Check F101, I101, Q110, Q111, Q112,

Q113 and repair them if be damaged

ACER G24

Go to cover page

29

Does I101 pin6 have 5V output?

OK

Does P101, P102, P103,

P104 be firmly connected?

OK

Does I101 pin4, pin5

have triangle pulse?

OK

Does I101 pin1 have soft

start edge up to 2.4V?

OK

Does I101 pin8 have

voltage up to 1.2V from output

detection?

NG

NG

NG

OK

Check I101 and repair them if be damaged

Check CCFL and repair if damage.NG

Check I101 and repair if damage

Repair 101

Check D102, D103, D107, D108, D114,

D115, D112, D113 and repair if damage.

NG

Does

half bridge (Q104,

Q105, Q106, Q107, Q108)

work successful?

OK

Does transformer

(T101, T102) have output AC

voltage to P101, P102, P103,

P104?

OK

Check panel module if damage

NG

NG

Check Q104, Q105, Q106, Q107, Q108 and

repair them if damage

Check T101 and T102 if damage

Page 31

30

ACER G24

Go to cover page

5.11 HDMI signal check

5.11.1 No video

5. Troubleshooting (continued)

Check the TMDS signal

from computer input on

HDMI connector

OK

Check the TMDS signal of

I322

NG

Failure Point

I314 was damaged

Failure Point

NG

1.Check the host PC to see if there’s no TMDS

signal output

2.HDMI cabled disconnected. Reconnect the

cable till firmly connected

3.P311 is disconnected. Reconnect the cable

till firmly connected

Failure Point

OK

I322 was damaged.

Page 32

6. Firmware Upgrade Process

ACER G24

Go to cover page

31

Hardware Configuration

Connect VGA

cable between

monitor and kit

Mstar ISP Utility Configuration:

Select AUTO DETECT button that will automatically detect

the device then shows “OK” on the right side.

S2. Press [Connect] button.

Connect printer

cable between

PC and kit

Launch the utility of “ISP_Tool Winbond 0315.exe”

Press Config button

There s a Dialog window shown on the screen. It is the

meaning of connection successful .

Check the video cable and ISP board (D-sub to Printer

port) between LCD monitor to PC host to see if it

disconnected.

Page 33

32

ACER G24

Go to cover page

6. Firmware Upgrade Process (continued)

Press [Device] button to select the WP pin pull to high

during ISP““

Press [Read] button.

1. Press Read folder to browse firmware image.

2.The position according to where the firmware be put

Press [Run] button and waiting for firmware upgrade

completed .The screen will show “PASS”

Check firmware version

Turn off the power,then press force on “ POWER ” and “ E ”

button at the same time then press on “ MENU ”button to

enter factory mode

Note: Please pay attention ,Don’t change any parameter

which is measured by precise machine before shipping out

1

2

Press [Auto] button

When you writing F/W face on interrupting that cause monitor

shut down .

You can unplug AC power then press “AUTO”button and plug

AC power at the same time to solve this problem then re-write

F/W again.

Page 34

7. Writing EDID Process

ACER G24

Go to cover page

33

1 Writing EDID Procedure

Hardware Configuration:

1.)Connect the PRINTER PLUG of DDC FIXTURE with the

printer port of Desktop PC. (Refer to figure 1)

2.)Plug USB A PLUG of DDC FIXTURE to USB socket of

Desktop PC (Refer to figure 2)

3.)Extend the DVI cable on DVI EXTENDING SOCKET of DDC

FIXTURE. (Refer to figure 3)

4.1)Connect the D-sub plug of Chroma with D-SUB PLUG of

DDC FIXTURE (Refer to figure 4)

4.2) Take a video cable then connect the D-SUB PLUG and the

D-sub socket of monitor. (Refer to figure 5)

5.)Connect the extended DVI cable to DVI socket of monitor

(Refer to figure 5)

6.)Re-confirm all the connectors are connected well.

