Page 1

|

Acer | HDS WMS100

User and Reference Guide

MK-95DF738-01

Page 2

Page 3

2005 Hitachi Data Systems Corporation, ALL RIGHTS RESERVED

Notice: No part of this publication may be reproduced or transmitted in any form or by any

electronic or mechanical means, including photocopying and recording, or sto red in a

database or retrieval system for any purpose without the express written permis sion of

Hitachi Data Systems Corporation (hereinafter referred to as “Hitachi Data Systems”).

Hitachi Data Systems reserves the right to make changes to this document at any time

without notice and assumes no responsibility for its use. Hitachi Data Systems products and

services can only be ordered under the terms and conditions of Hitachi Data Systems’

applicable agreements. All of the features described in this document may not be currently

available. Refer to the most recent product announcement or contact your local Hitachi

Data Systems sales office for information on feature and product ava ilability.

This document contains the most current information available at the time of publication.

When new and/or revised information becomes available, this entire document will be

updated and distributed to all registered users.

Trademarks

Hitachi Data Systems is a registered trademark and service mark of Hitachi, Ltd., and the

Hitachi Data Systems design mark is a trademark and service mark of Hitachi, Ltd.

Egenera and BladeFrame are registered trademarks of Egenera, Inc.

Emulex is a registered trademark of Emulex Corporation.

HP-UX, MC/ServiceGuard, and Tru64 are trademarks or registered trademarks of the

Hewlett-Packard Development Company, L.P.

AIX and RS/6000 are registered trademarks of International Business Machines Corporation.

Pentium is a registered trademark of Intel Corporation.

Linux is a registered trademark of Linus Torvalds.

Microsoft, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Netscape and Netscape Navigator are registered trademarks of Netscape Communications

Corporation in the U.S. and other countries.

NetWare is a registered trademark of Novell, Incorporated.

Oracle is a registered trademark of Oracle Corporation.

QLogic is a registered trademark of QLogic Corporation.

Java, Solaris, Sun, Sun Enterprise, and Sun Fire are trademarks of Sun Microsystems, Inc.

VERITAS is a trademark of VERITAS Software Corp.

Acer | HDS WMS100™ User and Reference Guide iii

Page 4

All other brand or product names are or may be registered trademarks, trademarks, or

service marks of and are used to identify products or services of their respective owners.

Notice of Export Controls

Export of technical data contained in this document may require an export license from the

United States government and/or the government of Japan. Please contact the Hitachi Data

Systems Legal Department for any export compliance questions.

Document Revision Level

Revision Date Description

MK-95DF713-00 September 2005 Initial Release

MK-95DF713-01 November 2005 Revision 1, supersedes and replaces MK-95DF738-00

Source Document(s) for this Revision

SANRISE AMS100 (Workgroup Modular Storage) Series Disk Array Subsystem User’s Guide,

RSD-95DF738-03

Changes in this Revision

Added an introductory paragraph and table to the introduction of Chapter 1

Changed section 1.1

Changed section 1.1.2

Changed section 1.2

Added an introductory paragraph and table to the introduction of Chapter 2

Changed section 2.2.3.1

Changed section 2.4.6

Added Figure 2.4

Added Table 2.5

Changed Table 2.6

Changed Table 2.7

Changed Table 2.11

Changed Table 2.13

Changed Table 2.14

Added an introductory paragraph and table to the introduction of Chapter 3

Changed section 3.1.1

iv Preface

Page 5

Added section 3.1.3

Added an introductory paragraph and table to the introduction of Chapter 4

Changed section 4.2

Changed section 4.3

Changed section 4.3.1

Changed section 4.3.3

Changed section 4.3.4

Added section 4.4

Changed section 4.6.3

Added section 4.6.3.3

Changed section 4.6.4

Changed Figure 4.1

Added Figure 4.2

Changed Figure 4.3

Changed Figure 4.4

Changed Figure 4.5

Changed Figure 4.6

Changed Figure 4.7

Changed Figure 4.8

Changed Figure 4.11

Changed Figure 4.19

Changed Figure 4.20

Changed Figure 4.27

Changed Table 4.3

Changed Table 4.4

Changed Table 4.6

Changed Table 4.13

Added an introductory paragraph and table to the introduction of Chapter 5

Changed section 5.1

Added an introductory paragraph and table to the introduction of Chapter 6

Changed section 6.2

Added an introductory paragraph and table to the introduction of Chapter 7

Changed section 7.3.4

Acer | HDS WMS100™ User and Reference Guide v

Page 6

Changed section 7.3.6

Changed section 7.4

Changed section 7.8

Changed section 7.9

Added section 7.12

Added section 7.13

Added section 7.14

Added Figure 7.3

Added Figure 7.6

Added an introductory paragraph and table to the introduction of Chapter 8

Changed section 8.1

Changed section 8.1.1

Changed section 8.1.2

Changed section 8.1.3

Changed section 8.1.5

Changed section 8.3.1

Added section 8.3.7

Added section 8.5

Added section 8.6

Changed Figure 8.2

Added Figure 8.3

Changed Figure 8.4

Changed Figure 8.5

Changed Figure 8.7

Changed Figure 8.11

Changed Figure 8.12

Changed Table 8.5

Changed Table 8.11

vi Preface

Page 7

Added an introductory paragraph and table to the introduction of the Appendices

Changed Table C.2

Added section D.2

Changed Table E.1

Changed Figure E.1

Changed Figure J.1

Added Figure J.2

Acer | HDS WMS100™ User and Reference Guide vii

viii Preface

Page 8

Page 9

Preface

This document describes the physical, functional, and operat ional characteristics of the

WMS100 subsystem. This document also provides operation instructions, installation details,

and configuration planning information for the WMS100 subsystem .

This User and Reference Guide assumes:

The user is familiar with the Acer | HDS AMS200/WMS100™ array subsystem, and

The user is familiar with the Windows

This subsystem complies with FDA radiation performance standards 21CFR, subchapter J.

Notes:

For further information, please contact your Hitachi Data Systems account team, or visit

®

95, Windows® 98, Windows® 2000, or

Windows NT

®

operating systems. These versions are abbreviated to Windows in this

document.

the Hitachi Data Systems worldwide web site at http://www.hds.com

.

The use of Acer | HDS WMS100 subsystem and all other Acer | HDS products is governed

by the terms of your agreement(s) with Acer | HDS.

Software Version

This document revision applies to Acer | HDS AMS Products versi on 2.0 and higher.

EMI Regulation

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate rad io frequency

energy and, if not installed and used in accordance with the instruction manual, may cau se

harmful interference in which case the user will be required to correct the interference at

his own expense. Testing was done with shielded cables. Therefore, in order to comply with

the FCC regulations, you must use shielded cables with you installation.

Acer | HDS WMS100™ User and Reference Guide ix

Page 10

If trouble occurs in a different configuration, the user may be requested to take appropriate

preventive measures. The EMI test was done in the following configuration:

WMS100-RKXS+H1J

WMS100-RKXS+RKAJAT+H2J

Convention for Storage Capacity Values

This document uses the following convention for storage capacity values:

1 KB (kilobyte) = 1,000 bytes

1 MB (megabyte) = 1,000,000 bytes

1 GB (gigabyte) = 1,000,000,000 bytes

1 TB (terabyte) = 1,000 Gbytes

Referenced Documents

Acer | HDS AMS Cache Residency Manager Software User’s Guid

Acer | HDS Adaptable Modular Storage Storage Navigator Modular Graphical User Interface

(GUI) User’s Guide, MK-95DF711

Hitachi TagmaStore™ Adaptable Modular Storage Storage Navigator Modul ar Command Line

Interface (CLI), MK-95DF712

Hitachi TagmaStore™ Adaptable Modular Storage ShadowImage™ In-System Replication

Software User’s Guide, MK-95DF709

Hitachi TagmaStore™ Adaptable Modular Storage TrueCopy™ Synchronous Remote

Replication Software User’s Guide, MK-95DF710

Hitachi TagmaStore™ Adaptable Modular Storage Copy-on-Write SnapShot User’s Guide,

MK-95DF708

Acer | HDS Global 19-Inch Rack Reference Guide

Hitachi TagmaStore™ Adaptable Modular Storage Performance Monitor Software User’s

Guide, MK-95DF706

x Preface

Page 11

Comments

Please send us your comments on this document. Make sure to include the document title,

number, and revision. Please refer to specific section(s) and paragraph(s) whenever possible.

E-mail: doc.comments@hds.com

Fax: 858-695-1186

Mail:

Technical Writing, M/S 35-10

Hitachi Data Systems

10277 Scripps Ranch Blvd.

San Diego, CA 92131

Thank you! (All comments become the property of Hitachi Data Systems Corporation.)

