Page 1

MW22

Service Manual

Service Manual

LCD Monitor MW22

Copyright

Copyright 2009 Innolux Display Corp. Ltd

All Rights Reserved

This manual may not, in whole or in part, be copied, Photocopied, reproduced, translated, or converted to any

electronic or machine readable form without prior written permission of Innolux Display Corp. Ltd.

MW22 Wide Service Manual

- 0 -

Page 2

1

Table of Contents

Important Safety Notice ......................................................................................02

01 Product Specification .......................................................................................03

02 Flat Panel Specification ....................................................................................29

03 Exploded Diagram ............................................................................................59

04 Troubleshooting..................................................................................................61

05 Spare Parts List .................................................................................................69

06 Schematics and Layouts....................................................................................73

07 Assembly and Disassembly .............................................................................88

1

Page 3

MW22

Service Manual

Important Safety Notice

1. Safety precautions

This monitor is manufactured and tested on a ground principle that a user’s safety comes first. However,

improper usage or installation may cause damage to the monitor as well as to the user.

Warnings:

z This monitor should be operated only at the correct power sources indicated on the label on the rear of the

monitor. If you’re unsure of the power supply in you residence, consult your local dealer or Power

Company.

z Do not try to repair the monitor by yourself, as it contains no user-serviceable parts. This monitor should

only be repaired by a qualified technician.

z Do not remove the monitor cabinet. There is high-voltage parts inside that may cause electric shock to

human bodies.

z Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

z Put your monitor only in a lean, cool, dry environment. If it gets wet, unplug the power cable immediately

and consult your closed dealer.

z Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth. Apply

non-ammonia based cleaner onto the cloth, not directly onto the class screen.

z Do not place heavy object on the monitor or power cord.

2. Product safety notice

Many electrical and mechanical parts in this chassis have special safety visual inspections and the

protection afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Before replacing any of these components read the parts list in this manual

carefully. The use of substitute replacement parts, which do not have the same safety characteristics as

specified in the parts list, may create shock, fire, or other hazards.

3. Service notes

z When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

z Keep wires away from high voltage, high temperature components and sharp edges.

z Keep wires in their original position so as to reduce interference.

z Adjustment of this product please refers to the user’s manual.

2

Page 4

MW22

Service Manual

01 Product Specification

1. General:

MW22 series LCD monitor is designed with a wide screen 22” WSXGA+ TFT LCD panel, LVDS interface, RGB analog and digital

input(option).

It featured with embedded universal AC power supply. This monitor can support maximum resolution up to 1680x1050@60Hz.

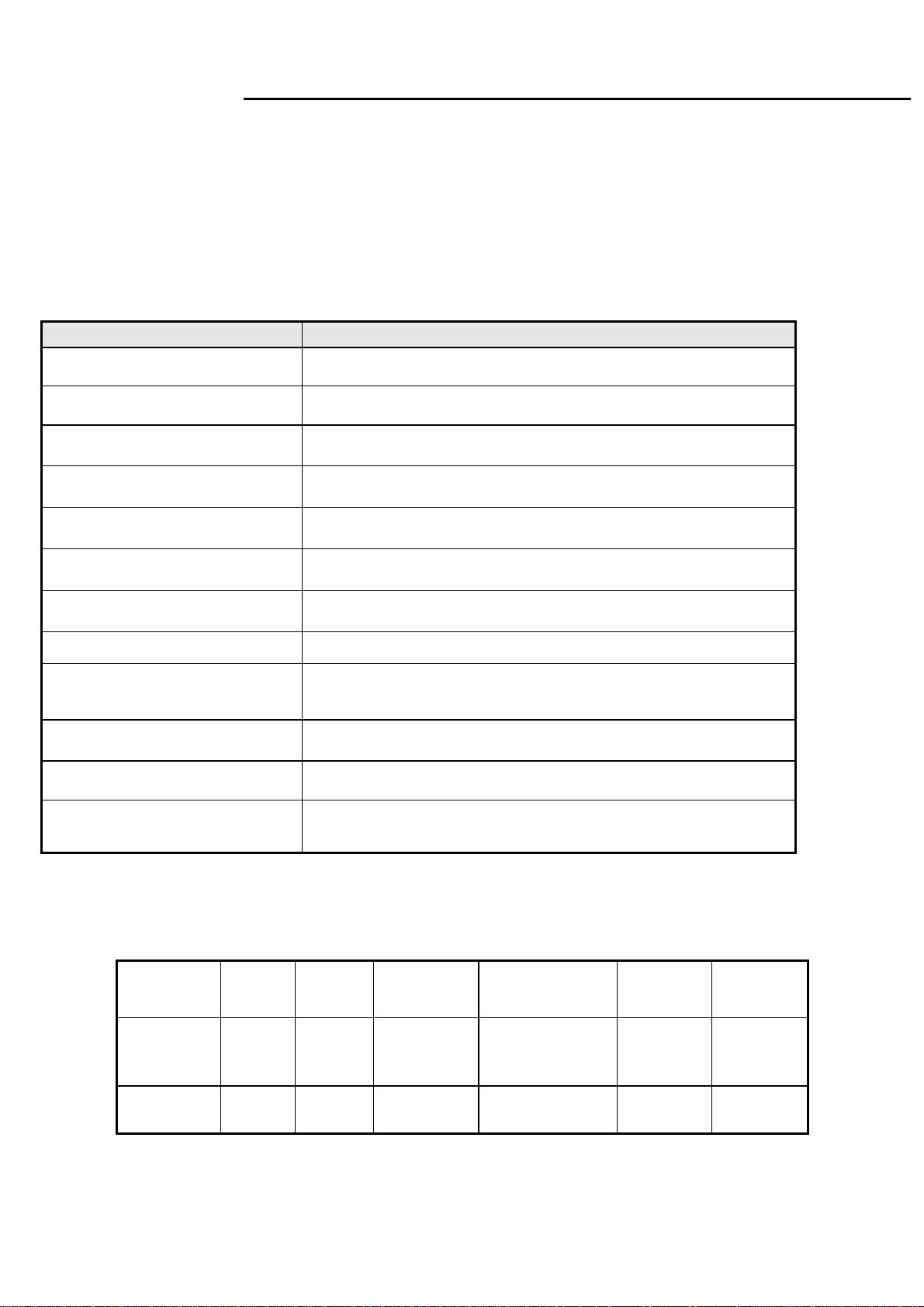

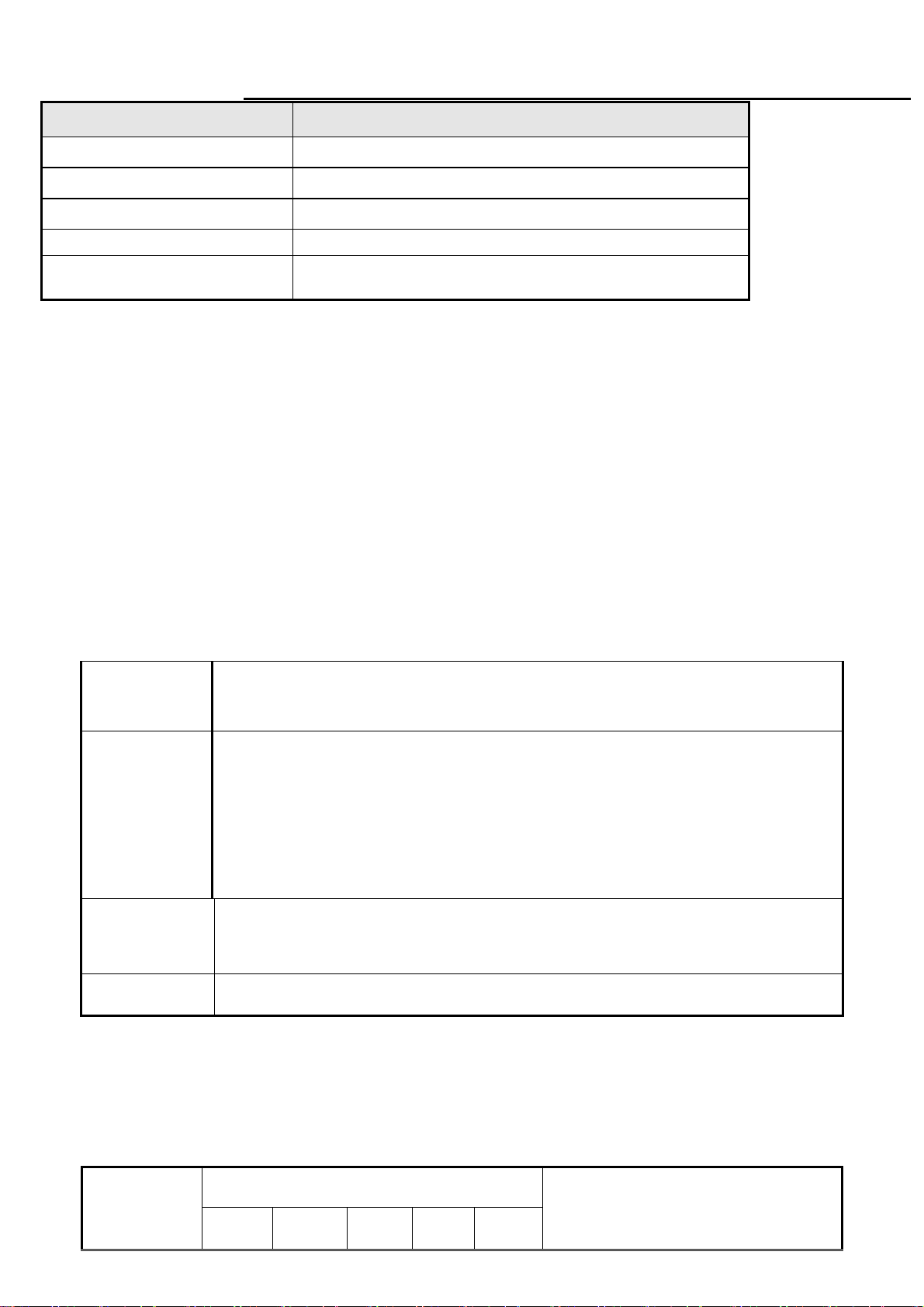

1.1 Main Features

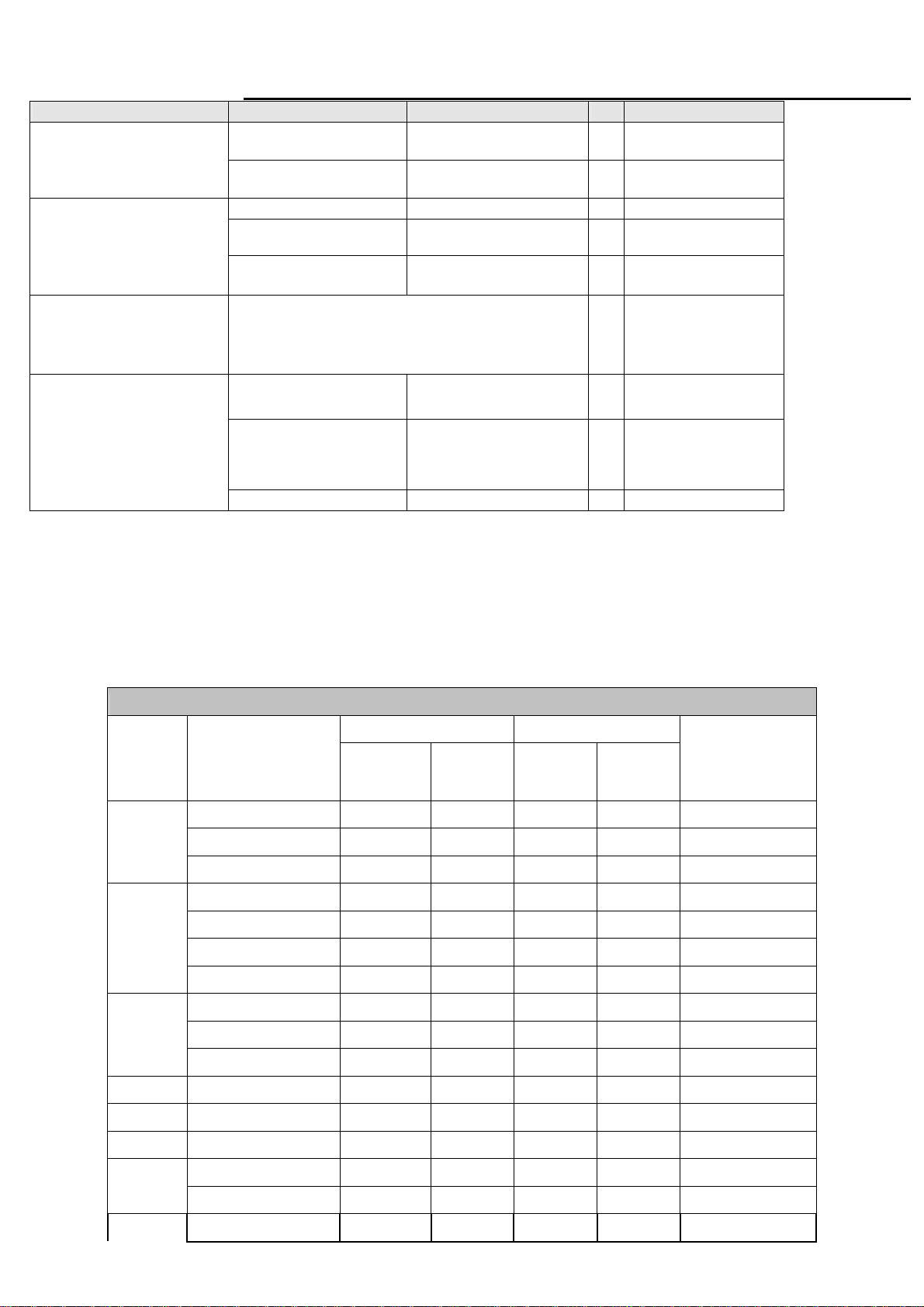

1.1.1 For SEC LTM220MT05 panel

Features Specifications

Maximum resolution

Back light system 2 CCFL

Actual Resolution display WSXGA + resolution(1680x1050)

Pixel pitch

Display area 473.76mm(H)x296.1mm(V)

Contrast ratio 600:1(min.),1000:1(typ.)10000:1(DCR)

Response time (Tr+Tf) 5ms(Typ.),8ms(Max)

Viewing angle

Input interface

Power management Compatible with VESA DPMS, Energy Star

Plug & Play VESA DDC/CI

1680x1050@60Hz

0.282mm(H)x0.282mm(W)

80°(L)/ 80°(R),80°(U)/80°(D) typ. (CR>=10)

Analog(D-sub 15pin);

Digital Optional (DVI-D with HDCP function)(option).

OSD language

English,French,Italian,Finnish,Spanish,German,Dutch,Russian

1.2 Accessories

AC

Items

Description 1.8m 1.8m 1.8m 1.8m Multi

Power

Cord

● ● ● ● ● ●

VGA

cable

Audio cable

3

DVI_D

Cable(option)

User’s

manual

Warranty

card

Page 5

MW22

Service Manual

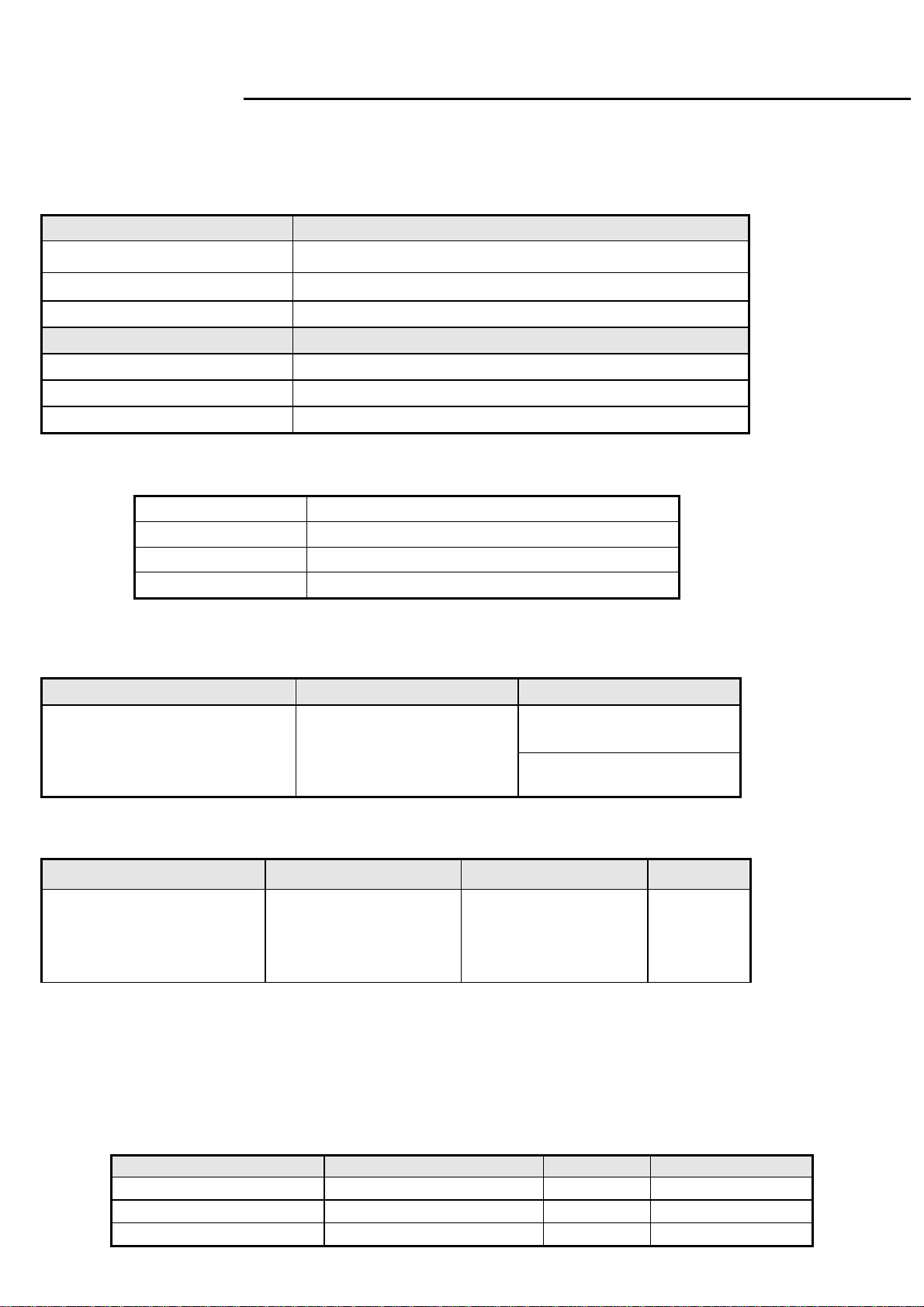

2. Operation Specifications

The unit should suffer no visible cosmetic damage and should operate with no degradation in display quality during

exposure to the operating conditions and after exposure to the non-operating conditions, in any sequence.

2.1 Environmental conditions

Operating Specification

Temperature range

Relative humidity 20% to 90%

Altitude 0 to 3048 M (10000 ft)

Storage

Temperature range

Relative humidity 10% to 90%

Altitude 0 to 12192M (40000 ft)

0°C to 50°C

-20°C to 60°C

2.2 Safety, EMC, Ergonomics and Compatibility Requirements

Safety & EMC

Ergonomics

Compatibility

Power Management

CB, VCCI, FCC-B, CCC, ,MET

MPRII, ISO-13406-2,

Windows 98/Me/2000, Windows XP, Window Vista

Energy Star

2.3 Electrostatic Discharge Requirements

Item Remark Spec

Contact discharge : ±8KV

Electrostatic Discharge

Air discharge : ±15KV

2.4 Reliability

Items Condition Spec Note

Temp: 25+/-2℃

CCFL Life time

Current: 7mA

Brightness: ≥50%

≧ 50,000 Hours

3. Electrical and Optical Characteristics and Performance

3.1 Main Power Supply

3.1.1

Input characteristics

Items Condition Spec Note

AC Input Voltage range Universal input full range 90~264Vac

AC Input Voltage rating Universal input full range 100~240Vac

AC input frequency range 90~264Vac 47~63Hz

Excluding the

LCD, CCFL

4

Page 6

MW22

A

Service Manual

AC input frequency rating 100~240Vac 50~60Hz

100Vac 1.2A

AC Input Current

240Vac 0.6A

Inrush Current

Regulator Efficiency

100 V AC cold star,25°C <35A

240 V AC cold star,25°C <70A

DC output full loading ≥80%

Note 1: Before each test, the buck capacitor needs to be discharged.