DVI EXTENDING

SOCKET

USB A

SOCKET

DVI EXTENDING

SOCKET

PRINTER PLUG

D-SUB PLUG

USB A

PLUG

2. Writing VGA/DVI Process

Chose the folder:”Acer-VGA&DVI” then double click

Select the “Acer-M1&M3-XPEDID-DVI-.exe” to execute it

3.Select Model: Key in password”cedid” then select model

which one you want to write EDID code that it depends on

panel type.

1

4

2

5

3

6

CAUTION: The timing of Chroma shall be setup at T254/ P41

before data recording. the detail setting parameter from

chroma .Please See below photo

cedid

Page 35

34

ACER G24

Go to cover page

7. Writing EDID Process (continued)

4. Choose "WRITE" from menu then select "Scan S/N And

Write EDID And Test DDC”

5. Key in series number(22 characters) in the input column

Press write button after key in S/N

Writing HDMI Process

Chose the folder:”Acer-HDMI” then double click

Select the “acer HDMI.EXE” to execute it

According to the previous process(step3-step6) to write

HDMI-EDID.

6. When EDID was written successfully that will show below

message on the screen

Page 36

G

F

E

D

C

B

8.Schematics and Layouts

A

1234567 8910111213

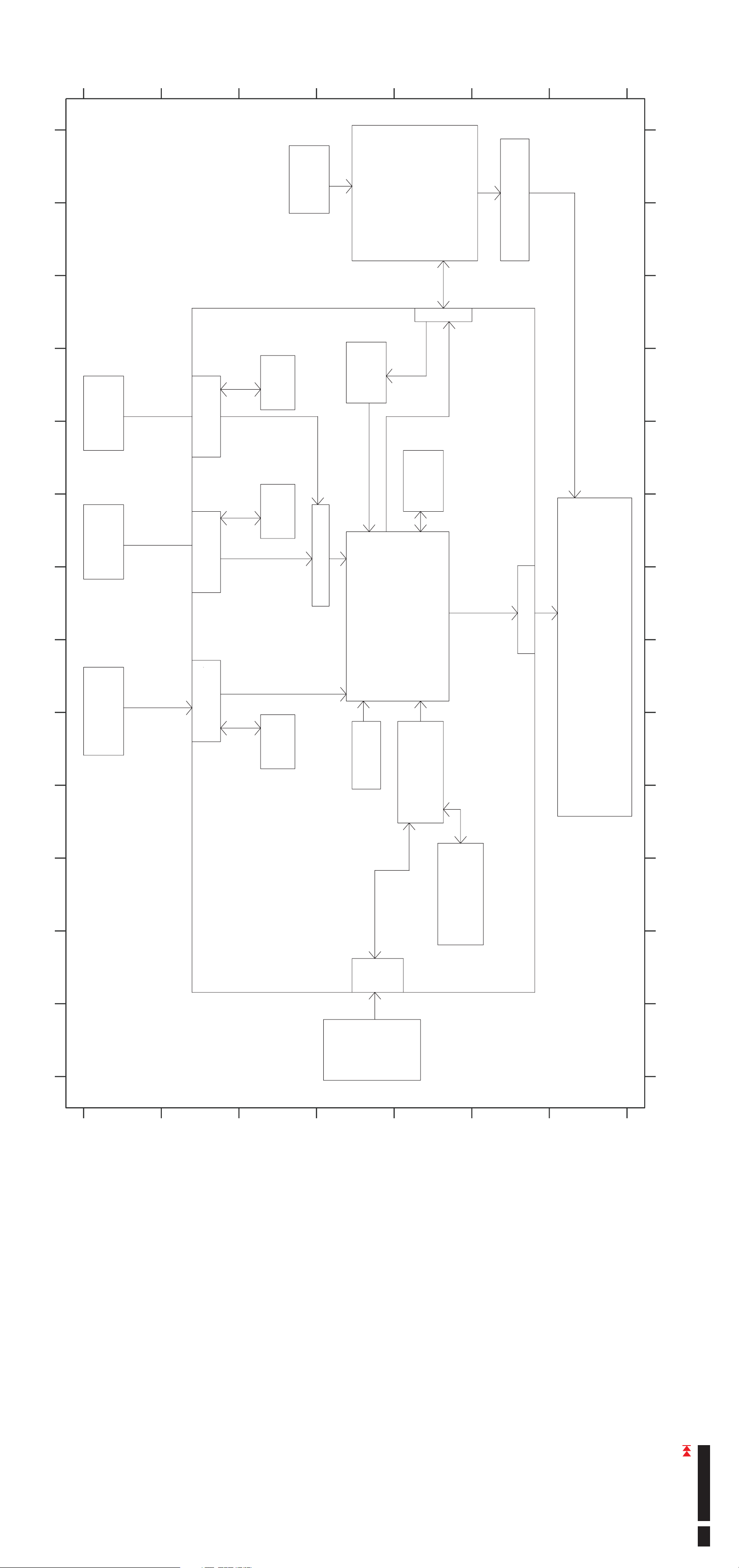

Digital

Video

Input

HDMI

DDC SCL D__

DDC SDA D__

Input

DDC

24LC02B

110 220v/

I321

AC

I302

33v 18v.-.

I320

5v 3 3v-.

I326

DC DC-

Power

Board

P301

Inverter Board

1234567 8910111213