Acer | HDS WMS100™ User and Reference Guide xi

xii Preface

Page 12

Page 13

Contents

Chapter 1 Overview of the WMS100 Subsystem...................................................................................1

1.1 Overview Features ...............................................................................2

1.1.1 High Data Availability...................................................................2

1.1.2 Connectivity..............................................................................2

1.1.3 Scalability ................................................................................3

1.1.4 Performance Reporting and Monitoring..............................................3

1.1.5 Reliability, Availability, and Serviceability ......................................... 4

1.2 Rack-Mount Model................................................................................5

1.3 Floor Model........................................................................................6

Chapter 2 Planning for Installation and Operation................................................................................7

2.1 User Responsibilities .............................................................................9

2.2 Safety Precautions ............................................................................. 10

2.2.1 Warning Labels......................................................................... 11

2.2.2 Repair, Modification, and Disassembly............................................. 11

2.2.3 Precautions for Using Equipment ................................................... 11

2.2.4 Inspection and Cleaning Precautions............................................... 15

2.2.5 Emergency Precautions............................................................... 16

2.2.6 Warning Notices ....................................................................... 17

2.2.7 Warning Label Locations ............................................................. 17

2.3 General Specifications and Requirements.................................................. 23

2.3.1 Dimensions and Weigh................................................................ 23

2.3.2 Service Clearance Requirements.................................................... 25

2.3.3 Floor Load Rating...................................................................... 26

2.3.4 Internal Logic Specifications......................................................... 27

2.3.5 Cable Function......................................................................... 27

2.4 Environmental Specifications and Requirements.......................................... 28

2.4.1 Environmental Hazards............................................................... 28

2.4.2 Temperature and Humidity Requirements ........................................ 29

2.4.3 Input Power and Insulation Performance Specifications........................ 29

2.4.4 Air Flow Requirements ............................................................... 30

2.4.5 Vibration and Shock Tolerances..................................................... 31

2.4.6 Reliability............................................................................... 32

Chapter 3 Powering On/Off Procedure.................................................................................................35

3.1 WMS100 Rack-Mount Model ................................................................... 36

3.1.1 Subsystem Power On.................................................................. 36

3.1.2 Subsystem Power Off ................................................................. 38

3.1.3 Stop/Start/Restart of the NAS OS .................................................. 38

3.2 WMS100 Floor Model ........................................................................... 40

3.2.1 Subsystem Power On.................................................................. 40

3.2.2 Subsystem Power Off ................................................................. 41

Chapter 4 Subsystem Architecture and Components........................................................................43

4.1 Configuration Block Diagrams ................................................................ 44

4.1.1 WMS100 Rack -Mount Model.......................................................... 44

Acer | HDS WMS100™ User and Reference Guide xiii

Page 14

4.1.2 WMS100 Floor Model.................................................................. 49

4.2 Redundant Power Supplies.................................................................... 53

4.3 Fibre Channel Interface ....................................................................... 54

4.3.1 Mini-HUB 54

4.3.2 Connection Specifications............................................................ 55

4.3.3 Fibre Channel Configuration......................................................... 57

4.3.4 Attention to the Host Direct Connection for WMS100........................... 57

4.4 Ethernet Interface.............................................................................. 58

4.5 Array Frame ..................................................................................... 58

4.5.1 WMS100 Rack -Mount Model.......................................................... 59

4.5.2 Floor Model............................................................................. 60

4.6 Component Names, Locations, and Functions ............................................. 61

4.6.1 Front Bezel Component Locations and Functions................................ 62

4.6.2 Component Locations................................................................. 64

4.6.3 Switch Locations and Functions..................................................... 65

4.6.4 Connector Locations and Functions ................................................ 67

4.6.5 LED Locations and Functions ........................................................ 70

Chapter 5 Functional and Operational Characteristics ......................................................................79

5.1 New WMS100 Features and Capabilities .................................................... 81

5.2 RAID Implementations ......................................................................... 82

5.3 Cache Management............................................................................. 84

5.4 Logical Units (LUs).............................................................................. 86

5.5 Open Systems Features and Functions ...................................................... 88

5.5.1 Open Systems Middleware ........................................................... 88

5.5.2 LUN Management...................................................................... 88

5.6 Data Management Features and Functions ................................................. 89

5.6.1 Cache Residency Manager Function ................................................ 89

5.6.2 LUN Manager Function................................................................ 89

5.6.3 Data Retention Utility Function..................................................... 89

5.6.4 LUN Expansion Function.............................................................. 89

5.6.5 Password Protection Function....................................................... 89

5.7 Copy Solution Features and Functions ...................................................... 90

5.7.1 ShadowImage In-System Replication Function.................................... 90

5.7.2 Copy-On-Write Snapshot Function.................................................. 90

5.7.3 NAS Backup Restore Modular Function............................................. 90

5.7.4 NAS SyncImage Modular Function................................................... 90

5.8 Performance Management Features and Functions....................................... 91

5.8.1 Performance Monitor Function...................................................... 91

5.8.2 Cache Partition Manager Function.................................................. 91

5.9 NAS Features and Functions .................................................................. 92

5.9.1 NAS Data Con trol Modular Function................................................ 92

5.9.2 NAS File Sharing Modular Function ................................................. 92

5.9.3 NAS Manager Modular Function ..................................................... 92

5.9.4 NAS Backup Restore Modular Function............................................. 92

5.9.5 NAS SyncImage Modular Function................................................... 92

5.9.6 NAS Anti-Virus Agent Modular Function............................................ 92

xiv Contents

Page 15

Chapter 6 Configuring the WMS100 Subsystem.................................................................................93

6.1 Overview of Configuration .................................................................... 95

6.1.1 Open Systems Configuration......................................................... 95

6.1.2 Defining LUNs.......................................................................... 95

6.1.3 Fibre Channel Interface Addressing ................................................ 96

6.1.4 Alternate Pathing...................................................................... 98

6.1.5 NAS Configuration..................................................................... 99

6.2 Configuring LAN Interfaces of the WMS100 Subsystem .................................. 100

6.3 Configuring the WMS100 Subsystem ........................................................ 101

6.4 Registering the WMS100 Subsystem for Control by Storage Navigator Modular ..... 102

6.5 Configuring the WMS100 Subsystem for the Desired Application ......................103

6.6 WMS100 Subsystem General Configuration................................................104

Chapter 7 Configuring Storage on the WMS100 Subsystem............................................................105

7.1 Software Composition ........................................................................ 107

7.1.1 Microprogram ......................................................................... 107

7.1.2 System Parameters................................................................... 107

7.1.3 Configuration Information ..........................................................107

7.1.4 SNMP Information ....................................................................107

7.1.5 Storage for Parameters.............................................................. 108

7.2 Setting Fibre Channel Information.......................................................... 109

7.3 Determining Space and RAID Level Requirements........................................111

7.3.1 Setting a Spare Disk.................................................................. 112

7.3.2 Canceling a Spare Disk Setting ..................................................... 115

7.3.3 Setting a RAID Group.................................................................116

7.3.4 Deleting a RAID Group............................................................... 119

7.3.5 Setting a Logical Unit................................................................121

7.3.6 Deleting the Last Logical Unit...................................................... 123

7.3.7 Formatting a Logical Unit........................................................... 125

7.3.8 Changing the Format Mode ......................................................... 129

7.3.9 Changing the Default Controller in Charge of an LU............................131

7.4 Setting Host Group Information.............................................................132

7.4.1 Setting Mapping Information ....................................................... 132

7.5 Transferring Configurations from One Array to Another ................................ 136

7.6 Storing Configuration Data................................................................... 137

7.6.1 System Parameter Information.....................................................137

7.6.2 RAID Group/LU information ........................................................ 138

7.6.3 Port/Host Group Informat ion.......................................................140

7.6.4 NAS System LU/User LU information.............................................. 141

7.7 Applying Configuration Data to Another WMS100 Subsystem........................... 142

7.7.1 System Parameters................................................................... 142

7.7.2 RAID Group/Logical unit.............................................................143

7.7.3 Port/Host Group......................................................................144

7.8 Setting Host Connection Parameters.......................................................145

7.8.1 Simple Setting ........................................................................ 145

7.8.2 Detailed Setting ......................................................................150

7.9 Setting the Subsystem when using Special Mode......................................... 151

7.10 Changing the Network Parameter...........................................................153

7.11 Setting the System LU and User LU in the NAS System..................................155

Acer | HDS WMS100™ User and Reference Guide xv

Page 16

7.11.1 Setting the System LU ...............................................................155

7.11.2 Setting the User LU ..................................................................157

7.12 Setting the System LU and User LU in the NAS System..................................159

7.12.1 Setting the System LU ...............................................................160

7.12.2 Setting the User LU ..................................................................162

7.13 Setting the NNC Management LAN Port Information in the NAS System..............164

7.14 Setting the Time Zone........................................................................167

Chapter 8 Troubleshooting.................................................................................................................171