Before each test, it must be 10 minutes at least after the latest test.

Hot star not component be damaged.

3.1.2 Output characteristics

Items Condition Spec Note

Ripple and Noise

DC Output Voltage

5v loading:0.04A~1.5

DC output loading capability

Rise Time

Dynamic load change

Hold-up time

Overshoot

Turn on delay time

+24V output <1000mv

+5V output <200mv

audio 5V output <300mv

24v loading:0.1A~0.7A

5v loading:0. 7A~1.5A

audio 5v loading:0A~1.0A

14V loading: 0A

audio 5v loading:0A

Vcc5V/1.5A

<50mS

AC input: 100V~240V >10mS

<10%

<2S

Vcc24V:23V~28V

Vcc5V:4.85V~5.35V

audio 5v:4.5V~5.5V

Vcc24V: 23V~30V

Vcc5V: 4.85V~5.35V

audio 5v:4.5V~5.5V

Vcc24V/0.7A

audio 5V/1.0A

See Note1

active

off

See note 2

For system

For power

saving or DC

Power management See Table-1

Note 2: Tested by DC loading side parallel with a 47uF/EC and 0.1uF/Ceramic Capacitors and measured band-width with

DC-20MHz.

DC 24V ripple =2400mV when inverter enters Burst Mode.

3.1.3 Protection characteristics

Protection Condition Spec

OPP nominal AC input 55W ( min )

SCP(short circuit protection) Before fuse with auto-recovery function

OVP(Over voltage protection) Auto recovery <output capacitor voltage

5

Page 7

MW22

Service Manual

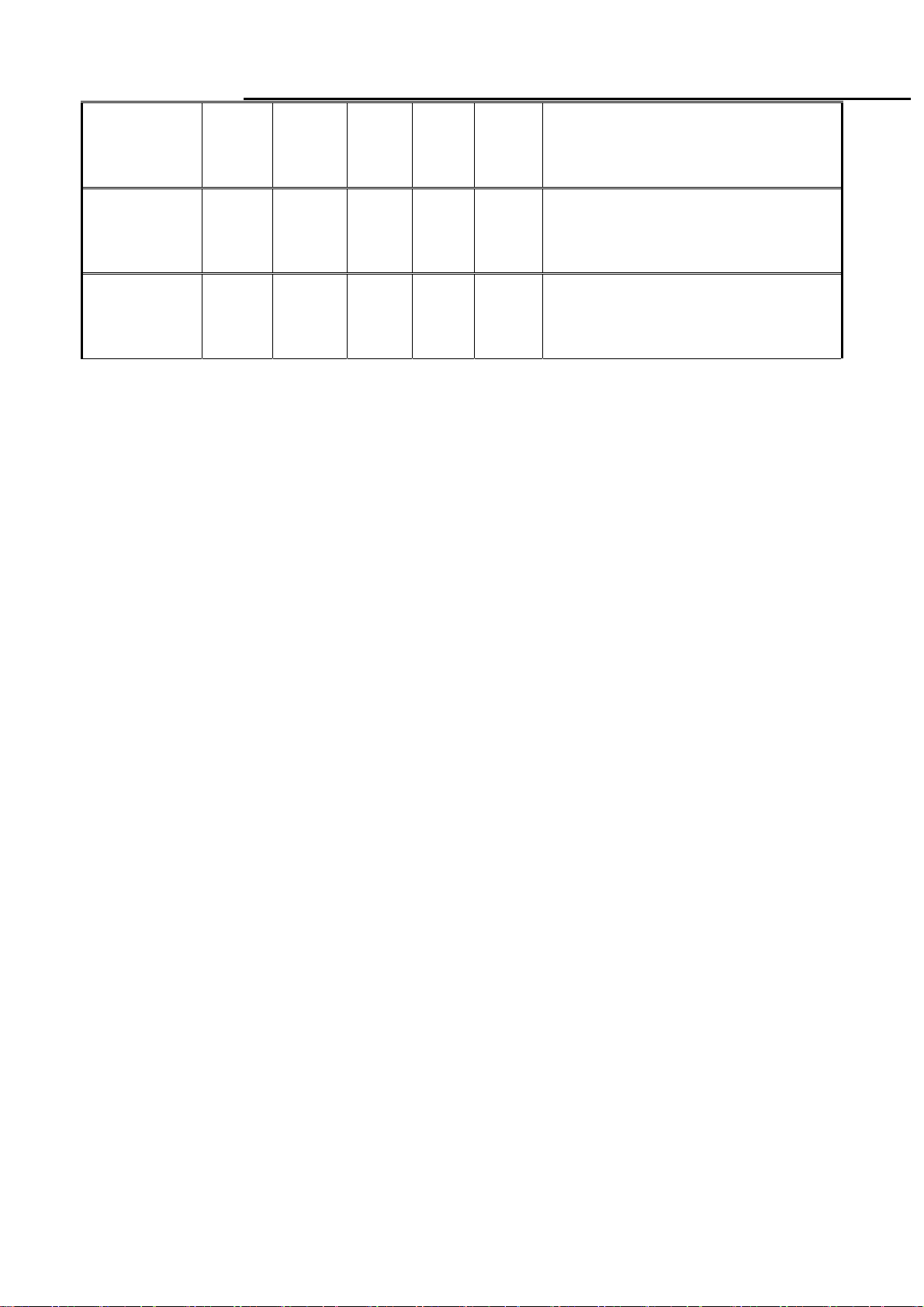

Table-1

Status

Power On(with audio)

Power Saving

Power Off -- -- -- < 1W Off

H-sy

nc

3.2 Backlight Power Supply

Items Specification

V-s y

nc

on on active ≤40W Blue

off on blanked < 2W Amber

on off blanked < 2W Amber

off off blanked < 2W Amber

Video Power LED

Panel

Lamp 2 CCFL

Input Voltage DC 23~28 V

Input current 0.55A (Typ.), 0.7A (Max.)

On/Off switch level

Brightness PWM Duty (ACM Off)

Brightness PWM Duty (ACM On)

CCFL operating Voltage 760Vrms (Typ.),

CCFL Current

SEC LTM220MT05 panel

5.5V≧Von≧ 2.0 V (on)

-0.3v ≤ Voff ≤ 0.8 V (off)

30%~100%

10%~100%

2.0 mA (min.)

7.5mA (Typ.)

8.0 mA (Max.)

CCFL startup voltage

Operating frequency 40~60KHz

Protect delay time > 1 second

Efficiency ≥70% (Using dummy load)

≧1700 Vrms (0˚C)

3.3 Input / Output Signal Specifications

3.3.1 Video signals

6

Page 8

MW22

Service Manual

Items Condition Spec OK

Signal Cable

Analog

Digital(option)

15 pin D-Sub

DVI-D(option)

Color: BLACK

Length: 1800

Color: BLACK

Length: 1800

+/-

+/-

20 mm

20 mm

Signal type Separate analog R,G,B

Level 700 mV +/- 5% (peak to

peak)

Impedance 75 Ohms +/- 2% Ohms

Base on TMDS technology

Monitor side should be

●

blue right angle.

NO DVI cable in carton

For 15 pin D-sub

●

●

●

●

Note

Signal type Separate H/V-sync

For 15 pin D-sub

●

(Positive/Negative)

Sync

Level Logic High: 2.0V ~ 5.5V

Logic Low: 0V ~ 0.8V

Refer to VESA VSIS

●

Standard V1R1

(TTL level)

Termi nal

≧

2.2k

Ω

●

Ω

for application

2.2K

3.3.2

Signal Timing

Through D-SUB and DVI(option) connectors, this unit can support FH= 31~83 KHz, Fv=56~76 Hz.

Modes details as below:

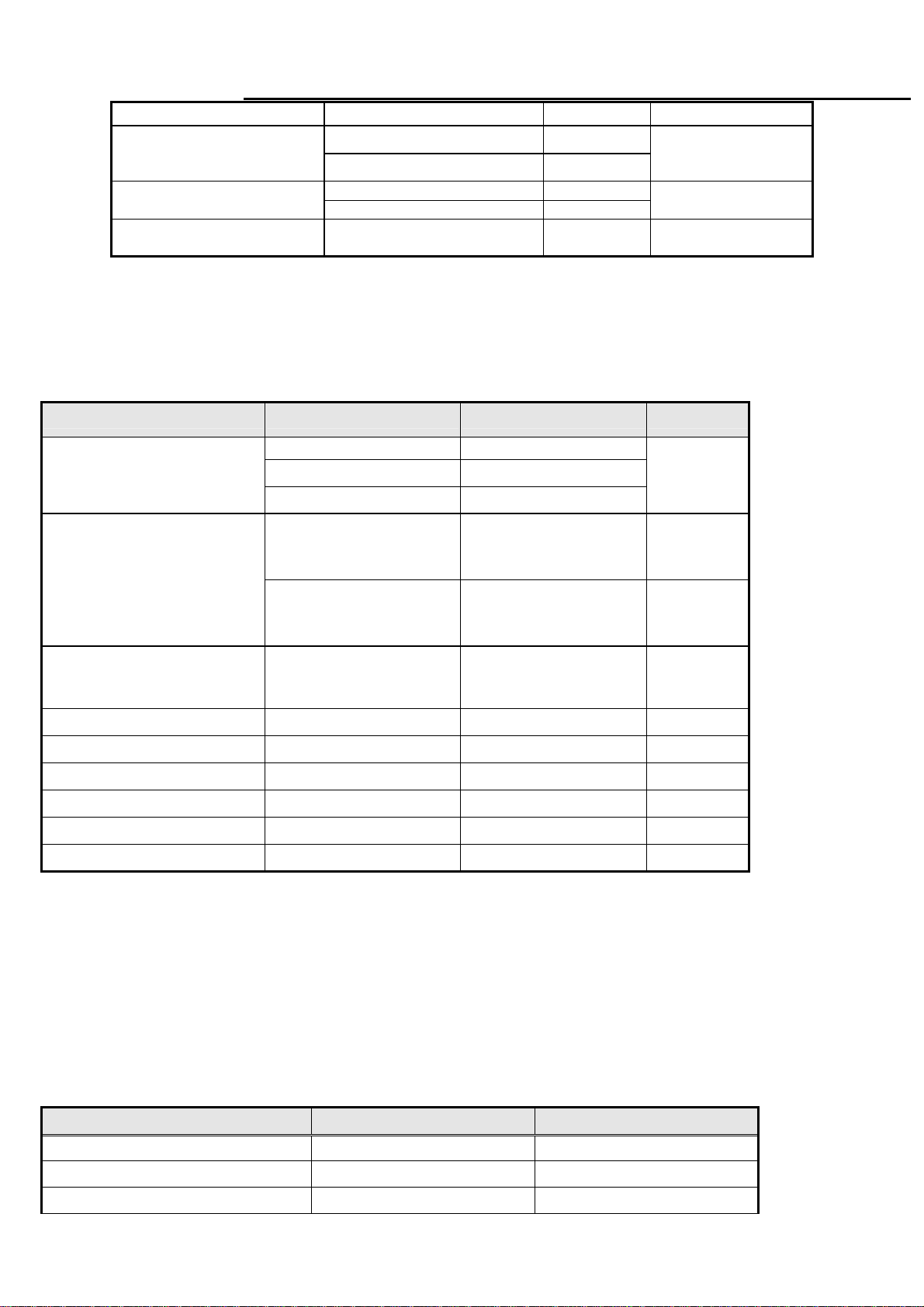

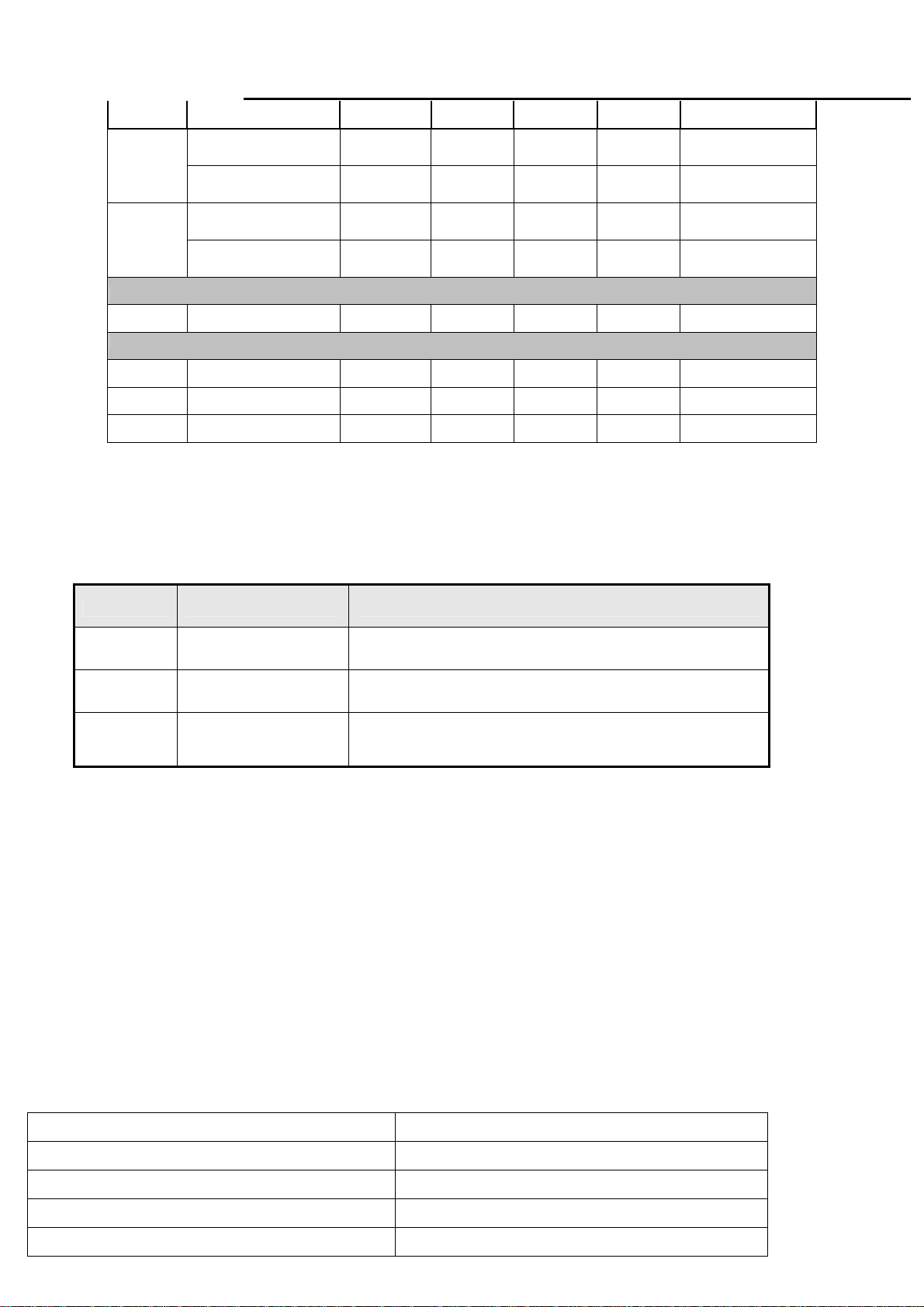

VESA MODES

Horizontal Vertical

Mode Resolution

640*480@60Hz 31.469 N 59.941 N 25.175

Nominal

Frequency

+/-0.5KHz

Sync

Polarity

Nominal

Frequency

+/-1Hz

Sync

Polarity

Nominal Pixel

Clock (MHz)

640*480@72Hz 37.861 N 72.809 N 31.5

VGA

SVGA

XGA

SXGA

WXGA

640*480@75Hz 37.5 N 75 N 31.5

800*600@56Hz 35.156 P 56.25 P 36

800*600@60Hz 37.879 P 60.317 P 40

800*600@72Hz 48.077 P 72.188 P 50

800*600@75Hz 46.875 P 75 P 49.5

1024*768@60Hz 48.363 N 60.004 N 65

1024*768@70Hz 56.476 N 70.069 N 75

1024*768@75Hz 60.023 P 75.029 P 78.75

1152*864@75Hz 67.5 P 75 P 108

1280*960@60Hz 60 P 60 P 108

1280*720@60Hz 44.955 P 59.94 P 74.176

1280x1024@60Hz 63.981 P 60.020 P 108.000

1280x1024@75Hz 79.976 P 75.025 P 135.000

1280*800@60Hz 49.702 N 59.810 P 83.500

7

Page 9

MW22

Service Manual

1360x768@60Hz 47.712 P 60.015 P 85.500

1440x900@60Hz 55.935

WXGA+

WSXGA+

VGA

SVGA

XGA

Note: 1. Non-interlace signals only (An interlace signal cannot be display)

2. Please refer to F/W specification for more detail

3. Each frequency of Power Macintosh and Sun Ultra is a reference value

3.3.3

Timing requirements

1440x900@75Hz 82.306

1680*1050@60Hz 65.290 N 59.954 P 146.250

IBM MODES

720x400@70Hz 31.469 N 70.087 P 28.322

MAC MODES

640*480@66.7Hz 35 P

832*624@74.55Hz 49.722 N 74.55 N 57.283

1152*870@75Hz 68.681 N 75.062 N 100

N

N

59.887

74.892

66.667 N 30.24

P

P

106.500

187

Item Condition Specification

Horizontal

Vertical

Out of range

3.3.4

DDC data

Sync polarity: (+) or (-)

Sync polarity: (+) or (-)

Excluding Horizontal

(31~83)KHz or

Vertical 56~76 Hz

31~83KHz

56~76 Hz

Message “

EDID Standard Compliance

EDID File Format : VESA’s EDID Standard Version #3, Revision #0,

EDID Structure : Version #1, Revision #3.

EDID Data Table : See the file of LE22T9-DR4-16

4. LCD Characteristic & Performance

4.1 Panel general specifications

Frequency out of range” on screen

General Specifications

(1) The test methods for the below items’ definition, please refer to the specification of SEC LTM220MT05 panel

Supplier SEC

Model name LTM220MT05

Display Area 473.76mm(H)x296.1mm(V)

Pixel Pitch 0.282mmx 0.282mm

Display Colors: 16.7Million (Hi-FRC)

8

Page 10

MW22

Service Manual

Number of Pixel 1680x1050 pixels

Pixel Arrangement RGB vertical stripe

Brightness 250cd/m2 (Typ.)

Contrast Ratio 1000:1 (Typ.)

Viewing Angle Hor:160°, Ver: 160°(Typ)

Brightness Uniformity

Display Mode Normally White

Response Time(Tr+Tf) 5ms (Typ.), 8ms (Max.)

Surface Treatment Haze 25%, Hard-coating (3H)

Lamp 2 CCFL

Notes: Other panel source, please refer to the panel specifications.

≧75%

4.2 Optical characteristic of LCD panel

(1) The test methods for the below items’ definition, please refer to the specification of SEC LTM220MT05panel.