_8.1 SCHEMATICS BLOCK DIAGRAMACER_LCD_G24_

+5V

Brightness Inv On Off,_/

Digital

Video

Input

Analog

Video

Input

P311

DVI D-

P305

DSUB

DDC SCL D1__

DDC SDA D1__

RGBHsVs,,, ,

DDC

24LC02B

I313

I322

Switch

TMDS

Scaler

MST 9259D

EM6A9320BI

DDR

I315

I314

LVDS

P306

LCD Module

LTM240CT03

LTM240CT01

PCB No.

P304

D SUB SCL__

D SUB SDA__

DDC

24LC02B

I312

14 3MHZ.

XTAL

MCU

W79L659A25FL

P303

I306

Flash

W39L040Ap70Z

I307

G

F

E

D

Function

Key

Board

C

B

A

Go to cover page

ACER G24

35

Page 37

G

F

E

D

C

B

A

1234567 8910111213

4 7U 50V./

C838

CON3

N

2

R846

100

R0805

C830

102P 0805

X7R

C857

0 1U 1206.

X7R

4700P 1KV/

510K

R879

100K 2W/

C843

D807

R874

VBUS

VBUS1

SG6901

103P 0805

X7R

X7R

C818

R847

33 2K.

R0805

3

4 5

VIN

RI RT

SG5841J

SENSE

470P 0805

C831

X7R

X7R

4

LTV 817

I804

1

23

R0805

R843

220

+

1K R0805

R842

470P 0805

4 7U 50V./

R1206

C832

10K

0332W.

C834

+

R851

R850

47U 50V/

R0805

C833

6

R853

100

1N4148

+

VAUX

FB

VDD

510K

R1206

1

2

GND

I803

GATE

7

8

R0805

10

1N4148

R849

R0805

100

D810

21

R845

7N65C

21

Q803

R877

D814

BEAD 6mm/

R1206

510K

R844

R1206

1

2

3

VA

1N4937 G-

D809

1KV X7R

2200P 250V/

100P

C812

C846

R75A

L805

R841

33.

CUT

641

PG108R

D808

2

P6KE150A

PQ2625

T805

FBPWM

R826

27K.

