Page 1

Aspire

easyStore H341/H342

Service Guide

PRINTED IN TAIWAN

Page 2

Revision History

Please refer to the table below for the updates made on Aspire easyStore H341/342 service guide.

Date Chapter Updates

ii

Page 3

Copyright

Copyright © 2010 by Acer Incorporated. All rights reserved. No part of this publication may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or computer language, in

any form or by any means, electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without

the prior written permission of Acer Incorporated.

iii

Page 4

Disclaimer

The information in this guide is subject to change without notice.

Acer Incorporated makes no representations or warranties, either expressed or implied, with respect to the

contents hereof and specifically disclaims any warranties of merchantability or fitness for any particular

purpose. Any Acer Incorporated software described in this manual is sold or licensed "as is". Should the

programs prove defective following their purchase, the buyer (and not Acer Incorporated, its distributor, or its

dealer) assumes the entire cost of all necessary servicing, repair, and any incidental or consequential

damages resulting from any defect in the software.

Acer is a registered trademark of Acer Corporation.

Intel is a registered trademark of Intel Corporation.

Other brand and product names are trademarks and/or registered trademarks of their respective holders.

iv

Page 5

Conventions

The following conventions are used in this manual:

SCREEN

MESSAGES

NOTE Gives additional information related to the current topic.

WARNING Alerts you to any physical risk or system damage that might result from doing

CAUTION Gives precautionary measures to avoid possible hardware or software

IMPORTANT Reminds you to do specific actions relevant to the accomplishment of

Denotes actual messages that appear on screen.

or not doing specific actions.

problems.

procedures.

v

Page 6

Service Guide Coverage

This Service Guide provides you with all technical information relating to the BASIC CONFIGURATION

decided for Acer's "global" product offering. To better fit local market requirements and enhance product

competitiveness, your regional office MAY have decided to extend the functionality of a machine (e.g. add-on

card, modem, or extra memory capability). These LOCALIZED FEATURES will NOT be covered in this generic

service guide. In such cases, please contact your regional offices or the responsible personnel/channel to

provide you with further technical details.

FRU Information

Please note WHEN ORDERING FRU PARTS, that you should check the most up-to-date information available

on your regional web or channel. If, for whatever reason, a part number change is made, it will not be noted in

the printed Service Guide. For ACER-AUTHORIZED SERVICE PROVIDERS, your Acer office may have a

DIFFERENT part number code to those given in the FRU list of this printed Service Guide. You MUST use the

list provided by your regional Acer office to order FRU parts for repair and service of customer machines.

vi

Page 7

Table of Contents

System Tour 1

Features 1

System Tour 2

Front Panel 2

Rear Panel 3

Internal Components 4

System LED Indicators 5

System Utilities 9

AMI BIOS Setup Utility 9

Entering the BIOS Setup Utility 10

Navigating Through the Setup Utility 11

Setup Utility Menus 12

System Disassembly 19

Disassembly Requirements 19

Pre-disassembly Procedure 20

Main Unit Disassembly 21

Removing the Hard Disk 22

Removing the System Cover 25

Removing the Front Bezel 26

Removing the Front I/O Board 28

Removing the Backplane Board 30

Removing the Power Supply 33

Removing the Fan 36

Removing the Memory Module 37

Removing the Mainboard 39

Removing the HDD Access LED cables 40

System Troubleshooting 41

Hardware Diagnostic Procedure 41

System Check Procedures 42

Power system check 42

System external inspection 42

System internal inspection 42

System Diagnosis 43

Hardware diagnostic program 43

Debug card 44

POST Code Checkpoints 45

Viewing BIOS checkpoints 45

POST code checkpoints list 45

System Status Error Codes 50

BIOS Recovery 51

Clearing CMOS 52

Undetermined Problems 53

System Block Diagram and Board Layout 55

System Block Diagram 55

Board Layout 56

Mainboard 56

System Jumpers 57

vii

Page 8

FRU (Field Replaceable Unit) List 59

Exploded Diagram 60

FRU List 62

Technical Specifications 65

viii

Page 9

Chapter 1

System Tour

Features

Below is a brief summary of the home server’s many feature:

NOTE: The features listed in this section is for your reference only. The exact configuration of the server

depends on the model purchased.

Processor

Onboard Intel Atom D410/D510 processor

Chipset

Intel 82801IR I/O Controller Hub (ICH 9R) (Southbridge)

Memory subsystem

Supports DDR2 unbuffered SDRAM

Media storage

Up to four 3.5-inch hot-swappable SATA hard disk drives

Networking

One Gigabit Ethernet LAN port (RJ-45)

I/O ports

USB 2.0 ports (1 front and 4 rear)

Gigabit LAN port

eSATA port

Power supply

220-watts (100/240 Vac) Energy Star compliant power supply

Operating system and software

Operating system:

Windows Home Server

Applications

Windows Home Server Connector

Lights Out Client

Software Update

Server Recovery

PC Recovery

Physical dimensions

WxHxD: 200 x 180 x 212 mm

Weight (without HDD): 4.5 kg (with 1 HDD): 5.1 kg

Chapter 1 1

Page 10

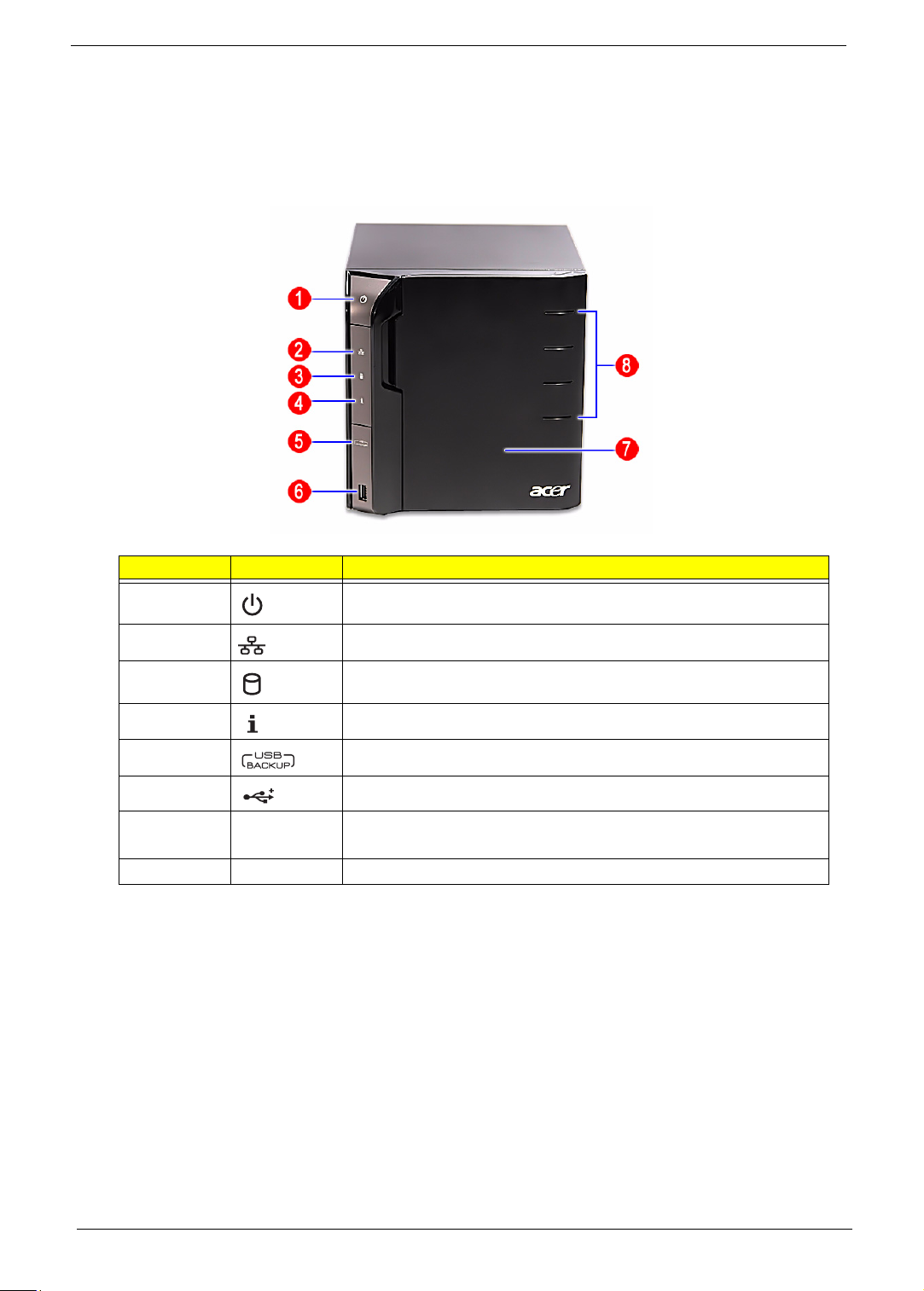

System Tour

This section is a virtual tour of the system’s interior and exterior components.

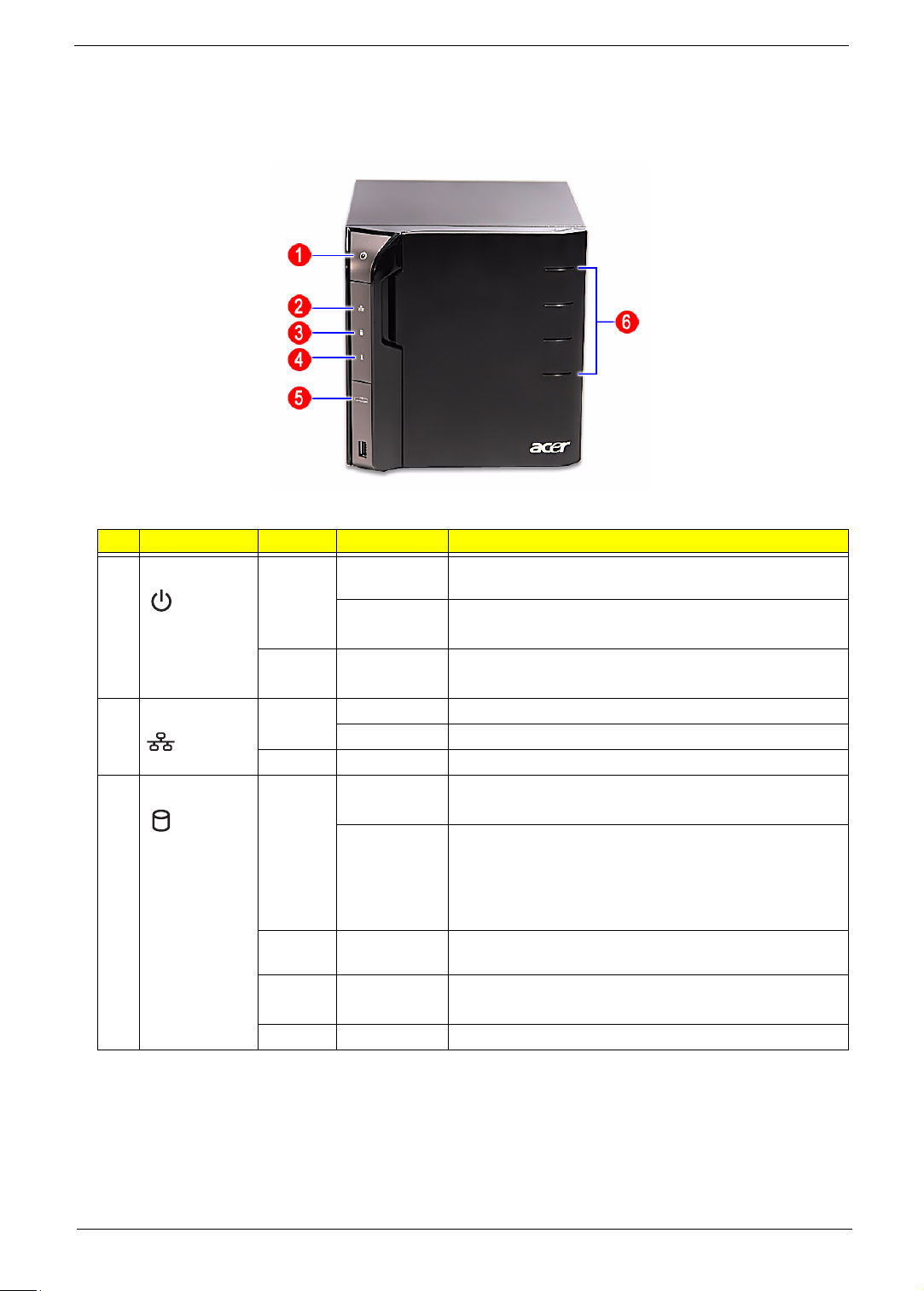

Front Panel

No. Icon Component

1 Power button/power indicator

2 Network indicator

3 Hard disk drive (HDD) status indicator

4 System status indicator

5 USB backup button/USB backup indicator

6 USB 2.0 port

7 Front door

Open the door to access the hot-swappable HDDs.