Item Unit Conditions Min. Typ. Max. Remark

Viewing Angle

Contrast ratio

Response Time

Color / Chromaticity

Coordinates (CIE)

Color Coordinates (CIE) White

Luminance Uniformity

White Luminance at

CCFL 6.5mA(center point)

[degree]

[degree]

[degree]

[degree]

Normal Direction 600 1000

[msec] Rising Time -

[msec] Falling Time -

[msec] Rising + Falling - 5 8

Red x

Red y 0.305 0.330 0.355

Green x 0.275 0.300 0.325

Green y 0.575 0.600 0.625

Blue x 0.125 0.150 0.175

Blue y 0.035 0.060 0.085

[%] 9 points measurement 75%

[cd/m2]

Horizontal (Right)

CR >= 10 (Left)

Vertical (Up)

CR >= 10 (Down)

White x 0.288 0.313 0.338

White y 0.304 0.329 0.354

250 -

70

70

70

70

0.615

80

80

80

80

0.640

-

-

-

-

0.665

4.3 Brightness output

The test to verify specifications in this section shall be performed under the following standard conditions unless otherwise

noted.

Temperature : 25 ± 5°C

Test pattern : white

Video Resolution : 1680x1050

Video input level : 700 mV ± 2%

Warm-up time : 30 minutes

9

Page 11

MW22

Service Manual

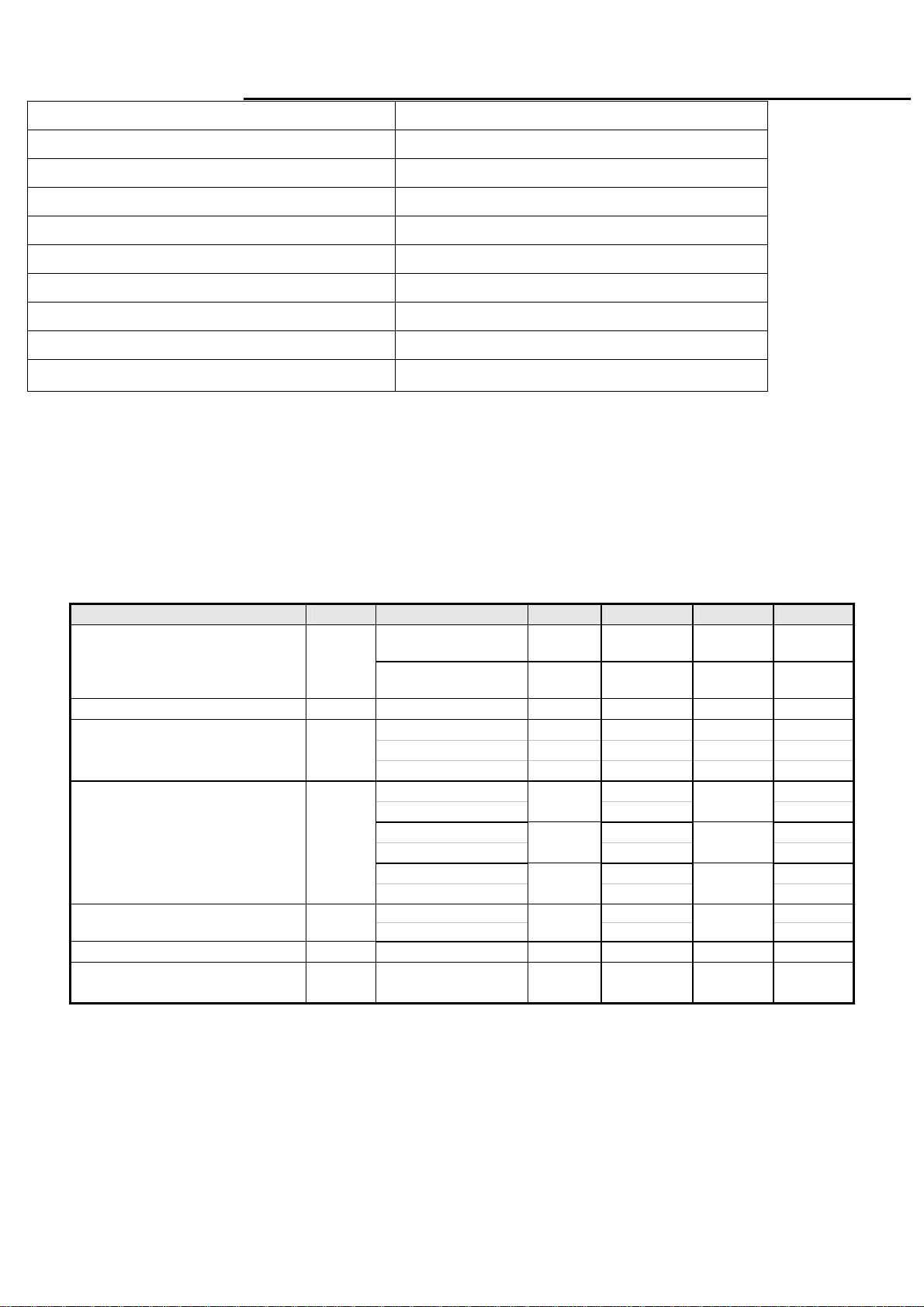

Item Condition SPEC

Brightness

Grey Scale

4.4 White balance

The test standard conditions refer to Sec 3.3. (Brightness control is at 100 contrast control is at 50.)

Brightness=100%

Contrast = 100%

Brightness=100%

Contrast = 100%

≧ 200 cd/m

the last 3~8 levels of 32

grey scales is combined

2

Cool

Warm

User

4.5 Brightness uniformity

The test standard conditions refer to Sec 3.4.

Mode

9300K 0.283 ± 0.030 0.297 ± 0.030

6500K 0.313 ± 0.030 0.329 ± 0.030

Panel While x Panel While y

)(backlight points nine of luminance Min.

≥

)(backlight points nine of luminance Max.

L/2

4 6

Chromaticity Coordinate

x y

(4)

%75

L/10

5

W/10

1 2

7

8

3

9

W/2

Fig.3

4.6 Audio Signal

10

Page 12

MW22

Service Manual

Items Specification

Input impedance

Frequency response range

Signal to noise ratio

Output power

Loading impedance

Note: The low pass RC Filter (R=100Ω / C=0.047uF) for Class-D output power and THD+N measurement, and under 1KHz, 1Vrms

and sine wave input.

≧ 10K ohm

200Hz –20kHz

≧ 40 dB

≦1 W + 1 W(±20% tolerance), THD 10%.

4 ohm

5. Function Specifications

All the tests to verify specifications in this section shall be performed under the following standard conditions unless

otherwise noted. The standard conditions are:

Temperature : 25 ± 5°C

Warm-up time : 30 minutes minimum

Checking display modes : All the specified modes

5.1 Keypad Function

5.1.1

注:1.if current Menu is Language menu, when you press

[AUTO] key, it will not save your select and

Control buttons

A. When OSD un-displays , press [AUTO] to perform auto-adjustment

[AUTO]

[MENU]

[>], [<]

[POWER] Power on or power off the monitor

B. When OSD displays, and the current Menu is Main Menu press [AUTO] to turn off the

Main Menu, or press [AUTO] to return to previous level menu.

A. When OSD isn’t shown on screen, press [MENU] to enter OSD interface.

B. When OSD displays, press [MENU] to perform function of menu icon that is highlight or

enter next level menu, and if the Menu is the last layer of OSD press [MENU] to finish

adjust and turn off Menu.

A. When “MENU OSD” displays, press these keys to change the contents of an

adjustment item, or change an adjustment value.

B. When “MENU OSD” un-displays, press [<] to show “Audio” OSD, press [>] to show

“Theme Mode” OSD.

return to

[MENU]

previous menu.

key, it will save your select and return to

previous menu. and when you press

5.1.2

Hot Key Operation

HOT KEY OPERATION

FUNCTION

AUTO MENU <

>

11

POWER

DESCRIPTION

Page 13

MW22

Service Manual

Press [AUTO] at the same time, and then press

FACTORY

MODE

●

ON

[POWER] for DC power on. OSD menu will be

shown with “F” on the left top. Select “F” for

entering factory mode

Volume

Theme Mode

●

●

Adjust Volume

Select Theme Mode

12

Page 14

MW22

Service Manual

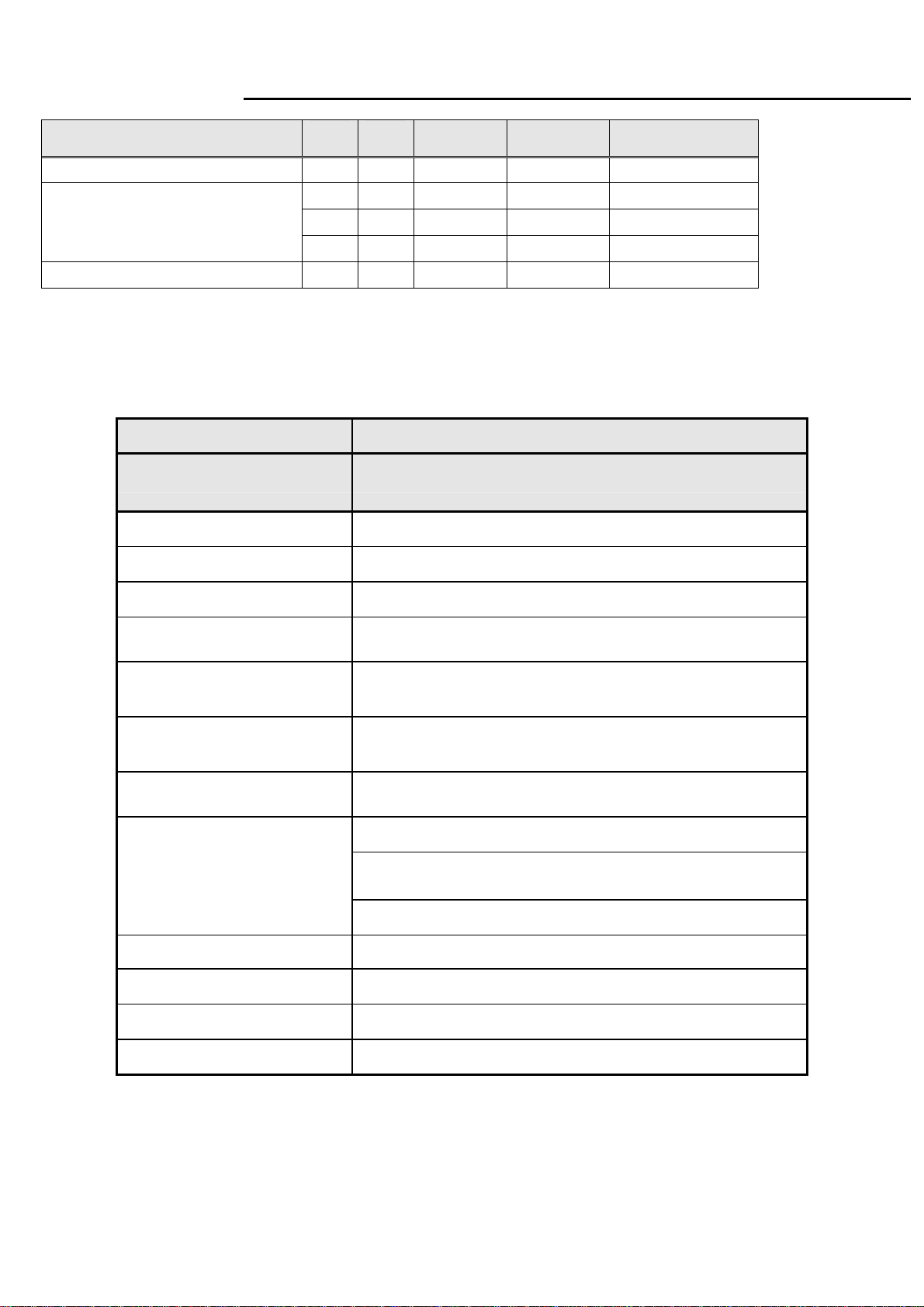

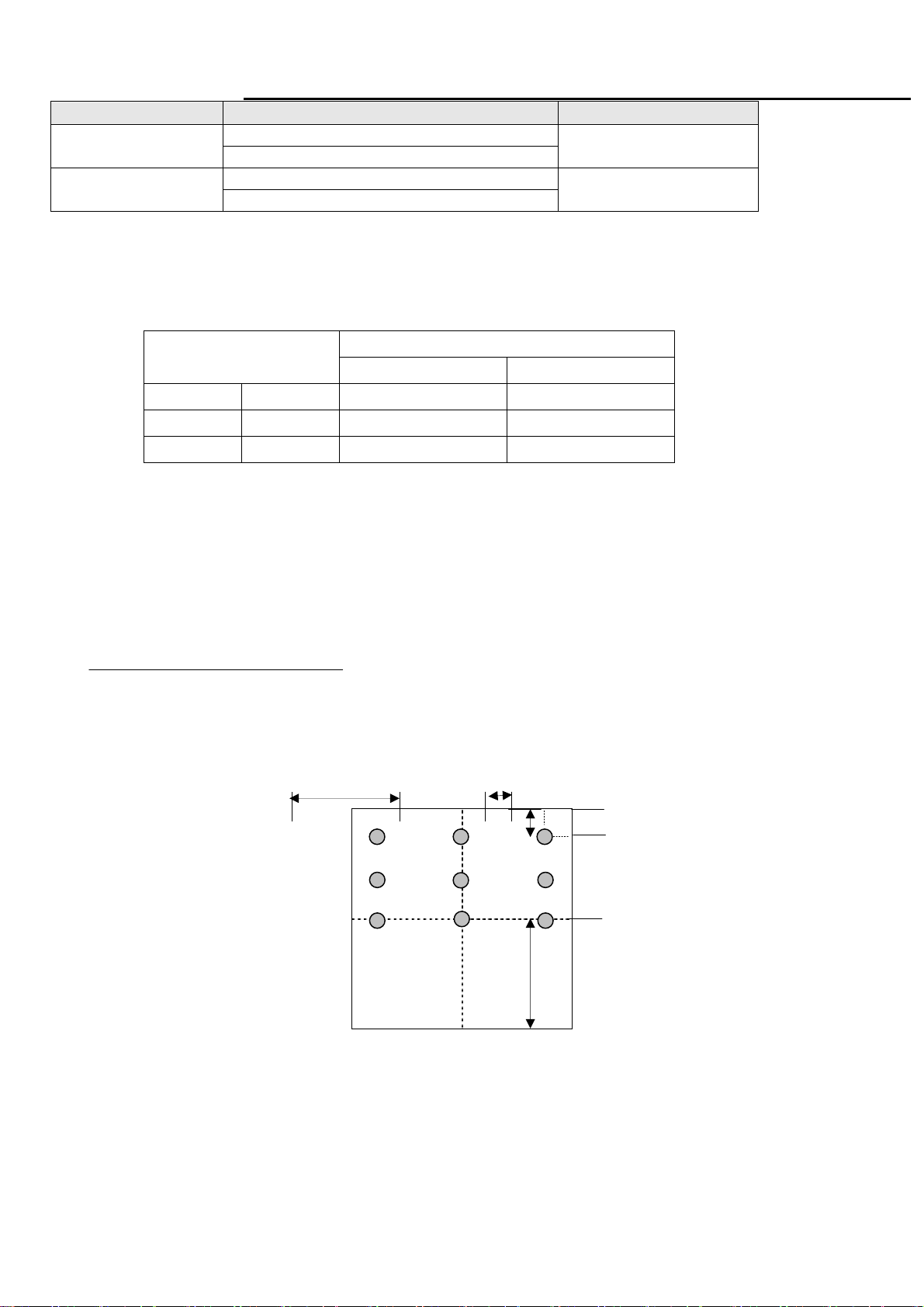

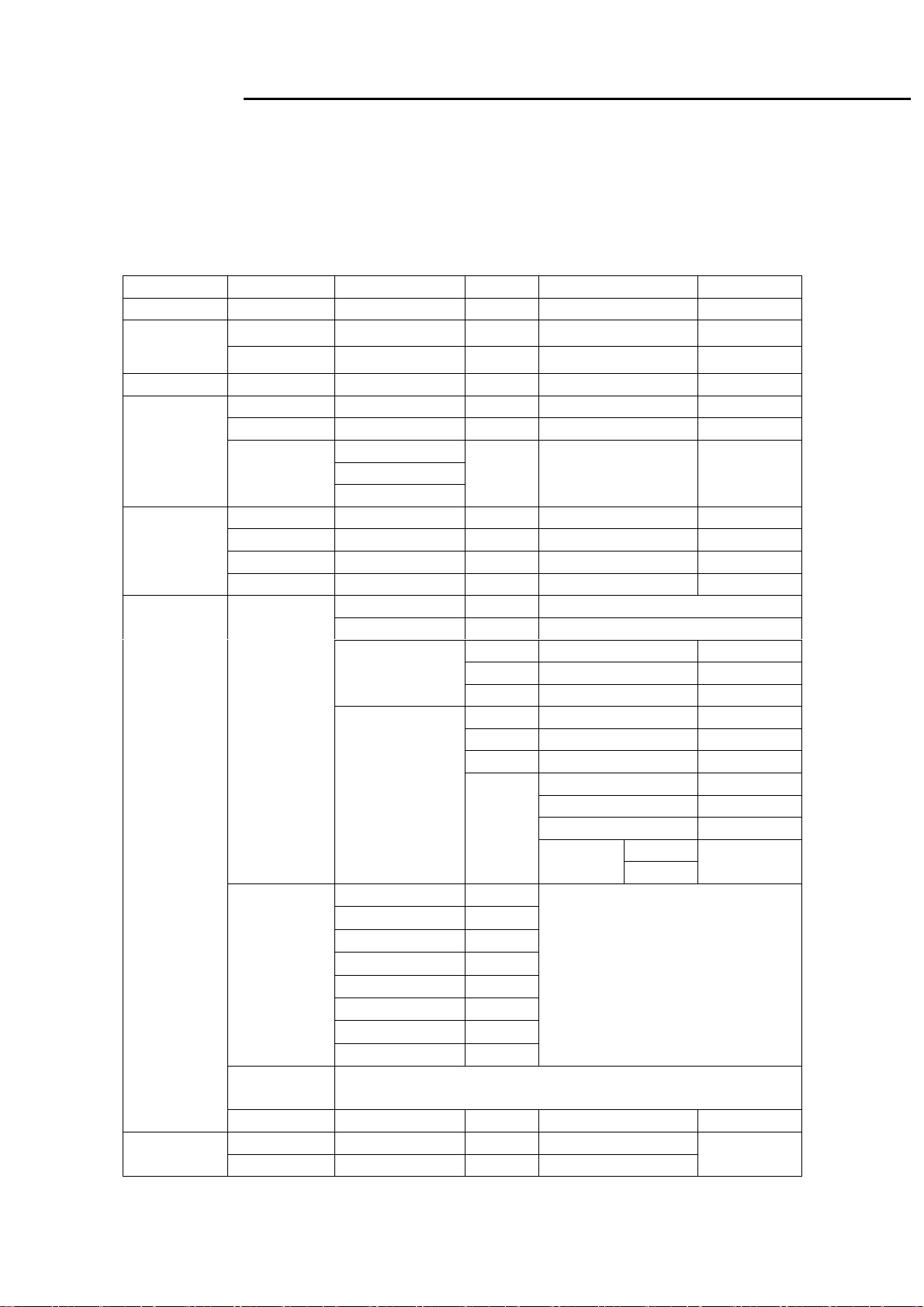

5.2 OSD Structure

The On-Screen Display (OSD) shall be an easy to use icon based menu through keypad OSD buttons or remote control

unit. The unit shall leave the factory with all OSD controls set to their default values.

Analog:

“Picture” will be the first selected function while user power on main menu.