8.1 Troubleshooting Based on LED Indications ................................................ 173

8.1.1 The POWER LED Does Not Turn On ................................................ 173

8.1.2 The POWER LED Has Turned off....................................................174

8.1.3 If the READY LED Does NotTurn On or has Turned On Once then Off........175

8.1.4 The Alarm LED Has Turned On .....................................................176

8.1.5 The WARNING LED Has Turned On or Blinks...................................... 177

8.2 Web Overview.................................................................................. 178

8.2.1 Operational Environment ...........................................................178

8.2.2 Characteristics of Network Functions............................................. 181

8.3 Web Operational Procedures ................................................................182

8.3.1 Connecting t o the Network using a LAN Interface..............................182

8.3.2 Screen Outlines....................................................................... 183

8.3.3 Main Screen in Normal Mode ....................................................... 186

8.3.4 Status Display of Replaceable Components......................................189

8.3.5 Information Message................................................................. 197

8.3.6 Setting the Buzzer Sound Volume..................................................198

8.3.7 Clear Specified Factors of NNC Partial Alarm....................................199

8.4 Troubleshooting Using a Web Connection ................................................. 202

8.4.1 Checking Subsystem Status......................................................... 202

8.4.2 Checking the Progress Condition Display.........................................203

8.4.3 Checking Component Status........................................................ 204

8.4.4 Checking Log Messages.............................................................. 205

8.4.5 Troubleshooting Using Messages ...................................................207

8.4.6 Reading Failure Information........................................................ 213

8.5 Determining the Failure of the Network Side in the NAS System......................215

8.6 Connecting Failure in Connection with the Web ......................................... 217

8.6.1 Collecting Simple Trace.............................................................217

8.6.2 NAS Log Collection...................................................................220

8.6.3 NAS Dump Generation...............................................................223

Appendix A Glossary..............................................................................................................................231

Appendix B System Parameter Settings List........................................................................................237

Appendix C Basic Specifications of the Subsystem............................................................................249

Appendix D Interfaces ............................................................................................................................ 255

D.1 Fibre Channel Connection Specifications..................................................255

D.2 Ethernet Connection Specifications ........................................................283

xvi Contents

Page 17

Appendix E Remote Adapter Specifications.........................................................................................285

E.1 Remote Adapter Specifications..............................................................285

E.2 Remote Adapter Dimensions.................................................................286

Appendix F List of Storage Capacities Corresponding to RAID Levels and Configurations ...........287

Appendix G Port Address Mapping Table.............................................................................................295

Appendix H Power Cables......................................................................................................................299

Appendix I Number of Logical Blocks.................................................................................................301

Appendix J Using LUN Security or LUN Management on a Fabric Switch Connection ...................305

J.1 When an FC Interface Board is Not Added to the Control Unit.........................305

J.2 When an FC Interface Board is Added to the Control Unit.............................. 306

Acer | HDS WMS100™ User and Reference Guide xvii

Page 18

List of Figures

Figure 2.1 Position of Labels on Floor Model RKXS+H1J......................................... 18

Figure 2.2 Position of Labels on Floor Model RKXS+RKAJAT+H2J .............................. 19

Figure 2.3 Position of Labels on Rack-Mount Model RKXS....................................... 20

Figure 2.4 Position of Labels on Rack-Mount Model RKNAS..................................... 21

Figure 2.5 Position of Labels on Rack-Mount Model RKAJAT ................................... 22

Figure 3.1 Subsystem Power On/Off (Example: Floor [RKXS+ RKAJ+H2J) .................... 41

Figure 4.1 RKXS System Configuration (When the FC Interface board is not added) ....... 45

Figure 4.2 RKXS and System Configuration (When the FC Interface board is added)...... 46

Figure 4.3 RKXS and RKNAS System Configuration ............................................... 47

Figure 4.4 RKAJAT System Configuration.......................................................... 48

Figure 4.5 Floor (RKXS+H1J) Model WMS100 System Configuration (When FC Interface

Figure 4.6 Floor (RKXS+RKAJAT+H2J) Model WMS100 System Configuration (When FC

Figure 4.7 Floor (RKXS+RKAJAT+H2J) Model WMS100 System Configuration (When FC

Figure 4.8 Floor (RKXS+RKAJAT+H2J) Model WMS100 System Configuration (When FC

Figure 4.9 WMS100 FC Connector................................................................... 54

Figure 4.10 Front Bezel Component Locations..................................................... 62

Figure 4.11 Front Bezel LED Locations .............................................................. 63

Figure 4.12 RKXS Component Locations............................................................. 64

Figure 4.13 RKAJAT Componen t Locations.......................................................... 64

Figure 4.14 Panel Assembly Switch Location....................................................... 65

Figure 4.15 Power Unit Switch Locations ........................................................... 66

Figure 4.16 RKNAS Switch Locations................................................................. 66

Figure 4.17 SENC Unit Connector Locations ....................................................... 67

Figure 4.18 Power Unit Connector Locations...................................................... 67

Figure 4.19 Control Unit Connector Locations..................................................... 68

Figure 4.20 RKNAS Connector Locations............................................................ 69

Figure 4.21 Disk Drive Display LED Locations...................................................... 70

Figure 4.22 Disk Drive Display (RKAJAT) LED Locations.......................................... 72

Figure 4.23 Battery Backup Unit LED Locations................................................... 72

Figure 4.24 SENC Unit LED Locations ................................................................ 73

Figure 4.25 Power Unit LED Locations.............................................................. 74

Figure 4.26 Fan Assembly LED Locations............................................................ 74

Figure 4.27 Control Unit LED Locations............................................................. 75

Figure 4.28 RKNAS (front) Connector Locations................................................... 77

Figure 4.29 RKNAS (rear) LED Locations........................................................... 78

Figure 5.1 Logical Units (When FC interface board is not added to the control unit)...... 86

Figure 5.2 Logical Units (When FC interface board is added to the control unit)........... 86

Figure 5.3 Logical Units (NAS Unit)................................................................. 87

Figure 6.1 Fibre Channel Port-to-LUN Addressing (When FC interface board is not added to

Figure 6.2 Fibre Channel Port-to-LUN Addressing (When FC interface board is added to the

Figure 6.3 Alternate Pathing ........................................................................ 98

Figure 7.1 Fibre Channel Setting...................................................................110

board is not added) ......................................................................

Interface board is added)...............................................................

Interface board is not added) ..........................................................

Interface board is added)...............................................................

the control unit)..........................................................................

control unit)...............................................................................

49

50

51

52

96

97

xviii Contents

Page 19

Figure 7.2 Logical Status Tab....................................................................... 116

Figure 7.3 Logical Status Tab (NAS) ...............................................................117

Figure 7.4 RAID Group Dialog Box.................................................................. 117

Figure 7.5 RAID Group is Updated ................................................................. 118

Figure 7.6 RAID Group is Updated (NAS)..........................................................118

Figure 7.7 Setting the Logical Unit Dialog Box................................................... 122

Figure 8.1 LAN Connector Location................................................................ 182

Figure 8.2 Main Screen Outline..................................................................... 183

Figure 8.3 Main Screen Outline..................................................................... 184

Figure 8.4 Subsystem Condition Display ..........................................................186

Table 8.5 Patrol Lamp Display..................................................................... 187

Table 8.6 Exchange Parts Status Display......................................................... 188

Acer | HDS WMS100™ User and Reference Guide xix

Page 20

List of Tables

Table 2.1 Caution Statements...................................................................... 17

Table 2.2 Symbols Contained in Warning Labels................................................. 17

Table 2.3 WMS100 Dimensions and Weight of Rack-Mount Model............................. 23

Table 2.4 WMS100 Dimensions and Weight of Floor Model..................................... 23

Table 2.5 WMS100 Dimensions and Weight of NAS Unit ........................................ 24

Table 2.6 Internal Logic Specification of WMS100 Rack-Mount Model ....................... 27

Table 2.7 Principal Functions of WMS100 Cables................................................ 27

Table 2.8 Environmental Specifications........................................................... 29

Table 2.9 Input Power and Insulation Performance Specifications for Rack-Mount Model

Table 2.10 Input Power and Insulation Performance Specifications for Floor Model........ 30

Table 2.11 Input Power and Insulation Performance Specifications for the NAS Unit ...... 30

Table 2.12 Vibration and Shock Tolerances........................................................ 31

Table 2.13 Reliability of WMS100 Rack-Mount Model............................................. 32

Table 2.14 Reliability of WMS100 Floor Model..................................................... 33

Table 4.1 Available Host Connectors of Each Topology Setting and Connection/Method. 55

Table 4.2 Available Host Connectors of Each Topology Setting and Connection/Method. 56

Table 4.3 Basic Specifications of Rack-Mount Model............................................ 59

Table 4.4 Basic Specifications of the Floor Model............................................... 60

Table 4.5 Front Bezel Component Functions..................................................... 62

Table 4.6 Front Bezel LED Functions .............................................................. 63