8 HDD access indicators

2 Chapter 1

Page 11

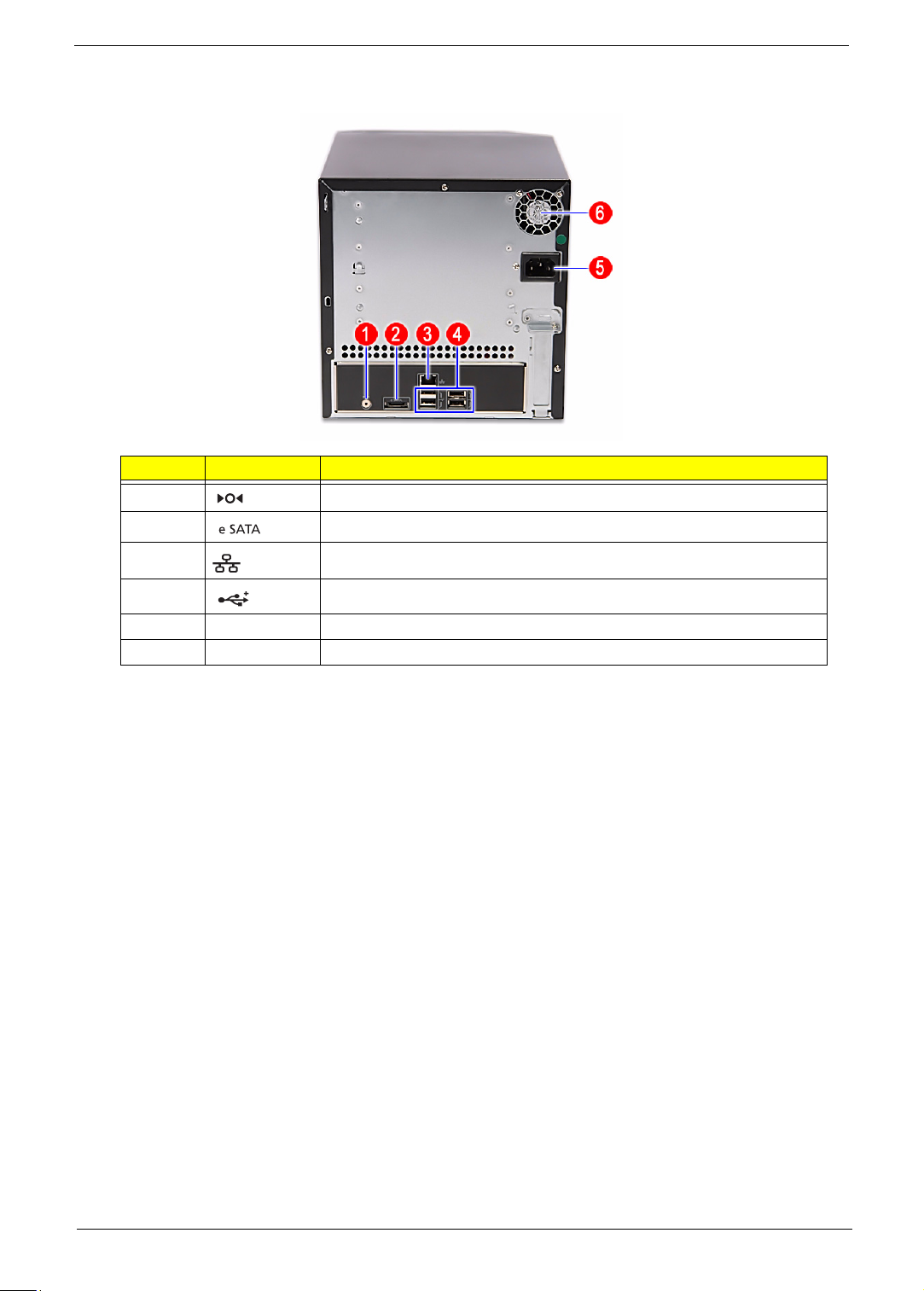

Rear Panel

No. Icon Component

1 Recovery/reset button

2eSATA port

3 Gigabit Ethernet port

4 USB ports

5 Power connector

6 Power fan

Chapter 1 3

Page 12

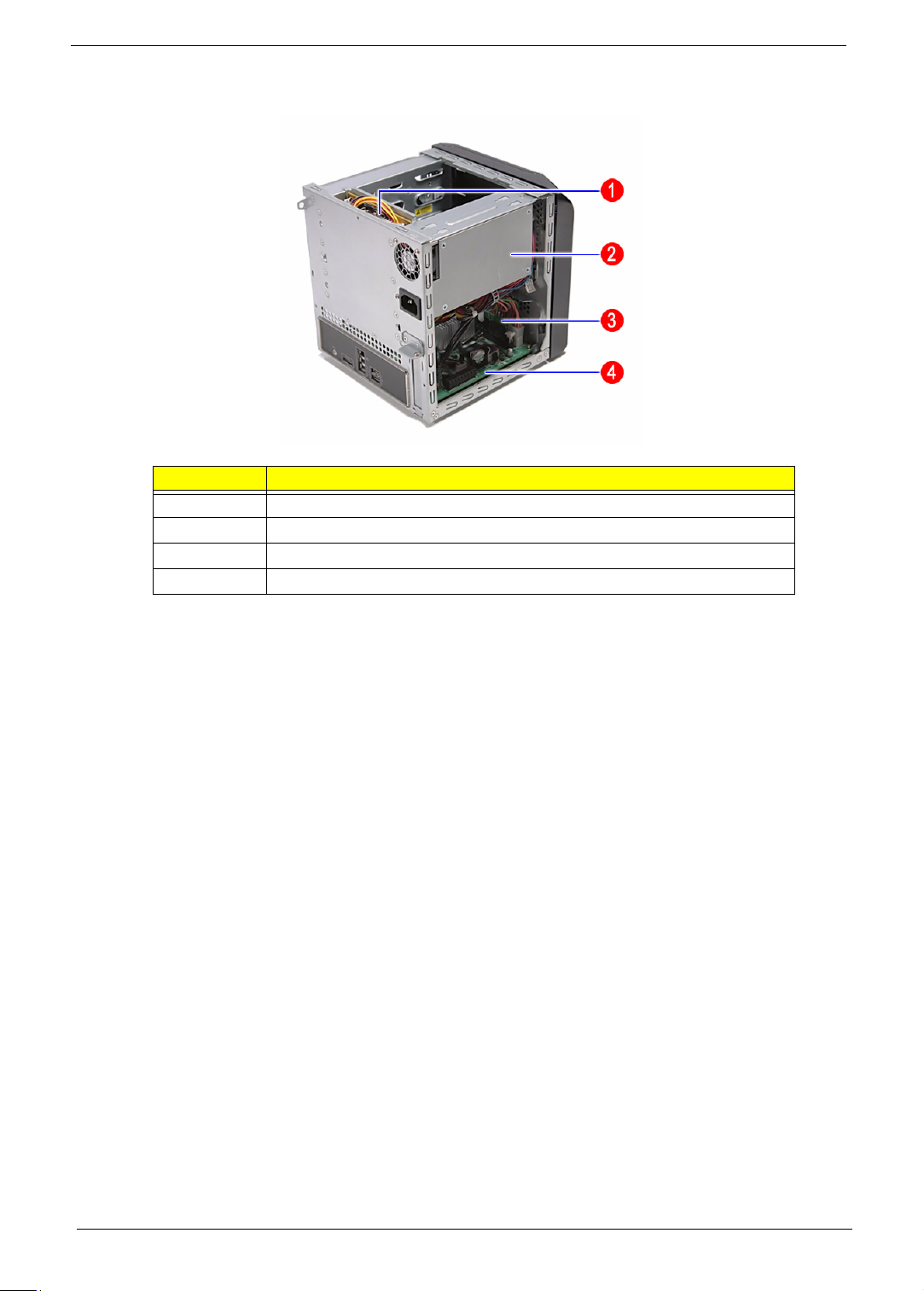

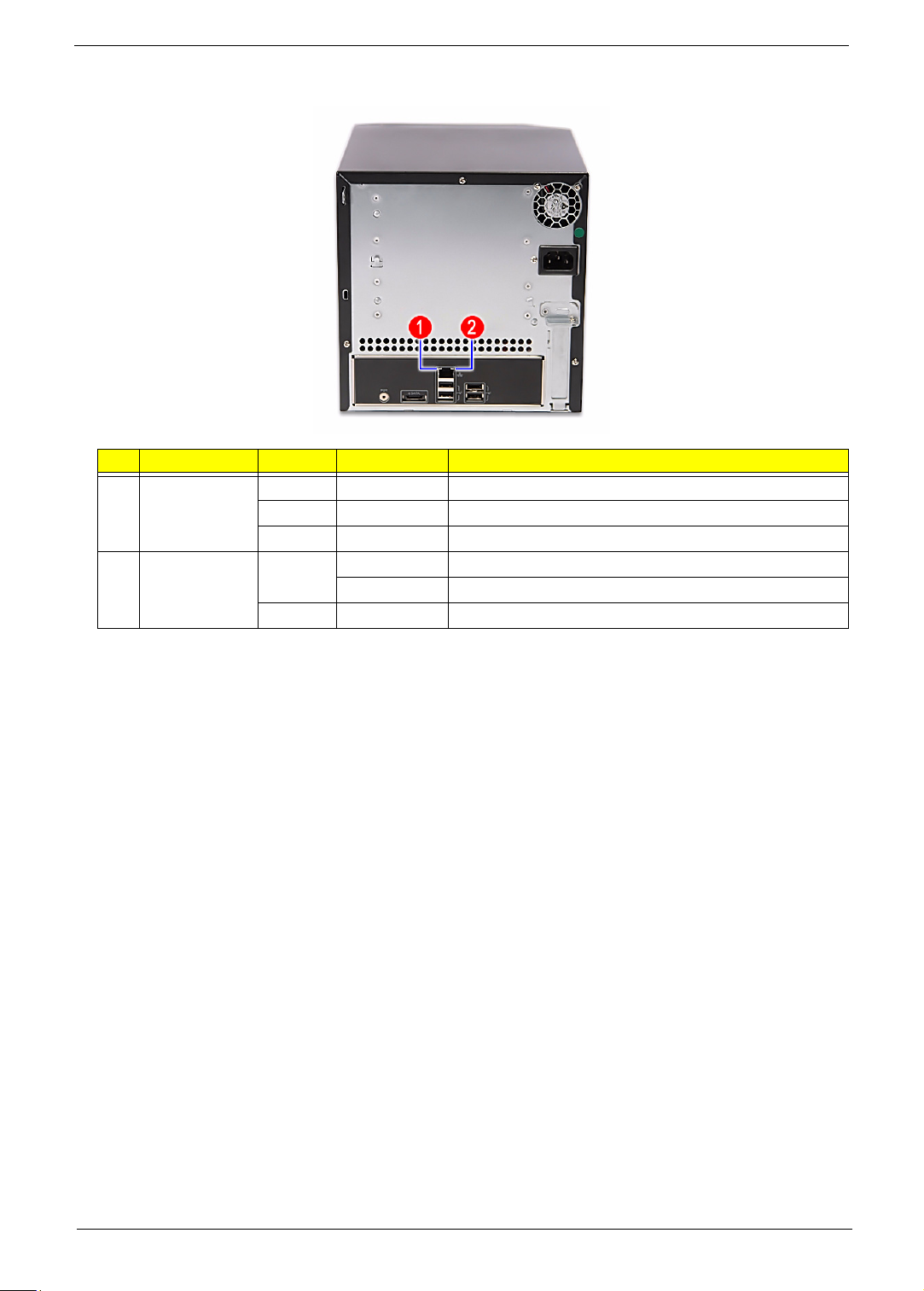

Internal Components

No. Component

1 Backplane board

2 Power supply

3 Memory module

4 Mainboard

4 Chapter 1

Page 13

System LED Indicators

Front panel

This section describes the different system LED indicators.