R0805

R828

100

R1206

100P 0805

C814

X7R

R825

10K

R827

IMP

VDD

6

15

C815 NC

R0805

47K

R0805

X7R

5

IPFC

RANGE

16

R830

102P 0805

IEA

OVP

C813

R0805

24K

3

4

RI

OTP

FBPFC

VEA

17

18

1U 1206

X7R

R824

2

19

C809

R1206

1

VRMS

IAC

20

R0805

I801

604K

R1206

R813

61 9K.

R1206

R1206

604K

R823

24M.

24M.

R812

X7R

1U 1206

R810

R811

C811

043 2W.

R815

C816

102P 0805

X7R

27K.

R0805

102P 0805

C817

10 11

AGND SS

9

IPWM

OPWM

12

8

FBPWM

GND

13

7

ISENSE

OPFC

14

SCK055

R801

R1206

R803

510K

1

2

1000P 250V/

C808

RING CHOKE

1

T803

2

680P 250V/

C829

1

C850

4700P 1KV

X7R

4A 800V/

D802

043 2W.

R814

2

1uF 450V/

MEF P15/

MEF P15/

4

C855

X7R

1uF 450V/

280uH

C856

R1206

-

+

4700P 1KV

L801

G

510K

3

4

3

4

3

1000P 250V/

680P 250V/

R802

C803

C849

ET 24-

C802

C828

3

L

1

0 47U 275V./

T802

0 33U 275V./

F801

P801

C806

3 15AH250V.