Table 4.7 Panel Assembly Switch Functions...................................................... 65

Table 4.8 Power Unit Switch Functions........................................................... 66

Table 4.9 RKNAS Switch Functions................................................................. 66

Table 4.10 Power Unit Connector Functions....................................................... 67

Table 4.11 Power Unit Connector Functions....................................................... 68

Table 4.12 Control Unit Connector Functions ..................................................... 68

Table 4.13 RKNAS Connector Functions ............................................................ 69

Table 4.14 Disk Drive Display LED Functions....................................................... 71

Table 4.15 Disk Drive Display (RKAJAT) LED Functions .......................................... 72

Table 4.16 Battery Backup Unit LED Functions.................................................... 72

Table 4.17 SENC Unit LED Functions................................................................ 73

Table 4.18 Power Unit LED Functions............................................................... 74

Table 4.19 Fan Assembly LED Functions............................................................ 74

Table 4.20 Control Unit LED Functions ............................................................. 75

Table 4.21 RKNAS (front) Connector Functions ................................................... 77

Table 4.22 RKNAS (rear) LED Functions ............................................................ 78

Table 5.1 Rack-Mount RAID Specifications........................................................ 83

Table 5.2 Floor Model RAID Specifications........................................................ 83

Table 5.3 Rack-Mount Model Cache Specifications.............................................. 84

Table 5.4 Floor Model Cache Specifications...................................................... 85

Table 7.1 Storage for Parameters................................................................. 108

Table 7.2 Formatting Message..................................................................... 128

Table 7.3 Simple Setting Item List................................................................146

Table 7.4 Simple Setting Item List................................................................147

Table 7.5 Additional Parameter Setting Items.................................................. 147

Table 7.6 List of Additional Parameter Setting Items .........................................159

Table 8.1 Web Operational Environment ........................................................ 178

(RKXS)......................................................................................

29

xx Contents

Page 21

Table 8.2 WMS100 WEB Function Supported Browser/Version ............................... 179

Table 8.3 Network Parameters....................................................................181

Table 8.4 Collection Mode .........................................................................220

Acer | HDS WMS100™ User and Reference Guide xxi

xxii Contents

Page 22

Page 23

Chapter 1 Overview of the WMS100 Subsystem

This chapter includes the following:

Overview Features (see section 1.1)

Rack-Mount Model (see section 1.2)

Floor Model (see section 1.3)

This chapter provides information on the Fibre and NAS models. The following table

illustrates sections that provide an explanation for each model.

Fibre Model: Connects disk array subsystem to a host computer with Fibre Channel

interface.

NAS Model: Connects NAS Unit connected to disk array subsystem to a host computer

with LAN interface.

Sections Fibre NAS

1.1 Overview Features { {

1.1.1 High Data Availability { {

1.1.2 Connectivity { {

1.1.3 Scalability { {

1.1.4 Performance Reporting and Monitoring { {

1.1.5 Reliability, Availability, and Serviceability { {

1.1.6 Hitachi Freedom Storage™ and Hitachi Freedom Data Networks™ { {

1.2 Rack-Mount Model { {

1.3 Floor Model { −

{: The explanation is provided.

—: The explanation is not provided.

Acer | HDS WMS100™ User and Reference Guide 1

Page 24

1.1 Overview Features

The Acer | HDS Workgroup Modular Storage WMS100 subsystem (hereafter referred to as the

WMS100) is available in two models: the floor model and the rack-mount model.

There are two types of the WMS100 floor model. The first type is a combination of the

DF700-RKXS (hereafter referred to as the RKXS) and the floor standing kit DF-F700-H1J

(hereafter referred to as the Floor [RKXS+H1J] Model). The second type is a combination of

the RKXS, the DF700-RKAJAT (hereafter referred to as RKAJAT), and the floor standing kit

DF-F700-H2J (hereafter referred to as the Floor [RKXS+RKAJAT+H2J] Model).

The WMS100 rack-mount model is a subsystem that combines the RKXS, the RKAJAT, and the

DF700-RKNAS2G (hereafter referred to as RKNAS). For information regarding model types,

see sections

The following WMS100 subsystem features are discussed in this section:

High Data Availability.

Connectivity.

Scalability.

Performance Reporting and Monitoring.

1.2 and 1.3.

Reliability, Availability, and Serviceability.

1.1.1 High Data Availability

The Acer | HDS WMS100 is designed for high performance and protection of user data. See

section

1.2 for additional information on the reliability and ava ilability features of the Acer

| HDS WMS100 subsystem.

1.1.2 Connectivity

The Acer | HDS WMS100 subsystem provides connectivity to most open systems through a

standard Fibre Channel interface or Network interfaces. The following paragraphs describe

the features of Fibre Channel and Ethernet:

High-Speed Data Transfer

Fibre Channel: When using the Fibre Channel interface for host interface, the WMS100

subsystem can transfer data between the host computer and the WMS100 at a maximum

speed of 200 MB/sec. Throughput can be accessed by connecting multiple devices

through the Fibre Channel, even when accessing from multiple hosts to the WMS100.

Ethernet: With the 1 G bps Ethernet connection, the subsystem can transfer data

between host computer and the subsystem at a maximum speed of 100 M bytes/s per

port via a network. Enough throughput can be got even when having multiple access to

the multiple devices connected to the same network loop.

2 Chapter 1 Overview of the WMS100 Subsystem

Page 25

Cable

Fibre Channel: With Fibre Channel, the subsystem can be located up to 300 meters from

the host.

Ethernet: With Ethernet, the subsystem can be located up to 100 meters from the host.

The subsystem can be installed in the location far from the host.

The Number of Connectable Devices

Fibre Channel: The WMS100 subsystem enables you to construct a system which can

connect up to 126 fibre channel devices by using the fibre channel interface and

connecting the FC-AL and FC-SW.

Security Function

Fibre Channel and Ethernet: When the system is configured to connect multiple hosts, a

function is provided which rejects a boot by any host except a specified host. This

function can prevent access from an illegal host.

1.1.3 Scalability

You can construct a variety of systems; for example, a system with 15 disk drives can be

configured using a single RKXS, or a more complex system can be set up using the

maximum of 105 disk drives, expanded by connecting up to 6 RKAJATs to the RKXS.

Up to 15 spare disks can be set up in any location. Use the system effectively by

configuring each spare disk in a disk drive slot left unused due to system construction.

From the host computer, the subsystem can be used as a single large-scale disk drive or

as 512 logical disks (LUs) maximum.

1.1.4 Performance Reporting and Monitoring

The Storage Navigator Modular program provides the capability to either monitor the disk

array in real-time or to collect historical data regarding the performance of the disk array.

Acer | HDS WMS100™ User and Reference Guide 3

Page 26

1.1.5 Reliability, Availability, and Serviceability

The WMS100 subsystem is not expected to fail in any way that would interrupt user access to

data. The WMS100 can sustain single component failures and still continue to provide full

access to all stored user data.

Note: While access to user data will not normally be compromised, the failure of any single

key component may degrade performance.

The reliability, availability, and serviceability features of the WMS100 subsystem include:

High-Availability capability. The Controller of the WMS100 subsystem increases data

reliability by adding original 8-byte data assurance codes to data from a host computer

by automatically generating them, writing them in the disk drive together with the data,

and checking them when reading the data. On the data bus in the controller, the

automatic generation of the data assurance codes and the check are executed to

enhance data reliability in data distribution/concentration control, particular to that

disk array.

This function monitors potential disk failure. Before failure o ccurs, the data copy

operation can be automatically performed in the background. The dynamic sparing

feature enables the subsystem to replace the spare disk due to redundancy and provides

high reliability.

Redundant power supply systems. Each WMS100 unit has a set of two power supplies.

Each power supply can provide power for the entire subsystem in the unlikely event of

power supply failure. The power supplies of each set can be connected across power

boundaries so that each set can continue to provide power if a power outage occurs.

Each unit of the WMS100 can sustain the loss of a single power su pply and still continue

operation.

High capacity cache. The WMS100 subsystem supports 1 GB high capacity cache per

controller. Writing completion can be reported to the host system when data is written

to cache.

Spare disk. To maintain the reliability, it is recommended that one spare disk is set for

15 disk drives in the subsystem with S-ATA disk drives.

4 Chapter 1 Overview of the WMS100 Subsystem

Page 27

1.2 Rack-Mount Model

The rack-mount model is composed of a single RKXS or a combination of the RKXS, RKAJAT,

and RKNAS mounted on a rack frame. The RKXS is capable of mounting up to 15 disk drives; a

controller to perform RAID control on the drives is included. The RKAJAT is capable of

mounting up to 15 disk drives and controls the drives through a connection with an RKXS.

The RKAJAT is provided with no controller.

Acer | HDS WMS100™ User and Reference Guide 5

Page 28

1.3 Floor Model

There are two floor model styles:

Floor (RKXS+H1J) Model.