First Second Third Fourth Control Value Default

Auto

VGA

Input

Audio Volume 50

Picture

Geometry

Advanced

DVI

Brightness 80

Contrast 50

Gamma

H-Position 50

V-Position 50

Clock 50

Phase

Color

Language

Resolution

Reminder

Information

Enable Reset

Disable

Gamma2.0

Gamma2.2

Gamma2.4

Warm Default color

Cool

Customer

Color

Theme Mode

English

Français

Italiano

Español

Hollands

Русский

Suomalainen

Deutsch

Gamma 2.2

Red 50

Green 50

Blue 50

Movie

Game

Picture

User

Tint/Hue 50

Saturation 50

Sharpness 50

Dynamic

Enable

Disable

English

Disable

Disable

13

Page 15

MW22

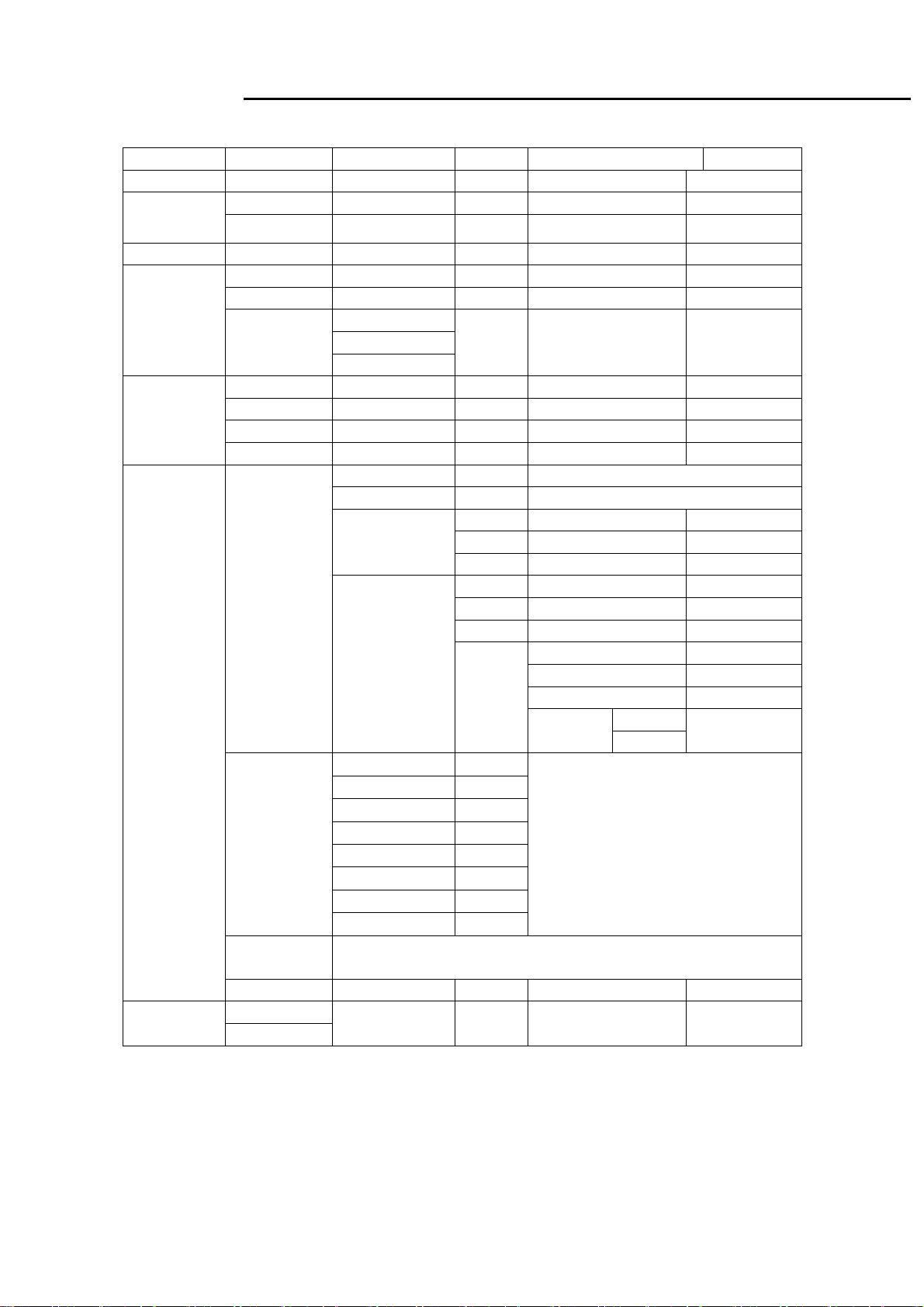

Service Manual

DVI(option):

If our monitor is in Dual mode, the gray area below will be the function which could not be adjusted.

First Second Third Fourth Control Value Default

Auto

VGA

Input

Audio Volume 50

Picture

Geometry

Advanced

DVI

Brightness 80

Contrast 50

Gamma

H-Position

V-Position

Clock

Phase

Color

Language

Resolution

Reminder

Information

Enable Reset

Disable

Gamma2.0

Gamma2.2

Gamma2.4

Warm Default color

Cool

Customer

Color

Theme Mode

English

Français

Italiano

Español

Hollands

Русский

Suomalainen

Deutsch

Disable

Gamma 2.2

Red 50

Green 50

Blue 50

Movie

Game

Picture

User

Tint/Hue 50

Saturation 50

Sharpness 50

Dynamic

Enable

Disable

English

Disable

14

Page 16

MW22

Service Manual

Theme Mode Brightness Contrast

Movie 100 54

Game 100 58

Picture 100 50

User(After Reset all) 80 50

Remark:

1. Main OSD will Show 10 Second on the Screen,if there is No Operation on the OSD,And ±1 Second is accepted.

2.Gamma 2.0(2.0±0.2), Gamma 2.2(2.2±0.2), Gamma 2.4(2.4±0.2).

3. When dynamic be enabled, after adjusting theme mode/Color Menu, DCR function will be turn off automatically.

5.3 Gateway OSD Message

Item Description

When User Press Hot-Key “Auto” or use main Menu “Auto processing”

Auto Processing

No Signal

Frequency out of

range

Resolution

Reminder

function, will show this message ,and the monitor do the auto process

function.

When the video cable is connect, but there is no active signal input, will

show this message, then enter into power saving mode.(will Show 3

seconds)

1. When meet the case as below:

a. Input signal is detected by the system;

b. Input signal is out of the system support rang or supported table which

may have following case:

-input signal is out of the support H or V frequency range;

-input signal is in specified blocked list;

-Input signal is out of the system support specification;

Then will show this message.

2. The menu will be shown as:

a. Move around the full screen;

b. Desktop background in Black;

c. Continue 5 minutes and then step into Power Saving Mode.

When user entering into “Advanced” menu, user could select “Resolution

reminder” item. After selecting “Resolution reminder”, main menu will show

“Your Computer screen resolution may not match this monitor’s optimum

1600x900 setting. To adjust your screen resolution and see your

computer’s printed or online documentation. Press the AUTO button on the

side of this monitor after adjusting the screen resolution. ”

Information

Reset

Input Menu

While user entering into “Advanced” menu, user could select “Information”.

Main menu will show “Mode:, Input: , OSD Vers: ,SN ”.

Go to “Main menu” and select “Reset” function. After select “Reset”,

monitor will show a “Reset All” pop up window.

This Menu will Show at the Cases Below(3 Seconds) :

1. AC/DC On;

2. Power Saving On;

3. Burn In On;

4. Switch Source;

5. Plug and pull out Cable.

15

Page 17

MW22

Service Manual

6. SOP of PCBA ISP Programming

6.1 Operational condition:

Equipment: PC, ISP card, signal cable and power cable.

ESD requirements: antistatic wrists, antistatic gloves(fingers), and connecting cable

Name of ISP program: ISP_Tool_V4.4.2.4

Manufacture of FW IC:PMC/SST/MX

6.2 Operational steps:

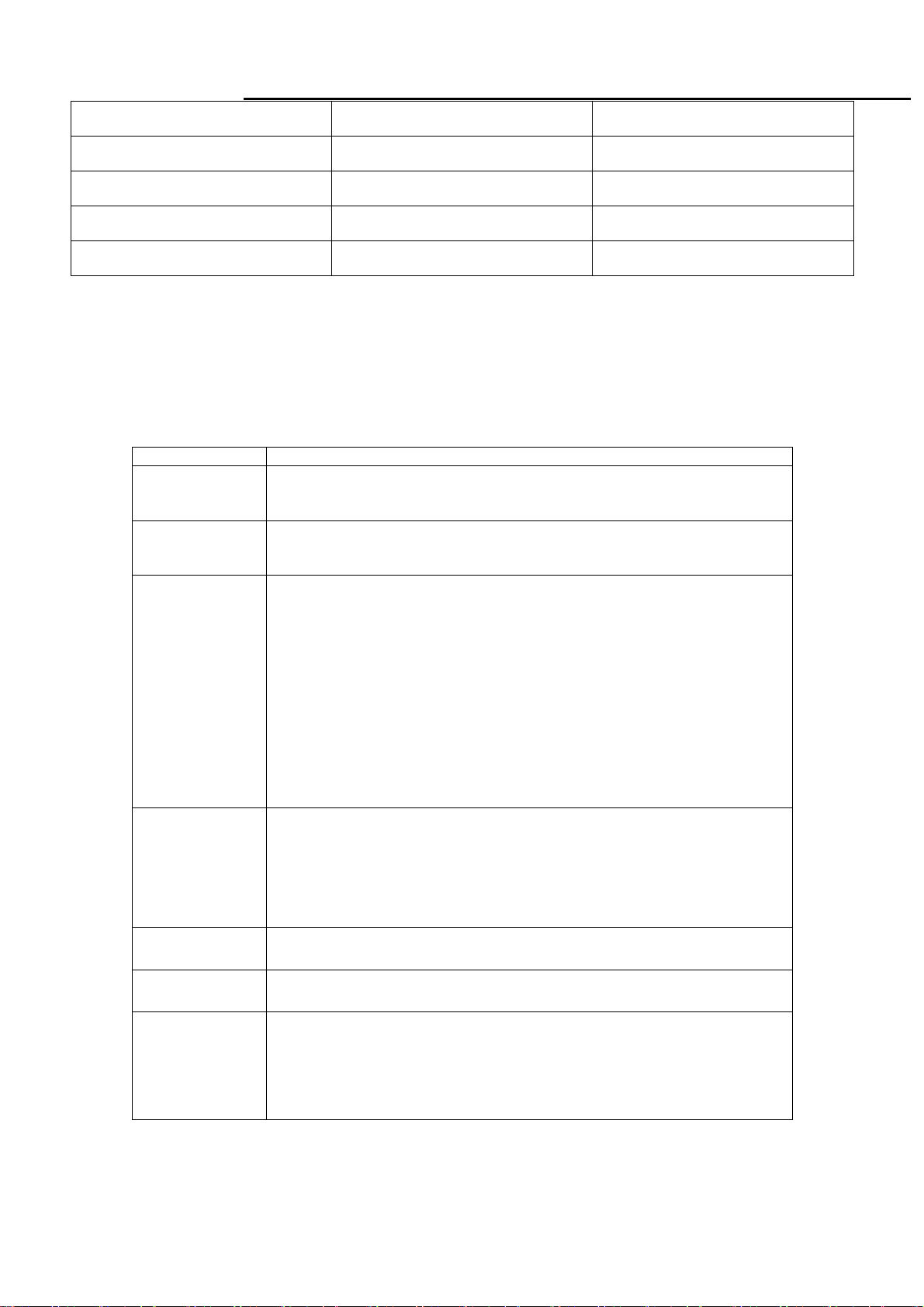

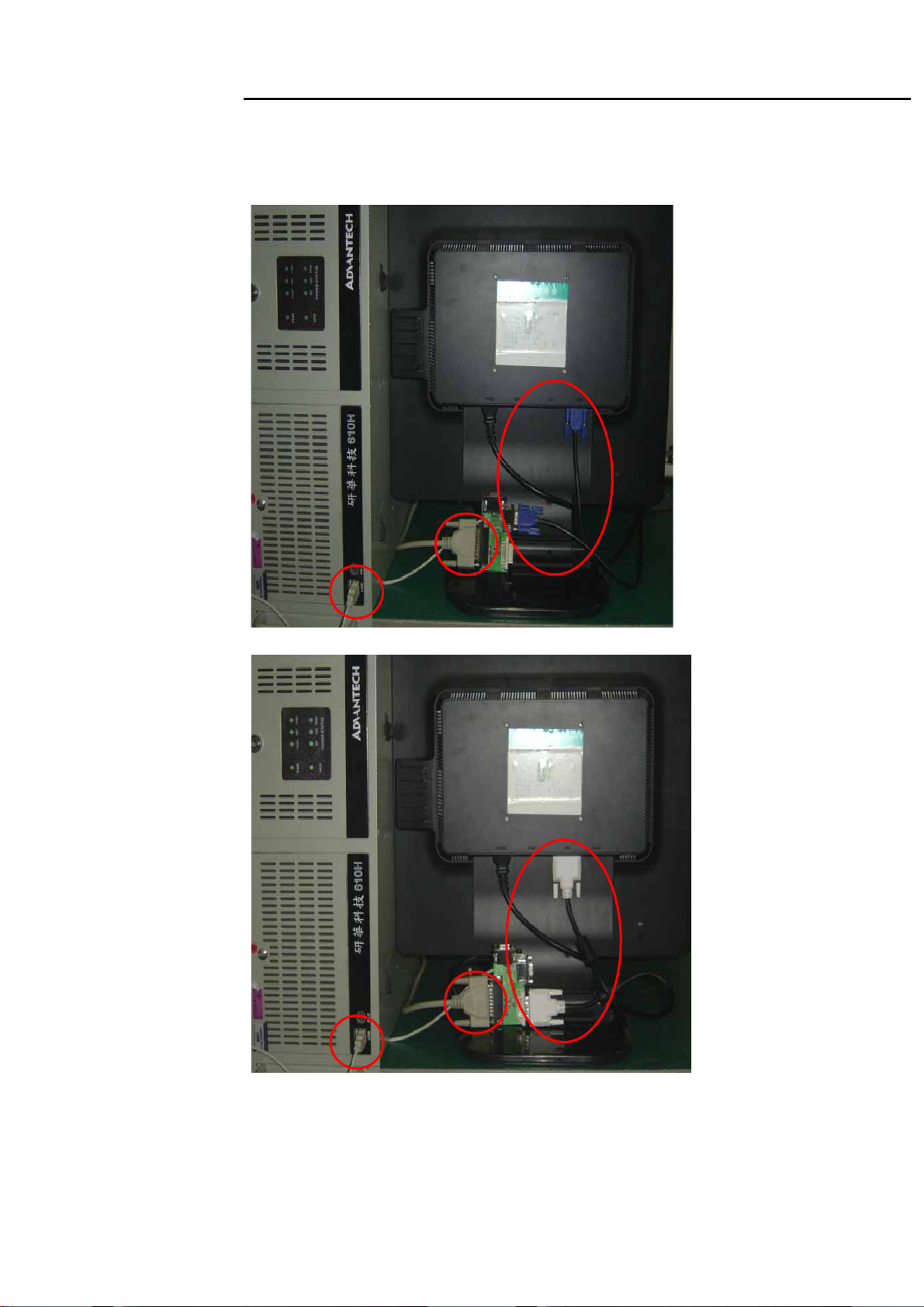

1. Connection: connect PC to PCBA with signal cable, and then keep AC and DC in open state.

Signal cable

One port of ISP

program card is

connected to

PC

2. Adjust ISP programming

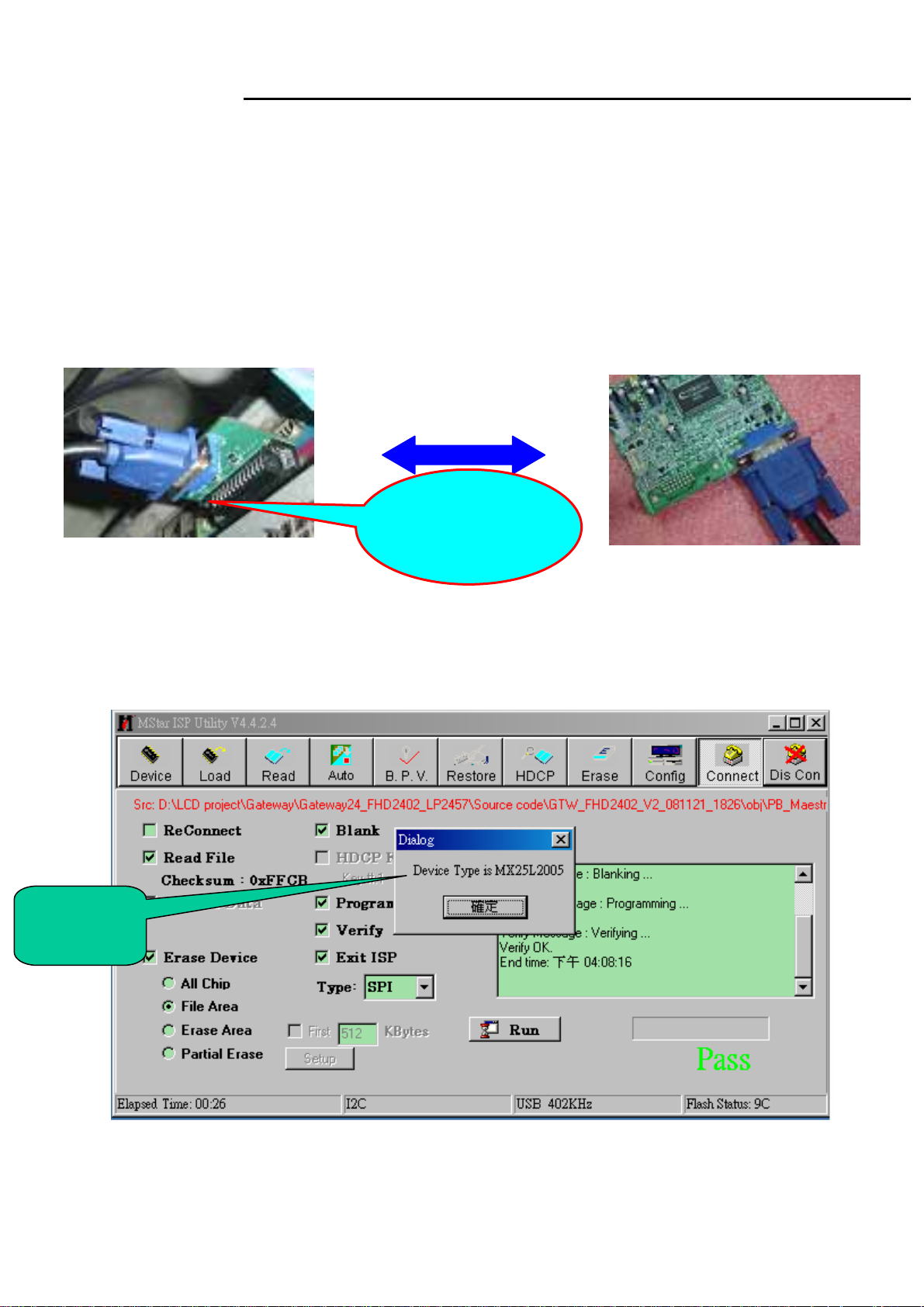

Firstly, double click ISP_Tool_ V4.4.2.4 exit and click “Connect ” button; The ISP tool will connect to