No. LED indicator Color LED status Description

1 Power Blue On System is connected to the power supply and turned on

and ready for use.

Random blink • System is booting

• System is in S3 sleep state (suspend to memory)

None Off • System is not powered on

• System initialize operation in progress

2 Network Blue On Link between system and network

Random blink Network access

None Off Network disconnected

3 HDD status Purple On • System not initialized

• HDD is not mounted into the drive bay

Random blink • HDD is mounted into the drive bay and is in the

process of being manually added into the server

storage

• HDD is in the process of being removed from the

server storage.

Blue On HDD is mounted into the drive bay and added into the

server storage

Red Random blink • HDD failure

• Windows Home Server cannot find HDD

None Off No HDD mounted in the drive bay

Chapter 1 5

Page 14

No. LED indicator Color LED status Description

4 System status Blue Random blink • System is booting

• System is shutting down

On System initialize operation completed.

Blue and

purple

Red On May indicate the following states:

5 USB device

backup

6 HDD access Blue Blink HDD is in use

Blue On • USB storage device is connected to the USB port

None Off USB storage device unmounted

None Off No HDD activity

Random blink System is booting from a USB device (Reserved for

BIOS update while boot block has been active)

• System failure

• HDD failure

• SATA controller failure

• USB controller failure

• LAN controller failure

• Fan failure

• Memory failure

• Boot device not found

Refer to “System Status Error Codes” on page 50 for

more information.

Random blink System recovery or reset is in progress

• Backup completed

Random blink System is backing up files from a USB storage device

6 Chapter 1

Page 15

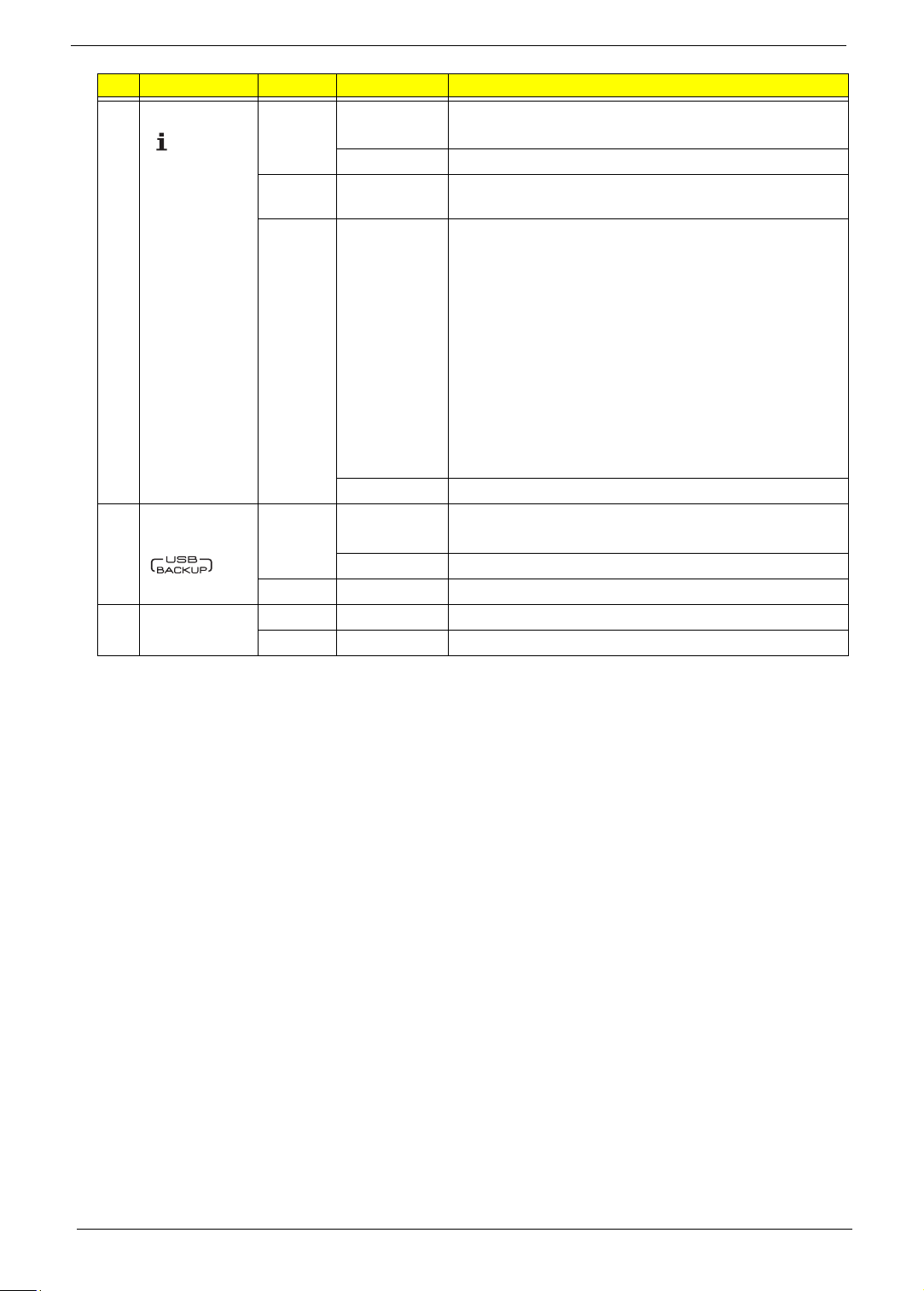

Rear panel

No. LED indicator Color LED status Description

1LAN port

network speed

LED

2LAN port

activity LED

Amber On 1000 Mbps network access

Green On 100 Mbps link network access

None Off 10 Mbps link network access

Green On Active network link

Random blink Transmit or receive activity

None Off No network connection

Chapter 1 7

Page 16

8 Chapter 1

Page 17

Chapter 2

System Utilities

AMI BIOS Setup Utility

BIOS setup is a hardware configuration program built into the system's Basic Input/Output System (BIOS).

Since most systems are already properly configured and optimized, there is no need to run this utility. You will

need to run this utility under the following conditions.

When changing the system configuration settings

When redefining the communication ports to prevent any conflicts

When modifying the power management configuration

When changing the password or making other changes to the security setup

When a configuration error is detected by the system and you are prompted ("Run Setup"

message) to make changes to the BIOS setup

NOTE: If you repeatedly receive Run Setup messages, the battery may be bad. In this case, the system

cannot retain configuration values in CMOS. Ask a qualified technician for assistance.

BIOS setup loads the configuration values in a battery-backed nonvolatile memory called CMOS RAM. This

memory area is not part of the system RAM which allows configuration data to be retained when power is

turned off.

Before you run the AMI BIOS Setup Utility, make sure that you have saved all open files. The system reboots

immediately after you close the Setup.

NOTE: AMI BIOS Setup Utility will be simply referred to as "Setup" or "Setup utility" in this guide.

The screenshots used in this guide display default system values. These values may not be the same

those found in your system.

Chapter 2 9

Page 18

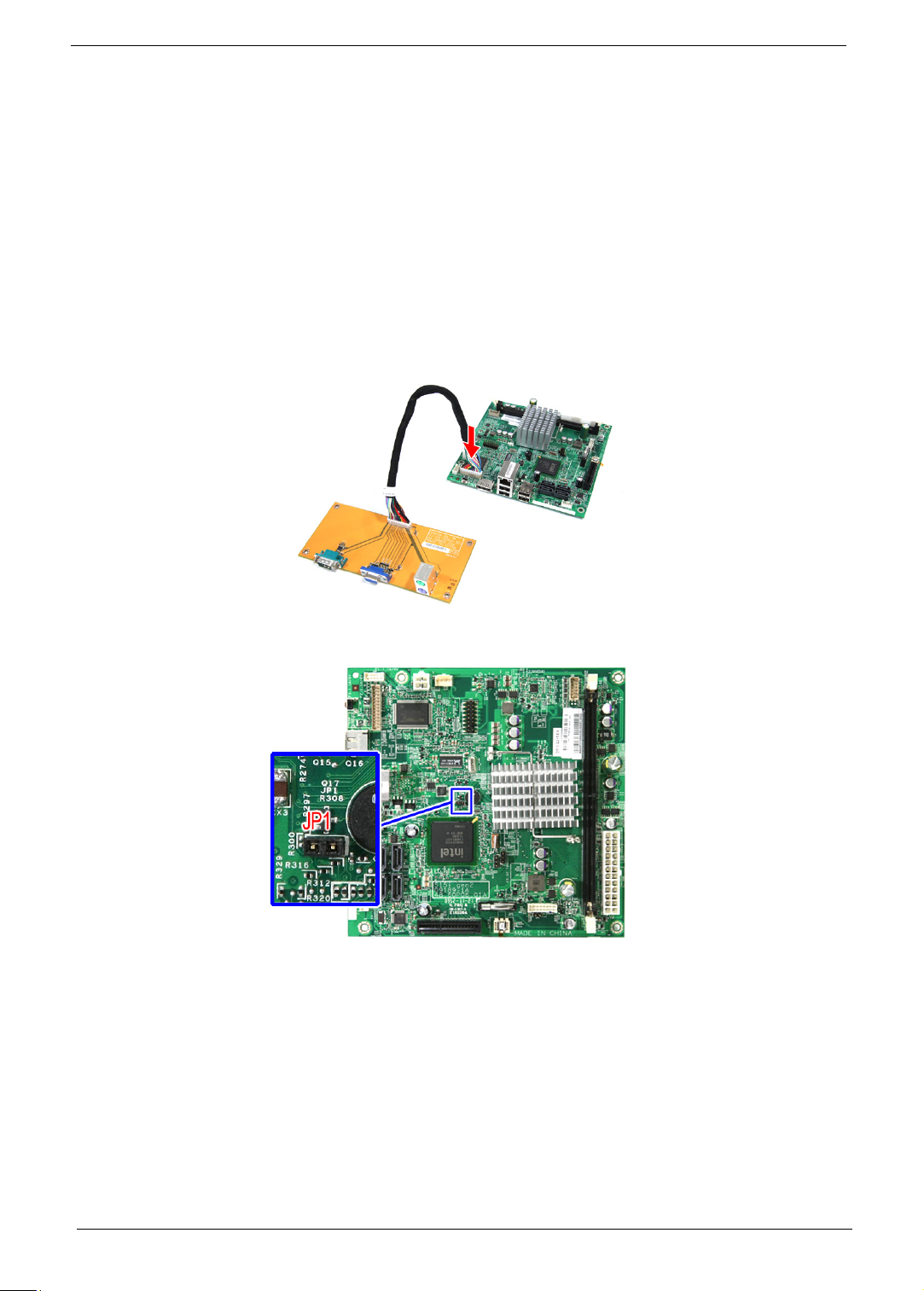

Entering the BIOS Setup Utility

Before you begin, prepare the following:

Wrist grounding strap and conductive mat for preventing electrostatic discharge

Philips screwdriver

Debug card - Refer to page 44 for details about the debug card.