Floor (RKXS+RKAJAT+H2J) Model.

The Floor (RKXS+H1J) Model is capable of mounting up to 15 disk drives and include a

controller to perform RAID control on the drives. The Floor (RKXS+RKAJAT+H2J) model is

capable of mounting up to 30 disk drives and includes a controller to perform RAID control

on the drives.

Note: For the specifications of the Floor model, refer to

Chapter 2.

6 Chapter 1 Overview of the WMS100 Subsystem

Page 29

Chapter 2 Planning for Installation and Operation

This chapter provides information for planning and preparing a site before and during

installation of the Acer | HDS WMS100 subsystem. Please read this chapter carefully before

beginning your installation planning.

Note: The general information in this chapter is provided to assist in installation planning

and is not intended to be complete. The internal WMS100 installation and maintenance

documents used by Acer | HDS personnel contain complete specifications. The exact

electrical power interfaces and requirements for each site must be determined and verified

to meet the applicable local regulations. For further information on site preparation for

WMS100 installations, contact your Acer | HDS account team or the Acer | HDS Support

Center.

This chapter includes the following:

User Responsibilities

Safety Precautions

Dimensions and Weight

Service Clearance Requirements

Floor Load Rating

Cable Requirements

Environmental Specifications

Acer | HDS WMS100™ User and Reference Guide 7

Page 30

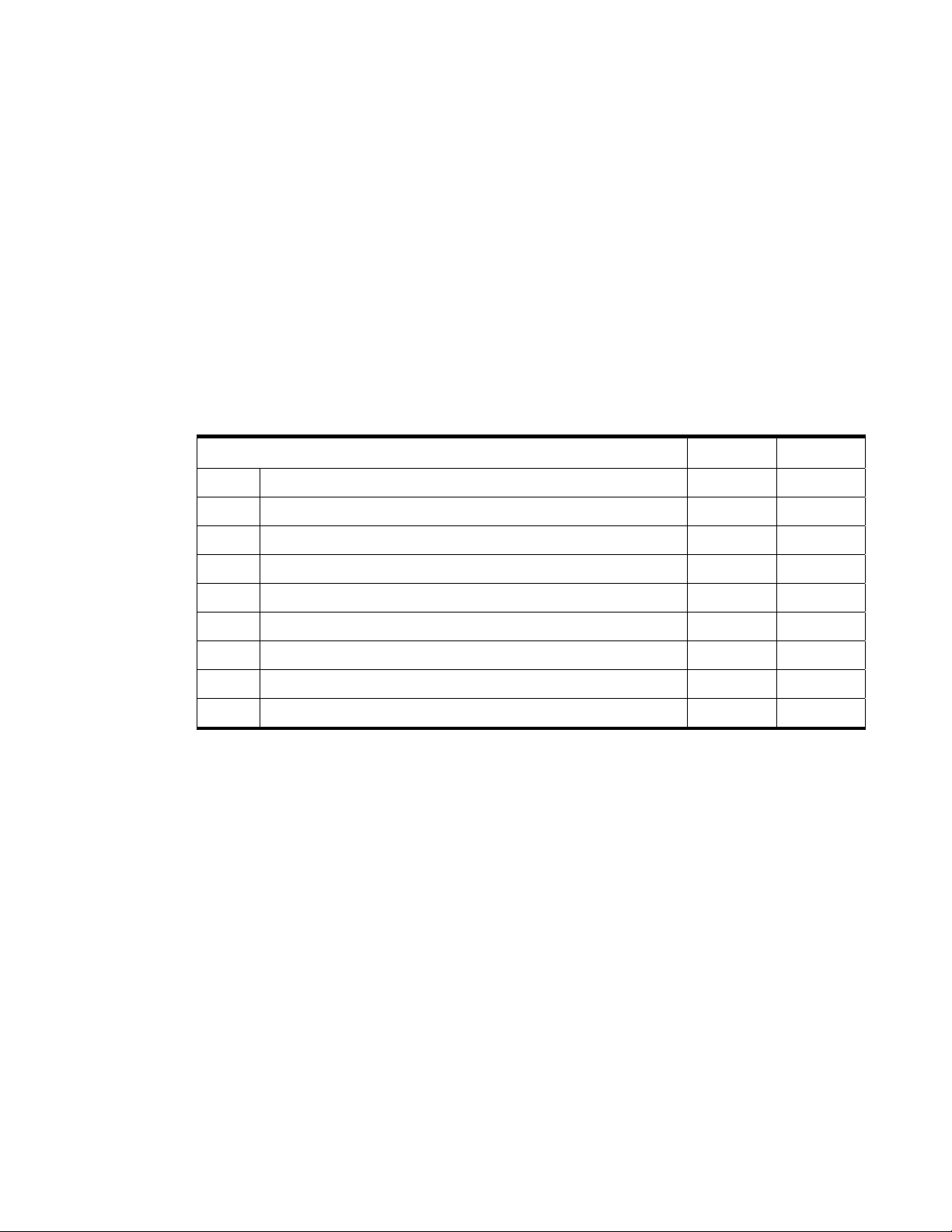

This chapter provides information on the Fibre and NAS models. The following table

illustrates sections that provide explanations for each model.

Fibre Model: Connects disk array subsystem to a host computer with Fibre Channel

interface.

NAS Model: Connects NAS Unit connected to disk array subsystem to a host computer

with LAN interface.

Sections Fibre NAS

2.1 User Responsibilities { {

2.2 2.2.1 Safety Precautions { {

2.2.2 Repair, Modification, and Diasasembly { {

2.2.3 Precautions for Using the Equipment { {

2.2.4 Precautions for Inspection and Cleaning { {

2.2.5 Emergency Precautions { {

2.2.6 Warning Notices { {

2.2.7 Locations of Warning Labels on the Equipment { {

2.3 2.3.1 Dimensions and Weight { {

2.3.2 Service Clearance Requirements { {

2.3.3.1 Floor Load Rating for the WMS100 Rack-Mount Model { {

2.3.3.2 Floor Load Rating for the WMS100 Floor Model { −

2.3.4 Internal Logic Specifications { {

2.3.5 Cable Function { {

2.4 2.4.1 Environmental Hazards { {

2.4.2 Temperature and Humidity Requirements { {

2.4.3 Input Power and Insulation Performance Specifications { {

2.4.4 Air Flow Requirements { {

2.4.5 Vibration and Shock Tolerances { {

2.4.6 Reliability { {

{: An explanation is provided.

—: An explanation is not provided.

8 Chapter 2 Planning for Installation and Operation

Page 31

2.1 User Responsibilities

Before the WMS100 subsystem arrives for installation, you must provide the following items

to ensure proper installation and configuration:

Physical space necessary for proper subsystem function and maintenance activity

Electrical input power

Connectors and receptacles

Air conditioning

Floor ventilation areas (recommended but not required)

Cable access holes

Acer | HDS WMS100™ User and Reference Guide 9

Page 32

2.2 Safety Precautions

When using the WMS100 disk array subsystem, follow these cautionary procedures:

Perform operations in accordance with the instructions or procedures descr ibed in this

manual.

Follow the cautionary notes written on labels affixed to the equipment.

Follow the cautionary notes written in this manual.

This disk array is a class 1 laser system which does not emit a hazardous laser beam.

Operate this subsystem using the instructions included in this gu ide; do not perform

operations that are not specified. Otherwise, unexpected failure s or accidents may

result.

It is impossible to describe every hazard that may exist with this equipment. Please be

aware of hazards not described in this manual. Work safely.

The following information is included in this section:

Warning Labels

Repair, Modification, and Disassembly

Precautions for Using the Equipment

Precautions for Inspection and Cleaning

Emergency Precautions

Warning Notices

10 Chapter 2 Planning for Installation and Operation

Page 33

2.2.1 Warning Labels

The warning labels which appear on the subsystem and/or in this guide indicate potential

safety hazards. When you see these symbols, observe the safety instructions that follow:

DANGER

WARNING

CAUTION

CAUTION

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

2.2.2 Repair, Modification, and Disassembly

Users must not repair, remodel, or disassemble the equipment. Such actions may cause

hazardous conditions for the user and/or the equipment.

2.2.3 Precautions for Using Equipment

Use special precautions for the following:

Equipment

Cables

Air vents

Battery unit

Nickel-Hydride rechargeable battery instructions

Miscellaneous and other

Acer | HDS WMS100™ User and Reference Guide 11

Page 34

2.2.3.1 Equipment

If you notice unusual heat generation, odors, or smoke emission, shut off the power feed

to the equipment and contact the Customer Engineer. Leaving such conditions

unattended may result in hazardous physical conditions and equipment failure.

Avoid physical disruption to the equipment. This may result in hazardous physical

conditions and equipment failure.

Do not place heavy objects on top of the disk array. Avoid using the equipment for any

use other than its original purpose; otherwise, an injury or equipment failure may result.