D812

1N4007 G-

1234567 8910111213

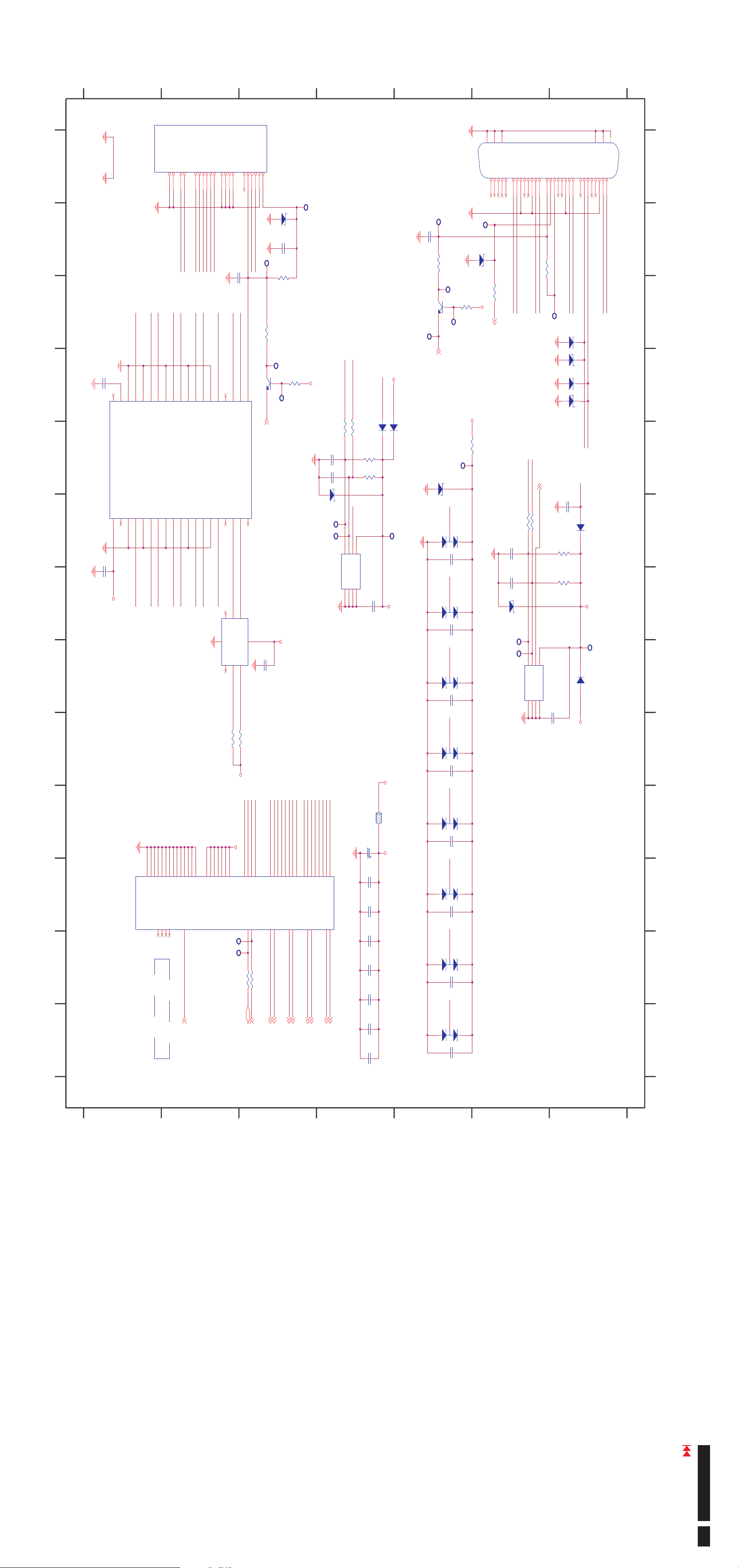

_8.2 SCHEMATICS POWER BOARDACER_LCD_G24_

D811

1N4007 G-

23

X7R

R0805

R1206

0 1 0805.

30K

10K

R0805

C841

1000U 25V/

1000U 25V/

1000U 25V/

1000U 25V/

D816

FCH30A10

+

C839

+

C835

+

C836

28U.

+

C837

L803

10

52V.

D815

FCH30A10

20

R1206

X7R

220P 100V X7R/

C845

20

R1206

1U 1206

C826

R873

R872

R809

R0805

104P 0805

D817

X

X7R

R0805

C819

VDD

R831

10K

R0805

1N4148

D805

21

R1206

R807

10K

1

10

R832

100

3

2200P 250V/

R1206

C805

680k

R805

150U 450V/

R1206

LT2A06 G-

6

C801

X7R

680k

D804

1KV X7R

103P 1KV

R804

R0805

R833

15K

222P 1206

C810

X7R

R820

10

R0805

R0805

R0805

R829

100

R1206

10K

FBPWM

1N4148

R817

R821

200

033 2W.

R818

1KV X7R

100P

21

C847

D806

17A 800V/

Q801

R1206

R806

24K

C807

10

1

100P

+

R1206

4

100P 1KV

X7R

2

C848

R878

680k

100K 2W/

4700P 1KV/

C804

P6KE180A

D801

CUT

3

2

C858

5A 600V/

R869

BEAD 6mm/

D803

4

5

CUT

3

0221W.

5

PQ2625

T804

L804

L806

Q802

FQPF13N50C

BEAD 6mm/

R868

VBUSVBUS1

PQ 3225-

T801

AP431 1%

R855

20K

R858

R859

4

LTV 817

1

I806

I807

VDD

R1206

47K.

R0805

2200P 0805

X7R

Q806

KN2907A

R860

270

C840

R60A

R856

R60A

KN2222A

VAUX

VA

Q807

R875

100

R854

22K

ZD801

22B

R857

1K

R60A

123

PCB No.

R1206

x

R876

AP431 1%

R0805

18 7K 1.%

X7R

I805

R839

1U 1206

C820

X7R

R0805

0 01U 0805.

C821

X7R

1U 1206

C827

12

220P 1KV X7R

C822

20A 150V/

D813

R870

20 R1206

R871

20

R1206

1000U 35V/

C823

+

1000U 35V/

C824

+

L802

28U.

1000U 35V/

C825

+

24V

4

LTV817

I802

1

R836

23

1 2K 0805.

1K 0805

169K 1%

***

R838

R835

R822

47K.

9

6832194100P01

G

F

E

12345678910111213

20.