Debug card cable

1. Turn off the computer and all attached devices.

2. Remove the cover. See “Removing the System Cover” on page 25.

3. Connect the debug card cable to the debug card cable connector on the mainboard.

4. Locate the JP1 Debug/User mode jumper on the mainboard.

5. Close the jumper to enable system for debug mode.

6. Connect the power cable to the rear panel.

7. Connect a PS/2 keyboard to the PS/2 keyboard port on the debug card.

8. Connect a monitor to the VGA port on the debug card.

9. Restart the system.

10. Turn on the monitor.

11. During POST, press <Delete>.

If you fail to press <Delete> before POST is completed, you will need to restart the system.

When the Setup Utility screen displays, use the left and right arrow keys to move through the menus.

10 Chapter 2

Page 19

Navigating Through the Setup Utility

Use the following keys to move around the Setup utility.

Left and Right arrow keys – Move between selections on the menu bar.

Up and Down arrow keys – Move the cursor to the field you want.

Pg Up and Pg Dn keys – Move the cursor to the previous and next page of a multiple page menu.

Home – Move the cursor to the first page of a multiple page menu.

End – Move the cursor to the last page of a multiple page menu.

+ and - keys – Select a value for the currently selected field (only if it is user-configurable). Press

these keys repeatedly to display each possible entry, or the Enter key to choose from a pop-up

menu.

NOTE: Grayed-out fields are not user-configurable.

Enter key – Display a submenu screen.

NOTE: Availability of submenu screen is indicated by a (>).

Esc – If you press this key:

On one of the primary menu screens, the Exit menu displays.

On a submenu screen, the previous screen displays.

When you are making selections from a pop-up menu, closes the pop-up without making a

selection.

F1 – Display the BIOS setup General Help panel.

F2 or F3 – Press to change setup menu colors.

F7 – Press to discard changes.

F9 – Press to load optimized default system values.

F10 – Save changes made the Setup and close the utility.

Chapter 2 11

Page 20

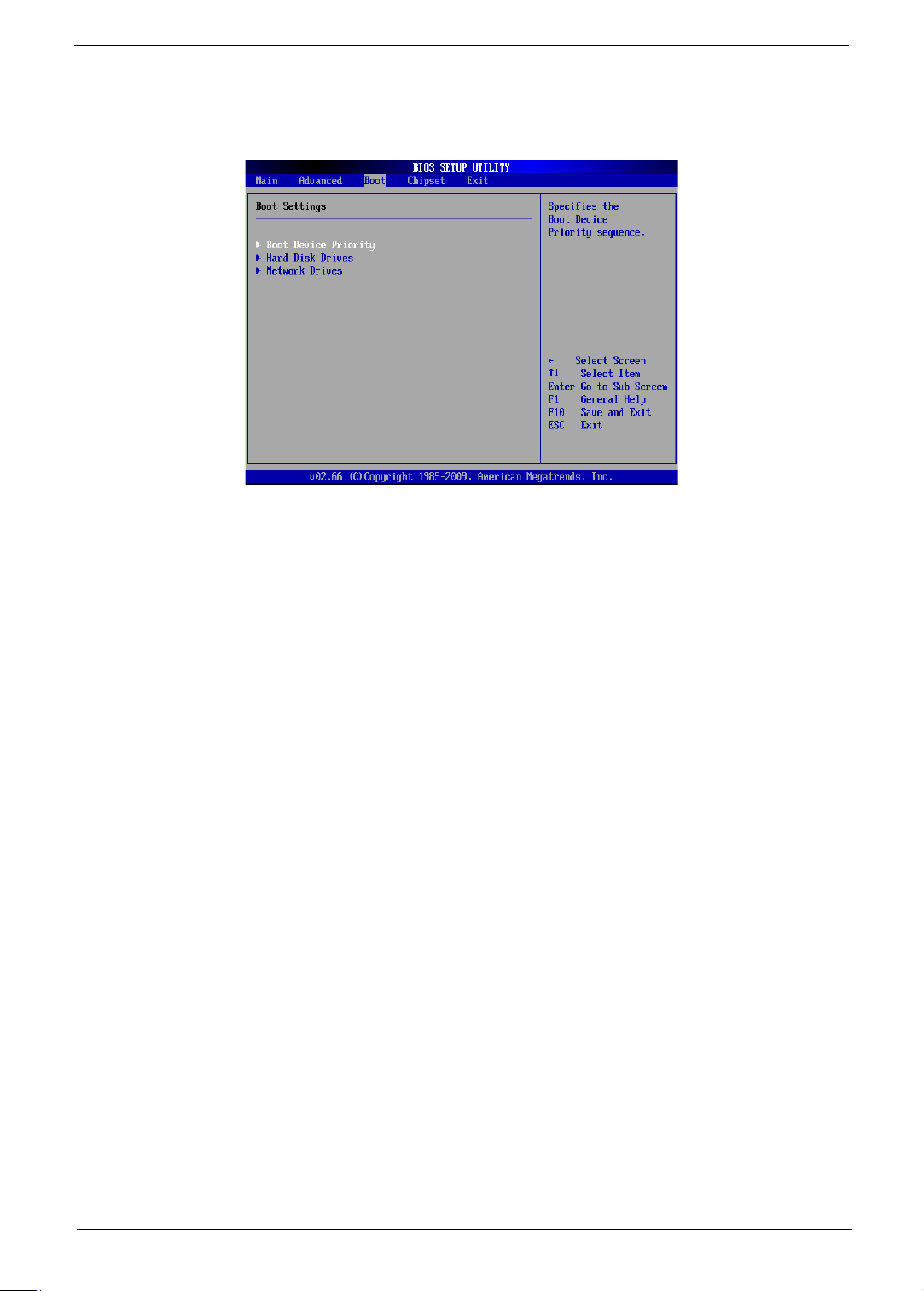

Setup Utility Menus

The Setup Main menu includes the following main setup categories.

Main

Advanced

Boot

Chipset

Exit

In the descriptive table following each of the menu screenshots, settings in boldface are the default and

suggested settings.

12 Chapter 2

Page 21

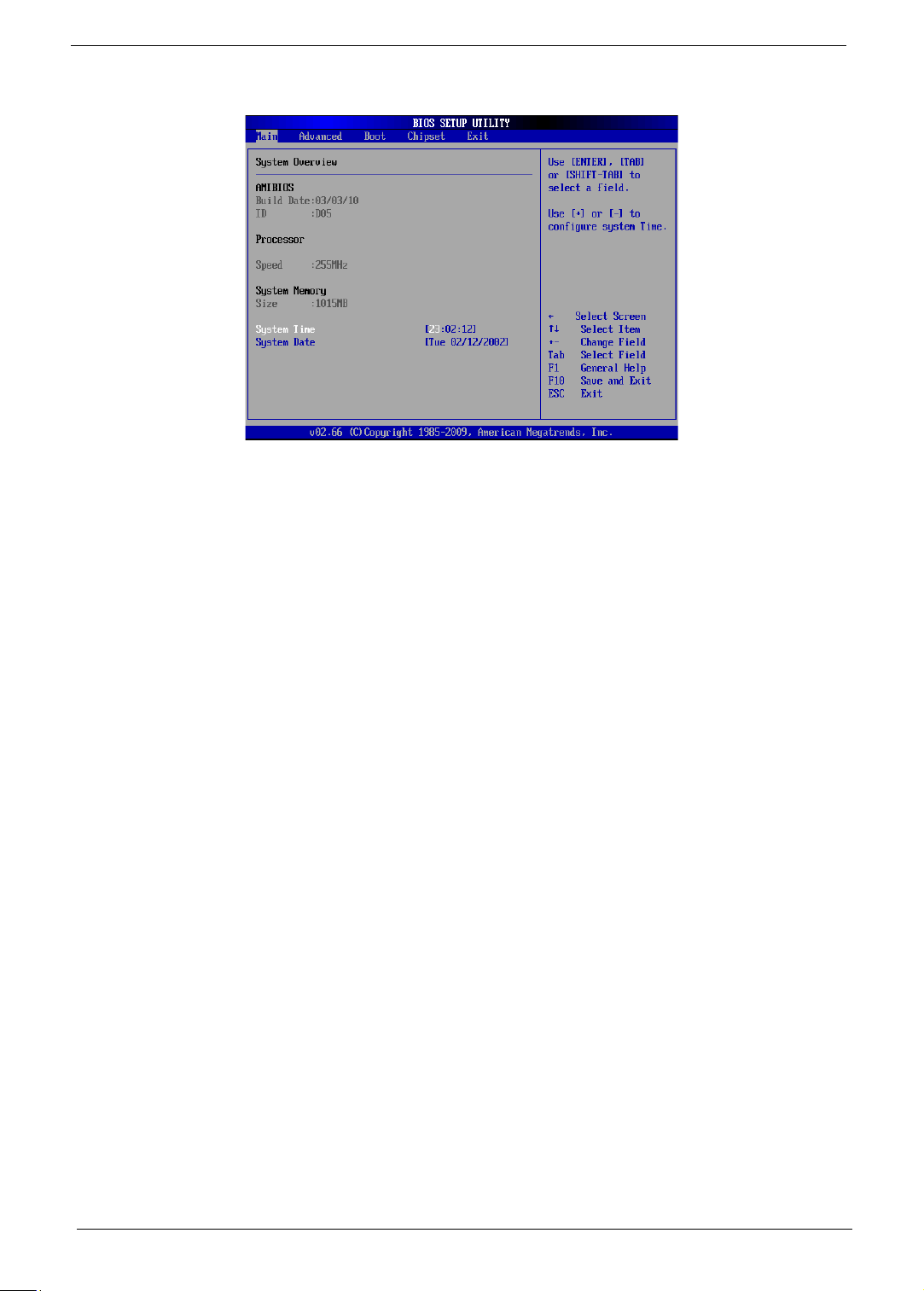

Main

The Main menu displays basic information about the system and lets you set the system date and time.

Parameter Description

AMIBIOS

Build Date

ID

Processor

Speed

System Memory Total size of system memory detected during POST.

System Time Set the system time following the hour-minute-second format.

System Date Set the date following the month-day-year format.

Version number of the BIOS Setup Utility. Date when the BIOS Setup Utility was created.

Displays the processor speed in MHz.