monitor automatically, and it will show flash IC type automatically

FW IC

Model

16

Page 18

MW22

Service Manual

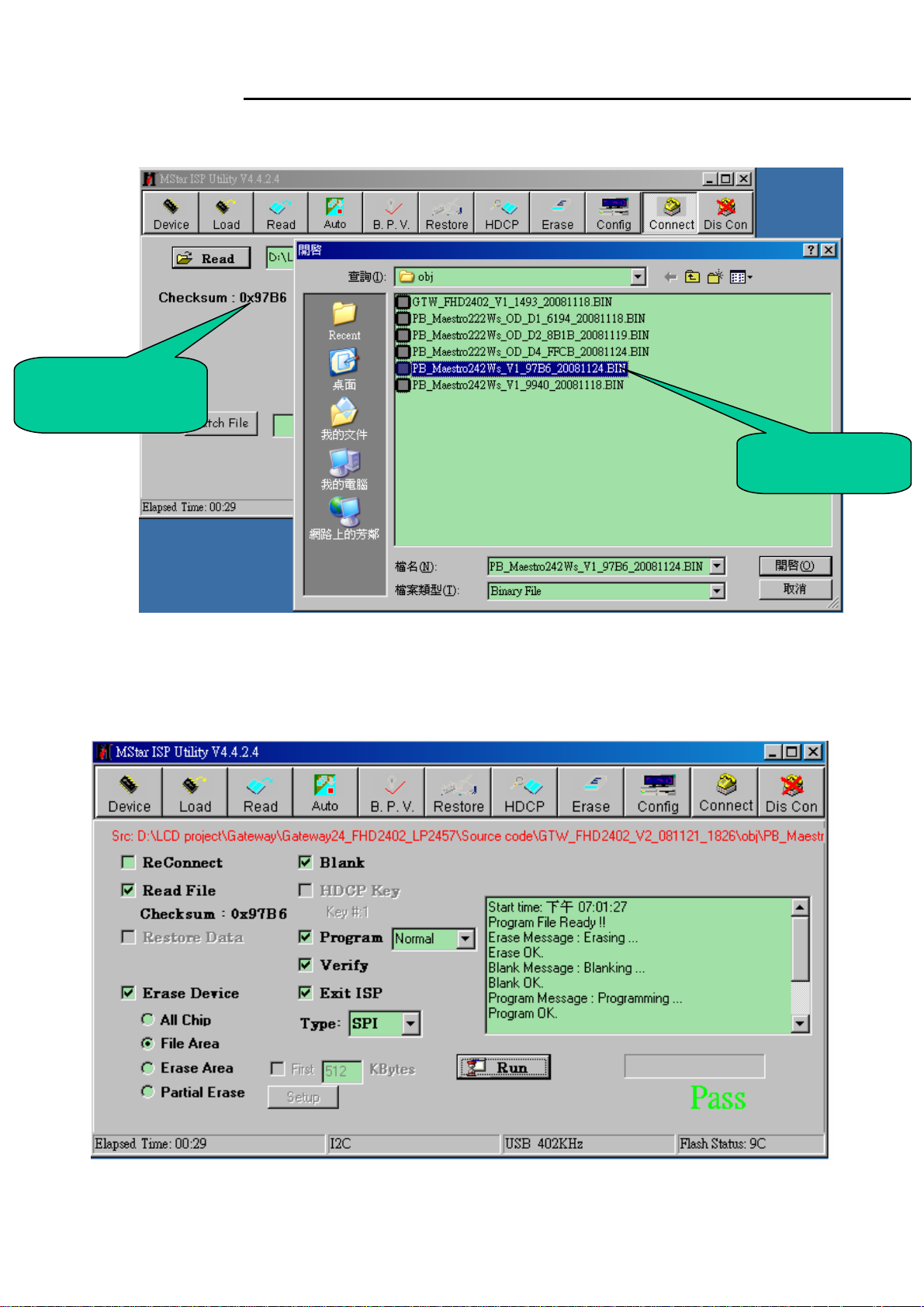

Secondly﹐download FW software: first select “READ”, and then load FW software in Rooter

(Fig.2).

Software

Checksum value

FW BIN file

Thirdly, select “AUTO”, and keep its default value. Click “RUN” for beginning programming. There will

be prompting if programming is OK.

17

Page 19

MW22

Service Manual

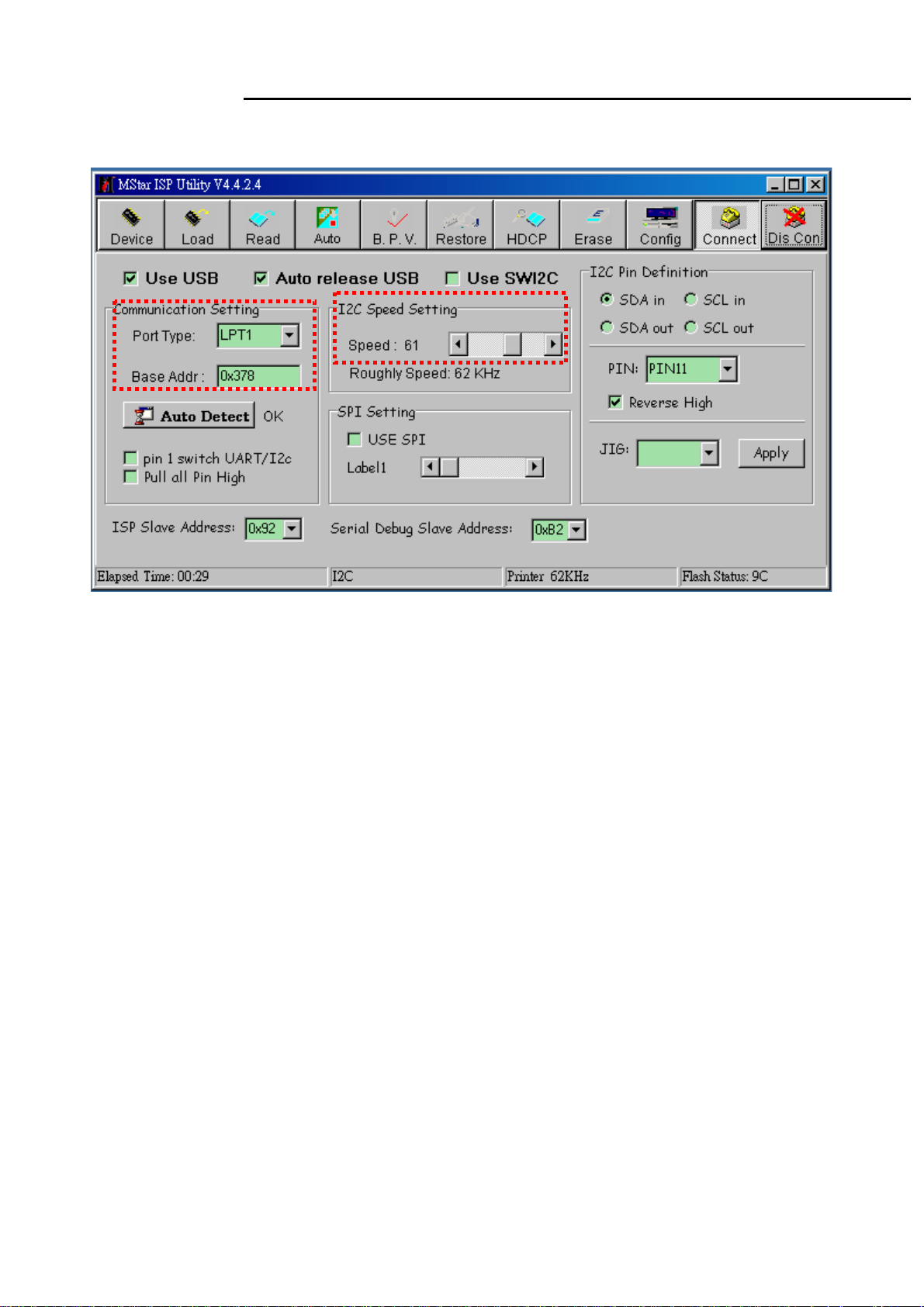

◆Note: if programming fails or success rate is not high, click “Config” and adjust its speed to lower

in “I2C Speed Setting”and check Communication Setting. If connect port is print port, please check

port type.

18

Page 20

MW22

Service Manual

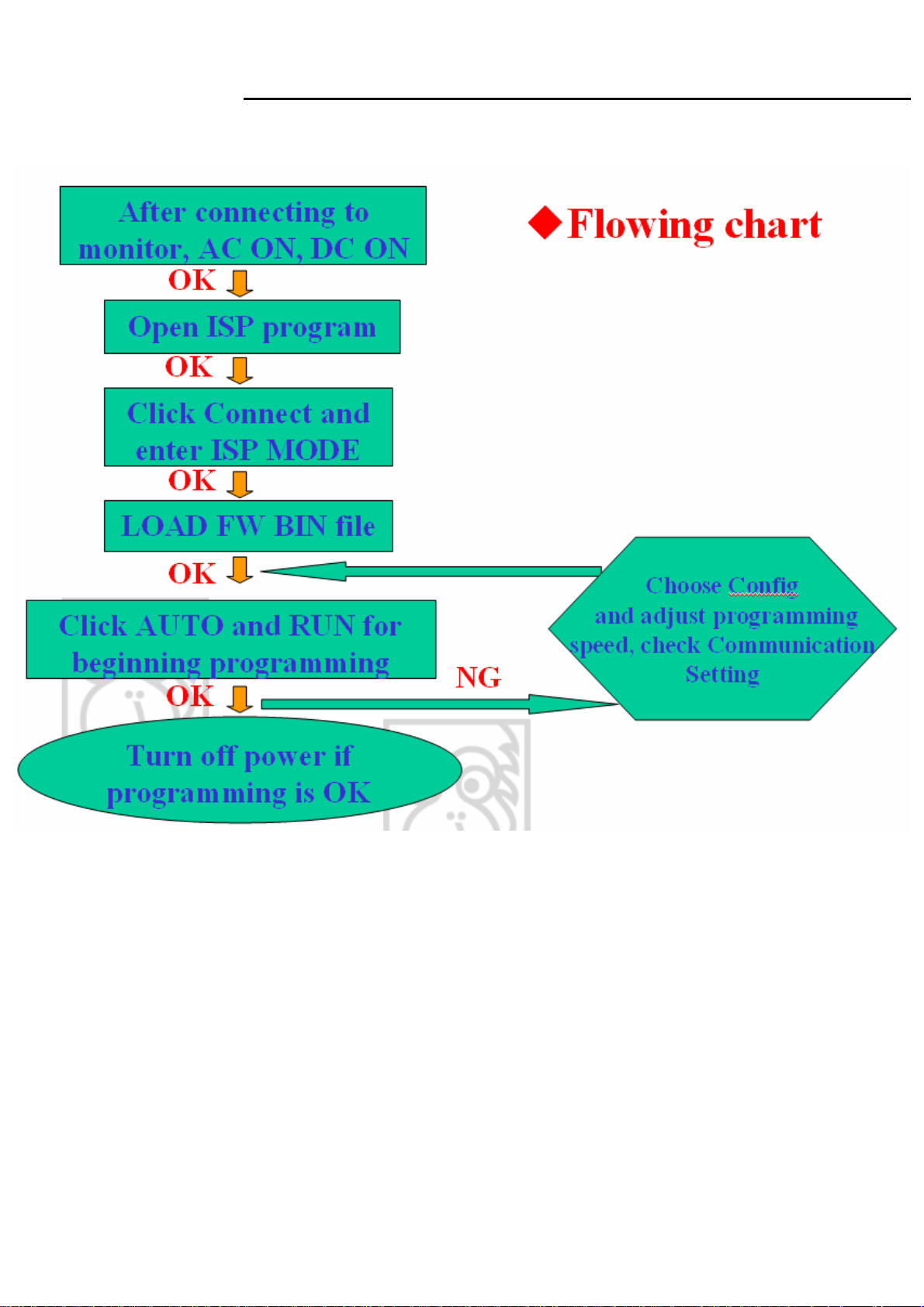

3. Flow Chart

19

Page 21

MW22

Service Manual

7. SOP of EDID

7.1 Request of hardware and software:

1. Software

a.port95nt.exe

b.Edid.exe

c.MW22 model

2. Hardware

a. PC(winXP or win2000)1PCS;

b. Tool(EDID Card、VGA cable & DVI cable)

7.2 Operational steps:

1. First set up Port95nt.exe

20

Page 22

MW22

Service Manual

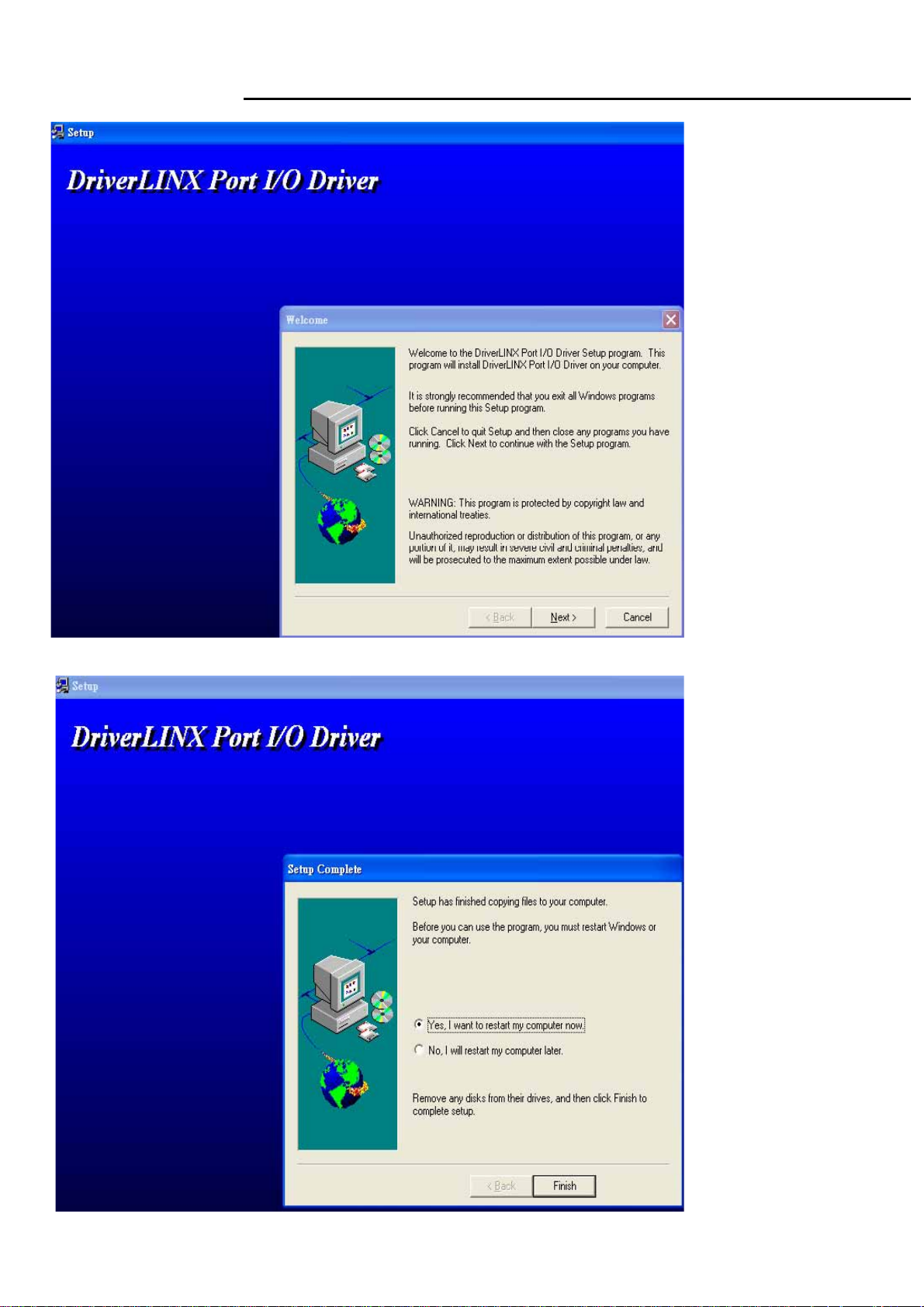

2. Click next button continually then can finish setting.

21

Page 23

MW22

Service Manual

EDID Tool Set up

A : USB interface provide +5V DC power(No Power is ok )

B : Connect DDC Card and PC with collateral interface ;

C :VGA、DVI use different cable to link DDC and PC

A

A

B

B

C

C

22

Page 24

MW22

B C

Service Manual

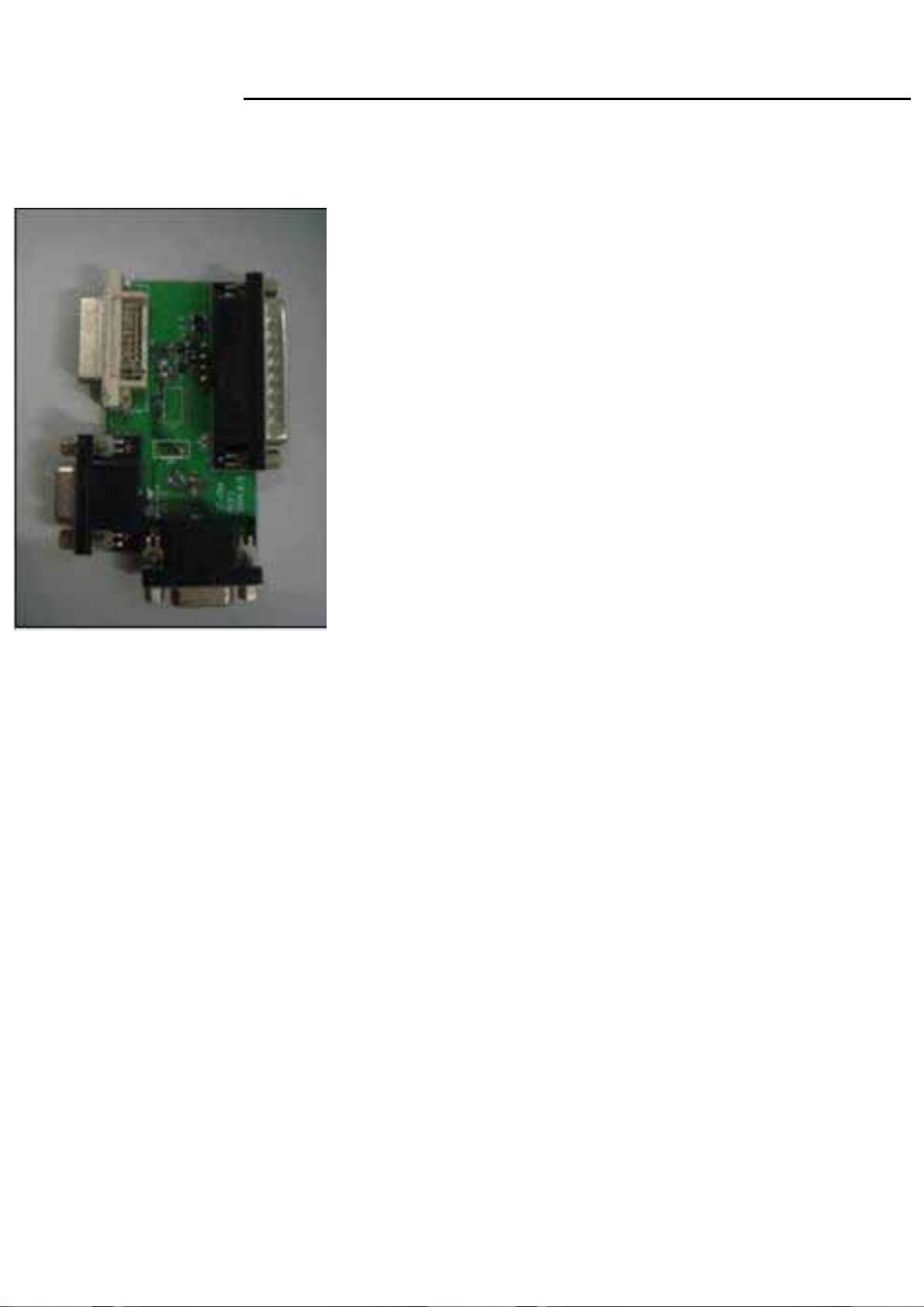

EDID ISP Card:

A

A:Collateral printing interface (connect with PC)

B : VGA interface (one VGA connect with PC to provide signal for monitor the other one connect with

PC VGA interface to write VGA EDID, Write EDID can without providing signal)

C : DVI interface (connect with Monitor)

23

Page 25

MW22

Service Manual

3. Write EDID Process:

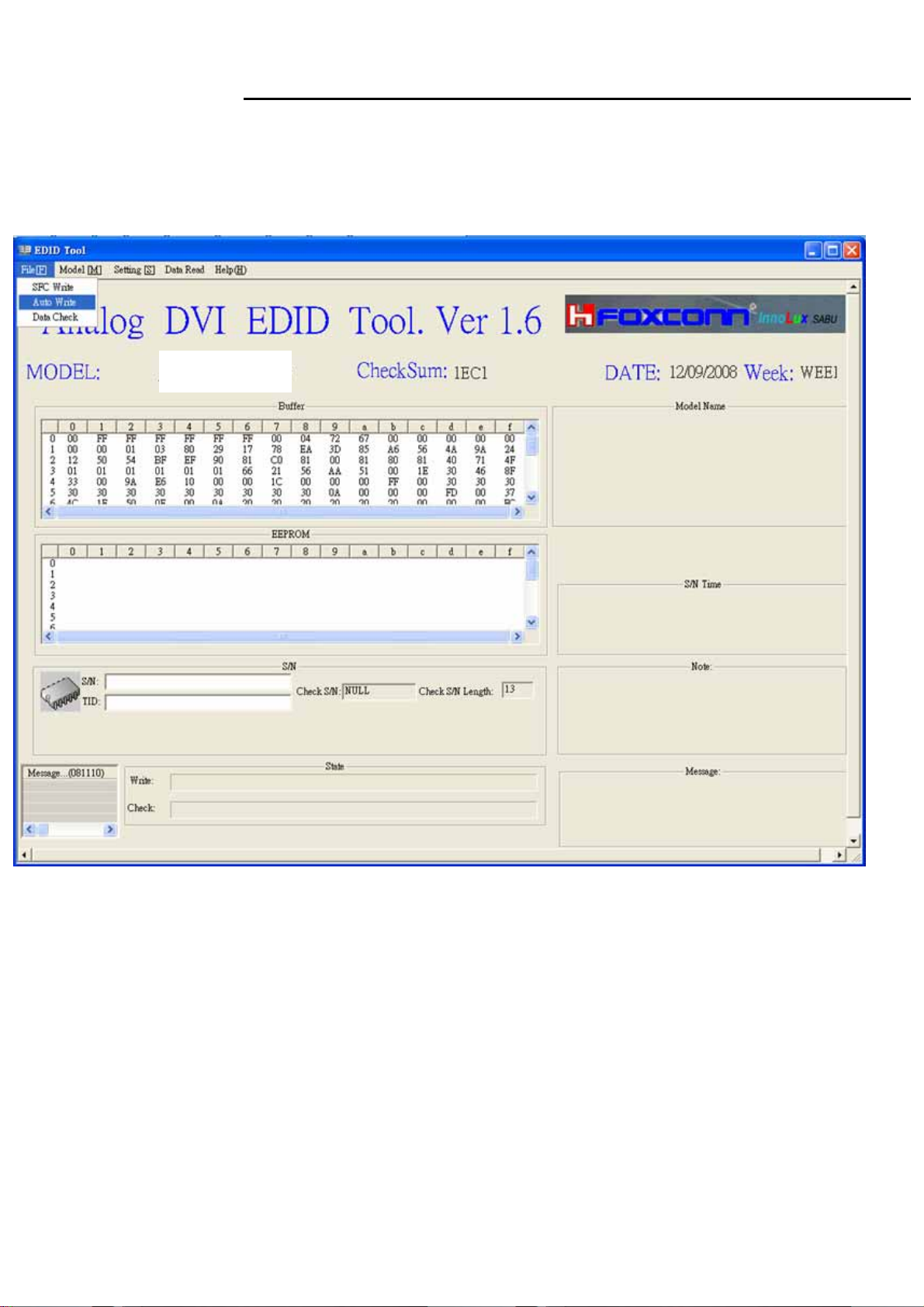

3.1 Choose File menu in main menu ,choose Auto Write button,click S/N blank .

MW22

24

Page 26

MW22

Service Manual

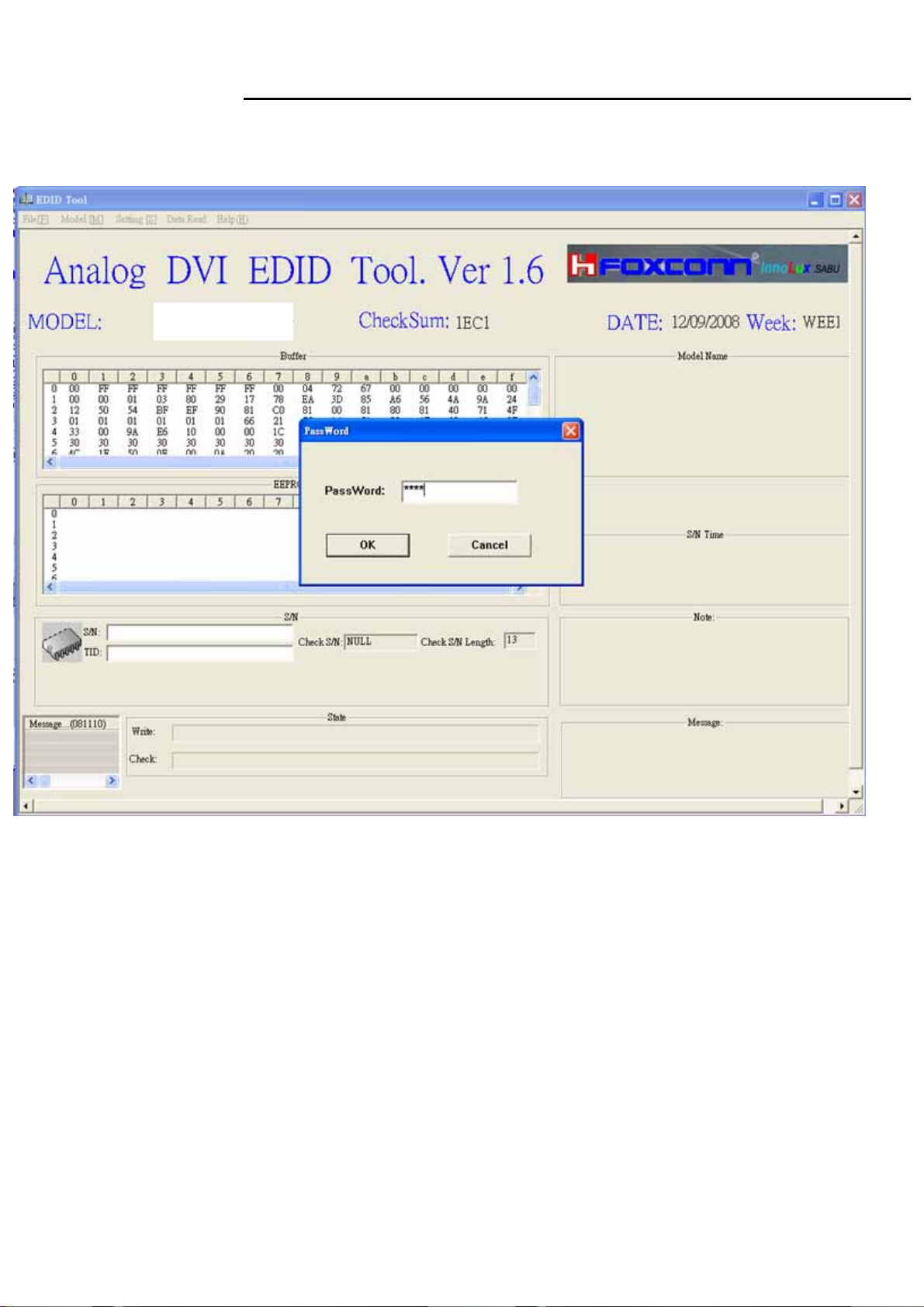

3.2 Cloose the Model in main menu, and the password is 1234.

MW22

25

Page 27

MW22

Service Manual

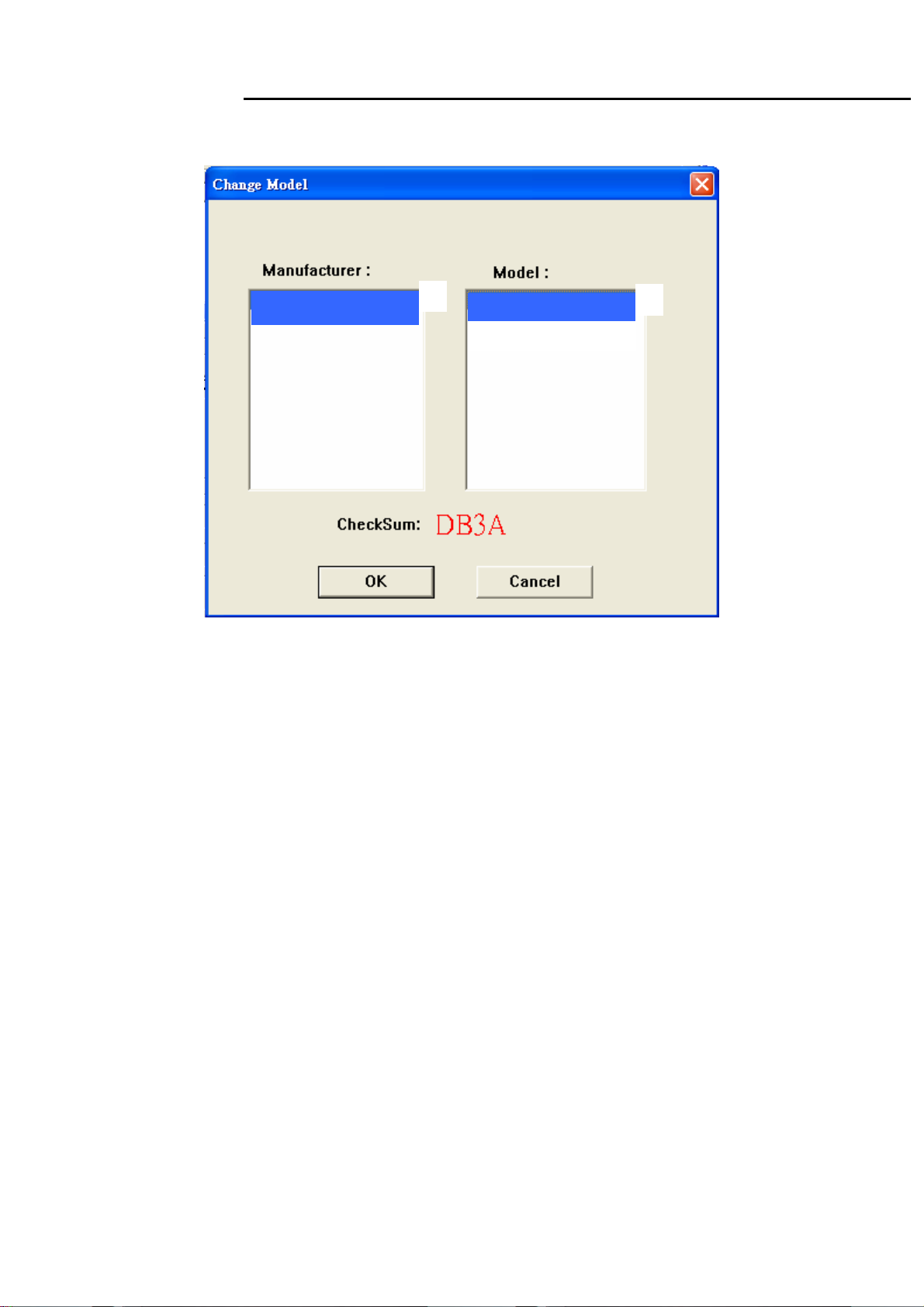

3.3 Choose the model, MW22_A(Update VGA) ,MW22_D(Update DVI) .

MW22

MW22_D

MW22_A

26

Page 28

MW22

Service Manual

3.4 Input S/N in the Blank , eg:ETLA10C109805111D94023,the program can write directly.

MW22

27

Page 29

MW22

Service Manual

3.5 After the process is ok , the program can check that automatically

MW22

28

Page 30

MW22

Service Manual

3.6 If write successfully , you can see PASS in the right

MW22

MW22

29

Page 31

MW22

Service Manual

02. Flat Panel Specification

30

Page 32

Mechanical Information

Approval Specification

Approval Specification

Module

size

Max.

494.2

320.6

17.0

2,600

mm493.7493.2Horizontal (H)

mm320.1319.6Vertical (V) w/o inverter ass’y

mm--Depth (D)

NoteUnitTyp.Min.Item

LCD module onlyg--Weight

Note (1) Mechanical tolerance is ± 0.5mm unless there is a special comment.

1. Absolute Maximum Ratings

If the condition exceeds maximum ratings, it can cause malfunction or unrecoverable

damage to the device.

Power Supply Voltage

Data Signal

Storage temperature

Center of Glass surface temperature

(Operation)

Shock ( non - operating )

Vibration ( non - operating )

Note (1) Ta= 25 ± 2 °C

DD

sig

STG

OPR

nop

nop

NoteUnitMax.Min.SymbolItem

(1)V6.5GND-0.5V

V5-V

60-25T

500T

℃

℃

(2)

(2)

(3)(5)G50-S

(4)(5)G1.5-V

5/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 33

Approval Specification

Approval Specification

(2) Temperature and relative humidity range are shown in the figure below.

a. 90 % RH Max. (Ta ≤ 39 °C)

b. Maximum wet-bulb temperature at 39 °C or less. (Ta ≤ 39 °C)

c. No condensation

(3) 11ms, sine wave, one time for ±X, ±Y, ±Z axis

(4) 10-300 Hz, Sweep rate 10min, 30min for X,Y,Z axis

(5) At vibration and shock test, the fixture which holds the module to be tested has to be

hard and rigid enough so that the module would not be twisted or bent by the fixture.

(39,90)

(39,90)

(50,50.4)

(50,50.4)

25,5)

((--25,5)

Fig. Temperature and Relative humidity range

(60,27.7)

(60,27.7)

6/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 34

Approval Specification

2. Optical Characteristics

Approval Specification

The optical characteristics should be measured in a dark room or equivalent.

Measuring equipment : SR-3, RD-80S (TOPCON), EZ-Contrast (Eldim)

(Ta = 25 ± 2°C, VDD=5V, fv= 60Hz, fDCLK=59.6MHz, IL = 7.5mArms)

NoteUnitMax.Typ.Min.ConditionSymbolItem

Contrast Ratio

(Center of screen)

Response

Time

Luminance of White

(Center of screen)

Green

Color

Chromaticity

(CIE 1931)

Blue

White

Red

Red

-1000600C/R

85-Tr + TfOn/Off

L

Normal

=0

θ

L,R

θ

=0

U,D

Viewing

Angle

-250200Y

0.6700.6400.610Rx

0.3600.3300.300Ry

0.3300.3000.270Gx

0.6300.6000.570Gy

0.1800.1500.120Bx

0.0900.0600.030By

0.3430.3130.283Wx

0.3590.3290.299Wy

-0.451-Ru'

-0.523-Rv'

msec

cd/m

2

(3)

SR-3

(5)

RD-80S

(6)

SR-3

(7),(8)

SR-3

Color

Chromaticity

(CIE 1976)

C.G.L

(ACC ONLY)

* C.G.L : Color Grayscale Linearity

Green

Blue

White

△u'v'White

-0.125-Gu'

-0.564-Gv'

-0.175-Bu'

-0.158-Bv'

-0.198-Wu'

-0.468-Wv'

(9)0.02--

7/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 35

Approval Specification

Approval Specification

NoteUnitMax.Typ.Min.ConditionSymbolItem

K-6500--Color Temperature

θ

Hor.

Viewing

Angle

Ver.

Brightness Uniformity

(9 Points)

L

θ

R

θ

U

θ

D

uni

Note (1) Test Equipment Setup

The measurement should be executed in a stable, windless and dark room between

30min after lighting the back light at the given temperature for stabilization

of the back light. This should be measured in the center of screen.

Single lamp current : 7.5mA

Environment condition : Ta = 25 ± 2 °C

CR≥10

-8070

-8070

Degrees

-8070

-8070

%25--B

(8)

EZ-

Contrast

(4)

SR-3

Field Photo detector

2°SR-3

TFT - LCD Module

Photo detector

Field

SR-3 : 40㎝

RD-80S : 50㎝

LCD Panel

The center of the screen

8/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 36

Note (2) Definition of test point

−

168 840 1512

Approval Specification

Approval Specification

Active Area

6

: Test Point

Note (3) Definition of Contrast Ratio (C/R)

: Ratio of gray max (Gmax) & gray min (Gmin) at the center point⑤ of the panel

3 2 1

G

CR

=

G

Gmax : Luminance with all pixels white

Gmin : Luminance with all pixels black

Note (4) Definition of 9 points brightness uniformity

BB

Buni

=×

(max min)

100

B

max

8 79

max

min

105

45

525

945

Bmax : Maximum brightness

Bmin : Minimum brightness

Note (5) Definition of Response time : Sum of Tr, Tf

Display Data White(TFT off) Black(TFT on) White(TFT off)

Optical Instruments

Response

100%

90%

10%

0%

9/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 37

Approval Specification

Approval Specification

Note (6) Definition of Luminance of White : Luminance of white at center point⑤

Note (7) Definition of Color Chromaticity (CIE 1931, CIE1976)

Color coordinate of Red, Green, Blue & White at center point⑤

Note (8) Definition of Viewing Angle

: Viewing angle range (CR ≥10)

10/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 38

Approval Specification

Approval Specification

Note (9) Color Grayscale Linearity

a. Test image : 100% full white pattern with a test pattern as below

b. Test pattern : Squares, 40mm by 40mm in size, filled with 255, 225, 195, 165, 135 and

105 grays steps should be arranged at the center⑤ of the screen.

c. Test method

st

-1

gray step : move a square of 255 gray level should be moved into the center of the

screen and measure luminance and u’ and v’ coordinates.

- Next gray step : Move a 225 gray square into the center and measure both

luminance and coordinates, too.

d. Test evaluation

Δu'v'= (u' -u' ) +(v' -v' )AB

Where A, B : 2 gray levels found to have the largest color differences between them

i.e. get the largest Δu’ and Δv’ of each 6 pair of u’ and v’ and calculate the Δu’v’.

2

AB

2

11/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 39

3. Electrical Characteristics

3.1 TFT LCD Module

The connector for display data & timing signal should be connected.

Approval Specification

Approval Specification

Ta = 25°C

NoteUnitMax.Typ.Min.SymbolItem

Voltage of Power Supply

Differential Input

Voltage for LVDS

Receiver Threshold

LVDS skew

LVDS

Input

Characteri

Differential input

voltage

stics

Input voltage range

(single-ended)

Common mode

voltage

(a) Black

Current of

Power

Supply

DD

SKEW

IN

V

CM

I

DD

|V

0+

ID

|/2

1.2

2.4-

|V

(1)V5.55.04.5V

(2)mV+100--High

mV---100Low

(3)ps300-300t

(4)mV600200|VID|

(4)V2.40V

(4)V

|/2

ID

mA-1,500mA-900-(b) White (5),(6)

mA1,9001,700-(c) Dot

Vsync Frequency

Hsync Frequency

Main Frequency

Rush Current

V

H

DCLK

RUSH

Note (1) The ripple voltage should be controlled under 10% of VDD.