2.2.3.2 Cables

Avoid obstructing walkways when routing cables.

Do not allow heavy material to be placed on cables. Do not place cables near any

apparatus that generates heat. Do not step on or subject cables or connectors to

shearing or pulling forces; the cable jacket can be damaged and can break, resulting in

an electric shock, fire, or loss of data.

Make sure that electrical and signal cables are clean before connecting them. Any dirt

on a connector should be removed before inserting the connector into a socket.

2.2.3.3 Air Vents

Make certain that the air vents are free of obstruction. They should be inspected

periodically.

Do not place metallic material such as paper clips or any combustible material such as

paper into or near the air vents. This may result in electric shock or fire.

2.2.3.4 Battery Unit

Observe the following when handling the battery:

Do not disassemble or tamper with the battery.

Do not allow the battery to be physically damaged. If the battery is physically damaged,

have it replaced as soon as possible.

Do not connect the two terminals of the battery directly to each other; this will create a

short circuit.

Do not tamper with cable insulation.

Do not connect the battery to any equipment other than the WMS100 subsystem.

Do not expose the battery to high temperatures.

Use only the specified battery.

12 Chapter 2 Planning for Installation and Operation

Page 35

2.2.3.5 Nickel-Hydride Rechargeable Battery Instructions

These instructions explain what you must observe when you use a nickel-hydride

rechargeable battery (hereafter it is referred to as the battery). If you use the battery

incorrectly, it can overheat ignite, burst, or explode, damaging and deteriora ting its

performance/life. Read and follow the instructions below:

Danger

1. Do not disassemble the case; do not modify it or peel off the label. There are high

voltage parts inside: if you attempt any of these actions, this can result in electrical

shock or burning.

2. Do not disassemble the battery; this can cause short circuits inside or outside of the

battery. If the components are exposed to the air, the battery can overheat, burst or

ignite. Disassembling the battery can expose you to alkaline solution, which can be

dangerous.

3. Do not cut the output cable. Do not modify the connector. If you attempt any of these

actions, an electrical shock or burn can result. A short-circuit may cause abnormal

chemical reactions inside the battery which leads to overheating, bursting or ig nition.

4. Follow the instructions when you recharge the battery pack. If you recharge it in a way

different from specified here, it may cause the following problems: The battery may

become charged excessively; excessive current may be produced; or the battery cannot

be recharged. As a result, the battery may leak, become overheated, burst, or ignite.

5. Do not use excessive force when you connect the battery pack to the charger or other

devices. If you cannot connect it easily, check that the positive and negative positions

are correct for the connector. If you connect the battery in reverse, it will be charged

incorrectly and abnormal chemical reactions may occur inside. As a result, the battery

may become overheated, burst or ignite.

6. Do not connect the battery to a power receptacle. If you apply an excessive amount of

voltage to the battery, it may produce excessive current making the battery overheat,

burst or ignite.

7. Do not use or leave the battery where the temperature can become high, such as, near a

fire or a heating element. High temperatures can damage the battery's separator, which

may cause short circuit, making it overheat, burst or ignite.

8. Do not incinerate or heat the battery pack. If you do so, the insulator may melt, the

safety fuse/mechanism may be damaged, or the electrolyte may gush out. As a result,

the battery can burst, explode or ignite.

9. Do not connect the negative terminal to the positive with metal wire. Do not carry or

store the battery with other metal parts. This can cause a short circuit or produce an

excessive current which can cause the battery to leak, overheat, burst or ignite.

10. Do not let the battery become wet by soaking it in the water or seawater. If the battery

becomes wet, a short circuit can occur and an excessive amount of current can be

produced, causing abnormal chemical reactions inside. As a result, the battery may

become overheated, burst or ignite.

Acer | HDS WMS100™ User and Reference Guide 13

Page 36

11. Do not nail or hammer the battery. The battery may be broken or dented and a short

circuit may occur inside. As a result, the battery may become overheated, burst or

ignite.

12. Do not solder directly to the battery. If you do so, heat will melt the insulator and

damage the safety fuse/mechanism. As a result, the battery may leak or may become

overheated, burst or ignite.

Warning

13. If you find anything strange or unusual with the battery when you use/carry/store it,

remove the battery from the device and stop using it. For example, strange smells,

strange colors, or deformation are a sign you must stop using the battery.

14. If it takes longer than the specified time to complete recharging, stop recharging the

battery; otherwise, the battery may become overheated, burst or ignite.

If the battery leaks and gets into your eyes, immediately flush your eyes with clean water

(tap water) and do not rub your eye. Visit the doctor immediately. If you do not seek any

treatment for your eyes, problems may occur later. Because the battery uses highly

concentrated alkaline as electrolyte, it can burn; you may lose your sight if it makes contact

with your eyes. If the battery's liquid contacts your skin or eyes, you must flush them with

plenty of clean water and visit a doctor at once.

2.2.3.6 Miscellaneous and Other

When a failure occurs in the unit, take action according to the procedures recommended in

this manual. If the difficulty does not correspond to the corrective measures documented in

this manual, contact the Customer Engineer.

14 Chapter 2 Planning for Installation and Operation

Page 37

2.2.4 Inspection and Cleaning Precautions

If a maintenance activity requires that the unit be powered off, make sure that the

power-off sequence described in the manual is performed before proceeding with

maintenance.

Do not work on the unit in a damp or flooded environment.

Do not obstruct access to the unit with parts or tools.

When performing the work with the door open, take off metal watches or jewelry to

prevent electric shock. If you wear metal-frame glasses, do not touch the equipment.

Ensure that loose clothing, jewelry, or hair do not become tangled in moving

components.

There are high-voltage parts in the equipment. Observe the cautionary statements in the

manual to make sure that high-voltage components are not touched during maintenance.

Another person should be on alert to shut off the power feed to the equipment.

After the power feed to the equipment is shut off, electricity remains in the equipment

for a period of time. Therefore, do not touch any components other than those indicated

in this manual.

The equipment can become extremely hot. Do not touch any part other than those

indicated in this manual.

When working with the door open, wear cotton gloves to prevent your hands from

touching sharp objects.

Acer | HDS WMS100™ User and Reference Guide 15

Page 38

2.2.5 Emergency Precautions

Follow these emergency precautions for the following:

Electric Shock

Fire

2.2.5.1 Electric Shock

Do NOT immediately touch the person struck by electricity. You could be the second

victim.

To shut off the electric flow to a victim, disconnect the power feed cable of the

equipment. In spite of this action, electricity may not be shut off. Separate the victim

from the current source by using a non-conductive material such as dry wooden bar.

Call an ambulance.

When the victim has lost consciousness, practice artificial respiration on the victim. To

prepare for such a case, learn how to practice artificial respiration.

When the victim’s heart has stopped, give a heart massage. This treatment should only

be conducted by a person who has been trained and qualified.

2.2.5.2 Fire

To shut off the electric flow to the equipment, pull out the power feed cable. This will

If a fire cannot be extinguished when the electric flow has been shut off, use fire-

terminate the power supply.

fighting procedures and contact the fire department.

16 Chapter 2 Planning for Installation and Operation

Page 39

2.2.6 Warning Notices

2.2.6.1 Caution Statements

Caution statements described in this manual and the pages where they appear are listed

below. Caution statements are indicated by the caution symbol:

Table 2.1 Caution Statements

Warning Statement Corresponding Page

Cooling fans rotate at a high speed. Keep body parts and loose clothing away

from the cooling fans.

When cleaning, take care not to touch electrically charged parts. Electric shock

may result.

Do not touch electrically charged components during parts replacement. Electric

shock may result.