Chapter 2 13

Page 22

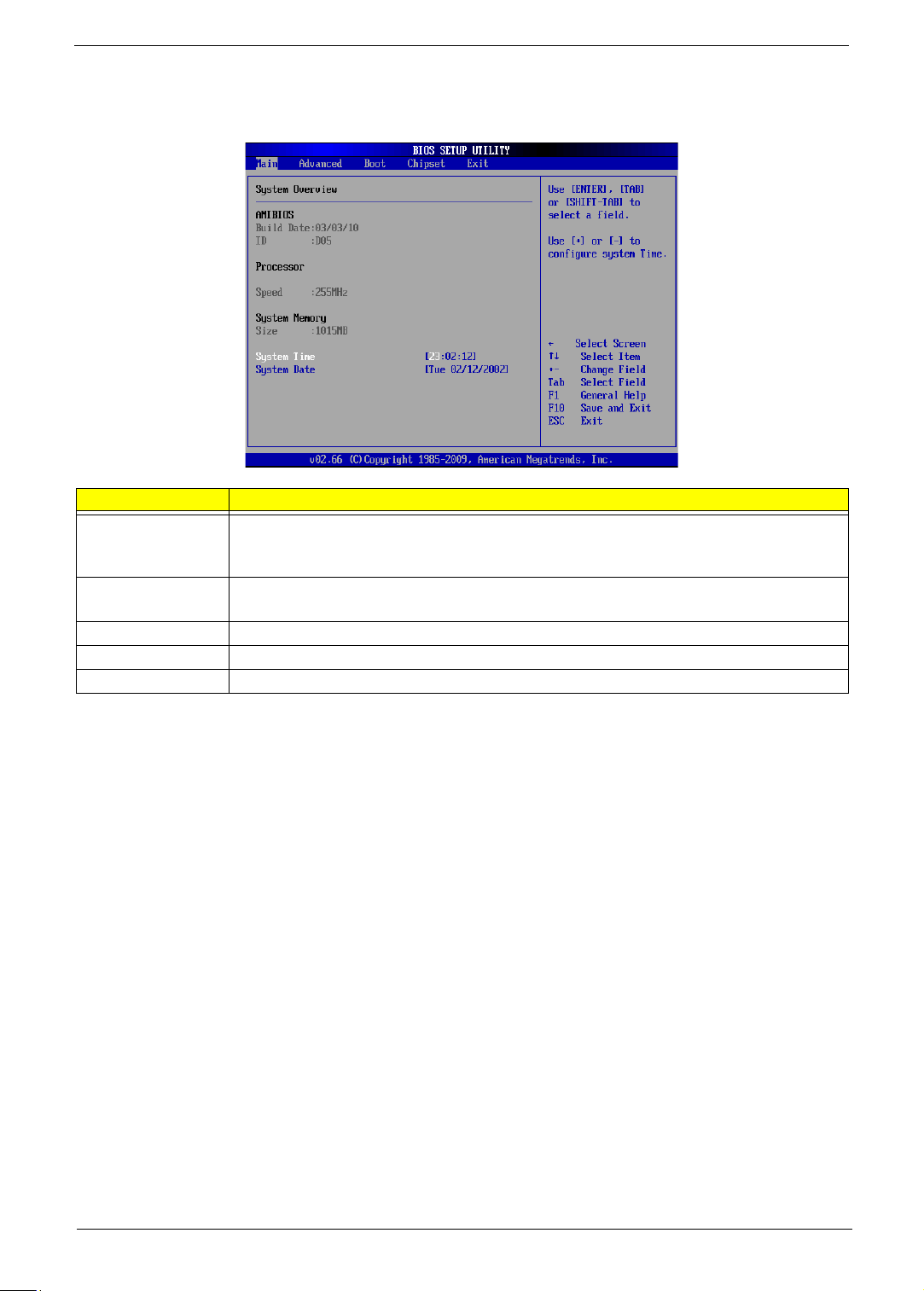

Advanced

The Advanced menu display submenu options for configuring the function of various hardware components.

Select a submenu item, then press <Enter> to access the related submenu screen.

Parameter Description

IDE Configuration Press <Enter> to select options for the IDE Configuration settings.

Hardware Health

Configuration

ACPI Configuration Press <Enter> to select options for ACPI Configuration settings.

AHCI Configuration Press <Enter> to select options for AHCI Configuration settings.

Press <Enter> to select options for the Hardware Health Configuration.

14 Chapter 2

Page 23

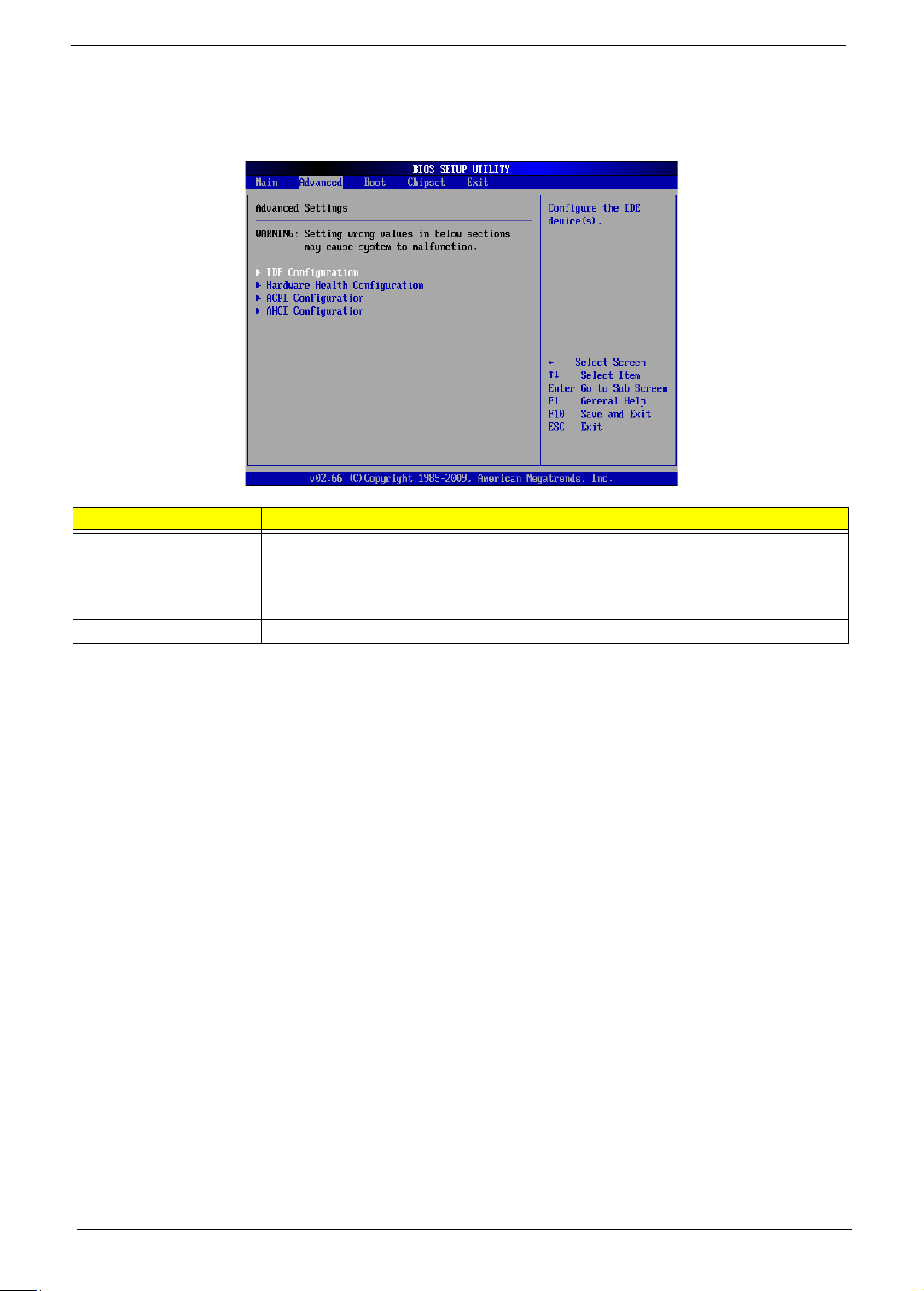

Boot

Use the Boot menu to specify the boot sequence from available devices. Select a submenu item, then press

<Enter> to access the related submenu screen.

Chapter 2 15

Page 24

Chipset

Use the Chipset menu to configure the south bridge chipset. Select the submenu item, then press <Enter> to

access the submenu screen.

Parameter Description

South Bridge Configuration Press <Enter> to select options for the South Bridge Configuration settings.

16 Chapter 2

Page 25

Exit

The Exit menu lists options for quitting the Setup Utility. Highlight any of the exit options, then press <Enter>.

Parameter Description

Save Changes and Exit Saves changes made and closes the utility.

Keyboard shortcut: F10

Discard Changes and Exit Discards changes made and closes the utility.

Discard Changes Discards all changes made to the utility and load previous configuration settings.

Load Optimal Defaults Loads the factory default settings for all setup parameters.

Keyboard shortcut: F9

Setup Defaults are quite demanding in terms of resources consumption. If you are using lowspeed memory chips or other kinds of low-performance components and you choose to load

these settings, the system might not function properly.

Chapter 2 17

Page 26

18 Chapter 2

Page 27

Chapter 3

System Disassembly

This chapter contains step-by-step procedures on how to disassemble the desktop computer for maintenance

and troubleshooting.

Disassembly Requirements

To disassemble the computer, you need the following tools:

Wrist grounding strap and conductive mat for preventing electrostatic discharge

Flat-blade screwdriver

Philips screwdriver

Hex screwdriver

Plastic flat-blade screwdriver

Plastic tweezers

NOTE: The screws for the different components vary in size. During the disassembly process, group the

screws with the corresponding components to avoid mismatch when putting back the components.

Chapter 3 19

Page 28

Pre-disassembly Procedure

Before proceeding with the disassembly procedure, perform the steps listed below:

1. Turn off the system and all the peripherals connected to it.

2. Unplug the power cord from the power outlets.

3. Unplug the power cord from the system.

4. Unplug all peripheral cables from the system.

5. Place the system unit on a flat, stable surface.

20 Chapter 3

Page 29

Main Unit Disassembly

TURN OFF POWER

MAIN UNIT DISASSEMBLY

SYSTEM COVER

HOUSING FRAME

HARD DISK DRIVE

MODULE

DRIVE CARRIER

HARD DISK DRIVE

BACKPLANE BOARD

BRACKET

FRONT BEZEL

FRONT I/O BRACKET

MAINBOARD

CARRIER

MEMORY MODULE

MAINBOARD

FRONT I/O BOARD

B x 4 C x 4

Ax 3

BACKPLANE BOARD

C x 7

POWER SUPPLY

SYSTEM FAN

Ax 4

Ax 4

C x 4

HDD ACCESS

LED CABLES

Screw List

Code Screw Part No.

A M3-0.5*4 86.1A524.4R0

B M3*6L 86.VA524.6R0

C M3*0.5*4L 86.19534.4R0

Chapter 3 21

Page 30

Removing the Hard Disk

1. Open the front panel.

2. Press to release the hard drive carrier handle.

22 Chapter 3

Page 31

3. Flex the carrier handle.

4. Slide the hard drive carrier out of the HDD bay.

Chapter 3 23

Page 32

5. Remove the carrier by gently prying open the left rail of the carrier (1) and lift the hard disk off the

carrier (2) .

24 Chapter 3

Page 33

Removing the System Cover

1. Perform the pre-disassembly procedure described on page 20.

2. Remove the three screws (A) that secure system cover.

Screw (Quantity) Color Tor que Part No.

M3-0.5*4 (3) Silver 5.1 to 6.9 kgf-cm 86.1A524.4R0

3. Slide the system cover toward the back of the chassis until the tabs on the cover disengage with the slots

on the chassis.