Hz766053f

kHz83.264.857.2f

MHz77.559.552.6f

(7)A4.0--I

12/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 40

Approval Specification

Approval Specification

(2) Differential receiver voltage definitions and propagation delay and transition time test

circuit

a. All input pulses have frequency = 10MHz, t

b. C

includes all probe and fixture capacitance

L

or tF=1ns

R

Note a.

Note b.

(3) LVDS Receiver DC parameters are measured under static and steady conditions

which may not be reflective of its performance in the end application.

T

LVDS Clk

V

= 0V

DIFF

LVDS Data

RX +/-

t

SKEW

where tskew : skew between LVDS clock & LVDS data,

T : 1 period time of LVDS clock

cf) (-/+) of 300psec means LVDS data goes before or after LVDS clock.

(4) Definition of V

ID

and V

using single-end signals

CM

V

= 0V

DIFF

Differential

Differential

13/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 41

(5) fV=60Hz, fDCLK = 59.6MHz, VDD = 5.0V, DC Current.

(6) Power dissipation check pattern (LCD Module only)

a) Black Pattern b) White Pattern c) Dot Pattern

(7) Measurement Condition

100%

90%

Approval Specification

Approval Specification

V

DD

10%

GND

Rush Current I

T

RUSH

can be measured when T

RUSH

=470㎲

. is 470㎲.

RUSH

14/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 42

Approval Specification

Approval Specification

3.2 Back Light Unit

The back light unit is an edge - lighting type with 2 dual CCFTs ( Cold Cathode

Fluorescent Tube ) The characteristics of two dual lamps are shown in the following tables.

Ta=25 ± 2°C

NoteUnitMax.Typ.Min.SymbolItem

Lamp Current

Lamp Voltage

Lamp Frequency

Asymmetry

Inverter

waveform

Note (1) Specified values are for a single lamp.

Lamp current is measured with current meter for high frequency as shown below.

Refer to the following block diagram of the back light unit for more information.

rate

Distortion

rate

L

L

L

(1)mArms8.07.54.0I

Vrms-760-V

(2)kHz60-40f

(3)Hour--50,000HrOperating Life Time

%10--Wasy

(4)

1.55541.4141.2726Wdis

--VsStartup Voltage

0℃ : 1,700

25℃: 1,400

(5)Vrms

LCD Module

HOT

COLD

I

1

A

INVERTER

HOT

COLD

Fig. Measurement point of Lamp Current

I2

A

15/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 43

Approval Specification

−

Approval Specification

(2) Lamp frequency which may produce interference with horizontal synchronous

frequency may cause line flow on the display. Therefore lamp frequency should be

detached from the horizontal synchronous frequency and its harmonics as far as

possible in order to avoid interference.

(3) Life time (Hr) is defined as the time when brightness of a lamp unit itself becomes

50% or less than its original value at the condition of Ta = 25±2°C and IL= 7.5mArms

(4) Designing a system inverter intended to have better display performance, power

efficiency and lamp reliability.

They would help increase the lamp lifetime and reduce leakage current.

a. The measurement should be done at typical lamp current.

b. The asymmetry rate of the inverter waveform should be less than 10%.

c. The distortion rate of the waveform should be √2 with ±10% tolerance.

- Inverter output waveform had better be more similar to ideal sine wave.

Asymmetry rate

p-p

I

p

I

-p

Fig. Wave form of the inverter

(5) If an inverter has shutdown function, it should keep its output for over 1 second

even if the lamp connector is open. Otherwise the lamps may not be turned on.

||II

I

rms

Distortion rate

I

p

||

I

or

rms

× 100

I

-p

||

I

rms

16/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 44

4. BLOCK DIAGRAM

4.1 TFT LCD Module

RSDS

Control signal

Approval Specification

Approval Specification

Source Driver ICs

LVDS

pair #1

LVDS

pair #2

CN1

(30pin)

LVDS (Rx)

LVDS(Tx)

Timing Controller

+5.0V

V

DD

Power

Circuit

4.2 Back Light Unit

Connector: YEONHO 35001HS-02L Or Compatible

S1 S1680

Control signal

Column Driver Circuit

TFT-LCD

(1680 x RGB x 1050 pixels)

LAMP(CCEL)

LAMP(CCEL)

LAMP(CCEL)

LAMP(CCEL)

HOT

1

COLD

2

HOT

1

COLD

2

17/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 45

Approval Specification

5. Input Terminal Pin Assignment

Approval Specification

5.1. Input Signal & Power ( Connector : UJU IS100-L30O-C23 or Compatible )

FUNCTIONSYMBOLPIN NO

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

RXO0P

RXO1N

Negative LVDS differential data outputRXO0N

Positive LVDS differential data output

Negative LVDS differential data output

Positive LVDS differential data outputRXO1P

Negative LVDS differential data outputRXO2N

Positive LVDS differential data outputRXO2P

GroundGND

Negative Sampling Clock (ODD data)RXOCPositive Sampling Clock (ODD data)RXOC+

Negative LVDS differential data outputRXO3N

Positive LVDS differential data outputRXO3P

Negative LVDS differential data outputRXE0N

Positive LVDS differential data outputRXE0P

GroundGND

Negative LVDS differential data outputRXE1N

Positive LVDS differential data outputRXE1P

GroundGND

18

19

21

22

24

25

26

28

29

30

VDD

VDD

VDD

Negative LVDS differential data outputRXE2N

Positive LVDS differential data outputRXE2P

Negative Sampling Clock (EVEN data)RXEC-20

Positive Sampling Clock (EVEN data)RXEC+

Negative LVDS differential data outputRXE3N

Positive LVDS differential data outputRXE3P23

GroundGND

* CE (For LCD internal use only. Do not connect)NC

* CTL (For LCD internal use only. Do not connect)NC

No ConnectionNC27

Power Supply : +5V

* If the system already uses the 25, 26pins, it should keep under GND level

The voltage applied to those pins should not exceed -200mV.

18/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 46

Note) Pin number starts from Left side

▼

UJU IS100-L30O-C23 or JAE FI-XB30SSL-HF15

PCB

▼

Pin No. 1 Pin No. 30

#30#1

Approval Specification

Approval Specification

#30#1

Fig. Connector diagram

a. All GND pins should be connected together and also be connected to the

LCD’s metal chassis.

b. All power input pins should be connected together.

c. All NC pins should be separated from other signal or power.

19/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 47

5.2 LVDS Interface (1)

5.2.1 Odd Pixel Data (1st pixel data)

LVDS Transmitter ( DS90C383, DS90C385 ) Signal Interface

Approval Specification

Approval Specification

Device Input SignalDevice Input Pin

Red Odd Pixel Data (LSB) RO0TXIN0 51

Red Odd Pixel Data RO1TXIN1 52

Red Odd Pixel Data RO2TXIN2 54

Red Odd Pixel Data RO3TXIN3 55

Red Odd Pixel Data RO4TXIN4 56

Red Odd Pixel Data (MSB) RO7TXIN5 2

Red Odd Pixel Data RO5TXIN6 3

Green Odd Pixel Data (LSB)GO0TXIN7 4

Green Odd Pixel Data GO1TXIN8 6

Green Odd Pixel Data GO2TXIN9 7

Green Odd Pixel Data GO6TXIN108

Green Odd Pixel Data (MSB)GO7TXIN1110

Output

Signal

TXOUT0-

TXOUT0+

TXOUT3-

TXOUT3+

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT3-

TXOUT3+

To LTM220MT

Interface ( CN101 )

SymbolTerminalFunctionSymbolSymbolNo

No. 1

No. 2

No. 10

No. 11

No. 1

No. 2

No. 3

No. 4

No. 10

No. 11

RXO0-

RXO0+

RXO3-

RXO3+

RXO0-

RXO0+

RXO1-

RXO1+

RXO3-

RXO3+

Green Odd Pixel Data GO3TXIN1211

Green Odd Pixel Data GO4TXIN1312

Green Odd Pixel Data GO5TXIN1414

Blue Odd Pixel Data (LSB) BO0TXIN1515

Blue Odd Pixel Data BO6TXIN1616

Blue Odd Pixel Data (MSB) BO7TXIN1718

Blue Odd Pixel Data BO1TXIN1819

Blue Odd Pixel Data BO2TXIN1920

Blue Odd Pixel Data BO3TXIN2022

Blue Odd Pixel Data BO4TXIN2123

Blue Odd Pixel Data BO5TXIN2224

Red Odd Pixel Data RO6TXIN2750

TXOUT1-

TXOUT1+

TXOUT3-

TXOUT3+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXOUT3-

TXOUT3+

No. 3

No. 4

No. 10

No. 11

No. 3

No. 4

No. 5

No. 6

No. 10

No. 11

RXO1-

RXO1+

RXO3-

RXO3+

RXO1-

RXO1+

RXO2-

RXO2+

RXO3-

RXO3+

20/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 48

5.2.2 Even Pixel Data (2nd pixel data)

LVDS Transmitter ( DS90C383, DS90C385 ) Signal Interface

Approval Specification

Approval Specification

Device Input SignalDevice Input Pin

Red Even Pixel Data (LSB) RE0TXIN0 51

Red Even Pixel Data RE1TXIN1 52

Red Even Pixel Data RE2TXIN2 54

Red Even Pixel Data RE3TXIN3 55

Red Even Pixel Data RE4TXIN4 56

Red Even Pixel Data (MSB) RE7TXIN5 2

Red Even Pixel Data RE5TXIN6 3

Green Even Pixel Data (LSB)GE0TXIN7 4

Green Even Pixel Data GE1TXIN8 6

Green Even Pixel Data GE2TXIN9 7

Green Even Pixel Data GE6TXIN108

Green Even Pixel Data (MSB)GE7TXIN1110

Output

Signal

TXOUT0-

TXOUT0+

TXOUT3-

TXOUT3+

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT3-

TXOUT3+

To LTM220MT

Interface ( CN101 )

SymbolTerminalFunctionSymbolSymbolNo

No. 12

No. 13

No. 22

No. 23

No. 12

No. 13

No. 15

No. 16

No. 22

No. 23

RXE0-

RXE0+

RXE3-

RXE3+

RXE0-

RXE0+

RXE1-

RXE1+

RXE3-

RXE3+

Green Even Pixel Data GE3TXIN1211

Green Even Pixel Data GE4TXIN1312

Green Even Pixel Data GE5TXIN1414

Blue Even Pixel Data (LSB) BE0TXIN1515

Blue Even Pixel Data BE6TXIN1616

Blue Even Pixel Data (MSB) BE7TXIN1718

Blue Even Pixel Data BE1TXIN1819

Blue Even Pixel Data BE2TXIN1920

Blue Even Pixel Data BE3TXIN2022

Blue Even Pixel Data BE4TXIN2123

Blue Even Pixel Data BE5TXIN2224

Red Even Pixel Data RE6TXIN2750

TXOUT1-

TXOUT1+

TXOUT3-

TXOUT3+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXOUT3-

TXOUT3+

No. 15

No. 16

No. 22

No. 23

No. 15

No. 16

No. 18

No. 19

No. 22

No. 23

RXE1-

RXE1+

RXE3-

RXE3+

RXE1-

RXE1+

RXE2-

RXE2+

RXE3-

RXE3+

21/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 49

5.2 LVDS Interface (2)

5.2.3 Odd Pixel Data (1st pixel data)

LVDS Transmitter ( DS90C387 ) Signal Interface

Approval Specification

Approval Specification

Device Input SignalDevice Input Pin

Red Odd Pixel Data (LSB) RO0R1010

Red Odd Pixel Data RO1R119

Red Odd Pixel Data RO2R12 8

Red Odd Pixel Data RO3R13 7

Red Odd Pixel Data RO4R14 6

Red Odd Pixel Data (MSB) RO7R17 3

Red Odd Pixel Data RO5R15 5

Green Odd Pixel Data (LSB)GO0G10 2

Green Odd Pixel Data GO1G11 1

Green Odd Pixel Data GO2G12 100

Green Odd Pixel Data GO6G1694

Green Odd Pixel Data (MSB)GO7G1793

Output

Signal

A0M

A0P

A3M

A3P

A0M

A0P

A1M

A1P

A3M

A3P

To LTM220MT

Interface ( CN101 )

SymbolTerminalFunctionSymbolSymbolNo

No. 1

No. 2

No. 10

No. 11

No. 1

No. 2

No. 3

No. 4

No. 10

No. 11

RXO0-

RXO0+

RXO3-

RXO3+

RXO0-

RXO0+

RXO1-

RXO1+

RXO3-

RXO3+

Green Odd Pixel Data GO3G1399

Green Odd Pixel Data GO4G1496

Green Odd Pixel Data GO5G1595

Blue Odd Pixel Data (LSB) BO0B1092

Blue Odd Pixel Data BO6B1686

Blue Odd Pixel Data (MSB) BO7B1785

Blue Odd Pixel Data BO1B1191

Blue Odd Pixel Data BO2B1290

Blue Odd Pixel Data BO3B1389

Blue Odd Pixel Data BO4B1488

Blue Odd Pixel Data BO5B1587

Red Odd Pixel Data RO6R164

A1M

A1P

A3M

A3P

A1M

A1P

A2M

A2P

A3M

A3P

No. 3

No. 4

No. 10

No. 11

No. 3

No. 4

No. 5

No. 6

No. 10

No. 11

RXO1-

RXO1+

RXO3-

RXO3+

RXO1-

RXO1+

RXO2-

RXO2+

RXO3-

RXO3+

22/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 50

5.2.4 Even Pixel Data (2nd pixel data)

LVDS Transmitter ( DS90C387 ) Signal Interface

Approval Specification

Approval Specification

Device Input SignalDevice Input Pin

Red Even Pixel Data (LSB) RE0R2084

Red Even Pixel Data RE1R2181

Red Even Pixel Data RE2R22 80

Red Even Pixel Data RE3R23 79

Red Even Pixel Data RE4R24 78

Red Even Pixel Data (MSB) RE7R27 75

Red Even Pixel Data RE5R25 77

Green Even Pixel Data (LSB)GE0G20 74

Green Even Pixel Data GE1G21 73

Green Even Pixel Data GE2G22 72

Green Even Pixel Data GE6G2666

Green Even Pixel Data (MSB)GE7G2765

Output

Signal

A4M

A4P

A7M

A7P

A4M

A4P

A5M

A5P

A7M

A7P

To LTM220MT

Interface ( CN101 )

SymbolTerminalFunctionSymbolSymbolNo

No. 12

No. 13

No. 22

No. 23

No. 12

No. 13

No. 15

No. 16

No. 22

No. 23

RXE0-

RXE0+

RXE3-

RXE3+

RXE0-

RXE0+

RXE1-

RXE1+

RXE3-

RXE3+

Green Even Pixel Data GE3G2371

Green Even Pixel Data GE4G2470

Green Even Pixel Data GE5G2569

Blue Even Pixel Data (LSB) BE0B2064

Blue Even Pixel Data BE6B2658

Blue Even Pixel Data (MSB) BE7B2757

Blue Even Pixel Data BE1B2163

Blue Even Pixel Data BE2B2262

Blue Even Pixel Data BE3B2361

Blue Even Pixel Data BE4B2460

Blue Even Pixel Data BE5B2559

Red Even Pixel Data RE6R2676

A5M

A5P

A7M

A7P

A5M

A5P

A6M

A6P

A7M

A7P

No. 15

No. 16

No. 22

No. 23

No. 15

No. 16

No. 18

No. 19

No. 22

No. 23

RXE1-

RXE1+

RXE3-

RXE3+

RXE1-

RXE1+

RXE2-

RXE2+

RXE3-

RXE3+

23/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 51

5.2.5 Timing Diagrams of LVDS For Transmitting

LVDS Receiver : Integrated T-CON

Approval Specification

Approval Specification

24/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 52

5.3 Back Light Unit

Upper

Lower

Connect

or

Part No.

Approval Specification

Approval Specification

YEONHO 35001HS-02L

FunctionColorInputPin No.

High VoltageRedHot1

GroundWhiteCold2

High VoltageRedHot1

GroundWhiteCold2

25/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 53

Approval Specification

Approval Specification

5.3 Input Signals, Basic Display Colors and Gray Scale of Each Color

DATA SIGNAL

OF

RED

OF

OF

DISPLAY

(8bit)

DARK

↑

↓

LIGHT

DARK

↑

↓

LIGHT

DARK

↑

↓

LIGHT

1111111100000000CYAN

1111111111111WHITE

:::::

00000000011111111RED

:::::::::

:::::::::::::

COLOR

BASIC

COLOR

GRAY

SCALE

GRAY

SCALE

GREEN

GRAY

SCALE

BLUE

BLUEGREENRED

B3B2B1B0G7G6G5G4G3G2G1G0R7R6R5R4R3R2R1R0

:::::::::::::

::::::::::::::::::

:::::::::

::::::::::::::::::

000001111111100000000GREEN

:::::

::::::::::::::::::

GRAY

SCALE

LEVEL

B7B6B5B4

-000000000000000000000000BLACK

-111111110000000000000000BLUE

-000000001111111100000000GREEN

-11111111

-000000000000000011111111RED

-111111110000000011111111MAGENTA

-000000001111111111111111YELLOW

-11111111111

R0000000000000000000000000BLACK

R1000000000000000000000001

R2000000000000000000000010

R3~

R252

R253000000000000000011111101

R254000000000000000011111110

R2550000000

G0000000000000000000000000BLACK

G1000000000000000100000000

G2000000000000001000000000

G3~

G252

G253000000001111110100000000

G254000000001111111000000000

G255000

B0000000000000000000000000BLACK

B1000000010000000000000000

B2000000100000000000000000

B3~

B252

B253111111010000000000000000

B254111111100000000000000000

B255111111110000000000000000BLUE

Note (1) Definition of Gray :

Rn : Red Gray, Gn : Green Gray, Bn : Blue Gray (n = Gray level)

Input Signal : 0 = Low level voltage, 1 = High level voltage

26/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 54

6. Interface Timing

6.1 Timing Parameters ( DE only mode )

Approval Specification

Approval Specification

NOTEUnitMAX.TYP.MIN.SYMBOLITEMSIGNAL

Clock

Hsync

Vsync

Frequency

C

H

V

Active

Vertical

Display Term

Display

Period

Vertical Total

VD

V

Active

Horizontal

Display

Period

HD

clocks840840840T

Display Term

Horizontal

Total

H

clocks1004920890T

Note (1) This product is DE only mode. The input of Hsync & Vsync signal does

not have an effect on normal operation.

-MHz77.559.652.61/T

-KHz83.264.857.2F

-Hz766053F

-lines105010501050T

-lines119510801059T

2pixel/

clock

2pixel/

clock

(2) Test Point : TTL control signal and CLK at LVDS Tx input terminal in system

(3) Internal Vcc = 3.3V

(4) Best operation clock frequency is 59.6MHz (60Hz)

T

(5) Clock frequency = Frame frequency x

(Typ) x TH(Typ)

V

(6) Max, Min variation range is at main clock Typ value (59.6MHz).

27/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 55

6.2 Timing diagrams of interface signal ( DE only mode )

TV

Approval Specification

Approval Specification

DE

DE

DCLK

DATA

SIGNALS

TVD

TVB

TH

THD

TC

DCLK

DISPLAY

DATA

DE

TC

TCH

TDS TDH

TES

TCL

0.5

V

0.5

V

CC

0.5

V

CC

CC

28/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 56

Approval Specification

Approval Specification

6.3 Power ON/OFF Sequence

To prevent a latch-up or DC operation of the LCD Module, the power on/off

sequence should be as the diagram below.

300㎲≤T1≤10msec

0≤T2≤50msec

0≤T3≤50msec

1sec≤T4

Back-Light

(Recommended)

500msec≤T5

100msec≤T6

T1 : VDDrising time from 10% to 90%

T2 : The time from V

T3 : The time from valid data off to V

T4 : V

off time for Windows restart

DD

to valid data at power ON.

DD

off at power Off.