OFF

52V.

52V.

52V.

GND

GND

GND

52V.

52V.

D

P802

ON OFF-

52V.

5V RTN-

BRI

C

B

10

20.

ON OFF-

BRI

GND

GND

GND

TO INV

123456789

P803

24V

24V

GND

24V

24V

A

Go to cover page

ACER G24

36

Page 38

G

F

E

D

C

B

A

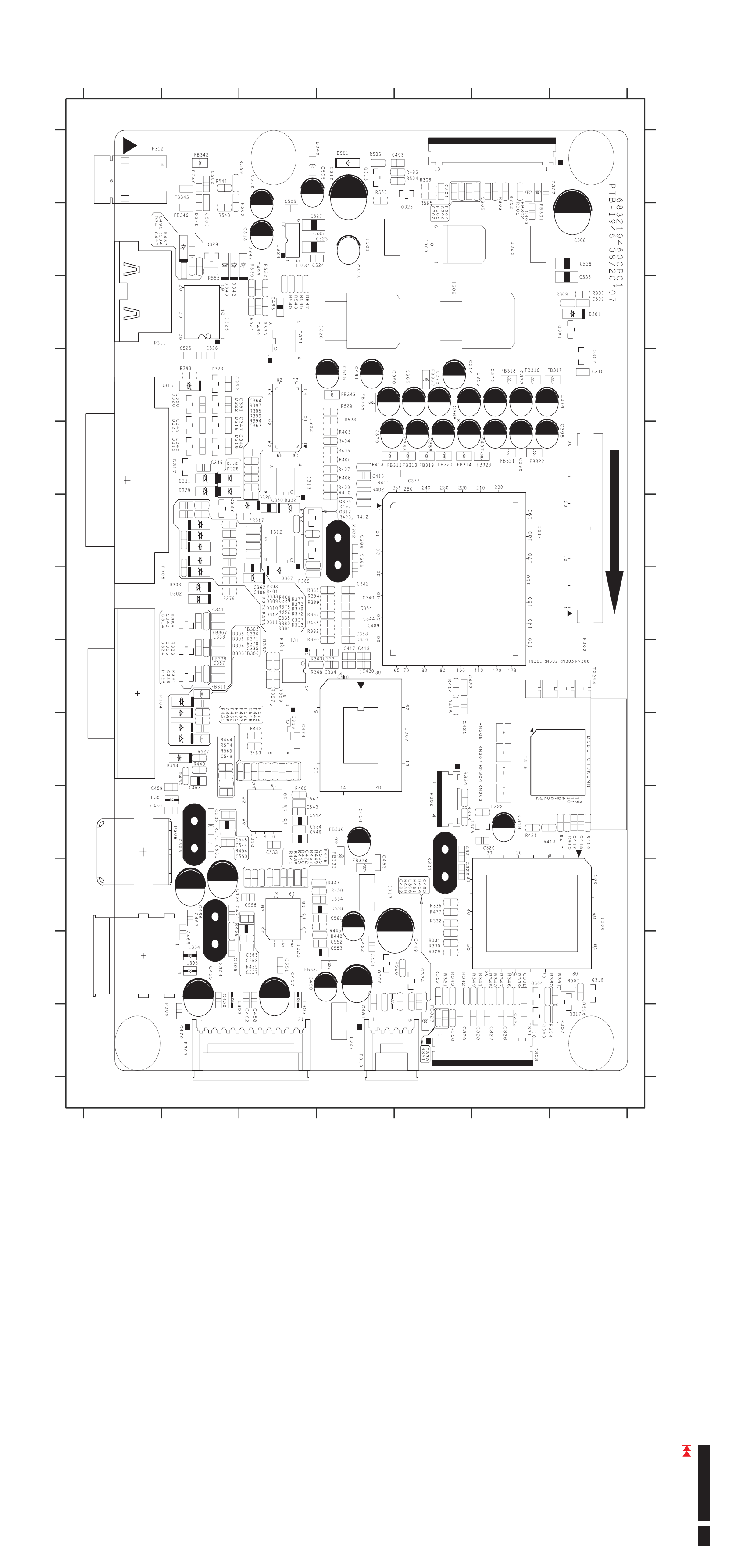

8.3 ACER __LCD_G24 SCHEMATICS_INTERFACE_BD_POWER

1234567 8910111213

R310 47K

Q301

MMBT3904

TP445

TP20

TP21

LCD EN_3

47K

Q309

MMBT3906

D301

MM4148

R489

47K

TP19

TP446

GND

R309 30KR488

220u 25V/

10K

C308

R307

+3V3

VCC LCD1_

TP14

FOR POWER SAVING CONTROL

OFF3

GND

220u 25V/

1

AIC1117A 33PYTR-

ADJ GND()

C312

I301

+5V

AUDIO EN_

AUDIO DET_

BKLT EN_

BKLT ADJ_

OFF

JWT A2001WV2 13P--

13

GND

GND

GND

6789101112

+.51V

+.51V

+.51V

5V RTN_

+.51V

P301

12345

1234567 8910111213

SOT 223-

+3V3

TP17

GND

TP1

TP13

R301 0

GND

R570 4 7K.

TP549

Q331

MMBT3904

TP546

10K

R568

+5V

VOUTVIN

TAB

23

4

C313

100u 10V/

GND GND GND GND

1

2

3

I316 FDS4435

C309

01u.

TP18

2 3

Q302

AO3401

1

GND

C310

01u.

FB303

C311

01u.

R308

100K

4

5

6

H161R315 8-

7

8

5

6

H161R315 8-

7

8

3

M301

2

1

4

3

M302

2

1

PBY201209T 300Y S--

VCC LCD2_

VCC LCD2_

GND

TP15

TP16

1

AIC1084 33PMTR-

ADJ GND()

TAB

4

+5VD