4. Lift the side panel away from the server and put it aside for reinstallation later.

Chapter 3 25

Page 34

Removing the Front Bezel

1. Remove the system cover. Refer to the previous section for instructions.

2. Release the front bezel retention tabs from the chassis interior.

3. Pull the bezel slightly outward, then disconnect the front I/O board cable.

26 Chapter 3

Page 35

4. Pull the bezel away from the chassis.

Chapter 3 27

Page 36

Removing the Front I/O Board

1. See “Removing the System Cover” on page 25.

2. See “Removing the Front Bezel” on page 26.

3. Remove the four screws (B) that secures the front I/O bracket.

Screw (Quantity) Color Tor que Part No.

M3*6L (4) Silver 5.1 to 6.9 kgf-cm 86.VA524.6R0

4. Remove the bracket.

28 Chapter 3

Page 37

5. Remove the four screws (C) that secure the front I/O board.

Screw (Quantity) Color Tor que Part No.

M3*0.5*4L (4) Silver 5.1 to 6.9 kgf-cm 86.19534.4R0

6. Remove the front I/O board.

Chapter 3 29

Page 38

Removing the Backplane Board

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. Disconnect the fan (1), LED (2), and power (3) cables from their backplane board connectors.

4. Disconnect the four HDD SATA cables from their mainboard connectors.

30 Chapter 3

Page 39

5. Pull the backplane board bracket out of the chassis.

6. Detach the four HDD SATA cables from their backplane board connectors.

7. Remove the seven screws (C) that secure the backplane board.

Screw (Quantity) Color Tor que Part No.

M3*0.5*4L (7) Silver 5.1 to 6.9 kgf-cm 86.19534.4R0

Chapter 3 31

Page 40

8. Lift the backplane board off the bracket.

32 Chapter 3

Page 41

Removing the Power Supply

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. See “Removing the Backplane Board” on page 30.

4. Release the power cables from the cable ties, as shown.

5. Disconnect the 4-pin power cable from its mainboard connector.

Chapter 3 33

Page 42

6. Remove the four screws (A) that secure the power supply.

Screw (Quantity) Color Tor que Part No.

M3-0.5*4 (4) Silver 5.1 to 6.9 kgf-cm 86.1A524.4R0

7. With the thumb in the thumb hole, press the tab to release the mainboard carrier from the chassis.

34 Chapter 3

Page 43

8. Slide the mainboard carrier out slightly, until you have access to the power cable.

9. While pressing the tab on the 24-pin power cable, pull the cable off the mainboard connector.

10. Pull the power supply out of the chassis.

Chapter 3 35

Page 44

Removing the Fan

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. See “Removing the Backplane Board” on page 30.

4. Remove the four screws (A) that secure the fan.

Screw (Quantity) Color Tor que Part No.

M3-0.5*4 (3) Silver 5.1 to 6.9 kgf-cm 86.1A524.4R0

5. Remove the fan.

36 Chapter 3

Page 45

Removing the Memory Module

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. See “Removing the Front Bezel” on page 26.

4. See “Removing the Backplane Board” on page 30.

5. See “Removing the Power Supply” on page 33.

6. See “Removing the Fan” on page 36.

7. Disconnect the HDD access LED cable from its mainboard connector.

8. Pull the mainboard carrier out of the chassis.

Chapter 3 37

Page 46

9. Press the holding clips on both sides of the DIMM slot outward to release the DIMM (1).

10. Gently pull the DIMM upward to remove it from the DIMM slot (2).

38 Chapter 3

Page 47

Removing the Mainboard

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. See “Removing the Front Bezel” on page 26.

4. See “Removing the Backplane Board” on page 30.

5. See “Removing the Power Supply” on page 33.

6. See “Removing the Fan” on page 36.

7. Remove the four screws (C) that secure the mainboard.

Screw (Quantity) Color Tor que Part No.

M3*0.5*4L (4) Silver 5.1 to 6.9 kgf-cm 86.19534.4R0

8. Lift the mainboard off the mainboard carrier.

Chapter 3 39

Page 48

Removing the HDD Access LED cables

1. See “Removing the Hard Disk” on page 22.

2. See “Removing the System Cover” on page 25.

3. See “Removing the Front Bezel” on page 26.

4. See “Removing the Backplane Board” on page 30.

5. See “Removing the Power Supply” on page 33.

6. See “Removing the Fan” on page 36.

7. See “Removing the Mainboard” on page 39.

8. Press the release tabs on the HDD access LED cables, then detach the cables.

40 Chapter 3

Page 49

Chapter 4

System Troubleshooting

This chapter provides instructions on how to troubleshoot system hardware problems.

Hardware Diagnostic Procedure

The system’s diagnostic function monitors system activity and performs

IMPORTANT:The diagnostic tests described in this chapter are only intended to test Acer products. Non-Acer

products, prototype cards, or modified options can give false errors and invalid system

responses.

1. Obtain the failing symptoms in as much detail as possible.

2. Verify the symptoms by attempting to recreate the failure by running the diagnostic tests or repeating the

same operation. Refer to the “System Diagnosis” on page 43 for more information.

3. Refer to the table below to determine which corrective action to perform.

System Check Procedures

System Diagnosis

Checkpoints

Undertermined Problems

Chapter 4 41

Page 50

System Check Procedures

Power system check

If the system will power on, skip this section. Refer to System External Inspection.

If the system will not power on, check if the power cable is properly connected to the system and AC source.

System external inspection

1. Inspect the LED indicators on the front panel, which can indicate the malfunction. For the LED locations

and description of their behaviour, see “System LED Indicators” on page 5.

2. Make sure that air flow is not blocked.

3. Make sure nothing in the system is making contact that could short out power.

4. If the problem is not evident, continue with System Internal Inspection.

System internal inspection

1. Turn off the system and all the peripherals connected to it.

2. Unplug the power cord from the power outlets.

3. Unplug the power cord from the system.

4. Unplug all peripheral cables from the system.

5. Place the system unit on a flat, stable surface.

6. Remove the system cover. For instructions on removing system cover, refer to “Removing the System

Cover” on page 25.

7. Verify that components are properly seated.

8. Verify that all cable connectors inside the system are firmly and correctly attached to their appropriate

connectors.

9. Verify that all components are Acer-qualified and supported.

10. Replace the system cover.

11. Power on the system.

12. If the problem with the system is not evident, you can try viewing the POST messages and BIOS event

logs during the system startup.

42 Chapter 4

Page 51

System Diagnosis

Hardware diagnostic program

The purpose of the hardware diagnostic program is to check hardware problems. It executes simple tests of

each hardware component to make sure the hardware is not the source of the problem. If hardware problems,

such as a fan, LED board, hard disk drive, memory; are confirmed, the diagnostic program can detect the

specific component causing the problem. The program needs to saved in a bootable USB device.

To run the diagnostic program:

1. Turn off the system.

2. Prepare a bootable USB device by copying or downloading the “ANNIE.GHO” diagnostic utility to the USB

device. The diagnostic utility may be obtained from the CD that came with the system.

3. Plug the bootable USB device to any USB port on the rear of the system.

4. Power on the system. The system status indicator blinks blue.

5. Immediately press and release the Recovery/reset button with the paper clip end. The system status

indicator blinks red and immediately starts the diagnostic process:

a. Onboard memory flash check

b. HDD account check

c. Memory size check (1024 or 2048 MB)

d. Fan speed check

e. CPU temperature check

f. MB voltage check

g. Backplane board temperature check

h. PQAF system test

i. PQAF memory test

j. PQAF HDD test

k. Read SN from DMI data check

l. End test

During the diagnostic process, the result of the test displays on the HDD status indicators. The

indicator(s) blinks blue when the system has passed each diagnostic test and blinks red when an error

condition occurs. After the system has completed the diagnostic procedure the HDD status indicators light

purple.

Test Items HDD LED status (normal) HDD LED status (failed)

Boot from

USB disk

Onboard memory

flash check

HDD account

check

Memory size check

Fan speed check

CPU temperature

check

MB voltage check

Chapter 4 43

HDD 0 HDD 1 HDD 2 HDD 3 HDD 0 HDD 1 HDD 2 HDD 3

Page 52

Test Items HDD LED status (normal) HDD LED status (failed)

Boot from

USB disk

Backplane board

temperature check

PQAF system test

PQAF memory test

PQAF HDD test

Read SN from

DMI data check

End test

6. After the diagnostic routine is completed, the HDD status indicator lights purple indicating the system has

passed all diagnostic tests.

7. A copy of the test result will be saved as a log file (i.e., 66380AC3.LOG) and stored in the Results

folder.The name of the log file is based on the last 8 bytes of the serial number

HDD 0 HDD 1 HDD 2 HDD 3 HDD 0 HDD 1 HDD 2 HDD 3

Debug card

The debug card is a diagnostic tool for technicians to configure the system BIOS settings and conveniently

troubleshoot various problems. This card can help you track the progress of a Power-On Self Test (POST) and

discover the cause of errors during system operations. The debug card connects to the system via its debug

card cable connector. It includes a VGA port for connecting an external monitor to view BIOS output

checkpoints. The debug card also provides a PS/2 mouse port, PS/2 keyboard port and a serial port.

Identifying the components

No. Component

1 Debug card cable connector

2 PS/2 mouse and keyboard port

3 VGA/monitor port

4 Serial port

For more information on how to connect the debug card to the system, refer to “Entering the BIOS Setup

Utility” on page 10.

44 Chapter 4

Page 53

POST Code Checkpoints

The Power-On Self Test (POST) is a BIOS procedure that boots the system, initializes and diagnoses the

system components, and controls the operation of the power-on password option. If POST discovers errors in

system operations at power-on, it displays error messages, generates a checkpoint code at port 80h or even

halts the system if the error is fatal.

The main components on the system board that must be diagnosed and/or initialized by POST to ensure

system functionality are as follows:

Microprocessor with built-in numeric coprocessor and cache memory subsystem

Direct memory access (DMA) controller (8237 module)

Interrupt system (8259 module)

Three programmable timers (system timer and 8254 module)

ROM subsystem

RAM subsystem

CMOS RAM subsystem and real time clock/calendar with battery backup

When POST executes a task, it uses a series of preset numbers called checkpoints to be latched at port 80h,

indicating the stages it is currently running. This latch can be read and shown on an external monitor

connected to the debug card.

Viewing BIOS checkpoints

Viewing all checkpoints generated by the BIOS requires a debug card and an external monitor. Checkpoints

may appear on the bottom right corner of the screen during POST.

POST code checkpoints list

Bootblock initialization code checkpoint

The following table describes the Award common tasks carried out by POST. An unique checkpoint number

denotes each task. .

Checkpoint Description

Before D1 Early chipset initialization is done. Early super I/O initialization is done including RTC

and keyboard controller. NMI is disabled.

D1 Perform keyboard controller BAT test. Check if waking up from power management

suspend state. Save power-on CPUID value in scratch CMOS.

D0 Go to flat mode with 4GB limit and GA20 enabled. Verify the bootblock checksum.

D2 Disable CACHE before memory detection. Execute full memory sizing module.

Verify that flat mode is enabled.

D3 If memory sizing module not executed, start memory refresh and do memory sizing in

Bootblock code. Do additional chipset initialization. Re-enable CACHE. Verify that

flat mode is enabled.

D4 Test base 512KB memory. Adjust policies and cache first 8MB. Set stack.

D5 Bootblock code is copied from ROM to lower system memory and control is given to

it. BIOS now executes out of RAM.

D6 Both key sequence and OEM specific method is checked to determine if BIOS

recovery is forced. Main BIOS checksum is tested. If BIOS recovery is necessary,

control flows to checkpoint E0. See Bootblock Recovery Code Checkpoints section

of document for more information.

Chapter 4 45

Page 54

Checkpoint Description

D7 Restore CPUID value back into register. The Bootblock-Runtime interface module is

moved to system memory and control is given to it. Determine whether to execute

serial flash.

D8 The Runtime module is uncompressed into memory. CPUID information is stored in

memory.