DD

T5 : The time from valid data to B/L enable at power ON.

T6 : The time from valid data off to B/L disable at power Off.

The supply voltage of the external system for the Module input should be the same

as the definition of V

DD

.

Apply the lamp voltage within the LCD operation range. When the back light turns on

before the LCD operation or the LCD turns off before the back light turns off,

the display may momentarily show abnormal screen.

In case of V

= off level,

DD

please keep the level of input signals low or keep a high impedance.

T4 should be measured after the Module has been fully discharged between power off

and on period.

Interface signal should not be kept at high impedance when the power is on.

29/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 57

6.4 VDD Power Dip Condition

V

DD

90%

Approval Specification

Approval Specification

T

d

80%

V

CC

GND

4.5V ≤ VDD≤ 5.5V

If VDD(typ.) x 80% ≤ VCC≤ VDD(typ) x 90%

Then, 0<Td ≤20msec

Note (1) The above conditions are for the glitch of the input voltage.

(2) For stable operation of an LCD Module power, please follow them.

i.e., if typ VDD x 80% ≤ Vcc ≤ typ VDD x 90%, then T

should be less than 20ms.

d

30/39Page05-000-G-080902Doc. NoLTM220MT05MODEL

Page 58

MW22

Service Manual

03. Exploded Diagram

3.1 Screw List

Fixed

Item Part No. Description Qty

T(kg*cm)

Remark

1 509146306200R SCREW,P,CROSS,

5 3.75±0.25 chassis&PCBA

W/WAS,M3*6,Zn-Cc

2 509116612102R SCREW,B,CROSS,

4 11±1 Hinge &support*3

M4*12,BLK-Zn,ROH

S(NYLOK)#

3 509000000700R BOLT,#4-40x11.8,Ni

4 4.0±0.25 D-SUB CON *2&DVI

ROHS

3.2 Exploded Diagram

31

Page 59

Page 60

MW22

Service Manual

04. TROUBLE SHOOTING

1. Common Acknowledge

z If you change the interface board, make sure that the U103, U105, U106, U108and U201 these five components also changed

to the new I/F board because there are program and data insides. If not, please re-write EDID or upload firmware into MCU via

VGA or DVI Cable.

z If you adjust clock and phase, please do it at the condition of Windows 98 or Windows 2000 shut down pattern.

z If you want to confirm the R.G.B. colors is normal or not, please do auto-balance under 32-grays scalar pattern.

z This LCM is analog/Dual interface. So if the entire screen is an abnormal color that means the problem happen in the analog

circuit part, if only some scale appears abnormal color that means the problem happen in the digital circuit part.

z If you check the H/V position, please use the crosshatch pattern.

z This LCM support more than 25 timing modes, if the input timing mode is out of specification, the picture may appears

abnormally.

z If brightness uneven, repairs inverter circuit or change a new panel.

z If you find the vertical line or horizontal line lost on the screen, please change panel.

32

Page 61

MW22

Service Manual

2. Backlight can’t be turned on

Is there high-level voltage

on pin4 of IC501?

Is there instantaneously pulse wave

on pin1, pin11, pin14 of IC501 at the

moment of restart?

No raster?

Ye s

LED orange?

Ye s

Backlight can’t

be turned on.

Ye s

Is there 24Vdc

voltage on pin9 of

IC501?

Ye s

Are connected rightly

CN501, CN502, CN503 and

CN504?

Ye s

Ye s

Is ok T501, T502?

Ye s

Check feedback circuit

No

No

No

Check power supply

Is Ok R502?

No Ye s

No

No Is Ok IC501?

Ye s

No

Check I/F

board

R502 open

Connecting the

output connector

again

Ye s

U501, U502 fail

IC501 fail

T501, T502 fail

END

33

Page 62

MW22

Service Manual

3. No Power & Power LED Off

Unstable power

Check sampling

Circuit

Check the R pin

voltage of IC803

about 2.5V

Check pin2 of

IC802 voltage is

3V

END

Check R822, R824,

R825,R826

Check the C pin

voltage of IC803

if 3V

Check R832

Check FB801, D803,

C807 if short

Change FB801,

D803,

C807

Change R822, R824,

R825,R826

Change

IC803

34

Page 63

MW22

Service Manual

4. Black Screen and backlight turn on

Black Screen

Check power supply:

Pin1, 2 of0 CN101

OK

Check pin53, 74,104, and126

Of U105

OK

Check pin40, 54, 58,59,60,

65,66,71,87,107,112,114,8,14

and 20

Of U105

OK

Check Reset (pin108)

Of U105

OK

Check Crystal: Pin127,

Pin128 Of U105

OK

Check CCFL - Enable

(pin109) of U105

NG

MCU Fail

NG

NG

NG

Check FB102,

NG

NG

Check C164

Check: X101, C157,

C158,R147,R148

OK

OK

Check pin5 of

CN101

NG

35

Power Fail

Check FB105

And U102

And U101

Inverter Fail

Check R105, Q103

R106, R103

Page 64

MW22

Service Manual

5. White Screen

White Screen

LVDS Cable

Reinsert

Change LVDS

NG

Cable

OK

Workmanship

OK

LVDS Cable NG

NG

Check VLCD

Is 5V?

NG

Check Panel - Enable

Of U105 (pin73) is High?

Check R107,

Q104, Q101

OK OK

NG

Check LVDS

Signals

NG

Check the HW Reset

Of U105 pin108

OK

Check the pins

Of U105

Panel Fail

NG

Check C164

END

36

Page 65

MW22

Service Manual

6. Bad Screen

Bad Screen

LVDS Cable

Reinsert

Change LVDS

NG

Cable

Check Crystal: Pin127,

Pin128 Of U105

NG

OK

Workmanship

OK

LVDS Cable NG

OK

Check: X101, C157,

C158,R147,R148

Check the communication

of the U108 and U105

Check the Pins of

The U108 and U105

END

NG

Check :SDO,CSZ,

SCK,SDO,Reset

37

Page 66

MW22

Service Manual

05. Spare parts List

ACER PART

NO.

55.C200J.001 793281300800H

19.C200J.001 793281400800H

OEM PART NO DESCRIPTIONPART NAME

POWER/INVERTER

BOARD W/SPK

MAIN BOARD

BOARD W/SPK

8221T981G120R

ET.C200C.003

PCBA,I/F

BOARD(EMEA,W/SPK)

,LE22T9-812

PCBA,P/I

BOARD,W/SPK,LE22T

9-812

55.C210J.002 793281500000H KEYPAD BOARD

PWRCORD

27.LBN0J.001 453070801190R

50.LBQ0J.001 453010100380R

16A/250V BLK 6FT

VDE/KTL H05VV-F

CABLE D-SUB 15P

BLACK

PCBA,KEYPAD

BOARD,LE22T9

PWRCORD 16A/250V

BLK 6FT VDE/KTL

H05VV-F

CABLE,D-SUB 15P

MALE 6FT

BLACK/BLUE, ROH

38

Page 67

MW22

Service Manual

50.L63VF.003 453030300120R

50.LA10J.003 453030300370R

50.C200J.001 430300803340H KEYPAD CABLE(1)

50.C210J.001 430300803320H KEYPAD CABLE(2)

CABLE AUDIO 1P

6FT

CABLE DVI-D

18+1P MALE 6FT

BLACK ROHS

CABLE AUDIO 1P 6FT

BLACK/GREEN

CP03B06P0

CABLE,DVI-D 18+1P

MALE 6FT BLACK ,

ROHS

HRN ASSY 2X4P TO

8P UL3302#28 150mm

HRN ASSY 8P

UL3302#28 150mm

50.C200J.002 430303001510H

23.C200J.001 618100200370H SPEAKER

60.C200J.001 714030032800R BEZEL

LVDS CABLE

(PANEL TO M/B)

HRN LVDS FFC 30P

228mm

SPEAKER 2.5W 4Ω

270mm R/B/G W/CASE

ASSY,FRONT,BEZEL,L

E22T9

39

Page 68

MW22

Service Manual

60.C200J.002 501020238200R

60.C200J.003 502020310001R STAND (BLACK) STAND,MW22,LE22T9

60.C210J.004 501240218600R BASE BASE,MR19,LE19U1

BACK COVER

(W/SPK,W/DVI)

COVER,BACK,W/D,W/

SW,LE22T9

60.C200J.004 701000019300R

LK.22006.013 631102220960HA

CHASSIS

(W/SPK,W/DVI)

LCP 19"

LM190E08TLJ2(A)(LPL)ROHS

ASSY,CHASSIS,W/D,

W/SW,LE22T9

LCP 22"LTM220MT05A01(A)(SAMSUNG)HF

40

Page 69

MW22

Service Manual

06. Schematics and Layouts

6.1 Lay Out

I/F Board Lay Out

41

Page 70

MW22

Service Manual

42

Page 71

MW22

Service Manual

P/I Board Lay Out

43

Page 72

MW22

Service Manual

44

Page 73

MW22

Service Manual

Keypad Board Lay out

6.2 Switching Mode Power Supply circui

45

Page 74

5

4

3

2

1

IC801

LTV817M

R827 56

14

13

D807 SRF10-06CT-LF

9

1

10

3

1

3

11

12

14

2

C805

4700p/400V

DC 380V Max.

D D

C C

B B

D801

BL4-06

3

AC 264V RMS

R801

1M

AC 264V RMS

RT801

NTC 5R

F801

3.15A/250V

1

4

L801

R802 1M

C803

0.47/275V

C804

+

100u/450V

2

-+

AC 264V RMSAC 264V RMS

34

17mH

21

CN803

Gate

Isense

GND

FB

GND

VDD

NC

Vin

CON8PIN

1

2

3

4

5

6

7

8

R805

68K 2W

D803

1N4003

+

C807

47u/25V

Q804

AP2761I

ZD803

P6KE150A

R814

10K

1

C806

4700p/400V

D802

MUR1100ERL

DC 650V Max

DC 650V Max

23

R815

0R47 2W

1

2

3

5

6

C808

47P/1KV

T801

SPW-101

3

C828

4700p/400V

C815

330p/500V

D804

SF50-04F69-LF

D805

SF50-04F69-LF

D806

SF50-04F69-LF

C816

2200p/500V

R816

10

2

R836

0R47 2W

2

D808

SRF10-06CT-LF

R829

10

C836

2200p/500V

R820

NC

C819

1000u/10V

+

C837

+

1000u/10V

L804

5uH

R832

270

C

R

A

+

C817

270u/50V

+

C823

1000u/10V

C827

NC

C821

0.1/100V

IC803

TLV431ALP

+

C839

270u/50V

L802

5uH

L803

5uH

+

470u/16V

R821

1K 1%

C840

470u/16V

R823

NC

C820

+

C830

270u/50V

+

C841

0.1/50V

R824

3K3 1%

C818

0.1/50V

+5V

C822

0.1/50V

R822

4K7 1%

Audio VCC5V 4

ZD801

R825

100K 1%

R826

10K

27V

R828

1K 1%

F802

5A/125V

F803

5A/125V

C826

NC

R831

1K 2W

2

R818

10K

31

Q801

2N4401

VCC5V

USB 5V

+24V 3,4

C801

1000p/400V

L

AC_SKT

A A

P801

C802

1000p/400V

1 2 345

N

5

TO SCALER BD CN801

CN801

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14P 2.0mm

C842

0.1/50V

C825

0.1/50V

usb5v

USB 5V

VCC5V

ON/OFF 3

BRIGHTNESS 3

VOLUME 6

MUTE 6

HDMI_AUDIO_L 6

HDMI_AUDIO_R 6

AUDIO_SW 6

4

CN802

1

2

3

4

100mm 4PR

usb5v

InnoLux

Document Number : SIZE :

Viseo200

APPRO BY :

Custom

TITLE :

POWER SUPPLY

DATE :

SHEET OF

3

2

2008-12-02

Rev :

CHECK BY :

DRAWN BY :

V0162

1

Page 75

5

4

3

2

1

R803

NC

8

HV

7

NC

1

RT

R807

100K 1%

R849

NC

R850

NC

6

IC802

LD7575

4

OUT

VCC

CS

COMP

GND

1000p/50V

R851

NC

C811

CN804

C810

0.1/50V

R804

NC

R813

5

3

2

20

R809

680R

C809

220p/50V

1

2

3

4

5

6

7

8

Gate

Isense

GND

FB

GND

VDD

NC

HV

CON8PIN

D D

R808

33K

R806

33K

C C

C812

B B

NC

R844

100K

C838

2.2uF

D812

SN4148

InnoLux

HD2202

Document Number : SIZE :

A

APPRO BY :

TITLE :

A A

DATE :

SHEET OF

5

4

3

POWER Control

2008-12-02

2

Rev :

V0163

CHECK BY :

DRAWN BY :

1

Page 76

5

D D

CN505

1

NC

2

NC

3

GND

4

GND

5

DRIV

6

DRIV

7

+24V

8

+24V

9

BRI

10

EN

LV4

LV3

GND

C C

B B

LV2

LV1

OL4

OL3

OL2

OL1

+5v

CON 20PIN

FB802

11

12

13

14

15

16

17

18

19

20

LV4

LV3

LV2

LV1

OL4

OL3

OL2

OL1

BRIGHTNESS

ON/OFF

+5V 2 +24V2,4

C501

270u/50V

4

2

3

6

7

T501

SPW-149

+

3

C514

5

4

8

1

NC

C515

NC

2

C516

NC

LV1

C517

12p/3KV

LV2

C518

12p/3KV

LV3

C519

NC

LV4

1

OL1

OL2

OL3

OL4

2

R515NCCN504

1

2

R516

316

1

2

R517

316

1

2

R518

NC

1

H

L

NC

CN501

4100-D02

H

L

CN503

4100-D02

H

L

CN502

NC

H

L

InnoLux

Document Number : SIZE :

Viseo200

APPRO BY :

A

TITLE :

A A

DATE :

SHEET OF

5

4

3

INVERTER SUPPLY

2008-12-02

Rev :

2

V0164

CHECK BY :

DRAWN BY :

1

Page 77

5

VIN

R501

91K

4

3

2

1

D D

32

1

R503

91K

R504

10K

3

Q502

MMBT4401

2

1

D503

BAW56

ON/OFF2

C C

BRIGHTNESS2

B B

LI1

C502

220p/50V

R509

2K

R502

30K

1

C505

220p/50V

OL3

OL1

32

Q501

MMBT4401

C503

2200p/50V

R505

110K 1%

C504

2.2u/16V

OV1

OV2

1

OV2

LI1

2

LI1

LI2

3

LI2

4

COMP

5

FT

6

FSET

7

BOSC

REF

8 9

DBRT VIN

IC501

MP1009

3

R527

2K

D501

BAV70

OV1

GND

BG

VCC

SW

TG

1

2

BT

LV1

LV3

OV1

16

C508

1u/16V

15

14

13

12

11

10

C507

0.1/50V

R511

NC

R512

10K

REF

R508

100

REF

R506

22

C506

0.047/50V

R507

22

1

1

U501

AP9971GH

2 3

U502

AP9971GH

2 3

C513

0.1/50V

C509

2.2u/25V

C510

2.2u/25V

C523

0R

LV4

LV3

C522

4700p/50V

BRIGHTNESS

ON/OFF

LV2

C521

4700p/50V

0R

LV1

C520

OL4

OL3

OL2

OL1

CN506

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CON 20PIN

NC

NC

GND

GND

DRIV

DRIV

+24V

+24V

BRI

EN

LV4

LV3

GND

LV2

LV1

OL4

OL3

OL2

OL1

+5V

R513

10K

R514

NC

InnoLux

HD2202

Document Number : SIZE :

APPRO BY :

LI2

R510

2K

D502

BAV70

LV2

1

LV4

2

OL4

2

3

1

D504

BAW56

OL2

OV2

R528

2K

3

A4

A A

5

4

3

TITLE :

Inverter control

DATE :

SHEET OF

2

2008-12-02

Rev :

CHECK BY :

DRAWN BY :

V0165

1

Page 78

5

4

3

2

1

D107

BAT750-LF/NC

+

1

2

D101

SSM24APT

DIO--SMA

R101

0/NC

R0805

3

C104

0.1/16V

DVI5V

D D

CN101

8P 2.0mm

1

2

3

4

5

6

7

8

CON--JWT-A2008WV08P-1

VCC5V

CCFL_ON/OFF

BRIGHTNESS 4

VOLUME 4

MUTE 4

C101

100u/16V

VCC4.5VVGA5V

R173 0/NC

U101

AP1084K33LA

3

VIN

VOUT

PAD

ADJ

1

100u/16V

R0805

C102

U102

2

4

+

C105

0.1/16V

+3.3V 4

C106

0.1/16V

LD1117AL-1.8V

3

VIN

VOUT

PAD

ADJ

1

2

4

C103

22u/16V

+1.8VVCC5V +3.3V+3.3V

+1.8V 4

+

C107

0.1/16V

To Power/Inverter

Board

C C

VCC5V VCC_ESD

ZD101

6V2/NC

R113

0

R0805

GND

C162 0.1/16V

C111

0.1/16V

C175 0.1/16V

GND

ZD107 6V2/NC

+3.3V

R102

10K

CCFL_ENABLE4

R106

100K

GND GND

R103

10K

R105

4K7

CCFL_ON/OFF

32

1

Q103

PMBT3904

PANEL_ENABLE4

GND

C108

0.1/16V

R107

100K

GND

C112

1u/16V

R109

100K

R108

47K

Q101

AP2305GN

1

32

1

32

Q104

PMBT3904

R112

51

R0603

1

Q102

VLCDVCC5V

VLCD 4

32

+

C110 0.1/16V

C109 100u/16V

B B

GNDGND

InnoLux

Document Number : SIZE :

MSTAR_TSUMU58EHJ

APPRO BY :

A4

A A

5

4

3

TITLE :

POWER (DC TO DC)

DATE :

SHEET OF

2

2009-01-05

41

Rev :

CHECK BY :

DRAWN BY :

V01

1

Page 79

5

CN102

DZ11AA1-H5W6-4F

11

12

13

D D

C C

14

15

1

6

2

7

3

8

4

9

5

10

17

16

GND

VGA5V

ZD102 6V2

R

G

B

C126 0.1/16V

R120 0/NC

R121 0

D102

3

BAV99

2

C122

0.1/16V/NC

4

75 1%

75 1%

R117

R118 75 1%

R119

VGA_DET

D103

3

BAV99

1

1

C127

0.1/16V

2

C123

0.1/16V/NC

D104

3

BAV99

2

C124

0.1/16V/NC

1

0.1/16V/NC

2

RB101 0

R0603

RB102 0

R0603

RB103 0

R0603

D105

3

BAV99

C125

3

C116

10p/50V/NC

1

VCC_ESD

C117

10p/50V/NC

C118

10p/50V/NC

2

R114 75 1%

R115 75 1%

R116 75 1%

R122 75 1%

R123 75 1%

R124 75 1%

C113 0.047u/16V

C114 0.047u/16V

C115 0.047u/16V

C119 0.047u/16V

C120 0.047u/16V

C121 0.047u/16V

VGA_DET

VCC5V

R126

0/NC

2

VGA5V

1

3

D106

BAV70

1

C128

0.1/16V

RED+ 4

GREEN+ 4

BLUE+ 4

SOG 4

RED- 4

GREEN- 4

BLUE- 4

VGA_DET 4

GND

VGA_SCL

VGA_SDA

FB101

120Ω

B B

GND

R135 2K2

C129 33p/50V

ZD103 6V2

ZD104 6V2

ZD105 6V2

ZD106 6V2

GND

R136 2K2

R133 1K

R134 1K

C130 33p/50V

C131

33p/50V/NC

GND

C132

33p/50V/NC

HSYNC 4

VSYNC 4

R131 100

R132 100

R127

R128

4K7

R129

10K

R130

1K

MSTAR_TSUMU58EHJ