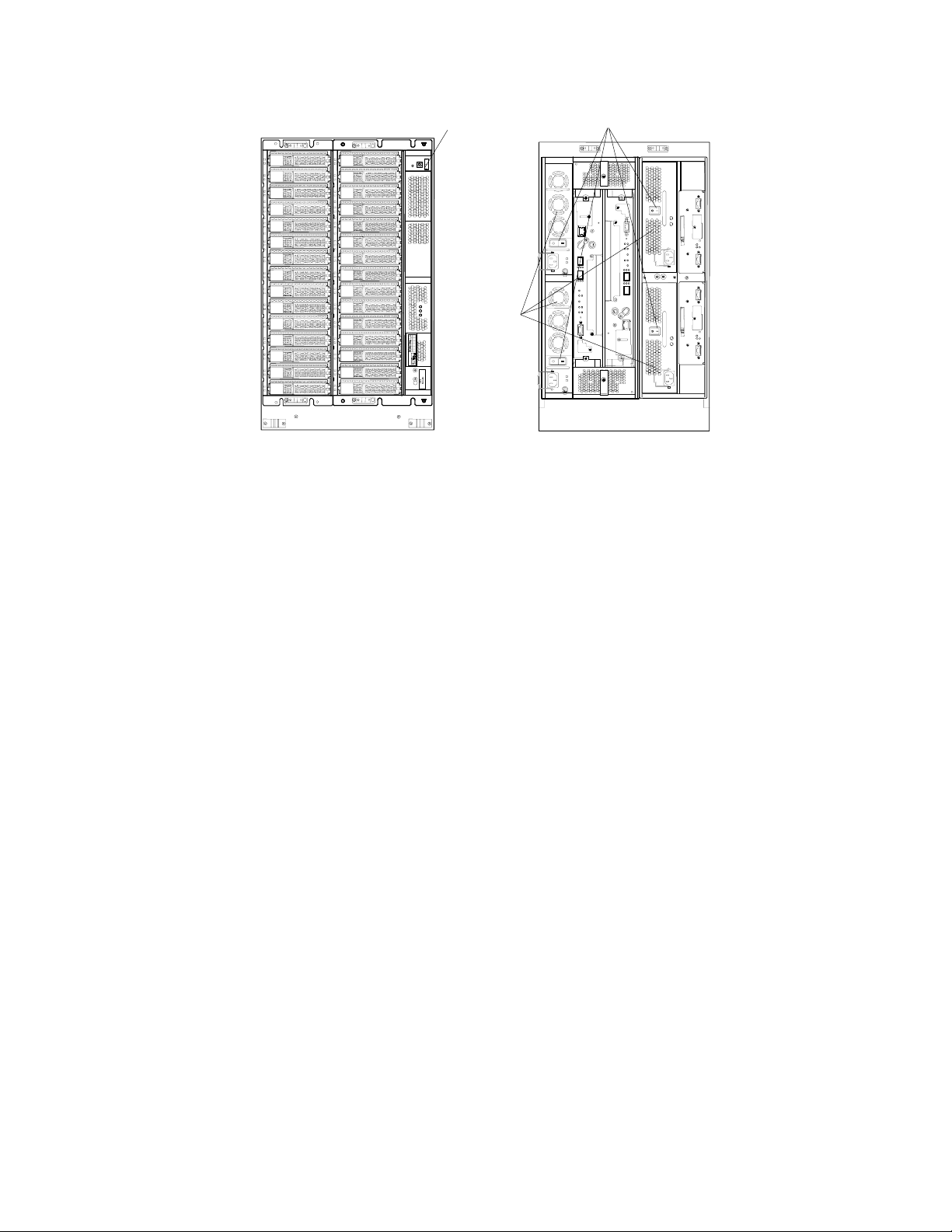

2.2.7 Warning Label Locations

Warning labels are pasted on sections of equipment which require special care. Read the

messages and observe the warning procedures. They are shown in the following figures:

Floor Model RKXS+H1J.

Rack-Mount Model RKXS+RKAJ+H2J.

Floor Model RKXS.

Rack-Mount Model RKAJAT.

Table 2.2 lists and describes the symbols contained in warning labels.

Table 2.2 Symbols Contained in Warning Labels

15

15, 16

16

Symbol Mark Description

Caution-electric shock.

Caution-very hot.

Acer | HDS WMS100™ User and Reference Guide 17

Page 40

Figure 2.1 Position of Labels on Floor Model RKXS+H1J

18 Chapter 2 Planning for Installation and Operation

Page 41

Figure 2.2 Position of Labels on Floor Model RKXS+RKAJAT+H2J

Acer | HDS WMS100™ User and Reference Guide 19

Page 42

Figure 2.3 Position of Labels on Rack-Mount Model RKXS

20 Chapter 2 Planning for Installation and Operation

Page 43

Figure 2.4 Position of Labels on Rack-Mount Model RKNAS

Acer | HDS WMS100™ User and Reference Guide 21

Page 44

Figure 2.5 Position of Labels on Rack-Mount Model RKAJAT

22 Chapter 2 Planning for Installation and Operation

Page 45

2.3 General Specifications and Requirements

This section describes the general specifications and requirements for the WMS100

subsystem. The following are included:

Dimensions and Weight

Service Clearance Requirements

Floor Load Rating

Internal logic specifications

Cable Requirements.

2.3.1 Dimensions and Weigh

The following table illustrates the dimensions and weight of the WMS100 rack-mount model

and the WMS100 floor model.

Table 2.3 WMS100 Dimensions and Weight of Rack-Mount Model

Rack-mount Model Item Model

RKXS RKAJAT

Physical

Specifications

Chassis size (W×D×H)

(mm)

Mass (kg) 56 approx 40 approx

Acoustic noise (dB) 59 approx 60 approx

Required height (EIA unit)

483×650×174 483×650×129

4 3

Table 2.4 WMS100 Dimensions and Weight of Floor Model

Floor Model Item Model

Physical

Specifications

Floor (RKXS+H1J) Model

Chassis size (W×D×H)

(mm)

Mass (kg) 70 approx 115 approx

Acoustic noise (dB) 59 approx 60 approx

260×737×540 309×737×540

Floor (RKXS+RKAJAT+H2J)

Model

Acer | HDS WMS100™ User and Reference Guide 23

Page 46

Table 2.5 WMS100 Dimensions and Weight of NAS Unit

Item Model

Physical

Specifications

Chassis size (W×D×H)

(mm)

Mass (kg) 15 approx

Acoustic noise (dB) 60 approx

483×650×43

RKNAS

24 Chapter 2 Planning for Installation and Operation

Page 47

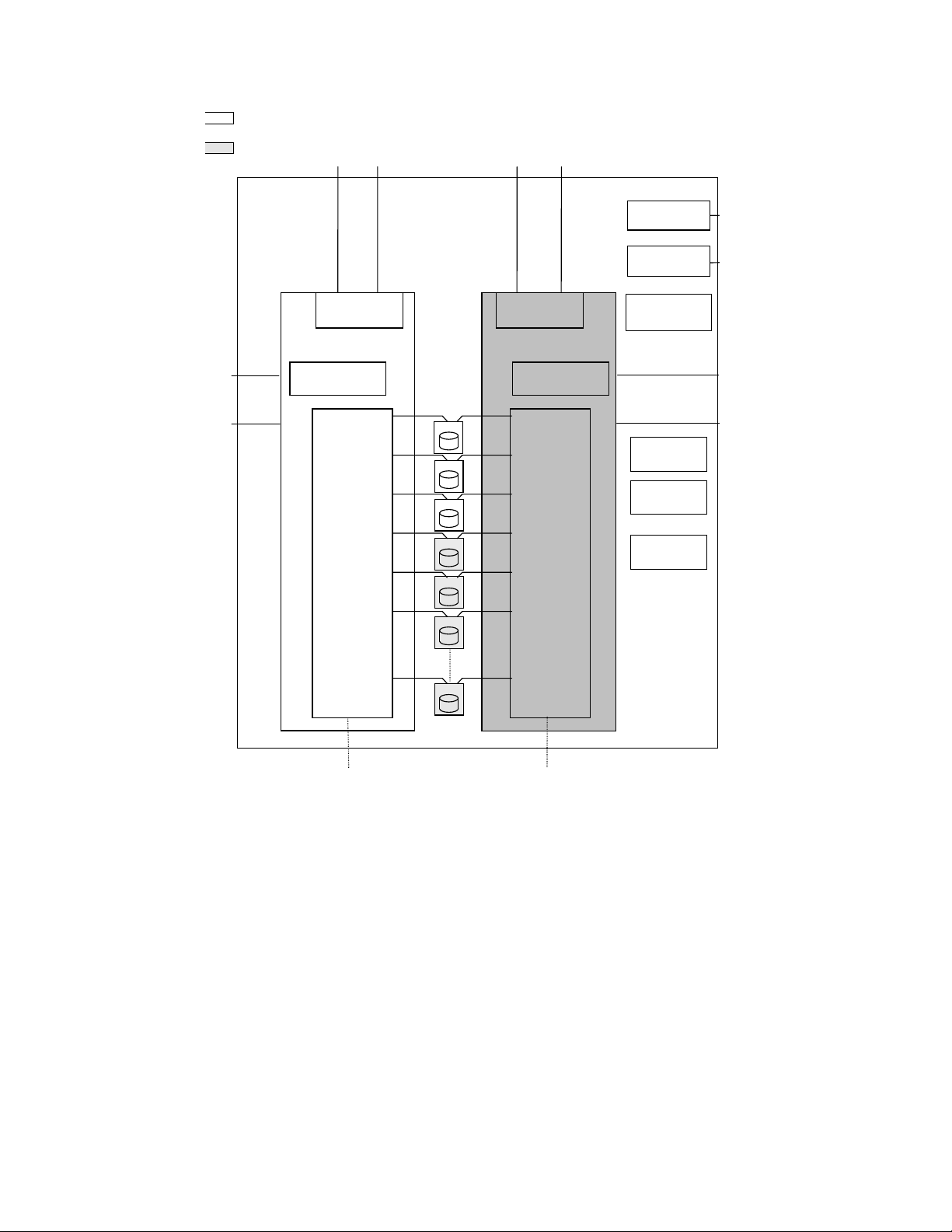

2.3.2 Service Clearance Requirements

The following figure shows the floor area required for installing the equipment. Install the

equipment in a place with the area shown in the figure to avoid problems suc h as inadequate

service clearance or insufficient ventilation. All distances in the following figure are stated

in millimeters (mm).