D9 Store the Uncompressed pointer for future use in PMM. Copying Main BIOS into

memory. Leaves all RAM below 1MB Read-Write including E000 and F000 shadow

areas but closing SMRAM.

DA Restore CPUID value back into register. Give control to BIOS POST

(ExecutePOSTKernel). See POST Code Checkpoints section of document for more

information.

Bootblock recovery code checkpoints

The Bootblock recovery code gets control when the BIOS determines that a BIOS recovery needs to occur

because the user has forced the update or the BIOS checksum is corrupt. The following table describes the

type of checkpoints that may occur during the Bootblock recovery portion of the BIOS:

Checkpoint Description

E0 Initialize the floppy controller in the super I/O. Some interrupt vectors are initialized.

DMA controller is initialized. 8259 interrupt controller is initialized. L1 cache is

enabled.

E9 Set up floppy controller and data. Attempt to read from floppy.

EA Enable ATAPI hardware. Attempt to read from ARMD and ATAPI CDROM.

EB Disable ATAPI hardware. Jump back to checkpoint E9.

EF Read error occurred on media. Jump back to checkpoint EB.

E9 no EA Determine information about root directory of recovery media.

F0 Search for pre-defined recovery file name in root directory.

F1 Recovery file not found.

F2 Start reading FAT table and analyze FAT to find the clusters occupied by the recovery

file.

F3 Start reading the recovery file cluster by cluster.

F5 Disable L1 cache.

FA Check the validity of the recovery file configuration to the current configuration of the

flash part.

FB Make flash write enabled through chipset and OEM specific method. Detect proper

flash part. Verify that the found flash part size equals the recovery file size.

F4 The recovery file size does not equal the found flash part size.

FC Erase the flash part.

FD Program the flash part.

FF The flash has been updated successfully. Make flash write disabled. Disable ATAPI

hardware. Restore CPUID value back into register. Give control to F000 ROM at

F000:FFF0h.

46 Chapter 4

Page 55

POST code checkpoints

The POST code checkpoints are the largest set of checkpoints during the BIOS pre-boot process. The

following table describes the type of checkpoints that may occur during the POST portion of the BIOS:

Checkpoint Description

03 Disable NMI, Parity, video for EGA, and DMA controllers. Initialize BIOS, POST,

Runtime data area. Also initialize BIOS modules on POST entry and GPNV area.

Initialized CMOS as mentioned in the Kernel Variable "wCMOSFlags."

04 Check CMOS diagnostic byte to determine if battery power is OK and CMOS

checksum is OK. Verify CMOS checksum manually by reading storage area. If the

CMOS checksum is bad, update CMOS with power-on default values and clear

passwords. Initialize status register A.

Initializes data variables that are based on CMOS setup questions. Initializes both

the 8259 compatible PICs in the system.

05 Initializes the interrupt controlling hardware (generally PIC) and interrupt vector table.

06 Do R/W test to CH-2 count reg. Initialize CH-0 as system timer. Install the

POSTINT1Ch handler. Enable IRQ-0 in PIC for system timer interrupt.

Traps INT1Ch vector to "POSTINT1ChHandlerBlock."

08 Initializes the CPU. The BAT test is being done on KBC. Program the keyboard

controller command byte is being done after Auto detection of KB/MS using

AMI KB-5.

0A Initializes the 8042 compatible Key Board Controller.

0B Detects the presence of PS/2 mouse.

0C Detects the presence of Keyboard in KBC port.

0E Testing and initialization of different Input Devices. Also, update the Kernel Variables.

Traps the INT09h vector, so that the POST INT09h handler gets control for IRQ1.

Uncompress all available language, BIOS logo, and Silent logo modules.

13 Early POST initialization of chipset registers.

24 Uncompress and initialize any platform specific BIOS modules.

30 Initialize System Management Interrupt.

2A Initializes different devices through DIM.

See DIM Code Checkpoints section of document for more information.

2C Initializes different devices. Detects and initializes the video adapter installed in the

system that have optional ROMs.

2E Initializes all the output devices.

31 Allocate memory for ADM module and uncompress it. Give control to ADM module

for initialization. Initialize language and font modules for ADM. Activate ADM

module.

33 Initializes the silent boot module. Set the window for displaying text information.

37 Displaying sign-on message, CPU information, setup key message, and any OEM

specific information.

38 Initializes different devices through DIM. See DIM Code Checkpoints section of

document for more information.

39 Initializes DMAC-1 & DMAC-2.

3A Initialize RTC date/time.

3B Test for total memory installed in the system. Also, Check for DEL or ESC keys to

limit memory test. Display total memory in the system.

3C Mid POST initialization of chipset registers.

40 Detect different devices (Parallel ports, serial ports, and coprocessor in CPU, … etc.)

successfully installed in the system and update the BDA, EBDA…etc.

Chapter 4 47

Page 56

Checkpoint Description

50 Programming the memory hole or any kind of implementation that needs an

adjustment in system RAM size if needed.

52 Updates CMOS memory size from memory found in memory test. Allocates memory

for Extended BIOS Data Area from base memory.

60 Initializes NUM-LOCK status and programs the KBD typematic rate.

75 Initialize Int-13 and prepare for IPL detection.

78 Initializes IPL devices controlled by BIOS and option ROMs.

7A Initializes remaining option ROMs.

7C Generate and write contents of ESCD in NVRam.

84 Log errors encountered during POST.

85 Display errors to the user and gets the user response for error.

87 Execute BIOS setup if needed / requested.

8C Late POST initialization of chipset registers.

8E Program the peripheral parameters. Enable/Disable NMI as selected

90 Late POST initialization of system management interrupt.

A0 Check boot password if installed.

A1 Clean-up work needed before booting to OS.

A2 Takes care of runtime image preparation for different BIOS modules. Fill the free

area in F000h segment with 0FFh. Initializes the Microsoft IRQ Routing Table.

Prepares the runtime language module. Disables the system configuration display if

needed.

A4 Initialize runtime language module.

A7 Displays the system configuration screen if enabled. Initialize the CPU's before boot,

which includes the programming of the MTRR's.

A8 Prepare CPU for OS boot including final MTRR values.

A9 Wait for user input at config display if needed.

AA Uninstall POST INT1Ch vector and INT09h vector. Deinitializes the ADM module.

AB Prepare BBS for Int 19 boot.

AC End of POST initialization of chipset registers.

B1 Save system context for ACPI.

00 Passes control to OS Loader (typically INT19h).

Device Initialization Manager code checkpoints

The Device Initialization Manager (DIM) module gets control at various times during BIOS POST to initialize

different BUSes. The following table describes the main checkpoints where the DIM module is accessed:

Checkpoint Description

2A Initialize different buses and perform the following functions: Reset, Detect, and

Disable (function 0); Static Device Initialization (function 1); Boot Output Device

Initialization (function 2). Function 0 disables all device nodes, PCI devices, and PnP

ISA cards. It also assigns PCI bus numbers. Function 1 initializes all static devices

that include manual configured onboard peripherals, memory and I/O decode

windows in PCI-PCI bridges, and noncompliant PCI devices. Static resources are

also reserved. Function 2 searches for and initializes any PnP, PCI, or AGP video

devices.

48 Chapter 4

Page 57

Checkpoint Description

38 Initialize different buses and perform the following functions: Boot Input Device

Initialization (function 3); IPL Device Initialization (function 4); General Device

Initialization (function 5). Function 3 searches for and configures PCI input devices

and detects if system has standard keyboard controller. Function 4 searches for and

configures all PnP and PCI boot devices. Function 5 configures all onboard

peripherals that are set to an automatic configuration and configures all remaining

PnP and PCI devices.

While control is in the different functions, additional checkpoints are output to port 80h as a word value to

identify the routines under execution. The low byte value indicates the main POST Code Checkpoint. The

high byte is divided into two nibbles and contains two fields. The details of the high byte of these checkpoints

are as follows:

HIGH BYTE XY

The upper nibble 'X' indicates the function number that is being executed. 'X' can be from 0 to 7.

0 = func#0, disable all devices on the BUS concerned.

1 = func#1, static devices initialization on the BUS concerned.

2 = func#2, output device initialization on the BUS concerned.

3 = func#3, input device initialization on the BUS concerned.

4 = func#4, IPL device initialization on the BUS concerned.

5 = func#5, general device initialization on the BUS concerned.

6 = func#6, error reporting for the BUS concerned.

7 = func#7, add-on ROM initialization for all BUSes.

8 = func#8, BBS ROM initialization for all BUSes.

The lower nibble 'Y' indicates the BUS on which the different routines are being executed. 'Y' can be from

0 to 5.

0 = Generic DIM (Device Initialization Manager).

1 = On-board System devices.

2 = ISA devices.

3 = EISA devices.

4 = ISA PnP devices.

5 = PCI devices

Chapter 4 49

Page 58

System Status Error Codes

NOTE: Perform the FRU replacement or actions in the sequence shown in FRU/Action column, if the FRU

replacement does not solve the problem, put the original part back in the computer. Do not replace a

non-defective FRU.

The error messages in the following table indicate the error signals on the HDD access LED indicators on the

front panel and the error symptoms.

Operating condition

System is booting

System has booted

HDD LED error codes

1 2 3 4

Description

SATA controller failed

USB controller failed

LAN controller failed

Fan failed

Memory failed

Boot device not found

Disk failure

50 Chapter 4

Page 59

BIOS Recovery

Perform the BIOS recovery if the BIOS flash ROM has become corrupted. The following sections provide

instructions on how to recover BIOS settings.

To create a BIOS Recovery disk:

1. Prepare a USB storage device.

2. Connect the USB storage device to a USB port on your computer.

3. Copy the target BIOS ROM file to a USB storage device.

4. Rename the target BIOS to “AMIBoot.ROM”.

5. Unplug the device.

To perform a BIOS recovery:

1. Create the BIOS Recovery disk as described in the previous section.

2. Connect the BIOS Recovery disk on the USB port on the system.

3. Depending on the current state of the system, do either of the following:

If the system has crashed:

Power on the system. The system initializes the BIOS recovery process and the system will reboot

automatically after the flash update is completed.

If the system has not crashed or if you want to revert BIOS to previous settings:

During POST, press <Ctrl> + <Home> during POST. This action will flash the BIOS from the USB

storage device to the system and reboot automatically after the flash update is completed.

4. Remove the BIOS Recovery disk.

Chapter 4 51

Page 60

Clearing CMOS

To clear the BIOS configuration you need to short the JP3 Clear CMOS jumper on the mainboard.

1. Turn off the computer and all attached devices.

2. Remove the system cover. See “Removing the System Cover” on page 25.

3. Locate the JP3 Clear CMOS jumper on the mainboard.

4. Remove the jumper from the default position.

5. Replace the jumper to connect the 2nd and 3rd pins.

6. Access the BIOS Setup Utility by connecting a debug card, keyboard, and a monitor to the system.

Perform steps 3 and 7 through 10 of the “Entering the BIOS Setup Utility” on page 10.

7. Press <F9> to load the system default values.

8. Press <F10> to save the changes made and close the Setup Utility.

52 Chapter 4

Page 61

Undetermined Problems

The diagnostic problems does not identify which adapter or device failed, which installed devices are incorrect,

whether a short circuit is suspected, or whether the system is inoperative.

NOTE: Verify that all attached devices are supported by the computer.

NOTE: Verify that the power supply being used at the time of the failure is operating correctly. (See “Power

system check” on page 42.)

Follow procedures below to isolate the failing FRU. Do not isolate non-defective FRU.