I320

VOUTVIN

23

TO 263-

TP547

GND

GND

4

5

6

7

8

C535

47u.

TP544

C537

47u.

+5VD

+5VD

1

ADJ GND()

I326

AIC1117A 33PYTR-

C493

01u.

C301

01u.

C302

01u.

C304

01u.

C305

01u.

C306

01u.

C307

01u.

FB301 PBY201209T 170Y S--

FB302 PBY201209T 170Y S--

VCC LCD1_

+5V

R496 100

R306 100

R305 100

SOT 223-

TP455

MMBT3904

Q325

Q315

MMBT3904

BKLT ADJ_6

10uF

TAB

4

C536

VOUTVIN

23

+3V3D

TP470

TP4

TP5

TP7

TP8

R304 100 NC()

R303 100 NC()

R302 5 6K NC.( )

+3V3

TP9

TP10

TP11

TP12

AUDIO DET_3

PCB No.

6832194600P0

4

5

6

H161R315 8-

7

8

5

6

H161R315 8-

7

8

3

M303

C491

100u 10V/

2

1

GND

4

3

M304

2

1

1

AIC1084 18PMTR-

ADJ GND()

TAB

4

100u 10V/

C314

VOUTVIN

TP428

I302

TO 263-

23

+1V8

TP22

GND

GND

10uF

AP1117E25L 13-

ADJ GND()

TAB

100u 10V/

C538

1

4

C315

VOUTVIN

23

TP23

TP545

+5VD

I303

TO 252 GOI--

+_2V5 VDDM

GND

Q314

MMBT3904

TP542

R567 100

TP543

HI POWER ON==>

TP458

R503

47K

TP459

BKLT EN_3OFF 3

10K

+3V3

R565 10K

R502

TP460

+5V

+5V

R504 10K

+5V

GND

R505 1K

Q313

MMBT3904 NC()

TP456

R501

47K NC()

TP457

AUDIO EN_3

10K NC()

+5V

R500

G

F

E

D

C

B

A

Go to cover page

ACER G24

37

Page 39

1234567 8910111213

+3V3

R507 4 7K.