420

622.5

18

Legend

: Area required for maintenance of the equipment

: Outside line of the equipment

: Area for opening/closing the door

: Leveling bolt position

: Caster position

: Front side of the equipment

255.8

219.8

18

75

562.5

30

75

472.5

420

18

622.5

305.9

269.9

18

75

30

562.5

75

472.5

75

300

30

18 18

59.7 59.7

136.4

Floor (RK X S+ H 1 J) M od e l

75

300

18 18

59.2 59.2

187.5

Floor (RKXS+RKAJAT+H2J) Model

30

Acer | HDS WMS100™ User and Reference Guide 25

Page 48

2.3.3 Floor Load Rating

This section includes:

Floor load rating for the WMS100 rack-mount model

Floor load rating for the WMS100 floor model

2.3.3.1 Floor Load Rating for WMS100 Rack-Mount Model

In the maximum configuration, the rack-mount model can be configured with 1 RKXS and 6

additional units (RKAJATs and RKNAS). The total weight of the subsystem in this

configuration is 530 kg.

Note: For information about the global rack-mount model, refer to the Acer | HDS Global

19-Inch Rack Reference Guide (MK-93DF665).

2.3.3.2 Floor Load Rating for WMS100 Floor Model

The Floor (RKXS+H1J) Model contains up to 2 controller boards and up to 15 disk drives. The

maximum configuration weighs 70 kg. To ensure adequate load-bearing capacity, plan for

the maximum configuration.

The Floor (RKXS+RKAJAT+H2J) Model contains up to 2 controller boards and up to 30 disk

drives. The maximum configuration weights 115kg. To ensure ad equate load-bearing

capacity, plan for the maximum configuration.

26 Chapter 2 Planning for Installation and Operation

Page 49

2.3.4 Internal Logic Specifications

The following table lists the internal logic specifications of the WMS100.

Table 2.6 Internal Logic Specification of WMS100 Rack-Mount Model

Item Specification

RKXS RKNAS

Internal logic

specification

Notes:

RKAJAT is not included in these specifications.

For information about the global rack-mount model, refer to the Acer | HDS Global 19-

Inch Rack Reference Guide.

2.3.5 Cable Function

The following table lists the principal functions of the WMS100 and RKNAS cable. Fibre

channel cables are available from Acer | HDS.

Control CPU Power PC7447A (500 MHz) Intel LV-Xeon 2.8GHz

Control memory Flash memory: 2 M bytes

L2 cache memory: 512 k bytes

SRAM: 64 M bytes

Data assurance method Data bus: Through-parity

Cache memory: ECC (1 bit for

correction, 2 bits for detection)

Disk drive: Data assurance code

Bios: 1 M bytes

L2 cache memory: 1M bytes

Data bus: Through-parity

Memory (DIMM): ECC (1 bit for

correction, 2 bits for detection)

Table 2.7 Principal Functions of WMS100 Cables

Cable Principal Use

Fibre Channel cable Connect with a host or HBA/Switch. (for Fibre Channel)

LAN cable (Cross/ Straight) Connect the PCs for user, monitoring and maintenance.

Connect with a HAB for Ethernet. (When RKNAS is connected)

Connect between RKM and RKNAS for maintenance management.

ENC (ENCLOSURE) cable Connect between the subsystems with Fibre Channel (FC_AL).

NAS interface cable Connect between RKM and RKNAS for NAS control. (When RKNAS is

connected)

Acer | HDS WMS100™ User and Reference Guide 27

Page 50

2.4 Environmental Specifications and Requirements

To maintain optimal WMS100 performance, the WMS100 subsystem must be installed in a

proper environment. This section discusses the following necessary environmental

specifications and requirements:

Environmental hazards

Temperature and humidity requirements

Input power and insulation performance specifications

Air flow requirements

Vibration and shock tolerances

Reliability

2.4.1 Environmental Hazards

Do not install the subsystem in the places described below; the life of equipment

functioning will be shortened and equipment failures will occur. Avoid the following:

Direct sunlight exposure

Temperature and humidity variation (for example, near an air conditioner)

Close proximity to a device that generates electrical noise and motion (for example, air

conditioner that is not grounded and washing machine motor)

Close proximity to an apparatus that generates a strong magnetic field

Excessive dust

Frequent vibrations

An inclined floor

Note: Do not store or install the equipment in a high temperature environment of 40 degrees

centigrade or more - battery life will be shortened.

28 Chapter 2 Planning for Installation and Operation

Page 51

2.4.2 Temperature and Humidity Requirements

Table 2.8 lists the temperature and humidity requirements for the WMS100 subsystem.

Table 2.8 Environmental Specifications

Item Specification

Temperature

Humidity

In operation (°C) 10 to 40

In non-operation (°C) -10 to 50

In transport/storage (°C) -30 to 60

Temperature change rate (°C/h) 10 or less

In operation (%) 8 to 80

In non-operation (%) 8 to 90

Maximum wet bulb temperature (°C) 29 (non-condensing)

In operation (m) -300 to 3,000 Altitude

In non-operation (m) -300 to 12,000

2.4.3 Input Power and Insulation Performance Specifications

The following tables list the input power and insulation performance specifications f or the

WMS100 rack-mount model and the WMS100 floor model.

Conductors shall be provided with 30 A over current protection in accordance with Article

240 of the National Electrical Code, ANSI/NFPA 70, and the Canadian Electrical Code, Part 1,

CSA C22.1, Section 14.

Table 2.9 Input Power and Insulation Performance Specifications for Rack-Mount Model (RKXS)

Rack-Mount Model Item Model

RKXS RKAJAT

Input power

specification

Insulation Insulation withstand voltage AC 1,500 V (10 mA, 1 min)

performance Insulation resistance DC 500 V, 10 M Ω or more

Note 1: Power current of Nx2 described above is required for operation by a single power supply unit.

Note 2: It indicates the current consumption in the usual state. When a power supply failure occurs, the power

consumption is provided by the single power supply for the subsystem.

Input voltage (V) AC 100/200 (100-120/200-240)

Frequency (Hz) 50/60 ± 1

Number of phases, cabling Single-phase with protective grounding

Steady-state current (A) (Note1) (Note2)

Breaking current (A) 16.0

Steady state (VA) 600 or less 480 or less Required power

Starting state (VA) 600 or less 480 or less

Heat value (kJ/h) 2,160 or less 1,730 or less

3.0×2/1.5×2 2.4×2/1.2×2

Acer | HDS WMS100™ User and Reference Guide 29

Page 52

Table 2.10 Input Power and Insulation Performance Specifications for Floor Model

Floor Model Item Model

Floor (RKXS+H1J) Model Floor (RKXS+RKAJAT+H2J)

Model

Input power

specification

Insulation

performance

Note: Power current of Nx2 described above is required for operation by a single power supply unit.

Input voltage (V) AC 100/200 (100-120/200-240)

Frequency (Hz) 50/60 ± 1

Number of phases,

cabling

Steady-state current (A)

(Note)

Breaking current (A) 16.0

Required

power

Heat value (kJ/h) 2,160 or less 3,890 or less

Insulation withstand

voltage

Insulation resistance DC 500 V, 10 M Ω or more

Steady state

(VA)

Starting

state (VA)

Single-phase with protective grounding

3.0×2/1.5×2 3.0×2+2.4×2/1.5×2+1.2×2

600 or less 1,080 or less

600 or less 1,080 or less

AC 1,500 V (10 mA, 1 min)

Table 2.11 Input Power and Insulation Performance Specifications for the NAS Unit

Item Model RKNAS

Input power

specification

Insulation

performance

Input voltage (V) AC 100/200 (100-120/200-240)

Frequency (Hz) 50/60 ± 1

Number of phases,

cabling

Steady-state current (A) 2.0/1.4

Breaking current (A) 16.0

Required

power

Heat value (kJ/h) 1,010 or less

Insulation withstand

voltage

Insulation resistance DC 500 V, 10 M Ω or more

2.4.4 Air Flow Requirements

The WMS100 subsystem is air-cooled. Air must enter the subsystem through the airflow

intakes at the front of each subsystem and must be exhausted out of the back.

Steady state

(VA)

Starting

state (VA)

Single-phase with protective grounding

280 or less

280 or less

AC 1,500 V (10 mA, 1 min)

30 Chapter 2 Planning for Installation and Operation

Page 53

2.4.5 Vibration and Shock Tolerances