1. Power off the computer.

2. Visually check them for damage. If any problems are found, replace the FRU.

3. Remove or disconnect all of the following devices:

Non-Acer devices

Printer, mouse, and other external devices

Hard disk drive

DIMM

CD/DVD-ROM drive

Adapter cards

4. Power on the computer.

5. Determine if the problem has been resolved.

6. If the problem does not recur, reconnect the removed devices one at a time until you find the failed FRU.

7. If the problem persists, replace the FRU one at a time. Do not replace a non-defective FRU.

Chapter 4 53

Page 62

54 Chapter 4

Page 63

System Block Diagram and Board Layout

System Block Diagram

Chapter 5

Chapter 5 55

Page 64

Board Layout

Mainboard

No Description No Description

1 SATA 1 port 13 Intel Atom D410/D510 processor

2 SATA 3 port 14 HDD access LED cable connector

3 SATA 4 port 15 DDR2 DIMM slot

4 SATA 2 port 16 24-pin power cable connector

5 USB ports 17 Front I/O board cable connector

6 Gigabit Ethernet port (top)

USB ports (bottom)

7 eSATA port 19 Clear CMOS jumper

8 Recovery/reset button 20 Battery

9 Debug card cable connector 21 Debug/user mode jumper

10 Backplane board LED cable connector 22 x1 PCI Express slot

11 4-pin power cable connector 23 Intel ICH9R chipset (south bridge)

12 Fan cable connector (reserved)

18 System type select jumper

56 Chapter 5

Page 65

System Jumpers

Name Location Settings

Clear CMOS jumper JP3 1-2 Normal (default)

System type select jumper JP2 1-2 Aspire system (default)

Debug/user mode jumper JP1 Open User mode enabled (default)

2-3 Clear CMOS

2-3 Other model

Closed Debug mode enabled

Chapter 5 57

Page 66

58 Chapter 5

Page 67

Chapter 6

FRU (Field Replaceable Unit) List

This chapter offers the FRU (Field Replaceable Unit) list in global configuration of the home server. Refer to

this chapter whenever ordering the parts to repair or for RMA (Return Merchandise Authorization).

NOTES:

When ordering FRU parts, check the most up-to-date information available on your regional web

or channel. For whatever reasons a part number is changed, it will NOT be noted on the printed

Service Guide. For Acer authorized service providers, your Acer office may have a different part

number code from those given in the FRU list of this printed Service Guide. You MUST use the

local FRU list provided by your regional Acer office to order FRU parts for service.

To scrap or to return the defective parts, follow the local government ordinance or regulations on

how to dispose it properly, or follow the rules set by your regional Acer office on how to return it.

This document will be updated as more information about the FRU list becomes available.

Chapter 6 59

Page 68

Exploded Diagram

60 Chapter 6

Page 69

Item Part No. Part Name QTY.

1 42.60P02.001 Handle HDD carrier HT-361 1

2 42.60P03.001 Latch HDD carrier HT-361 1

3 34.60P07.001 Axis HDD carrier HT-361 1

4 34.60P05.001 SPG HDD carrier HT-361 1

5 34.60P04.001 EMI HDD carrier HT-361 1

6 47.60M06.001 HDD ear rubber pin HT-360 4

7 42.60P01.001 HDD carrier HT-361 1

8 40.60P04.001 PLT as Icon HT-361 1

9 40.60P03.001 PLT as power HT-361 1

10 41.60P02.001 Bezel as main HT-361 1

11 42.55S13.001 Tie mount HU-139 1

12 42.91F07.001 Wire saddle CHF-8 HU122G 2

13 42.5E309.001 LED housing CLED-1A 4

14 50.60P04.001 C.A. HDD LED B/R HT-361 1

15 33.60P09.001 BRKT PCI LP dummy HT-361 1

16 33.60P05.001 BRKT BP HT-361 1

17 30.60P02.001 CAS UP HT-361 1

18 86.1A524.4R0 SCRW MACH PAN M3-0.5*4 NI 4

19 60.60P14.001 ASSY rear I/O cover HT-361 1

20 86.1A524.4R0 SCRW MACH PAN M3-0.5*4 NI 4

21 60.60P11.001 ASSY fan 120x120x25 S15 1

22 33.60P04.001 BRKT fan HT-361 2

23 60.60P02.001 ASSY main chassis HT-361 1

24 45.00049.001 Label spec dummy art UB series 1

25 42.60P11.001 Rubber foot R1907 19D7H 4

26 47.60P05.001 Sponge HDD LED HT-361 4

27 38.09008.001 Dessicant silica gel 30G H25 1

28 40.60P07.001 LBL 24*8MM warning HT-361 2

29 60.60P03.001 ASSY MB tray HT-361 1

30 40.60P06.001 PLT AS USB HT-361 1

31 42.60P17.001 Lens as door HT-361 1

32 42.60P16.001 Door as bezel HT-361 1

Chapter 6 61

Page 70

FRU List

Component QTY Part Name Description

Board

Front I/O board 1 FRONT I/O BOARD S15I ASPIRE FRONT I/O BD DIP 55.R3601.002

Backplane board 1 BACKPLANE BOARD S15I BACKPLANE BOARD DIP 55.R3601.001

Cable

Backplane board

cable

HDD SATA cable 1 HDD SATA CABLE C.A. HDD SATA CABLE HT-361 50.R3601.003

Front I/O board

cable

HDD access LED

cable

Power cord 1 POWER CORD 2.5A 250V 1800MM

Case/Cover/Bracket Assembly

Front I/O dummy

bracket

Power supply

support bracket

Front bezel 1 FRONT BEZEL W/KEY LOCK&KEY ASSY ASPIRE BEZEL HT-361 60.R3601.002

1 BACKPLANE BOARD CABLE C.A. 2CON 10PIN HT361 50.R3601.001

1 FRONT I/O BOARD CABLE C.A. 2CON 26PIN HT361 50.R3601.002

HDD LED CABLE C.A. HDD LED B/R HT-361 50.R3601.004

BLACK UK SING

2 POWER CORD 1800MM BLACK

EUR

POWER CORD 7A 125V 1800MM

BLACK US

POWER CORD 7A 125V JAPAN CORD VCTF 3G 7A/125V(JAPAN) 27.01518.181

POWER CORD 250V 10A 1800MM

SWISS

EXTERNAL ETHERNET CAT5E

CABLE BLACK 2M

1 FRONT I/O DUMMY BRACKET BRKT FRONT I/O HT-361 33.R3601.003

1 POWER SUPPLY SUPPORT

BRACKET

CORD AC UK/SING 2.5A250V 1800 27.R3601.003

CORD PWR AC LINE EUR 1.8M

BLK

CORD SVT 10A 125V 1800MM BLK 27.R3601.001

CORD 250V 10A 1800MM SWISS 27.01518.251

C.A. CAT5E STRAI BLACK_2M BIZ 50.R3601.005

BRKT PSU SUPPORT HT-361 33.R3601.002

Acer

Part Number

27.R3601.002

Housing frame 2 ASSEMBLY CHASSIS W/HDD LED

CABLE&FAN&UPPER

CASE&LOWER CASE&HDD

BRACKET&MAIN BOARD

CARRIRE&FAN BRACKET

HOUSING ASSY HT-361 60.R3601.001

62 Chapter 6

Page 71

Component QTY Part Name Description

Front I/O bracket FRONT I/O BOARD BRACKET ASSY BRKT AS FRONT I/O HT-361 33.R3601.001

HDD carrier HDD CARRIER ASSY HDD CARRIER HT-361 42.R3601.001

Backplane bracket Backplane bracket BRKT BP HT361 N/A

Mainboard carrier Mainboard carrier ASSY MB TRAY HT-361 N/A

System cover System cover CAS UP HT-361 N/A

Acer

Part Number

Key MASTER KEY DK103-KY05 MASTER KEY HT-361 33.R3601.004

Fan

FAN W/FAN RUBBER ASSY FAN 120X120X25 S15 23.R3601.001

Hard disk drive

Mainboard

1 HDD SEAGATE 3.5" 7200RPM

1000GB ST31000333AS BRINKS

SATA II LF F/W:SD45

1 HDD SEAGATE 3.5" 7200RPM

640GB ST3640623AS BRINKS

SATA II 16MB LF F/W:SD43

1 MAINBOARD S15I INTEL ATOM

D410/D510 ICH9R V1.0 LF FOR

ASPIRE/ALTOS ESAYSTORE W/

CPU&HEATSINK

HDD 1TB SGT ST31000333AS

7.2KR

HDD 640GB 3.5" SGT

ST3640623AS

S15I GEN2 MAIN BOARD W/O

CPU,DIMM D

KH.01K01.005

KH.64001.001

MB.TIA01.001

MB.T1B01.001

Chapter 6 63

Page 72

Component QTY Part Name Description

Memory

1 MEMORY UNIFOSA UNB-DIMM

DDRII 800 1GB

GU341G0ALEPR6B2C6CE LF

1 MEMORY UNIFOSA UNB-DIMM

DDRII 800MHZ 1GB

GU341G0ALEPR6B2C6CE LF

Power supply

1 PSU DELTA GPS-200AB B 200W

100-240V S1

Screws

1 SCRW TAP PAN M3*6L 2LEAD NI SCRW TAP PAN M3*6L 2LEAD NI 86.VA524.6R0

1 SCRW MACH P/WS M3*0.5*4L NI SCRW MACH P/WS M3*0.5*4L NI 86.19534.4R0

1 SCRW MACH PAN M3-0.5*4 NI SCRW MACH PAN M3-0.5*4 NI 86.1A524.4R0

DIMM 1G

GU341G0ALEPR6B2C6CE

DIMM 1G

GU341G0ALEPR6B2C6CE

SPS 200W 1U DELTA GPS-200AB B PY.20009.001

Acer

Part Number

KN.51203.034

KN.1GB0H.009

64 Chapter 6

Page 73

Technical Specifications

This section provides technical specifications for the system.

Processor

Item Specification

Type Onboard Intel Atom series

Model number D410 D510

Core 1 2

Threads 2 4

Clock speed (GHz) 1.66 1.66

L2 cache size 512 KB 1 MB

Bus type DMI DMI

Manufacturing tech

(CMOS)

Max TDP (W) 10 13

Socket type Micro-FCBGA8559 Micro-FCBGA8559

Embedded Yes Yes

45 nm 45 nm

Appendix A

System Board Major Chips

Item Specification

System core logic Intel Atom D410/D510 processor + Intel ICH9R

Storage controller Intel ICH9R

Graphics memory

controller

Flash disk controller Intel ICH9R + SM321

LAN controller Intel ICH9R + Marvell Yukon 88E8071

Hardware sensors

monitor

Integrated in the Intel Atom D410/D510 processor

Intel ICH9R + SMSC SCH5127 Super I/O

Appendix A 65

Page 74

System Memory

Item Specification

Memory type DDR2-800 unbuffered DIMM

Organization Unbuffered, non-ECC

Pin count 240

DIMM sockets 1

DIMM size 1 GB or 2 GB

Minimum memory 1 GB

Maximum memory 2 GB

Vendor Unifosa

Model name

GU341G0ALEPR6B2C6CE

GU342G0ALEPR692C6CE

System BIOS

Item Specification

BIOS vendor AMI

BIOS version D05

Flash memory 256 MB

PCI Interface

Item Specification

PCI Express controller Intel ICH9R

Number of slots One PCI Express x 1 slot

Network Interface

Item Specification

LAN controller Intel ICH9R + Marvell Yukon 88E8071

Supports LAN protocol 10/100/1000 Mbps

LAN connector type RJ45

SATA Interface

Item Specification

SATA controller SATA: Intel ICH9R

eSATA: Intel ICH7R + Marvell 88SE6111

Connectors • Four SATA ports

• One eSATA port (optional)

66 Appendix A

Loading...

Loading...