G

TP110

LED A_

GND

+_3V3 VDD

MMBT3904 NC()

Q324

A

+_3V3 VDD

CAM MIC DIAG__8

1234567 8910111213

_8.4 SCHEMATICS INTERFACE_BD_MCU AND FUNCTION KEYACER_LCD_G24_

+3V3

R526

10K NC()

TP469

VSS SDA

4 5

SCL

R345 0

MSDA

WP

678

R344 0

MSCL

C

C324

01u.

TP67

WE

R328 0

GND

01u.

SELECT

VGA SDA 3V_ _ TXD

R524 0

123

I309

A0A1A2

VCC

WP

R337

10K

+_3V3 VDD

R338

10K

D

TP81

TP82

R333

47K NC.( )

R334

47K NC.( )

JWT A2001WV2 4--

+_3V3 VDD

P302

GND

TP100

TP101

24LC16B

TP46

TP438

TP47

TP48

ISPTDINT

TRST

DVI HDMI SW__

TP99

TP102

TP103

TP600

TP439

TDO

TP98

E

TP440

TP97

TP441

TMS

TP442

TCK

GND

123

+_3V3 VDD

123

RXD

TXD

4

4

F

TP53

TP49

TP51

TP50

TP52

HP DET DVI__

HWRESET

ALE

DVI DET_

DSUB DET_

+3V3

LED B ACTIVE LOW_

TP108

LED B_ LED BLUE_

R506 4 7K.

LED A ACTIVE LOW_

GND

C320

1

47KNC.( )

R322

VCC

3

B

OUT

2

10u 50V NC/()

I305

STL8110PCH300

C318

TP54

+3V3

+_3V3 VDD

TP465

GND

TP116

TP117

TP113

01u.

C332

MMBT3904

Q317

R361 10K

MMBT3906

LED AMBER_

Q304

TP463

MMBT3904

TP540

TP109

TP105

01u.

C331

Q316

R357 10K

MMBT3906

+5V

R354 4 7K.

Q303

GNDGND GND

GNDGND

GND

GND

+5V

R360 4 7K.

GND

DOWN

POWER

MENUUPSELECT

R339

10K

R340

10K

R341

10K

R342

10K

R343

10K

R352

10K

R347 1K

R348 1K

R346 1K

R349 1K

R350 1K

R351 1K

TP90

C325

01u.

TP91

C326

01u.

TP92

C327

01u.

TP93

C328

01u.

TP94

C329

01u.

TP601

C330

01u.

GND

123456789

SELECT

EXE

MINUS

MENU

PLUS

POWER

LED AMBER_

LED BLUE_

10

P303 JWT A2001WV2 10p--

+_3V3 VDD

RD6

WP

R336

10K

C322 22p

TP84

GNDGND

R478 4 7K NC.( )

R479 4 7K NC.( )TP89

R477 4 7K NC.( )

+_3V3 VDD

AUDIO DET_2

AUDIO EN_2

OFF 2

DVI HDMI SW__ 5

TP85

TP86

TP87

TP88

AD0

24MHz

AD1

X301

AD2

R335

47K.

C321 22p

TP77

A10

A9

AD3

A11

A8

TP80

TP83

TP78

TP79

R329

10K

R330

10K

R331

10K

R332

10K

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

TP76

P37RD./

XTAL2

XTAL1

NC

AVSS

VSS

VSS

NC

P4 0.

P7 0.

P7 1.

P7 2.

P7 3.

P6 0.

P6 1.

P6 2.

P6 3.

P20A8./

P2 1 A9./

P2 2 A10./

P2 3 A11./

NC

NC

NC

NC

NC

+_3V3 VDD

TP96

TP95